The Impact on Cow Performance and Feed Efficiency When Individual Cow Milk Composition and Energy Intake Are Accounted for When Allocating Concentrates

Abstract

1. Introduction

2. Materials and Methods

2.1. Animals, Pre-Experimental Diets and Housing

2.2. Treatments

2.3. Cow Measurements

2.4. Feed Analysis

2.5. Statistical Analysis

3. Results

4. Discussion

4.1. Cow Intake and Performance

4.2. Feed Use Efficiency

4.3. Practical Implications

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Finneran, E.; Crosson, P.; O’Kiely, P.; Shalloo, L.; Forristal, D.; Wallace, M. Stochastic simulation of the cost of home-produced feeds for ruminant livestock systems. J. Agric. Sci. 2012, 150, 123–139. [Google Scholar] [CrossRef]

- Wu, Y.; Liang, D.; Shaver, R.D.; Cabrera, V.E. An income over feed cost nutritional grouping strategy. J. Dairy Sci. 2019, 5, 4682–4693. [Google Scholar] [CrossRef] [PubMed]

- Lawrence, D.; O’Donovan, M.; Boland, T.M.; Lewis, E.; Kennedy, E. The effect of concentrate feeding amount and feeding strategy on milk production, dry matter intake, and energy partitioning of autumn-calving Holstein-Friesian cows. J. Dairy Sci. 2015, 98, 338–348. [Google Scholar] [CrossRef] [PubMed]

- Lawrence, D.; O’Donovan, M.; Boland, T.M.; Lewis, E.; Kennedy, E. An examination of two concentrate allocation strategies which are based on the early lactation milk yield of autumn calving Holstein Friesian cows. Animal 2016, 5, 796–804. [Google Scholar] [CrossRef]

- Little, M.W.; O’Connell, N.E.; Ferris, C.P. A comparison of individual cow versus group concentrate allocation strategies on dry matter intake, milk production, tissue changes, and fertility of Holstein-Friesian cows offered a grass silage diet. J. Dairy Sci 2016, 99, 4360–4373. [Google Scholar] [CrossRef] [PubMed]

- Purcell, P.J.; Law, R.A.; Gordon, A.W.; McGettrick, S.A.; Ferris, C.P. Effect of concentrate feeding method on the performance of dairy cows in early to mid lactation. J. Dairy Sci. 2016, 99, 2811–2824. [Google Scholar] [CrossRef] [PubMed]

- Purcell, P.J.; Law, R.A.; Ferris, C.P. Effect of concentrate feed rate within a feed-to-yield system on the performance of dairy cows in early to mid-lactation. In Proceedings of the British Society of Animal Science Annual Conference, Chester, UK, 14–15 April 2015. [Google Scholar]

- Craig, A.L.; Gordon, A.W.; Hamill, G.; Ferris, C.P. Milk Composition and Production Efficiency within Feed-To-Yield Systems on Commercial Dairy Farms in Northern Ireland. Animals 2022, 14, 1771. [Google Scholar] [CrossRef] [PubMed]

- Maltz, E.; Devir, S.; Kroll, O.; Zur, B.; Spahr, S.L.; Shanks, R.D. Comparative responses of lactating cows to total mixed ration or computerized individual concentrates feeding. J. Dairy Sci. 1992, 75, 1588–1603. [Google Scholar] [CrossRef]

- Maltz, E.; Devir, S.; Metz, J.H.M.; Hogeveen, H. The body weight of the dairy cow: I. Introductory study into body weight changes in dairy cows as a management aid. Lives. Prod. Sci. 1997, 48, 175–186. [Google Scholar] [CrossRef]

- Bossen, D.; Weisbjerg, M.R. Allocation of feed based on individual dairy cow live weight changes II: Effect on milk production. Livest. Sci. 2009, 126, 273–285. [Google Scholar] [CrossRef]

- Maltz, E.; Barbosa, L.F.; Bueno, P.; Scagion, L.; Kaniyamattam, K.; Greco, L.F.; De Vries, A.; Santos, J.E. Effect of feeding according to energy balance on performance, nutrient excretion and feeding behavior of early lactation dairy cows. J. Dairy Sci. 2013, 96, 5249–5264. [Google Scholar] [CrossRef]

- Berger, R.; Hovav, A. Using a Dairy Management Information System to Facilitate Precision Agriculture: The Case of the AfiMilk (R) System. Inf. Syst. Manag. 2013, 30, 21–34. [Google Scholar] [CrossRef]

- Huhtanen, P.; Nousiainen, J. Production responses of lactating dairy cows fed silage-based diets to changes in nutrient supply. Livest. Sci. 2012, 148, 146–158. [Google Scholar] [CrossRef]

- Bercovich, A.; Edan, Y.; Alchanatis, V.; Moallem, U.; Parmet, Y.; Honig, H.; Maltz, E.; Antler, A.; Halachmi, I. Development of an automatic system for cow body condition scoring using body shape signature. J. Dairy Sci. 2013, 96, 8047–8059. [Google Scholar] [CrossRef] [PubMed]

- Cabezas-Garcia, E.H.; Gordon, A.W.; Mulligan, F.J.; Ferris, C.P. Revisiting the Relationships between Fat-to-Protein Ratio in Milk and Energy Balance in Dairy Cows of Different Parities, and at Different Stages of Lactation. Animals 2021, 11, 3256. [Google Scholar] [CrossRef]

- Agnew, R.E.; Yan, T.; France, J.; Kebreab, E.; Thomas, C. Energy Requirement and Supply. In Feed into Milk; Thomas, C., Ed.; Nottingham University Press: Nottingham, UK, 2004. [Google Scholar]

- Tyrrell, H.F.; Reid, J.T. Prediction of the energy value of cow’s milk. J. Dairy Sci. 1965, 48, 1215–1223. [Google Scholar] [CrossRef]

- McDonald, P.; Edwards, R.A.; Greenhalgh, J.F.D.; Morgan, C.A. Animal Nutrition, 6th ed.; Pearson Education Limited: Essex, UK, 2002. [Google Scholar]

- Munoz, C.; Hube, S.; Morales, J.M.; Yan, T.; Ungerfeld, E.M. Effects of concentrate supplementation on enteric methane emissions and milk production of grazing dairy cows. Livest. Sci. 2015, 175, 37–46. [Google Scholar] [CrossRef]

- Edmondson, A.J.; Lean, I.J.; Weaver, L.D.; Farver, T.; Webster, G. A body condition scoring chart for Holstein dairy cows. J. Dairy Sci. 1989, 72, 68–78. [Google Scholar] [CrossRef]

- Park, R.S.; Agnew, R.E.; Gordon, F.J.; Steen, R.W.J. The use of near infrared reflectance spectroscopy (NIRS) on undried samples of grass silage to predict chemical composition and digestibility parameters. Anim. Feed Sci. Technol. 1998, 72, 155–167. [Google Scholar] [CrossRef]

- Maltz, E.; Kroll, O.; Sagi, R.; Devir, S.; Spahr, S.L.; Genizi, A. Milk yield, parity and cow potential as variables for computerized concentrates supplementation strategy. J. Dairy Sci. 1991, 74, 2277–2289. [Google Scholar] [CrossRef]

- Maltz, E. Individual dairy cow management: Achievements, obstacles and prospects. J. Dairy Res. 2020, 87, 145–157. [Google Scholar] [CrossRef]

- Osorio, J.S.; Lohakare, J.; Bionaz, M. Biosynthesis of milk fat, protein, and lactose: Roles of transcriptional and posttranscriptional regulation. Physiol. Genom. 2016, 48, 231–256. [Google Scholar] [CrossRef] [PubMed]

- Lokhorst, C.; Groot Koerkamp, P.W.G. (Eds.) Precision Livestock Farming ’09: Papers Presented at the 4th European Conference, on Precision Livestock Farming, Wageningen, The Netherlands, 6–8 July 2009; Wageningen Academic Publishers: Wageningen, The Netherlands, 2009. [Google Scholar]

- Tedde, A.; Grelet, C.; Ho, P.N.; Pryce, J.E.; Hailemariam, D.; Wang, Z.Q.; Plastow, G.; Gengler, N.; Froidmont, E.; Dehareng, F.; et al. Multiple Country Approach to Improve the Test-Day Prediction of Dairy Cows’ Dry Matter Intake. Animals 2021, 11, 5. [Google Scholar] [CrossRef] [PubMed]

- Wilkinson, J.M. Re-defining efficiency of feed use by livestock. Animal 2011, 5, 1014–1022. [Google Scholar] [CrossRef]

- Shirali, M.; Hynes, D.; Ferris, C.F. Using herd information and milk production data to predict dry matter intake within feed-to-yield concentrate allocation strategies. In Proceedings of the British Society of Animal Science Annual Conference, Nottingham, UK, 30 March–1 April 2020. [Google Scholar]

- Bresolin, T.; Dorea, J.R.R. Infrared Spectrometry as a High-Throughput Phenotyping Technology to Predict Complex Traits in Livestock Systems. Front. Genet. 2020, 11, 923. [Google Scholar] [CrossRef] [PubMed]

- Shelley, A.N.; Lau, D.L.; Stone, A.E.; Bewley, J.M. Short communication: Measuring feed volume and weight by machine vision. J. Dairy Sci. 2016, 99, 386–391. [Google Scholar] [CrossRef]

- Bloch, V.; Levit, H.; Halachmi, I. Assessing the potential of photogrammetry to monitor feed intake of dairy cows. J. Dairy Res. 2019, 86, 34–39. [Google Scholar] [CrossRef]

- Grelet, C.; Vanlierde, A.; Hostens, M.; Foldager, L.; Salavati, M.; Ingvartsen, K.; Crowe, M.; Sorensen, M.T.; Froidmont, E.; Ferris, C.P.; et al. Potential of milk mid-IR spectra to predict metabolic status of cows through blood components and an innovative clustering approach. Animal 2018, 13, 649–658. [Google Scholar] [CrossRef] [PubMed]

- Gaillard, C.; Friggens, N.C.; Taghipoor, M.; Weisbjerg, M.R.; Lehmann, J.O.; Sehested, J. Effects of an individual weight-adjusted feeding strategy in early lactation on milk production of Holstein cows during extended lactation. J. Dairy Sci. 2016, 99, 2221–2236. [Google Scholar] [CrossRef]

- Fischer, A.; Edouard, N.; Faverdin, P. Precision feed restriction improves feed and milk efficiencies and reduces methane emissions of less efficient lactating Holstein cows without impairing their performance. J. Dairy Sci. 2020, 103, 4408–4422. [Google Scholar] [CrossRef]

| Mean | SD | |

|---|---|---|

| Oven dry matter (g/kg) | 292 | 29.2 |

| VCODM (g/kg) | 303 | 28.7 |

| Crude protein (g/kg DM) | 130 | 8.4 |

| Ash (g/kg DM) | 95 | 3.4 |

| Acid detergent fibre (g/kg DM) | 286 | 4.5 |

| Neutral detergent fibre (g/kg DM) | 482 | 9.0 |

| Gross energy (MJ/kg DM) | 18.5 | 1.57 |

| Metabolisable energy (MJ/kg DM) | 11.1 | 0.26 |

| pH | 4.01 | 0.103 |

| Lactic acid (g/kg DM) | 97 | 23.0 |

| Acetic acid (g/kg DM) | 19.2 | 4.15 |

| Ethanol (g/kg DM) | 13.1 | 3.37 |

| Ammonia (g/kg total N) | 75 | 0.81 |

| Concentrate Offered via OPF | Concentrate Offered in Basal Ration | |

|---|---|---|

| Ingredients | ||

| Wheat | 17.4 | |

| Maize meal | 17.5 | 28.0 |

| Extruded rapeseed meal | 19.0 | |

| Distillers dried grains | 8.5 | |

| Maize gluten | 11.0 | |

| Sugar beet pulp | 6.1 | |

| Soyabean meal (high protein) | 8.6 | 19.1 |

| Soya hulls | 17.5 | 25.4 |

| Molaferm | 8.0 | 2.5 |

| Palm fatty acid distillate | 1.0 | |

| Protected fat (Megalac) 1 | 1.5 | 3.0 |

| Limestone (CaCO3) | 0.9 | 0.6 |

| Calcined magnesite | 0.2 | 0.2 |

| Salt | 0.6 | 0.9 |

| RumiTech 2 | 0.7 | 0.7 |

| Mineral/vitamin mix | 0.7 | 0.7 |

| Chemical Composition | ||

| Oven dry matter (g/kg) | 888 (4.6) | 894 (4.5) |

| Starch (g/kg DM) | 262 (8.0) | 193 (34.0) |

| Crude protein (g/kg DM) | 169 (2.5) | 239 (16.8) |

| ADF (g/kg DM) | 152 (5.8) | 191 (47.7) |

| NDF (g/kg DM) | 295 (24.0) | 342 (80.0) |

| Ash (g/kg DM) | 77 (2.0) | 79 (8.0) |

| Metabolisable energy (MJ/kg DM) 3 | 13.5 | 13.3 |

| Treatment | p Values | ||||||

|---|---|---|---|---|---|---|---|

| Control 1 | Precision 1 2 | Precision 2 3 | SED 4 | Treatment | Week | Week × Treatment | |

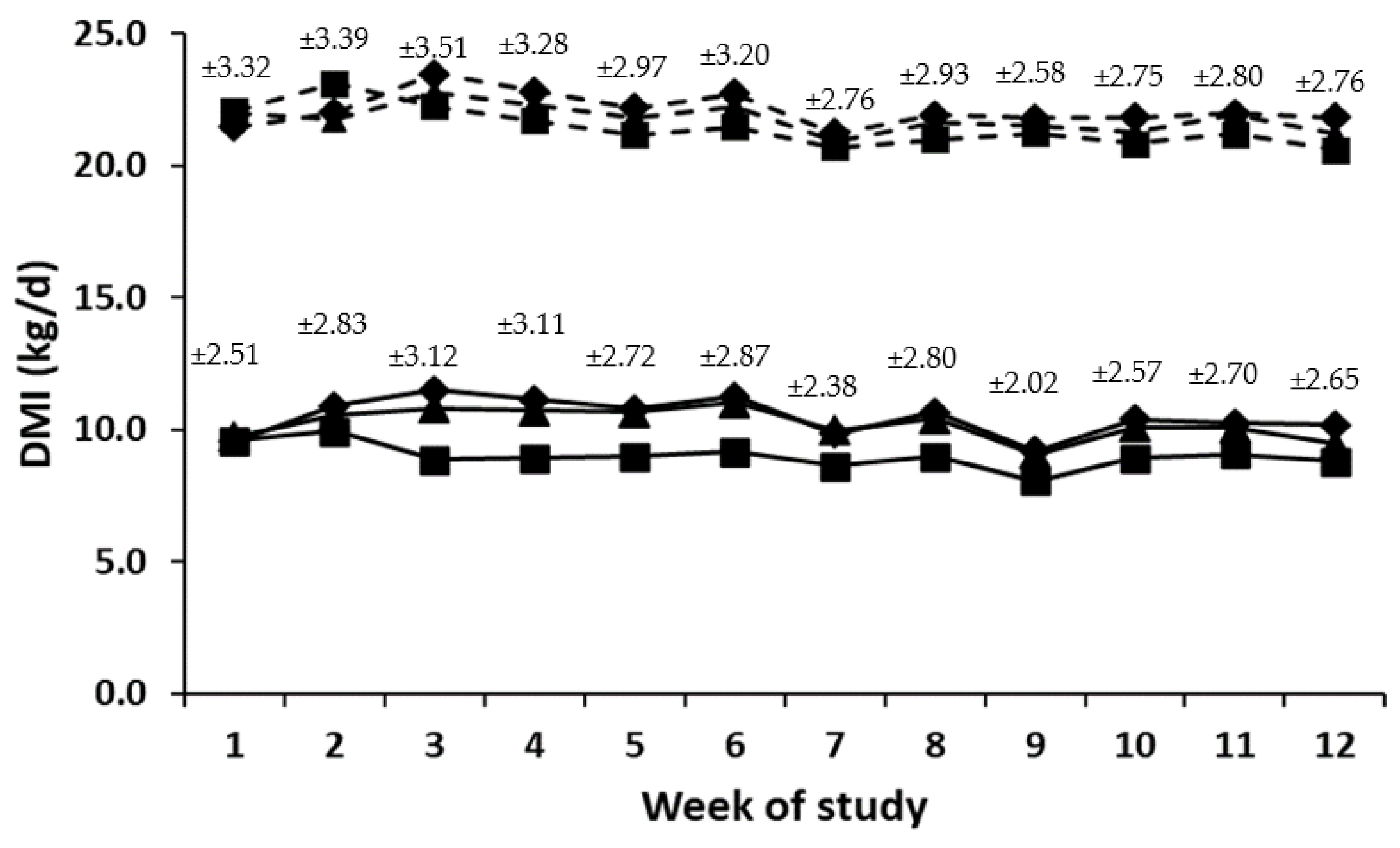

| Grass silage DMI (kg/d) | 12.4 | 11.6 | 11.5 | 0.36 | 0.242 | <0.001 | <0.001 |

| Concentrate DMI (kg/d) | 9.4 a | 10.5 b | 10.3 b | 0.43 | 0.044 | <0.001 | <0.001 |

| Total DMI (kg/d) | 21.2 | 21.8 | 21.5 | 0.24 | 0.113 | <0.001 | <0.001 |

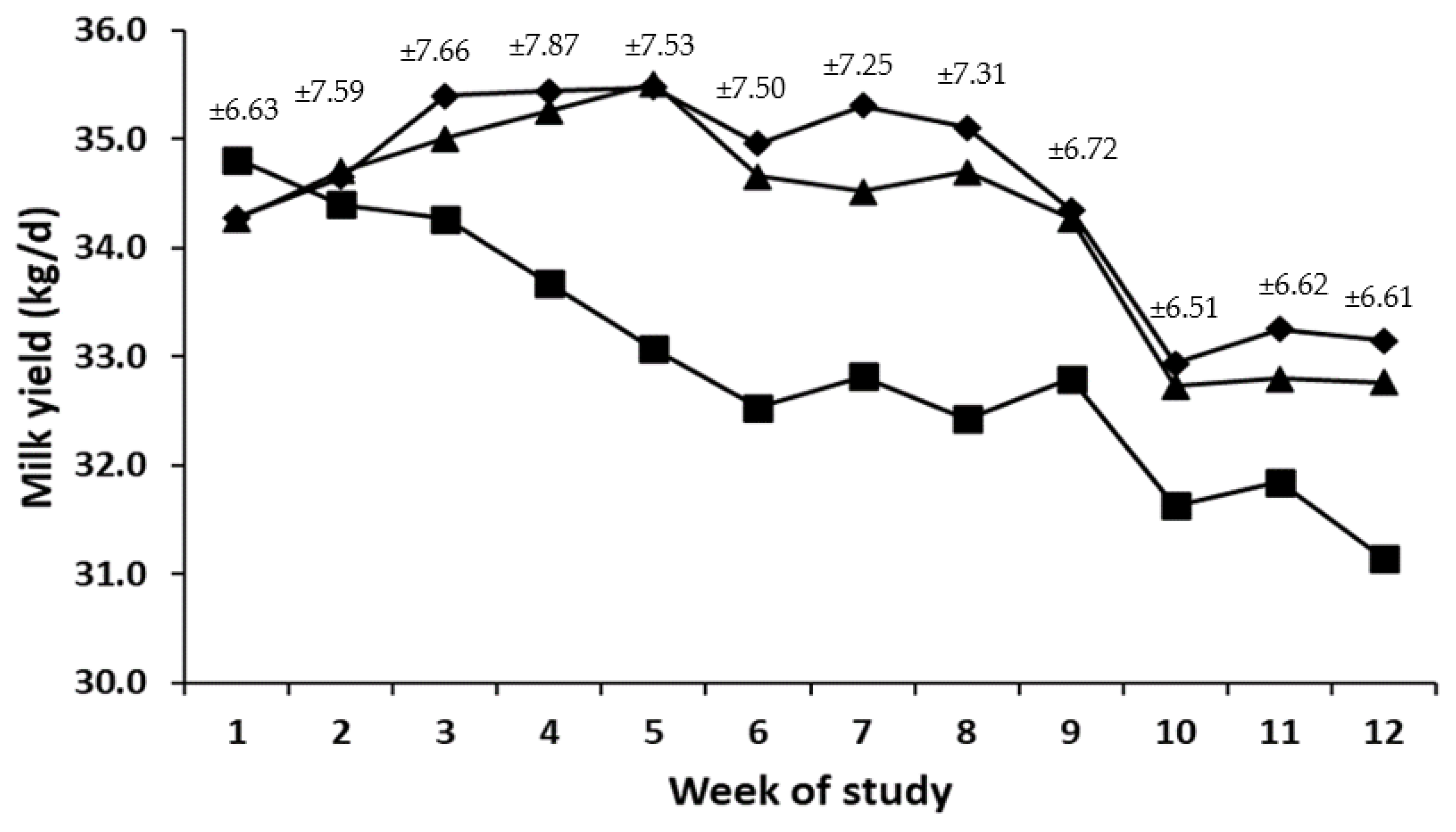

| Milk yield (kg/d) | 32.9 | 34.5 | 34.3 | 0.68 | 0.181 | <0.001 | 0.002 |

| Fat (g/kg) | 45.1 | 44.9 | 43.1 | 0.81 | 0.055 | <0.001 | 0.767 |

| Protein (g/kg) | 32.7 a | 33.5 b | 33.1 b | 0.24 | 0.003 | 0.059 | 0.910 |

| Lactose (g/kg) | 48.0 | 48.1 | 48.1 | 0.20 | 0.940 | 0.192 | 0.972 |

| Fat yield (kg/d) | 1.47 | 1.54 | 1.46 | 0.035 | 0.064 | <0.001 | 0.726 |

| Protein yield (kg/d) | 1.07 a | 1.15 b | 1.13 b | 0.022 | 0.001 | <0.001 | 0.461 |

| Fat plus protein yield (kg/d) | 2.54 a | 2.69 b | 2.58 a | 0.052 | 0.017 | <0.001 | 0.607 |

| Energy corrected milk (kg/d) | 34.6 | 37.0 | 36.3 | 1.93 | 0.563 | <0.001 | 0.578 |

| ECM/DMI (kg/kg) | 1.63 | 1.65 | 1.64 | 0.031 | 0.783 | <0.001 | 0.092 |

| ECM/ME intake (kg/MJ) | 0.14 | 0.14 | 0.13 | 0.002 | 0.984 | <0.001 | 0.187 |

| Concentrate DMI/milk yield (kg/kg) | 0.27 a | 0.31 b | 0.30 b | 0.007 | <0.001 | <0.001 | <0.001 |

| Concentrate DMI/ECM (kg/kg) | 0.25 a | 0.29 b | 0.29 b | 0.007 | <0.001 | <0.001 | <0.001 |

| Energy balance (MJ/d) | 8.7 | 10.9 | 11.1 | 2.51 | 0.592 | <0.001 | 0.021 |

| Body weight (kg) | 626 | 644 | 645 | 19.8 | 0.416 | <0.001 | 0.181 |

| Body condition score | 2.1 | 2.3 | 2.4 | 0.20 | 0.694 | <0.001 | 0.798 |

| Locomotion score | 2.3 | 2.4 | 2.5 | 0.07 | 0.958 | <0.001 | 0.397 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Craig, A.-L.; Gordon, A.W.; Ferris, C.P. The Impact on Cow Performance and Feed Efficiency When Individual Cow Milk Composition and Energy Intake Are Accounted for When Allocating Concentrates. Dairy 2023, 4, 423-434. https://doi.org/10.3390/dairy4030028

Craig A-L, Gordon AW, Ferris CP. The Impact on Cow Performance and Feed Efficiency When Individual Cow Milk Composition and Energy Intake Are Accounted for When Allocating Concentrates. Dairy. 2023; 4(3):423-434. https://doi.org/10.3390/dairy4030028

Chicago/Turabian StyleCraig, Aimee-Louise, Alan W. Gordon, and Conrad P. Ferris. 2023. "The Impact on Cow Performance and Feed Efficiency When Individual Cow Milk Composition and Energy Intake Are Accounted for When Allocating Concentrates" Dairy 4, no. 3: 423-434. https://doi.org/10.3390/dairy4030028

APA StyleCraig, A.-L., Gordon, A. W., & Ferris, C. P. (2023). The Impact on Cow Performance and Feed Efficiency When Individual Cow Milk Composition and Energy Intake Are Accounted for When Allocating Concentrates. Dairy, 4(3), 423-434. https://doi.org/10.3390/dairy4030028