Abstract

This study investigates the impact of digital transformation on a Brazilian post-harvest engineering company. The manuscript examines how digital technologies impact performance and competitive advantages, providing actionable insights for practitioners. The methodology is a twofold case study. First, it describes the company’s technology development process, examining the journey from initial implementations to its current state over the past ten years. Then, it focuses on the recommendations for future advancements, provided by a leading technology research institute located in Germany. Data collection involved observation, interviews (personnel, clients, experts), document analysis, and facility tours. The findings include qualitative (grain quality, agility) and quantitative impacts (EBITDA increase, 84% storage efficiency). Barriers included mechanical adaptation and costs. Opportunities related by BIBA include advanced technologies (such as AI and digital twins), aligning with a proposed six-level digital maturity model for post-harvest systems. Regarding practical implications, the findings emphasize the need for a strategic vision for digital technology adoption in the post-harvest industry, which is crucial for addressing labor shortages, reducing losses, and promoting sustainability, with potential annual gains of $700 million. The main novelty introduced by this study is a novel, empirically derived six-level digital maturity model. It provides comprehensive qualitative/quantitative impact analysis, highlighting advanced technologies for industry challenges.

1. Introduction

The rapid advancement of the digital economy has led to substantial digital transformation in various sectors, including the food production sector. For established companies, embracing digital transformation is crucial to staying competitive, as it significantly alters operations and business models [1] and leads to modifications in activities and processes [2]. Innovation and technology have introduced new structures and practices [3], altering competitive landscapes and ecosystems within organizations of all sizes [4]. Key elements of this transformation include (i) redefining company boundaries, (ii) expanding products and services to reach a wider audience, and (iii) reconfiguring organizational identities while reducing property rights [5]. As companies implement digital transformation strategies to enhance value creation, they update their value frameworks and refresh business models to align with overall strategy and maintain a competitive edge [6,7,8]. The food production sector has also experienced a similar evolution [9].

Digital transformation enables organizations to overcome the limitations of their established structures, processes, and technological systems, thereby creating new avenues for delivering customized and value-added experiences to their customers. Despite this potential, the practical realization of such transformations has been far less successful. Empirical evidence indicates that over 90% of digital transformation initiatives fail to achieve their intended outcomes. The most frequently cited shortcomings include projects falling outside their original scope, significant delays in implementation schedules, and expenditures that exceed planned budgets [10].

To avoid such outcomes, companies must align the formulation and implementation of digital transformation strategies, adopting a phased approach throughout their growth [11]. Strategy formulation involves defining a policy for creating and capturing value through digital technologies, considering environmental factors, which require business model changes [12]. Conversely, implementation translates this strategy into actionable steps [13]. Effective execution is crucial for aligning actions with strategic objectives and responding to the complex organizational and technological challenges inherent to digitalization [14]. However, the literature often assumes that strategy will lead to automatic implementation [15]. In practice, companies frequently fail to achieve the expected benefits due to a lack of readiness, limited digital skills, and insufficient alignment between strategy and operational capacity [14]. The success of implementation is more critical than the quality of strategy formulation itself, as precise execution enables adaptive responses and mitigates the risks imposed by digital complexity [13].

In particular, the agri-food industry has been required to find sustainable long-term solutions to its operations [16]. Historically, it has evolved from focusing on food safety (up to 1950) to flavor enhancement (1950–1980) and health concerns (1980–2000), with a current emphasis on societal health [17,18]. Digital transformation, utilizing advanced technologies such as IoT, automation, and big data, enhances operational efficiency and informs strategic decision-making across various business functions [19,20,21]. In post-harvest activities, grain management addresses challenges such as meeting quality standards, reducing energy consumption, and minimizing costs, while also mitigating risks in agri-food supply chains [22]. The digitization of post-harvest processes improves resource efficiency, reduces waste, and supports sustainability [23]. However, the adoption of technologies for digital transformation differs among companies, with the agri-food sector receiving less focus than manufacturing [24,25]. Most research on digital transformation in agri-food consists of literature reviews and theoretical studies [26], primarily focusing on agricultural applications [27].

Research on the impact of digital transformation on post-harvest activities and technology adoption is limited [23]. A Scopus search (in October 2025) under the keywords “digital transformation” AND “manufacturing” returned 1620 articles in English published only in journals, between 2020 and 2026. A second similar search, using the keywords “digital transformation” and “agriculture,” returned 317. A final similar search under the keywords “digital transformation” AND “post-harvest” returned three articles. Thus, while digital transformation in manufacturing is a mature research topic, it remains less explored in agriculture and is almost unexplored in post-harvest activities, creating a gap in the literature that this study aims to bridge. Furthermore, although digital transformation in agriculture has been widely studied [28], rigorous, quantitative, and internationally comparative research on its application to grain post-harvest engineering remains scarce. Empirical studies that simultaneously measure economic impacts (e.g., EBITDA), operational efficiency, and food safety outcomes and benchmark findings against cutting-edge industrial technologies, are notably lacking. This article addresses these gaps by a case study focused on a Brazilian engineered solutions provider for post-harvesting activities. In short, the research gap this article aims to bridge, the research question it answers, and the novelty it brings are as follows:

- Research gap: The absence of integrated, quantitative, and comparative analyses of digital transformation’s impacts on post-harvest processes, particularly those that combine economic, operational, and food safety performance indicators.

- Research question: How does digital transformation influence the economic performance, operational efficiency, and food safety outcomes of post-harvest grain handling systems when benchmarked against industrial best practices?

- Novelty: The study presents a comprehensive, metrics-based framework for evaluating digital transformation in post-harvest engineering, integrating financial, operational, and technological indicators within a real-world industrial context—something not previously reported in the literature.

The purpose of this article is to describe the case of a company based in southern Brazil that specializes in providing engineered and integrated solutions for grain post-harvest operations. The research methodology is the case study, which is better suited to answer the “how” research question. The case is two-fold. First, it describes the company’s technology development process, examining the journey from initial implementations to its current state over the past ten years. This part is descriptive, reflecting on past actions and discussing their consequences and implications. The second part focuses on the recommendations for future advancements, provided by a leading technology research institute located in Germany. This part of the research is prescriptive, as the proposed actions have yet to be implemented. The research question is how digital transformation can influence outcomes and provide a competitive edge for a provider of engineered solutions in grain post-harvest, as well as for its clients.

The remainder of this article is structured as follows. Section 2 presents the materials and methods employed in the study. Section 3 describes the first part of the case study, focusing on the digital transformation within the Brazilian company, its qualitative and quantitative impacts, and the context of digitalization. Section 4 relies on the second part of the case study, presenting the context of digitalization in Germany and the potential impact of projects developed by the research institute on the company’s strategy. Finally, Section 5 presents the concluding remarks.

2. Materials and Methods

The study examines a Brazilian company, established in 1925, that leads the Latin American market of engineered solutions for post-harvesting, with a 40% share in Brazil. It offers solutions for grain processing, handling, and preservation, covering the entire value chain from farms to port terminals or processing facilities. Publicly traded since 1980, it operates in over 50 countries. Additionally, the study involves the Bremer Institut für Produktion und Logistik GmbH (BIBA) of the University of Bremen, Germany, which is involved in 40 funded research projects as of April 2024. BIBA facilitates technology transfers through published research, securing more than 50 patents from its projects.

The digital transformation process in post-harvest engineering solutions is only partially understood [23], which justifies an exploratory study that addresses lesser-known and complex phenomena [14]. The strategy is the case study, which effectively answers “how” research questions. The research techniques are non-participant direct observation and semi-structured interviews with practitioners and clients. References to recent, high-impact literature ensure the study’s internal validity. Comparing with a structure of international best practices derived from observations and interviews with experts from a German research institute ensures external validity.

The first part of the study, in Brazil, included the following:

- An examination and review of documents provided by the company;

- Guided tours of the company’s facilities;

- Interviews with eight portfolio managers and specialists;

- Interviews with two practitioners from two clients;

- Guided tours in two client facilities, accompanied by two practitioners;

- A comparison with a structure of best practices retrieved from BIBA;

- A final feedback meeting to review findings and ensure reliability.

The second part, in Germany, included the following:

- Review of projects, documents, and technologies provided by the institute.

- Guided tours of BIBA’s facilities, with discussions led by professors and researchers involved in relevant projects.

The interviews employed open-ended questions and were structured to last no longer than 90 min each. To facilitate subsequent analysis, data were organized and documented for retrieval. The researchers ensured that participant consent was obtained and that all necessary data protection protocols were followed to adhere to ethical requirements. All interviews were audio-recorded and transcribed. The qualitative data were examined through a thematic analysis, which combined deductive coding (evolution, qualitative impacts, quantitative impacts, digitalization context), based on predefined technological, organizational, and strategic dimensions, with inductive coding to capture emerging themes (overall sustainability of the industry). Two researchers independently coded and compared results to ensure consistency, providing a transparent and reliable analytical process. Table 1 informs the qualifications of the interviewees in both locations.

Table 1.

Profile of Interviewees.

3. Results: The Engineered Solutions Provider

This section reflects the content retrieved from the company’s documents, interviews, guided tours, and two clients’ applications. Eventually, references to literature empirically support the findings.

3.1. Evolution of the Company

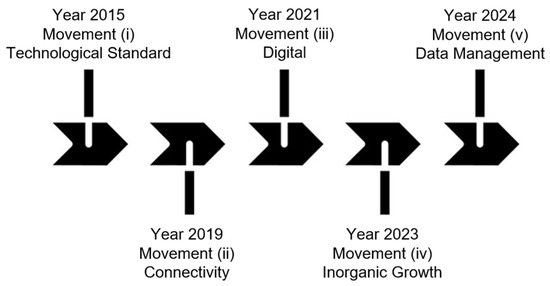

Digital transformation in agriculture varies across sectors. In the specific case of the company, improvements in machinery and resources have increased yields per hectare for its clients. At the same time, enhancements in seed genetics have improved resistance to pesticides. New developments in pesticide formulations and precision farming have refined pest control and optimized practices. Machinery for planting, protection, and harvesting has increased productivity and accuracy, and new techniques in planting, fertilization, and irrigation have further enhanced land efficiency. Meanwhile, post-harvest grain processing has focused on maintaining quality and capacity with expansions in silos, dryers, and conveyors [29]. The company developed digital technologies for autonomous operations, loss reduction, and a data-driven revenue model through a phased digital transformation of its product development process. The evolution encompassed six stages identified from interviews: (i) technological evolution and standardization; (ii) connectivity; (iii) digital new structure; (iv) inorganic growth; (v) data management, which the company is now entering, and (vi) an emerging phase characterized by a growing emphasis on sustainability.

The company’s transformation began with the development of a technological platform to oversee and automate storage units, mitigating dependence on heterogeneous suppliers and systems. Drawing on Industry 4.0 principles, automation was unified, and equipment architecture was standardized through the integration of PLCs. This advancement reinforced local automation networks, enabled interoperability of communication protocols, and consolidated centralized control. The outcome was measurable: post-harvest quality improved, equipment efficiency increased, operational safety was strengthened, and labor and storage losses were reduced.

The second phase enhanced connectivity, data collection, and storage capabilities. Embedded automation solutions were designed to perform dual functions: real-time operational adjustments and synchronization with a cloud platform via an internet gateway. This connectivity allowed remote monitoring, alert generation, and access to historical records from any connected device. For the first time, the organization gained visibility into equipment parameters and conditions in real time after delivery and startup.

In the third phase, digital technologies and data assumed strategic relevance, a dedicated digital division was created within the strategic services pillar. This division was tasked with coordinating digital innovations across products and services, defining business rules, and developing advanced solutions for automation and connectivity. By formalizing governance and centralizing responsibility, the company established a sustainable structure to drive digital transformation initiatives.

In the fourth phase, to accelerate progress, the company acquired a leading technology firm with expertise in digital products and an extensive client base. This acquisition reinforced the digital division and catalyzed new developments in post-harvest grain processing. It also enabled the provision of remote monitoring, consultancy, and subscription-based services, generating recurring revenue streams. Furthermore, control over the production of critical technology components was secured, reducing dependency on external suppliers and ensuring long-term strategic autonomy. In short, within the framework of inorganic growth, the digital division prioritized establishing a robust research and analytics infrastructure.

The rapid growth of field data volumes motivated a strategic initiative to transform information into actionable insights for both the company and its clients, characterizing the fifth phase in which the company recently entered. Ongoing projects focus on detecting patterns and opportunities through advanced analytical techniques, supported by a centralized data lake and a data warehouse designed for large-scale processing. Mathematical models and artificial intelligence methods, including generative neural networks, are utilized to transform raw data into structured knowledge, thereby creating new value for operations and informed decision-making.

Figure 1 illustrates the past movements and the pace at which the company implemented digital transformation actions.

Figure 1.

Strategic movements of the company.

The absence of a long-term digital transformation strategy is evident as new initiatives emerge to improve the product portfolio. Key projects include launching e-commerce sales and implementing Building Information Modeling (BIM) for grain storage units. BIM enhances collaboration through 3D models that represent the lifecycle information of storage units, improving visualization and communication among stakeholders. It creates detailed models that optimize project planning and execution, leading to enhanced efficiency, reduced costs, and improved sustainability. These efforts underscore the urgent need for a clear corporate digital transformation strategy to ensure alignment across the organization.

3.2. Qualitative Impacts for the Company

The impacts of digital transformation refer to the effects experienced by business organizations during this process. Ref. [30] identifies that digital transformation can have a significant impact on both organizational capabilities and customer value, mediated by enhanced agility and data capabilities. These impacts can be either positive or negative for both parties. Despite varying terminologies in the literature, Ref. [30] emphasizes that the primary goal of leveraging digital transformation is to foster innovation and create value for both organizations and their stakeholders. Implementing digital transformation enables organizations to achieve industry differentiation. Ref. [30] highlights that competitive priorities for post-harvest solution providers shift as the market evolves with technological advancements in grain storage facilities.

Likewise, other companies in the post-harvest engineering sector have begun their digital transformations, following the market leader, boosting a broader industry shift towards digitalization. The primary goal is to create value by aligning digital strategies with business objectives and market demands, benefiting all stakeholders. In the company’s case, Table 2 outlines key impacts identified in the company, stemming from strategic moves toward digital transformation in post-harvest processes. The first three impacts address customer value, while the others focus on organizational value.

Table 2.

Qualitative Impacts.

3.3. Quantitative Impacts: EBITDA and Efficiency

The EBITDA margin indicates an organization’s operating profit as a percentage of net revenue. EBITDA consistently grew from 2010 to 2014, when the company made its first strategic move, introducing digital technologies into post-harvest solutions. Initially, profitability declined significantly due to a lack of market knowledge and understanding of the company. As soon as the market became aware of the benefits of early applications, profitability rose, reaching a level never seen before. Small tactical movements also occurred during this period, but profitability remained high as advanced digital technologies in 2015 significantly enhanced financial outcomes. Table 3 displays the EBITDA margin by the movements mentioned in Figure 1.

Table 3.

EBITDA.

The second analysis focused on the efficiency of the company’s grain storage solutions, particularly silos equipped with digital technology linked to a cloud platform. Using the Data Envelopment Analysis (DEA) model, the study evaluated 6000 silos across Brazil, which represent approximately 12% of the nation’s total storage capacity. It examined quantitative efficiency (technical losses due to moisture), qualitative efficiency (grain mass temperature reduction), and energy efficiency (the power ratio of aeration systems). The results showed an average efficiency of 84%, with a 91% reduction in moisture-related losses for digitally equipped silos compared to the national average. Additionally, automatic aeration systems improved quantitative efficiency by 5% over systems with only digital monitoring. This study, along with its complete related details, has not yet been published.

Digital technologies have enhanced the grain drying process, enabling the safe storage of soybeans at a moisture content of 13%. Grain dryers are essential for removing excess moisture, and even a 1% error in drying can lead to significant economic losses. For instance, a silo with a capacity of 100,000 sacks, valued at about US$2.8 million, could face a loss of US$28,000 due to a 1% error. In Brazil (153.8 million tons of soybeans in 2023), this could translate to a potential loss of USD 700 million. Thus, incorporating digital technology to monitor and control moisture levels can significantly reduce post-harvest losses. Investments in such technology typically account for approximately 3.2% of total spending on storage equipment, but clients often see a return on investment in early harvests.

While recognizing that external factors—such as growth in Brazilian soybean production, global grain price fluctuations, or non-digital initiatives—may have influenced the company’s performance between 2015 and 2023, the analysis attributes improvements primarily to digital transformation based on triangulated evidence. Internal performance data, project documentation, and managerial interviews consistently linked gains in EBITDA and warehouse efficiency to specific digital initiatives, including automation, data-driven inventory control, and predictive maintenance. Nevertheless, causal attribution in a single-case study remains inherently limited. Future research should validate these relationships across multiple firms and contexts to isolate the specific effects of digital transformation on performance outcomes.

3.4. The Context of Digitalization in the Company

Implementing a digital transformation strategy in post-harvest grain management involves addressing several barriers and risks that the organization must overcome. A key challenge was adapting existing mechanical designs for automation, as many systems were not originally designed for this purpose. The adaptation requires significant investments in research and development (R&D) as well as retrofitting. Consequently, many projects face delays as mechanical adjustments take precedence over automation activities. Financial implications also play a role in market competitiveness. While investing in digital technology can benefit the client, it can raise product prices, potentially affecting customer willingness to change. Furthermore, the rapid advancement of technology can render solutions obsolete, necessitating ongoing updates and investment, primarily due to the need for integrating diverse technologies. Moreover, sustainability concerns and social responsibility require alignment with environmental and regulatory standards. Resistance to change within organizations poses another significant challenge, as management and employees may struggle to adapt to new roles and technologies, underscoring the need for effective training and strategic alignment.

To tackle such challenges, the company has created dedicated internal units for digital transformation, positioned between R&D and information technology (IT) departments. This new unit, comprising experts in automation, electrical engineering, and software development, became important for bridging the gap between R&D and IT and integrating advancements into digital products. Data collection from post-harvest equipment is essential for modernization, enhancing decision-making while also introducing security and privacy challenges, particularly with IoT solutions. Robust security measures, including firewalls and data encryption, have been proven crucial in protecting against cyber threats. Additionally, managing collected data—such as grain status and storage conditions—contributes to maintaining competitiveness, customer trust, and compliance with data privacy regulations. Furthermore, workforce qualifications extended beyond the digital unit, encompassing all levels of the organization. The company had to invest in training or recruiting skilled talent to meet the demand for specialized knowledge and support customer personnel in maintaining automation systems.

Addressing these areas—sustainable product portfolio, digital infrastructure, cultural barriers, technology costs, workforce qualification, technological challenges, and strategy review—was critical for the company to overcome obstacles to digital transformation in post-harvest grain management. In summary, the analysis identifies seven key areas that must be addressed for the successful implementation of digital technologies in the company: (i) sustainable product portfolio, (ii) digital infrastructure, (iii) cultural and human resource barriers, (iv) technology costs, (v) workforce skills, (vi) technological and integration challenges, and (vii) strategy review.

4. Results: The Contribution of the Research Institute

This part reflects the content of the second part of the research at the BIBA Institute in Germany. Eventually, references to literature empirically support the findings.

4.1. The Local Context of Digitalization

Digitalization in agriculture is a strategic priority for the modernization and sustainability of the German agri-food sector, guided by both national and European innovation policies [31,32]. Although key technologies are transforming farming practices, challenges such as limited infrastructure still constrain adoption [33]. A nationwide consultation with stakeholders and experts in Germany identified six critical obstacles to digital transformation in agriculture [31]:

- Economic and ecological advantages: Digitalization benefits, such as cost savings and increased efficiency, are more widely recognized by larger, more educated farmers than by small ones.

- Improved intercompany coordination: The lack of a standardized data management system hinders transparency and complicates intercompany coordination.

- Socioeconomic risks: Concerns about control, data protection, and system complexity indicate that data safety is necessary for implementation.

- Financial risk: Concerns about investment returns and feasibility indicate that profitability is necessary for implementation.

- Educational deficits: A lack of digital literacy and technology knowledge are significant barriers to further implementation.

- Lack of infrastructure: A lack of infrastructure is a significant barrier to further implementation.

Such factors highlight key challenges in adopting digital technologies in the German agricultural sector. Addressing infrastructure, data management, knowledge gaps, and risk-mitigating policies may require standardized data, improved education, stronger collaboration, and clear regulations to build trust among stakeholders.

This study examined seven pioneering projects from BIBA in the German digital arena. Each project faces unique challenges and presents opportunities for significant advancements. The projects are ErgoKI, MaxManter, Digikleb, Port2Connect, Syditil, SafetyDrone, and Heatrix. Here is a description of each one.

ErgoKI develops a system for acquiring and analyzing ergonomic data in manual assembly using wearables and machine vision. Its main challenge is accurately integrating sensors in dynamic environments. At the same time, its opportunity lies in utilizing AI analyses to identify workers’ ergonomic needs and implement targeted improvements for safer and more efficient workplaces.

MaxManter creates a control platform for effluent treatment stations using augmented reality (AR) and intelligent scheduling. The challenge is ensuring reliable AR-based remote diagnostics in complex wastewater environments. Its opportunity is reducing downtime and costs through remote monitoring and real-time support, improving maintenance efficiency.

Digikleb digitizes adhesive processes in the automotive sector through advanced process modeling. The challenge is accurately predicting the behavior of adhesive systems amid complex variables. Its opportunity lies in the rapid identification of quality deviations and the proactive implementation of corrective measures, thereby improving efficiency and product quality.

Port2Connect designs a digital port logbook with intelligent monitoring. The challenge is ensuring resilience under adverse port conditions. The opportunity lies in achieving greater transparency, efficiency, emission reduction, and protection of infrastructure.

Syditil develops digital twins for logistics optimization via advanced simulations and risk forecasting. The challenge is integrating complex logistics data into reliable models. The opportunity is continuous process improvement through accurate simulations, which enhance efficiency and lower costs.

SafetyDrone develops autonomous drones that utilize AI and sensors to identify safety risks in the shipbuilding industry. The challenge is to ensure robust operation in dynamic environments. The opportunity lies in improving worker safety through autonomous aerial monitoring and early hazard detection.

Finally, Heatrix provides carbon-free high-temperature industrial heat, targeting decarbonization in energy-intensive industries. The challenge is delivering continuous heat up to 1500 °C with efficiency and cost competitiveness. Thermal storage enables 24/7 green heat despite the intermittency of renewable energy sources. This provides an opportunity for scalable, modular, and competitive green heat that can transform industrial energy use, supporting global decarbonization goals.

The projects highlight the currently explored digital technologies with the potential to improve efficiency in the grain post-harvest sector. Such advancements focus on enhancing processes such as receiving, cleaning, drying, storage, and shipping, thereby improving product quality and sustainability. For the studied Brazilian company and other local companies engaged in post-harvest grain solutions, such technologies may present valuable opportunities for leveraging results. Innovations such as smart sensors, artificial intelligence (AI), and advanced monitoring systems can boost efficiency, safety, and quality, positioning companies for a digitally advanced future. Key trends include remote monitoring, AI integration, data analysis for optimization, and sustainable, flexible solutions adaptable to multiple conditions. Investing in training and education may be necessary to maximize benefits and maintain global competitiveness.

4.2. How Can the Institute Impact the Company’s Strategy?

Evaluating the potential impact of BIBA’s technological developments requires linking them to the studied company’s current strategic orientation. Between 2015 and 2023, the company pursued a digital diversification strategy based on an entrepreneurial orientation. In this period, the company integrated digital technologies, acquired external competencies, and explored new monetization models. This trajectory is consistent with disruptive innovation theories, which emphasize how new technologies alter development trajectories and challenge incumbent structures [34]. It also reflects diversification principles grounded in the identification of interdependencies between markets, technologies, and organizational capabilities to enhance competitiveness [35].

To support this trajectory, a cross-functional digital unit was established, bridging the gap between engineering and IT. Although results show significant operational gains (e.g., higher EBITDA margins, reduced drying losses), the transformation faced challenges, including increased technology integration costs, re-engineering requirements, workforce qualifications, and cultural resistance. These difficulties are similar to those observed in the German context [30], highlighting opportunities for knowledge transfer and exchange. BIBA projects provide solutions that can directly reinforce the company’s qualitative impacts, previously identified as follows: grain quality, customer experience, product innovation, brand reputation, agility and flexibility, new business models, and organizational culture.

Criteria and sources were used to assess the institute’s potential impact and to identify the challenges and opportunities associated with the projects. This identification followed a structured case study protocol using multiple evidence sources, including internal company reports, semi-structured interviews with managers and engineers, and technical documentation from BIBA projects. The impacts were organized according to qualitative impacts and technologies, ensuring a systematic and theoretically grounded assessment. Table 4 maps the potential impacts of BIBA projects on the qualitative outcomes of the Brazilian company.

Table 4.

Potential impacts of BIBA projects on the qualitative outcomes of the Brazilian company.

Grain quality can be enhanced through the adoption of digital twins and artificial intelligence algorithms for monitoring and predictive control, as exemplified by the SYDITIL and Digikleb projects. Customer experience can be enhanced through the use of augmented reality technologies and remote monitoring, as demonstrated in the MaxManter and Port2Connect projects. Product innovation initiatives, such as ErgoKI, SafetyDrone, and Heatrix, provide sensor devices and sustainable thermal solutions that are applicable to drying processes and operational safety. Brand reputation can be positively impacted by control and traceability systems based on data analysis, such as those used by Digikleb. At the same time, operational agility and responsibility are fostered through the use of communication networks and predictive methods, enabling rapid responses to operational variations. New business models may emerge from the integration of service platforms and remote automation. Port2Connect can drive both attributes. Finally, organizational culture can be transformed through the adoption of collaborative practices among companies, universities, and government institutions, as exemplified by the institutional model established at BIBA.

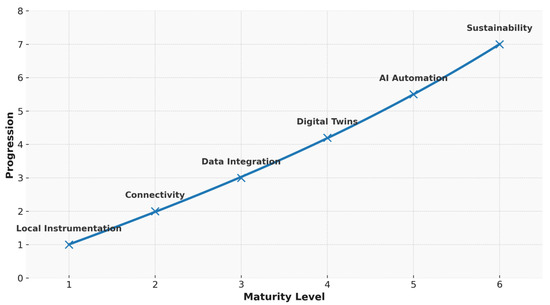

Qualitative advances and impacts can serve as a structuring axis for the adoption of technology. Such an approach not only aligns solutions with the company’s strategic priorities but also supports investment planning and the definition of performance targets within the digital transformation process. The process can be systematized through a progressive digital maturity model comprising six sequential levels, each associated with specific organizational capabilities and enabling technologies:

- (i)

- Local instrumentation—basic automation and sensorization at the equipment level;

- (ii)

- Connectivity and data collection—establishment of networks and digital infrastructure for real-time monitoring;

- (iii)

- Data integration and analysis—centralization of information and use of analytics for decision support;

- (iv)

- Simulation and prediction—application of digital twins and modeling tools for performance optimization;

- (v)

- Intelligent automation—integration of artificial intelligence, machine learning, and augmented reality for autonomous processes; and

- (vi)

- Operational sustainability—deployment of clean energy solutions and circular practices to ensure long-term efficiency.

Figure 2 shows the evolution of the maturity model.

Figure 2.

Digital Maturity Curve for Post-Harvest Systems.

The definition of the six maturity stages was derived from an articulation of three complementary sources: (i) the empirical analysis of the company’s digital transformation trajectory within the post-harvest grain sector; (ii) the observation of advanced technologies implemented in projects conducted by a German research institute specializing in industrial innovation; and (iii) established theoretical models in the literature, including CMMI [36], the Smart Industry Maturity Index, and frameworks grounded in the Technology–Organization–Environment (TOE) approach [37]. The latter underpins both the conceptual structure of the maturity levels and the logic of the curve’s vertical progression axis, which links digital evolution to the gradual accumulation of technological capabilities.

In contrast to the CMMI, which primarily emphasizes software process improvement and organizational capability development, and the Smart Industry Maturity Index, which targets general industrial digitalization, the proposed model adapts these conceptual foundations to the agri-industrial domain. Specifically, it integrates technological, organizational, and environmental dimensions unique to the post-harvest context—such as data-driven traceability, automation in drying and storage, and the application of IoT systems for grain quality monitoring. This approach aligns with recent TOE-based maturity models [38], which conceptualize digital advancement through the joint evolution of technology, organization, and environment while complementing sector-specific adaptations designed for manufacturing SMEs [39].

Based on empirical evidence, the case company is positioned at Level IV, characterized by integrated process instrumentation, digital sensors, centralized monitoring systems, and early simulation tools for operational optimization data platforms. It is now advancing toward Level V, where predictive analytics and decision-support systems become embedded in operational management. The technologies analyzed in the BIBA projects are predominantly concentrated in the last two levels, offering tangible support for the company’s ongoing digital evolution. This positioning not only demonstrates the applicability of the proposed framework but also underscores its distinct contribution by contextualizing digital maturity within the operational, technological, and environmental specificities of the post-harvest grain industry. This foundation supports the subsequent analysis, which examines how the assessed maturity level aligns with the company’s performance outcomes and strategic priorities.

Additionally, the role of collaborative innovation networks stands out as a driver of technological advancement. The structure adopted by BIBA, based on public–private partnerships, serves as a reference for creating technological co-creation environments applicable to the Brazilian agricultural sector. Participation in joint projects with universities and research centers, combined with the use of innovation incentive programs and the establishment of applied experimentation environments, can expand the company’s internal capabilities and accelerate the implementation of emerging technologies. Despite the benefits already documented in the digital transformation process, technical gaps persist, particularly in the area of real-time integration between predictive models based on artificial intelligence and physical control systems. Overcoming this barrier requires the development of platforms that can connect automated decisions to industrial operations, which demands coordinated efforts in applied research, systems engineering, and validation within operational environments.

5. Final Remarks: Conclusion, Limitation, Further Research

The analysis of profit margin increases and their impact on agricultural communities, operational efficiency, and perceived value reveals that the digital revolution is more than just a technological transformation; it marks a significant cultural shift that directly affects agricultural systems. This evolution reflects not only the adaptation to new technologies but also the leadership needed to shape industry trends. Despite the challenges and barriers, a strategic vision enables these obstacles to be transformed into opportunities. Value creation was demonstrated through both qualitative and quantitative impacts. The findings indicate a positive alignment between organizational goals, market demands, and the tangible benefits derived from integrating digital technologies.

In light of the growing shortage of qualified workforce and the complexities of managing storage units, clients should invest in digital technologies to maintain operational efficiency and sustainability. Additionally, technology plays a crucial role in reducing post-harvest losses and preserving grain quality, which are critical factors for market competitiveness and profitability. Investing in digital solutions not only enhances operational efficiency but also fortifies clients’ capacity to tackle emerging sector challenges, positioning them as innovative and sustainable leaders.

The company must realign its strategy to prioritize the creation and appropriation of value through digital technologies as a means to achieve long-term competitiveness. The digital strategy should explicitly account for external environmental dynamics, technological potential within the competitive landscape, and market evolution. Defining the scope of digital transformation and adjusting the business model accordingly are critical to sustaining strategic advantage. Importantly, the company should avoid transferring the full potential value of digital transformation to the acquired technological player, as this would weaken its capacity for innovation and differentiation. Instead, the acquired technology must be actively integrated into the company’s portfolio to generate a competitive advantage through innovative application rather than mere business expansion.

Proper integration of the organizational structures, processes, and cultures of both companies is crucial for the technology to become a true competitive differentiator. The value generated by the technology must be directly reflected in the company’s operations, thereby strengthening its market position and transforming the acquisition into a strategic advantage. The results also highlight the impact of these innovations on reducing energy consumption, improving grain quality control, ensuring process efficiency, and enhancing food safety. In the drying process, identified innovations demonstrate potential operational gains estimated at USD 700 million annually in Brazil. Furthermore, the research indicates that these innovations can create both quantitative and qualitative economic value, benefiting not only the post-harvest sector but also the entire agricultural supply chain.

The primary implication of this research is the necessity of creating an internal digital structure essential for the success of digital transformation. Acquiring a technological player should form part of a broader strategy that minimizes dependence on external suppliers, ensures greater control over innovations and costs, and, most importantly, integrates the technology into the company’s portfolio to differentiate it in the market. Emerging technologies identified in Germany are particularly relevant for addressing the challenges of digital transformation and guiding corporate strategies. This study provides insights for companies and researchers seeking to explore digitization opportunities in the post-harvest grain sector, with a focus on achieving economic and efficiency gains in drying and storage units.

Future research may extend findings by examining the long-term effects of digital transformation and by developing structured frameworks for implementing digital strategies in post-harvest systems. Further investigations should also address how digital technologies can enhance the management of waste and by-products, adapting established recovery practices—such as reuse, recycling, resale, and controlled re-disposal [40]—to agricultural contexts. Although the proposed model has not yet undergone validation through expert panels or multi-case analysis, it constitutes an original conceptual contribution that advances understanding of digital transformation within post-harvest engineering. Subsequent studies are encouraged to define control metrics, apply, and validate the model across diverse organizational environments to strengthen its robustness and generalizability.

Finally, the findings and the proposed maturity model, although grounded in empirical evidence, derive from the experience of a single leading company in the post-harvest grain sector. Consequently, their generalizability should be interpreted with caution. Overall, this study advances our understanding of how digital maturity can inform strategic alignment and value creation in agri-industrial environments, contributing to both the academic discourse on digital transformation and managerial practice in technology-intensive sectors. In particular, the emerging technologies observed in Germany provide a reference for continuous innovation, delineating a trajectory toward a future in which digital transformation, sustainability, and value creation increasingly converge in post-harvest grain processing.

Author Contributions

Conceptualization, D.S., and M.A.S.; methodology, D.S., E.M.F., S.O., and H.E.; validation, E.M.F., S.O., and H.E.; formal analysis, E.M.F.; investigation, D.S., S.O., and H.E.; resources, E.M.F.; data curation, S.O., and H.E.; writing—original draft preparation, D.S.; writing—review and editing, M.A.S.; visualization, D.S., E.M.F., S.O., and H.E.; supervision, M.A.S.; project administration, E.M.F.; funding acquisition, M.A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding. M.S. funded the APC.

Institutional Review Board Statement

This research was classified as an exempt study. According to Brazilian legislation Resolução Nº 510/2016, Article 1, Section VII, studies that deepen theoretical understanding of situations emerging spontaneously in professional practice, without collecting identifiable personal data, are exempt from evaluation by an ethics committee. No identifiable information was obtained in this study.

Informed Consent Statement

Informed consent for participation was obtained from all subjects involved in the study.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author(s).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Vuoso, V.; Mondelli, A.; Ceniti, C.; Venuti, I.; Ciardella, G.; Proroga, Y.; Nisci, B.; Ambrosio, R.L.; Anastasio, A. Assessing Risks and Innovating Traceability in Campania’s Illegal Mussel Sale: A One Health Perspective. Foods 2025, 14, 2672. [Google Scholar] [CrossRef]

- Fatorachian, H.; Kazemi, H. A critical investigation of Industry 4.0 in manufacturing: Theoretical operationalization framework. Prod. Plan. Control 2018, 29, 633–644. [Google Scholar] [CrossRef]

- Westerman, G.; Bonnet, D.; McAfee, A. The nine elements of digital transformation. MIT Sloan Manag. Rev. 2014, 55, 1–6. [Google Scholar]

- Ardito, L.; Petruzzelli, A.; Panniello, U.; Garavelli, A. Towards Industry 4.0: Mapping digital technologies for supply chain management-marketing integration. Bus. Process Manag. J. 2019, 25, 323–346. [Google Scholar] [CrossRef]

- Parmentier, G.; Mangematin, V. Orchestrating innovation with user communities in the creative industries. Technol. Forecast. Soc. Change 2014, 83, 40–53. [Google Scholar] [CrossRef]

- Iansiti, M.; Lakhani, K.R. Digital ubiquity: How connections, sensors, and data are revolutionizing business. Harv. Bus. Rev. 2014, 92, 90–99. [Google Scholar]

- Pigni, F.; Piccoli, G.; Watson, R. Digital data streams: Creating value from the real-time flow of big data. Calif. Manag. Rev. 2016, 58, 5–25. [Google Scholar] [CrossRef]

- Warner, K.; Wäger, M. Building dynamic capabilities for digital transformation: An ongoing process of strategic renewal. Long Range Plan. 2019, 52, 326–349. [Google Scholar] [CrossRef]

- Baierle, I.; Silva, F.; Correa, R.; Schaefer, J.; Costa, M.; Benitez, G.; Nara, E. Competitiveness of food industry in the era of digital transformation towards agriculture 4.0. Sustainability 2022, 14, 11779. [Google Scholar] [CrossRef]

- Mctaggart, V.; Loonam, J. Exploring top management support for digital transformation: A case study of a European Financial Services organization. IEEE Trans. Eng. Manag. 2023, 71, 13787–13801. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Wang, H.; Zhang, S. The impact of digital transformation on enterprise performance: An empirical analysis based on China’s manufacturing export enterprises. PLoS ONE 2025, 19, e0299723. [Google Scholar] [CrossRef] [PubMed]

- Correani, A.; De Massis, A.; Frattini, F.; Petruzzelli, A.M.; Natalicchio, A. Implementing a digital strategy: Learning from the experience of three digital transformation projects. Calif. Manag. Rev. 2020, 62, 37–56. [Google Scholar] [CrossRef]

- Gimbert, X.; Bisbe, J.; Mendoza, X. The role of performance measurement systems in strategy formulation processes. Long Range Plan. 2010, 43, 477–497. [Google Scholar] [CrossRef]

- Limani, Y.; Hajrizi, E.; Stapleton, L. The complexity of business process digitalization and organisational challenges. IFAC-PapersOnLine 2022, 55, 346–351. [Google Scholar] [CrossRef]

- Feurer, R.; Chaharbaghi, K.; Wargin, J. Analysis of strategy formulation and implementation at Hewlett-Packard. Manag. Decis. 1995, 33, 4–16. [Google Scholar] [CrossRef]

- Jambrak, A.R.; Nutrizio, M.; Djekic, I.; Pleslic, S.; Chemat, F. Internet of nonthermal food processing technologies (IoNTP): Food industry 4.0 and sustainability. Appl. Sci. 2021, 11, 686. [Google Scholar] [CrossRef]

- Silva, V.L.; Sereno, A.M.; Sobral, P.J. Food industry and processing technology: On time to harmonize technology and social drivers. Food Eng. Rev. 2018, 10, 1–13. [Google Scholar] [CrossRef]

- Ding, H.; Tian, J.; Yu, W.; Wilson, D.I.; Young, B.R.; Cui, X.; Xin, X.; Wang, Z.; Li, W. The application of artificial intelligence and big data in the food industry. Foods 2023, 12, 4511. [Google Scholar] [CrossRef]

- Hasnan, N.Z.N.; Yusoff, Y.M. Application areas of Industry 4.0 technologies in food processing sector. In Proceedings of the 2018 IEEE Student Conference on Research and Development (SCOReD), Selangor, Malaysia, 26–28 November 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Marinelli, S.; Butturi, M.A.; Rimini, B.; Gamberini, R.; Sellitto, M.A. Estimating the circularity performance of an emerging industrial symbiosis network: The case of recycled plastic fibers in reinforced concrete. Sustainability 2021, 13, 10257. [Google Scholar] [CrossRef]

- Ferraris, A.; Mazzoleni, A.; Devalle, A.; Couturier, J. Big data analytics capabilities and knowledge management: Impact on firm performance. Manag. Decis. 2019, 57, 1923–1936. [Google Scholar] [CrossRef]

- Lezoche, M.; Hernandez, J.E.; Díaz, M.D.M.E.A.; Panetto, H.; Kacprzyk, J. Agri-food 4.0: A survey of the supply chains and technologies for the future agriculture. Comput. Ind. 2020, 117, 103187. [Google Scholar] [CrossRef]

- Schmidt, D.; Casagranda, L.F.; Butturi, M.A.; Sellitto, M.A. Digital technologies, sustainability, and efficiency in grain post-harvest activities: A bibliometric analysis. Sustainability 2024, 16, 1244. [Google Scholar] [CrossRef]

- Muller, J.M.; Buliga, O.; Voigt, K.I. Fortune favours the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Change 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for Industry 4.0 requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Rana, R.L.; Tricase, C.; De Cesare, L. Blockchain technology for a sustainable agri-food supply chain. Br. Food J. 2021, 123, 3471–3485. [Google Scholar] [CrossRef]

- Trivelli, L.; Apicella, A.; Chiarello, F.; Rana, R.; Fantoni, G.; Tarabella, A. From precision agriculture to Industry 4.0. Br. Food J. 2019, 121, 1730–1743. [Google Scholar] [CrossRef]

- Bidyalakshmi, T.; Jyoti, B.; Mansuri, S.M.; Srivastava, A.; Mohapatra, D.; Kalnar, Y.B.; Narsaiah, K.; Indore, N. Application of artificial intelligence in food processing: Current status and future prospects. Food Eng. Rev. 2025, 17, 27–54. [Google Scholar] [CrossRef]

- Schmidt, D.; Butturi, M.A.; Sellitto, M.A. Opportunities of digital transformation in post-harvest activities: A single case study of an engineering solutions provider. AgriEng. 2023, 5, 1226–1242. [Google Scholar] [CrossRef]

- Xu, M.; Zhang, Y.; Sun, H.; Tang, Y.; Li, J. How digital transformation enhances corporate innovation performance: The mediating roles of big data capabilities and organizational agility. Heliyon 2024, 10, e34905. [Google Scholar] [CrossRef]

- Geppert, F.; Krachunova, T.; Mouratiadou, I.; von der Nuell, J.; Bellingrath-Kimura, S.D. Digital and smart technologies to enhance biodiversity in agricultural landscapes: An analysis of stakeholders’ perceptions of opportunities and challenges for broader adoption. Environ. Sustain. Indic. 2024, 23, 100444. [Google Scholar] [CrossRef]

- El Bilali, H.; Allahyari, M.S. Transition towards sustainability in agriculture and food systems: Role of information and communication technologies. Inf. Process. Agric. 2018, 5, 456–464. [Google Scholar] [CrossRef]

- MacPherson, J.; Rosman, A.; Helming, K.; Burkhard, B. A participatory impact assessment of digital agriculture: A Bayesian network-based case study in Germany. Agric. Syst. 2025, 224, 104222. [Google Scholar] [CrossRef]

- Ahmadov, T.; Durst, S.; Eriksson, T.; Jussila, M.; Saaristo, A. How far has research into disruptive innovations in the field of sustainability come to date? Heliyon 2024, 10, e39134. [Google Scholar] [CrossRef]

- Dzimba, E.; van der Poll, J.A. Disruptive innovation capability in resource-constrained environments: The role of strategic posture and human capital. Sustain. Futures 2024, 8, 100326. [Google Scholar] [CrossRef]

- Niazi, M.; Wilson, D.; Zowghi, D. A Maturity Model for the Implementation of Software Process Improvement: An Empirical Study. J. Syst. Softw. 2005, 74, 155–172. [Google Scholar] [CrossRef]

- Toscano-Jara, J.; Loza-Aguirre, E.; Segura, M.; Franco-Crespo, A. Digital Transformation: A Systematic Literature Review from the Theoretical Lenses of the TOE Framework. Innovar: Rev. De Cienc. Adm. Y Soc. 2024, 34. [Google Scholar] [CrossRef]

- Senna, P.; Barros, A.; Roca, J.; Azevedo, A. Development of a digital maturity model for Industry 4.0 based on the technology-organization-environment framework. Comput. Ind. Eng. 2023, 185, 109645. [Google Scholar] [CrossRef]

- Bohórquez, J.; Herrera, R. Proposal and Validation of an Industry 4.0 Maturity Model for SMEs. J. Ind. Eng. Manag. 2022, 15, 91–108. [Google Scholar] [CrossRef]

- Sellitto, M.; Almeida, F. Strategies for value recovery from industrial waste: Case studies of six industries from Brazil. Benchmarking Int. J. 2020, 27, 867–885. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).