Alternative Fuels for Agriculture Sustainability: Carbon Footprint and Economic Feasibility

Abstract

1. Introduction

- ▪

- Making farm income more profitable;

- ▪

- Maintaining a sustainable environment, such as:

- (a)

- Improving and protecting soil quality;

- (b)

- Reducing dependence on non-renewable resources, such as artificial fertilizers, fuel, and pesticides;

- (c)

- Achieving a minimal impact on water quality, safety, wildlife, and other environmental resources.

- ▪

- Strengthening farming communities and families [11]

2. Conventional Fuels and Challenges

3. Alternative Fuels

3.1. First-Generation Biofuels

3.1.1. Biofuel Types According to First Generation

- (a)

- Bioalcohols: Through the alcohol fermentation of cellulose, glucose, carbohydrates, starches, and other sugars, enzymes and microbes help produce bioalcohol. Bioethanol, biomethanol, biopropanol, and biobutanol are the other examples of bioalcohols [43].

- (b)

- Biodiesel: Diesel produced from long-chain fatty acid esters found in plants, animals, or crops is biodiesel. A methyl, ethyl, or propyl ester is formed by chemically combining lipids like animal fat (tallow), soybean oil, or other vegetable oils with alcohol [44].

- (c)

- Green diesel: Hydrotreating the vegetable oil triglycerides with hydrogen is another potential biosource of energy. Sunflower, soybean, and palm oils are utilised as feedstock for manufacturing. Three immediate reactions are involved in the hydrotreating process, namely decarbonylation (DCO), hydrodeoxygenation (HDO), and decarboxylation (DCO2) [45,46].

- (d)

- Solid biofuels: Solid biofuel is the most functional and significant bioenergy carrier. Some commonly utilised biofuels include wood, leaves, sawdust, and animal manure [47].

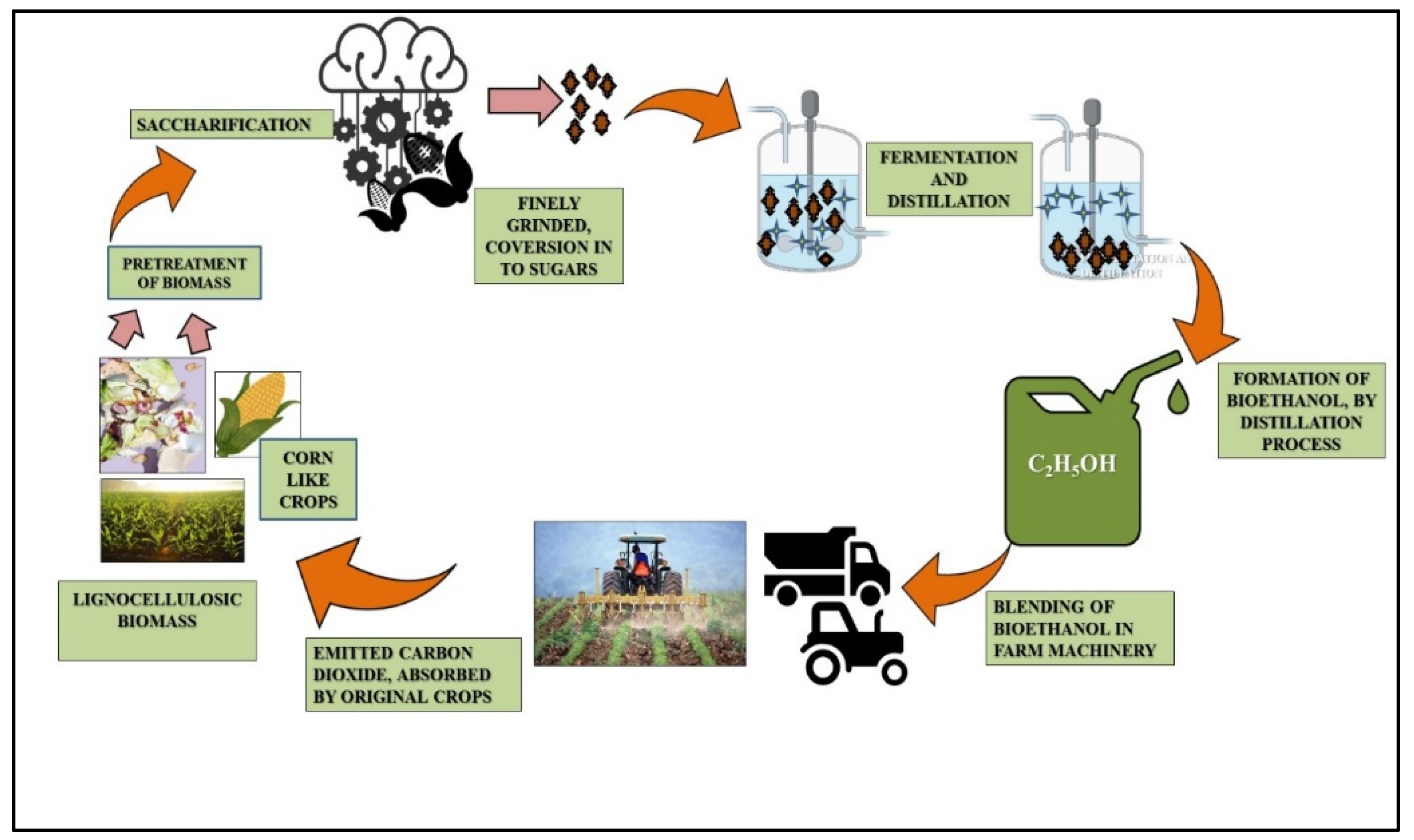

3.1.2. Bioethanol

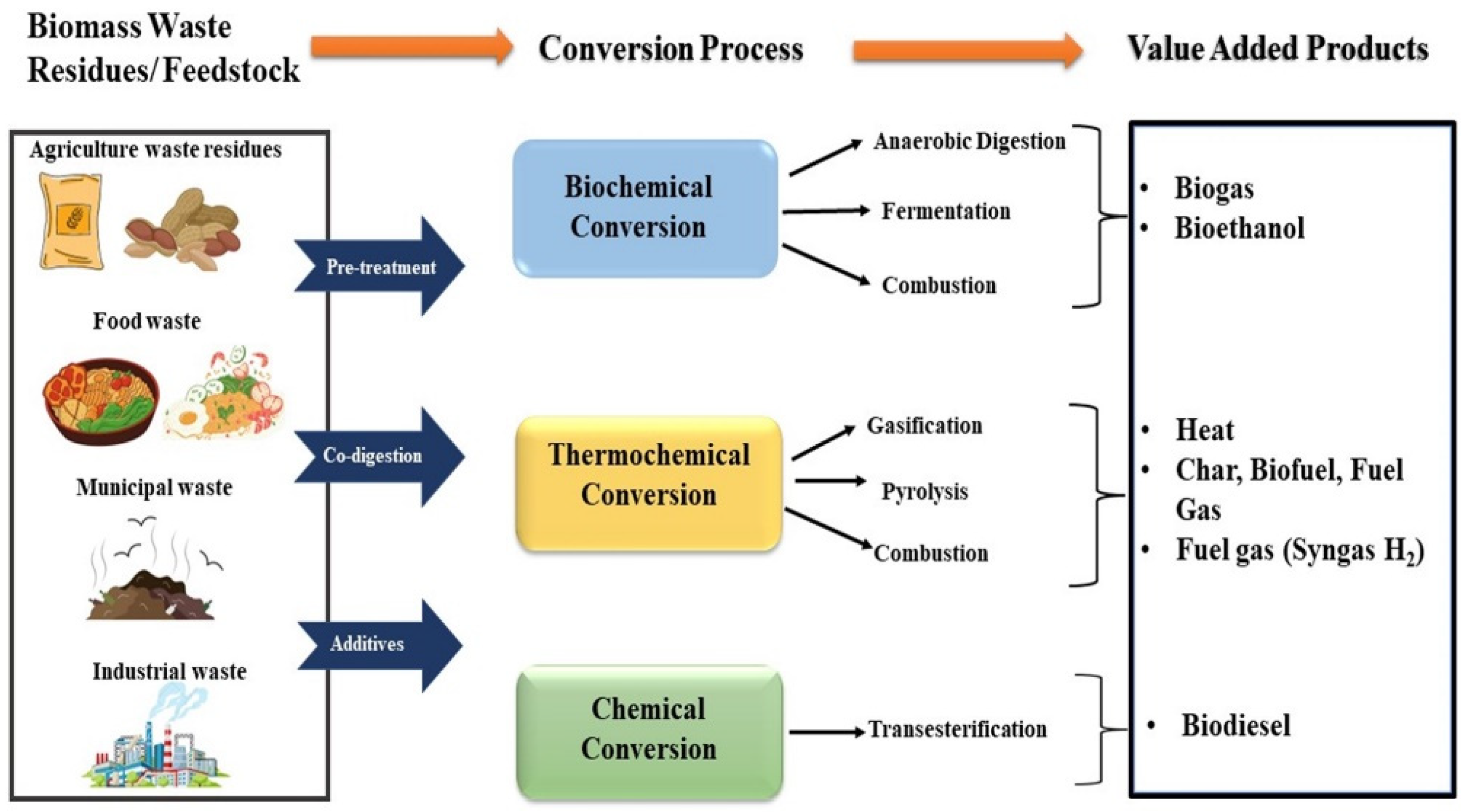

3.2. Second-Generation Biofuel

3.2.1. Second-Generation Biofuel Is of the Following Types

- (a)

- Ethanol cellulosic: This biofuel is produced by fermenting sugar sourced from cellulose and polyose, a lignocellulose compound.

- (b)

- Algae-based biofuel: Algae can flourish in open and closed systems (like lakes, ponds, etc.). Algae has the advanced ability to be modified into a variety of biofuels, including biodiesel, biogas, and hydrogen [58]. The biomass concentration and extraction techniques include aggregation, centrifugation, purification, floatation, and flocculation [42].

- (c)

- Alcohol: mixed alcohols or methanol are recovered from syngas via catalytic synthesis. By fermenting biomass with a specific type of microbe, syngas can also produce alcohol [59].

| Generation | Biomass Type | Feedstocks Used | Production Technology | Process | Products | References |

|---|---|---|---|---|---|---|

| Second (Non-edible-based) Biofuels | Non-food biomass | Non-edible oil seeds, waste cooking oil. | Chemical | Acid pre-treatment | Alcohol, dimethylfuran | [60,61,62,63,64] |

| Alkali pre-treatment | ||||||

| Organosolv pre-treatment ionic | Cellulosic ethanol, bio-SNG | |||||

| liquids | ||||||

| Biochemical production | Enzymatic hydrolysis | |||||

| Forest residues (Saw dust, thinned wood, stem, leaves, pulp waste) | Physical pre-treatment of feedstock | Milling | Biofuels such as biobutanol, | [63,64,65] | ||

| Microwave | ||||||

| Mechanical extrusion | bioethanol, biodiesel, syngas | |||||

| Pulse electric field | ||||||

| Thermochemical | Direct combustion | Biogas | ||||

| Gasification | ||||||

| Liquification | ||||||

| Liquification | Liquid fuel | |||||

| Ligno-cellulosic feedstock materials (agricultural residues): cereal straw, sugarcane bagasse, forest residues. | Hydrolysis | Fermentation | Ethanol, butanol | |||

| Pyrolysis | Refining | Bio-oil | ||||

| Gasification | Condensation/synthesis | Fischer–Tropsch liquids (FTL) | [63,65,66] | |||

| DME | ||||||

| MeOH | ||||||

| Mixed alcohol | [63,64,67,68,69] | |||||

| Wet biomass | Hydro-thermal upgrading | Refining | Green diesel | [70] | ||

| Food biomass | Vegetable oil | Transesterification | Refining | Biodiesel | [70] | |

| Sugars | Fermentation | Refining | Biodiesel | [70] | ||

| Starch cereals | Hydrolysis | Bioethanol |

- (d)

- (e)

- Natural gas produced synthetically (bio-SNG): Anaerobic digestion and some bacteria can produce biogas. Carbonic acid gas and mash gas combine to create this biogas. In addition to being used to refuel natural gas cylinders, biologically derived SNG is also employed in cars in the form of LNG and CNG [73].

3.2.2. Green or Biodiesel

3.3. Third-Generation Biofuel

3.3.1. Production of Biofuels Based on Algae

3.3.2. Biohythane

3.3.3. Biomethane

3.4. Fourth-Generation Biofuel

3.4.1. Biobutanol

3.4.2. Biohydrogen

4. Role of Alternative Fuels

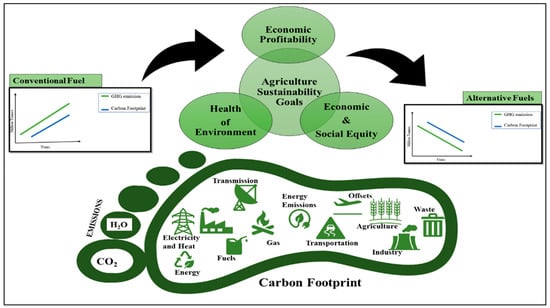

4.1. In Sustainable Agriculture

4.2. In Reducing Carbon Footprint and Attaining Carbon Neutrality

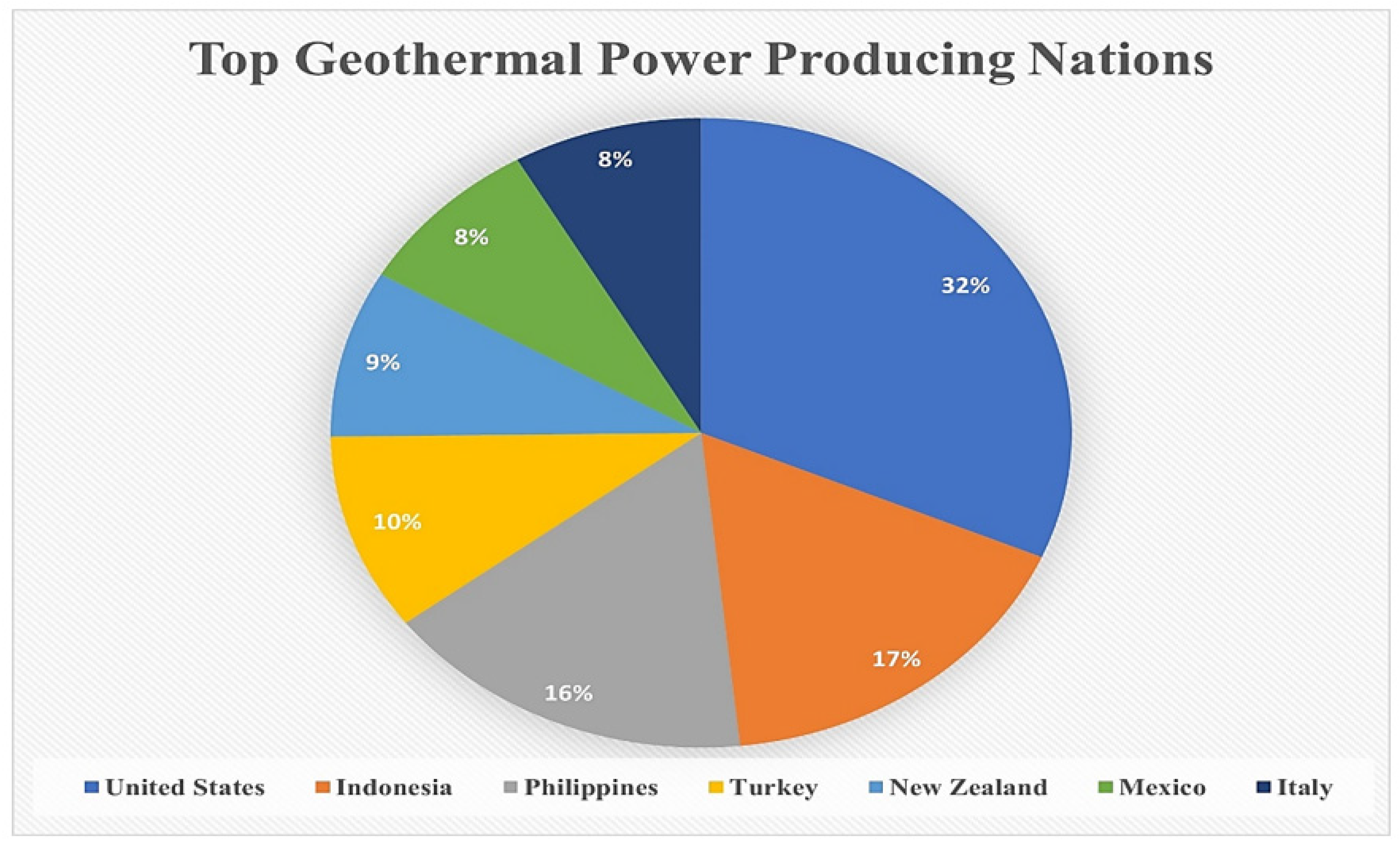

5. Global Status of Alternative Fuels

6. Applications

7. Environmental Impact and Economic Feasibility

8. Shortcomings of Alternative Fuels

9. Conclusions and Future Scope

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khan, N.; Sudhakar, K.; Mamat, R. Role of biofuels in energy transition, green economy and carbon neutrality. Sustainability 2021, 13, 12374. [Google Scholar] [CrossRef]

- Bamisile, O.; Huang, Q.; Hu, W.; Dagbasi, M.; Kemena, A.D. Performance analysis of a novel solar PTC integrated system for multi-generation with hydrogen production. Int. J. Hydrogen Energy 2020, 45, 190–206. [Google Scholar] [CrossRef]

- Saleem, M. Possibility of utilizing agriculture biomass as a renewable and sustainable future energy source. Heliyon 2022, 8, e08905. [Google Scholar] [CrossRef] [PubMed]

- Srithar, K.; Balasubramanian, K.A.; Pavendan, V.; Kumar, B.A. Experimental investigations on mixing of two biodiesels blended with diesel as alternative fuel for diesel engines. J. King Saud Univ.-Eng. Sci. 2017, 29, 50–56. [Google Scholar] [CrossRef]

- Stančin, H.; Mikulčić, H.; Wang, X.; Duić, N. A review on alternative fuels in future energy system. Renew. Sustain. Energy Rev. 2020, 128, 109927. [Google Scholar] [CrossRef]

- Bundschuh, J.; Chen, G.; Chandrasekharam, D.; Piechocki, J. (Eds.) Geothermal, Wind and Solar Energy Applications in Agriculture and Aquaculture; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Keller, V.; Lyseng, B.; English, J.; Niet, T.; Palmer-Wilson, K.; Moazzen, I.; Robertson, B.; Wild, P.; Rowe, A. Coal-to-biomass retrofit in Alberta—Value of forest residue bioenergy in the electricity system. Renew. Energy 2018, 125, 373–383. [Google Scholar] [CrossRef]

- Bolyssov, T. Features of the use of renewable energy sources in agriculture. Int. J. Energy Econ. Policy. 2019, 9, 363–368. [Google Scholar] [CrossRef]

- Arefin, M.A.; Rashid, F.; Islam, A. A review of biofuel production from floating aquatic plants: An emerging source of bio-renewable energy. Biofuels Bioprod. Biorefining 2021, 15, 574–591. [Google Scholar] [CrossRef]

- Chel, A.; Kaushik, G. Renewable energy for sustainable agriculture. Agron. Sustain. Dev. 2011, 31, 91–118. [Google Scholar] [CrossRef]

- Lichtfouse, E.; Navarrete, M.; Debaeke, P.; Souchère, V.; Alberola, C.; Ménassieu, J. Agronomy for sustainable agriculture: A review. Sustain. Agric. 2009, 29, 1–7. [Google Scholar]

- IEA. Energy and Climate Change. 2015. Available online: https://www.iea.org/publications/freepublications/publication/WEO2015SpecialReportonEnergyandClimateChange.pdf (accessed on 18 March 2019).

- Pachauri, R.K.; Meyer, L.A. Climate Change 2014: Synthesis Report. In Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Inter-Governmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- WB. Energy Use (kg of Oil Equivalent per Capita): World. 2017. Available online: http://data.worldbank.org/indicator/EG.USE.PCAP.KG.OE (accessed on 27 July 2017).

- Hoekstra, A.Y.; Wiedmann, T.O. Humanity’s unsustainable environmental footprint. Science 2014, 344, 1114–1117. [Google Scholar] [CrossRef] [PubMed]

- Wiedmann, T.; Minx, J. A definition of ‘carbon footprint’. Ecol. Econ. Res. Trends 2008, 1, 1–11. [Google Scholar]

- Ilari, A.; Duca, D.; Boakye-Yiadom, K.A.; Gasperini, T.; Toscano, G. Carbon Footprint and Feedstock Quality of a Real Biomass Power Plant Fed with Forestry and Agricultural Residues. Resources 2022, 11, 7. [Google Scholar] [CrossRef]

- dos Santos Bernardes, M.A. Biofuel Production-Recent Developments and Prospects; InTech: Osaka, Japan, 2011. [Google Scholar]

- Soccol, C.R.; Vandenberghe, L.P.; Costa, B.; Woiciechowski, A.L.; Carvalho, J.C.D.; Medeiros, A.B.; Francisco, A.M.; Bonomi, L.J. Brazilian biofuel program: An overview. J. Sci. Ind. Res. 2005, 64, 897–904. [Google Scholar]

- Elbehri, A.; Segerstedt, A.; Liu, P. Biofuels and the Sustainability Challenge: A Global Assessment of Sustainability Issues, Trends and Policies for Biofuels and Related Feed-Stocks; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013. [Google Scholar]

- EPA. Renewable Fuel Standard Program (RFS2) Regulatory Impact Analysis; United States Environmental Protection Agency: Washington, DC, USA, 2010.

- Gromada, A.; Trebska, P.; Wysokinski, M. Use of renewable energy in the European Union—Trends of change. In Proceedings of the Economic Science for Rural Development Conference Proceedings, Jelgava, Latvia, 11–14 May 2019; Volume 51, pp. 122–128. [Google Scholar]

- World Bank. GDP Data for India. 2019. Available online: https://data.worldbank.org/indicator/NY.GDP.MKTP.CD?locations=IN (accessed on 2 April 2021).

- International Energy Agency. India Energy Outlook 2021, Paris. 2021. Available online: https://www.iea.org/reports/india-energy-outlook-2021 (accessed on 16 March 2021).

- Mona, S.; Malyan, S.K.; Saini, N.; Deepak, B.; Pugazhendhi, A.; Kumar, S.S. Towards sustainable agriculture with carbon sequestration, and greenhouse gas mitigation using algal biochar. Chemosphere 2021, 275, 129856. [Google Scholar] [CrossRef]

- Sedaoui, R. Energy and the Economy in the Middle East and North Africa. In The Palgrave Handbook of International Energy Economics; Palgrave Macmillan: Cham, Switzerland, 2022; pp. 667–691. [Google Scholar]

- Rahman, M.M.; Khan, I.; Field, D.L.; Techato, K.; Alameh, K. Powering agriculture: Present status, future potential, and challenges of renewable energy applications. Renew. Energy 2022, 188, 731–749. [Google Scholar] [CrossRef]

- Chugh, S.; Chaudhari, C.; Sharma, A.; Kapur, G.S.; Ramakumar, S.S.V. Comparing prospective hydrogen pathways with conventional fuels and grid electricity in India through well-to-tank assessment. Int. J. Hydrogen Energy 2022, 47, 18194–18207. [Google Scholar] [CrossRef]

- International Energy Agency. Annual Report; JICA: Tokyo, Japan, 2013.

- Gorjian, S.; Fakhraei, O.; Gorjian, A.; Sharafkhani, A.; Aziznejad, A. Sustainable Food and Agriculture: Employment of Renewable Energy Technologies. Curr. Robot. Rep. 2022, 3, 153–163. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A. Hydrogen production from renewable and sustainable energy resources: Promising green energy carrier for clean development. Renew. Sustain. Energy Rev. 2016, 57, 850–866. [Google Scholar] [CrossRef]

- Sun, H.; Wang, E.; Li, X.; Cui, X.; Guo, J.; Dong, R. Potential biomethane production from crop residues in China: Contributions to carbon neutrality. Renew. Sustain. Energy Rev. 2021, 148, 111360. [Google Scholar] [CrossRef]

- Xing, H.; Stuart, C.; Spence, S.; Chen, H. Alternative fuel options for low carbon maritime transportation: Pathways to 2050. J. Clean. Prod. 2021, 297, 126651. [Google Scholar] [CrossRef]

- Tilman, D.; Socolow, R.; Foley, J.A.; Hill, J.; Larson, E.; Lynd, L.L.; Pacala, S.; Reilly, J.; Searchinger, T.; Somerville, C.; et al. Beneficial biofuels—The food, energy, and environment trilemma. Science 2009, 325, 270–271. [Google Scholar] [CrossRef] [PubMed]

- Kulyal, L.; Jalal, P. Bioenergy, a finer alternative for India: Scope, barriers, socio-economic benefits and identified solution. Bioresour. Technol. Rep. 2022, 17, 100947. [Google Scholar] [CrossRef]

- Alexander, B.R.; Mitchell, R.E.; Gür, T.M. Experimental and modeling study of biomass conversion in a solid carbon fuel cell. J. Electrochem. Soc. 2012, 159, B347. [Google Scholar] [CrossRef]

- Antolini, D.; Piazzi, S.; Menin, L.; Baratieri, M.; Patuzzi, F. High hydrogen content syngas for biofuels production from biomass air gasification: Experimental evaluation of a char-catalyzed steam reforming unit. Int. J. Hydrogen Energy 2022, 47, 27421–27436. [Google Scholar] [CrossRef]

- Rodionova, M.V.; Poudyal, R.S.; Tiwari, I.; Voloshin, R.A.; Zharmukhamedov, S.K.; Nam, H.G.; Zayadan, B.K.; Bruce, B.D.; Hou, H.J.; Allakhverdiev, S.I. Biofuel production: Challenges and opportunities. Int. J. Hydrogen Energy 2017, 42, 8450–8461. [Google Scholar] [CrossRef]

- Mat Aron, N.S.; Khoo, K.S.; Chew, K.W.; Show, P.L.; Chen, W.H.; Nguyen, T.H.P. Sustainability of the four generations of biofuels—A review. Int. J. Energy Res. 2020, 44, 9266–9282. [Google Scholar] [CrossRef]

- Wang, M.; Han, J.; Dunn, J.B.; Cai, H.; Elgowainy, A. Well-to-wheels energy use and greenhouse gas emissions of ethanol from corn, sugarcane and cellulosic biomass for US use. Environ. Res. Lett. 2012, 7, 045905. [Google Scholar] [CrossRef]

- Subhash, G.V.; Rajvanshi, M.; Kumar GR, K.; Sagaram, U.S.; Prasad, V.; Govindachary, S.; Dasgupta, S. Challenges in microalgal biofuel production: A perspective on techno economic feasibility under biorefinery stratagem. Bioresour. Technol. 2022, 343, 126155. [Google Scholar] [CrossRef]

- Demirbas, A.A. Competitive liquid biofuels from biomass. Appl. Energy 2011, 88, 17–28. [Google Scholar] [CrossRef]

- Obergruber, M.; Hönig, V.; Procházka, P.; Kučerová, V.; Kotek, M.; Bouček, J.; Mařík, J. Physicochemical properties of biobutanol as an advanced biofuel. Materials 2021, 14, 914. [Google Scholar] [CrossRef] [PubMed]

- Hajjari, M.; Tabatabaei, M.; Aghbashlo, M.; Ghanavati, H. A review on the prospects of sustainable biodiesel production: A global scenario with an emphasis on waste-oil biodiesel utilization. Renew. Sustain. Energy Rev. 2017, 72, 445–464. [Google Scholar] [CrossRef]

- Kubička, D.; Kaluža, L. Deoxygenation of vegetable oils over sulfided Ni, Mo and NiMo catalysts. Appl. Catal. A Gen. 2010, 372, 199–208. [Google Scholar] [CrossRef]

- Faungnawakij, K.; Suriye, K. New and Future Developments in Catalysis: Chapter 4. Current Catalytic Processes with Hybrid Materials and Composites for Heterogeneous Catalysis; Elsevier Inc. Chapters: Singapore, 2013. [Google Scholar]

- Kaltschmitt, M.; Weber, M. Markets for solid biofuels within the EU-15. Biomass Bioenergy 2006, 30, 897–907. [Google Scholar] [CrossRef]

- Gil, L.S.; Maupoey, P.F. An integrated approach for pineapple waste valorisation. Bioethanol production and bromelain extraction from pineapple residues. J. Clean. Prod. 2018, 172, 1224–1231. [Google Scholar]

- Available online: https://www.google.com/amp/s/www.financialexpress.com/auto/bike-news/bajaj-and-tvs-to-roll-out-bio-ethanol-vehicles-after-transport-ministrys-nod-benefits-you-can-expect/1157152/lite/ (accessed on 3 September 2022).

- Susmozas, A.; Martín-Sampedro, R.; Ibarra, D.; Eugenio, M.E.; Iglesias, R.; Manzanares, P.; Moreno, A.D. Process strategies for the transition of 1G to advanced bioethanol production. Processes 2020, 8, 1310. [Google Scholar] [CrossRef]

- Available online: https://afdc.energy.gov/files/u/publication/biodiesel_handling_use_guide.pdf (accessed on 3 September 2022).

- Prasad, M.; Ranjan, R.; Ali, A.; Goyal, D.; Yadav, A.; Singh, T.B.; Shrivastav, P.; Dantu, P.K. Efficient transformation of agricultural waste in India. In Contaminants in Agriculture; Springer: Cham, Switzerland, 2020; pp. 271–287. [Google Scholar]

- Li, Y.; Kesharwani, R.; Sun, Z.; Qin, R.; Dagli, C.; Zhang, M.; Wang, D. Economic viability and environmental impact investigation for the biofuel supply chain using co-fermentation technology. App. Energy 2020, 259, 114235. [Google Scholar] [CrossRef]

- Wyman, C.E.; Dale, B.E.; Elander, R.T.; Holtzapple, M.; Ladisch, M.R.; Lee, Y.Y. Comparative sugar recovery data from laboratory scale application of leading pretreatment technologies to corn stover. Bioresour. Technol. 2005, 96, 2026–2032. [Google Scholar] [CrossRef]

- Yang, B.; Wyman, C.E. Pretreatment: The key to unlocking low-cost cellulosic ethanol. Biofuels Bioprod. Biorefining Innov. A Sustain. Econ. 2008, 2, 26–40. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, P.; Liu, D.; Pei, Z.J.; Cong, W. Ultrasonic Vibration-Assisted Pelleting of Cellulosic Biomass for Biofuel Manufacturing: A Study on Pellet Cracks. J. Manuf. Sci. Eng. 2012, 134, 051016. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, P.; Pei, Z.; Rys, M.; Wang, D.; Zhou, J. Ultrasonic vibration-assisted pelleting of cellulosic biomass for ethanol manufacturing: An investigation on pelleting temperature. Renew. Energy 2016, 86, 895–908. [Google Scholar] [CrossRef]

- Posten, C.; Schaub, G. Microalgae and terrestrial biomass as source for fuels—A process view. J. Biotechnol. 2009, 142, 64–69. [Google Scholar] [CrossRef] [PubMed]

- Hong, M.; Zhukareva, V.; Vogelsberg-Ragaglia, V.; Wszolek, Z.; Reed, L.; Miller, B.I.; Geschwind, D.H.; Bird, T.D.; McKeel, D.; Goate, A.; et al. Mutation-specific functional impairments in distinct tau isoforms of hereditary FTDP-17. Science 1998, 282, 1914–1917. [Google Scholar] [CrossRef] [PubMed]

- Bioenergy, I.E.A. From 1st-to 2nd-Generation BioFuel technoloGies. In An Overview of Current Industry and Rd&D Activities; IEA-OECD: Paris, France, 2008. [Google Scholar]

- Sims, R.E.; Mabee, W.; Saddler, J.N.; Taylor, M. An overview of second generation biofuel technologies. Bioresour. Technol. 2008, 101, 1570–1580. [Google Scholar] [CrossRef] [PubMed]

- Tye, Y.Y.; Lee, K.T.; Abdullah, W.N.W.; Leh, C.P. Potential of Ceiba pentandra (L.) Gaertn.(kapok fiber) as a resource for second generation bioethanol: Effect of various simple pretreatment methods on sugar production. Bioresour. Technol. 2012, 116, 536–539. [Google Scholar] [CrossRef]

- Gomez, L.D.; Steele-King, C.G.; McQueen-Mason, S.J. Sustainable liquid biofuels from biomass: The writing’s on the walls. New Phytol. 2008, 178, 473–485. [Google Scholar] [CrossRef]

- Balat, M. Sustainable transportation fuels from biomass materials. Energy Educ. Sci. Technol. 2006, 17, 83. [Google Scholar]

- Lee, S.; Speight, J.G.; Loyalka, S.K. Hand Book of Alternative Fuel Technologies; CRC Taylor and Francis Group: Boca Raton, FL, USA, 2007. [Google Scholar]

- Demirbas, A. Current technologies for the thermo- conversion of biomass into fuels and chemicals. Energy Sour. 2004, 26, 715–730. [Google Scholar] [CrossRef]

- Zaman, C.Z.; Pal, K.; Yehye, W.A.; Sagadevan, S.; Shah, S.T.; Adebisi, G.A.; Johan, R.B. Pyrolysis: A Sustainable Way to Generate Energy from Waste; IntechOpen: Rijeka, Croatia, 2017; Volume 1, p. 316806. [Google Scholar]

- Zabaniotou, A.; Ioannidou, O.; Skoulou, V. Rapeseed residues utilization for energy and 2nd generation biofuels. Fuel 2008, 87, 1492–1502. [Google Scholar] [CrossRef]

- Aftab, M.N.; Iqbal, I.; Riaz, F.; Karadag, A.; Tabatabaei, M. Different pretreatment methods of lignocellulosic biomass for use in biofuel production. Biomass Bioenergy-Recent Trends Future Chall 2019, 1–24, Chapter no. 2. [Google Scholar]

- Naik, S.N.; Goud, V.V.; Rout, P.K.; Dalai, A.K. Production of first and second generation biofuels: A comprehensive review. Renew. Sustain. Energy Rev. 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Xu, H.; Wang, C. A Comprehensive Review of 2, 5-Dimethylfuran as a Biofuel Candidate. In Biofuels from Lignocellulosic Biomass: Innovations beyond Bioethanol; Wiley-VCH: Weinheim, Germany, 2016; pp. 105–129. [Google Scholar]

- Chen, G.; Shen, Y.; Zhang, Q.; Yao, M.; Zheng, Z.; Liu, H. Experimental study on combustion and emission characteristics of a diesel engine fueled with 2,5-dimethylfuran–diesel, n-butanol–diesel and gasoline–diesel blends. Energy 2013, 54, 333–342. [Google Scholar] [CrossRef]

- Zhang, W.; He, J.; Engstrand, P.; Björkqvist, O. Economic evaluation on bio-synthetic natural gas production integrated in a thermomechanical pulp mill. Energies 2015, 8, 12795–12809. [Google Scholar] [CrossRef]

- Vignesh, P.; Kumar AR, P.; Ganesh, N.S.; Jayaseelan, V.; Sudhakar, K. Biodiesel and green diesel generation: An overview. Oil Gas Sci. Technol. Rev. d’IFP Energ. Nouv. 2021, 76, 6. [Google Scholar] [CrossRef]

- Venkateswaran, C.; Fegade, V.; Ramachandran, M.; Saravanan, V.; Tamilarasan, V. Review on Various Application Bio Fuels. Mater. Its Charact. 2022, 1, 17–27. [Google Scholar] [CrossRef]

- Scott, S.A.; Davey, M.P.; Dennis, J.S.; Horst, I.; Howe, C.J.; Lea-Smith, D.J.; Smith, A.G. Biodiesel from algae: Challenges and prospects. Curr. Opin. Biotechnol. 2010, 21, 277–286. [Google Scholar] [CrossRef]

- Darzins, A.; Pienkos, P.; Edye, L. Current status and potential for algal biofuels production. In A Report to IEA Bioenergy Task; IEA: Paris, France, 2010; Volume 39, pp. 403–412. [Google Scholar]

- Carriquiry, M.A.; Du, X.; Timilsina, G.R. Second generation biofuels: Economics and policies. Energy Policy 2011, 39, 4222–4234. [Google Scholar] [CrossRef]

- Kafarov, V.; Rosso-Cerón, A.M. Biomass as a Source for Heat, Power and Chemicals. In Advances in Carbon Management Technologies; CRC Press: Boca Raton, FL, USA, 2021; pp. 3–36. [Google Scholar]

- Dragone, G.; Fernandes, B.D.; Vicente, A.A.; Teixeira, J.A. Third generation biofuels from microalgae. In Current Research, Technology and Education Topics in Applied Microbiology and Microbial Biotechnology; World Scientific Publishing Company: Singapore, 2010. [Google Scholar]

- Romero-Garcia, J.M.; Martínez-Patio, C.; Ruiz, E.; Romero, I.; Castro, E. Ethanol production from olive stone hydrolysates by xylose fermenting microorganisms. Bioethanol 2016, 2, 51–65. [Google Scholar] [CrossRef]

- Chung, D.; Cha, M.; Guss, A.M.; Westpheling, J. Direct conversion of plant biomass to ethanol by engineered Caldicellulosiruptor bescii. Proc. Natl. Acad. Sci. USA 2014, 111, 8931–8936. [Google Scholar] [CrossRef]

- Kremer, T.A.; LaSarre, B.; Posto, A.L.; McKinlay, J.B. N2 gas is an effective fertilizer for bioethanol production by Zymomonas mobilis. Proc. Natl. Acad. Sci. USA 2015, 112, 2222–2226. [Google Scholar] [CrossRef] [PubMed]

- Higo, M.; Dowaki, K. A Life Cycle Analysis on a Bio-DME production system considering the species of biomass feedstock in Japan and Papua New Guinea. Appl. Energy 2010, 87, 58–67. [Google Scholar] [CrossRef]

- Shen, C.R.; Lan, E.I.; Dekishima, Y.; Baez, A.; Cho, K.M.; Liao, J.C. Driving forces enable high-titer anaerobic 1-butanol synthesis in Escherichia coli. Appl. Environ. Microbiol. 2011, 77, 2905–2915. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, Q.A.; Yang, J.; Bae, H.J. Bioethanol production from individual and mixed agricultural biomass residues. Ind. Crops Prod. 2017, 95, 718–725. [Google Scholar] [CrossRef]

- Nielsen, D.R.; Leonard, E.; Yoon, S.H.; Tseng, H.C.; Yuan, C.; Prather KL, J. Engineering alternative butanol production platforms in heterologous bacteria. Metab. Eng. 2009, 11, 262–273. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://www.statista.com/statistics/274168/biofuel-production-in-leading-countries-in-oil-equivalent/#:~:text=The%20United%20States%20was%20the,840%20and%20312%20petajoules%2C%20respectively (accessed on 2 August 2022).

- Available online: https://www.statista.com/statistics/1295828/eu-fuel-ethanol-production/ (accessed on 2 August 2022).

- Balitskiy, S.; Bilan, Y.; Strielkowski, W.; Štreimikienė, D. Energy efficiency and natural gas consumption in the context of economic development in the European Union. Renew. Sustain. Energy Rev. 2016, 55, 156–168. [Google Scholar] [CrossRef]

- Dang, B.; Zhang, H.; Li, Z.; Ma, S.; Xu, Z. Coexistence of the blaNDM-1-carrying plasmid pWLK-nDM and the blaKPC-2-carrying plasmid pWLK-KPC in a Raoultella ornithinolytica isolate. Sci. Rep. 2020, 10, 1–9. [Google Scholar] [CrossRef]

- Available online: https://www.iea.org/reports/outlook-for-biogas-and-biomethane-prospects-for-organic-growth/an-introduction-to-biogas-and-biomethane (accessed on 2 August 2022).

- Available online: https://www.researchandmarkets.com/reports/4515064/bio-butanol-market-growth-trends-covid-19 (accessed on 2 August 2022).

- Lay, C.-H.; Kumar, G.; Mudhoo, A.; Lin, C.Y.; Leu, H.-J.; Shobana, S.; Nguyen, M.-L.T. Recent trends and prospects in biohythane research: An overview. Int. J. Hydrogen Energy 2020, 45, 5864–5873. [Google Scholar] [CrossRef]

- Meena, R.A.A.; Banu, J.R.; Kannah, R.Y.; Yogalakshmi, K.N.; Kumar, G. Biohythane production from food processing wastes—Challenges and perspectives. Bioresour. Technol. 2019, 298, 122449. [Google Scholar] [CrossRef]

- Abanades, S.; Abbaspour, H.; Ahmadi, A.; Das, B.; Ehyaei, M.A.; Esmaeilion, F.; El Haj Assad, M.; Hajilounezhad, T.; Jamali, D.H.; Hmida, A.; et al. A critical review of biogas production and usage with legislations framework across the globe. Int. J. Environ. Sci. Technol. 2021, 19, 1–24. [Google Scholar] [CrossRef]

- Feng, J.; Chen, C.; Zhang, Y.; Song, Z.; Deng, A.; Zheng, C.; Zhang, W. Impacts of cropping practices on yield-scaled greenhouse gas emissions from rice fields in China: A meta-analysis. Agric. Ecosyst. Environ. 2013, 164, 220–228. [Google Scholar] [CrossRef]

- Zacharia, K.M.B.; Yadav, S.; Machhirake, N.P.; Kim, S.H.; Lee, B.D.; Jeong, H.; Singh, L.; Kumar, S.; Kumar, R. Bio-hydrogen and bio-methane potential analysis for production of bio-hythane using various agricultural residues. Bioresour. Technol. 2020, 309, 123297. [Google Scholar]

- Brennan, L.; Owende, P. Biofuels from microalgae—A review of technologies for production, processing, and extractions of biofuels and co-products. Renew. Sustain. Energy Rev. 2010, 14, 557–577. [Google Scholar] [CrossRef]

- Sajjadi, B.; Chen, W.-Y.; Raman, A.A.A.; Ibrahim, S. Microalgae lipid and biomass for biofuel production: A comprehensive review on lipid enhancement strategies and their effects on fatty acid composition. Renew. Sustain. Energy Rev. 2018, 97, 200–232. [Google Scholar] [CrossRef]

- Shuba, E.; Kifle, D. Microalgae to biofuels: ‘Promising’alternative and renewable energy, review. Renew. Sustain. Energy Rev. 2018, 81, 743–755. [Google Scholar] [CrossRef]

- Sasaki, K.; Tsuge, Y.; Sasaki, D.; Kawaguchi, H.; Sazuka, T.; Ogino, C.; Kondo, A. Repeated ethanol production from sweet sorghum juice concentrated by membrane separation. Bioresour. Technol. 2015, 186, 351–355. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Dimaratos, A.M.; Giakoumis, E.G.; Rakopoulos, D.C. Study of turbocharged diesel engine operation, pollutant emissions and combustion noise radiation during starting with bio-diesel or n-butanol diesel fuel blends. Appl. Energy 2011, 88, 3905–3916. [Google Scholar] [CrossRef]

- Lee, S.Y.; Park, J.H.; Jang, S.H.; Nielsen, L.K.; Kim, J.; Jung, K.S. Fermentative butanol production by Clostridia. Biotechnol. Bioeng. 2008, 101, 209–228. [Google Scholar] [CrossRef]

- Alias, N.H.; Ibrahim, M.F.; Salleh MS, M.; Jenol, M.A.; Abd-Aziz, S.; Phang, L.Y. Biobutanol Production from Agricultural Biomass. In Sustainable Bioeconomy; Springer: Singapore, 2021; pp. 67–84. [Google Scholar]

- Chandrasekhar, K.; Kumar, S.; Lee, B.D.; Kim, S.H. Waste based hydrogen production for circular bioeconomy: Current status and future directions. Bioresour. Technol. 2020, 302, 122920. [Google Scholar] [CrossRef]

- Ajanovic, A.; Haas, R. Economic challenges for the future relevance of biofuels in transport in EU countries. Energy 2010, 35, 3340–3348. [Google Scholar] [CrossRef]

- Nagarajan, D.; Lee, D.J.; Chen, C.Y.; Chang, J.S. Resource recovery from wastewaters using microalgae-based approaches: A circular bioeconomy perspective. Bioresour. Technol. 2020, 302, 122817. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.Y.; Lay, C.H.; Chen, C.C.; Wu, S.Y. Lipid accumulating microalgae cultivation in textile wastewater: Environmental parameters optimization. J. Taiwan Inst. Chem. Eng. 2017, 79, 1–6. [Google Scholar] [CrossRef]

- Binod, P.; Gnansounou, E.; Sindhu, R.; Pandey, A. Enzymes for second generation biofuels: Recent developments and future perspectives. Bioresour. Technol. Rep. 2019, 5, 317–325. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, B.; Patwardhan, S.B.; Dwivedi, S.; Sarkar, S.; Roy, A.; Pandit, S. Brief Introduction to First, Second, and Third Generation of Biofuels. In Bio-Clean Energy Technologies: Volume 1; Springer: Singapore, 2022; pp. 1–29. [Google Scholar]

- Piechocki, J.; Sołowiej, P.; Neugebauer, M.; Chen, G. Development in energy generation technologies and alternative fuels for agriculture. In Advances in Agricultural Machinery and Technologies; CRC Press: Boca Raton, FL, USA, 2018; pp. 89–112. [Google Scholar]

- Ibáñez, G.R.; Ruíz, J.M.; Sánchez, M.R.; López, J.C. A corporate water footprint case study: The production of Gazpacho, a chilled vegetable soup. Water Resour. Ind. 2017, 17, 34–42. [Google Scholar] [CrossRef]

- Čuček, L.; Klemeš, J.J.; Varbanov, P.S.; Kravanja, Z. Significance of envi-ronmental footprints for evaluating sustainability and security of development. Clean Technol. Environ. Policy 2015, 17, 2125–2141. [Google Scholar] [CrossRef]

- Holmatov, B.; Hoekstra, A.Y.; Krol, M.S. Land, water and carbon foot-prints of circular bioenergy production systems. Renew. Sustain. Energy Rev. 2019, 111, 224–235. [Google Scholar] [CrossRef]

- Reiche, D. Renewable energy policies in the Gulf countries: A case study of the carbon-neutral “Masdar City” in Abu Dhabi. Energy Policy 2010, 38, 378–382. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The role of renewable energy in the global energy transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Doman, L. Eia Projects 28% Increase in World Energy Use by 2040; US Energy Information Administration: Washington, DC, USA, 2017.

- Weiss, M.; Haufe, J.; Carus, M.; Brandão, M.; Bringezu, S.; Hermann, B.; Patel, M.K. A review of the environmental impacts of biobased materials. J. Ind. Ecol. 2012, 16, S169–S181. [Google Scholar] [CrossRef]

- Wood, S.W.; Cowie, A. A Review of Greenhouse Gas Emission Factors for Fertiliser Production; IEA: Paris, France, 2004. [Google Scholar]

- Wiloso, E.I.; Heijungs, R.; Huppes, G.; Fang, K. Effect of biogenic carbon inventory on the life cycle assessment of bioenergy: Challenges to the neutrality assumption. J. Clean. Prod. 2016, 125, 78–85. [Google Scholar] [CrossRef]

- Haberl, H.; Sprinz, D.; Bonazountas, M.; Cocco, P.; Desaubies, Y.; Henze, M.; Hertel, O.; Johnson, R.K.; Kastrup, U.; Laconte, P. Correcting a fundamental error in greenhouse gas accounting related to bioenergy. Energy Policy 2012, 45, 18–23. [Google Scholar] [CrossRef] [PubMed]

- Zanchi, G.; Pena, N.; Bird, N. Is woody bioenergy carbon neutral? A comparative assessment of emissions from consumption of woody bioenergy and fossil fuel. Gcb Bioenergy 2012, 4, 761–772. [Google Scholar] [CrossRef]

- Brandão, M.; Azzi, E.; Novaes, R.M.; Cowie, A. The modelling approach determines the carbon footprint of biofuels: The role of LCA in informing decision makers in government and industry. Clean. Environ. Syst. 2021, 2, 100027. [Google Scholar] [CrossRef]

- Searchinger, T.; Heimlich, R.; Houghton, R.A.; Dong, F.; Elobeid, A.; Fabiosa, J.; Tokgoz, S.; Hayes, D.; Yu, T.H. Use of US croplands for biofuels increases greenhouse gases through emissions from land-use change. Science 2008, 319, 1238–1240. [Google Scholar] [CrossRef] [PubMed]

- Union, E. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the promotion of the use of energy from renewable sources and amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC. Off. J. Eur. Union 2009, 5, 2009. [Google Scholar]

- Ou, X.; Zhang, X.; Chang, S. Scenario analysis on alternative fuel/vehicle for China’s future road transport: Life-cycle energy demand and GHG emissions. Energy Policy 2010, 38, 3943–3956. [Google Scholar] [CrossRef]

- Pragya, N.; Sharma, N.; Gowda, B. Biofuel from oil-rich tree seeds: Net energy ratio, emissions saving and other environmental impacts associated with agroforestry practices in Hassan district of Karnataka, India. J. Clean. Prod. 2017, 164, 905–917. [Google Scholar] [CrossRef]

- Alkimim, A.; Clarke, K.C. Land use change and the carbon debt for sugarcane ethanol production in Brazil. Land Use Policy 2018, 72, 65–73. [Google Scholar] [CrossRef]

- Farrell, A.E.; Plevin, R.J.; Turner, B.T.; Jones, A.D.; O’hare, M.; Kammen, D.M. Ethanol can contribute to energy and environmental goals. Science 2006, 311, 506–508. [Google Scholar] [CrossRef]

- Lantz, M.; Prade, T.; Ahlgren, S.; Björnsson, L. Biogas and ethanol from wheat grain or straw: Is there a trade-off between climate impact, avoidance of iLUC and production cost? Energies 2018, 11, 2633. [Google Scholar] [CrossRef]

- Tetteh, E.K.; Amankwa, M.O.; Yeboah, C. Emerging carbon abatement technologies to mitigate energy-carbon footprint-a review. Clean. Mater. 2021, 2, 100020. [Google Scholar] [CrossRef]

- Karwacka, M.; Ciurzyńska, A.; Lenart, A.; Janowicz, M. Sustainable development in the agri-food sector in terms of the carbon footprint: A review. Sustainability 2020, 12, 6463. [Google Scholar] [CrossRef]

- Jaiswal, B.; Agrawal, M. Carbon footprints of agriculture sector. Carbon Footpr. 2020, 81–99. [Google Scholar]

- Payne, J.E. A survey of the electricity consumption-growth literature. Appl. Energy 2010, 87, 723–731. [Google Scholar] [CrossRef]

- Le Qu´er´e, C.; Andrew, R.M.; Friedlingstein, P.; Sitch, S.; Hauck, J.; Pongratz, J.; Pickers, P.A.; Korsbakken, J.I.; Peters, G.P.; Canadell, J.G.; et al. Global Carbon Budget 2018. Earth Syst. Sci. Data 2018, 10, 2141–2194. [Google Scholar] [CrossRef]

- Friedlingstein, P.; Sullivan, M.; Jones, M.W.; Andrew, R.M.; Hauck, J.; Olsen, A.; Peters, G.P.; Peters, W.; Pongratz, J.; Sitch, S.; et al. Global carbon budget 2020, Earth Syst. Sci. Data 2020, 12, 3269–3340. [Google Scholar] [CrossRef]

- Countries in the World by Population. 2021. Woldometer. Available online: https://www.worldometers.info/world-population/population-by-country/ (accessed on 24 August 2021).

- IEA. Coal-Global Energy Review, 2019; IEA: Paris, France, 2019. [Google Scholar]

- Odell, P.R. The global energy market in the long term: The continuing dominance of affordable nonrenewable reouurces. Global Energy Market in the Long Term: Dominance of Non-Renewable Resources. Energy Explor. Exploit. 2000, 18, 599–613. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M. CO2 and Greenhouse Gas Emissions. Our World in Data. 2020. Available online: https://ourworldindata.org/CO2-and-other-greenhouse-gas-emissions (accessed on 18 September 2021).

- Alabdali, Q.A.; Bajawi, A.M.; Fatani, A.M.; Nahhas, A.M. Review of recent advances of Wind Energy. Sustain. Energy 2020, 8, 12–19. [Google Scholar] [CrossRef]

- NS Energy (Ed.) Profiling the Top Geothermal Power Producing Countries in the World. 2020. Available online: https://www.nsenergybusiness.com/features/top-geothermal-power-producing-countries/ (accessed on 16 July 2021).

- Leading Countries on the Basis of Biofuels Production Worldwide. 2021. Statista. Available online: https://www.statista.com/statistics/274168/biofuel-production-in-leading-countries-in-oil-equivalent/ (accessed on 2 November 2021).

- Hossen, M.M.; Rahman, A.H.M.S.; Kabir, A.S.; Hasan, M.M.F.; Ahmes, S. Systematic assessment of the availability and utilization potential of biomass in Bangladesh. Renew. Sustain. Energy Rev. 2017, 67, 94–105. [Google Scholar] [CrossRef]

- Monjurul Hasan, A.S.M.; Kabir, A.M.; Hoq, M.T.; Johansson, M.T.; Thollander, P. Drivers and barriers to the implementation of biogas technologies in Bangladesh. Biofuels 2020, 13, 643–655. [Google Scholar] [CrossRef]

- Tauro, R.; Garcia, A.C.; Skutsch, M.; Masera, O. The potential for sustainable biomass pellets in Mexico: An analysis of energy potential, logistic costs and market demand. Renew. Sustain. Energy Rev. 2018, 81, 380–389. [Google Scholar] [CrossRef]

- Montero, G.; Stoytcheva, M.; Marcos, C.; Garcia, C.; Cerezo, J.; Toscano, L.; Vazqez, M.A. An Overview of Biodiesel Production in Mexico. In Biofuels—Status and Perspective; IntechOpen: London, UK, 2015. [Google Scholar] [CrossRef]

- World Bank. Population Data for India. 2019. Available online: https://data.worldbank.org/indicator/SP.POP.TOTL?locations=IN (accessed on 2 April 2021).

- PWC UK. The World in 2050, the Long View: How Will the Global Economic Order Change by 2050? 2017. Available online: https://www.pwc.com/gx/en/issues/economy/the-world-in-2050.html (accessed on 2 April 2021).

- United Nations. Department of Economic and Social Affairs, World Population Prospect: Probabilistic Projections. 2019. Available online: https://population.un.org/wpp/Download/Probabilistic/Population/ (accessed on 2 April 2021).

- Central Statistical Office, Government of India. Energy Statistics 2019. 2019. Available online: https://www.mospi.gov.in/sites/default/files/publication_reports/Energy%20Statistics%202019-finall.pdf (accessed on 2 April 2021).

- Ministry of Coal, Government of India. Production and Supply. 2021. Available online: https://www.coal.nic.in/ (accessed on 16 March 2021).

- Workman, D. Crude Oil Imports by Country, World’s Top Exports. 2020. Available online: https://www.worldstopexports.com/crude-oil-imports-by-country/ (accessed on 2 April 2021).

- Energy Information Administration, US. Energy Information and Statistics. 2020. Available online: https://www.eia.gov/international/data/world (accessed on 16 March 2021).

- Petroleum Planning and Analysis Cell, Ministry of Petroleum and Natural Gas, Government of India. Import/Export Data for Crude and Products—Value in Dollars. 2020. Available online: https://www.ppac.gov.in/content/212_1_ImportExport.aspx (accessed on 2 April 2021).

- Ministry of Commerce & Industry, Government of India. Press Release on India’s Foreign Trade: March 2019. 2019. Available online: https://pib.gov.in/PressReleasePage.aspx?PRID=1570702 (accessed on 2 April 2021).

- Financial Express, Govt Aims to Raise Domestic Gas Production by 75% in Three Years. 2021. Available online: https://www.financialexpress.com/industry/govt-aims-to-raise-domestic-gas-production-by-75-in-three-years/2269909/ (accessed on 15 June 2021).

- Demirbas, A. Relationships derived from physical properties of vegetable oil and biodiesel fuels. Fuel 2008, 87, 1743–1748. [Google Scholar] [CrossRef]

- Christopher, L.P.; Kumar, H.; Zambare, V.P. Enzymatic biodiesel: Challenges and opportunities. Appl. Energy 2014, 119, 497–520. [Google Scholar] [CrossRef]

- Fang, Z.; Zhang, F.; Zeng, H.Y.; Guo, F. Production of glucose by hydrolysis of cellulose at 423 K in the presence of activated hydrotalcite nanoparticles. Bioresour. Technol. 2011, 102, 8017–8021. [Google Scholar] [CrossRef]

- Available online: https://home.iitd.ac.in/news-hydrogen-fuel.php (accessed on 23 July 2022).

- Mittal, S.; Ahlgren, E.O.; Shukla, P.R. Barriers to biogas dissemination in India: A review. Energy Policy 2018, 112, 361–370. [Google Scholar] [CrossRef]

- Dey, S.; Reang, N.M.; Das, P.K.; Deb, M. A comprehensive study on prospects of economy, environment, and efficiency of palm oil biodiesel as a renewable fuel. J. Clean. Prod. 2021, 286, 124981. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Chilvers, A.; Azapagic, A. Environmental sustainability of biofuels: A review. Proc. R. Soc. A 2020, 476, 20200351. [Google Scholar] [CrossRef]

- Satari, B.; Jaiswal, A.K. Green fractionation of 2G and 3G feedstocks for ethanol production: Advances, incentives and barriers. Curr. Opin. Food Sci. 2021, 37, 1–9. [Google Scholar] [CrossRef]

- Markov, V.; Kamaltdinov, V.; Devyanin, S.; Sa, B.; Zherdev, A.; Furman, V. Investigation of the influence of different vegetable oils as a component of blended biofuel on performance and emission characteristics of a diesel engine for agricultural machinery and commercial vehicles. Resources 2021, 10, 74. [Google Scholar] [CrossRef]

| Biofuels Classification | Feedstock’s | Production Process | Products | Microorganisms Used | Challenges | Applications | References |

|---|---|---|---|---|---|---|---|

| First-generation biofuels (based on edible food sources) | Vegetable oils (peanut oil), sugar crops and sweeteners, switch grass, starch crops | Transesterification | Bioethanol | Escherichia coli, Zymomonas mobilis, Caldicellulosiruptor bescii, Trichoderma reesei | Limitation in feed stock, issues in food chain security | Applicable for use in electricity generation, vehicle fuel. | [80,81,82,83] |

| Biodiesel | |||||||

| Fermentation | Methanol | ||||||

| Biogas | |||||||

| Second-generation biofuels (Based on non- edible food sources) | Waste of Wood Municipal Solid Waste Forest/agricultural residues of non- edible crop plants such as Calotropis gigantia, Jatropha curcas | Hydrogenation | Butanol Vegetable Oil Mixed alcohols Cellulosic ethanol Jet fuels Dimethyl-furan Alcohol | Escherichia coli, Cryptococcus vishniaccii | Efficiency is very low; feedstock production cost is comparatively high | Used in chemical industries, specially designed for CI engines | [84,85] |

| Third-generation biofuels (based on algae) | Autotrophic aquatic organism (algae) | Gasification | Biodiesel and green diesel (1.64 billion gallons) Ethanol (5.4 billion liters) Propanol Butanol | Pseudomonas putida | Used in transportation, in home as heating oil. | [38,86,87,88,89] | |

| Pyrolysis | |||||||

| Fourth generation (biofuels based on microalgae) | Cyanophyceae, algae-based biomass, Bacillus Escherichia coli | Hydrolysis | Bio-butanol (15 million metric ton) Bio-hydrogen (1200 TJ) Synthetic biofuels Bio-methane (3.5 Mtoe) | Clostridium acetobutylicum | Usage in transportation fuel, as IC engine fuel. | [80,90,91,92,93] | |

| Fischer–Tropsch Fermentation | |||||||

| Hydrolysis |

| Countries | Biofuel Produced (In Petajoules) |

|---|---|

| USA | 1435.8 |

| Brazil | 839.5 |

| Indonesia | 311.9 |

| China | 142.7 |

| Germany | 121.2 |

| France | 107 |

| Thailand | 89.8 |

| Argentina | 85.6 |

| Netherlands | 84.6 |

| Spain | 71.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mathur, S.; Waswani, H.; Singh, D.; Ranjan, R. Alternative Fuels for Agriculture Sustainability: Carbon Footprint and Economic Feasibility. AgriEngineering 2022, 4, 993-1015. https://doi.org/10.3390/agriengineering4040063

Mathur S, Waswani H, Singh D, Ranjan R. Alternative Fuels for Agriculture Sustainability: Carbon Footprint and Economic Feasibility. AgriEngineering. 2022; 4(4):993-1015. https://doi.org/10.3390/agriengineering4040063

Chicago/Turabian StyleMathur, Shivangi, Hunny Waswani, Deeksha Singh, and Rajiv Ranjan. 2022. "Alternative Fuels for Agriculture Sustainability: Carbon Footprint and Economic Feasibility" AgriEngineering 4, no. 4: 993-1015. https://doi.org/10.3390/agriengineering4040063

APA StyleMathur, S., Waswani, H., Singh, D., & Ranjan, R. (2022). Alternative Fuels for Agriculture Sustainability: Carbon Footprint and Economic Feasibility. AgriEngineering, 4(4), 993-1015. https://doi.org/10.3390/agriengineering4040063