Evaluating the Performance of Flexible, Semi-Transparent Large-Area Organic Photovoltaic Arrays Deployed on a Greenhouse

Abstract

1. Introduction

2. Materials and Methods

2.1. OPV Device Characterization

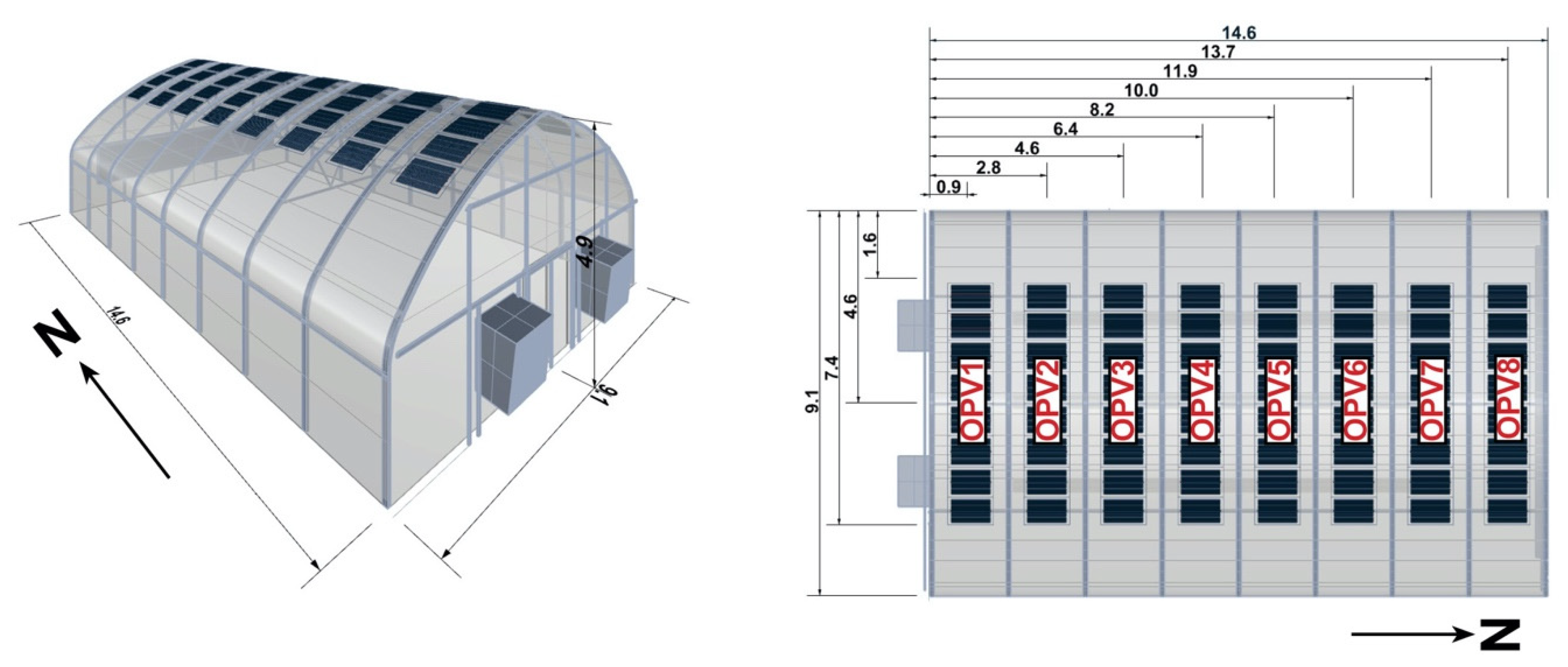

2.2. Study Greenhouse

2.2.1. Environmental Data

2.2.2. Solar Irradiance Data

2.3. OPV Array Electrical Data Collection

2.3.1. I-V Curve Measurement System

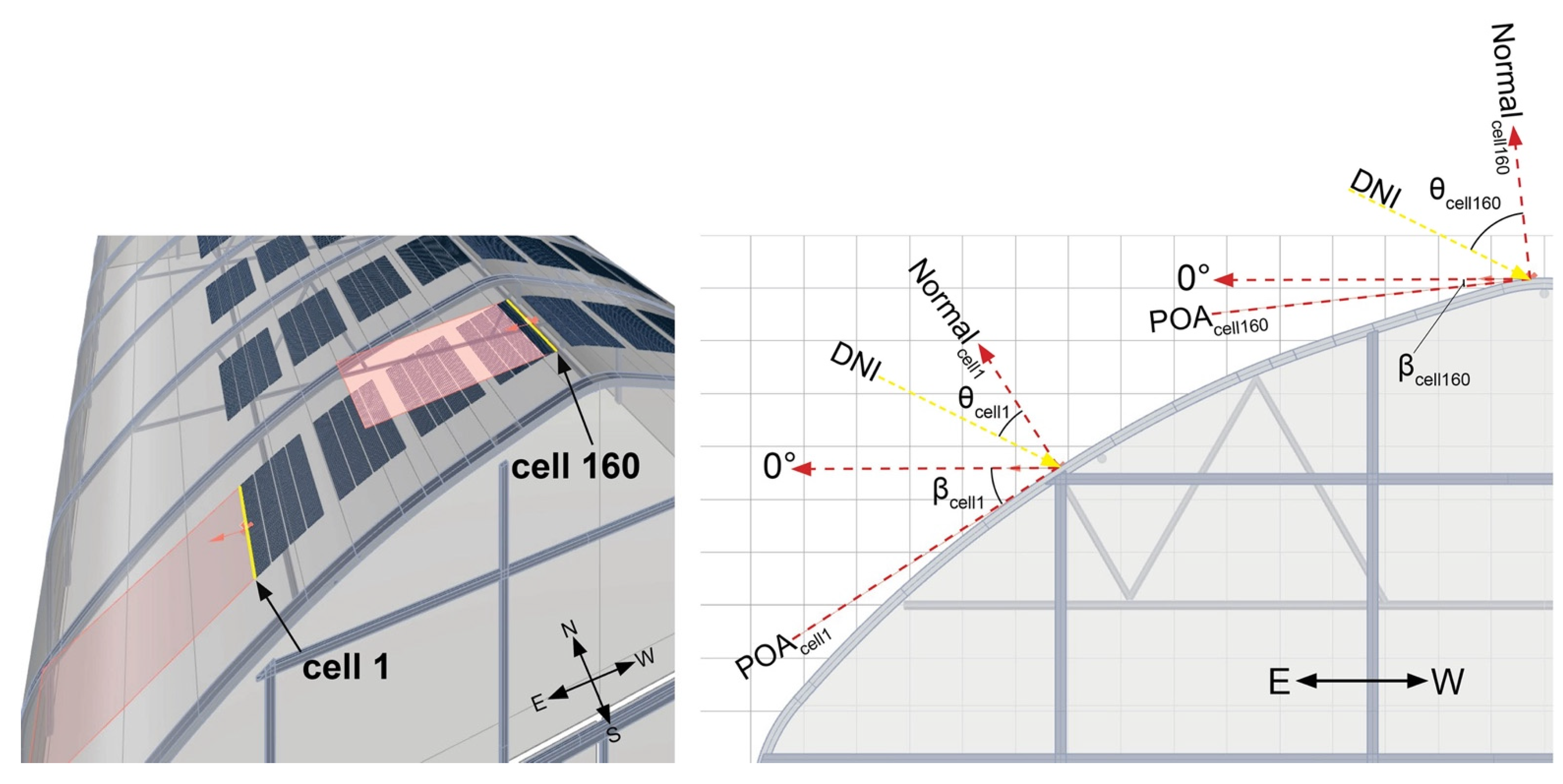

2.4. Modeling of Curved OPV Arrays on Greenhouse

2.5. Modeling Incident Solar Irradiance on the Curved OPV Array Surface

3. Results and Discussion

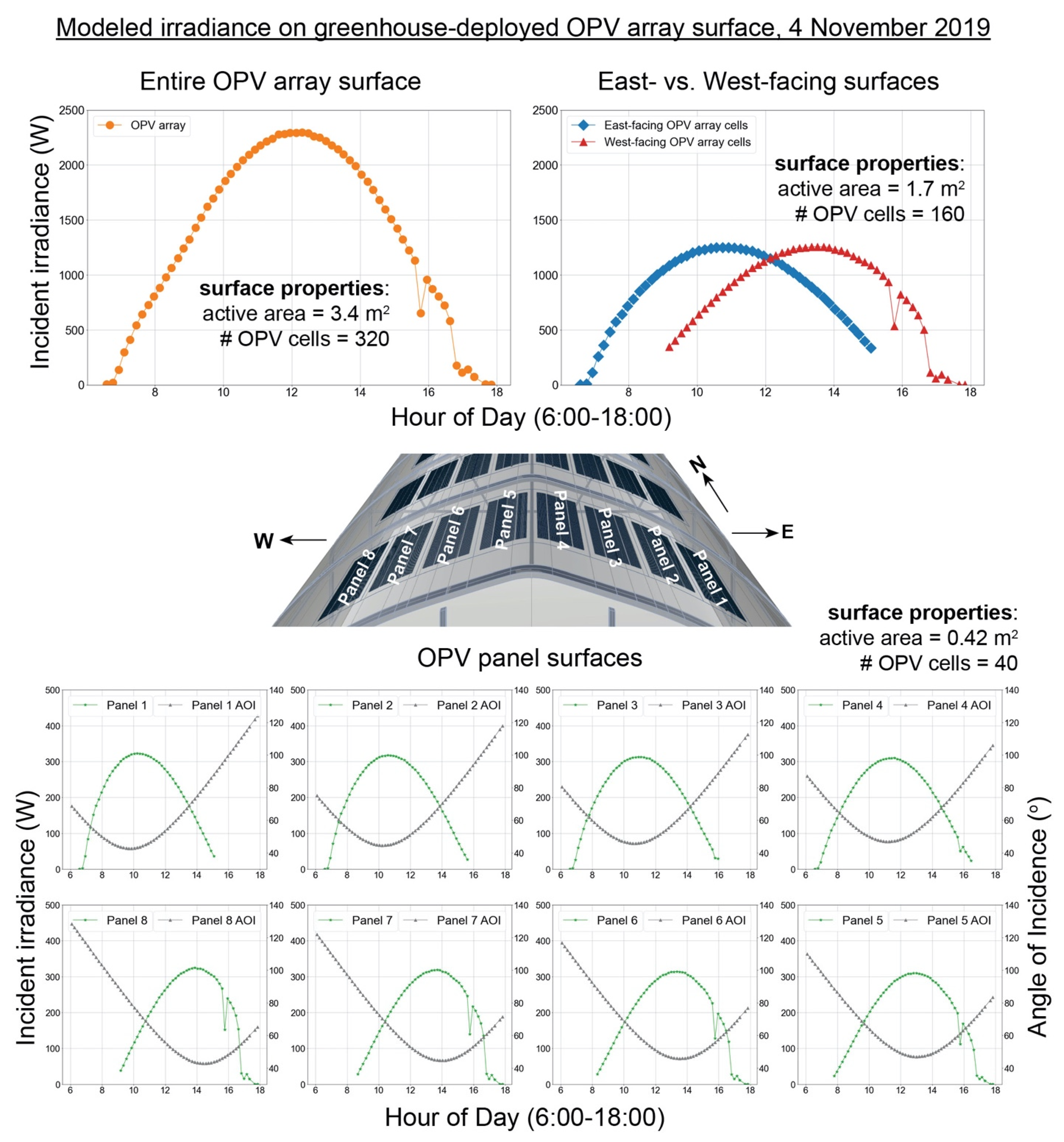

3.1. Irradiance Model Functionality

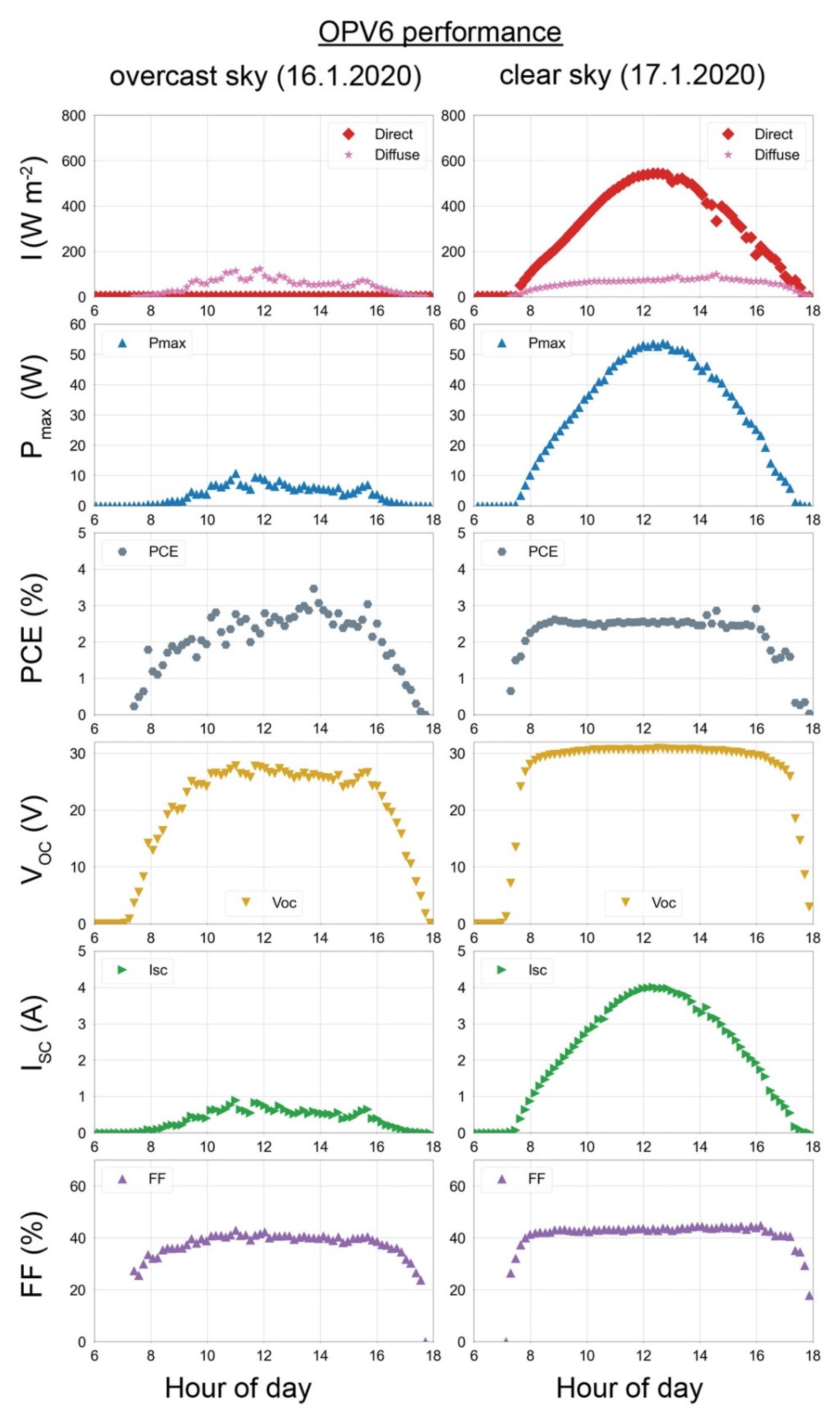

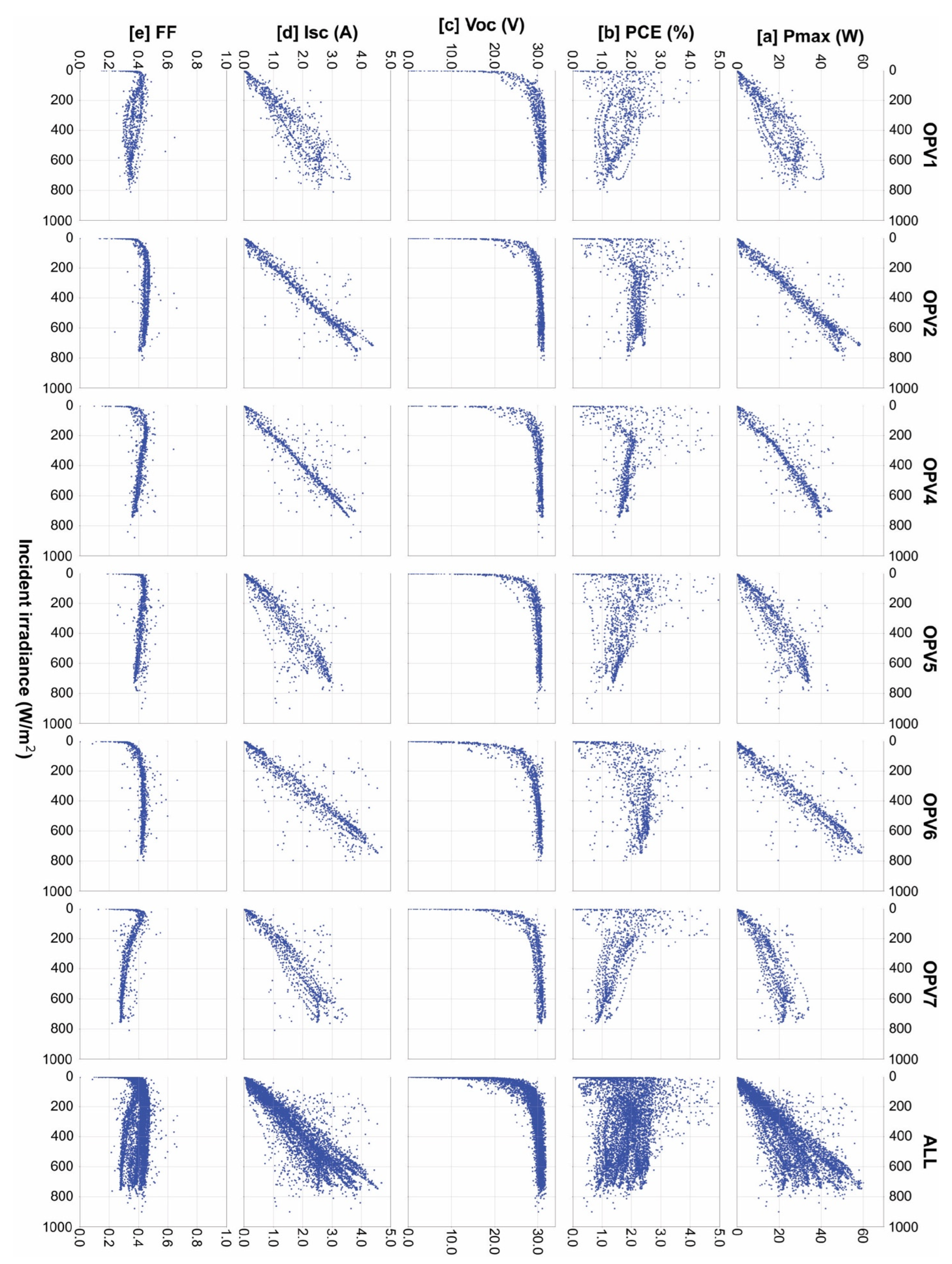

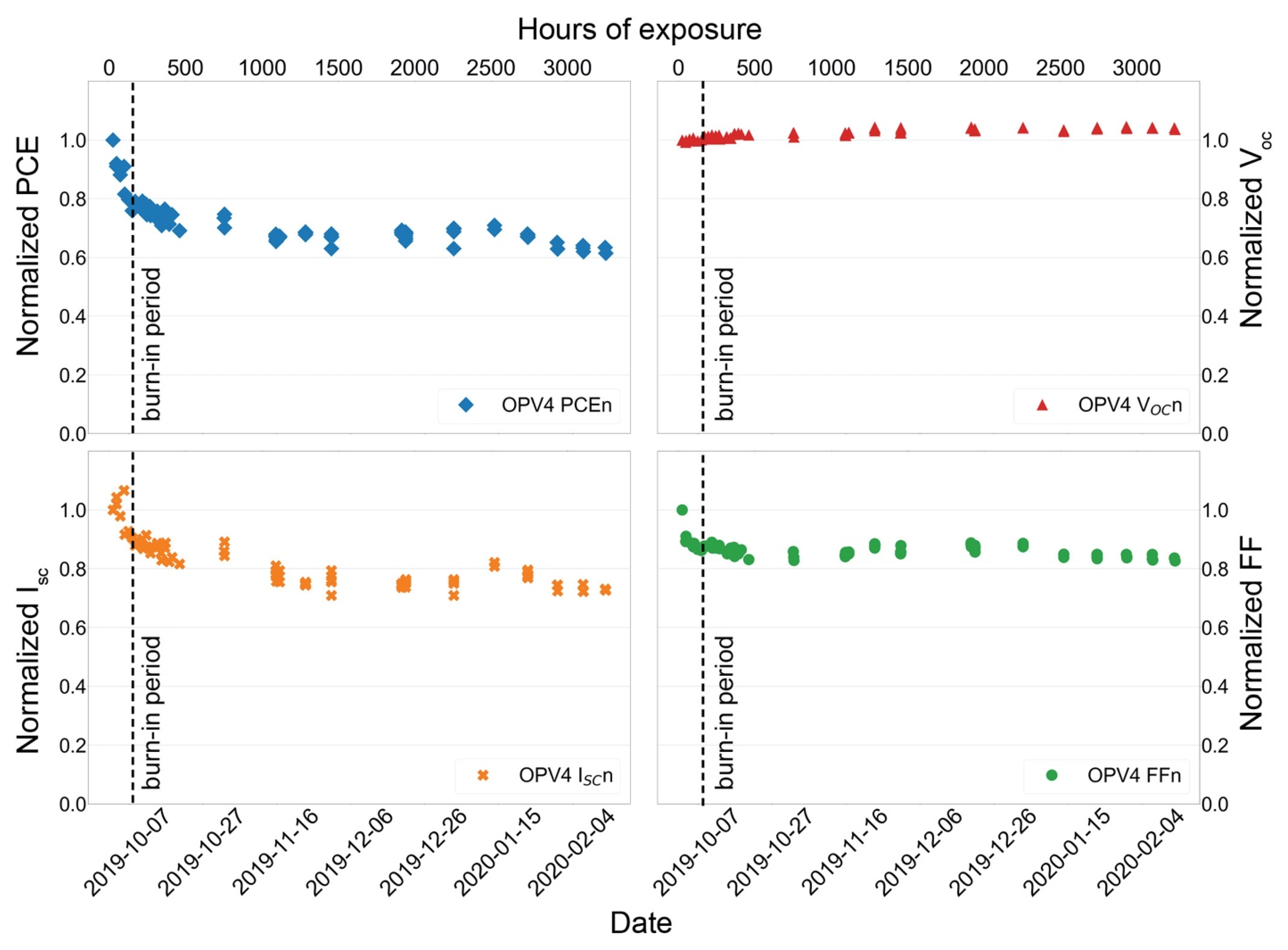

3.2. Electrical Performance of OPV Arrays

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dupraz, C.; Marrou, H.; Talbot, G.; Dufour, L.; Nogier, A.; Ferard, Y. Combining solar photovoltaic panels and food crops for optimising land use: Towards new agrivoltaic schemes. Renew. Energy 2011, 36, 2725–2732. [Google Scholar] [CrossRef]

- Barbosa, G.; Gadelha, F.; Kublik, N.; Proctor, A.; Reichelm, L.; Weissinger, E.; Wohlleb, G.; Halden, R. Comparison of Land, Water, and Energy Requirements of Lettuce Grown Using Hydroponic vs. Conventional Agricultural Methods. Int. J. Environ. Res. Public Health 2015, 12, 6879–6891. [Google Scholar] [CrossRef] [PubMed]

- Cook, R.L.; Calvin, L. Greenhouse Tomatoes Change the Dynamics of the North American Fresh Tomato Industry; U.S. Department of Agriculture Economic Research Service: Washington, DC, USA, 2005.

- Yano, A.; Cossu, M. Energy sustainable greenhouse crop cultivation using photovoltaic technologies. Renew. Sust. Energy Rev. 2019, 109, 116–137. [Google Scholar] [CrossRef]

- Al-Ibrahim, A.; Al-Abbadi, N.; Al-Helal, I. PV greenhouse system—System description, performance and lesson learned. Acta Hortic. 2006, 710, 251–264. [Google Scholar] [CrossRef]

- Juang, P.; Kacira, M. System dynamics of a photovoltaic integrated greenhouse. Acta Hortic. 2014, 1037, 107–112. [Google Scholar] [CrossRef]

- Cossu, M.; Murgia, L.; Ledda, L.; Deligios, P.A.; Sirigu, A.; Chessa, F.; Pazzona, A. Solar radiation distribution inside a greenhouse with south-oriented photovoltaic roofs and effects on crop productivity. Appl. Energy 2014, 133, 89–100. [Google Scholar] [CrossRef]

- Kavga, A.; Strati, I.F.; Sinanoglou, V.J.; Fotakis, C.; Sotiroudis, G.; Christodoulou, P.; Zoumpoulakis, P. Evaluating the experimental cultivation of peppers in low-energy-demand greenhouses. An interdisciplinary study. J. Sci. Food Agric. 2019, 99, 781–789. [Google Scholar] [CrossRef] [PubMed]

- Bulgari, R.; Cola, G.; Ferrante, A.; Franzoni, G.; Mariani, L.; Martinetti, L. Micrometeorological environment in traditional and photovoltaic greenhouses and effects on growth and quality of tomato (Solanum lycopersicum L.). Ital. J. Agrometeorol. 2015, 20, 27–38. [Google Scholar]

- Bambara, J.; Athienitis, A.K. Energy and economic analysis for the design of greenhouses with semi-transparent photovoltaic cladding. Renew. Energy 2019, 131, 1274–1287. [Google Scholar] [CrossRef]

- Cossu, M.; Yano, A.; Li, Z.; Onoe, M.; Nakamura, H.; Matsumoto, T.; Nakata, J. Advances on the semi-transparent modules based on micro solar cells: First integration in a greenhouse system. Appl. Energy 2016, 162, 1042–1051. [Google Scholar] [CrossRef]

- Hassanien, R.H.E.; Li, M.; Yin, F. The integration of semi-transparent photovoltaics on greenhouse roof for energy and plant production. Renew. Energy 2018, 121, 377–388. [Google Scholar] [CrossRef]

- Ntinas, G.K.; Kadoglidou, K.; Tsivelika, N.; Krommydas, K.; Kalivas, A.; Ralli, P.; Irakli, M. Performance and Hydroponic Tomato Crop Quality Characteristics in a Novel Greenhouse Using Dye-Sensitized Solar Cell Technology for Covering Material. Horticulturae 2019, 5, 42. [Google Scholar] [CrossRef]

- Corrado, C.; Leow, S.W.; Osborn, M.; Carbone, I.; Hellier, K.; Short, M.; Alers, G.; Carter, S.A. Power generation study of luminescent solar concentrator greenhouse. J. Renew. Sustain. Energy 2016, 8, 043502. [Google Scholar] [CrossRef]

- Shi, H.; Xia, R.; Zhang, G.; Yip, H.-L.; Cao, Y. Spectral Engineering of Semitransparent Polymer Solar Cells for Greenhouse Applications. Adv. Energy Mater. 2019, 9, 1803438. [Google Scholar] [CrossRef]

- Lizin, S.; van Passel, S.; de Schepper, E.; Maes, W.; Lutsen, L.; Manca, J.; Vanderzande, D. Life cycle analyses of organic photovoltaics: A review. Energy Environ. Sci. 2013, 11, 3136–3149. [Google Scholar] [CrossRef]

- Muteri, V.; Cellura, M.; Curto, D.; Franzitta, V.; Longo, S.; Mistretta, M.; Parisi, M.L. Review on Life Cycle Assessment of Solar Photovoltaic Panels. Energies 2020, 13, 252. [Google Scholar] [CrossRef]

- Okada, K.; Kacira, M.; Teitel, M.; Yehia, I. Crop production and energy generation in a greenhouse integrated with semi-transparent organic photovoltaic film. Acta Hortic. 2018, 1227, 231–240. [Google Scholar]

- Ravishankar, E.; Booth, R.E.; Saravitz, C.; Sederoff, H.; Ade, H.W.; O’Connor, B.T. Achieving Net Zero Energy Greenhouses by Integrating Semitransparent Organic Solar Cells. Joule 2020, 4, 490–506. [Google Scholar] [CrossRef]

- Hollingsworth, J.A.; Ravishankar, E.; O’Connor, B.; Johnson, J.X.; DeCarolis, J.F. Environmental and economic impacts of solar-powered integrated greenhouses. J. Ind. Ecol. 2020, 24, 234–247. [Google Scholar] [CrossRef]

- Galagan, Y.; Fledderus, H.; Gorter, H.; ’tMannetje, H.H.; Shanmugam, S.; Mandamparambil, R.; Bosman, J.; Rubingh, J.E.J.M.; Teunissen, J.P.; Salem, A.; et al. Roll-to-Roll Slot-Die Coated Organic Photovoltaic (OPV) Modules with High Geometrical Fill Factors. Energy Technol.-Ger. 2015, 3, 834–842. [Google Scholar] [CrossRef]

- Grossiord, N.; Kroon, J.M.; Andriessen, R.; Blom, P.W.M. Degradation mechanisms in organic photovoltaic devices. Org. Electron. 2012, 13, 432–456. [Google Scholar] [CrossRef]

- Krebs, F.C.; Gevorgyan, S.A.; Gholamkhass, B.; Holdcroft, S.; Schlenker, C.; Thompson, M.E.; Thompson, B.C.; Olson, D.; Ginley, D.S.; Shaheen, S.E.; et al. A round robin study of flexible large-area roll-to-roll processed polymer solar cell modules. Sol. Energy Mat. Sol. C 2009, 93, 1968–1977. [Google Scholar] [CrossRef]

- Emmott, C.J.M.; Moia, D.; Sandwell, P.; Ekins-Daukes, N.; Hösel, M.; Lukoschek, L.; Amarasinghe, C.; Krebs, F.C.; Nelson, J. In-situ, long-term operational stability of organic photovoltaics for off-grid applications in Africa. Sol. Energy Mat. Sol. C 2016, 149, 284–293. [Google Scholar] [CrossRef]

- Friman-Peretz, M.; Geoola, F.; Yehia, I.; Ozer, S.; Levi, A.; Magadley, E.; Brikman, R.; Rosenfeld, L.; Levy, A.; Kacira, M.; et al. Testing organic photovoltaic modules for application as greenhouse cover or shading element. Biosys. Eng. 2019, 184, 24–36. [Google Scholar] [CrossRef]

- Magadley, E.; Teitel, M.; Peretz, M.F.; Kacira, M.; Yehia, I. Outdoor behaviour of organic photovoltaics on a greenhouse roof. Sustain. Energy Technol. Assess 2020, 37, 100641. [Google Scholar] [CrossRef]

- Zhang, H.; Balog, R.S. Experimental verification of energy harvest from non-planar photovoltaic surfaces. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, ECCE, Denver, CO, USA, 15–19 September 2013; pp. 4481–4487. [Google Scholar] [CrossRef]

- Hofer, J.; Nagy, Z.; Schlueter, A. Electrical Design and Layout Optimization of Flexible Thin-Film Photovoltaic Modules. In Proceedings of the 32nd European Photovoltaic Solar Energy Conference and Exhibition, Munich, Germany, 20–24 June 2016; pp. 2481–2485. [Google Scholar] [CrossRef]

- Groenewolt, A.; Bakker, J.; Hofer, J.; Nagy, Z.; Schlüter, A. Methods for modelling and analysis of bendable photovoltaic modules on irregularly curved surfaces. Int. J. Energy Environ. Eng. 2016, 7, 261–271. [Google Scholar] [CrossRef]

- Teitel, M.; Baeza, E.J.; Montero, J.I. Greenhouse design: Concepts and trends. In Proceedings of the Acta Horticulturae. International Symposium on Advanced Technologies and Management Towards Sustainable Greenhouse Ecosystems: Greensys2011, Athens, Greece, 5 June 2011; pp. 605–620. [Google Scholar] [CrossRef]

- Hirata, Y.; Watanabe, Y.; Yachi, T. Evaluation of output of transparent organic photovoltaic modules on curved surfaces depending on azimuth. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; pp. 1112–1115. [Google Scholar] [CrossRef]

- Berny, S.; Blouin, N.; Distler, A.; Egelhaaf, H.-J.; Krompiec, M.; Lohr, A.; Lozman, O.R.; Morse, G.E.; Nanson, L.; Pron, A.; et al. Solar Trees: First Large-Scale Demonstration of Fully Solution Coated, Semitransparent, Flexible Organic Photovoltaic Modules. Adv. Sci. 2016, 3, 1500342. [Google Scholar] [CrossRef] [PubMed]

- Andreas, A.; Wilcox, S. Observed Atmospheric and Solar Information System (OASIS); Tucson, Arizona (Data); NREL Report No. DA-5500-56494; National Renewable Energy Laboratory: Golden, CO, USA, 2010.

- Hagan, H. Topics in Surface Modeling; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 1992. [Google Scholar]

- AlPuerto, L.G. Modeling of Nonplanar Photovoltaic Arrays. Master’s Thesis, Texas A&M University, College Station, TX, USA, 2016. [Google Scholar]

- Holmgren, W.; Hansen, C.; Mikofski, M. pvlib python: A python package for modeling solar energy systems. J. Open Source Softw. 2018, 3, 884. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Loutzenhiser, P.G.; Manz, H.; Felsmann, C.; Strachan, P.A.; Frank, T.; Maxwell, G.M. Empirical validation of models to compute solar irradiance on inclined surfaces for building energy simulation. Sol. Energy 2007, 81, 254–267. [Google Scholar] [CrossRef]

- Perez, R.; Ineichen, P.; Seals, R.; Michalsky, J.; Stewart, R. Modeling daylight availability and irradiance components from direct and global irradiance. Sol. Energy 1990, 44, 271–289. [Google Scholar] [CrossRef]

- Fontes, A.F. Soil Albedo in Relation to Soil Color, Moisture and Roughness. Ph.D. Thesis, University of Arizona, Tucson, AZ, USA, 1996. [Google Scholar]

- Wang, G.; Adil, M.A.; Zhang, J.; Wei, Z. Large-Area Organic Solar Cells: Material Requirements, Modular Designs, and Printing Methods. Adv. Mater. 2019, 31, 1805089. [Google Scholar] [CrossRef]

- Katz, E.A.; Gevorgyan, S.; Krebs, F.C. Out-door testing and long-term stability of plastic solar cells. Eur. Phys. J. Appl. Phys. 2007, 36, 307–311. [Google Scholar] [CrossRef]

- Tromholt, T.; Manor, A.; Katz, E.A.; Krebs, F.C. Reversible degradation of inverted organic solar cells by concentrated sunlight. Nanotechnology 2011, 22, 225401. [Google Scholar] [CrossRef] [PubMed]

- Lima, A.; Bagnis, D.; De, G.; Soares, A.; Galindo, A.; Chabanel, M. Lifetime study on multiple organic photovoltaic materials through outdoor tests. In Proceedings of the VII Brazilian Conference of Solar Energy, Gramado, Brazil, 23–25 August 2018. [Google Scholar]

- Bristow, N.; Kettle, J. Outdoor performance of organic photovoltaics: Diurnal analysis, dependence on temperature, irradiance, and degradation. J. Renew. Sustain. Energy 2015, 7, 013111. [Google Scholar] [CrossRef]

- Chief, M.; Boyer, K.; Simmons-Potter, K. In-situ testing of organic photovoltaic (OPV) modules to examine modes of degradation in an arid-hot climate. In Proceedings of the SPIE Organic Photonics + Electronics, Online Only, CA, USA, 24–28 August 2020. [Google Scholar] [CrossRef]

- Soares, G.A.; David, T.W.; Anizelli, H.; Miranda, B.; Rodrigues, J.; Lopes, P.; Martins, J.; Cunha, T.; Vilaça, R.; Kettle, J.; et al. Outdoor performance of organic photovoltaics at two different locations: A comparison of degradation and the effect of condensation. J. Renew. Sustain. Energy 2020, 12, 063502. [Google Scholar] [CrossRef]

- Elumalai, N.K.; Uddin, A. Open circuit voltage of organic solar cells: An in-depth review. Energy Environ. Sci. 2016, 9, 391–410. [Google Scholar] [CrossRef]

- Riedel, I.; Parisi, J.; Dyakonov, V.; Lutsen, L.; Vanderzande, D.; Hummelen, J.C. Effect of temperature and illumination on the electrical characteristics of polymer-fullerene bulk-heterojunction solar cells. Adv. Funct. Mater. 2004, 14, 38–44. [Google Scholar] [CrossRef]

- Green, M.; Dunlop, E.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Hao, X. Solar cell efficiency tables (version 57). Prog. Photovolt. Res. Appl. 2021, 29, 3–15. [Google Scholar] [CrossRef]

- Riede, M.; Spoltore, D.; Leo, K. Organic Solar Cells—The Path to Commercial Success. Adv. Energy Mater. 2021, 11, 2002653. [Google Scholar] [CrossRef]

- Mateker, W.R.; McGehee, M.D. Progress in Understanding Degradation Mechanisms and Improving Stability in Organic Photovoltaics. Adv. Mater. 2017, 29, 1603940. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Zhang, S.; Wang, J.; Xu, Y.; Hou, J. Recent advances in non-fullerene organic solar cells: From lab to fab. Chem. Commun. 2020, 56, 14337–14352. [Google Scholar] [CrossRef]

| Nominal Power | 115 Wp |

|---|---|

| Tolerance | 10% |

| Voc | 25 V |

| Vmpp | 19.3 V |

| Isc | 8 × 1.0 A |

| Impp | 8 × 0.7 A |

| Max system voltage | 120 V |

| Temperature coefficient Voc | −0.19%/K |

| Temperature coefficient Isc | +0.08%/K |

| Temperature coefficient Pmax | +0.02%/K |

| STC cell efficiency | 3.3% |

| OPV1 | OPV2 | OPV4 | OPV5 | OPV6 | OPV7 | ALL | |

|---|---|---|---|---|---|---|---|

| Daily average PCE (%) (6:00–18:00) | 1.53 | 2.08 | 1.87 | 1.69 | 2.13 | 1.49 | 1.82 |

| Morning average PCE (%) (6:00–10:00) | 1.93 | 2.04 | 1.85 | 2.00 | 2.07 | 1.86 | 1.96 |

| Midday average PCE (%) (10:00–14:00) | 1.52 | 2.29 | 2.03 | 1.73 | 2.51 | 1.45 | 1.95 |

| Afternoon average PCE (%) (14:00–18:00) | 1.24 | 1.89 | 1.73 | 1.42 | 1.80 | 1.25 | 1.57 |

| Daily average FF (%) | 36.7 | 43.3 | 40.4 | 41.3 | 40.5 | 33.1 | 0.39 |

| PCEn,initial–PCEn,final (%) | 50.6 | 31.5 | -- | 33.1 | 33.4 | 44.3 | 38.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waller, R.; Kacira, M.; Magadley, E.; Teitel, M.; Yehia, I. Evaluating the Performance of Flexible, Semi-Transparent Large-Area Organic Photovoltaic Arrays Deployed on a Greenhouse. AgriEngineering 2022, 4, 969-992. https://doi.org/10.3390/agriengineering4040062

Waller R, Kacira M, Magadley E, Teitel M, Yehia I. Evaluating the Performance of Flexible, Semi-Transparent Large-Area Organic Photovoltaic Arrays Deployed on a Greenhouse. AgriEngineering. 2022; 4(4):969-992. https://doi.org/10.3390/agriengineering4040062

Chicago/Turabian StyleWaller, Rebekah, Murat Kacira, Esther Magadley, Meir Teitel, and Ibrahim Yehia. 2022. "Evaluating the Performance of Flexible, Semi-Transparent Large-Area Organic Photovoltaic Arrays Deployed on a Greenhouse" AgriEngineering 4, no. 4: 969-992. https://doi.org/10.3390/agriengineering4040062

APA StyleWaller, R., Kacira, M., Magadley, E., Teitel, M., & Yehia, I. (2022). Evaluating the Performance of Flexible, Semi-Transparent Large-Area Organic Photovoltaic Arrays Deployed on a Greenhouse. AgriEngineering, 4(4), 969-992. https://doi.org/10.3390/agriengineering4040062