Abstract

The high rate of perishability of fruits such as cagaita (Eugenia dysenterica DC.), seriguela (Spondias purpurea L.), mangaba (Hancornia speciosa Gomes) and pitomba (Talisia esculenta Radlk.) makes it necessary to develop adequate conservation techniques to increase post-harvest shelf life. The aim of this research was to evaluate the post-harvest quality attributes of cagaita, seriguela, mangaba and pitomba fruits stored in different types of packaging during certain periods. The treatments were defined by the combination of three types of packaging (low-density polyethylene (LDPE), polyvinyl chloride (PVC) and without packaging) and seven storage periods. Total soluble solids, titratable acidity, hydrogen potential (pH), fruit firmness and loss of fresh mass were analyzed. Fruits packaged with LDPE presented the lowest values of fresh mass loss: 2.7, 2.3, 4.2 and 1.1% for cagaita, seriguela, mangaba and pitomba, respectively. Furthermore, LPDE packaging maintained the quality attributes in all fruits analyzed. PVC packaging was more efficient in maintaining fruit firmness, with average values of 0.03 N. Atmospheric modification techniques, such as LDPE and PVC packaging, make it possible to reduce metabolic activity, ensuring better post-harvest quality and increasing the storage period of fruits that occur in the semiarid region of Minas Gerais.

Keywords:

cagaita; fruit quality; mangaba; modified atmosphere; native fruits; pitomba; plastic films; seriguela 1. Introduction

Species of fruits occurring in the semiarid region of Minas Gerais, such as cagaita (Eugenia dysenterica DC.) seriguela (Spondias purpurea L.), mangaba (Hancornia speciosa Gomes) and pitomba (Talisia esculenta Radlk.), unknown to the majority of the population, have great potential for use and expansion in Brazilian cuisine, considering the demand of the domestic and foreign market for exotic flavors [1]. However, the high perishability of these fruits, due to the continuity of their metabolic processes in the post-harvest phase and their rustic transport and storage, is the main factor responsible for compromising their quality [2].

To maintain the quality characteristics of fruits, such as sugar content, color, firmness and acidity, for a longer period of time than is normally achieved under natural ripening conditions, post-harvest conservation techniques or methods are used [3]. These techniques include, but are not limited to, edible coatings, gamma irradiation chemical applications, effective packaging, gas manipulation and storage environment composition [4,5].

Modified atmosphere is a preservation technique used to expand shelf life and maintain fruit quality [6]. The use of this technique using plastic films limits fruit mass loss and gas exchange with the environment, reducing chemical and biochemical reactions that deteriorate the fruits. In addition, it provides other desirable effects, such as maintaining the color, texture, flavor and nutritional value of the product by changing the composition of the gases surrounding the fruits [7,8]. The integration of modified atmosphere packaging with refrigerated storage has shown significant reductions in post-harvest losses and considerable extension of the commercial life of fruits [4,9].

There are several polymeric packages available for fruits and vegetables [10]. Among the available polymer packaging are low-density polyethylene (LDPE) and polyvinyl chloride (PVC) films [11]. Low-density polyethylene films have good O2 and CO2 permeability characteristics and good water vapor barrier properties. Polyvinyl chloride films are thinner and about twice as permeable as LDPE films [12].

Maryam et al. [4], in a study involving strawberries, found that LDPE film effectively preserves the physical and biochemical properties of fresh fruits and prolongs their storage capacity in low temperature conditions, an important aspect for long-distance local marketing and exporting. They further stated that the research findings can be translated to other highly perishable crops. Therefore, the use of these conservation techniques can be fundamental to minimize post-harvest losses of fruits present in the semiarid region and promote their appreciation, always aiming to obtain a quality final product appreciated by the consumer market.

Thus, the aim of this research was to evaluate the post-harvest quality attributes of cagaita, seriguela, mangaba and pitomba fruits stored in different types of packaging during certain periods.

2. Materials and Methods

2.1. Collection of Fruits and Experimental Conditions

The cagaita, mangaba, pitomba and seriguela fruits were harvested on private properties in the cities of Patis and Japonvar in the semiarid region of Minas Gerais, Brazil, a place known as the Banda dos Gerais, located at 16° 5′ 18″ S and 44° 5′ 17″ W.

The region’s climate is type Aw according to the Koppen–Geiger classification [13]. Rain is concentrated from November to March, with five months of the year not experiencing significant amounts of rainfall. The region’s tropical climate is characterized by high air temperatures, with an average of 24.7 °C [14].

The soils in the study areas are, in general, classified as Red-Yellow Oxisols, which have low natural fertility, ranging from deep to very deep, permeable and of medium texture. The relief is gently undulating and there is a predominance of Caatinga vegetation with areas of transition to the Cerrado biome [14].

The harvests of cagaita, seriguela, mangaba and pitomba fruits occurred during the months of November to January, November to February, December to March and January to March, respectively. Fruits were considered ripe and ready for harvest when they had the following characteristics: pitomba fruits were totally green with brown peel; mangaba fruits were totally green, with yellowish-green peels and red pigmentation in half of the fruit; seriguela fruits had an onset of red pigmentation on the peel; and cagaita fruits were totally green with the green/yellowish peel on half of the fruit, following the local traditions for harvesting the fruits (Figure 1).

Figure 1.

Photos of cagaita (A), seriguela (B), mangaba (C) and pitomba (D) fruits harvested in the semiarid region of Minas Gerais.

The fruits were transferred to the Fruit Post-harvest Laboratory of the State University of Montes Claros (UNIMONTES) in Janaúba-MG, Brazil, where they were washed in water and 0.2% neutral detergent for surface cleaning and immersed in a solution of sodium hypochlorite (200 mg L−1) for 15 min to reduce the microbial load coming from the field. Fruits with mechanical damage, disease, malformation and with spots on the peel were discarded.

2.2. Experimental Design and Treatments

The experimental design used was completely randomized (DIC) in a 3 × 7 factorial scheme. The treatments were composed of the combination of three types of packaging (LDPE with a thickness of 16 µm, PVC and without packaging) and seven storage periods defined by intervals of two days for each evaluation, totaling 12 days of storage after harvesting the fruits. To determine the average values of each variable analyzed, four repetitions were considered, each repetition corresponding to an evaluation of 20 fruits.

The fruits were stored during the evaluation period at 13 ± 1 °C, with a relative humidity of 85 ± 5%, which is the refrigeration standard for preserving commercial fruits [15]. Due to the fruit-harvest period occurring between the months of November and April, the experiment was set up with the harvest of two species in the first year (mangaba and pitomba) and two species in the second year (seriguela and cagaita).

2.3. Physical and Chemical Analysis

Five variables related to post-harvest fruit quality, namely, total soluble solids, titratable acidity, hydrogen potential (pH), pulp firmness and loss of fresh mass were evaluated. For the analysis of soluble solids, titratable acidity and pH, we used four crushed fruits as samples. The determination of total soluble solids was performed by refractometry, using an ABBE benchtop digital refractometer, with readings in the range of 0 to 95 °Brix and the results expressed in °Brix. The titratable acidity was determined by titration, and the results were expressed in g of citric acid per 100 g of pulp. The pH was determined in a benchtop pH meter.

Fruit firmness was determined using a Brookfield digital texturometer, model CT3 10 kg. The measurements were performed in the median region of the fruit, determined by the penetration force, measured in Newtons (N). Fresh mass loss of the fruits was determined by the difference in fruit mass accumulated during the storage periods, considering the difference between the initial mass of the fruit and that obtained in each sampling period, and the result was expressed as a percentage (%). The fruits were weighed using a semi-analytical digital scale.

2.4. Statistical Analysis

All the statistical analyses were performed with the R software (R Project for Statistical Computing, Vienna, Austria, version 4.1.2). Analyses of variance (ANOVA) were performed after testing the homogeneity of variances and normality of the residuals by the Levene and Shapiro–Wilks tests, respectively. Variables with a significant F value at 5% probability were subjected to regression analysis and the post-hoc Tukey test at 5% probability.

3. Results and Discussion

3.1. Cagaita

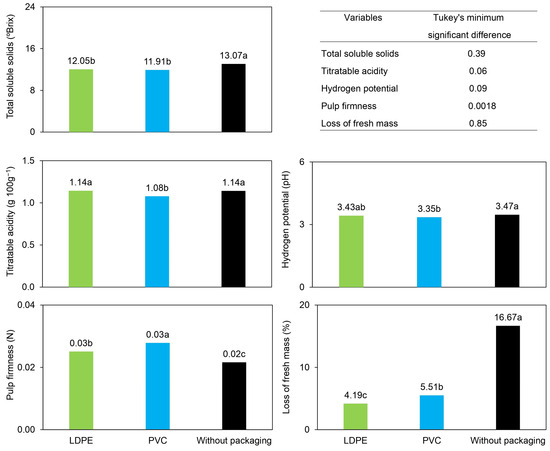

Considering cagaita fruits, the treatments of the types of packaging (P) and storage periods (S) resulted in significant differences in the average values of all variables evaluated. The P × S interaction did not result in significant differences for any of the variables analyzed (Table A1). The coefficients of variation for total soluble solids, titratable acidity, pH, pulp firmness and loss of fresh mass were 7.6, 6.9, 1.1, 32.4 and 19.3%, respectively. The general media values were 7.5 °Brix, 0.8 g of citric acid 100 g−1 of pulp, 2.9, 0.02 N and 6.3% for total soluble solids, titratable acidity, pH, pulp firmness and loss of fresh mass, respectively.

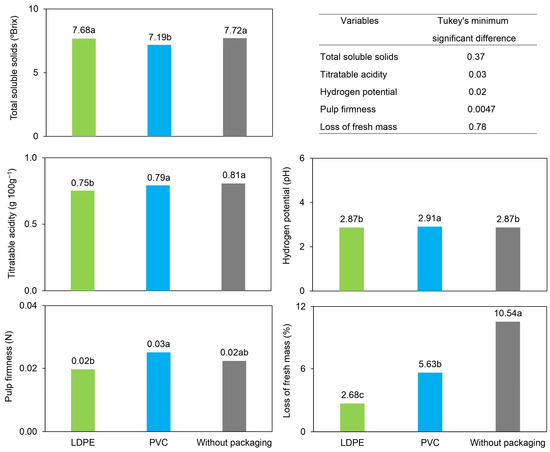

It was observed that cagaita fruits stored with LDPE and without packaging presented higher averages (7.7 °Brix) for total soluble solids when compared to the treatment with PVC (7.2 °Brix) (Figure 2). Cardoso et al. [15] and Camilo et al. [16] analyzed ripe cagaita fruits and obtained average values between 5.2 and 9.1 °Brix. Studying Paluma guavas stored without packaging, Grigio et al. [17] also observed high average values of total soluble solids, corroborating the findings of this research.

Figure 2.

Total soluble solids, titratable acidity, hydrogen potential, pulp firmness and loss of fresh mass of cagaita fruits stored in different types of packaging. LDPE—low-density polyethylene; PVC—polyvinyl chloride. Letters indicate significant differences among treatment and control samples (p < 0.05).

Higher average titratable acidity values were obtained with the use of PVC and without packaging (Figure 2). Grigio et al. [17] reported that titratable acidity decreases continuously throughout the storage period, highlighting LDPE packaging with the lowest reduction observed. This demonstrates the influence of LDPE packaging on delaying ripening through lower titratable acidity consumption.

Higher pH averages were obtained in cagaita fruits packaged with PVC (2.9), with no difference between the other treatments (2.87) (Figure 2). PVC packaging provided higher average firmness values for cagaita fruits (0.03 N). PVC packaging promotes an excellent balance between CO2 and O2, resulting in greater fruit firmness.

Higher average values of fresh mass loss were observed in cagaita fruits without packaging, reaching more than 10% loss (Figure 2). Meanwhile, the loss of fresh mass was lower in cagaita fruits stored in PVC (5.6%) and LDPE (2.7%) packaging after 12 days of storage. The positive effects of PVC and LDPE packaging were also verified in conde fruit [18], passion fruit [19] and pitomba fruit [20].

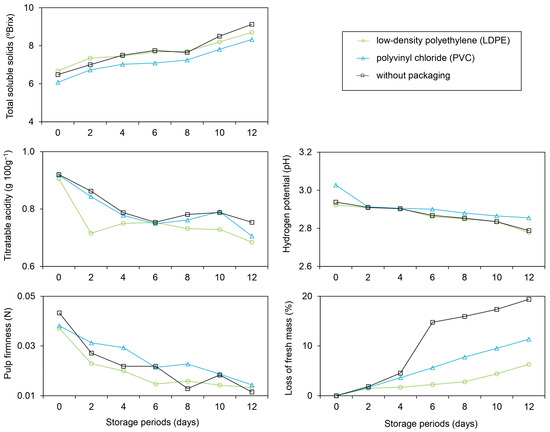

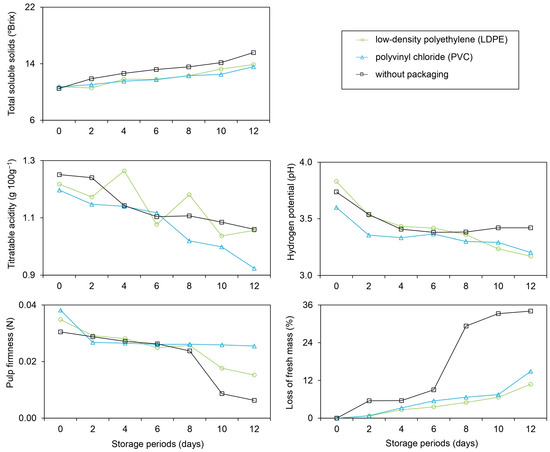

Total soluble solids in cagaita fruits increased as the storage period increased (Figure 3). At the end of the storage period, the average values of total soluble solids were 8.7, 8.3 and 9.1 °Brix for the LDPE, PVC and without packaging treatments, respectively. These values are close to those reported by Camilo et al. [16] and higher than those found by Araújo et al. [21] (5.2 °Brix) and Braz et al. [22] (5 °Brix) for fruits of this same species. Although cagaita is not a fruit with a very sweet flavor, this increase in total soluble solids during the storage period occurs due to the degradation of starch into simple sugars. This reaction occurs mainly during the climacteric period, due to the induction of ethylene [23].

Figure 3.

Total soluble solids, titratable acidity, hydrogen potential, pulp firmness and loss of fresh mass of cagaita fruits in different storage periods.

Among the various components of cagaita fruit, total soluble solids play a fundamental role in its quality, as it is responsible for the flavor and, consequently, its acceptance by consumers. Total soluble solids are also used as chemical indicators to characterize the maturation stages of a fruit and subsequently define the harvest point [24]. Cagaita, as it is a climacteric fruit, can be harvested before reaching the final stage of maturation, known as ripening. According to the results obtained in this research, cagaita can be harvested when it presents total soluble solids of 8.5 °Brix.

The average titratable acidity values decreased throughout the storage period, reaching 0.7, 0.7 and 0.8 g of citric acid per 100 g−1 of pulp on the 12th day for the LDPE, PVC and without packaging treatments, respectively (Figure 3). This was also verified by Santos et al. [25], during a storage period of 20 days. During ripening, a decrease in titratable acidity is expected, since organic acids are used in metabolism, being converted into sugars or serving as a substrate for the respiratory process [23].

A decrease in the pH of cagaita fruits was observed for each day of storage (Figure 3). Similar values were obtained by Araujo et al. [21]. This decrease in pH may be associated with the accumulation of sugars and organic acids during fruit ripening [26].

A decline in fruit firmness was also observed, reaching 0.01 N on the 12th day for all treatments (Figure 3). The softening of the pulp can be attributed to the activity of hydrolytic enzymes, such as polygalacturonase and pectinmethylesterase, which promote intense solubilization of pectins, constituents of the cell wall, resulting in a loss of firmness [27,28]. Asif and Nath [29] also reinforce the concept that the solubilization and depolymerization of pectins and hemicelluloses result in extensive degradation of cell walls and, as a consequence, in the softening of fruits with ripening. As cagaita has a high water content, around 95%, and a very thin skin, its firmness is greatly influenced during texture analysis due to the immediate flow of the juice, which can interfere with the results [30].

It can be observed that the loss of fresh mass was more intense in treatments without packaging, reaching almost 20% losses at the end of the evaluation period (Figure 3). On the other hand, it was less intense in fruits stored in PVC (11.3%) and LDPE (6.3%). The positive effects of PVC and LDPE were also verified in custard apple [18], passion fruit [19] and pitomba fruit [26].

According to Chitarra and Chitarra [12], the maximum loss of fresh mass varies between 5 and 10%. Taking this into consideration, the cagaita fruits in the present study would last two days without packaging the fruits and five to ten days for fruits stored with PVC and LDPE, respectively. The positive effect observed for LDPE packaging is due to the maintenance of high relative humidity inside, which prevented the increase in vapor pressure deficit and, consequently, reduced the loss of water from the fruits through the transpiration process [31]. Thus, treatments with LDPE showed more stable results in reducing the loss of fresh mass, in addition with allowing greater post-harvest conservation of the fruits.

3.2. Seriguela

Considering seriguela fruits, the treatments of the types of packaging (P) and storage periods (S) resulted in significant differences in the average values of all variables evaluated, with the exception of pulp firmness. The P × S interaction resulted in significant differences for the total soluble solids, titratable acidity and loss of fresh mass variables (Table A2). The coefficients of variation for the total soluble solids, titratable acidity, pH, pulp firmness and loss of fresh mass were 6.6, 5.7, 5.8, 13.2 and 9.6%, respectively. The general media values were 16.5 °Brix, 0.6 g of citric acid 100 g−1 of pulp, 3.2, 0.03 N and 7.2% for total soluble solids, titratable acidity, pH, pulp firmness and loss of fresh mass, respectively.

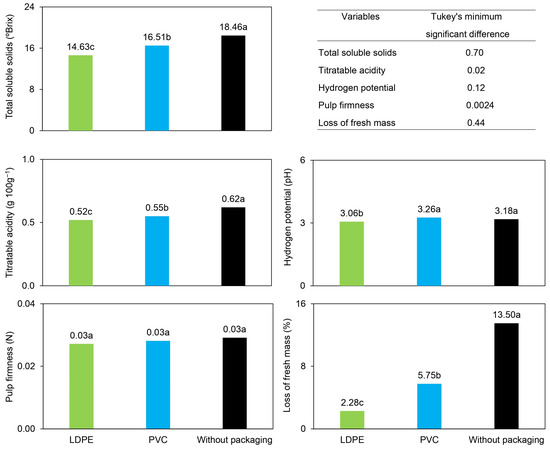

It was observed that seriguela fruits stored without packaging had a higher average (18.5 °Brix) of total soluble solids when compared to treatments with PVC (16.5 °Brix) and LDPE (14.7 °Brix) (Figure 4). Higher mean titratable acidity values were obtained in the treatment without packaging (0.62 g of citric acid 100 g−1 of pulp).

Figure 4.

Total soluble solids, titratable acidity, hydrogen potential, pulp firmness and loss of fresh mass of seriguela fruits stored in different types of packaging. LDPE—low-density polyethylene; PVC—polyvinyl chloride. Letters indicate significant differences among treatment and control samples (p < 0.05).

The PVC packaging provided a higher average pH of the seriguela fruits (3.3) compared to the LDPE packaging (3.1) (Figure 4). Almeida et al. [20] also observed higher averages in fruits packaged in PVC (4.3) compared to LDPE and treatment without packaging. However, all pH values found in the types of packaging studied were close to the values obtained by Sanches et al. [31], Freire et al. [32] and Silva et al. [24].

The types of packaging did not affect the pulp firmness of the seriguela fruits (0.03 N for all treatments). Higher average values of fresh mass loss were observed in seriguela fruits without packaging, reaching 13.5% losses (Figure 4). Meanwhile, the loss of fresh mass was lower in seriguela fruits stored in PVC (5.8%) and LDPE (2.3%) packaging after 12 days of storage.

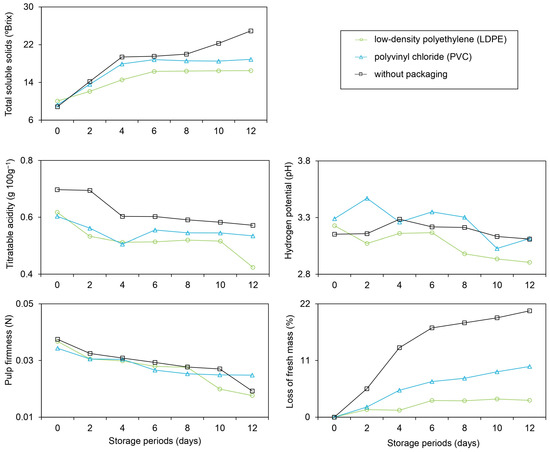

Total soluble solids in seriguela fruits showed higher average values with an increasing storage period (Figure 5). At the end of the storage period, the average values of total soluble solids were 16.5, 18.9 and 24.9 °Brix for LDPE, PVC and without packaging treatments, respectively. Total soluble solids tend to increase with ripening, either due to biosynthesis, excessive degradation of polysaccharides, or excessive loss of water from the fruit [12]. This coincides with results observed in other fruits such as bananas and mangos, which accumulate starch reserves. In these species, starch hydrolysis occurs during fruit ripening, which results in an increase in total soluble solids [33].

Figure 5.

Total soluble solids, titratable acidity, hydrogen potential, pulp firmness and loss of fresh mass of seriguela fruits in different storage periods.

In treatments with PVC packaging, it was noted that total soluble solids remained stable from the 6th to the 10th day, with little variation on the last day of storage. In the treatment with LDPE packaging, total soluble solids remained constant from the 8th to the 12th day of storage. These results demonstrate that seriguela fruits packaged with LDPE presented better maintenance of total soluble solids when compared to fruits without packaging. According to Santos et al. [34], this maintenance of total soluble solids occurs because packaging allows the fruit to reduce metabolic activity, delaying its ripening. Siqueira et al. [35] state that the decrease in the metabolic activity of packaged fruits is due to atmospheric changes inside the packages, causing a decrease in the ripening speed.

The values of total soluble solids obtained in this study are higher than those reported for other species of the genus Spondias, such as umbu (Spondias tuberosa Arruda) and umbu-cajá (Spondias sp.) [36,37]. Among the fruits of this genus, the seriguela is considered the sweetest of all. Total soluble solids closest to this species are only found in this group among the fruits of umbuguela (Spondias sp.), a hybrid of umbu [38] and seriguela [9].

The average titratable acidity values decreased throughout the storage period, reaching 0.4, 0.5 and 0.6 g of citric acid per 100 g−1 of pulp on the 12th day for the LDPE, PVC and without packaging treatments, respectively (Figure 5). For Minas et al. [37] fruit maturation drastically reduced titratable acidity values. The same behavior was observed by Aroucha et al. [33], studying the post-harvest quality of cajarana at different stages of maturation during refrigerated storage, and by Lima et al. [36], with umbu-cajazeira.

Fruits stored in PVC maintained an acidity of 0.5 g of citric acid per 100 g−1 of pulp from the 6th to the 12th day, possibly due to the decrease in cellular metabolism caused by the modification of the atmosphere inside the packaging. The decrease in the concentration of O2 and the increase in the concentration of CO2 inside the packaging decrease the activity of the enzymes involved in the respiratory process, maintaining a higher content of organic acids [39].

A decrease in the pH of seriguela fruits was observed throughout the storage periods (Figure 5). Sanches et al. [31] also noticed a reduction in pH (3.1) in seriguela fruits until the last day of storage. According to Chitarra and Chitarra [12], maintaining or reducing pH values post-harvest is fundamental to the palatability and flavor characteristics of foods. Thus, increasing values with storage time indicate high acidity and, consequently, a more advanced stage of maturation/senescence.

Pulp firmness was significantly affected by the storage period (Figure 5). Similar results were obtained by Sanches et al. [31], evaluating a 15-day storage period. The loss of fruit firmness during storage is probably related to the solubilization of pectin, which contributes to the softening of fruit tissues due to the reduction in cohesion strength between cells [12].

There was also a loss of fresh mass in seriguela fruits during the days of storage in all treatments (Figure 5). The loss of fresh mass was more intense in fruits without packaging, with a loss of more than 20%. The loss of fresh mass was lower in fruits packaged in PVC (9.8%) and LDPE (3.3%).

The loss of fresh mass is directly related to the loss of moisture to the environment, which is related to storage and other conservation techniques [40]. Knowing that moisture losses of 5 to 10% promote visible wrinkling of the fruits [41], the seriguela fruits would would generally last 1 day without packaging, 5 days stored with PVC and 16 days with LDPE.

3.3. Mangaba

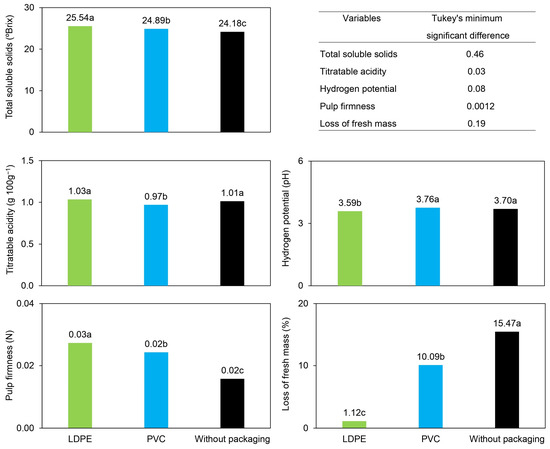

Considering mangaba fruits, the treatments of types of packaging (P) and storage periods (S) resulted in significant differences in the average values of all variables evaluated. The P × S interaction results in significant differences in the pulp firmness and loss of fresh mass variables (Table A3). The coefficients of variation for total soluble solids, titratable acidity, pH, pulp firmness and loss of fresh mass were 4.9, 7.9, 4.3, 11.4 and 15%, respectively. The general media values were 12.3 °Brix, 1.1 g of citric acid 100 g−1 of pulp, 3.4, 0.02 N and 8.8% for total soluble solids, titratable acidity, pH, pulp firmness and loss of fresh mass, respectively.

It was observed that mangaba fruits stored without packaging had a higher average of total soluble solids (13.1 °Brix) when compared to treatments with PVC (11.9 °Brix) and LDPE (12.1 °Brix) (Figure 6). Higher average titratable acidity values were obtained in treatments without packaging and with LDPE (1.14 g of citric acid per 100 g−1 of pulp).

Figure 6.

Total soluble solids, titratable acidity, hydrogen potential, pulp firmness and loss of fresh mass of mangaba fruits stored in different types of packaging. LDPE—low-density polyethylene; PVC—polyvinyl chloride. Letters indicate significant differences among treatment and control samples (p < 0.05).

The treatment without packaging provided a higher average pH of mangaba fruits (3.5) compared to PVC (3.4) and LDPE (3.4) packaging (Figure 6).

The type of packaging that resulted in greater pulp firmness of mangaba fruits was PVC (0.03 N). Higher average values of fresh mass loss were observed in mangaba fruits without packaging, reaching 16.7% losses (Figure 6). Meanwhile, the loss of fresh mass was lower in mangaba fruits stored in PVC (5.5%) and LDPE (4.2%) packaging after 12 days of storage.

Total soluble solids in mangaba fruits increased with increasing storage period (Figure 7). At the end of the storage period, the average values of total soluble solids were 13.6, 13.6 and 15.6 °Brix for the LDPE, PVC and without packaging treatments, respectively. These values are close to those obtained by Campos et al. [42] and Nascimento et al. [43] in mangaba fruits. Maturation occurred more quickly in fruits stored without packaging, in which a greater accumulation of total soluble solids was observed over the days of storage.

Figure 7.

Total soluble solids, titratable acidity, hydrogen potential, pulp firmness and loss of fresh mass of mangaba fruits in different storage periods.

The increase in total soluble solids is well characterized as the fruit ripens. Dissolved substances, mainly sugars, tend to increase with ripening, which characterizes the sweetness of the fruit. In this way, PVC and LDPE packaging contributed to better conservation of the fruits, keeping the total soluble solids with less variation.

The average titratable acidity values decreased throughout the storage period, reaching 1.1, 0.9 and 1.1 g of citric acid per 100 g−1 of pulp on the 12th day for the LDPE, PVC and without packaging treatments, respectively (Figure 7). These values allow mangaba fruits to have a moderate flavor and be well accepted for fresh consumption. According to Sacramento et al. [44], a fruit that has citric acid levels between 0.08 and 1.95 g per 100 g−1 of pulp can be classified as having a moderate flavor and well accepted for fresh fruit consumption.

A decrease in the pH of mangaba fruits was observed throughout the storage periods (Figure 7). These values are close to those obtained by Nascimento et al. [43] and Perfeito et al. [45]. According to Azeredo and Brito [46], fruits with a pH value below 4.5 are classified as very acidic.

The firmness of the pulp was significantly affected by the storage period (Figure 7). Higher pulp firmness values at the end of the storage period were observed in treatments with PVC packaging (0.03 N) and LDPE (0.02 N), meanwhile, lower pulp firmness values were observed in the treatment without packaging (0.01 N). These values are close to those obtained by Mariano-Nasser et al. [47]. The greater firmness of the pulp presented by fruits with plastic films is related to the decrease in the activity of pectinolytic enzymes, caused by the decrease in the action of ethylene. This substance stimulates processes such as acid consumption, color changes and loss of pulp firmness [48].

There was also a loss of fresh mass in mangaba fruits during the days of storage in all treatments (Figure 7). The lowest loss of fresh mass was observed in the treatment with LDPE packaging (10.8%), followed by PVC (14.9%). The use of plastic packaging also reduced mass loss in custard apple (Annona squamosa L.) in the research by Mizobutsi et al. [18] and Reges et al. [2].

The fresh mass loss results show that the packaging used was semi-permeable and that the fruits continued to breathe, but with less water loss and, consequently, less fresh mass loss throughout the storage period.

The reduction in fresh mass loss observed in mangaba fruits was due to the thickness of the polymer used in the manufacturing of LDPE. This increased the air’s relative humidity inside the packages, saturating the atmosphere, leading to a decrease in vapor pressure deficit and, consequently, reducing the transpiration of the fruits [49]. Thus, it was found that the use of LDPE packaging was efficient in reducing the loss of fresh mass in mangaba fruits.

3.4. Pitomba

Considering pitomba fruits, the treatments of the types of packaging (P) and storage periods (S) resulted in significant differences in the average values of all variables evaluated. The P × S interaction resulted in significant differences for the titratable acidity, pulp firmness and loss of fresh mass variables (Table A4). The coefficients of variation for total soluble solids, titratable acidity, pH, pulp firmness and loss of fresh mass were 2.9, 4.4, 3.3, 8.4 and 3.3%, respectively. The general media values were 24.9 °Brix, 1 g of citric acid 100 g−1 of pulp, 3.7, 0.02 N and 8.9% for total soluble solids, titratable acidity, pH, pulp firmness and loss of fresh mass, respectively.

It was observed that pitomba fruits stored with LDPE packaging presented a higher average of total soluble solids (25.5 °Brix) when compared to treatments with PVC (24.9 °Brix) and without packaging (24.2 °Brix) (Figure 8). These values are higher than those obtained by Almeida et al. [20] using LDPE (15.3 °Brix) and treatments without packaging (16.7 °Brix) on fruits of the same species. The high values of total soluble solids can be explained by the concentration of these compounds as a result of weight loss (loss of water through the respiratory process), which leads to a higher concentration of sugars in the fruits [50].

Figure 8.

Total soluble solids, titratable acidity, hydrogen potential, pulp firmness and loss of fresh mass of pitomba fruits stored in different types of packaging. LDPE—low-density polyethylene; PVC—polyvinyl chloride. Letters indicate significant differences among treatment and control samples (p < 0.05).

Higher average titratable acidity values were obtained in treatments with LDPE and without packaging (1.03 and 1.01 g of citric acid per 100 g−1 of pulp, respectively). The PVC treatment provided a higher average pH of pitomba fruits (3.8) compared to the treatments without packaging (3.7) and with LDPE (3.6) (Figure 8). According to Oliveira et al. [51], a lower value obtained in treatment with LDPE favors the inhibition of the development of microorganisms responsible for fruit deterioration, thus increasing the storage period.

The type of packaging that resulted in greater firmness of the pitomba fruit pulp was LDPE (0.03 N). Higher average values of fresh mass loss were observed in pitomba fruits without packaging, reaching 15.5% losses (Figure 8). Meanwhile, the loss of fresh mass was lower in pitomba fruits stored in PVC (10.1%) and LDPE (1.1%) packaging after 12 days of storage.

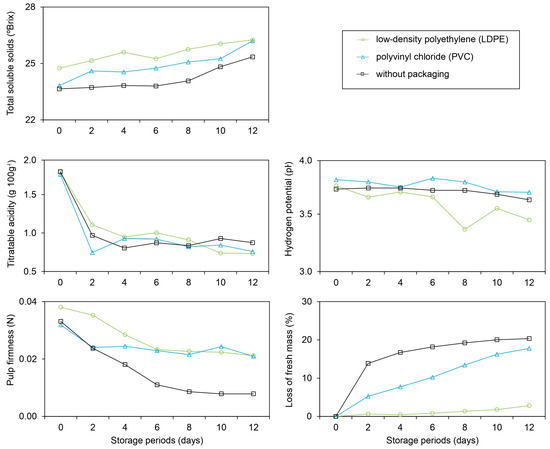

Total soluble solids in pitomba fruits increased with increasing storage period (Figure 9). At the end of the storage period, the average values of total soluble solids were 26.2, 26.2 and 23.4 °Brix for the LDPE, PVC and without packaging treatments, respectively. This behavior can be explained both by the hydrolysis of starch into reducing sugars (fructose and glucose), which occurs during ripening, and by the loss of water, which contributes to the concentration of soluble solids [52]. Mendonça and Vieites [53], in studies with pitomba, sapodilla, cabeludinha, yellow grumixama and seriguela, observed that pitomba had a higher content of soluble solids (24.6 °Brix), close to that obtained in this research.

Figure 9.

Total soluble solids, titratable acidity, hydrogen potential, pulp firmness and loss of fresh mass of pitomba fruits in different storage periods.

The average titratable acidity values decreased throughout the storage period, reaching 0.8, 0.8 and 0.9 g of citric acid per 100 g−1 of pulp on the 12th day for the LDPE, PVC and without packaging treatments, respectively (Figure 9). Almeida et al. [20] also obtained higher acidity (1.1 g of citric acid per 100 g−1 of pulp) at the end of the 12th day of storage of pitomba fruits stored without packaging. The lower titratable acidity values observed in treatments with plastic films can be explained by a greater retention in the transformation of organic acids, caused by the physical barrier of the packaging [54].

A decrease in the pH of the pitomba fruits was observed throughout the storage periods (Figure 9). The pH values found were consistent with those obtained by Queiroga et al. [55] (3.7) and Mendonça and Vieites [53] (3.4).

Pulp firmness decreased over the days of storage for all packages (Figure 9). Pitomba fruits packaged with PVC and LDPE showed a higher pulp firmness value (0.02 N) on the 12th day of storage. The use of PVC and LDPE was also efficient in maintaining the pulp firmness of the golden apple [56] and custard apple [2], probably as a reflection of the increased CO2 concentration inside these packages.

There was also a loss of fresh mass in pitomba fruits during the days of storage in all treatments (Figure 9). The loss of fresh mass in treatments without packaging was 20.3%. In treatments with PVC and LDPE packaging, the values obtained were 17.8 and 2.8%, respectively. The natural transpiration of pitomba, associated with the loss of carbon through fruit respiration [57] may explain the loss of fresh mass during storage, as well as the low efficiency of PVC packaging as a barrier to O2 and CO2 gases [12]. These results follow the behavior of the pulp firmness variable (Figure 9), as pitomba fruits without packaging lose more water and appear firmer, but are simply drier and more wrinkled. Likewise, Almeida et al. [20] observed lower losses of fresh mass (0.6%) using LDPE packaging in the preservation of pitomba fruits.

For Kader [58] the loss of fresh mass is strongly reduced by the use of flexible plastic films. The positive effect observed for LDPE packaging is due to the maintenance of high relative humidity inside. This prevents an increase in vapor pressure deficit and, consequently, reduces water loss from the fruits through the transpiration process [31].

4. Conclusions

Fruits packaged with low-density polyethylene (LDPE) presented the lowest values of fresh mass loss: 2.7, 2.3, 4.2 and 1.1% for cagaita, seriguela, mangaba and pitomba, respectively. Furthermore, LPDE packaging maintained the quality attributes in all fruits analyzed. Polyvinyl chloride (PVC) packaging was more efficient in maintaining fruit firmness, with an average value of 0.03 N. The soluble solids contents during the 12 days of storage increased in the cagaita and pitomba fruits, while the titratable acidity decreased in the mangaba and cagaita fruits. Atmospheric modification techniques, such as LDPE and PVC packaging, make it possible to reduce metabolic activity, ensuring better post-harvest quality and increasing the storage period of fruits that occur in the semiarid region of Minas Gerais.

Author Contributions

Conceptualization, R.R.S.S. and G.P.M.; methodology, R.R.S.S. and G.P.M.; software, R.R.S.S. and G.P.M.; validation, R.R.S.S. and G.P.M.; formal analysis, R.R.S.S. and G.P.M.; investigation, R.R.S.S., G.P.M., E.H.M. and F.S.A.; resources, R.R.S.S. and G.P.M.; data curation, R.R.S.S., G.P.M., E.H.M. and J.d.O.C.; writing—original draft preparation, R.R.S.S., G.P.M., E.H.M., F.S.A., L.B.d.A., L.B.A., R.C.d.S., L.M.d.O., D.B.S. and J.d.O.C.; writing—review and editing, R.R.S.S., G.P.M., E.H.M., F.S.A., L.B.d.A., L.B.A., R.C.d.S., L.M.d.O., D.B.S. and J.d.O.C.; visualization, R.R.S.S., G.P.M., E.H.M., F.S.A., L.B.d.A., L.B.A., R.C.d.S., L.M.d.O., D.B.S. and J.d.O.C.; supervision, G.P.M.; project administration, R.R.S.S. and G.P.M.; funding acquisition, R.R.S.S. and G.P.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Fundação de Amparo à Pesquisa do Estado de Minas Gerais (FAPEMIG), project number APQ-00181-17.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

To the Minas Gerais Research Funding Foundation (FAPEMIG) for research funding.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

Analysis of variance (ANOVA) to compare the means of the studied variables for cagaita fruits.

Table A1.

Analysis of variance (ANOVA) to compare the means of the studied variables for cagaita fruits.

| Source of Variation | Sum of Squares | Mean Square | F | p-Values | |

|---|---|---|---|---|---|

| Total soluble solids (°Brix) | |||||

| Types of packaging (P) | 4.90 | 2.45 | 7.48 | 0.0013 * | |

| Storage periods (S) | 40.41 | 6.73 | 20.57 | 0.0000 * | |

| Interaction (P × S) | 0.96 | 0.08 | 0.24 | 0.9949 ns | |

| Coefficient of variation (%) | 7.60 | ||||

| General media | 7.53 | ||||

| Titratable acidity (g of citric acid 100 g−1 of pulp) | |||||

| Types of packaging (P) | 0.04 | 0.02 | 7.55 | 0.0012 * | |

| Storage periods (S) | 0.29 | 0.04 | 16.93 | 0.0000 * | |

| Interaction (P × S) | 0.04 | 0.00 | 1.03 | 0.4316 ns | |

| Coefficient of variation (%) | 6.86 | ||||

| General media | 0.78 | ||||

| Hydrogen potential (pH) | |||||

| Types of packaging (P) | 0.03 | 0.01 | 15.06 | 0.0000 * | |

| Storage periods (S) | 0.18 | 0.03 | 32.72 | 0.0000 * | |

| Interaction (P × S) | 0.02 | 0.00 | 1.80 | 0.0682 ns | |

| Coefficient of variation (%) | 1.06 | ||||

| General media | 2.88 | ||||

| Pulp firmness (N) | |||||

| Types of packaging (P) | 0.0004 | 0.0002 | 3.88 | 0.0260 * | |

| Storage periods (S) | 0.0006 | 0.0009 | 17.92 | 0.0000 * | |

| Interaction (P × S) | 0.0004 | 0.0000 | 0.66 | 0.7857 ns | |

| Coefficient of variation (%) | 32.41 | ||||

| General media | 0.0224 | ||||

| Loss of fresh mass (%) | |||||

| Types of packaging (P) | 882.04 | 441.02 | 301.41 | 0.0000 * | |

| Storage periods (S) | 1579.73 | 263.29 | 179.94 | 0.0000 * | |

| Interaction (P × S) | 517.93 | 43.16 | 29.50 | 0.0000 * | |

| Coefficient of variation (%) | 19.25 | ||||

| General media | 6.28 | ||||

ns not significant; * significant at a probability level of 5%.

Table A2.

Analysis of variance (ANOVA) to compare the means of the studied variables for seriguela fruits.

Table A2.

Analysis of variance (ANOVA) to compare the means of the studied variables for seriguela fruits.

| Source of Variation | Sum of Squares | Mean Square | F | p-Values | |

|---|---|---|---|---|---|

| Total soluble solids (°Brix) | |||||

| Types of packaging (P) | 205.27 | 102.63 | 86.87 | 0.0000 * | |

| Storage periods (S) | 1051.61 | 175.27 | 148.35 | 0.0000 * | |

| Interaction (P × S) | 125.96 | 10.50 | 8.89 | 0.0000 * | |

| Coefficient of variation (%) | 6.58 | ||||

| General media | 16.53 | ||||

| Titratable acidity (g of citric acid 100 g−1 of pulp) | |||||

| Types of packaging (P) | 0.14 | 0.07 | 78.83 | 0.0000 * | |

| Storage periods (S) | 0.13 | 0.02 | 21.02 | 0.0000 * | |

| Interaction (P × S) | 0.04 | 0.00 | 2.97 | 0.0026 * | |

| Coefficient of variation (%) | 5.65 | ||||

| General media | 0.56 | ||||

| Hydrogen potential (pH) | |||||

| Types of packaging (P) | 0.54 | 0.27 | 8.20 | 0.0007 * | |

| Storage periods (S) | 0.62 | 0.10 | 3.13 | 0.0099 * | |

| Interaction (P × S) | 0.37 | 0.03 | 0.93 | 0.5285 ns | |

| Coefficient of variation (%) | 5.75 | ||||

| General media | 3.17 | ||||

| Pulp firmness (N) | |||||

| Types of packaging (P) | 0.0004 | 0.0000 | 1.97 | 0.1489 ns | |

| Storage periods (S) | 0.0019 | 0.0003 | 22.39 | 0.0000 * | |

| Interaction (P × S) | 0.0002 | 0.0000 | 1.38 | 0.2022 ns | |

| Coefficient of variation (%) | 13.24 | ||||

| General media | 0.0281 | ||||

| Loss of fresh mass (%) | |||||

| Types of packaging (P) | 1848.10 | 924.05 | 1949.37 | 0.0000 * | |

| Storage periods (S) | 1288.15 | 214.69 | 452.91 | 0.0000 * | |

| Interaction (P × S) | 541.58 | 45.13 | 95.21 | 0.0000 * | |

| Coefficient of variation (%) | 9.59 | ||||

| General media | 7.18 | ||||

ns not significant; * significant at a probability level of 5%.

Table A3.

Analysis of variance (ANOVA) to compare the means of the studied variables for mangaba fruits.

Table A3.

Analysis of variance (ANOVA) to compare the means of the studied variables for mangaba fruits.

| Source of Variation | Sum of Squares | Mean Square | F | p-Values | |

|---|---|---|---|---|---|

| Total soluble solids (°Brix) | |||||

| Types of packaging (P) | 22.46 | 11.23 | 30.19 | 0.0000 * | |

| Storage periods (S) | 113.62 | 18.94 | 50.90 | 0.0000 * | |

| Interaction (P × S) | 8.23 | 0.69 | 1.85 | 0.0609 ns | |

| Coefficient of variation (%) | 4.94 | ||||

| General media | 12.34 | ||||

| Titratable acidity (g of citric acid 100 g−1 of pulp) | |||||

| Types of packaging (P) | 0.08 | 0.04 | 4.97 | 0.0101 * | |

| Storage periods (S) | 0.45 | 0.07 | 9.46 | 0.0000 * | |

| Interaction (P × S) | 0.10 | 0.00 | 1.11 | 0.3703 ns | |

| Coefficient of variation (%) | 7.91 | ||||

| General media | 1.12 | ||||

| Hydrogen potential (pH) | |||||

| Types of packaging (P) | 0.20 | 0.10 | 4.80 | 0.0117 * | |

| Storage periods (S) | 1.64 | 0.27 | 12.78 | 0.0000 * | |

| Interaction (P × S) | 0.25 | 0.02 | 0.98 | 0.4854 ns | |

| Coefficient of variation (%) | 4.28 | ||||

| General media | 3.41 | ||||

| Pulp firmness (N) | |||||

| Types of packaging (P) | 0.0005 | 0.0003 | 33.24 | 0.0000 * | |

| Storage periods (S) | 0.0030 | 0.0005 | 62.30 | 0.0000 * | |

| Interaction (P × S) | 0.0010 | 0.0000 | 10.01 | 0.0000 * | |

| Coefficient of variation (%) | 11.35 | ||||

| General media | 0.0249 | ||||

| Loss of fresh mass (%) | |||||

| Types of packaging (P) | 2633.86 | 1316.93 | 756.29 | 0.0000 * | |

| Storage periods (S) | 4171.30 | 695.22 | 399.25 | 0.0000 * | |

| Interaction (P × S) | 2043.82 | 170.32 | 97.81 | 0.0000 * | |

| Coefficient of variation (%) | 15.01 | ||||

| General media | 8.79 | ||||

ns not significant; * significant at a probability level of 5%.

Table A4.

Analysis of variance (ANOVA) to compare the means of the studied variables for pitomba fruits.

Table A4.

Analysis of variance (ANOVA) to compare the means of the studied variables for pitomba fruits.

| Source of Variation | Sum of Squares | Mean Square | F | p-Values | |

|---|---|---|---|---|---|

| Total soluble solids (°Brix) | |||||

| Types of packaging (P) | 26.09 | 13.05 | 25.97 | 0.0000 * | |

| Storage periods (S) | 27.45 | 4.58 | 9.11 | 0.0000 * | |

| Interaction (P × S) | 2.39 | 0.20 | 0.40 | 0.9597 ns | |

| Coefficient of variation (%) | 2.85 | ||||

| General media | 24.87 | ||||

| Titratable acidity (g of citric acid 100 g−1 of pulp) | |||||

| Types of packaging (P) | 0.06 | 0.03 | 15.10 | 0.0000 * | |

| Storage periods (S) | 8.73 | 1.46 | 729.43 | 0.0000 * | |

| Interaction (P × S) | 0.42 | 0.04 | 17.68 | 0.0000 * | |

| Coefficient of variation (%) | 4.44 | ||||

| General media | 1.01 | ||||

| Hydrogen potential (pH) | |||||

| Types of packaging (P) | 0.42 | 0.21 | 13.99 | 0.0000 * | |

| Storage periods (S) | 0.29 | 0.05 | 3.27 | 0.0075 * | |

| Interaction (P × S) | 0.25 | 0.02 | 1.41 | 0.1861 ns | |

| Coefficient of variation (%) | 3.31 | ||||

| General media | 3.68 | ||||

| Pulp firmness (N) | |||||

| Types of packaging (P) | 0.0020 | 0.0010 | 285.37 | 0.0000 * | |

| Storage periods (S) | 0.0031 | 0.0005 | 145.05 | 0.0000 * | |

| Interaction (P × S) | 0.0006 | 0.0001 | 14.72 | 0.0000 * | |

| Coefficient of variation (%) | 8.37 | ||||

| General media | 0.0224 | ||||

| Loss of fresh mass (%) | |||||

| Types of packaging (P) | 2942.98 | 1471.49 | 17,001.90 | 0.0000 * | |

| Storage periods (S) | 1539.92 | 256.65 | 2965.42 | 0.0000 * | |

| Interaction (P × S) | 673.04 | 56.09 | 648.03 | 0.0000 * | |

| Coefficient of variation (%) | 3.31 | ||||

| General media | 8.89 | ||||

ns not significant; * significant at a probability level of 5%.

References

- Carvalho, A.V.; do Nascimento, W.M.O. Caracterização Físico-Química e Química da Polpa de Frutos de Muruci. Embrapa Amazônia Oriental-Boletim de Pesquisa e Desenvolvimento (INFOTECA-E). 2016. Available online: https://www.infoteca.cnptia.embrapa.br/infoteca/bitstream/doc/1054673/1/BOLETIMPD108OnLine.pdf (accessed on 15 June 2024).

- Reges, B.M.; Batista, E.M.; do Nascimento, A.É.J.; dos Reis Lemos, L.M.; da Silva, E.; de Souza, P.A. Pós-colheita de Annona squamosa L. recobertas com filme PVC. Rev. Verde Agroecol. Desenvolv. Sustentável 2018, 13, 445–451. [Google Scholar] [CrossRef]

- Ayala-Zavala, J.F.; Wang, S.Y.; Wang, C.Y.; González-Aguilar, G.A. Effect of storage temperatures on antioxidant capacity and aroma compounds in strawberry fruit. LWT-Food Sci. Technol. 2004, 37, 687–695. [Google Scholar] [CrossRef]

- Maryam, A.; Anwar, R.; Malik, A.U.; Khan, S.A. Influence of macro-perforated polyethylene terephthalate and low-density polyethylene packaging films on quality and storability of strawberries. J. Food Process. Preserv. 2021, 45, e15068. [Google Scholar] [CrossRef]

- Zhao, X.; Xia, M.; Wei, X.; Xu, C.; Luo, Z.; Mao, L. Consolidated cold and modified atmosphere package system for fresh strawberry supply chains. LWT 2019, 109, 207–215. [Google Scholar] [CrossRef]

- Singh, R.; Giri, S.K.; Kotwaliwale, N. Shelf-life enhancement of green bell pepper (Capsicum annuum L.) under active modified atmosphere storage. Food Packag. Shelf Life 2014, 1, 101–112. [Google Scholar] [CrossRef]

- Oshiro, A.M.; Dresch, D.M.; Scalon, S.P.Q. Atmosfera modificada e temperaturas de armazenamento na conservação pós-colheita de guavira (Campomanesia adamantium Camb.). J. BioSci. 2013, 29, 1421–1430. [Google Scholar]

- Edusei, V.O.; Ofosu-Anim, J. Biochemical changes in green chilli pepper fruits during storage in polymeric films. J. Res. Agric. 2013, 2, 187–192. [Google Scholar]

- Sanches, A.G.; da Silva, M.B.; Moreira, E.G.S.; dos Santos, E.X. Delay maturation and post-harvest quality of seriguela exposed by ultraviolet irradiation. Nativa 2018, 6, 225–232. [Google Scholar] [CrossRef]

- Soethe, C.; Mattos, L.M.; Steffens, C.A. Armazenamento refrigerado de pimenta dedo-de-moça ‘BRS Mari’ em embalagem polimérica. R. Cienc. Agrovet. 2017, 16, 214–220. [Google Scholar] [CrossRef][Green Version]

- Barbosa, L.A.; Dreger, A.A.; Schneider, E.L.; Morisso, F.D.P.; Santana, R.M. Polietileno de baixa densidade—PEBD: Mercado, produção, principais propriedades e aplicações. Rev. Espac. 2017, 38, 1–13. [Google Scholar]

- Chitarra, M.I.F.; Chitarra, A.B. Pós-Colheita de Frutos e Hortaliças: Fisiologia e Manuseio, 2nd ed.; UFLA: Lavras, Brazil, 2005; 783p. [Google Scholar]

- Alvares, C.A.; Stape, J.L.; Sentelhas, P.C.; Gonçalves, J.D.M.; Sparovek, G. Köppen’s climate classification map for Brazil. Meteorol. Z. 2013, 22, 711–728. [Google Scholar] [CrossRef]

- Costa, J.O.; Coelho, R.D.; Guimarães, E.A.; Quiloango-Chimarro, C.A.; Fernandes, A.L.T. Assessing the water use efficiency of irrigated fruit crops in semi-arid regions of Brazil using remote sensing and meteorological data. Irrig. Drain. 2024, 73, 974–987. [Google Scholar] [CrossRef]

- Cardoso, L.M.; Martino, H.S.D.; Moreira, A.V.B.; Ribeiro, S.M.R.; Pinheiro-Sant’ana, H.M. Cagaita (Eugenia dysenterica DC.) of the Cerrado of Minas Gerais, Brazil: Physical and Chemical characterization, carotenoids and vitamins. Food Res. Int. 2011, 44, 2151–2154. [Google Scholar] [CrossRef]

- Camilo, Y.M.V.; Souza, E.R.B.; Vera, R.; Naves, R.V. Caracterização de frutos e seleção de progênies de cagaiteiras (Eugenia dysenterica DC.). Científica 2014, 42, 1–10. [Google Scholar] [CrossRef][Green Version]

- Grigio, M.L.; Neves, L.C.; Tosin, J.M.; Nascimento, C.R.; Chagas, E.A.; Vieites, R.L. Efeito da modificação atmosférica em goiabas var. Paluma na redução de danos mecânicos em pós-colheita. Rev. Agro Mbiente-Line 2011, 5, 57–65. [Google Scholar] [CrossRef][Green Version]

- Mizobutsi, G.P.; Silva, J.M.D.; Mizobutsi, E.H.; Rodrigues, M.L.M.; Lopes, R.S.; Fernandes, M.B.; Oliveira, F.S. Conservação de pinha com uso de atmosfera modificada e refrigeração. Rev. Ceres 2012, 59, 751–757. [Google Scholar] [CrossRef]

- Vespucci, I.L.; Silva, D.D.A.; Machado, V.S.; Campos, A.J. Conservação de maracujá silvestre sob atmosfera modificada passiva. Rev. Eletr. Educ. Fac. Araguaia 2018, 13, 32–43. [Google Scholar]

- Almeida, R.R.; Morgado, C.M.A.; Almeida, V.F.R.; Nascimento, L.M.; Gomes, N.R.; de Campos, A.J. Refrigerated storage of pitombas subjected to different packaging. Comun. Sci. 2020, 11, 3256. [Google Scholar] [CrossRef]

- Araújo, F.F.; Neri-Numa, I.A.; Farias, D.P.; Cunha, G.R.M.C.; Pastore, G.M. Wild Brazilian species of Eugenia genera (Myrtaceae) as an innovation hotspot for food and pharmacological purposes. Food Res. Int. 2019, 121, 57–72. [Google Scholar] [CrossRef]

- Braz, A.J.; Nascente, L.P.; Corrêa, N.C.; Rocha, R.A.; Souza, E.R.B.; Siqueira, A.P.S. Influence of coverage based on biopolymers on the maturation of cagaita (Eugenia dysenterica). J. Neotrop. Agric. 2020, 7, 62–65. [Google Scholar] [CrossRef]

- Dantas, A.L.; Silva, S.D.M.; Dantas, R.L.; Sousa, A.S.B.D.; Schunemann, A.P.P. Desenvolvimento, fisiologia da maturação e indicadores do ponto de colheita de frutos da umbugueleira (Spondias sp.). Rev. Bras. Frut. 2016, 38, 33–42. [Google Scholar] [CrossRef]

- Silva, Q.J.D.; Figueiredo, F.J.D.; Lima, V.L.A.G.D. Características físicas e químicas de cirigueleiras cultivadas na Zona da Mata Norte de Pernambuco. Rev. Ceres 2016, 63, 285–290. [Google Scholar] [CrossRef]

- Santos, P.R.G.; Cardoso, L.D.M.; Bedetti, S.D.F.; Hamacek, F.R.; Moreira, A.V.B.; Martino, H.S.D.; Pinheiro-Sant’ana, H.M. Geleia de cagaita (Eugenia dysenterica DC.): Desenvolvimento, caracterização microbiológica, sensorial, química e estudo da estabilidade. Rev. Inst. Adolfo Lutz 2012, 71, 281–290. [Google Scholar] [CrossRef]

- Siqueira, C.L.; Lopes, O.P.; Batista, P.S.C.; Rodrigues, M.L.M.; Serpa, M.F.P.; MIzobutsi, G.P.; Mota, W.F. Atmosfera modificada e refrigeração na conservação pós-colheita de bananas ‘Tropical’ e ‘Thap Maeo’. Nativa 2017, 5, 157–162. [Google Scholar] [CrossRef]

- Anthon, G.E.; Sekine, Y.; Watanabe, N. Thermal inactivation of pectin methylesterase, polygalacturonase, and peroxidase in tomato juice. J. Agric. Food Chem. 2002, 50, 6153–6159. [Google Scholar] [CrossRef]

- Silva, P.A.; de Abreu, C.M.P.; Correa, A.D.; Asmar, S.A. Modificações nas atividades da poligalacturonase e pectinametilesterase em morangos armazenados à temperatura ambiente. Ciência Agrotecnologia 2009, 33, 1953–1958. [Google Scholar] [CrossRef]

- Asif, M.H.; Nath, P. Expression of multiple forms of polygalacturonase gene during ripening in banana fruit. Plant Phys. Biochem. 2005, 43, 177–184. [Google Scholar] [CrossRef]

- Martinotto, C.; Paiva, R.; Soares, P.F.; Santos, D.B.; Nogueira, C.R. Cagaiteira (Eugenia dysenterica DC). Boletim Técnico—N°. 78. Lavras—MG. 2008, pp. 1–21. Available online: http://repositorio.ufla.br/bitstream/1/48179/1/BT%2078.pdf (accessed on 15 June 2024).

- Sanches, A.G.; Silva, M.B.; Moreira, E.G.S.; Cordeiro, A.M. Relação entre a embalagem e a temperatura de armazenamento na conservação do pimentão vermelho cv. Rubi. Acta Iguazu 2015, 4, 1–12. [Google Scholar]

- Freire, E.C.B.; Silva, F.V.G.; Santos, A.F.; Medeiros, I.F. Avaliação da qualidade de seriguela, Spondias purpurea, L., em diferentes estádios de maturação. Rev. Verde Agroecol. Desenvolv. Sustentável 2011, 6, 11. [Google Scholar]

- Aroucha, E.M.M. Qualidade pós-colheita da cajarana em diferentes estádios de maturação durante armazenamento refrigerado. Rev. Bras. Frut. 2012, 34, 391–399. [Google Scholar] [CrossRef][Green Version]

- Santos, A.E.O.; Assis, J.S.; Batista, P.F.; Santos, O.O. Utilização de atmosfera modificada na conservação pós-colheita de mangas ‘Tommy Atkins’. Rev. Semiárido Visu 2011, 1, 10–17. [Google Scholar] [CrossRef]

- Siqueira, C.L.; Rodrigues, M.L.M.; Mizobutsi, G.P.; Santos, P.G.; Mota, W.F.; Mizobutsi, E.H.; Oliveira, G.B. Características físico-químicas, análise sensorial e conservação de frutos de cultivares de bananeira resistente à sigatoca-negra. Rev. Ceres 2010, 57, 673–678. [Google Scholar] [CrossRef]

- Lima, M.S.S.; Dantas, A.C.V.L.; Fonseca, A.A.O.; Barroso, J.P. Caracterização de frutos de genótipos selecionados de umbu-cajazeira (Spondias sp.). Interciencia 2015, 40, 311–316. [Google Scholar]

- Minas, I.S.; Crisosto, G.M.; Holcroft, D.; Vasilakakis, M.; Crisosto, C.H. Postharvest handling of plums (Prunus salicina Lindl.) at 10 °C to save energy and preserve fruit quality using an innovative application system of 1-MCP. Posthar. Biol. Technol. 2013, 76, 1–9. [Google Scholar] [CrossRef]

- Menezes, P.H.S.; Souza, A.A.; Silva, E.S.; Medeiros, R.D.; Barbosa, N.C.; Soria, D.G. Influência do estádio de maturação na qualidade físico-química de frutos de umbu (Spondias tuberosa). Sci. Agropec. 2017, 8, 73–78. [Google Scholar]

- Cia, P.; Benato, E.A.; Signist, J.M.M.; Sarantopoulos, C.; Oliveira, L.M.; Padula, M. Modified atmosphere packaging for extending the storage life of ‘Fuyu’ persimmon. Posthar. Biol. Technol. 2006, 42, 228–234. [Google Scholar] [CrossRef]

- Kluge, R.A.; Preczenhak, A.P. Betalaínas Em beterraba minimamente processada: Perdas e formas de preservação. Rev. Iberoam. Tecnol. Postcosecha 2016, 17, 175–192. [Google Scholar]

- Vieira, E.L. Apontamentos e Práticas de Fisiologia Pós-Colheita de Frutos e Hortaliças; Centro de Ciências Agrárias, Ambientais e Biológicas–CCAAB. Universidade Federal do Recôncavo da Bahia–UFRB: Cruz das Almas, Brazil, 2019. [Google Scholar]

- Campos, R.P.; Knoch, B.; Hiane, P.A.; Ramos, M.I.L.; Ramos Filho, M.M. 1-MCP on Mangaba stored at ambiental temperature and 11 °C. Rev. Bras. Frut. 2012, 33, 206–212. [Google Scholar] [CrossRef][Green Version]

- Nascimento, R.S.; Cardoso, J.A.; Cocozza, F.D. Physical and physicochemical characterization of mangabeira fruits (Hancornia speciosa Gomes) in Western Bahia. Rev. Bras. Eng. Agric. Ambien. 2014, 18, 856–860. [Google Scholar] [CrossRef][Green Version]

- Sacramento, C.K.; Matos, C.B.; Souza, C.N.; Barretto, W.S.; Faria, J.C. Características físicas, físico-químicas e químicas de cajás oriundos de diversos municípios da região sul da Bahia. Magistra 2007, 19, 283–289. [Google Scholar]

- Perfeito, D.G.A.; Carvalho, N.; Lopes, M.C.M.; Schmidt, F.L. Caracterização de frutos de mangabas (Hancornia speciosa Gomes) e estudo de processos de extração da polpa. Rev. Agric. Neotrop. 2015, 2, 1–7. [Google Scholar] [CrossRef]

- Azeredo, H.M.C.; Brito, E.S. Tendências em conservação de alimentos. In Fundamentos de Estabilidade de Alimentos; Azeredo, H.M.C., Ed.; Embrapa Agroindústria Tropical: Fortaleza, Brazil, 2004; pp. 135–150. [Google Scholar]

- Mariano-Nasser, F.; Boliani, A.; Nasser, M.; Alves-Prado, H.; Pagliarini, M.; Moreira, E. Modified atmosphere in post-harvest mangaba fruit conservation in three maturity degrees. Colloq. Agrar. 2018, 14, 111–121. [Google Scholar] [CrossRef][Green Version]

- Gupta, K.J.; Zabalza, A.; Van Dongen, J.T. Regulation of respiration when the oxygen availability changes. Physiol. Plant. 2009, 137, 383–391. [Google Scholar] [CrossRef] [PubMed]

- Oliveira Junior, L.F.G.; Coelho, E.M.; Coelho, F.C. Caracterização pós-colheita de mamão armazenado em atmosfera modificada. Rev. Bras. Eng. Agric. Ambien. 2006, 10, 660–664. [Google Scholar] [CrossRef]

- Brackmann, A.; Weber, A.; Giehl, R.F.H.; Einsermann, A.C.; Sautter, C.K.; Gonçalves, E.D.; Antunes, L.E.C. Armazenamento de mirtilo ‘Bluegem’ em atmosfera controlada e refrigerada com absorção e inibição do etileno. Rev. Ceres 2010, 57, 6–11. [Google Scholar] [CrossRef]

- Oliveira, M.E.B.; Guerra, N.B.; Maia, A.H.N.; Alves, R.E.; Matos, N.M.S.; Sampaio, F.G.M.; Lopes, M.M.T. Características Químicas e Físico-Químicas de pequi da Chapada do Araripe. Rev. Bras. Frut. 2010, 32, 114–125. [Google Scholar] [CrossRef]

- Seleguini, A.; Faria Júnior, M.J.D.A.; Seno, S.; Santos, J.I.; Silva, K.S.D.; Lemos, O.L. Vida útil e qualidade de frutos de tomateiros tratados com paclobutrazol. Rev. Ceres 2011, 58, 470–475. [Google Scholar] [CrossRef]

- Mendonça, V.Z.; Vieites, R.L. Physical-chemical properties of exotic and native Brazilian fruits. Acta Agronómica 2019, 68, 175–181. [Google Scholar] [CrossRef]

- Neves, L.C.; Rodrigues, A.C.; Vieites, R.L. Polietileno de baixa densidade (PEBD) na conservação póscolheita de figos cv “Roxo de Valinhos”. Rev. Bras. Frut. 2002, 24, 57–62. [Google Scholar] [CrossRef][Green Version]

- Queiroga, A.X.; Costa, F.B.; Santiago, M.D.M.; Sousa, F.F.; Santos, K.P.; da Silva, J.L.; Filho, R.B. Physical, Chemical-Physical Characterization and Determination of Bioactives Compounds of the Pimtobeira Fruits (Talisia esculenta). J. Agric. Sci. 2019, 11, 303–312. [Google Scholar] [CrossRef]

- Vasconcelos, L.H.C.; Evangelista, Z.R.; Campos, A.J.; Teixeira, I.R. Diferentes embalagens na conservação pós-colheita de Cajá-Manga. Rev. Espac. 2017, 38, 1–10. [Google Scholar]

- Kader, A.A. Posthavest biology and technology: An overview. In Posthavest Technology of Horticultural Crops, 3rd ed.; University of California: Berkeley, CA, USA, 2002; pp. 435–461. [Google Scholar]

- Kader, A.A. Future of Modified Atmosphere Research. Acta Hortic. 2010, 857, 212–217. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).