1. Introduction

The most common amendment that is used as a horticultural substrate for growing trees in containers is peat [

1]. Since peat is the primary ingredient in growing media for both conventional and organic seedling production, there has been an increase in environmental concern related to its extraction and rising demand, as the use of peat involves the exploitation of slowly renewable resources and the degradation of valuable ecosystems such as peatlands [

2]. Therefore, many countries have established several restrictions concerning its use. As a consequence of this practice, many researchers have looked for affordable alternatives to use as environmentally friendly components for substrates. Many organic resources, including residual biomass [

3,

4], green and municipal wastes, and manure [

5,

6,

7,

8], have been used as partial or total ingredients in growing media.

Composts may partly replace peat and mineral-based fertilizers while enhancing the properties of the growing medium and lessening the risk of pathogens and parasites, whose presence could be harmful [

2,

9,

10,

11,

12]. Vermicompost is the product generated when earthworms absorb, consume, and decompose a variety of organic wastes, including manure, crop residues, sewage sludge, and industrial wastes [

1,

2,

13,

14]. Vermicompost is advantageous to compost because of its high resistance, abundance of nutrients like nitrogen, phosphorus, potassium, calcium, and magnesium, and suitable level of microelements like iron, zinc, copper, and manganese [

15]. This conclusion contributes significantly to the fact that vermicomposting increases the humic acid content and emits fewer air pollutants, enhancing microbial biomass potential and enzymatic activities [

16]. Enzymes and microorganisms, such as gibberellins, cytokines, auxins, nitrogen-fixing bacteria, mycorrhizae, etc., contained in vermicompost enrich the soil and convert the humic and fulvic acids into humic and fulvic ions, which are readily taken up by the root system and feed the plants.

Earthworm composting is carried out with different species of earthworms, but the species

Eisenia foedita is best adapted to the climatic conditions of Greece [

17]. This earthworm is terrestrial and lives at a depth of less than 10 cm in soil aggregates at temperatures ranging from 10 °C to 30 °C. It dislikes light and produces a cocoon every 10 days, which, after about 15 days, gives 4 to 12 new embryos. Embryos mature in 70 days and double every two to three months at 25 °C, while at 5 °C they double in six months. Earthworms accelerate the ripening of compost, and this is due to two factors: firstly, in their mechanical action, as the excreta of the earthworms stratifies the organic matter, which facilitates, at the end of the ripening of the compost, its separation from the inert non-fermentable materials and therefore the homogenization of the final product. Secondly, in their biological action, earthworms show intense bacterial activity, creating intense trophic competition with pathogenic microorganisms such as salmonella, staphylococci, and enterobacteria (

E. coli), which disappear during the earthworm composting of 90 days [

18,

19]. This disappearance is due to simple microbial competition, which reduces the need for substrate nutrition [

20].

Meanwhile, the rapid increase in human population has led to a corresponding increase in the amount of wastewater to be treated [

21]. Therefore, the amount of sewage sludge produced from wastewater treatment has also increased. During the process of treating wastewater, and especially municipal wastewater, sewage sludge is a by-product containing different nutrients (nitrogen compounds, phosphorus, and potassium) and pollutants such as colloids, pathogenic bacteria, recalcitrant organic compounds, microplastics, etc. [

22]. Inadequate handling of sewage sludge could lead to serious environmental harm and several human health problems, such as diarrhea and acute respiratory illnesses. Sewage sludge has been utilized in composting for land filling purposes since its direct field application is not a viable option due to the presence of potentially toxic elements and pathogens, as well as for energy recovery via pyrolysis, incineration, gasification, and methane production [

23]. Particularly, although approximately one-third to half of the sewage sludge is recycled for agricultural use, landfilling and incineration are the most common disposal treatments in many countries [

24]. According to FAO 2020 [

25], sludge treatment and disposal account for 50% of the operational costs of secondary sewage treatment plants in Europe. Raw or treated sewage sludge applied to the soil can meet a considerable portion of the nitrogen and phosphorus needs of many crops while also lowering the cost of sludge disposal in the sewage treatment process. This, combined with the fact that landfilling of all untreated waste, including mixed municipal waste, has been banned [

26,

27], makes finding sustainable and efficient solutions for sewage treatment a necessity.

The International Olive Council [

28] estimates that 43.5 million olive plants are produced worldwide each year. Eighty-four percent of it is produced in the Mediterranean region, with the remaining percentage coming from other nations. Therefore, there could be a significant economic and environmental gain if peat could be replaced by another eco-friendly substrate for nursery olive cultivation. Moreover, to achieve the resource efficiency goals set forth in the Europe 2020 Strategy for smart, sustainable, and inclusive growth [

29], it is crucial to move toward a more circular economy.

During this project, sewage sludge stabilization, which is a necessary process to reduce the content of heavy metals and pathogens, took place using earthworms to degrade organic matter and produce a material with very good physical properties, which is odorless and high in essential enzymes, humic acids, microorganisms, and trace elements. The objective of this study was to evaluate the effect of vermicomposted sludge on the growth of young olive trees and to assess the impact of peat replacement with vermicompost, both partially and entirely, on the development and nutrition of olive-rooted cuttings cultivated in a nursery, while searching for integrated, eco-friendly, and financially beneficial solutions and recovering urban wastewater treatment sludge sequentially. Furthermore, a feasibility study took place to evaluate and validate the possible profit of nursery owners, pursuing the objective of sustainable intensification of the circular economy.

2. Materials and Methods

The research was conducted at the olive nursery “Phytogonia” in Kavala, Eastern Macedonia, Greece, during the year 2019. The growth and nutrition of olive-rooted cuttings in a commercial peat-based and non-fertilized substrate were compared with the growth and nutrition in peat-based media substituted with different proportions of vermicompost. The vermicompost was produced from anaerobically composted sewage sludge derived from the wastewater treatment facility “Aeneia” of the Municipality of Thermaikos, Thessaloniki, Greece, using the earthworm

Eisenia foedita, in the facilities of AKTOR Company, Thessaloniki, Greece, the biggest subsidiary of the ELLAKTOR infrastructure group. The chemical content of peat and vermicompost is presented in

Table 1.

2.1. Earthworms Compost Preparation

Recently deposited anaerobically composted sewage sludge was collected from the wastewater treatment facility “Aeneia” of the Municipality of Thermaikos, Thessaloniki. Approximately 4 m3 of the sewage sludge (water content 85%, organic matter 58%) was placed on the premises of AKTOR Company.

Sewage sludge was accumulated in a high pile and mixed with commercial wheat straw suitable for animal feed in order to adjust the C/N ratio, balance the creamy texture, and absorb, drain, and evaporate gravity and interval water. Since the initial C/N ratio of the sludge was low (≈8.2), a sufficient amount of straw was added to increase the C/N ratio to 22. However, the composting process was sped up as organic matter was already high (58%).

Sewage sludge was mixed twice a week, and the temperature was monitored. Initially, the temperature increased to 65 °C and was maintained at this value for seven days, while subsequently it gradually decreased and stabilized at 45 °C. During these seven days, the pathogens were destroyed and suitable sanitation conditions were created for the earthworm composting, during which the temperature remained lower than 30 °C so that the earthworms did not die.

Then the pile with the compost was transferred, and two rows of dimensions 4 m × 2 m × 0.5 m (length, width, and height) were formed on a concrete platform. The sewage sludge was transferred into containers, and after two weeks, they were vaccinated with earthworms (almost 1 kg m−2). A sprinkler irrigation system was installed on the rows. The rows were irrigated twice a day for 30′ to adjust soil moisture to 65% and stirred twice a week with special shovels. After the earthworms multiplied, their concentration was higher than 2.5 kg m−2. Earthworm composting lasted 90 days, and afterwards, the vermicompost was reduced by about half compared to the sludge. It was then spread on a platform for sun drying in order to minimize the soil moisture from 65% to 25% for pellet production.

2.2. Experimental Treatments

Pilot tests of the produced composted sludge were carried out in an olive-growing nursery. The tests were performed on olive-rooted cuttings of the

Arbequina olive variety in a mist propagation system. The progress of the plants’ growth (height and diameter of the central trunk of the plants) was compared to that of corresponding plants in which commercial peat had been used as substrate. The pilot tests included, in addition to the use of 100% vermicomposted sludge and 100% commercial peat, mixtures of different percentages of the two materials. All of the substrates received a 10%

v/

v addition of commercial perlite as an inert ingredient, while no fertilizer was added, in order to examine the real effect of the substrate. The proportions (%

v/

v) of each component regarding each treatment are presented in

Table 2. The number of tests was enough to ensure statistical processing of the results obtained. Specifically,

Arbequina olive-rooted cuttings were transplanted from plug trays under mist propagation conditions into pots (0.6 L) that contained a mixture of commercial peat substrate and different substitutions (0%, 25%, 50%, 75%, and 100%) of vermicompost. Each treatment included 18 replications. Likewise, olive cuttings after the 1st transplanting were transplanted into larger pots (3 L) that also contained a mixture of commercial peat substrate and different substitutions (0%, 25%, 50%, 75%, and 100%) of vermicompost. Each treatment included 12 replications. The potted plants were maintained under nursery conditions, and they were regularly irrigated, depending on shading temperature and solar radiation, to avoid any symptoms of water stress. Chemical analysis of the mixtures was performed, as well as chemical analysis of the leachates from each treatment.

Measurements that took place during this experiment were: chemical and microbial analysis of the partially sun-dried vermicompost and commercial peat used; chemical analysis of all treatments’ substrates; chemical analysis of leachates; and a record of plant growth measuring the height of the plants every 24 days as well as the diameter of the plants’ trunks. All the chemical analysis took place at the laboratory of the Soil and Water Resources Institute (SWRI) of the Hellenic Agricultural Organization ‘DEMETER’ in Sindos, Greece, while microbiological analysis was carried out at the laboratory of the Veterinary Research Institute of the Hellenic Agricultural Organization ‘DEMETER’ in Thessaloniki, Greece.

2.3. Analytical Methods

Regarding mixtures and leachates, pH was determined using a JENWAY 3520 pH meter, while a CRISON GLP 32 conductimeter was used to assess electrical conductivity (EC) in 1:10

w/

v water-diluted samples. The electrical conductivity (EC) was measured by a CRISON GLP 32 conductimeter in 1:10

w/

v water-diluted samples. The analysis of the organic matter (OM) in the biomixture was performed using the loss-on-ignition method [

30]. Using the automatic digital soil calcimeter Fogl, CaCO

3 was determined, while a Perkin Elmer Lambda 35 Uv/vIS spectrophotometer was used to colorimetrically measure the extractable amounts of phosphorus (P) and boron (B). After extraction with ammonium acetate, exchangeable potassium (K) and sodium (Na) were measured using a Sherwood M410 flame photometer, while after extraction with ammonium acetate, exchangeable calcium (Ca) and magnesium (Mg) were measured using a Perkin Elmer AAnalyst 200 atomic absorption spectrometer. Following DTPA extraction, the amounts of iron (Fe), copper (Cu), manganese (Mn), and zinc (Zn) were quantified using a Perkin Elmer AAnalyst 200 atomic absorption spectrometer. Based on

Methods of Soil Analysis—Part 3—Chemical Methods, 1996, Chapter 38 Nitrogen—Inorganic Forms [

31], NO

3- determination was carried out after KCl extraction and after passing through a column of copperized cadmium. NH

4+ was determined using a Perkin Elmer Lambda 35 UV/VIS spectrophotometer at 667 nm. The total nitrogen (TN) was determined according to ISO 11261:1995,

Soil quality—Determination of total nitrogen—Modified Kjeldahl Method [

32]. Cl was determined by the Mohr titration method [

33]. The following equation was used to compute the exchangeable sodium percentage (ESP), which describes the amount of adsorbed Na in soil: ESP = (exchangeable Na/cation exchange capacity) × 100.

2.4. Statistical Analysis

Software entitled SPSS v27 was used to carry out the statistical analysis. For comparison of soil chemical characteristics between the treatments, a one-way ANOVA was conducted. In the present situation, we were looking to test the statistical hypothesis that a mean population set is equal while considering the treatments as a component. The Duncan test (p < 0.05) was used to determine whether there were any significant differences between the mean values of the measured parameters.

2.5. Feasibility Study

A technical-economic analysis was carried out in order to investigate the practicality and the possible total profit for an olive nursery owner, taking into account the quantity and quality of the total production, the economic value of peat and vermicompost, whether it is purchased or produced by the nursery owner himself, as well as the partial or total peat substitution by vermicompost, the amount of irrigation water required, and the gain from not using fertilizer throughout the transplanting process.

3. Results and Discussion

3.1. Experimental Outcomes

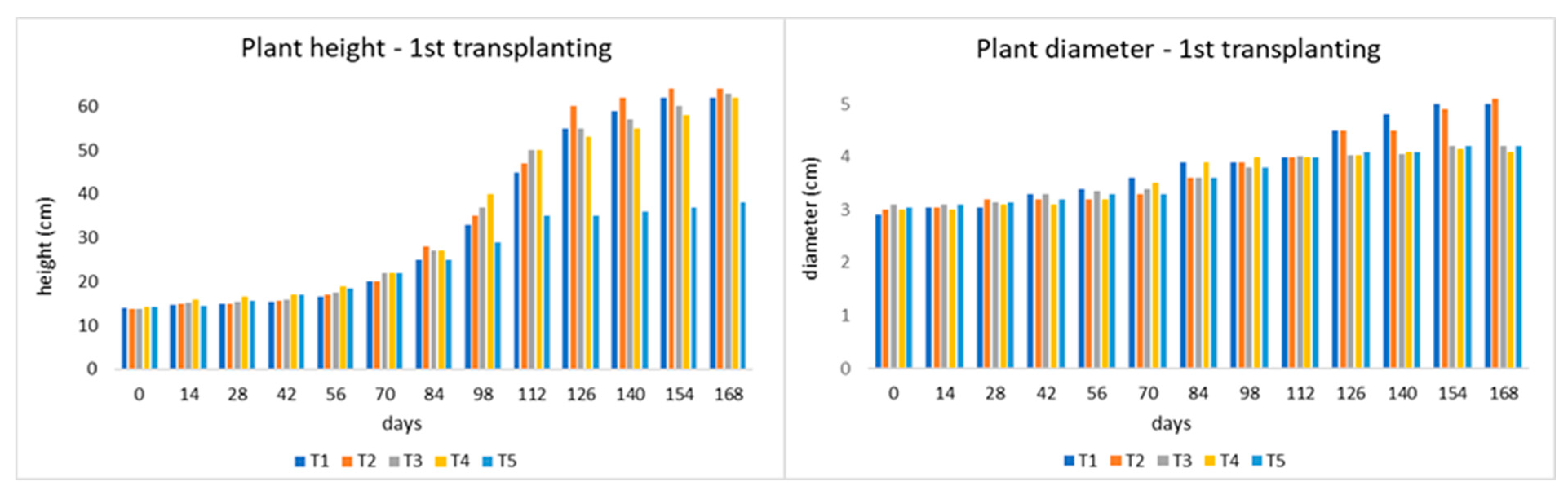

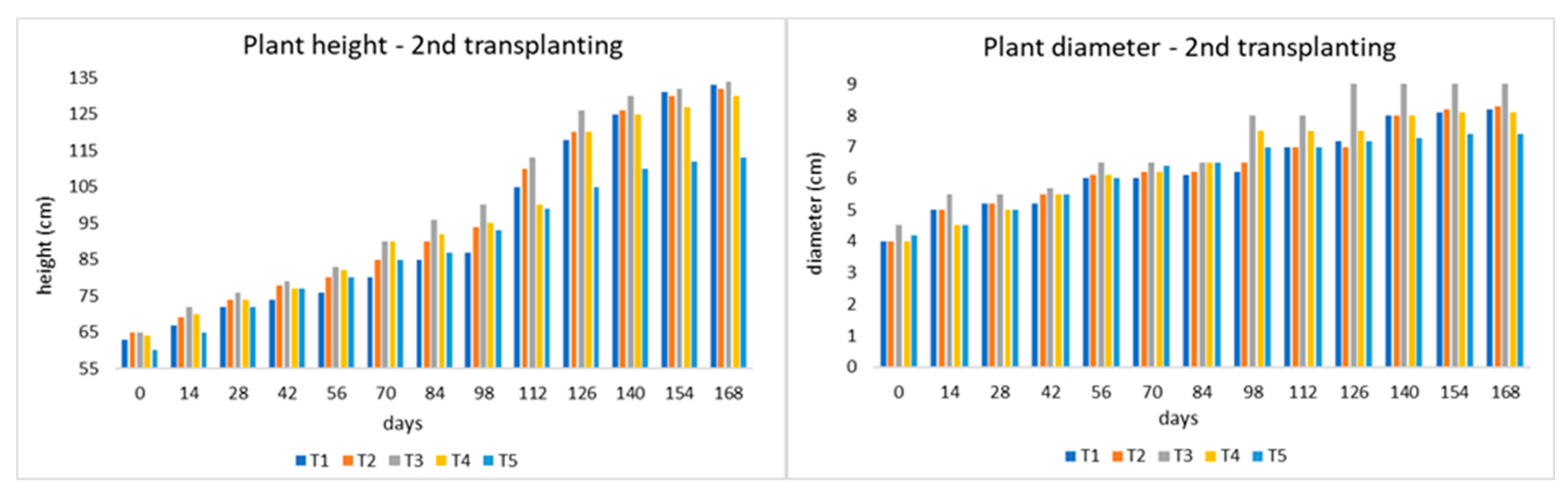

The partial and total substitution of peat by vermicompost increased the height and the diameter of the olive-rooted cuttings at both the 1st and 2nd transplantings (

Figure 1 and

Figure 2). These outcomes were quite encouraging, contrary to Regni et al. [

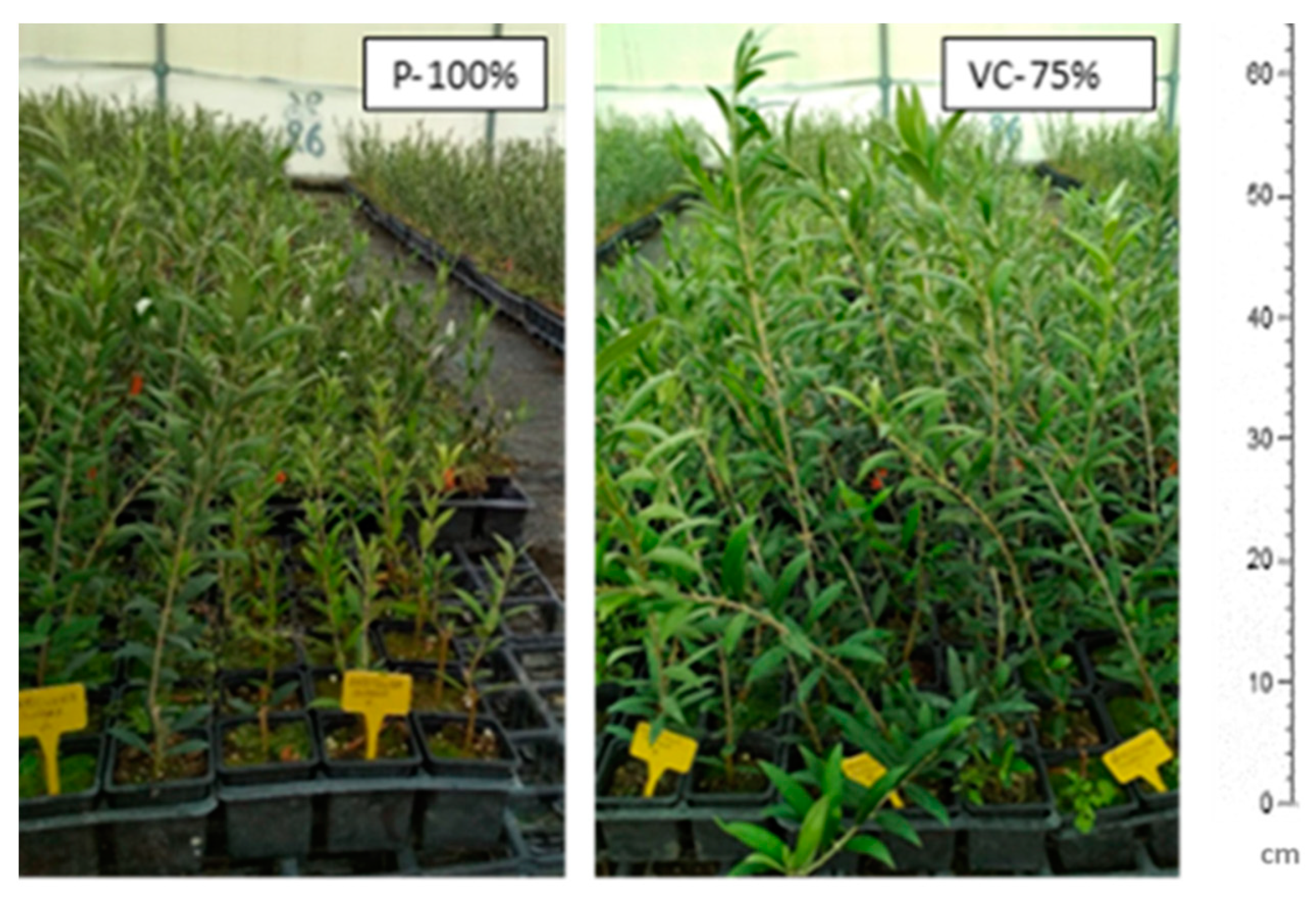

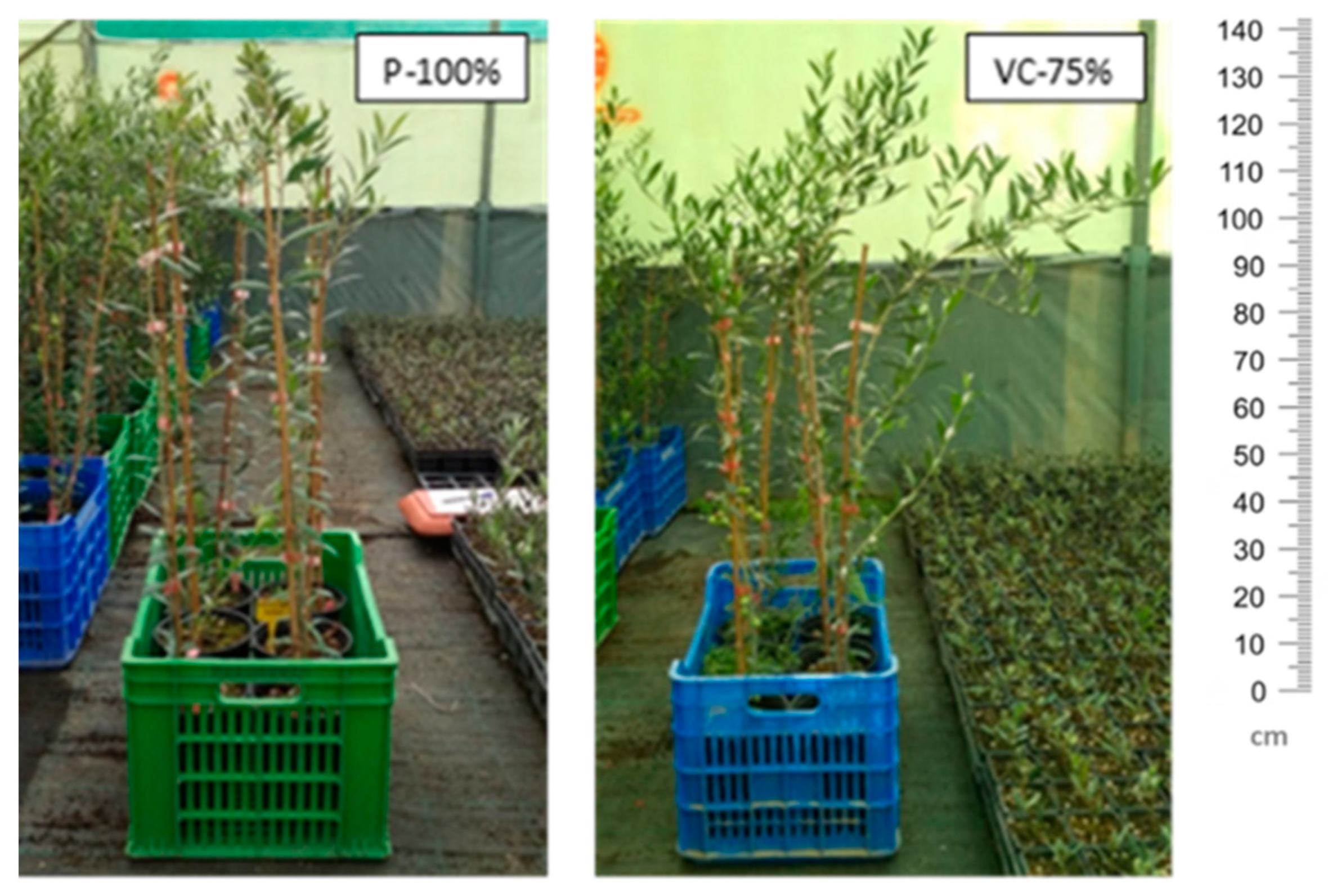

34], who evaluated the impact of peat substitution by new-type olive mill pomace and its compost on the vegetative activity of potted olive trees and came to the conclusion that up to 50% of peat could be replaced with compost without substantially decreasing the development of plants in the end. It was also observed that the height of the plants in the T2 (VC-75%) treatment was almost twice the height of the T5 (P-100%) treatment after the 1st transplanting (

Figure 3). Similarly, after the 2nd transplanting, all the treatments with vermicompost were much more effective than T5 substrate. These results were rather positive compared to the observations by Tosca et al. [

35], who replaced peat with biochar and green compost for olive tree cultivation, and no significant effect on plant height was detected, whereas branching was slightly diminished in some treatments. As concluded by the experimental outcomes, cuttings of the compost-based substrates grew better than olive cuttings grown in the peat-based substrate, especially when the mix composition was 75% compost–25% peat (T2) (

Figure 3 and

Figure 4). At this point, it is worth noting that the materials of the treatments VC-100% presented inhomogeneity in their composition, shrinkage into the pots, as well as difficulty in draining.

The results of the chemical analysis of the different growing media after the 1st and 2nd transplanting are presented in

Table 3 and

Table 4, while in

Table 5 and

Table 6, the concentration range of chemical parameters of the treatments’ leachates after the 1st and 2nd transplanting and during the irrigation scheme are demonstrated.

Based on the statistical analysis of the outcomes presented in

Table 3 and

Table 4, it is observed that after the 1st transplanting, the highest values of pH and EC as well as the highest concentrations of TN, N-NO

3, Na, B, Cu, Zn, and Fe were recorded in T1 treatment, while the highest values of C/N and the highest concentrations of OM, N-NH

4, P, K, and Ca were recorded in T5 treatment. Except for the case of P, these results are in accordance with the chemical characteristics of peat and vermicompost presented in

Table 1. Concerning the measurements after the 2nd transplanting, similar trends to those of the 1st transplanting were recorded except for the case of P, whose highest concentration was measured in T1 treatment instead of T5, and the case of K, which showed the same concentrations in both T1 and T5 treatments.

It has been ascertained that compost made from green leftovers works well as part of growing media [

36]. Particularly, it was discovered that adding small amounts of green compost made from municipal biosolids to a peat-based medium might significantly improve the growth of olive seedlings [

37]. Meanwhile, in order to assess the potential of green nursery compost to replace different percentages of peat in potting mixes used for growing olive pot plants, the nitrogen mineralization ability and the identification of olive tree growth parameters were utilized. The results showed that green compost may serve as an appropriate portion of mixed-peat substrates for olive trees, delivering a 15% or 30% peat replacement [

38]. Our outcomes proved that peat might be effectively replaced by vermicomposted sludge, promoting the development of plants without further fertilizer. As the substrate becomes favorably less acidic compared to olive cuttings developing in a peat-based medium, cuttings of the compost-based mediums received adequate nutrients, with OM content, C/N ratio, P, K, and Ca concentrations in peat-vermicompost mixtures being quite sufficient, while Na, Mg, N-NO

3, TN, B, Cu, Zn, Fe, and Mn content reaching higher values than those in peat substrate. Specifically, K content after the 1st and 2nd transplanting of T2, T3, and T4 treatments ranged between 1000 and 2000 mg kg

−1, and P content after the 1st and 2nd transplanting of T2, T3, and T4 treatments ranged between 300 and 500 mg kg

−1. Moreover, the concentrations of NO

3-N in treatments T2, T3, and T4 are lower than in vermicompost, and in fact, in all treatments of the 2nd transplanting, they are even lower than in the 1st transplanting, which is attributed to the absorption of nitrate nitrogen by the plants as well as its leaching and the fact that the rate at which nitrification occurs typically decreases as substrate pH reduces [

39]. Actually, the procedure of nitrification begins when the pH of the substrates is more than 6.0 [

40]. Meanwhile, the high Na content of vermicompost is reflected in all the treatments, as is the boron, copper, zinc, and iron content.

Concerning the leachates’ chemical characteristics, the outcomes indicated that their nutrient content was quite high, indicating adequate coverage of nutrient needs, while the amounts of heavy metals were significantly lower than those deemed dangerous for soil and groundwater (

Table 7). Initially, soil, peat, and vermicompost contained some heavy metals in small concentrations, which were further reduced during mixing, apparently due to their complexation with organic matter. Also worth noting is the fact that low boron and zinc concentrations were observed in the leachates, apparently due to both selective assimilation by plants and the low mobility of these elements, indicating that there is a reserve of these trace elements as they are retained in the substrate, which is an advantage for olive cultivation [

41,

42].

Regarding the results of the microbiological analyses, it appears that the produced vermicomposted sludge is a sanitized product, with the absence of salmonella/25 g and

E. coli content of 10

3/g, which is below the limit value of 2 × 10

6 CFU/g DS of the Class B pathogen requirement set forth by the U.S. Environmental Protection Agency (EPA) [

44], while the anaerobic sludge showed the presence of salmonella/25 g and

E. coli values of 10

6/g, which are very high. This fact indicated that pathogens had been diminished to values that preserved both nature and public health, and strategies for using sludge involved limitations on agriculture harvesting, livestock grazing, and public engagement [

45].

3.2. Feasibility Study Outcomes

Regarding the financial aspect, the annual cost reduction was calculated in the specific olive nursery where the experiment was carried out, which produces 260,000 plants of the 1st transplanting in pots with a volume of 0.6 L and 40,000 large plants of the 2nd transplanting in pots with a volume of 3 L.

The treatment that gave the best results was T2 (75% vermicompost–25% peat). Therefore, in the 260,000 pots with a volume of 0.6 L, 117,000 L (260,000 × 0.6 × 0.75) of peat were replaced by vermicomposted sludge, while in the 40,000 pots with a volume of 3 L, 90,000 L (40,000 × 3 × 0.75) of peat were replaced by earthworm composted sludge. That is, in this nursery, 117,000 + 90,000 = 207,000 L of peat were replaced by earthworm-composted sludge. Nowadays, the cost of peat amounts to 0.1 EUR/L.

Vermicomposting of the anaerobically composted sewage sludge costs 30 EUR/ton when it takes place at the Wastewater Treatment Facility, while the transport costs amount to 10 EUR/ton. The price of the vermicomposted sludge ranges from 110 to 120 EUR/ton, as long as it contains all the necessary nutrients. Considering that the vermicomposted sludge has a bulk density value of about 0.9 ton/m3, so the ton is about 1100 L, the purchase cost of the vermicomposted sludge is 0.1 EUR/L, similar to peat. On the other hand, when vermicomposted sludge is produced at the nursery, the cost amounts to 0.035 EUR/L. Thus, in this case, there is a significant profit of 0.065 × 207,000 = EUR 13,455 per year for the nursery, while in the case of purchasing the vermicompost, there is no profit.

Irrigation of the plants is considered necessary throughout the year, but it varies every month as it depends on the prevailing weather conditions. According to the data from 2019 presented in

Table 8, we found that the cost of irrigation for the months with the highest temperatures was EUR 97 per month. Therefore, it was estimated that for 300,000 plants, the irrigation cost in 2019 amounted to EUR 711.65. From the results of the T2 treatment, we conclude that by replacing the peat with VC-75%, we achieve a reduction in irrigation needs of approximately 30%, so the total cost of irrigation for a year is reduced to EUR 498.16. This reduction is attributed to the soil structure, to which a higher percentage of vermicompost is added, leading to greater water retention.

Regarding fertilization, the usual fertilizer used in the nursery costs 109 EUR/25 kg. Standard nursery practice is to use 2 kg of fertilizer per m3 of substrate. So, it was calculated that for about 300,000 plants (260,000 × 0.6 L + 40,000 × 3 L = 276 m3), 552 kg of fertilizer is needed. Then, the total cost for fertilization amounts to EUR 2406.72.

Therefore, vermicomposted sludge is a substrate that can act as a substitute for peat and fertilizer; it is easy to prepare; it is environmentally friendly; and at the same time, it offers a reduction in the cost of olive tree production. Specifically, the reduction in costs is presented in

Table 9.

To summarize, regarding the technical-economic analysis that took place, it was concluded that the annual cost reduction for an olive tree nursery that produces about 300,000 olive trees, in case the peat is substituted by a mixture of 75% vermicompost–25% peat as a growing medium, will be around EUR 2500 if the vermicompost is purchased commercially, while the annual reduction will be around EUR 16,000 if the compost is produced at the nursery. This reduction lies both in the replacement of peat by vermicompost and the non-use of fertilizer throughout the production process and in the reduced irrigation needs, while it was noticed that the irrigation dosages were much lower in the treatments that had a high proportion of vermicompost as the water drained more slowly.

4. Conclusions

Due to ecological restrictions linked to peat use, peat replacement is becoming more and more necessary in the production of pots and transplants. Vermicomposting and using the final product to partially replace peat in nursery activities allow for a reduction in the financial and environmental costs associated with the production of potted plants. This work evaluated the utilization of vermicomposted sludge as an alternate growing medium instead of peat for the transplanting of olive-rooted cuttings and young trees in olive tree nurseries. The results of partial and total peat substitution experiments indicated that cuttings of the compost-based media obtained greater development and nutrient levels in comparison to olive-rooted cuttings grown in peat-based media, especially when the mix composition was 75% compost–25% peat, while the irrigation doses were found to be much lower in treatments that contained a high percentage of vermicomposted sludge because the water drained more slowly. So, minimized irrigation needs, in combination with the fact that plant growth was enhanced while no fertilization took place, pointed out the potential economic benefit arising from peat substitution by earthworm compost sludge for the owner of the nursery. On the other hand, the materials of the vermicompost 100% presented inhomogeneity in their composition, shrinkage into the pots, as well as difficulty in draining. Also, leachates from each treatment were analyzed, and the findings demonstrated that trace element and heavy metal content were much below those regarded as dangerous for aquifers. In conclusion, the observed boost in plant quality makes the use of vermicomposted sludge an advantageous substitute for the use of peat in olive tree nurseries, but also because of the associated economic and ecological advantages, as reusing and employing urban wastewater treatment plants’ sludge is a cost-effective and sustainable approach. Further research is needed to optimize the vermicomposting process by including other parameters to be investigated, such as root length, number of leaves, leaf area, etc. Also, further investigation is needed to reduce pathogens and assess the vermicomposting effect on older olive trees.