Controlled Solar Drying as a Sustainable Strategy to Preserve Color and Minimize Food Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Description of Dryers

2.3. Drying Kinetics Determination

2.4. Effective Moisture Diffusivity

2.5. Color Change Kinetics

2.6. Statistical Analysis

3. Results

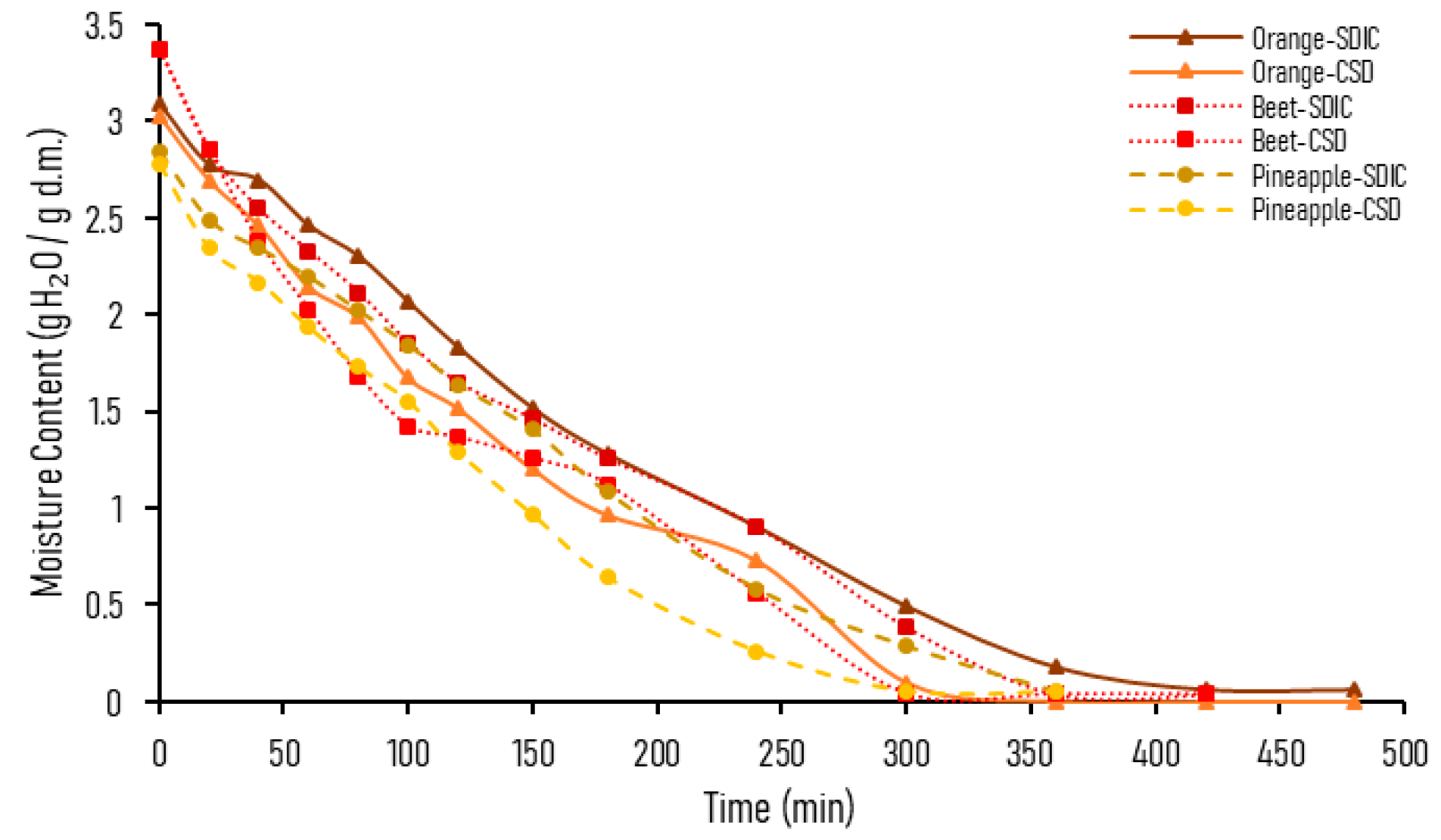

3.1. Moisture Content

3.2. Drying Kinetics and Data Variability

3.3. Determination of Effective Moisture Diffusivity

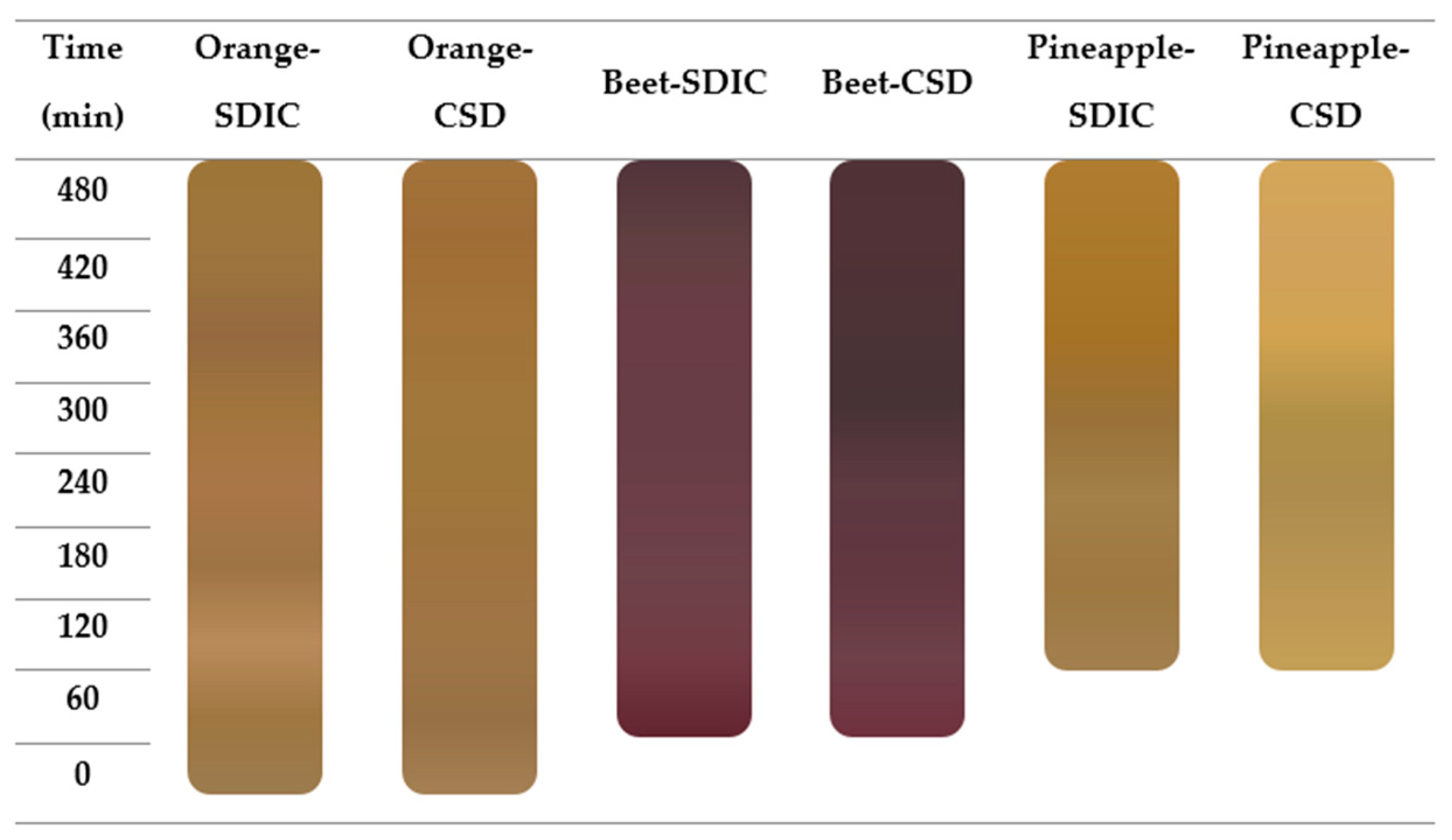

3.4. Color Change

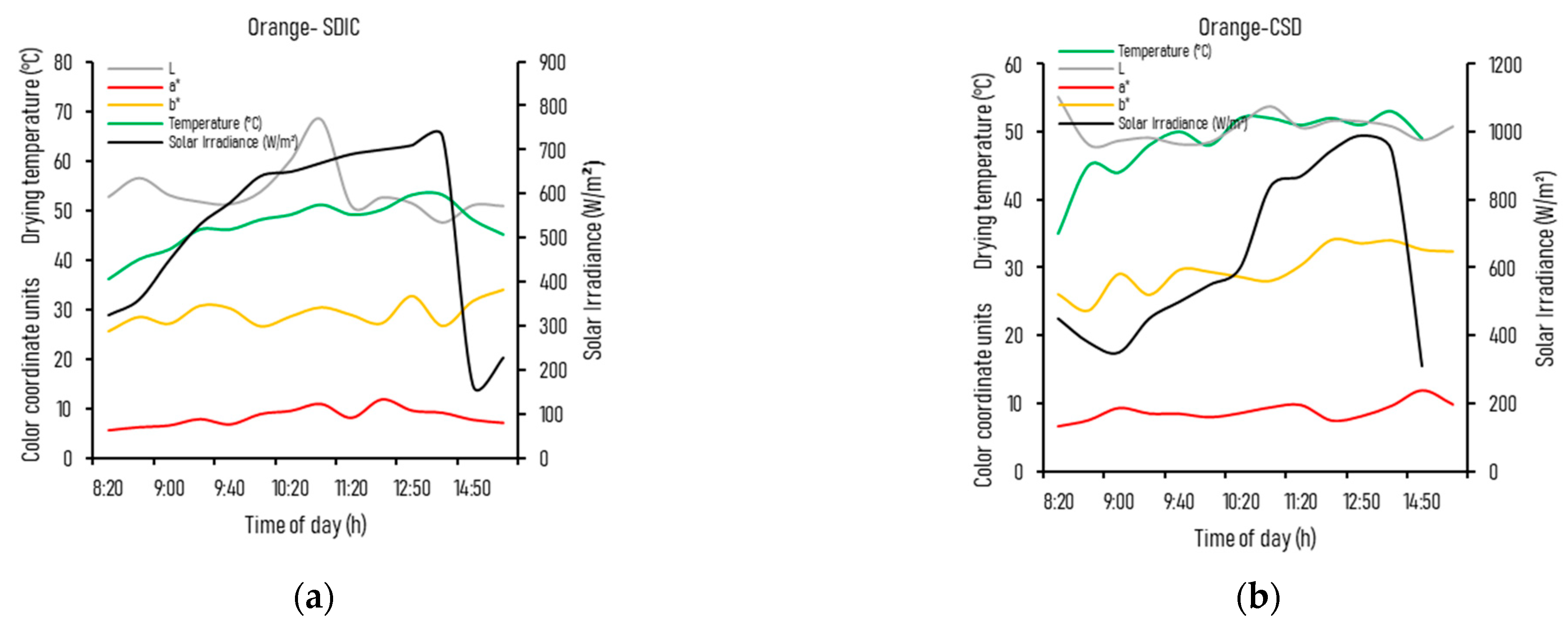

3.4.1. Orange Color Change

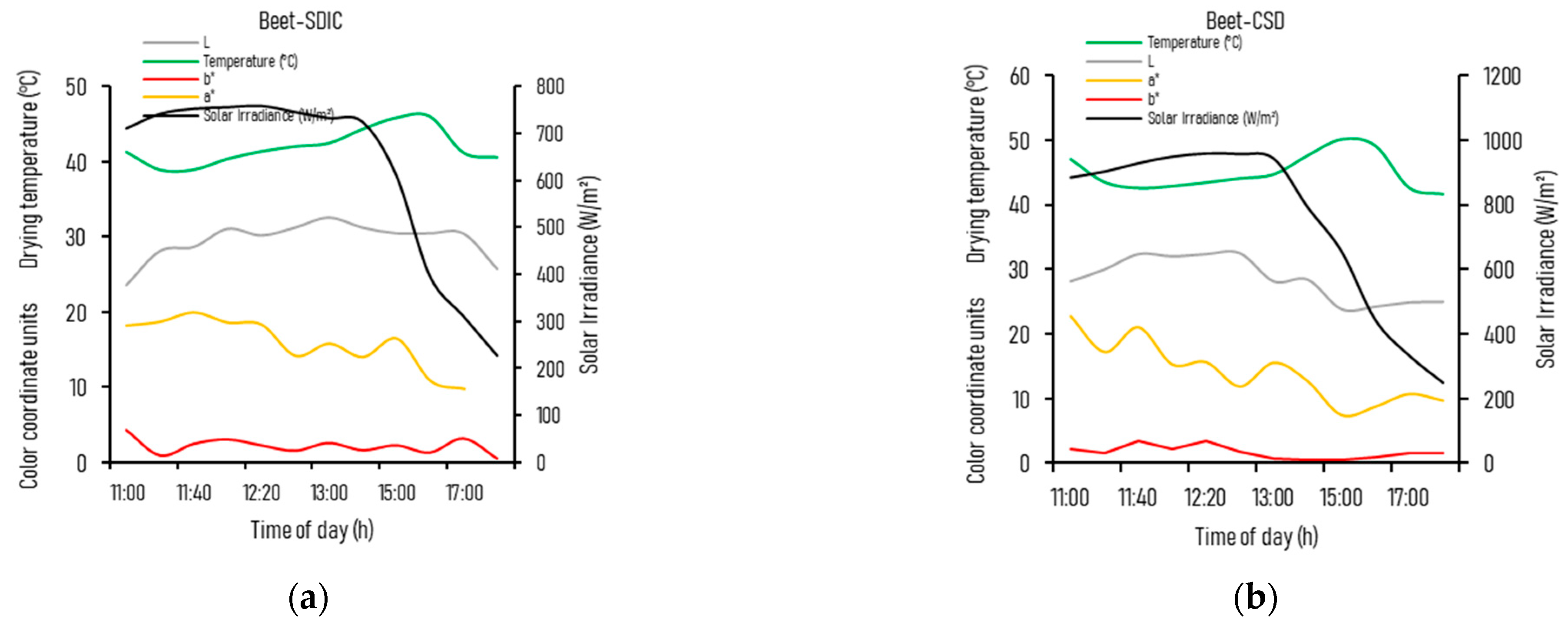

3.4.2. Beet Color Change

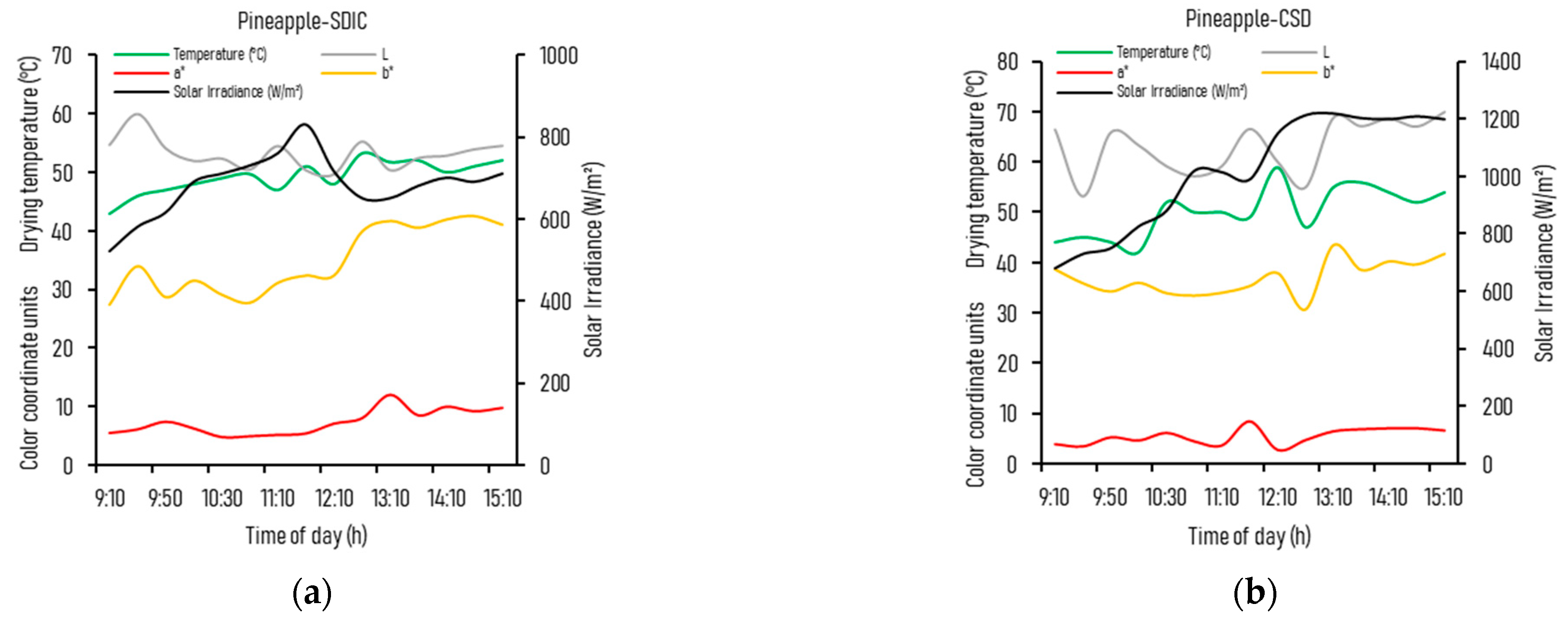

3.4.3. Pineapple Color Change

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Karim, M.A.; Hawlader, M.N.A. Drying characteristics of banana: Theoretical modelling and experimental validation. J. Food Eng. 2005, 70, 35–45. [Google Scholar] [CrossRef]

- Valin, H.; Sands, R.D.; van der Mensbrugghe, D.; Nelson, G.C.; Ahammad, H.; Blanc, E.; Bodirsky, B.; Fujimori, S.; Hasegawa, T.; Havlik, P.; et al. The future of food demand: Understanding differences in global economic models. Agric. Econ. 2014, 45, 51–67. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). Global Food Losses and Food Waste: Extent, Causes and Prevention; FAO: Rome, Italy, 2011; Available online: https://www.fao.org/4/mb060e/mb060e.pdf (accessed on 26 September 2025).

- Stehfest, E.; Bouwman, L.; van Vuuren, D.P.; den Elzen, M.G.J.; Eickhout, B.; Kabat, P. Climate benefits of changing diet. Clim. Change 2009, 95, 83–102. [Google Scholar] [CrossRef]

- Xiao, H.-W.; Mujumdar, A.S. Importance of drying in support of human welfare. Dry. Technol. 2020, 38, 1542–1543. [Google Scholar] [CrossRef]

- Raghavan, V.; Martynenko, A.; Shirkole, S.S. Role of drying in food quality, security, and sustainability. Dry. Technol. 2022, 40, 1499. [Google Scholar] [CrossRef]

- Deng, Z.; Li, M.; Xing, T.; Zhang, J.; Wang, Y.; Zhang, Y. A literature research on the drying quality of agricultural products with using solar drying technologies. Sol. Energy 2021, 229, 69–83. [Google Scholar] [CrossRef]

- Ibrahim, A.; Cattaneo, T.M.; Amer, A.; Helyes, L. Drying Technology Evolution and Global Concerns Related to Food Security and Sustainability. In Food Preservation and Packaging—Recent Process and Technological Advancements; IntechOpen: London, UK, 2023. [Google Scholar]

- García-Moreira, D.P.; Hernández-Guzmán, H.; Pacheco, N.; Cuervas-Bernardino, J.C.; Herrera-Pool, E.; Moreno, I.; López-Vidaña, E.C. Solar and Convective Drying: Modeling, Color, Texture, Total Phenolic Content, and Antioxidant Activity of Peach (Prunus persica (L.) Batsch) Slices. Processes 2023, 11, 1280. [Google Scholar] [CrossRef]

- Krokida, M.K.; Tsami, E.; Maroulis, Z.B. Kinetics on color changes during drying of some fruits and vegetables. Dry. Technol. 1998, 16, 667–685. [Google Scholar] [CrossRef]

- Tan, S.; Miao, Y.; Zhou, C.; Luo, Y.; Lin, Z.; Xie, R.; Li, W. Effects of Hot Air Drying on Drying Kinetics and Anthocyanin Degradation of Blood-Flesh Peach. Foods 2022, 11, 1596. [Google Scholar] [CrossRef]

- Bekbólet, M. Light effects on food. J. Food Prot. 1990, 53, 430–440. [Google Scholar] [CrossRef]

- Nair, P.K.; Espinosa-Santana, A.L.; Guerrero-Martínez, L.; López-Ortiz, A.; Nair, M.T.S. Prospects toward UV-blue filtered solar drying of agricultural farm produce using chemically deposited copper chalcogenide thin films on cellular polycarbonate. Sol. Energy 2020, 203, 123–135. [Google Scholar] [CrossRef]

- Manzocco, L.; Kravina, G.; Calligaris, S.; Nicoli, M.C. Shelf Life Modeling of Photosensitive Food: The Case of Colored Beverages. J. Agric. Food Chem. 2008, 56, 5158–5164. [Google Scholar] [CrossRef] [PubMed]

- García-Moreira, D.P.; López-Vidaña, E.C.; Moreno, I.; Rodríguez-Ortíz, D. Optical characterization and thermal performance of a novel solar dryer with dynamic control of solar radiation. Case Stud. Therm. Eng. 2024, 61, 105075. [Google Scholar] [CrossRef]

- Zhu, A.; Shen, X. The model and mass transfer characteristics of convection drying on peach slices. Int. J. Heat Mass Transf. 2014, 72, 345–351. [Google Scholar] [CrossRef]

- Krokida, M.K.; Karathanos, V.T.; Maroulis, Z.B.; Marinos-Kouris, D. Drying kinetics of some vegetables. J. Food Eng. 2002, 59, 391–403. [Google Scholar] [CrossRef]

- Teguia, M.S.; Chabane, F.; Arif, A.; Aouissi, Z. Drying of the orange slices, and energetic analysis of the drying chamber alimented by a solar air collector for extraction of the water from an orange slice. Sci. Afr. 2024, 24, e02149. [Google Scholar] [CrossRef]

- Nayi, P.; Ma, F.Y.; Huang, T.C.; Lee, Y.C.; Kumar, N.; Chen, H.H. Effect of solar radiation and full spectrum artificial sun light drying on the drying characteristics, ultra-structural and textural properties of white radish (Raphanus sativus L.). Sol. Energy 2024, 272, 112465. [Google Scholar] [CrossRef]

- Komonsing, N.; Reyer, S.; Khuwijitjaru, P.; Mahayothee, B.; Müller, J. Drying Behavior and Curcuminoids Changes in Turmeric Slices during Drying under Simulated Solar Radiation as Influenced by Different Transparent Cover Materials. Foods 2022, 11, 696. [Google Scholar] [CrossRef]

- Zogzas, N.P.; Maroulis, Z.B.; Marinos-Kouris, D. Moisture diffusivity data compilation in foodstuffs. Dry. Technol. 1996, 14, 2225–2253. [Google Scholar] [CrossRef]

- Onwude, D.I.; Hashim, N.; Janius, R.B.; Nawi, N.M.; Abdan, K. The effectiveness of combined drying techniques for agricultural products: A review. J. Food Eng. 2016, 188, 4–16. [Google Scholar]

- Liu, Y.; Duan, Z.; Sabadash, S. Effect of hot air drying temperatures on drying characteristics and physicochemical properties of beetroot (Beta vulgaris) slices. IOP Conf. Ser. Earth Environ. Sci. 2020, 548, 032058. [Google Scholar] [CrossRef]

- Chandran, J.; Nisha, P.; Singhal, R.S.; Pandit, A.B. Degradation of colour in beetroot (Beta vulgaris L.): A kinetics study. J. Food Sci. Technol. 2012, 51, 2678–2684. [Google Scholar] [CrossRef] [PubMed]

- Hamid, M.G.; Nour, A.A.A.M. Effect of different drying methods on quality attributes of beetroot (Beta vulgaris) slices. World J. Sci. Technol. Sustain. Dev. 2018, 15, 287–298. [Google Scholar] [CrossRef]

- García-Moreira, D.P.; López-Vidaña, E.C.; Moreno, I.; Delgadillo-Ruiz, L. Impact of Spectral Irradiance Control on Bioactive Compound and Color Preservation in Solar-Dried Papaya. Processes 2025, 13, 2311. [Google Scholar] [CrossRef]

- Pani, A.; Shirkole, S.S.; Mujumdar, A.S. Importance of renewable energy in the fight against global climate change. Dry. Technol. 2022, 40, 2571–2582. [Google Scholar] [CrossRef]

- Sugiyama, M.; Katsube, T.; Koyama, A.; Itamura, H. Effect of solar radiation on the functional components of mulberry (Morus alba L.) leaves. J. Sci. Food Agric. 2016, 96, 3915–3921. [Google Scholar] [CrossRef]

| Product | Moisture Content (g H2O/g d.m.) | Color Coordinates | ||

|---|---|---|---|---|

| L | a* | b* | ||

| Pineapple | 2.81 ± 0.12 | 54.75 ± 1.85 | 5.42 ± 0.31 | 27.37 ± 1.15 |

| Orange | 3.03 ± 0.15 | 52.67 ± 2.10 | 5.51 ± 0.28 | 25.53 ± 1.42 |

| Beet | 3.36 ± 0.18 | 28.2 ± 1.55 | 22.72 ± 0.95 | 2.21 ± 0.25 |

| Time (min) | Orange-SDIC | Orange-CSD | Beet-SDIC | Beet-CSD | Pineapple-SDIC | Pineapple-CSD |

|---|---|---|---|---|---|---|

| 0 | 3.09 ± 0.00 | 3.03 ± 0.00 | 3.37 ± 0.00 | 3.37 ± 0.00 | 2.84 ± 0.00 | 2.78 ± 0.00 |

| 20 | 2.78 ± 0.05 | 2.70 ± 0.06 | 2.85 ± 0.04 | 2.85 ± 0.06 | 2.49 ± 0.03 | 2.34 ± 0.05 |

| 40 | 2.70 ± 0.06 | 2.46 ± 0.09 | 2.55 ± 0.05 | 2.37 ± 0.08 | 2.34 ± 0.04 | 2.17 ± 0.07 |

| 60 | 2.46 ± 0.08 | 2.15 ± 0.10 | 2.33 ± 0.06 | 2.03 ± 0.09 | 2.20 ± 0.05 | 1.93 ± 0.08 |

| 80 | 2.30 ± 0.09 | 1.99 ± 0.12 | 2.11 ± 0.07 | 1.68 ± 0.10 | 2.02 ± 0.06 | 1.73 ± 0.09 |

| 100 | 2.07 ± 0.10 | 1.67 ± 0.13 | 1.85 ± 0.08 | 1.42 ± 0.11 | 1.85 ± 0.07 | 1.55 ± 0.10 |

| 120 | 1.83 ± 0.11 | 1.52 ± 0.13 | 1.65 ± 0.09 | 1.37 ± 0.12 | 1.64 ± 0.08 | 1.29 ± 0.11 |

| 150 | 1.52 ± 0.12 | 1.20 ± 0.15 | 1.46 ± 0.10 | 1.26 ± 0.13 | 1.41 ± 0.09 | 0.97 ± 0.12 |

| 180 | 1.28 ± 0.13 | 0.97 ± 0.16 | 1.26 ± 0.11 | 1.12 ± 0.14 | 1.08 ± 0.09 | 0.64 ± 0.13 |

| 240 | 0.90 ± 0.15 | 0.73 ± 0.17 | 0.90 ± 0.12 | 0.56 ± 0.16 | 0.58 ± 0.10 | 0.26 ± 0.15 |

| 300 | 0.49 ± 0.16 | 0.10 ± 0.19 | 0.38 ± 0.13 | 0.04 ± 0.17 | 0.29 ± 0.11 | 0.06 ± 0.16 |

| 360 | 0.18 ± 0.17 | 0.00 ± 0.19 | 0.04 ± 0.14 | 0.04 ± 0.18 | 0.06 ± 0.12 | 0.06 ± 0.17 |

| 420 | 0.06 ± 0.17 | 0.00 ± 0.20 | 0.04 ± 0.14 | 0.04 ± 0.18 | - | - |

| 480 | 0.06 ± 0.18 | 0.00 ± 0.21 | - | - | - | - |

| Sample Name | Slope (s−1) | R2 | Effective Moisture Diffusivity Deff (m2/s) |

|---|---|---|---|

| Orange-SDIC | −1.407 × 10−4 | 0.984 | 1.43 × 10−9 |

| Orange-CSD | −1.792 × 10−4 | 0.981 | 1.82 × 10−9 |

| Beet-SDIC | −1.548 × 10−4 | 0.991 | 1.57 × 10−9 |

| Beet-CSD | −2.235 × 10−4 | 0.987 | 2.27 × 10−9 |

| Pineapple-SDIC | −1.381 × 10−4 | 0.992 | 1.40 × 10−9 |

| Pineapple-CSD | −1.922 × 10−4 | 0.982 | 1.95 × 10−9 |

| Product | Parameter | SDIC (Mean ± SD) | CSD (Mean ± SD) | p-Value |

|---|---|---|---|---|

| Pineapple | ΔL | 54.6 ± 0.8 | 69.8 ± 1.2 | <0.001 |

| Δa* | 9.8 ± 0.5 | 6.55 ± 0.3 | 0.002 | |

| Δb* | 41.0 ± 1.1 | 41.7 ± 0.9 | 0.45 | |

| Beet | Δa* | 9.72 ± 0.6 | 9.62 ± 0.4 | 0.78 |

| Δb* | 0.47 ± 0.1 | 1.55 ± 0.2 | 0.03 | |

| Orange | Δb* | 32.77 ± 1.3 | 33.6 ± 1.1 | 0.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Moreira, D.P.; Moreno, I.; López-Vidaña, E.C. Controlled Solar Drying as a Sustainable Strategy to Preserve Color and Minimize Food Waste. AgriEngineering 2025, 7, 392. https://doi.org/10.3390/agriengineering7110392

García-Moreira DP, Moreno I, López-Vidaña EC. Controlled Solar Drying as a Sustainable Strategy to Preserve Color and Minimize Food Waste. AgriEngineering. 2025; 7(11):392. https://doi.org/10.3390/agriengineering7110392

Chicago/Turabian StyleGarcía-Moreira, Diana Paola, Ivan Moreno, and Erick César López-Vidaña. 2025. "Controlled Solar Drying as a Sustainable Strategy to Preserve Color and Minimize Food Waste" AgriEngineering 7, no. 11: 392. https://doi.org/10.3390/agriengineering7110392

APA StyleGarcía-Moreira, D. P., Moreno, I., & López-Vidaña, E. C. (2025). Controlled Solar Drying as a Sustainable Strategy to Preserve Color and Minimize Food Waste. AgriEngineering, 7(11), 392. https://doi.org/10.3390/agriengineering7110392