Agronomic Performance and Technological Attributes of Sugarcane Cultivars Under Split-Irrigation Management

Abstract

1. Introduction

2. Materials and Methods

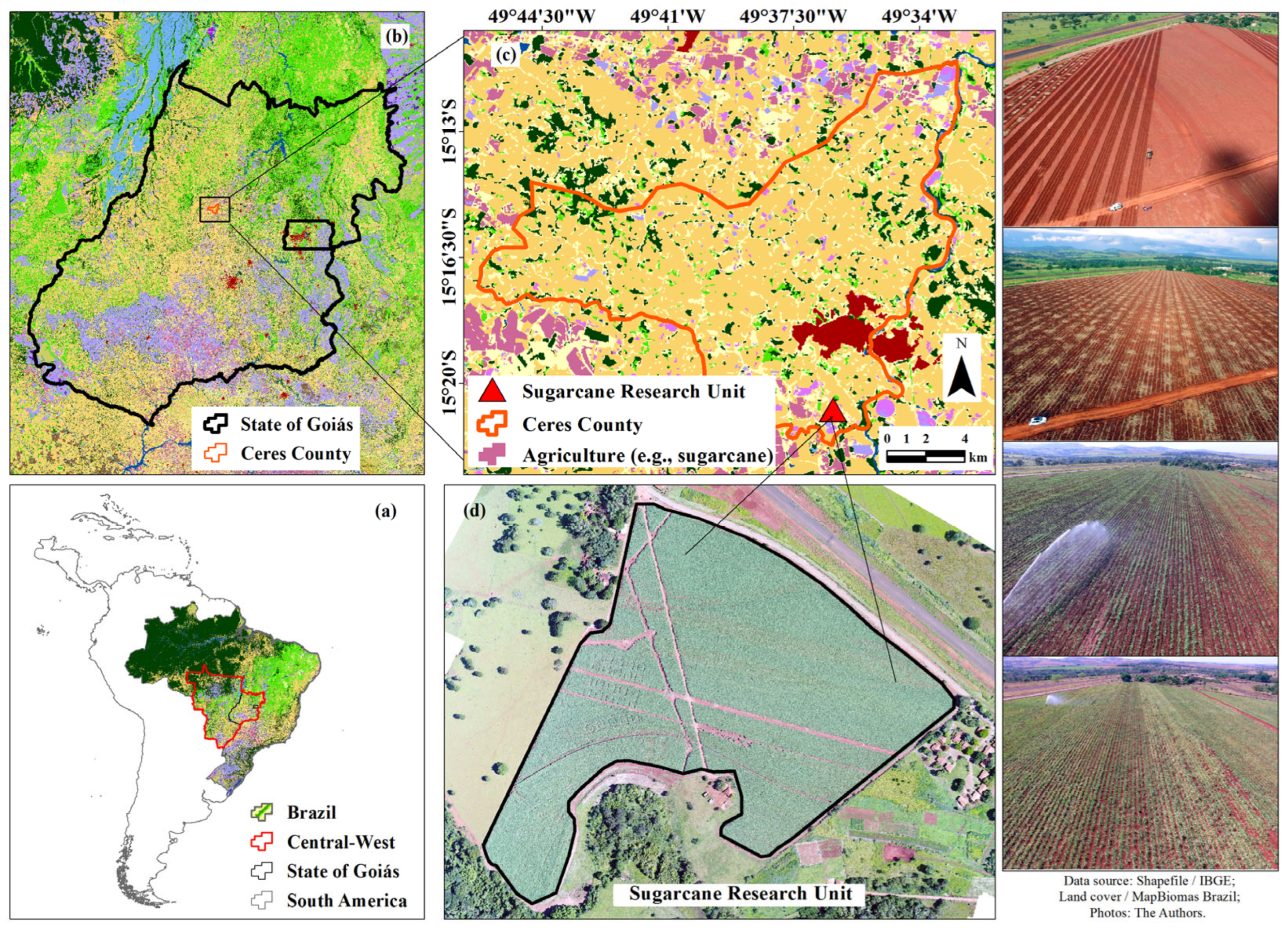

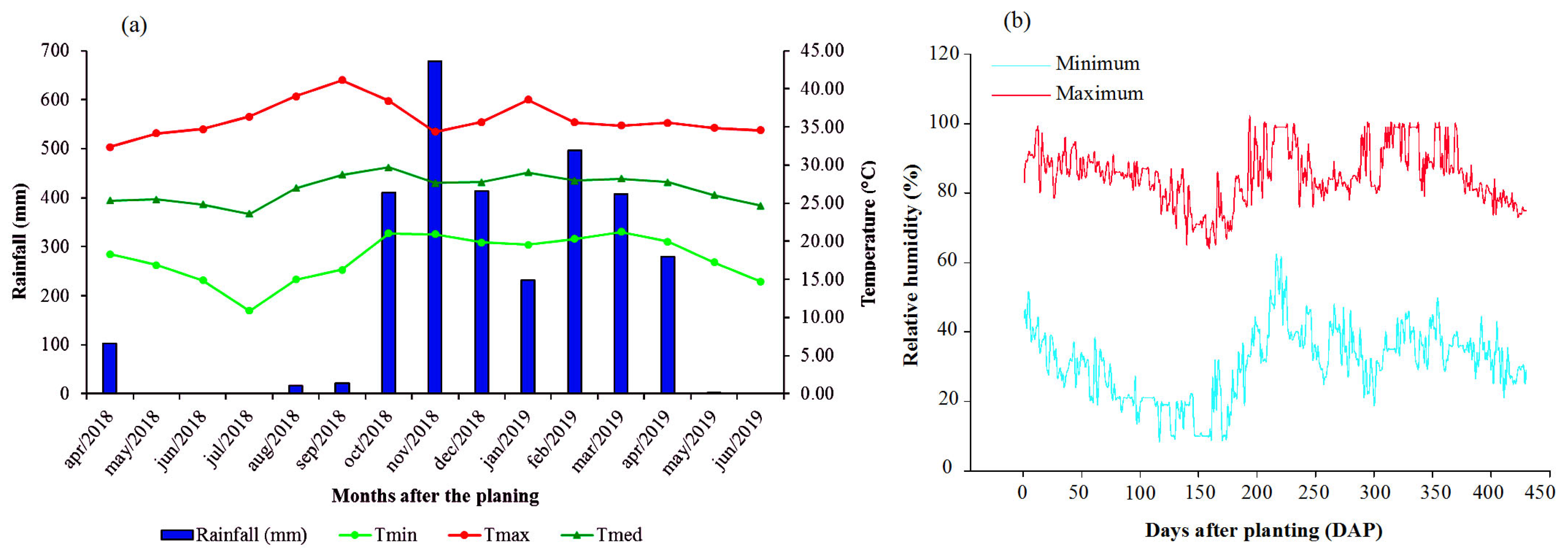

2.1. Study Area

2.2. Experimental Split-Irrigation Management

2.3. Biometric and Technological Attributes

2.4. Crop Yield

2.5. Statistical Analysis

3. Results and Discussion

3.1. Biometric Attributes

3.2. Technological Characteristics of Sugarcane

3.3. Yield Characteristics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lipiäinen, S.; Vakkilainen, E. Role of the Finnish Forest Industry in Mitigating Global Change: Energy Use and Greenhouse Gas Emissions towards 2035. Mitig. Adapt. Strateg. Glob. Chang. 2021, 26, 9. [Google Scholar] [CrossRef]

- de Morais, J.E.F.; Silva, Ê.F.d.F.e.; Godoi Neto, A.H.; Lima, B.L.d.C.; de Lira, R.M.; Berto, S.D.d.C.; Jardim, A.M.d.R.F.; Simões Neto, D.E.; da Silva, T.G.F.; Rolim, M.M. Sugarcane (Saccharum officinarum, L.) under Saline Stress: Growth, Productivity, Technological Quality, and Industrial Yield. Ind. Crops Prod. 2022, 188, 115642. [Google Scholar] [CrossRef]

- De Menezes, S.M.; da Silva, G.F.; da Silva, M.M.; de Morais, J.E.F.; de Vasconcelos, M.C.; de Souza, C.S.; Neto, D.E.S.; Rolim, M.M. Pulsed Drip Irrigation Reduces Sugarcane Water Consumption and Improves Growth, Productivity, Sugar and Ethanol Yields. Bioenergy Res. 2024, 17, 1413–1424. [Google Scholar] [CrossRef]

- De Menezes, S.M.; da Silva, G.F.; da Silva, M.M.; de Oliveira Filho, R.A.; Jardim, A.M.d.R.F.; Silva, J.R.I.; Silva, Ê.F.d.F.e.; Silva, J.V.; dos Santos, M.A.L. Pulse Drip Irrigation Improves Yield, Physiological Responses, and Water-Use Efficiency of Sugarcane. Water Conserv. Sci. Eng. 2024, 9, 25. [Google Scholar] [CrossRef]

- Grandis, A.; Fortirer, J.S.; Navarro, B.V.; de Oliveira, L.P.; Buckeridge, M.S. Biotechnologies to Improve Sugarcane Productivity in a Climate Change Scenario. Bioenergy Res. 2024, 17, 1–26. [Google Scholar] [CrossRef]

- Almada, E.D.D.B.; Sousa, A.E.C.; Soares, F.A.L. Vinasse Application Management on Two Sugarcane Varieties in the Cerrado Goiano. Rev. Caatinga 2021, 34, 39–49. [Google Scholar] [CrossRef]

- Osaki, M.R. An Energy Optimization Model Comparing the Use of Sugarcane Bagasse for Power or Ethanol Production. Ind. Crops Prod. 2022, 187, 115284. [Google Scholar] [CrossRef]

- Miranda, A.S.; Domingues, F.N.; Godoy, B.S.; Do Rêgo, A.C.; Faturi, C.; De Azevedo, J.C. Yield and Technological Performance of Sugarcane Cultivars Grown under Af Climate Conditions. Semin. Agrar. 2020, 41, 73–81. [Google Scholar] [CrossRef]

- Portz, G.; Molin, J.P.; Jasper, J. Active Crop Sensor to Detect Variability of Nitrogen Supply and Biomass on Sugarcane Fields. Precis. Agric. 2012, 13, 33–44. [Google Scholar] [CrossRef]

- Bordonal, R.d.O.; Carvalho, J.L.N.; Lal, R.; de Figueiredo, E.B.; de Oliveira, B.G.; La Scala, N. Sustainability of Sugarcane Production in Brazil. A Review. Agron. Sustain. Dev. 2018, 38, 1–23. [Google Scholar] [CrossRef]

- OECD. Agricultural Outlook 2022–2031; FAO: Rome, Italy, 2022; ISBN 9789264588707. [Google Scholar]

- CONAB. Acompanhamento Da Safra Brasileira 2023/2024. Cia. Nac. Abast. 2024, 11, 110. [Google Scholar]

- Da Cruz, T.V.; Machado, R.L. Measuring Climate Change’s Impact on Different Sugarcane Varieties Production in the South of Goiás. Sci. Rep. 2023, 13, 11637. [Google Scholar] [CrossRef] [PubMed]

- Viana, J.L.; de Souza, J.L.M.; Hoshide, A.K.; de Oliveira, R.A.; de Abreu, D.C.; da Silva, W.M. Estimating Sugarcane Yield in a Subtropical Climate Using Climatic Variables and Soil Water Storage. Sustainability 2023, 15, 4360. [Google Scholar] [CrossRef]

- Tanure, T.M.P.; Domingues, E.P.; Magalhães, A.S. Regional Impacts of Climate Change on Agricultural Productivity: Evidence on Large-Scale and Family Farming in Brazil. Rev. Econ. Sociol. Rural 2023, 62, e262515. [Google Scholar] [CrossRef]

- Fernandes, G.C.; Rosa, P.A.L.; Jalal, A.; Oliveira, C.E.d.S.; Galindo, F.S.; Viana, R.d.S.; De Carvalho, P.H.G.; Silva, E.C.d.; Nogueira, T.A.R.; Al-Askar, A.A.; et al. Technological Quality of Sugarcane Inoculated with Plant-Growth-Promoting Bacteria and Residual Effect of Phosphorus Rates. Plants 2023, 12, 2699. [Google Scholar] [CrossRef]

- Mall, A.K.; Misra, V.; Pathak, A.D.; Srivastava, S. Breeding for Drought Tolerance in Sugarcane: Indian Perspective. Sugar Tech 2022, 24, 1625–1635. [Google Scholar] [CrossRef]

- Kumar, R.; Sagar, V.; Verma, V.C.; Kumari, M.; Gujjar, R.S.; Goswami, S.K.; Kumar Jha, S.; Pandey, H.; Dubey, A.K.; Srivastava, S.; et al. Drought and Salinity Stresses Induced Physio-Biochemical Changes in Sugarcane: An Overview of Tolerance Mechanism and Mitigating Approaches. Front. Plant Sci. 2023, 14, 1225234. [Google Scholar] [CrossRef]

- Li, H.; Gui, Y.; Zhu, K.; Wei, J.; Zhang, R.; Yang, R.; Tang, L.; Zhou, H.; Liu, X. Comparative Transcriptomic Analyses of Two Sugarcane Saccharum L. Cultivars Differing in Drought Tolerance. Front. Plant Sci. 2023, 14, 1243664. [Google Scholar] [CrossRef]

- Ferreira, T.H.S.; Tsunada, M.S.; Bassi, D.; Araújo, P.; Mattiello, L.; Guidelli, G.V.; Righetto, G.L.; Gonçalves, V.R.; Lakshmanan, P.; Menossi, M. Sugarcane Water Stress Tolerance Mechanisms and Its Implications on Developing Biotechnology Solutions. Front. Plant Sci. 2017, 8, 1077. [Google Scholar] [CrossRef]

- Marcos, F.C.C.; Silveira, N.M.; Mokochinski, J.B.; Sawaya, A.C.H.F.; Marchiori, P.E.R.; Machado, E.C.; Souza, G.M.; Landell, M.G.A.; Ribeiro, R.V. Drought Tolerance of Sugarcane Is Improved by Previous Exposure to Water Deficit. J. Plant Physiol. 2018, 223, 9–18. [Google Scholar] [CrossRef]

- Gomathi, R.; Krishnapriya, V.; Arunkumar, R.; Govindaraj, P.; Ram, B. Physiological Traits Imparting Drought Stress Tolerance to Promising Sugarcane (Saccharum Spp.) Clones. Plant Physiol. Rep. 2020, 25, 509–515. [Google Scholar] [CrossRef]

- De Carvalho, A.A.; Montenegro, A.A.D.A.; Silva, H.P.; Lopes, I. Trends of Rainfall and Temperature in Northeast Brazil Tendências Da Precipitação Pluvial e Da Temperatura No Nordeste Brasileiro. Rev. Bras. Eng. Agrícola Ambient. 2020, 24, 15–23. [Google Scholar]

- Singh, K.; Mishra, S.K.; Brar, A.S. Optimizing Sugarcane and Water Productivity Through Surface and Subsurface Drip Fertigation in Subtropical India. Sugar Tech 2024, 26, 63–76. [Google Scholar] [CrossRef]

- Da Silva, C.T.S.; de Azevedo, H.M.; de Azevedo, C.A.V.; Dantas Neto, J.; de Carvalho, C.M.; Gomes Filho, R.R. Growth of Sugar Cane With and Without Irrigation Additional Under Different Levels of Coverage Fertilization of Nitrogen and Potassium. Rev. Bras. Agric. Irrig. RBAI 2009, 3, 3–12. [Google Scholar]

- Aparecido, L.E.d.O.; de Moraes, J.R.d.S.C.; de Meneses, K.C.; Torsoni, G.B.; Costa, C.T.S.e.; Mesquita, D.Z. Climate Efficiency for Sugarcane Production in Brazil and Its Application in Agricultural Zoning. Sugar Tech 2021, 23, 776–793. [Google Scholar] [CrossRef]

- Obaideen, K.; Yousef, B.A.A.; AlMallahi, M.N.; Tan, Y.C.; Mahmoud, M.; Jaber, H.; Ramadan, M. An Overview of Smart Irrigation Systems Using IoT. Energy Nexus 2022, 7, 100124. [Google Scholar] [CrossRef]

- Riajaya, P.D.; Hariyono, B.; Cholid, M.; Kadarwati, F.T.; Santoso, B.; Djumali; Subiyakto. Growth and Yield Potential of New Sugarcane Varieties during Plant and First Ratoon Crops. Sustainability 2022, 14, 14396. [Google Scholar] [CrossRef]

- De Mendoça, M.F.; Neto, J.D.; da Silva, P.F.; de Oliveira, E.C.A. Yield and Technological Quality of Sugarcane under Irrigation Depths and Nitrogen Fertilization. Rev. Bras. Eng. Agric. Ambient. 2020, 24, 482–489. [Google Scholar] [CrossRef]

- Célia de Matos Pires, R.; Barbosa, E.A.A.; Arruda, F.B.; Sakai, E.; Araujo da Silva, T.J. Effects of Subsurface Drip Irrigation and Different Planting Arrangements on the Yields and Technological Quality of Sugarcane. J. Irrig. Drain. Eng. 2014, 140, A5014001. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World Map of the Köppen-Geiger Climate Classification Updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef]

- SiBCS. Sistema Brasileiro de Classificação de Solos, 5th ed.; Embrapa Solos: Brasília, Brazil, 2018; ISBN 978-85-7035-198-2. [Google Scholar]

- Molin, J.P.; Frasson, F.R.; Do Amaral, L.R.; Povh, F.P.; Salvi, J.V. Capacidade de Um Sensor Ótico Em Quantificar a Resposta Da Cana-de-Açúcar a Doses de Nitrogênio Capability of an Optical Sensor in Verifying the Sugarcane Response to Nitrogen Rates. Rev. Bras. Eng. Agrícola Ambient. 2010, 14, 1345–1349. [Google Scholar] [CrossRef]

- Costa, C.T.S.; Ferreira, V.M.; Endres, L.; Ferreira, D.T.d.R.G.; Gonçalves, E.R. Crescimento e Produtividade de Quatro Variedades de Cana-Deaçúcar No Quarto Ciclo de Cultivo. Rev. Caatinga 2011, 24, 56–63. [Google Scholar]

- De Oliveira, F.M.; De Aguilar, P.B.; Teixeira, M.F.F.; Aspiazú, I.; Moņão, F.P.; Da Silva Antunes, A.P. Características Agrotecnólogicas de Cana-de-Açúcar Em Diferentes Épocas de Supressão de Irrigação e Níveis de Adubação. Semin. Agrar. 2014, 35, 1587–1606. [Google Scholar] [CrossRef][Green Version]

- CONSECANA. Cons. dos Prod. Cana-de-Açúcar, Açúcar e Álcool do Estado São Paulo; CONSECANA: Sao Paulo, Brazil, 2006; 54p. [Google Scholar]

- Pires Marques, W.; Teixeira, M.B.; Soares, F.A.L.; Ribeiro, W.A.; Lopes Filho, L.C. Cultivo Da Cana-De-Açúcar Sob Diferentes Níveis De Reposição Hídrica, Com E Sem Adição De Nitrogênio. Científic Multidiscip. J. 2018, 5, 56–87. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Viena, Áustria, 2020. Available online: https://www.R-project.org/ (accessed on 19 August 2021).

- Marin, F.R.; Inman-Bamber, G.; Silva, T.G.F.; Vianna, M.S.; Nassif, D.S.P.; Carvalho, K.S. Sugarcane Evapotranspiration and Irrigation Requirements in Tropical Climates. Theor. Appl. Climatol. 2020, 140, 1349–1357. [Google Scholar] [CrossRef]

- Santana, P.; Aspiazú, I.; Costa, É.; Pinheiro, D.; Teixeira, M.; Silva, J.; Junior, H. Agronomical Performance of Sugarcane Varieties in Function of Different Irrigation Depths in Semi-Arid Conditions. J. Exp. Agric. Int. 2017, 17, 35775. [Google Scholar] [CrossRef]

- Tew, T.L.; Cobill, R.M. Genetic Improvement of Sugarcane (Saccharum Spp.) as an Energy Crop. In Genetic Improvement of Bioenergy Crops; Springer: Berlin/Heidelberg, Germany, 2008; pp. 273–294. [Google Scholar] [CrossRef]

- Mirajkar, S.J.; Devarumath, R.M.; Nikam, A.A.; Sushir, K.V.; Babu, H.; Suprasanna, P. Sugarcane (Saccharum Spp.): Breeding and Genomics; Springer: Berlin/Heidelberg, Germany, 2019; Volume 6, ISBN 9783030232658. [Google Scholar]

- Madala, H.V.; Lesmes-Vesga, R.A.; Odero, C.D.; Sharma, L.K.; Sandhu, H.S. Effects of Planting Pre-Germinated Buds on Stand Establishment in Sugarcane. Agronomy 2023, 13, 1001. [Google Scholar] [CrossRef]

- Cheavegatti-Gianotto, A.; de Abreu, H.M.C.; Arruda, P.; Bespalhok Filho, J.C.; Burnquist, W.L.; Creste, S.; di Ciero, L.; Ferro, J.A.; de Oliveira Figueira, A.V.; de Sousa Filgueiras, T.; et al. Sugarcane (Saccharum X Officinarum): A Reference Study for the Regulation of Genetically Modified Cultivars in Brazil. Trop. Plant Biol. 2011, 4, 62–89. [Google Scholar] [CrossRef]

- Chandran, K.; Nisha, M.; Gopi, R.; Mahendran, B.; Chandran, D.; Mahesh, P.; Arun Kumar, R.; Krishnapriya, V.; Gomathi, R.; Malathi, P.; et al. Sugarcane Genetic Resources for Challenged Agriculture. Sugar Tech 2023, 25, 1285–1302. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X.; Tang, H.; Zhang, Q.; Hua, X.; Ma, X.; Zhu, F.; Jones, T.; Zhu, X.; Bowers, J.; et al. Allele-Defined Genome of the Autopolyploid Sugarcane Saccharum spontaneum L. Nat. Genet. 2018, 50, 1565–1573. [Google Scholar] [CrossRef]

- Qi, Y.; Gao, X.; Zeng, Q.; Zheng, Z.; Wu, C.; Yang, R.; Feng, X.; Wu, Z.; Fan, L.; Huang, Z. Sugarcane Breeding, Germplasm Development and Related Molecular Research in China. Sugar Tech 2022, 24, 73–85. [Google Scholar] [CrossRef]

- Cunha, F.N.; Silva, N.F.; Sousa, A.E.C.; Teixeira, M.B.; Soares, F.A.L.; Vidal, V.M. Yield of Sugarcane Submitted to Nitrogen Fertilization and Water Depths by Subsurface Drip Irrigation a Adubação Nitrogenada e a Lâminas de Irrigação Por Gotejamento Subsuperficial. In Revista Brasileira de Engenharia Agrícola e Ambiental; SciELO: São Paulo, Brazil, 2016; pp. 841–846. [Google Scholar]

- Oliveira, A.R.O.; Braga, M.B.; Walker, A.M. Comportamento Vegetativo e Qualidade Tecnológica de Cultivares de Cana-de-Açúcar Submetidas Ao Estresse Hídrico Em Condições Semiáridas Do Brasil. Rev. Bras. Geogr. Física 2015, 8, 525–541. [Google Scholar]

- De Oliveira, A.R.; Braga, M.B.; Santos, B.L.S.; Walker, A.M. Biometria de Cultivares de Cana-De-Açúcar Sob Diferentes Reposições Hídricas no vale do Submédio São Francisco. Rev. Energ. Na Agric. 2016, 31, 48–58. [Google Scholar]

- Da Silva, T.G.F.; de Moura, M.S.B.; Zolnier, S.; de Souza, L.S.B. Biomassa Seca Acumulada, Partições e Rendimento Industrial Da Cana-de-Açúcar Irrigada No Semiárido Brasileiro. Rev. Ceres 2014, 61, 686–696. [Google Scholar] [CrossRef]

- Macêdo, G.A.R.; Da Costa, É.L.; Viana, M.C.M.; Freire, F.M. Características Produtivas e Tecnológicas de Variedades de Cana-de-Açúcar Em Sucessão a Diferentes Cultivos Em Pastagem Degradada. Rev. Bras. Cienc. Agrar. 2013, 8, 223–228. [Google Scholar] [CrossRef]

- Endres, L.; Silva, J.V.; Ferreira, V.M.; Barbosa, G.V.D.S. Photosynthesis and Water Relations in Brazilian Sugarcane. Open Agric. J. 2010, 4, 31–37. [Google Scholar] [CrossRef]

- Pereira, L.F.M.; Ferreira, V.M.; de Oliveira, N.G.; Sarmento, P.L.V.S.; Endres, L.; Teodoro, I. Sugars Levels of Four Sugarcane Genotypes in Different Stem Portions during the Maturation Phase. An. Acad. Bras. Cienc. 2017, 89, 1231–1242. [Google Scholar] [CrossRef]

- Barbosa, M.H.P.; da Silveira, L.C.I.; Paes, G.A.; Macêdo, R.; Valente, J.M. Cana-de-Açúcar; EPAMIG: Informe Agropecuário: Belo Horizonte, Brazil, 2007; Volume 28, pp. 1–120. [Google Scholar]

- Simões, W.L.; Calgaro, M.; Coelho, D.S.; de Souza, M.A.; Lima, J.A. Respostas de Variáveis Fisiológicas e Tecnológicas Da Cana-de-Açúcar A. Rev. Ciência Agronômica 2015, 46, 11–20. [Google Scholar] [CrossRef]

- Silva, M.D.A.; Arantes, M.T.; Rhein, A.F.d.L.; Gava, G.J.C.; Kolln, O.T. Potencial Produtivo Da Cana-de-Açúcar Sob Irrigação Por Gotejamento Em Função de Variedades e Ciclos. Rev. Bras. Eng. Agrícola Ambient. 2014, 18, 241–249. [Google Scholar] [CrossRef]

- Gava, G.J.d.C.; Silva, M.d.A.; da Silva, R.C.; Jeronimo, E.M.; Cruz, J.C.S.; Kölln, O.T. Produtividade de Três Cultivares de Cana-de-Açúcar Sob Manejos de Sequeiro e Irrigado Por Gotejamento. Rev. Bras. Eng. Agrícola Ambient. 2011, 15, 250–255. [Google Scholar] [CrossRef]

- Roberto, G.G.; Cunha, C.; Sales, C.R.G.; Silveira, N.M.; Ribeiro, R.V.; Machado, E.C.; Lagôa, A.M.M.A. Variation of Photosynthesis and Carbohydrate Levels Induced by Ethephon and Water Deficit on the Ripening Stage of Sugarcane. Bragantia 2015, 74, 379–386. [Google Scholar] [CrossRef]

- Dias, H.B.; Sentelhas, P.C. Dimensioning the Impact of Irrigation on Sugarcane Yield in Brazil. Sugar Tech 2019, 21, 29–37. [Google Scholar] [CrossRef]

- Gonçalves, I.Z.; Barbosa, E.A.A.; Santos, L.N.S.; Nazário, A.A.; Feitosa, D.R.C.; Tuta, N.F.; Matsura, E.E. Water Relations and Productivity of Sugarcane Irrigated with Domestic Wastewater by Subsurface Drip. Agric. Water Manag. 2017, 185, 105–115. [Google Scholar] [CrossRef]

- Endres, L.; dos Santos, C.M.; de Souza, G.V.; Menossi, M.; dos Santos, J.C.M. Morphological Changes Recorded in Different Phenophases of Sugarcane Plants Subjected to Water Stress in Tropical Field Conditions. Aust. J. Crop Sci. 2018, 12, 1041–1050. [Google Scholar] [CrossRef]

- Singh, S. My Experiences on Physiological Research on Sugarcane in India. Sugar Tech 2015, 17, 227–234. [Google Scholar] [CrossRef]

- Graça, J.P.d.; Rodrigues, F.A.; Farias, J.R.B.; de Oliveira, M.C.N.; Hoffmann-Campo, C.B.; Zingaretti, S.M. Physiological Parameters in Sugarcane Cultivars Submitted to Water Deficit. Braz. J. Plant Physiol. 2010, 22, 189–197. [Google Scholar] [CrossRef]

- Da Silva, V.d.P.R.; Da Silva, B.B.; Albuquerque, W.G.; Borges, C.J.R.; de Sousa, I.F.; Neto, J.D. Crop Coefficient, Water Requirements, Yield and Water Use Efficiency of Sugarcane Growth in Brazil. Agric. Water Manag. 2013, 128, 102–109. [Google Scholar] [CrossRef]

- Medeiros, D.B.; Silva, E.C.d.; Nogueira, R.J.M.C.; Teixeira, M.M.; Buckeridge, M.S. Physiological Limitations in Two Sugarcane Varieties under Water Suppression and after Recovering. Theor. Exp. Plant Physiol. 2013, 25, 213–222. [Google Scholar] [CrossRef]

- Da Silva, J.A.G.; De, M.; Jifon, J.L.; Dos Santos, C.M.; Sharma, V. Relationships between Physiological Traits and Productivity of Sugarcane in Response to Water Deficit. J. Agric. Sci. 2014, 152, 104–118. [Google Scholar] [CrossRef]

| Chemical properties | ||||||||||

| Soil (layers) | pH CaCl2 | P | K | Ca2+ | Mg2+ | Al3+ | T | Zn | V | OM |

| mg dm−3 | cmol dm−3 | mg dm−3 | % | g dm−3 | ||||||

| 0–20 cm | 5.8 | 3.0 | 41.22 | 3.9 | 1.6 | 0.0 | 7.4 | 2.3 | 45.71 | 18.0 |

| 20–40 cm | 5.8 | 2.1 | 27.8 | 3.1 | 1.3 | 0.0 | 5.9 | 6.3 | 74.87 | 15.0 |

| Physical properties | ||||||||||

| Soil (layers) | Sand (%) | Silt (%) | Clay (%) | |||||||

| 0–20 cm | 34.63 | 17.52 | 47.85 | |||||||

| 20–40 cm | 31.81 | 16.94 | 51.25 | |||||||

| Split-irrigation water (mm) | DAP | ||||||||

| 180 | 210 | 240 | 270 | 300 | 330 | 360 | 390 | 420 | |

| Plant height—PH (cm) | |||||||||

| 00 + 00 | 36.09 a | 70.32 b* | 138.32 a | 177.70 a | Table 3 | 271.20 a | 305.28 b* | 350.67 a | Table 3 |

| 20 + 40 | 38.28 a | 92.10 a* | 161.86 a | 191.00 a | 290.42 a | 323.50 a* | 357.10 a | ||

| 30 + 30 | 35.76 a | 81.37 ab* | 160.78 a | 198.52 a | 283.52 a | 317.20 ab* | 355.35 a | ||

| 40 + 20 | 36.52 a | 82.67 ab* | 157.18 a | 194.67 a | 277.10 a | 329.15 a* | 357.55 a | ||

| 60 + 00 | 41.56 a | 86.32 a* | 155.17 a | 194.82 a | 286.85 a | 312.75 ab* | 356.42 a | ||

| Standard error | 1.95 | 3.41 | 5.31 | 5.70 | 7.96 | 3.70 | 6.74 | ||

| Stalk diameter—SD (mm) | |||||||||

| 00 + 00 | Table 3 | 29.81 a | 30.75 a | 29.03 a | 27.41 a | 29.04 a | 28.99 a | Table 3 | Table 3 |

| 20 + 40 | 30.67 a | 32.56 a | 29.22 a | 28.39 a | 27.41 a | 28.18 a | |||

| 30 + 30 | 30.31 a | 30.28 a | 28.49 a | 28.55 a | 27.37 a | 29.14 a | |||

| 40 + 20 | 32.46 a | 30.90 a | 29.13 a | 29.70 a | 27.86 a | 28.77 a | |||

| 60 + 00 | 29.97 a | 30.90 a | 28.39 a | 27.07 a | 27.32 a | 28.61 a | |||

| Standard error | 0.94 | 0.84 | 0.56 | 0.63 | 0.59 | 0.38 | |||

| Cultivars | Plant height—PH (cm) | ||||||||

| RB92579 | 33.61 b* | 69.88 b* | 140.67 b* | 177.68 b* | Table 3 | 273.78 b* | 300.79 b* | 347.42 b* | Table 3 |

| SP80–1816 | 41.67 a* | 95.24 a* | 168.66 a* | 205.01 a* | 289.85 a* | 334.36 a* | 363.42 a* | ||

| Standard error | 1.26 | 2.78 | 2.47 | 2.57 | 3.60 | 3.05 | 3.67 | ||

| Stalk diameter—SD (mm) | |||||||||

| RB92579 | Table 3 | 31.36 a | 31.90 a | 29.79 a | 28.63 a | 27.61 a | 28.46 a | Table 3 | Table 3 |

| SP80–1816 | 29.93 a | 30.25 b | 27.71 b | 27.81 a | 27.99 a | 29.02 a | |||

| Standard error | 0.87 | 0.42 | 0.33 | 0.32 | 0.44 | 0.31 | |||

| Split-irrigation water (mm) | Plant height—PH (cm) | ||||||||

| 300 DAP * | 420 DAP ** | ||||||||

| RB92579 | SP80–1816 | RB92579 | SP80–1816 | ||||||

| 00 + 00 | 223.65 aB | 236.95 bA | 356.20 aA | 366.20 aA | |||||

| 20 + 40 | 223.15 aB | 275.95 aA | 376.90 aA | 382.85 aA | |||||

| 30 + 30 | 233.10 aB | 268.45 aA | 361.95 aA | 369.07 aA | |||||

| 40 + 20 | 234.85 aB | 267.25 aA | 355.85 aB | 392.50 aA | |||||

| 60 + 00 | 231.15 aB | 263.20 aA | 363.90 aA | 379.00 aA | |||||

| Standard error | 5.06 | 5.06 | 8.24 | 8.24 | |||||

| Split-irrigation water (mm) | Stalk diameter—SD (mm) | ||||||||

| 180 DAP ** | 390 DAP ** | 420 DAP * | |||||||

| RB92579 | SP80–1816 | RB92579 | SP80–1816 | RB92579 | SP80–1816 | ||||

| 00 + 00 | 20.79 abB | 24.48 aA | 28.65 aA | 29.71 aA | 29.78 aA | 31.15 aA | |||

| 20 + 40 | 20.33 bB | 25.81 aA | 27.64 aA | 27.37 aA | 28.81 aA | 27.59 aA | |||

| 30 + 30 | 23.25 abA | 22.66 aA | 27.94 aA | 24.67 bB | 29.43 aA | 27.37 aB | |||

| 40 + 20 | 24.64 aA | 24.06 aA | 27.59 aA | 29.02 aA | 28.28 aB | 32.63 aA | |||

| 60 + 00 | 23.01 abA | 25.08 aA | 28.01 aA | 27.33 aA | 28.46 aA | 28.91 aA | |||

| Standard error | 1.02 | 1.07 | 1.63 | 1.83 | 0.59 | 1.83 | |||

| Split-irrigation water (mm) | Soluble Solids Content—°Brix (%) | Sucrose Content—POL (%) | ||

| RB92579 | SP80–1816 | RB92579 | SP80–1816 | |

| 00 + 00 | 16.95 cA | 18.10 bA | 13.96 cA | 14.85 bA |

| 20 + 40 | 19.40 bcA | 20.92 aA | 16.03 bA | 17.16 aA |

| 30 + 30 | 20.57 abA | 21.05 aA | 16.76 abA | 17.27 aA |

| 40 + 20 | 22.02 aA | 19.42 abB | 18.01 aA | 16.04 abB |

| 60 + 00 | 20.62 abA | 19.12 abA | 16.89 abA | 15.74 abA |

| Fiber (%) | Broth POL—BP (%) | |||

| RB92579 | SP80–1816 | RB92579 | SP80–1816 | |

| 00 + 00 | 10.84 aB | 12.46 aA | 12.05 cA | 12.46 cA |

| 20 + 40 | 10.96 aB | 11.98 aA | 13.65 bA | 14.53 abA |

| 30 + 30 | 11.58 aA | 10.91 bA | 14.29 abA | 14.89 aA |

| 40 + 20 | 10.86 aA | 11.68 abA | 15.55 aA | 13.65 abcB |

| 60 + 00 | 10.78 aB | 12.24 aA | 14.60 abA | 13.27 bcA |

| Split-irrigation water (mm) | Juice Purity—PZA (%) | |||

| RB92579 | SP80–1816 | |||

| 00 + 00 | 82.38 aA | 82.11 aA | ||

| 20 + 40 | 82.62 aA | 82.07 aA | ||

| 30 + 30 | 81.53 aA | 82.05 aA | ||

| 40 + 20 | 81.82 aA | 82.61 aA | ||

| 60 + 00 | 81.96 aA | 82.36 aA | ||

| Split-irrigation water (mm) | Fresh stalk mass (kg m–1) | Plant weight (kg m–1) | ||

| RB92579 | SP80–1816 | RB92579 | SP80–1816 | |

| 00 + 00 | 18.86 aA | 19.49 aA | 23.13 aA | 22.95 aA |

| 20 + 40 | 19.83 aA | 18.23 aA | 23.37 aA | 20.49 aA |

| 30 + 30 | 18.33 aA | 15.88 aA | 21.92 aA | 18.43 aA |

| 40 + 20 | 16.69 aA | 16.77 aA | 20.00 aA | 20.75 aA |

| 60 + 00 | 23.77 aA | 13.45 aB | 28.07 aA | 16.23 aB |

| Shoot productivity (t ha–1) | Cane production (t ha–1) | |||

| RB92579 | SP80–1816 | RB92579 | SP80–1816 | |

| 00 + 00 | 154.21 aA | 153.00 aA | 125.75 aA | 129.93 aA |

| 20 + 40 | 155.78 aA | 136.57 aA | 132.25 aA | 121.56 aA |

| 30 + 30 | 146.11 aA | 122.86 aA | 122.20 aA | 105.90 aA |

| 40 + 20 | 133.31 aA | 138.35 aA | 111.26 aA | 111.83 aA |

| 60 + 00 | 187.15 aA | 108.23 aB | 158.51 aA | 89.68 aB |

| Total recoverable sugar (kg ton–1) | Reducing sugars—RS (%) | |||

| RB92579 | SP80–1816 | RB92579 | SP80–1816 | |

| 00 + 00 | 122.57 cA | 126.42 cA | 0.70 bA | 0.69 aA |

| 20 + 40 | 139.48 bA | 146.39 abA | 0.80 aA | 0.69 aB |

| 30 + 30 | 144.25 abA | 150.04 aA | 0.84 aA | 0.71 aB |

| 40 + 20 | 156.50 aA | 137.89 abcB | 0.72 bA | 0.69 aA |

| 60 + 00 | 147.24 abA | 134.18 bcB | 0.71 bA | 0.69 aA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, H.F.E.d.; Arriel, F.H.; Soares, F.A.L.; Silva, E.C.d.; Mesquita, M.; Silva, T.D.; Silva, J.L.B.d.; Sousa, C.M.; Silva, M.V.d.; Carvalho, A.A.d.; et al. Agronomic Performance and Technological Attributes of Sugarcane Cultivars Under Split-Irrigation Management. AgriEngineering 2024, 6, 4337-4352. https://doi.org/10.3390/agriengineering6040245

Oliveira HFEd, Arriel FH, Soares FAL, Silva ECd, Mesquita M, Silva TD, Silva JLBd, Sousa CM, Silva MVd, Carvalho AAd, et al. Agronomic Performance and Technological Attributes of Sugarcane Cultivars Under Split-Irrigation Management. AgriEngineering. 2024; 6(4):4337-4352. https://doi.org/10.3390/agriengineering6040245

Chicago/Turabian StyleOliveira, Henrique Fonseca Elias de, Fernando Henrique Arriel, Frederico Antônio Loureiro Soares, Edson Cabral da Silva, Marcio Mesquita, Thiago Dias Silva, Jhon Lennon Bezerra da Silva, Cleiton Mateus Sousa, Marcos Vinícius da Silva, Ailton Alves de Carvalho, and et al. 2024. "Agronomic Performance and Technological Attributes of Sugarcane Cultivars Under Split-Irrigation Management" AgriEngineering 6, no. 4: 4337-4352. https://doi.org/10.3390/agriengineering6040245

APA StyleOliveira, H. F. E. d., Arriel, F. H., Soares, F. A. L., Silva, E. C. d., Mesquita, M., Silva, T. D., Silva, J. L. B. d., Sousa, C. M., Silva, M. V. d., Carvalho, A. A. d., & Silva, T. G. F. d. (2024). Agronomic Performance and Technological Attributes of Sugarcane Cultivars Under Split-Irrigation Management. AgriEngineering, 6(4), 4337-4352. https://doi.org/10.3390/agriengineering6040245