Vegetables Treated before Drying with Natural Antioxidants plus UV-C Improve Colour and Bioactive Compounds

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Pre-Treatments

2.3. Drying Equipment

2.4. Drying Methodology

2.5. Drying Kinetics

2.6. Colour Determination

2.7. Extraction and Quantification of Vitamin C by HPLC

2.8. Carotenoids Determination

2.9. Statistical Analysis

3. Results and Discussion

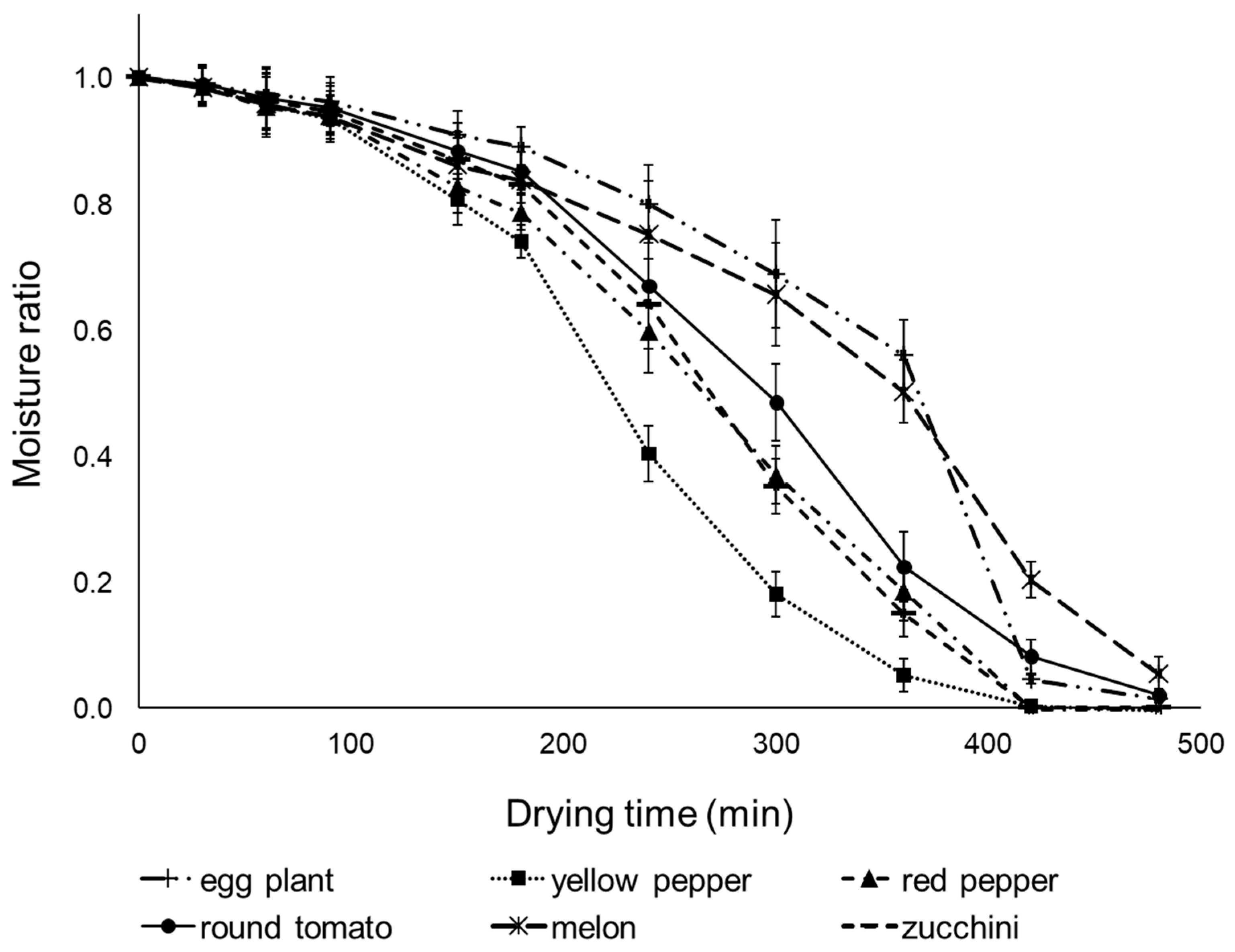

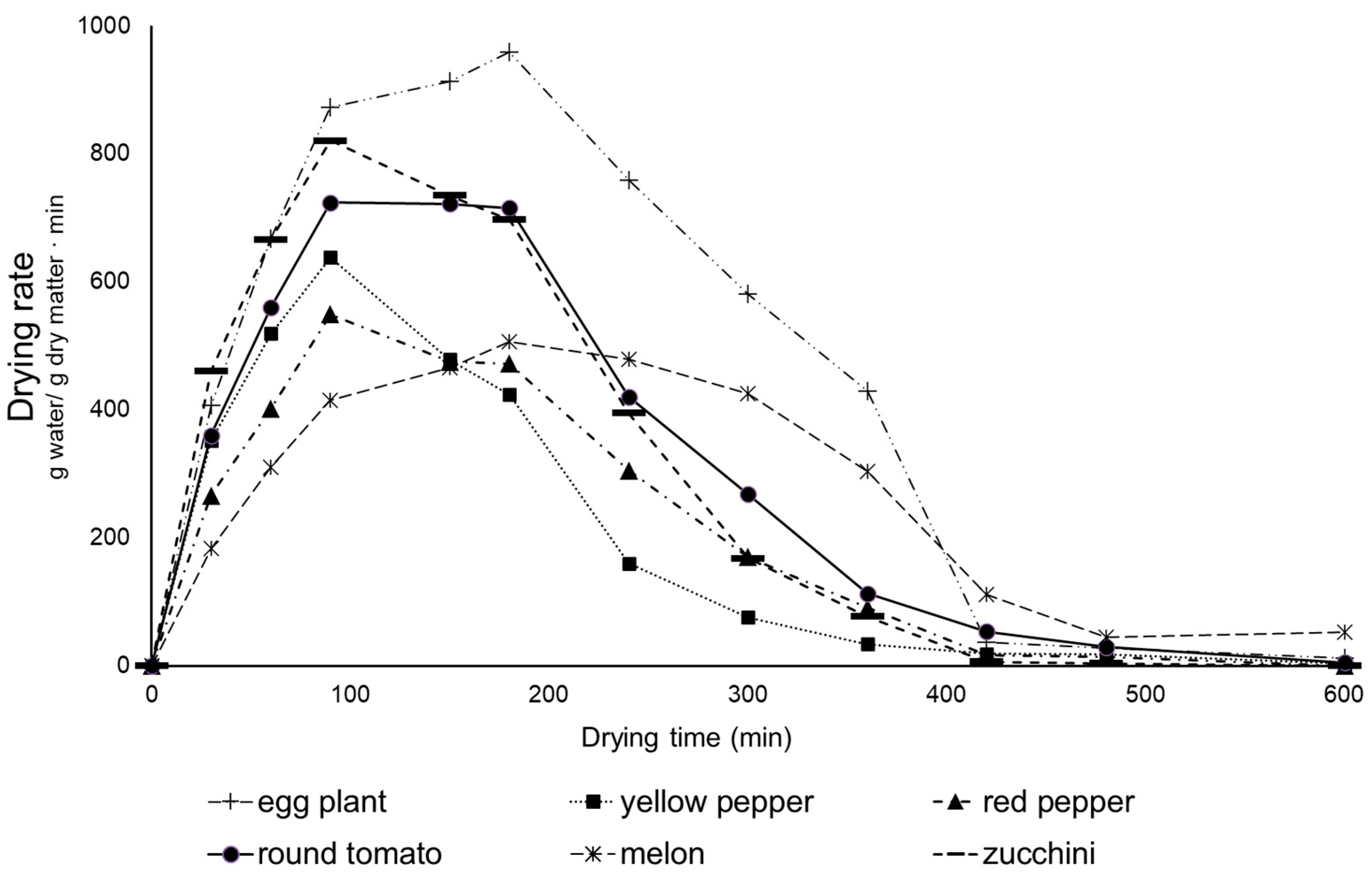

3.1. Dehydration Kinetics

3.2. Selection of Pre-Treatments for Drying

3.3. Colour and Nutritional Quality of Oved-Dried Vegetables

3.3.1. Zucchini

3.3.2. Eggplant

3.3.3. Melon

3.3.4. Tomato

3.3.5. Red Bell Pepper

3.3.6. Yellow Bell Pepper

3.4. Practical Applications of the Methodology Developed in This Work

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baldwin, E.A.; Nisperos-Carriedo, M.O.; Baker, R.A. Quality of Minimally Processed Fruits and Vegetables. Hortic. Rev. 1995, 5, 157–202. [Google Scholar]

- Kalder, L. Consumer Demands and Fresh Produce Quality. Food Qual. Prefer. 2008, 19, 10–21. [Google Scholar]

- Rusolillo, G. Phytochemicals in Fruits and Vegetables. Antioxidants 2009, 2, 85–97. [Google Scholar]

- Ortega, R.M. Importance of functional foods in the Mediterranean diet. Public Health Nutr. 2006, 9, 110–120. [Google Scholar] [CrossRef]

- Sagar, V.R.; Kumar, S. Recent advances in drying and dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef]

- Waliszewski, K.N. The Role of Vegetables in the Prevention of Diseases. Nutrition 2010, 11, 32–45. [Google Scholar]

- Griep, L.M.; Geleijnse, J.M.; Kromhout, D.; Ocké, M.C. Dietary Intake and Health Effects of Fruit and Vegetable Consumption. Nutr. Epidemiol. 2011, 3, 45–67. [Google Scholar]

- Barrett, D.M.; Beaulieu, J.C.; Shewfelt, R. Color, flavor, texture, and nutritional quality of fresh-cut fruits and vegetables: Desirable levels, instrumental and sensory measurement, and the effects of processing. Crit. Rev. Food Sci. Nutr. 2010, 50, 369–389. [Google Scholar] [CrossRef]

- Swain, S.; Samuel, D.V.K.; Bal, L.M.; Kar, A. Thermal kinetics of colour degradation of yellow sweet pepper (Capsicum annum L.) undergoing microwave assisted convective drying. Int. J. Food Prop. 2014, 17, 1946–1964. [Google Scholar] [CrossRef]

- Soliva-Fortuny, R.; Martín-Belloso, O. Effects of Minimal Processing on the Quality of Fresh Produce. Food Control 2003, 14, 41–52. [Google Scholar]

- Huang, H.; Zhang, Y. Dehydration Technologies for Fruits and Vegetables. Food Sci. Biotechnol. 2012, 21, 299–304. [Google Scholar]

- Grabowski, S.; Marcotte, M.; Ramaswamy, H.S. Drying of fruits, vegetables, and spices. In Handbook of Postharvest Technology: Cereals, Fruits, Vegetables, Tea, and Spices; Chakraverty, A., Mujumdar, A.S., Raghavan, G.S.V., Rawaswamy, H.S., Eds.; Marcel Dekker: New York, NY, USA, 2003; pp. 653–695. [Google Scholar]

- Nijhuis, H.H.; Torringa, H.M.; Muresan, S.; Yukel, D.; Leguijt, C.; Kloek, W. Approaches to improving the quality of dried fruits and vegetables. Food Sci. Technol. 1998, 9, 13–20. [Google Scholar] [CrossRef]

- Sablani, S.S. Drying of fruits and vegetables: Retention of nutritional/functional quality. Dry. Technol. 2006, 24, 123–135. [Google Scholar] [CrossRef]

- Gamboa-Santos, J.; Montilla, A.; Cárcel, J.A.; Carrasco, J.A.; Villegas, E. Vitamin C Loss in Dried Fruits and Vegetables. J. Agric. Food Chem. 2013, 61, 8512–8519. [Google Scholar]

- Sagar, V.R.; Kumar, P.S. Texture and Flavor Changes in Dehydrated Vegetables. Food Res. Int. 2010, 43, 1205–1212. [Google Scholar]

- Remacha, J.; Ibarz, A.; Giner, J. Evolución del color por efecto de la temperatura en pulpas de fruta. Rev. Aliment. 1992, 234, 59–68. [Google Scholar]

- Singh, U.; Sagar, V.R.; Behera, T.K.; Suresh, K.P. Effect of drying conditions on the quality of dehydrated selected leafy vegetables. J. Food Sci. Technol. 2006, 43, 579–582. [Google Scholar]

- Maeda, E.E.; Salunkhe, D.K. Retention of ascorbic acid and total carotene in solar dried vegetables. J. Food Sci. 1981, 46, 1288–1290. [Google Scholar] [CrossRef]

- Mulokozi, G.; Svanberg, U. Effect of traditional open sun-drying and solar cabinet drying on carotene content and vitamin A activity of green leafy vegetables. Plant Foods Hum. Nutr. 2003, 58, 1–15. [Google Scholar] [CrossRef]

- Deng, L.Z.; Mujumdar, A.S.; Zhang, Q.; Yang, X.H.; Wang, J.; Zheng, Z.A.; Gao, Z.J.; Xiao, H.W. Chemical and physical pretreatments of fruits and vegetables: Effects on drying characteristics and quality attributes—A comprehensive review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1408–1432. [Google Scholar] [CrossRef]

- Llavata, B.; García-Pérez, J.V.; Simal, S.; Cárcel, J.A. Innovative pre-treatments to enhance food drying: A current review. Curr. Opin. Food Sci. 2020, 35, 20–26. [Google Scholar] [CrossRef]

- Raybaudi-Massilia, R.M.; Soliva, R.F.; Martín, O.B. Uso de agentes antimicrobianos para la conservación de frutas frescas y frescas cortadas. In Actas del I Simpósio Ibero-Americano de Vegetais Frescos Cortados 2006, San Pedro, SP, Brazil; CYTED: San Pedro, Brazil, 2006; pp. 15–21. [Google Scholar]

- Zhang, D.; Butelli, E.; De Stefano, R.; Schoonbeek, H.J.; Magusin, A.; Pagliarani, C.; Jones, J.D. Anthocyanins double the shelf life of tomatoes by delaying overripening and reducing susceptibility to gray mold. Curr. Biol. 2013, 23, 1094–1100. [Google Scholar]

- Liu, C.; Stevens, C.; Khan, V.A.; Lu, J.Y.; Wilson, C.L.; Adeyeye, O.; Droby, S. Application of Ultraviolef-C Light on Storage Rots and Ripening of Tomatoes. J. Food Prot. 1993, 56, 868–873. [Google Scholar]

- Civello, P.M.; Vicente, A.R.; Martínez, G.A. UV-C technology to control postharvest diseases of fruits and vegetables. Recent advances in alternative postharvest technologies to control fungal diseases in fruits and vegetables. Trans. Res. Netw. 2006, 37, 2. [Google Scholar]

- Gil, M.I.; Aguayo, E.; Kader, A.A. Quality changes and nutrient retention in fresh-cut versus whole fruits during storage. J. Agric. Food Chem. 2006, 54, 4284–4296. [Google Scholar]

- Manzocco, L.; Da Pieve, S.; Maifreni, M. Impact of UV-C light on safety and quality of fresh-cut melon. Innov. Food Sci. Emerg. Technol. 2011, 12, 13–17. [Google Scholar]

- Costa, L.; Vicente, A.R.; Civello, P.M.; Chaves, A.R.; Martínez, G.A. UV-C treatment delays postharvest senescence in broccoli florets. Postharvest Biol. Technol. 2006, 39, 204–210. [Google Scholar] [CrossRef]

- Robles Sánchez, P.A.; Campos, A.D.; Artés Hernández, F.D.; Gómez di Marco, P.A.; Calderón García, A.A.; Ferrer Ayala, M.Á.; Artés Calero, F. Acción combinada de la radiación UV-C y la atmósfera controlada para optimizar la calidad del tomate. In Proceedings of the V Congreso Iberoamericano de Tecnología Postcosecha Y Agroexportaciones, Cartagena, Spain, 29 May–1 June 2007. [Google Scholar]

- Rodoni, L.M.; Concellón, A.; Chaves, A.R.; Vicente, A.R. Use of UV-C Treatments to Maintain Quality and Extend the Shelf Life of Green Fresh-cut Bell Pepper (Capsicum annuum L.). J. Food Sci. 2012, 77, 632–639. [Google Scholar] [CrossRef]

- Zhang, W.; Jiang, W. UV treatment improved the quality of postharvest fruits and vegetables by inducing resistance. Trends Food Sci. Technol. 2019, 92, 71–80. [Google Scholar] [CrossRef]

- Vallespir, F.; Rodríguez, Ó.; Eim, V.S.; Rosselló, C.; Simal, S. Freezing pre-treatments on the intensification of the drying process of vegetables with different structures. J. Food Eng. 2018, 239, 83–91. [Google Scholar] [CrossRef]

- Maurya, V.K.; Gothandam, K.M.; Ranjan, V.; Shakya, A.; Pareek, S. Effect of drying methods (microwave vacuum, freeze, hot air and sun drying) on physical, chemical and nutritional attributes of five pepper (Capsicum annuum var. annuum) cultivars. J. Sci. Food Agric. 2018, 98, 3492–3500. [Google Scholar] [CrossRef] [PubMed]

- Arslan, A.; Soysal, Y.; Keskin, M. Comparing hot air drying kinetics and color quality of organic and conventional sweet red peppers. Mustafa Kemal Üniversitesi Tarım Bilim. Derg. 2020, 25, 271–283. [Google Scholar] [CrossRef]

- Kheto, A.; Dhua, S.; Nema, P.K.; Sharanagat, V.S. Influence of drying temperature on quality attributes of bell pepper (Capsicum annuum L.): Drying kinetics and modeling, rehydration, color, and antioxidant analysis. J. Food Process Eng. 2021, 44, e13880. [Google Scholar] [CrossRef]

- Yang, L.; Hu, Z.; Yang, L.; Xie, S.; Yang, M. Hot-air drying characteristics and quality evaluation of bitter melon slice. INMATEH-Agric. Eng. 2018, 55, 53–62. [Google Scholar]

- Nakilcioğlu-Taş, E.; Coşan, G.; Ötleş, S. Optimization of process conditions to improve the quality properties of healthy watermelon snacks developed by hot-air drying. J. Food Meas. Charact. 2021, 15, 2146–2160. [Google Scholar] [CrossRef]

- Bashir, N.; Bhat, M.A.; Dar, B.N.; Shah, M.A. Effect of different drying methods on the quality of tomatoes. Adv. Food Sci. 2014, 36, 65–69. [Google Scholar]

- Kutlu, N.; Isci, A. Drying characteristics of zucchini and empirical modeling of its drying process. Int. J. Food Stud. 2017, 6, 232–244. [Google Scholar] [CrossRef]

- Andreou, V.; Dimopoulos, G.; Tsonas, T.; Katsimichas, A.; Limnaios, A.; Katsaros, G.; Taoukis, P. Pulsed electric fields-assisted drying and frying of fresh zucchini. Food Bioprocess Technol. 2021, 14, 2091–2106. [Google Scholar] [CrossRef]

- Dajbych, O.; Kabutey, A.; Mizera, Č.; Herák, D. Investigation of the effects of infrared and hot air oven drying methods on drying behaviour and colour parameters of red delicious apple slices. Processes 2023, 11, 3027. [Google Scholar] [CrossRef]

- Chouaibi, M.; Snoussi, A.; Attouchi, S.; Ferrari, G. Influence of drying processes on bioactive compounds profiles, hydroxymethylfurfural, color parameters, and antioxidant activities of Tunisian eggplant (Solanum melongena L.). J. Food Process. Preserv. 2021, 45, e15460. [Google Scholar] [CrossRef]

- Muhamad, N.; Redzuan, N.A.M. Effects of drying methods on the quality parameters of dried Manis Terengganu Melon (Cucumis melo). J. Agrobiotechnol. 2019, 10, 46–58. [Google Scholar]

- Çetin, N. Comparative assessment of energy analysis, drying kinetics, and biochemical composition of tomato waste under different drying conditions. Sci. Hortic. 2022, 305, 111405. [Google Scholar] [CrossRef]

- Santacatalina, J.V.; Soriano, J.R.; Cárcel, J.A.; Garcia-Perez, J.V. Influence of air velocity and temperature on ultrasonically assisted low temperature drying of eggplant. Food Bioprod. Process. 2016, 100, 282–291. [Google Scholar] [CrossRef]

- Xu, B.; Tiliwa, E.S.; Yan, W.; Azam, S.R.; Wei, B.; Zhou, C.; Ma, H.; Bhandari, B. Recent development in high quality drying of fruits and vegetables assisted by ultrasound: A review. Food Res. Int. 2022, 152, 110744. [Google Scholar] [CrossRef] [PubMed]

- Jafari, F.; Movagharnejad, K.; Sadeghi, E. Infrared drying effects on the quality of eggplant slices and process optimization using response surface methodology. Food Chem. 2020, 333, 127423. [Google Scholar] [CrossRef] [PubMed]

- Jafari, F.; Movagharnejad, K.; Sadeghi, E. Evaluation of far-infrared drying on the quality properties of zucchini slices: Influence of operating parameters. Innov. Food Technol. 2023, 11, 47–59. [Google Scholar]

- Aktaş, M.; Şevik, S.; Amini, A.; Khanlari, A. Analysis of drying of melon in a solar-heat recovery assisted infrared dryer. Sol. Energy 2016, 137, 500–515. [Google Scholar] [CrossRef]

- Erol, N.T.; Incedayi, B.; Sari, F.; Copur, O.U. A comparative study of electrical and conventional pre-treatments for quality assessment of hot air dried green bell pepper. Food Sci. Technol. Int. 2024, 30, 185–196. [Google Scholar] [CrossRef]

- Horuz, E.; Jaafar, H.J.; Maskan, M. Ultrasonication as pretreatment for drying of tomato slices in a hot air–microwave hybrid oven. Dry. Technol. 2017, 35, 849–859. [Google Scholar] [CrossRef]

- Sharma, R.; Joshi, V.K.; Kaushal, M. Effect of pre-treatments and drying methods on quality attributes of sweet bell-pepper (Capsicum annum) powder. J. Food Sci. Technol. 2015, 52, 3433–3439. [Google Scholar] [CrossRef]

- Vinci, G.; Botrè, F.; Mele, G.; Ruggieri, G. Ascorbic acid in exotic fruits: A liquid chromatographic investigation. Food Chem. 1995, 53, 211–214. [Google Scholar] [CrossRef]

- Gornicki, K.; Kaleta, A. Drying curve modelling of blanched carrot cubes under natural convection condition. Journal of Food Eng. 2007, 82, 160–170. [Google Scholar] [CrossRef]

- Prakash, S.; Jha, S.K.; Datta, N. Performance evaluation of blanched carrots dried by three different driers. J. Food Eng. 2004, 62, 305–313. [Google Scholar] [CrossRef]

- Tesfamichael, A.; Assefa, A. Experimental Analysis of Potato Silces Drying Characteristics using Solar Dryer. J. Appl. Sci. 2013, 13, 939–943. [Google Scholar] [CrossRef]

- Mujumdar, A.S.; Devahastin, S. Fundamental principles of drying. In Mujumdar’s Practical Guide to Industrial Drying: Principles, Equipment and New Developments; Exergex: Brossard, QC, Canada, 2000; Volume 1, pp. 1–22. [Google Scholar]

- Santos, P.H.S.; Silva, M.A. Retention of vitamin C in drying processes of fruits and vegetables—A review. Dry. Technol. 2008, 26, 1421–1437. [Google Scholar] [CrossRef]

- Idah, P.A.; Musa, J.J.; Olaleye, S.T. Effect of temperature and drying time on some nutritional quality parameters of dried tomatoes. AU J. Technol. 2010, 14, 25–32. [Google Scholar]

- Kacjan Maršić, N.; Mikulič-Petkovšek, M.; Štampar, F. Grafting influences phenolic profile and carpometric traits of fruits of greenhouse-grown eggplant (Solanum melongena L.). J. Agric. Food Chem. 2014, 62, 10504–10514. [Google Scholar] [CrossRef]

- Barbagallo, R.N.; Chisarib, M.; Patanèc, C. Use in vivo of natural anti-browning agents against polyphenol oxidase activity in minimally processed eggplant. Chem. Eng. Transations 2012, 27, 49–54. [Google Scholar]

- Ferrão, A.C.; Guiné, R.; Correia, T.; Rodrigues, R. Analysis of drying kinetics of eggplant through thin layer models and evaluation of texture and colour properties. Chem. Res. J. 2019, 4, 24–32. [Google Scholar]

- Mishra, B.B.; Gautam, S.; Sharma, A. Browning of fresh-cut eggplant: Impact of cutting and storage. Postharvest Biol. Technol. 2012, 67, 44–51. [Google Scholar] [CrossRef]

- Siems, W.G.; Sommerburg, O.; Van Kuijk, F.J. Lycopene and\beta-carotene decompose more rapidly than lutein and zeaxanthin upon exposure to various pro-oxidants in vitro. Biofactors 1999, 10, 105–113. [Google Scholar] [CrossRef] [PubMed]

- Arslan, D.; Özcan, M.M. Drying of tomato slices: Changes in drying kinetics, mineral contents, antioxidant activity and color parameters. CyTA-J. Food 2011, 9, 229–236. [Google Scholar] [CrossRef]

- Shi, J.; Le Maguer, M.; Kakuda, Y.; Liptay, A.; Kiekamp, F. Lycopene degradation and isomerisation in tomato dehydration. Food Res. Int. 1999, 32, 15–21. [Google Scholar] [CrossRef]

- Artés-Hernández, F.; Robles, P.A.; Gómez, P.A.; Tomás-Callejas, A.; Artés, F. Low UV-C illumination for keeping overall quality of fresh-cut watermelon. Postharvest Biol. Technol. 2010, 55, 114–120. [Google Scholar] [CrossRef]

- Caminiti, I.M.; Palgan, I.; Muñoz, A.; Noci, F.; Whyte, P.; Morgan, D.J.; Cronin, D.A.; Lyng, J.G. The effect of ultraviolet light on microbial inactivation and quality attributes of apple juice. Food Bioprocess Technol. 2012, 5, 680–686. [Google Scholar] [CrossRef]

- Lante, A.; Tinello, F.; Nicoletto, M. UV-A light treatment for controlling enzymatic browning of fresh-cut fruits. Innov. Food Sci. Emerg. Technol. 2016, 34, 141–147. [Google Scholar] [CrossRef]

- Zanoni, B.; Peri, C.; Nani, R.; Lavelli, V. Oxidative heat damage of tomato halves as affected by drying. Food Res. Int. 1999, 31, 395–401. [Google Scholar] [CrossRef]

- Georgé, S.; Tourniaire, F.; Gautier, H.; Goupy, P.; Rock, E.; Caris-Veyrat, C. Changes in the contents of carotenoids, phenolic compounds and vitamin C during technical processing and lyophilisation of red and yellow tomatoes. Food Chem. 2011, 124, 1603–1611. [Google Scholar] [CrossRef]

- Kocabiyik, H.; Yilmaz, N.; Tuncel, N.B.; Sumer, S.K.; Burak Buyukcan, M. The effects of middle infrared radiation intensity on the quality of dried tomato products. Int. J. Food Sci. Technol. 2014, 49, 703–710. [Google Scholar] [CrossRef]

- Giovanelli, G.; Zanoni, B.; Lavelli, V.; Nanic, R. Water sorption, drying and antioxidant properties of dried tomato products. J. Food Eng. 2002, 52, 135–141. [Google Scholar] [CrossRef]

- Rhim, J.W.; Hong, S.I. Effect of water activity and temperature on the color change of red pepper (Capsicum annuum L.) powder. Food Sci. Biotechnol. 2011, 20, 215–222. [Google Scholar] [CrossRef]

- Cuastumal, H.G.; Ledesma, M.A.; Ordoñez, L.E. Vitamin C and surface color in tomato and green pepper: Effect of heat treatments. Entre Cienc. E Ing. 2016, 10, 32–36. [Google Scholar]

- Swain, S.; Samuel, D.; Kar, A.; Sahoo, L.B.A.G. Optimization of color parameters and drying efficiency in osmotically pretreated microwave assisted drying of yellow sweet pepper (Capsicum annum L.) using response-surface methodology. J. Food Res. Technol. 2014, 2, 67–76. [Google Scholar]

- Eissa, H.A.; Bareh, G.F.; Ibrahim, A.A.; Moawad, R.K.; Ali, H.S. The effect of different drying methods on the nutrients and non-nutrients composition of zucchini (green squash) rings. J. Appl. Sci. Res 2013, 9, 5380–5389. [Google Scholar]

- Urun, G.B.; Yaman, Ü.R.; Köse, E. Determination of drying characteristics and quality properties of eggplant in different drying conditions. Ital. J. Food Sci. 2015, 27, 459–467. [Google Scholar]

- Ahmed, I.A.M.; Al Juhaimi, F.; Özcan, M.M.; Uslu, N.; Babiker, E.E.; Ghafoor, K.; Osman, M.A.; Salih, H.A. A comparative study of bioactive compounds, antioxidant activity and phenolic compounds of melon (Cucumis melo L.) slices dehydrated by oven, microwave and infrared systems. J. Food Process. Preserv. 2021, 45, e15605. [Google Scholar] [CrossRef]

- Kerkhofs, N.S.; Lister, C.E.; Savage, G.P. Change in colour and antioxidant content of tomato cultivars following forced-air drying. Plant Foods Hum. Nutr. 2005, 60, 117–121. [Google Scholar] [CrossRef]

- Chang, C.H.; Liu, Y.C. Study on lycopene and antioxidant contents variations in tomatoes under air-drying process. J. Food Sci. 2007, 72, E532–E540. [Google Scholar] [CrossRef]

- Çağlarırmak, N.; Hepçimen, A.Z. Evaluation Data of Dried Vegetables and Fruits. Turk. J. Agric. -Food Sci. Technol. 2021, 9, 2649–2658. [Google Scholar] [CrossRef]

- Babatunde, O.E.; Onabanjo, O.O.; Adebowale, A.A.; Adegunwa, M.O.; Sobukola, O.P.; Kajihausa, O.E.; Omohimi, C.I.; Dairo, O.U.; Abdulsalam-Saghir, P.; Sanni, L.O.; et al. Effects of Variety and Drying Methods on the Nutrient Retention in Tomato (Solanum lycopersicum L.) Slices. Niger. Food J. 2023, 41. [Google Scholar]

- Vega-Gálvez, A.; Di Scala, K.; Rodríguez, K.; Lemus-Mondaca, R.; Miranda, M.; López, J.; Perez-Won, M. Effect of air-drying temperature on physico-chemical properties, antioxidant capacity, colour and total phenolic content of red pepper (Capsicum annuum, L. var. Hungarian). Food Chem. 2009, 117, 647–653. [Google Scholar] [CrossRef]

- Dağhan, Ş.; Yildirim, A.; Yilmaz, F.M.; Vardin, H.; Karaaslan, M. The effect of temperature and method of drying on Isot (Urfa pepper) and its vitamin C degradation kinetics. Ital. J. Food Sci. 2018, 30. [Google Scholar]

- Santos, N.C.; Barros, S.L.; Silva, S.D.N.; Ribeiro, V.D.A.; Melo, M.O.P.; Silva, W.D.; Almeida, R.L.J.; Pereira, T.D.S.; de Brito Araújo, A.J.; Gomes, J.P.; et al. Physico-chemical characterization and kinetics of drying of organic yellow bell pepper (Capsicum annuum L.). Afr. J. Agric. Res. 2019, 14, 1247–1253. [Google Scholar]

| Colour Parameters | ||||

|---|---|---|---|---|

| Vegetables | L* | a* | b* | |

| Zucchini | ||||

| 0 | Fresh | 84.6 ± 1.3 a | −2.50 ± 0.71 a | 25.6 ± 3.3 a,b |

| 1 | Dehydrated | 77.5 ± 1.0 c | −0.97 ± 0.54 c | 29.3 ± 3.5 a |

| 2 | Dehydrated + antiox | 81.0 ± 3.2 b,c | −1.97 ± 0.54 b | 29.5 ± 2.6 a |

| 3 | Dehydrated + UV | 81.9 ± 2.1 b | −2.17 ± 0.78 a,b | 29.5 ± 1.6 a |

| 4 | Dehydrated + antiox + UV | 83.4 ± 2.3 a,b | −1.77 ± 0.59 b | 23.6 ± 2.2 b |

| 5 | Dehydrated + UV + antiox | 82.5 ± 5.3 a,b | −2.19 ± 0.48 a,b | 23.5 ± 1.3 cb |

| Eggplant | ||||

| 0 | Fresh | 85.9 ± 2.9 a | −1.6 ± 0.6 d | 25.2 ± 3.9 b,c |

| 1 | Dehydrated | 63.4 ± 5.8 c | 9.0 ± 1.8 a | 28.9 ± 1.1 a,b |

| 2 | Dehydrated + antiox | 73.2 ± 5.6 b | 5.2 ± 2.0 b,c | 23.7 ± 1.9 c |

| 3 | Dehydrated + UV | 69.1 ± 3.9 b,c | 6.1 ± 2.1 b,c | 31.6 ± 3.8 a |

| 4 | Dehydrated + antiox + UV | 73.8 ± 4.3 b | 5.4 ± 1.5 b,c | 26.8 ± 1.3 b,c |

| 5 | Dehydrated + UV + antiox | 74.9 ± 4.3 b | 4.0 ± 2.1 c | 25.2 ± 2.6 b,c |

| Melon | ||||

| 0 | Fresh | 74.0 ± 2.7 b,c | −0.58 ± 0.47 c | 9.97 ± 1.53 c |

| 1 | Dehydrated | 69.0 ± 3.0 c | 5.05 ± 1.21 a | 18.8 ± 4.2 a |

| 2 | Dehydrated + antiox | 78.7 ± 6.6 a,b | 0.24 ± 0.15 b | 16.9 ± 3.9 a,b |

| 3 | Dehydrated + UV | 74.9 ± 6.7 b | −1.83 ± 0.31 d | 14.5 ± 3.6 b,c |

| 4 | Dehydrated + antiox + UV | 82.3 ± 6.9 a | −0.56 ± 0.32 c | 10.6 ± 3.3 c |

| 5 | Dehydrated + UV + antiox | 81.4 ± 4.4 a | −0.59 ± 0.12 c | 15.1 ± 3.0 a,b |

| Tomato | ||||

| 0 | Fresh | 40.9 ± 3.0 a | 18.9 ± 1.9 c | 16.5 ± 2.1 c |

| 1 | Dehydrated | 39.4 ± 2.6 a | 29.0 ± 5.0 a | 25.0 ± 2.3 a,b |

| 2 | Dehydrated + antiox | 42.5 ± 3.7 a | 30.4 ± 2.7 a | 27.0 ± 2.9 a |

| 3 | Dehydrated + UV | 37.3 ± 2.2 a,b | 25.4 ± 4.2 b | 20.2 ± 2.1 b,c |

| 4 | Dehydrated + antiox + UV | 38.4 ± 3.1 a,b | 28.1 ± 2.9 a,b | 20.9 ± 2.5 b |

| 5 | Dehydrated + UV + antiox | 35.2 ± 1.0 b | 27.3 ± 3.0 a,b | 22.9 ± 1.8 b |

| Red bell pepper | ||||

| 0 | Fresh | 31.5 ± 0.9 c | 25.6 ± 1.8 c | 12.3 ± 1.0 b |

| 1 | Dehydrated | 36.7 ± 1.8 a,b | 31.4 ± 1.5 a,b | 19.1 ± 0.7 a |

| 2 | Dehydrated + antiox | 38.1 ± 0.7 a | 31.2 ± 1.9 a,b | 20.6 ± 2.0 a |

| 3 | Dehydrated + UV | 36.9 ± 1.2 a,b | 29.7 ± 2.2 b | 22.7 ± 3.0 a |

| 4 | Dehydrated + antiox + UV | 36.1 ± 1.0 a,b | 34.4 ± 1.5 a | 22.2 ± 1.5 a |

| 5 | Dehydrated + UV + antiox | 35.8 ± 0.9 b | 29.0 ± 1.6 b,c | 21.2 ± 1.2 a |

| Yellow bell pepper | ||||

| 0 | Fresh | 54.2 ± 2.3 a | 10.3 ± 1.8 a | 53.3 ± 4.4 a |

| 1 | Dehydrated | 49.9 ± 1.7 b | 10.1 ± 2.1 a | 41.4 ± 3.0 b |

| 2 | Dehydrated + antiox | 50.7 ± 2.1 b | 11.4 ± 2.9 a | 40.2 ± 3.7 b |

| 3 | Dehydrated+ UV | 49.6 ± 1.5 b | 10.5 ± 2.2 a | 40.9 ± 3.2 b |

| 4 | Dehydrated+ antiox + UV | 53.6 ± 1.8 a,b | 10.4 ± 2.3 a | 48.8 ± 3.9 a |

| 5 | Dehydrated + UV + antiox | 55.0 ± 1.9 a | 8.8 ± 2.6 a | 49.2 ± 3.1 a |

| Moisture g/100 g | Vitamin C c mg·100 g−1 | Main Carotenoids µg·g−1 Dry wt | ||||||

|---|---|---|---|---|---|---|---|---|

| 50 °C | 105 °C d | Fresh wt | Lycopene | β-Carotene | Lutein | Other Carotenoids e | Total Carotenoids | |

| Zucchini | ||||||||

| Fresh | 93.0 ± 0.1 a | 94.9 ± 0.2 | 18.5 ± 0.5 a | - | 23.3 ± 2.1 a | 231 ± 14 a | - | 255 ± 13 a |

| Dehydrated | 6.0 ± 0.1 b | 14.7 ± 0.2 b | - | 18.9 ± 1.7 b | 170 ± 12 b | - | 189 ± 12 b | |

| Dehydrated + UV | 5.5 ± 0.1 b | 9.8 ± 0.4 c | - | 17.0 ± 1.9 b | 131 ± 14 c | - | 148 ± 15 c | |

| Dehydrated + antiox + UV | 5.8 ± 0.1 b | 15.7 ± 0.3 b | - | 21.9 ± 1.8 a,b | 172 ± 14 b | 194 ± 14 b | ||

| Eggplant | ||||||||

| Fresh | 92.0 ± 0.1 a | 91.7 ± 0.1 | 4.3 ± 0.9 a | 12.7 ± 1.2 a | 4.3 ± 0.2 a | 18.0 ± 0.9 a | - | 35.0 ± 1.0 a |

| Dehydrated | 7.3 ± 0.1 b | 3.4 ± 0.5 b | 9.4 ± 1.1 b | 3.9 ± 0.1 b | 12.7 ± 0.3 c | - | 31.3 ± 0.9 b | |

| Dehydrated + UV | 7.5 ± 0.1 b | 2.1 ± 0.4 c | 7.5 ± 1.9 c | 3.3 ± 0.3 c | 12.3 ± 0.4 c | - | 23.1 ± 1.8 c | |

| Dehydrated+ antiox + UV | 7.4 ± 0.1 b | 3.9 ± 0.2 a,b | 9.7 ± 1.3 b | 3.8 ± 0.2 b | 17.2 ± 0.5 a | 30.7 ± 1.2 b | ||

| Melon, var. “Yellow” | ||||||||

| Fresh | 94.5 ± 0.1 a | 94.9 ± 0.2 | 22.5 ± 2.4 a | - | 40.8 ± 2.1 a | 26.8 ± 1.3 a | - | 67.6 ± 2.0 a |

| Dehydrated | 10.0 ± 0.1 b | 17.7 ± 1.8 b | - | 30.9 ± 2.3 b | 15.7 ± 3.1 b,c | - | 46.6 ± 3.0 b | |

| Dehydrated + UV | 9.1 ± 0.1 c | 10.2 ± 3.0 c | - | 28.1 ± 5.0 b | 13.2 ± 1.3 c | - | 41.3 ± 4.3 b | |

| Dehydrated+ antiox + UV | 9.0 ± 0.1 c | 17.2 ± 3.0 b | - | 30.1 ± 3.0 b | 16.6 ± 1.3 b | 46.7 ± 2.8 b | ||

| Tomato | ||||||||

| Fresh | 95.0 ± 0.1 a | 96.1 ± 0.2 | 41.9 ± 6.2 a | 491 ± 12 a | 46.4 ± 0.9 a | 73.8 ± 11.0 a | x 245 ± 30 a | 856 ± 54 a |

| Dehydrated | 11.0 ± 0.1 b | 25.4 ± 3.5 c,d | 333 ± 12 c | 34.8 ± 0.3 b | 55.3 ± 4.8 c | x 189 ± 25 b | 610 ± 67 b | |

| Dehydrated + UV | 8.5 ± 0.1 d | 21.9 ± 1.8 d | 202 ± 20 d | 22.9 ± 0.4 c | 32.1 ± 3.8 d | x 178 ± 33 b | 566 ± 58 b | |

| Dehydrated+ antiox + UV | 9.6 ± 0.1 c | 32.0 ± 3.8 b | 445 ± 21 b | 33.9 ± 0.5 b | 63.5 ± 5.4 b | x 188 ± 23 b | 619 ± 51 b | |

| Red bell pepper | ||||||||

| Fresh | 93.5 ± 0.1 a | 95.4 ± 0.2 | 60.6 ± 5.5 a | - | 346 ± 7.5 a | 73.9 ± 3.0 a | y 330 ± 35 a | 859 ± 43 a |

| Dehydrated | 10.0 ± 0.1 b | 55.9 ± 3.1 b | - | 310 ± 12 b | 55.7 ± 2.1 c | y 307 ± 41 a,b | 791 ± 33 a,b | |

| Dehydrated + UV | 9.5 ± 0.1 c | 43.7 ± 3.3 c | - | 213 ± 16 c | 22.0 ± 1.4 d | y 267 ± 29 b | 688 ± 46 c | |

| Dehydrated+ antiox + UV | 9.2 ± 0.1 c | 58.7 ± 3.5 a,b | - | 335 ± 14 a,b | 62.4 ± 1.4 b | y 298 ± 23 a,b | 715 ± 39 b,c | |

| Yellow bell pepper | ||||||||

| Fresh | 94.0 ± 0.1 a | 95.1 ± 0.2 | 86.6 ± 6.3 a | - | 284 ± 16 a | 18.5 ± 3.9 a | y 208 ± 19 a | 510 ± 39 a |

| Dehydrated | 11.0 ± 0.1 b | 62.6 ± 7.4 b | - | 229 ± 13 b | 13.5 ± 2.0 b | y 178 ± 13 a,b | 431 ± 28 b | |

| Dehydrated + UV | 9.6 ± 0.1 c | 46.0 ± 5.2 c | - | 215 ± 24 b | 8.4 ± 2.5 c | y 151 ± 15 b | 398 ± 42 b | |

| Dehydrated+ antiox + UV | 9.9 ± 0.1 c | 62.9 ± 5.2 b | - | 220 ± 15 b | 13.8 ± 2.7 b | y 190 ± 15 a,b | 417 ± 33 b | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramírez-Fajardo, A.-F.; Martín-Vizcaíno, C.; Rodríguez-García, I.; Guil-Guerrero, J.L. Vegetables Treated before Drying with Natural Antioxidants plus UV-C Improve Colour and Bioactive Compounds. AgriEngineering 2024, 6, 3635-3651. https://doi.org/10.3390/agriengineering6040207

Ramírez-Fajardo A-F, Martín-Vizcaíno C, Rodríguez-García I, Guil-Guerrero JL. Vegetables Treated before Drying with Natural Antioxidants plus UV-C Improve Colour and Bioactive Compounds. AgriEngineering. 2024; 6(4):3635-3651. https://doi.org/10.3390/agriengineering6040207

Chicago/Turabian StyleRamírez-Fajardo, Antonio-Fer, Cristina Martín-Vizcaíno, Ignacio Rodríguez-García, and José Luis Guil-Guerrero. 2024. "Vegetables Treated before Drying with Natural Antioxidants plus UV-C Improve Colour and Bioactive Compounds" AgriEngineering 6, no. 4: 3635-3651. https://doi.org/10.3390/agriengineering6040207

APA StyleRamírez-Fajardo, A.-F., Martín-Vizcaíno, C., Rodríguez-García, I., & Guil-Guerrero, J. L. (2024). Vegetables Treated before Drying with Natural Antioxidants plus UV-C Improve Colour and Bioactive Compounds. AgriEngineering, 6(4), 3635-3651. https://doi.org/10.3390/agriengineering6040207