An Apparatus and Method for Evaluating Particle-Size Distribution of Small Grain Crop Residues

Abstract

1. Introduction

2. Materials and Methods

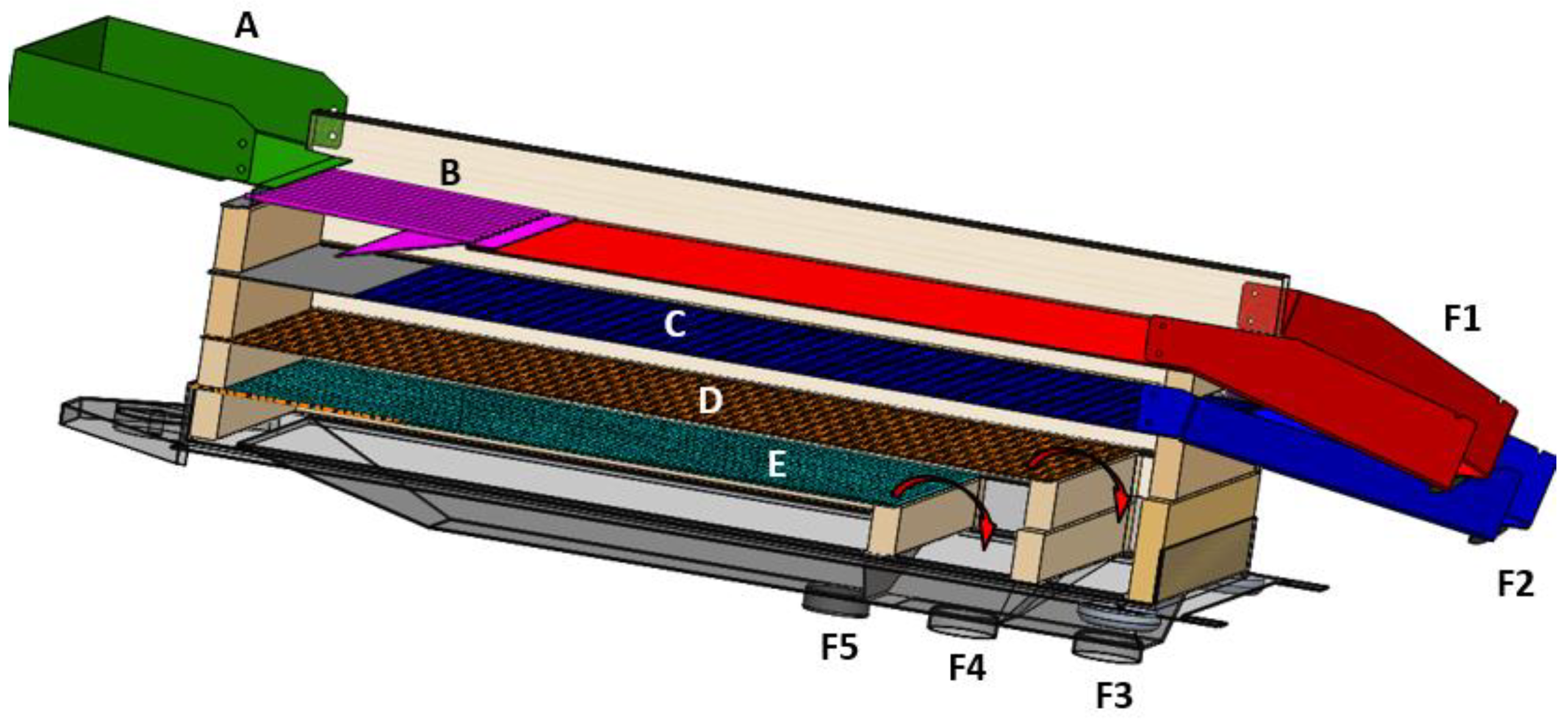

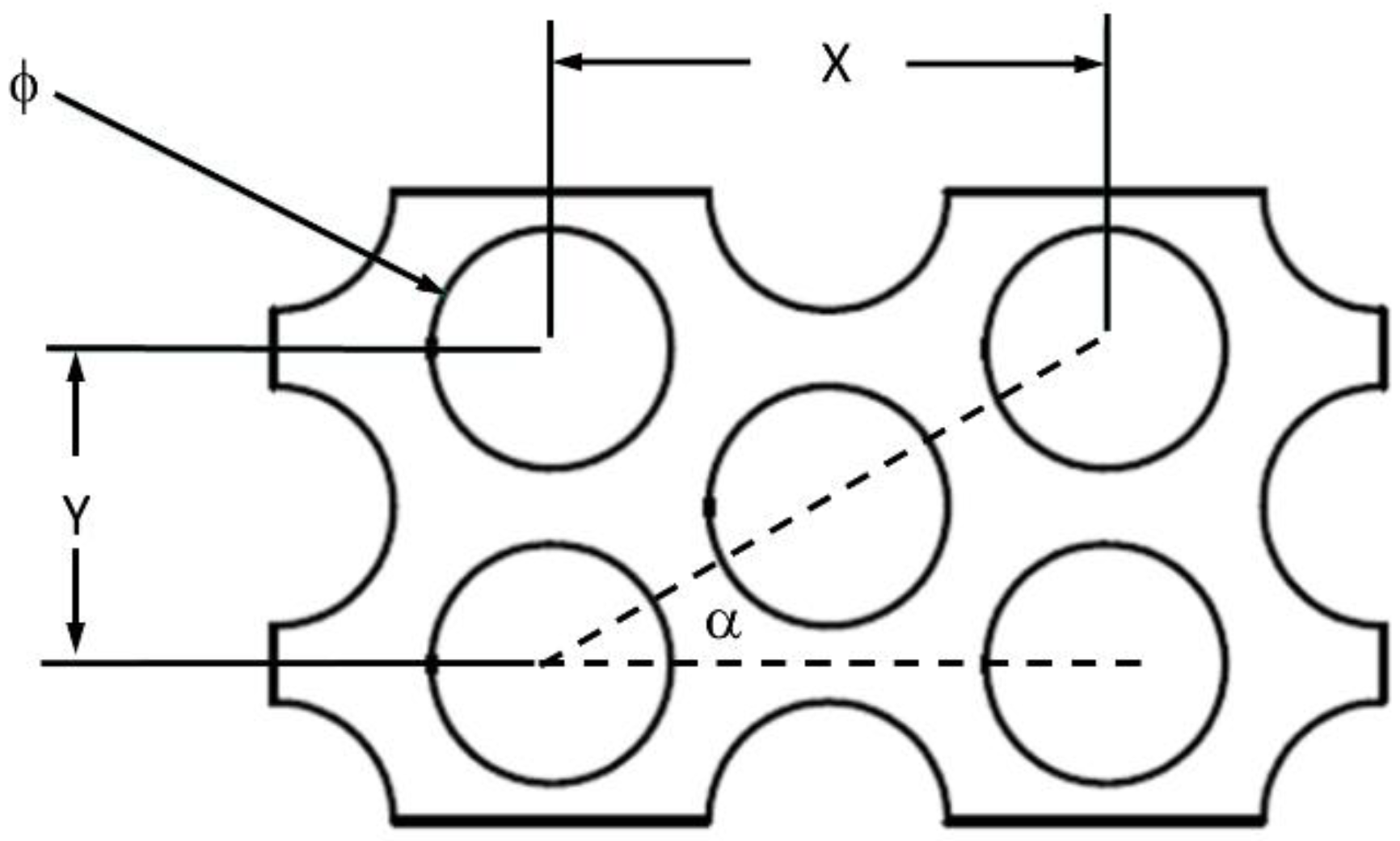

2.1. Apparatus Development

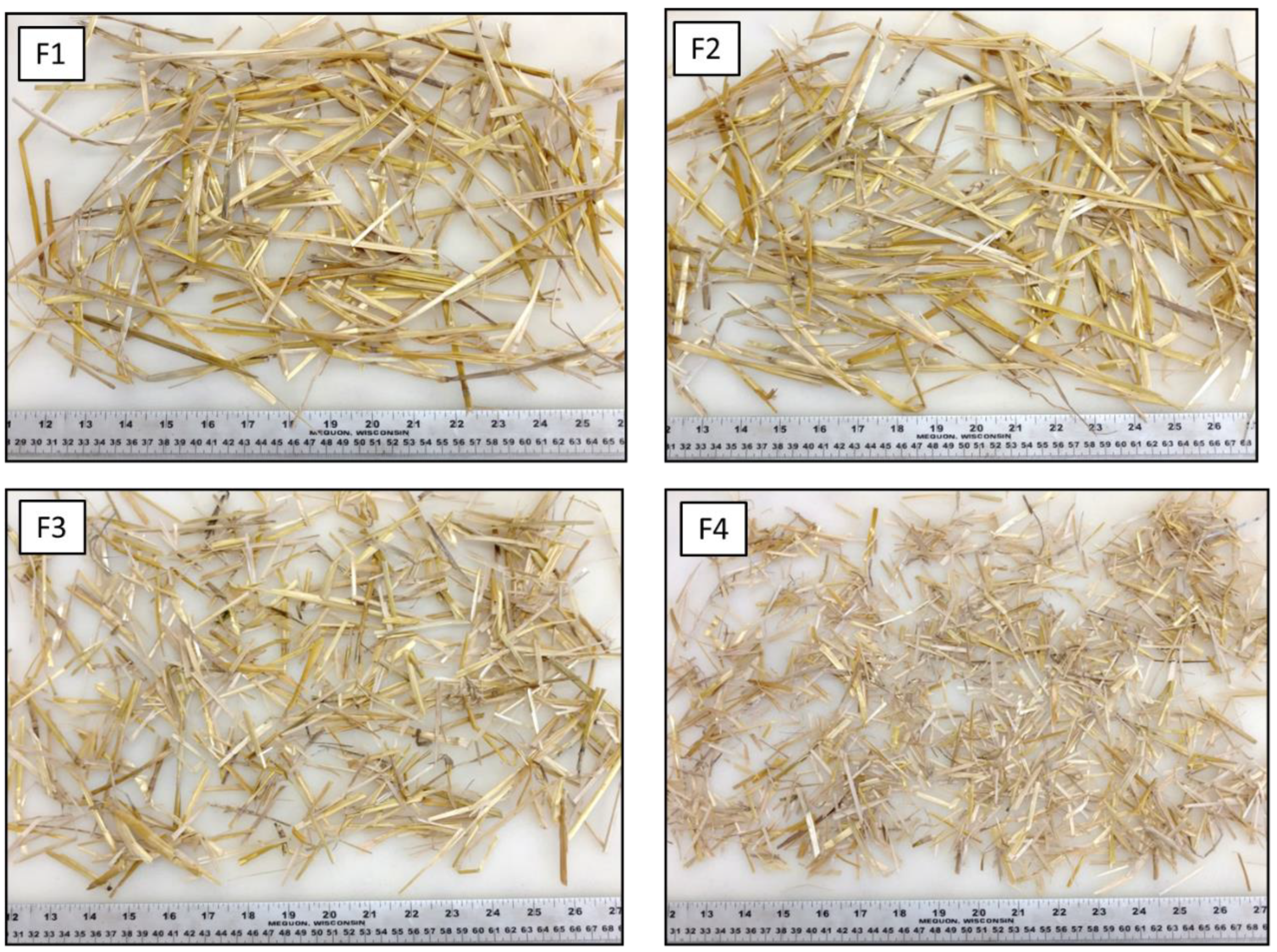

2.2. Experiments Conducted

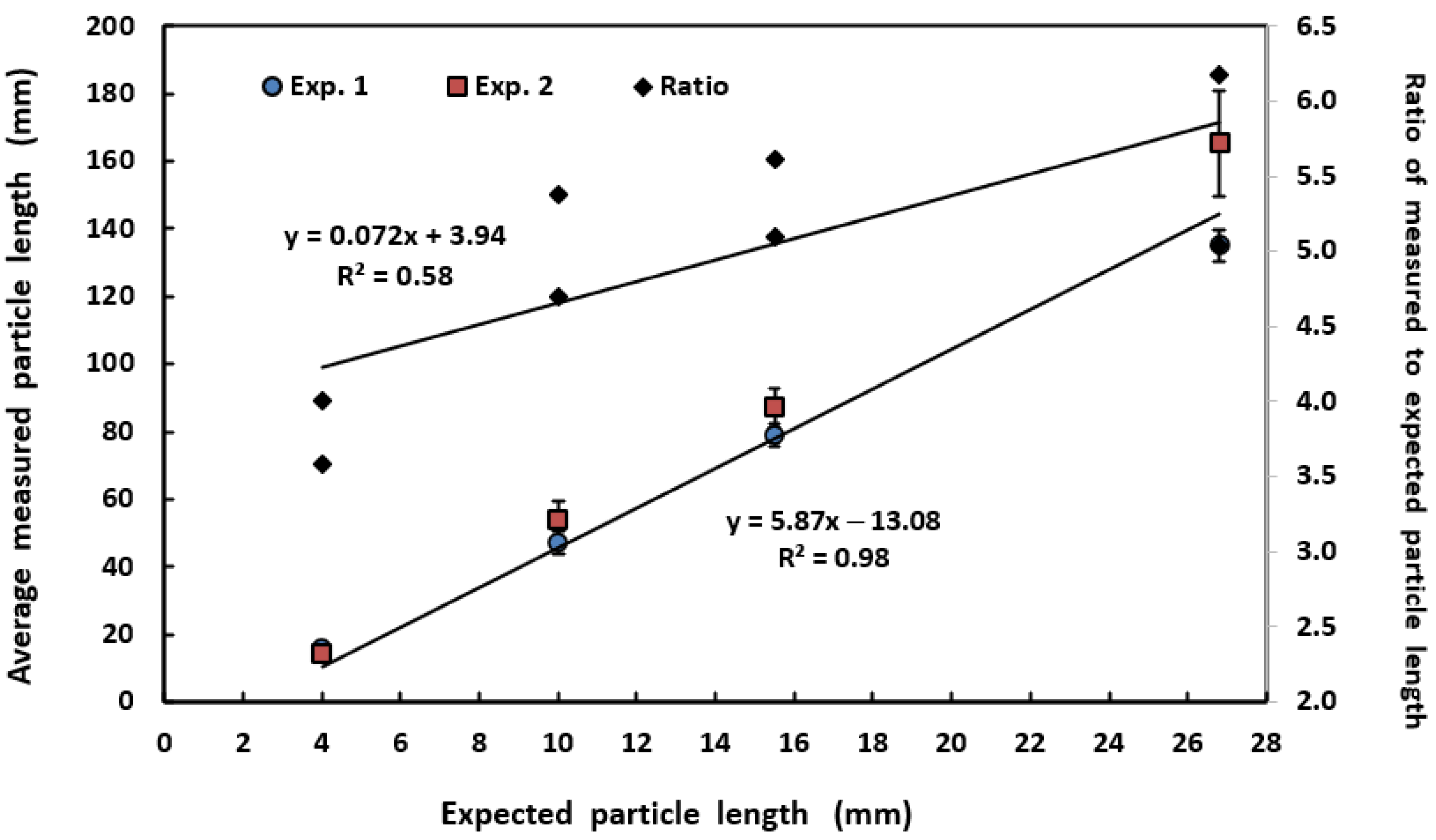

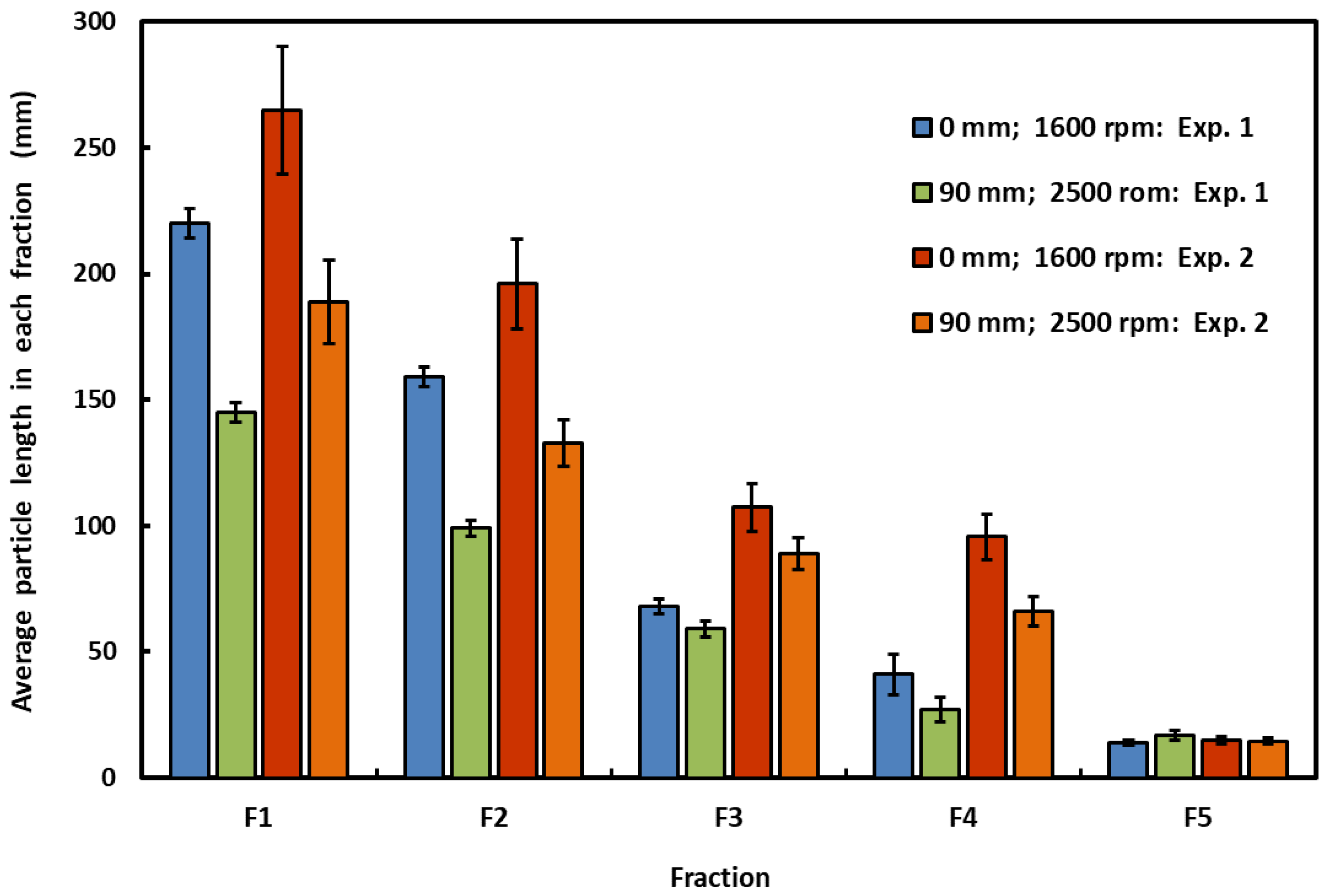

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hobbs, P.R. Conservation agriculture: What is it and why is it important for future sustainable food production? J. Agric. Sci. 2007, 14, 127–137. [Google Scholar] [CrossRef]

- Derpsh, R.; Fridrich, T.; Kassam, A.; Hongwen, L. Current status of adoption of no-till farming in the world and some of its main benefits. Int. J. Agric. Biol. Eng. 2010, 3, 1–26. [Google Scholar]

- Henriksen, T.M.; Breland, T.A. Carbon mineralization, fungal and bacterial growth, and enzyme activities as affected by contact between crop residues and soil. Biol. Fertil. Soils 2002, 35, 41–48. [Google Scholar] [CrossRef]

- Giacomini, S.J.; Recous, S.; Mary, B.; Aita, C. Simulating the effects of N availability, straw particle size and location in soil on C and N mineralization. Plant Soil 2007, 301, 289–301. [Google Scholar] [CrossRef]

- Travis, A.J.; Murison, S.D.; Hirst, D.J.; Walker, K.C.; Chesson, A. Comparison of the anatomy and degradability of straw from varieties of wheat and barley that differ in susceptibility to lodging. J. Agric. Sci. 1996, 127, 1–10. [Google Scholar] [CrossRef]

- Zheng, M.; Chen, J.; Shi, Y.; Li, Y.; Yin, Y.; Yang, D.; Luo, Y.; Pang, D.; Xu, X.; Li, W.; et al. Manipulation of lignin metabolism by plant densities and its relationship with lodging resistance in wheat. Sci. Rep. 2017, 7, 41805. [Google Scholar] [CrossRef]

- Kumar, K.; Goh, K.M. Crop residues and management practices: Effects on soil quality, soil nitrogen dynamics, crop yield, and nitrogen recovery. Adv. Agron. 1999, 68, 197–319. [Google Scholar]

- Flower, K.C.; Ward, P.R.; Passaris, N.; Cordingley, N. Uneven crop residue distribution influences soil chemical composition and crop yield under long-term no-tillage. Soil Tillage Res. 2022, 223, 105498. [Google Scholar] [CrossRef]

- Jokiniemi, H.T. Effect of cereal stubble management on the combine harvester performance and energy requirements. Agric. Eng. Int. CIGR J. 2015, 17, 64–72. [Google Scholar]

- Douglas, C.L.; Rasmussen, P.E.; Allmaras, R.R. Cutting height, yield level, and equipment modification effects on residue distribution by combines. Trans. ASAE 1989, 32, 1258–1262. [Google Scholar] [CrossRef]

- Carter, M.R. A review of conservation tillage strategies for humid temperate regions. Soil Till. Res. 1994, 31, 289–301. [Google Scholar] [CrossRef]

- Chen, Y.; Tessier, S.; Irvine, B. Drill and crop performances as affected by different drill configurations for no-till seeding. Soil Till. Res. 2003, 77, 147–155. [Google Scholar] [CrossRef]

- Ruan, H.; Ahuja, L.R.; Green, T.R.; Benjamin, J.G. Residue cover and surface-sealing effects on infiltration: Numerical simulations for field applications. Soil Sci. Soc. Am. J. 2001, 65, 853–861. [Google Scholar] [CrossRef]

- Siemens, M.C.; Wilkins, D.E. Effect of residue management methods on no-till drill performance. Appl. Eng. Agric. 2006, 22, 51–60. [Google Scholar] [CrossRef]

- ASABE. S424.1: Method of Determining and Expressing Particle Size of Chopped Forage Materials by Screening; ASABE: St. Joseph, MI, USA, 2017. [Google Scholar]

- Schwarz, M.; von Chappuis, A. DLG evaluation scheme for the work quality of combine straw choppers. Agric. Eng. 2007, 62, 26–27. [Google Scholar]

- Vosshenrich, H.-H. Straw distribution and chop quality in the field. Agric. Eng. 1999, 54, 306–308. [Google Scholar] [CrossRef]

- DLG Prüfbericht 5445F: Häckselqualität John Deere 9880i STS. DLG Testzentrum, DLG Verlag. 2005. Available online: http://www.dlg-test.de/pbdocs/5445F.pdf (accessed on 14 October 2022).

- Miu, P. Combine Harvesters: Theory, Modeling, and Design; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Savoie, P.; Audy-Dubé, M.A.; Pilon, G.; Morissette, R. Chopped forage particle-size analysis in one, two, and three dimensions. Trans. ASABE 2014, 57, 1549–1555. [Google Scholar]

- Yang, Y. Image and Sieve Analysis of Biomass Particle Sizes and Separation after Size Reduction. Master’s Thesis, University of Tennessee, Knoxville, TN, USA, 2007. [Google Scholar]

- Belal, E.; Okinda, C.; Qishuo, D.; Talha, Z. Mass-based image analysis for evaluating straw cover under high-residue farming conditions in rice–wheat cropping system. Agric. Res. 2017, 6, 359–367. [Google Scholar] [CrossRef]

- Silva, A.G.; Lisboa, I.P.; Cherubin, M.R.; Cerri, C.E. How much sugarcane straw is needed for covering the soil? BioEnergy Res. 2019, 12, 858–864. [Google Scholar] [CrossRef]

- Kumhála, F.; Kvíz, Z.; Mašek, J.; Procházka, P. The measurement of plant residues distribution quality after harvest by conventional and axial combine harvesters. Plant Soil Environ. 2005, 51, 249–254. [Google Scholar] [CrossRef]

- Paulsen, D. Sorting out screening performance: Consider particle characteristics when selecting screening media and machine configuration. Chem. Eng. 2004, 111, 33–37. [Google Scholar]

- Igathinathane, C.; Pordesimo, L.O.; Columbus, E.P.; Batchelor, W.D.; Sokhansanj, S. Sieveless particle size distribution analysis of particulate materials through computer vision. Comput. Electron. Agric. 2009, 66, 147–158. [Google Scholar] [CrossRef]

- Finner, M.F.; Hardzinski, J.E.; Pagel, L.L. Measuring particle length of chopped forage. In Proceedings of the Int’l. Grain & Forage Harvesting Conference, Ames, IA, USA, 25–29 September 1977; ASABE: St. Joseph, MI, USA, 1978; pp. 265–269. [Google Scholar]

- Gale, G.E.; O’Dogherty, M.J. An apparatus for the assessment of the length distribution of chopped forage. J. Agric. Eng. Res. 1982, 27, 35–43. [Google Scholar] [CrossRef]

- Nigon, C.M. Methods for Analyzing the Performance of Combine Harvester Residue Management Systems. Master’s Thesis, University of Wisconsin, Madison, WI, USA, 2016. [Google Scholar]

- ASABE. S343.4: Terminology for Combines and Grain Harvesting; ASABE: St. Joseph, MI, 2017. [Google Scholar]

- Kenney, K.L.; Wright, C.T.; Hoskinson, R.L.; Hess, J.R.; Muth, D.J. Engineering High-Fidelity Residue Separations for Selective Harvest; ASABE Technical Paper No. 066171; ASABE: St. Joseph, MI, USA, 2006. [Google Scholar]

- ASABE. S352.2: Moisture Measurement—Unground Grain and Seeds; ASABE: St. Joseph, MI, USA, 2017. [Google Scholar]

- ASABE. S358.3: Moisture Measurement—Forages; ASABE: St. Joseph, MI, USA, 2017. [Google Scholar]

- Lundin, G. Chop length capability and wearing qualities for two types of straw chopper knives at combine harvesting. J. Agric. Mach. Sci. 2008, 4, 99–103. [Google Scholar]

- El-Hanfy, E.H.; Shalby, S.A. Performance evaluation and modification of the Japanese combine chopping unit. MISR J. Agric. Eng. 2009, 26, 1021–1035. [Google Scholar] [CrossRef]

- Stubbe, A.K.M. Development of Systems to Spatially Quantify Grain Flow from the Threshing and Separating Systems of a Combine Harvester. Master’s Thesis, University of Wisconsin, Madison, WI, USA, 2015. [Google Scholar]

- Kattenstroth, R.; Harms, H.H.; Frerichs, L. Influence of the straw alignment on the cutting quality of a combine’s straw chopper. Landtechnik 2012, 67, 244–246. [Google Scholar]

- ISO 9276-1:1998(E); Representation of Results of Particle Size Analyses—Part I: Graphical Representation. International Standards Organization: Geneva, Switzerland, 2008.

| Screen | Screen Length [b] | Hole Diameter | Hole Location | Screen Thickness | Total Screen Area | Screen Open Area | |

|---|---|---|---|---|---|---|---|

| f [c] | X [c] | Y [c] | |||||

| Position [a] | (mm) | (mm) | (mm) | (mm) | (mm) | (m2) | (%) |

| C | 1000 | 19.0 | 44 | 25 | 5.0 | 0.55 | 51 |

| D | 990 | 12.7 | 30 | 17 | 2.7 | 0.54 | 48 |

| E | 810 | 7.9 | 16 | 9 | 1.9 | 0.45 | 63 |

| Experiment Number | Stationary Knife Engagement [a] | Residue Chopper Speed | Ground Speed | Replicate Samples per Experimental Condition | Moisture Content | |

|---|---|---|---|---|---|---|

| (mm) | (rpm) | (km × h−1) | (% w.b.) | |||

| Grain | Residue | |||||

| 1 [b] | 0.90 | 1600, 2500 | 3.2 | 9 | 15 | 29 |

| 2 [c] | 0.90 | 1600, 2500 | 3.2 | 3 | 14 | 24 |

| Residue Chopper Speed (rpm) | Stationary Knife Engagement [a] (mm) | Average Particle Length [b] (mm) | Proportion of Total Sample Mass [d] (%) | |||

|---|---|---|---|---|---|---|

| Straw & Chaff [c] | Straw [c] | |||||

| <50 mm | 50–125 mm | >125 mm | ||||

| 1600 | 0 | 84a | 96ab | 23c | 35c | 42a |

| 1600 | 90 | 69b | 87ab | 26bc | 40b | 34b |

| 2500 | 0 | 72b | 101a | 27b | 39b | 34b |

| 2500 | 90 | 55c | 80b | 32a | 44a | 24c |

| SEM [e] | 1.5 | 4.0 | 0.7 | 1.0 | 0.6 | |

| p-value | 0.525 | 0.007 | 0.235 | 0.390 | 0.707 | |

| Averaged by knife engagement | ||||||

| 0 | 77a | 98a | 24b | 38b | 38a | |

| 90 | 64b | 84b | 29a | 42a | 29b | |

| SEM [e] | 1.04 | 2.9 | 0.5 | 0.7 | 0.4 | |

| p-value | <0.001 | 0.001 | <0.001 | <0.001 | <0.001 | |

| Averaged by chopper speed | ||||||

| 1600 | 78a | 92a | 25b | 37b | 38a | |

| 2500 | 62b | 91a | 29a | 42a | 29b | |

| SEM [e] | 1.04 | 2.9 | 0.5 | 0.7 | 0.4 | |

| p-value | <0.001 | 0.801 | <0.001 | <0.001 | <0.001 | |

| Residue | Stationary | Average Particle Length [b] (mm) | Proportion of Total Sample Mass [d] (%) | |||

|---|---|---|---|---|---|---|

| Chopper | Knife | |||||

| Speed | Engagement [a] | Straw & Chaff [c] | Straw [c] | |||

| (rpm) | (mm) | <50 mm | 50–125 mm | >125 mm | ||

| [e] | [e] | 133a | 249a | 34b | 7b | 59a |

| 1600 | 0 | 77b | 233a | 40b | 9b | 52a |

| 2500 | 90 | 42c | 110b | 54a | 28a | 18b |

| SEM [f] | 5.7 | 6.6 | 1.2 | 2.2 | 2.9 | |

| p-value | 0.003 | 0.001 | 0.003 | 0.012 | 0.004 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nigon, C.M.; Shinners, K.J.; Friede, J.C. An Apparatus and Method for Evaluating Particle-Size Distribution of Small Grain Crop Residues. AgriEngineering 2022, 4, 1016-1029. https://doi.org/10.3390/agriengineering4040064

Nigon CM, Shinners KJ, Friede JC. An Apparatus and Method for Evaluating Particle-Size Distribution of Small Grain Crop Residues. AgriEngineering. 2022; 4(4):1016-1029. https://doi.org/10.3390/agriengineering4040064

Chicago/Turabian StyleNigon, Cyrus M., Kevin J. Shinners, and Joshua C. Friede. 2022. "An Apparatus and Method for Evaluating Particle-Size Distribution of Small Grain Crop Residues" AgriEngineering 4, no. 4: 1016-1029. https://doi.org/10.3390/agriengineering4040064

APA StyleNigon, C. M., Shinners, K. J., & Friede, J. C. (2022). An Apparatus and Method for Evaluating Particle-Size Distribution of Small Grain Crop Residues. AgriEngineering, 4(4), 1016-1029. https://doi.org/10.3390/agriengineering4040064