Performance Analysis of Different Borehole Heat Exchanger Configurations: A Case Study in NW Italy

Abstract

Highlights

- A good knowledge of the underground parameters and of the aquifer characteristics are essential in the design of borehole heat exchangers as part of a shallow geothermal plant integrated in a district heating and cooling grid.

- Borehole heat exchangers with a coaxial configuration outperform double U pipes in terms of energy efficiency, especially during intermittent operation modes of the geothermal heating system.

- Proper design of a shallow geothermal plant can potentially reduce the cost of drilling boreholes and make the installation easier on site, also improving the sustainability of urban environments.

- A geothermal-based district heating and cooling grid can be combined with other renewable energies, achieving the best thermal energy performance, improving smart energy systems, and the decarbonisation of the building sector.

Abstract

1. Introduction

2. Geological Setting

- “Marne di Sant’Agata Fossili” (Tortonian/Lower Messinian), bioturbated clayey to calcareous foraminifers-rich marl sediments, showing a gradual transition toward the top into a rhythmic alternation of marls and organic-rich, extremely laminated mudstones (VGS3, in Figure 1);

- “Membro di Nizza Monferrato” (Messinian), belonging to the “Gessoso-Solfifera” geological unit mainly composed of clays, silts, and subordinate sandstones with a variable colour including dark yellow, grey, cream-white, and purple, in which a primary laminated microcrystalline gypsum bed is recognizable (CCS, in Figure 1);

- “Quaternary succession” (Holocene–present), consisting of sandy-gravelly and silty-sandy fluvial deposits which overlie all the stratigraphic succession; it is present in the shallower 30 m (MEA3 and CMT3, in Figure 1).

3. Materials and Methods

- 2U150 m: polyethylene double U pipe with a depth of 150 m, which corresponds to the pilot borehole (borehole diameter: 0.152 m; pipe diameter: 0.032 m; pipe wall thickness: 0.0029 m);

- 2U36 m: polyethylene double U pipe with a depth of 36 m, in light of the base of the aquifer highlighted by the pilot drilling (borehole diameter: 0.152 m; pipe diameter: 0.032 m; pipe wall thickness; 0.0029 m);

- Coax 36 m: coaxial configuration with stainless steel outer casing (outer diameter: 0.061 m; wall thickness: 0.008 m) and polyethylene inner pipe (outer diameter: 0.025 m; wall thickness: 0.0023 m) with a depth of 36 m.

3.1. Field Tests

- Tf(t) is the average fluid temperature (Tin and Tout) depending on the test time, expressed in °C.

- q is the injected power in the unit of time and depth, expressed in W/m and is equal to Q/H (H is the drilling depth), in which Q is the injected power in the unit of time, expressed in W.

- λ is the ground thermal conductivity, expressed in W/m/K.

- γ is the Eulero constant, equal to 0.5772.

- α is the thermal diffusivity, expressed in m2/s.

- t is the test time, expressed in s.

- r is the borehole radius, expressed in m.

- Rb is the borehole thermal resistance, expressed in K/(W/m).

- Tg is the undisturbed temperature, expressed in °C.

3.2. Numerical Simulations

- Tf is the average fluid temperature (Tin and Tout) depending on the test time, expressed in °C.

- q is the injected power in the unit of time and depth, expressed in W/m and is equal to Q/H (H is the drilling depth), in which Q is the injected power in the unit of time, expressed in W.

- Tb is the borehole wall temperature expressed in °C.

- Rb is the borehole thermal resistance, expressed in m K W−1.

4. Results

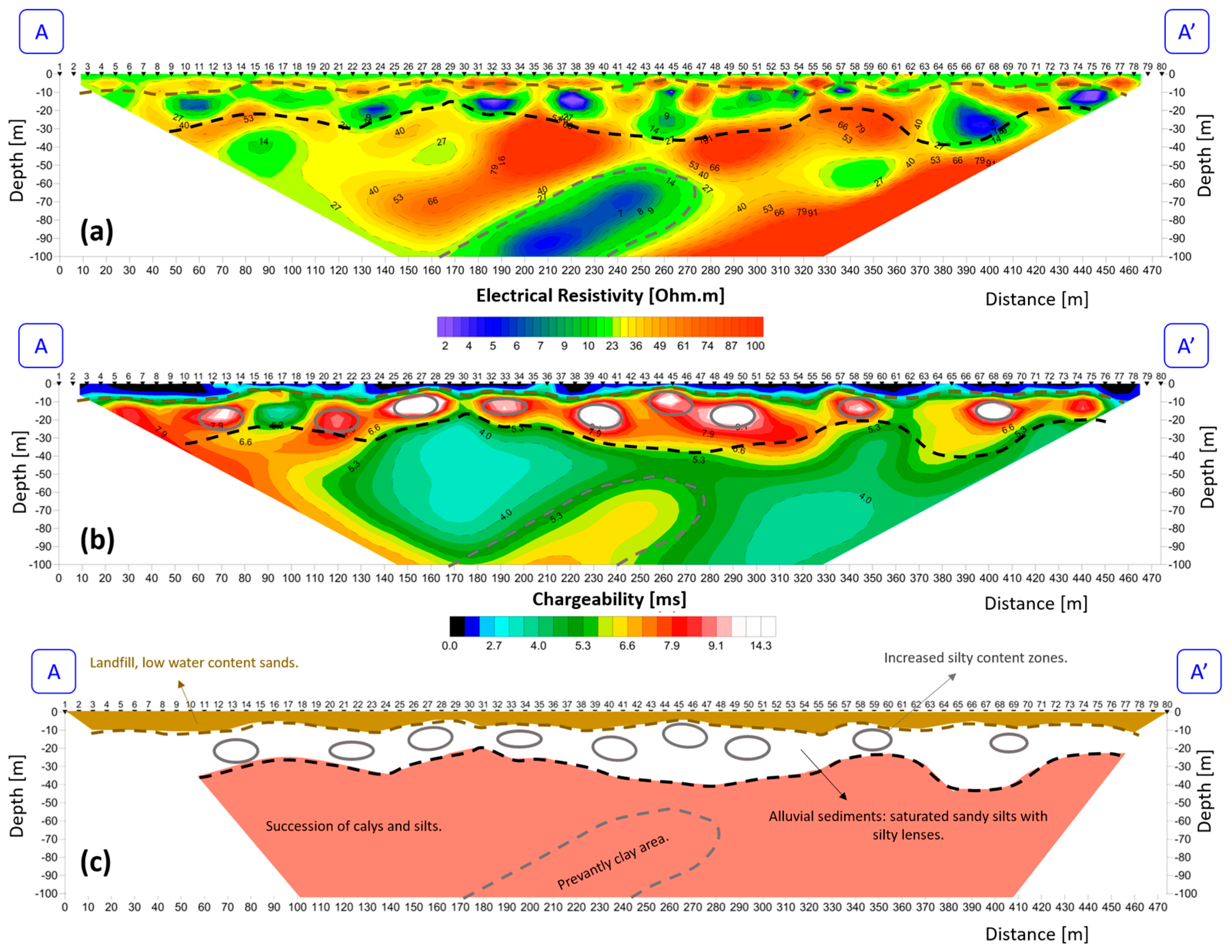

4.1. Thermo-Geological Conceptual Model

4.2. Comparison of Different BHE Configurations

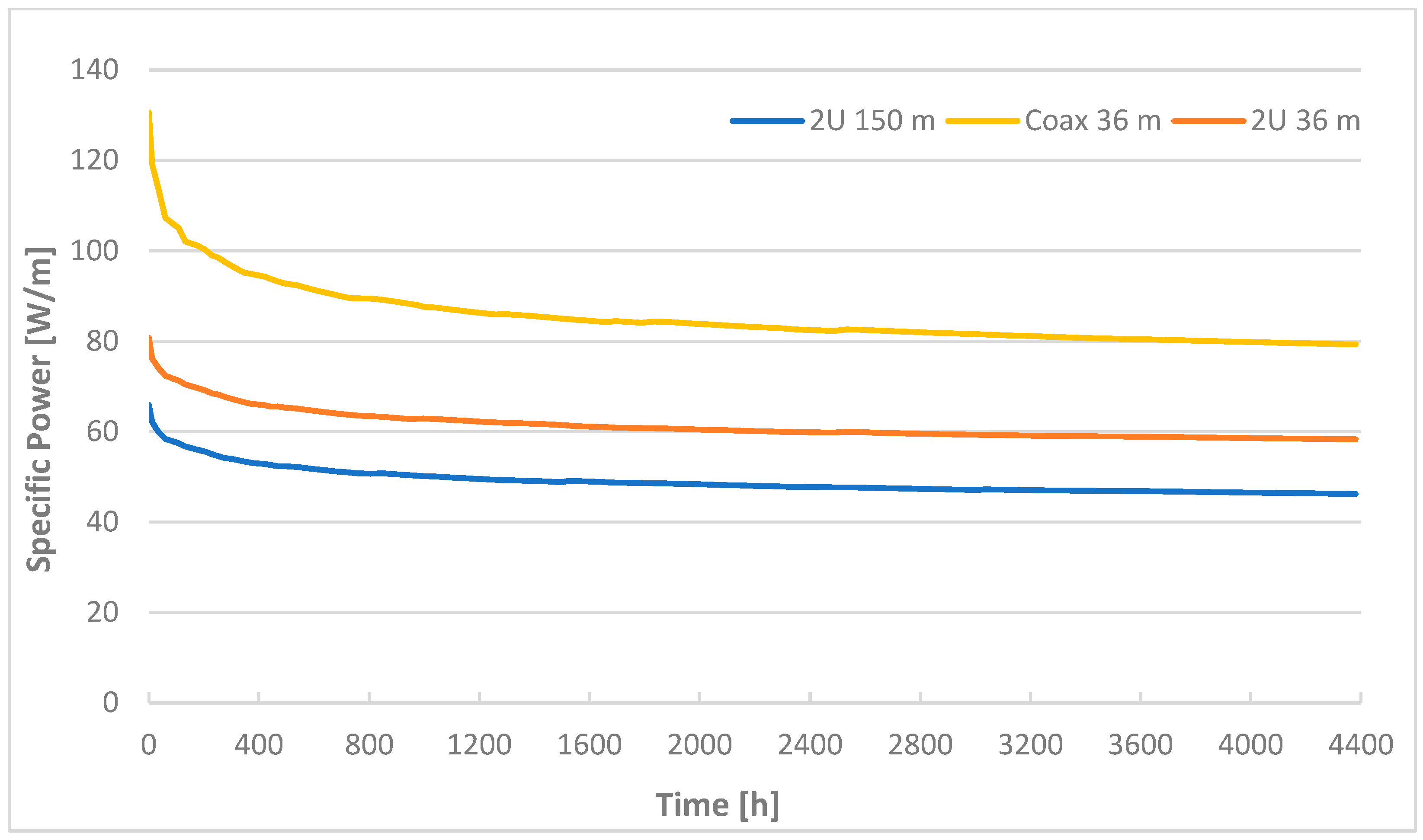

- With the same BHE geometry and material, the 2U 36 m BHE allowed for better linear thermal power extraction (56.03 W/m) compared to the 2U 150 m, which recorded a value of 42.47 W/m.

- Using the coaxial steel geometry (Coax 36 m), the linear thermal power that can be extracted increases to 74.51 W/m.

- The specific thermal power at the end of the first six months of simulation shows very similar values (2U 150 m = 46.24 W/m; 2U 36 m = 58.29 W/m; Coax 36 m = 79.32 W/m) to those recorded at the end of the five years of system operation (2U 150 m = 42.46 W/m; 2U 36 m = 55.51 W/m; Coax 36 m = 74.51 W/m). Therefore, thermal specific power decreases quite slowly after the first six months (about 5% for all the BHEs), then shows a thermal stabilization in the next few months; these results thus confirm how these data can also be used to describe the thermal performance of each BHE in long-term analysis.

5. Discussion

- Knowledge of the right geological, hydrogeological, and thermo-physical properties of the ground is of paramount importance in correctly evaluating the thermal efficiency of BHEs.

- The specific thermal power of each BHEs records similar values to those displayed at the end of the five-year simulation already starting from the fifth month, ensuring the long-term stability of the system.

- Maintaining the same geometry and material (double U pipes in polyethylene), the pipe at −36 m showed a higher specific thermal power than that at −150 m. This confirms how at −36 m the same BHE configuration fully exploits the only aquifer present in the subsurface; as shown in Figure 4, the most favourable thermal conditions indeed occur between −9 and −36 m where the hydrodynamic characteristics of the groundwater can significantly increase the thermal efficiency. This helps in understanding how the 2U 36m BHE can be the best solution than the deeper one with the same geometry, strongly reducing drilling costs.

- The higher specific power of 80 [W/m] for the coaxial configuration differs from values found in the literature for which the highest value recorded is equal to 42.2 W/m [46], which is, however, based only on the thermo-technical characteristics of the BHE without considering the hydrogeological and geological parameters that can potentially contribute to the heat power also exceeding 80 W/m in some scenarios.

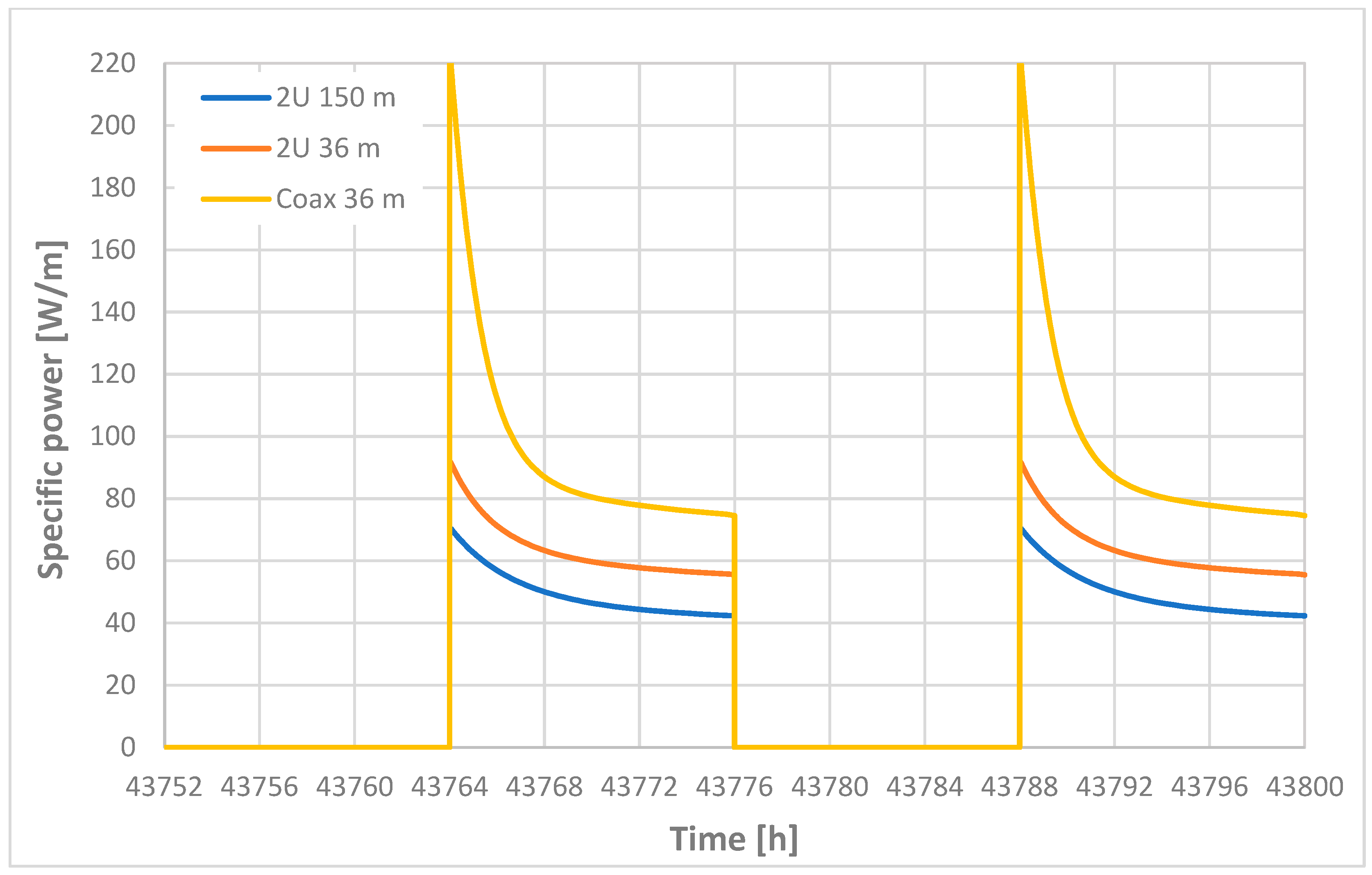

- The coaxial geometry proved to be not only the most efficient among the scenarios in terms of thermal power extracted but also the most thermally stable, as evidenced during intermittent operating modes with daily-on and -off cycles (12 h each); it was also easier to install on site.

6. Conclusions

- Geological, hydro-geological, and thermo-physical models should be validated through a back-analysis of the ground response test, especially for medium-large systems.

- Numerical simulations help in selecting the best heat exchanger geometry, based not only on the design or on the duty cycle but also on the thermal efficiency of the ground in terms of the amount of heat which can be extracted from it.

- Where there are lithologies with an overall thermal conductivity from medium to high, steel coaxial pipes usually perform better than conventional double U BHEs.

- The coaxial configuration outperforms the double U pipes, especially during intermittent operation modes.

- Using the coaxial loop design could potentially reduce the cost of drilling boreholes and make the installation easier on site, as the effective diameter would be smaller than a comparable double U BHE.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BHE | borehole heat exchanger |

| DH | district heating |

| DHC | district heating and cooling |

| GSHP | ground source heat pump |

| 2U BHE | double u borehole heat exchanger |

| Coax BHE | coaxial borehole heat exchanger |

References

- Sgaravatti, G.; Tagliapietra, S.; Trasi, C.; Zachmann, G. National Fiscal Policy Responses to the Energy Crisis. Bruegel Datasets 2023. Available online: https://www.bruegel.org/dataset/national-policies-shield-consumers-rising-energy-prices (accessed on 18 March 2025).

- Lee, H.; Calvin, K.; Dasgupta, D.; Krinner, G.; Mukherji, A.; Thorne, P.; Trisos, C.; Romero, J.; Aldunce, P.; Barrett, K.; et al. Climate Change 2023: Synthesis Report. Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Lee, H., Romero, J., Eds.; IPCC: Geneva, Switzerland, 2023; pp. 35–115. [Google Scholar] [CrossRef]

- Moreno, D.; Nielsen, S.; Sorknæs, P.; Lund, H.; Thellufsen, J.Z.; Mathiesen, B.V. Exploring the location and use of baseload district heating supply. What can current heat sources tell us about future opportunities? Energy 2024, 288, 129642. [Google Scholar] [CrossRef]

- Chicco, J.M.; Antonijevic, D.; Bloemendal, M.; Cecinato, F.; Goetzl, G.; Hajto, M.; Hartog, N.; Mandrone, G.; Vacha, D.; Vardon, P.J. Improving the Efficiency of District Heating and Cooling Using a Geothermal Technology: Underground Thermal Energy Storage (UTES). In New Metropolitan Perspectives NMP 2022; Lecture Notes in Networks and Systems; Calabrò, F., Della Spina, L., Piñeira Mantiñán, M.J., Eds.; Springer: Cham, Switzerland, 2022; Volume 482. [Google Scholar] [CrossRef]

- Kavvadias, K.; Jiménez-Navarro, J.P.; Thomassen, G. Decarbonising the EU Heating Sector—Integration of the Power and Heating Sector; EUR 29772 EN; JRC114758; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar] [CrossRef]

- Goetzl, G.; Chicco, J.; Schifflechner, C.; Figueira, J.; Tsironis, G.; Zajacs, A. Pathways to better integrate geothermal energy at its full technological scale in European heating and cooling networks. Eur. Geol. 2022, 1–7. [Google Scholar] [CrossRef]

- Boesten, S.; Ivens, W.I.; Dekker, S.C.; Eijdems, H. 5th generation district heating and cooling systems as a solution for renewable urban thermal energy supply. Adv. Geosci. 2019, 49, 129–136. [Google Scholar] [CrossRef]

- Dumas, P. Policy and Regulatory Aspects of Geothermal Energy: A European Perspective. In Geothermal Energy and Society; Lecture Notes in Energy; Manzella, A., Allansdottir, A., Pellizzone, A., Eds.; Springer: Cham, Switzerland, 2019; Volume 67. [Google Scholar] [CrossRef]

- Tsagarakis, K.P.; Efthymiou, L.; Michopoulos, A.; Mavragani, A.; Anđelković, A.S.; Antolini, F.; Bacic, M.; Bajare, D.; Baralis, M.; Bogusz, W.; et al. A review of the legal framework in shallow geothermal energy in selected European countries: Need for guidelines. Renew. Energy 2020, 147, 2556–2571. [Google Scholar] [CrossRef]

- Kupfernagel, J.H.; Hesse, J.C.; Schedel, M.; Welsch, B.; Anbergen, H.; Müller, L.; Sass, I. Impact of operational temperature changes and freeze–thaw cycles on the hydraulic conductivity of borehole heat exchangers. Geotherm. Energy 2021, 9, 24. [Google Scholar] [CrossRef] [PubMed]

- Walch, A.; Mohajeri, N.; Gudmundsson, A.; Scartezzini, J.-L. Quantifying the technical geothermal potential from shallow borehole heat exchangers at regional scale. Renew. Energy 2021, 165, 369–380. [Google Scholar] [CrossRef]

- Casasso, A.; Sethi, R. Efficiency of closed loop geothermal heat pumps: A sensitivity analysis. Renew. Energy 2014, 62, 737–746. [Google Scholar] [CrossRef]

- Brown, C.S.; Kolo, I.; Banks, D.; Falcone, G. Comparison of the thermal and hydraulic performance of single U-tube, double U-tube and coaxial medium to deep borehole heat exchangers. Geothermics 2024, 117, 102888. [Google Scholar] [CrossRef]

- Quaggiotto, D.; Zarrella, A.; Emmi, G.; De Carli, M.; Pockelé, L.; Vercruysse, J.; Psyk, M.; Righini, D.; Galgaro, A.; Mendrinos, D.; et al. Simulation-Based Comparison Between the Thermal Behavior of Coaxial and Double U-Tube Borehole Heat Exchangers. Energies 2019, 12, 2321. [Google Scholar] [CrossRef]

- Morchio, S.; Fossa, M.; Beier, R.A. Study on the best heat transfer rate in thermal response test experiments with coaxial and U-pipe borehole heat exchangers. Appl. Therm. Eng. 2022, 200, 117621. [Google Scholar] [CrossRef]

- Bidarmaghz, A.; Narsilio, G.; Johnston, I. Numerical Modelling of Ground Heat Exchangers with Different Ground Loop Configurations for direct Geothermal Applications. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013; pp. 3343–3346. [Google Scholar]

- Zarrella, A.; Scarpa, M.; Carli, M.D. Short time-step performances of coaxial and double U-tube borehole heat exchangers: Modeling and measurements. HVAC&R Res. 2011, 17, 959–976. [Google Scholar] [CrossRef]

- Harris, B.; Lightstone, M.F.; Reitsma, S.; Cotton, J.S. A numerical study on the intermittent operation of u-tube and coaxial borehole heat exchangers. Geothermics 2024, 121, 103030. [Google Scholar] [CrossRef]

- Wood, C.J.; Liu, H.; Riffat, S.B. Comparative performance of ‘U-tube’ and ‘coaxial’ loop designs for use with a ground source heat pump. Appl. Therm. Eng. 2012, 37, 190–195. [Google Scholar] [CrossRef]

- Wang, J. Comparative heat transfer efficiency study of coaxial and U-loop boreholes. GSTF J. Eng. Technol. 2014, 2, 1–6. [Google Scholar] [CrossRef]

- Liu, Q.; Weiland, F.; Pärisch, P.; Kracht, N.; Huang, M.; Ptak, T. Influence of site characteristics on the performance of shallow borehole heat exchanger arrays: A sensitivity analysis. Geothermics 2023, 114, 102785. [Google Scholar] [CrossRef]

- Schelenz, S.; Vienken, T.; Shao, H.; Firmbach, L.; Dietrich, P. On the importance of a coordinated site characterization for the sustainable intensive thermal use of the shallow subsurface in urban areas: A case study. Environ. Earth Sci. 2017, 76, 73. [Google Scholar] [CrossRef]

- Rossi, M.; Craig, J. A new perspective on sequence stratigraphy of syn-orogenic basins: Insights from the Tertiary Piedmont Basin (Italy) and implications for play concepts and reservoir heterogeneity. Geol. Soc. Lond. Spec. Publ. 2016, 436, 93–133. [Google Scholar] [CrossRef]

- Bertotti, G.; Mosca, P.; Juez, J.; Polino, R.; Dunai, T. Oligocene to Present kilometres scale subsidence and exhumation of the Ligurian Alps and the Tertiary Piedmont Basin (NW Italy) revealed by apatite (U-Th)/He thermochronology: Correlation with regional tectonics. Terra Nova 2006, 18, 18–25. [Google Scholar] [CrossRef]

- Federico, C.; Pizzino, L.; De Gregorio, S.; Favara, R.; Galli, G.; Giudice, G.; Gurrieri, S.; Quattrocchi, F.; Voltattorni, N. Inverse and forward modelling of groundwater circulation in a seismically active area (Monferrato, Piedmont, NW Italy): Insights into stress-induced variation in water chemistry. Chem. Geol. 2008, 248, 14–39. [Google Scholar] [CrossRef]

- Giraudi, C. Quaternary evolution of the plain between Casale Monferrato and Valenza: Implications for the tectonics of the Monferrato thrust front (Piedmont, NW Italy). Alp. Mediterr. Quat. 2015, 28, 71–92. [Google Scholar]

- D’Atri, A.; Irace, A.; Piana, F.; Tallone, S.; Varrone, D.; Bellino, D.; Fioraso, G.; Cadoppi, P.; Fusetti, E.; Morelli, M.; et al. Note Illustrative Della Carta Geologica d’Italia Alla Scala 1: 50.000, Foglio 194 Acqui Terme; Istituto Superiore per la Protezione e la Ricerca Ambientale (ISPRA): Rome, Italy, 2014; pp. 1–229. [Google Scholar]

- Quattrocchi, F.; Favara, R.; Capasso, G.; Pizzino, L.; Bencini, R.; Cinti, D.; Galli, G.; Grassa, F.; Francofonte, S.; Volpicielli, G. Thermal anomalies and fluid geochemistry framework in occurrence of the 2000–2011 Nizza Monferrato seismic sequence (northern Italy): Episodic changes in the fault zone heat flow or chemical mixing phenomena? Nat. Hazards Earth Syst. Sci. 2003, 3, 269–277. [Google Scholar] [CrossRef]

- D’Atri, A.; Irace, A.; Piana, F.; Tallone, S.; Varrone, D.; Bellino, D.; Fioraso, G.; Cadoppi, P.; Fusetti, E.; Morelli, M.; et al. Carta Geologica d’Italia Alla Scala 1: 50.000, Foglio 194 Acqui Terme; Istituto Superiore per la Protezione e la Ricerca Ambientale (ISPRA): Rome, Italy, 2014. [Google Scholar]

- Ghielmi, M.; Rogledi, S.; Vigna, B.; Violanti, D. La successione messiniana e plio-pleistocenica del Bacino di Savigliano (settore occidentale del Bacino Terziario Piemontese). Geol. Insubrica 2019, 13, 3–141. [Google Scholar]

- Carrier, W.D. Goodbye, Hazen; Hello, Kozeny-Carman. J. Geotech. Geoenviron. 2003, 129, 1054–1056. [Google Scholar] [CrossRef]

- Slater, L. Near surface electrical characterization of hydraulic conductivity: From petrophysical properties to aquifer geometries—A review. Surv. Geophys. 2007, 28, 169–197. [Google Scholar] [CrossRef]

- Hoffmann, R.; Dietrich, P. Geoelectrical measurements for the determination of groundwater flow directions and velocities. Grundwasser 2007, 9, 194–203. [Google Scholar] [CrossRef]

- Bibby, H.M.; Dawson, G.B.; Rayner, H.H.; Bennie, S.L.; Bromley, C.J. Electrical resistivity and magnetic investigations of the geothermal systems in the Rotorua area, New Zealand. Geothermics 1992, 21, 43–64. [Google Scholar] [CrossRef]

- Arato, A.; Boaga, J.; Comina, C.; De Seta, M.; Di Sipio, E.; Galgaro, A.; Giordano, N.; Mandrone, G. Geophysical monitoring for shallow geothermal applications—Two Italian case histories. First Break 2015, 33, 75–79. [Google Scholar] [CrossRef]

- Giordano, N.; Chicco, J.; Mandrone, G.; Verdoya, M.; Wheeler, W.H. Comparing transient and steady-state methods for the thermal conductivity characterization of a borehole heat exchanger field in Bergen, Norway. Environ. Earth Sci. 2019, 78, 460. [Google Scholar] [CrossRef]

- Chicco, J.M.; Fonte, L.; Mandrone, G.; Tartaglino, A.; Vacha, D. Hybrid (Gas and Geothermal) Greenhouse Simulations Aimed at Optimizing Investment and Operative Costs: A Case Study in NW Italy. Energies 2023, 16, 3931. [Google Scholar] [CrossRef]

- Chicco, J.M.; Mandrone, G. Modelling the energy production of a borehole thermal energy storage (BTES) system. Energies 2022, 15, 9587. [Google Scholar] [CrossRef]

- Eklöf, C.; Gehlin, S. Ted-a Mobile Equipment for Thermal Response Test: Testing and Evaluation. Master’s Thesis, Luleå University of Technology, Luleå, Sweden, 1996; pp. 11–62. Available online: http://www.divaportal.org/smash/get/diva2:1032479/FULLTEXT01.pdf (accessed on 18 March 2025).

- Chicco, J.M.; Mandrone, G. How a sensitive analysis on the coupling geology and borehole heat exchangers characteristics can improve efficiency and production of shallow geothermal system. Heliyon 2022, 8, e9545. [Google Scholar] [CrossRef] [PubMed]

- Al-Khoury, P.G.; Bonnier, R. Efficient finite element formulation for geothermal heating systems. Part II: Transient. Int. J. Numer. Methods Eng. 2006, 67, 725–745. [Google Scholar] [CrossRef]

- Diersch, H.-J.G. FEFLOW–Finite Element Modeling of Flow, Mass and Heat Transport in Porous and Fractured Media. Earth Environ. Sci. 2014, 1, 1–996. [Google Scholar]

- Claesson, J.; Eskilsson, P. Conductive Heat Extraction by a Deep Borehole; Analytical Studies Thermal Analysis of Heat Extraction Boreholes; Department of Mathematical Physics, University of Lund: Lund, Sweden, 1987; pp. 1–26. [Google Scholar]

- Gehlin, S.; Bo, N. Determining undisturbed ground temperature for thermal response test. ASHRAE Trans. 2003, 109, 151–156. [Google Scholar]

- Chicco, J.M.; Verdoya, M.; Giuli, G.; Invernizzi, C. Thermophysical properties and mineralogical composition of the Umbria-Marche carbonate Succession (Central Italy). In The Geological Society of America. Special Paper. 250 Million Years of Earth History in Central Italy: Celebrating 25 Years of the Geological Observatory of Coldigioco; Koeberl, C., Bice, D.M., Eds.; The Geological Society of America: Boulder, CO, USA, 2019; p. 542. [Google Scholar] [CrossRef]

- He, X.; Li, J.; Chen, Y.; Niu, B. Analysis on heat transfer performance of coaxial borehole heat exchanger in a layered subsurface with groundwater. Heliyon 2024, 10, e37442. [Google Scholar] [CrossRef] [PubMed]

- Javed, S.; Spitler, J. Accuracy of borehole thermal resistance calculation methods for grouted single U-tube ground heat exchangers. Appl. Energy 2017, 187, 790–806. [Google Scholar] [CrossRef]

- Jia, G.S.; Ma, Z.D.; Xia, Z.H.; Wang, J.W.; Zhang, Y.P.; Jin, L.W. Influence of groundwater flow on the ground heat exchanger performance and ground temperature distributions: A comprehensive review of analytical, numerical and experimental studies. Geothermics 2022, 100, 102342. [Google Scholar] [CrossRef]

- Chen, J.; Qiao, W.; Xue, Q.; Zheng, H.; An, E. Research on ground-coupled heat exchangers. Int. J. Low-Carbon Technol. 2010, 5, 35–41. [Google Scholar] [CrossRef]

| BHE Configuration | L (m) | din (m) | bin (m) | dout (m) | bout (m) | D (m) | λin (W × m−1 K−1) | λout (W × m−1 K−1) | Shank Spacing (m) | Grout Sealing Wall BHE |

|---|---|---|---|---|---|---|---|---|---|---|

| Double U (PE100 SDR11) | 150 | 0.026 | - | 0.032 | 0.0029 | 0.152 | - | 0.42 | 0.12 | Bentonite |

| Double U (PE100 SDR11) | 36 | 0.026 | - | 0.032 | 0.0029 | 0.152 | - | 0.42 | 0.12 | Bentonite |

| Coaxial | 36 | 0.025 | 0.0023 | 0.065 | 0.0080 | 0.178 | 0.42 | 52 | - | Bentonite |

| Depth b.g.l. (m) | Lithology | Temperature (°C) |

|---|---|---|

| 10 | Sands | 13.9 |

| 30 | Sands and saturated silts | 14.2 |

| 60 | Silts and clays | 14.6 |

| 100 | Marls | 15.6 |

| 120 | Marls | 16.2 |

| 150 | Marls | 16.7 |

| Depth (m) | Lithology | λs (W × m−1 K−1) | Φ | Kxx (m/s) | Kyy (m/s) | Kzz (m/s) | T (°C) |

|---|---|---|---|---|---|---|---|

| 0–9 | Sands | 0.48 | 0.40 | 1.00 × 10−4 | 1.00 × 10−4 | 1.00 × 10−5 | 15.2 |

| 9–36 | Sands and saturate silts | 2.58 | 0.30 | 5.00 × 10−5 | 5.00 × 10−5 | 5.00 × 10−6 | 15.2 |

| 36–113 | Silts and clays | 2.56 | 0.45 | 1.00 × 10−6 | 1.00 × 10−6 | 1.00 × 10−7 | 15.2 |

| 113–150 | Marls | 2.46 | 0.20 | 1.00 × 10−7 | 1.00 × 10−7 | 1.00 × 10−8 | 15.2 |

| BHE Type | Power 0–36 m [W] | Specific Power [W m−1] | Rb [m K W−1] |

|---|---|---|---|

| 2U 150 m | 1869.63 | 45.26 | 0.085 |

| 2U 36 m | 2084.05 | 57.89 | 0.081 |

| Coax 36 m | 2839.88 | 78.89 | 0.020 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chicco, J.M.; Giordano, N.; Comina, C.; Mandrone, G. Performance Analysis of Different Borehole Heat Exchanger Configurations: A Case Study in NW Italy. Smart Cities 2025, 8, 121. https://doi.org/10.3390/smartcities8040121

Chicco JM, Giordano N, Comina C, Mandrone G. Performance Analysis of Different Borehole Heat Exchanger Configurations: A Case Study in NW Italy. Smart Cities. 2025; 8(4):121. https://doi.org/10.3390/smartcities8040121

Chicago/Turabian StyleChicco, Jessica Maria, Nicolò Giordano, Cesare Comina, and Giuseppe Mandrone. 2025. "Performance Analysis of Different Borehole Heat Exchanger Configurations: A Case Study in NW Italy" Smart Cities 8, no. 4: 121. https://doi.org/10.3390/smartcities8040121

APA StyleChicco, J. M., Giordano, N., Comina, C., & Mandrone, G. (2025). Performance Analysis of Different Borehole Heat Exchanger Configurations: A Case Study in NW Italy. Smart Cities, 8(4), 121. https://doi.org/10.3390/smartcities8040121