Plate-Type Acoustic Metamaterials: Experimental Evaluation of a Modular Large-Scale Design for Low-Frequency Noise Control

Abstract

1. Introduction

2. Materials and Methods

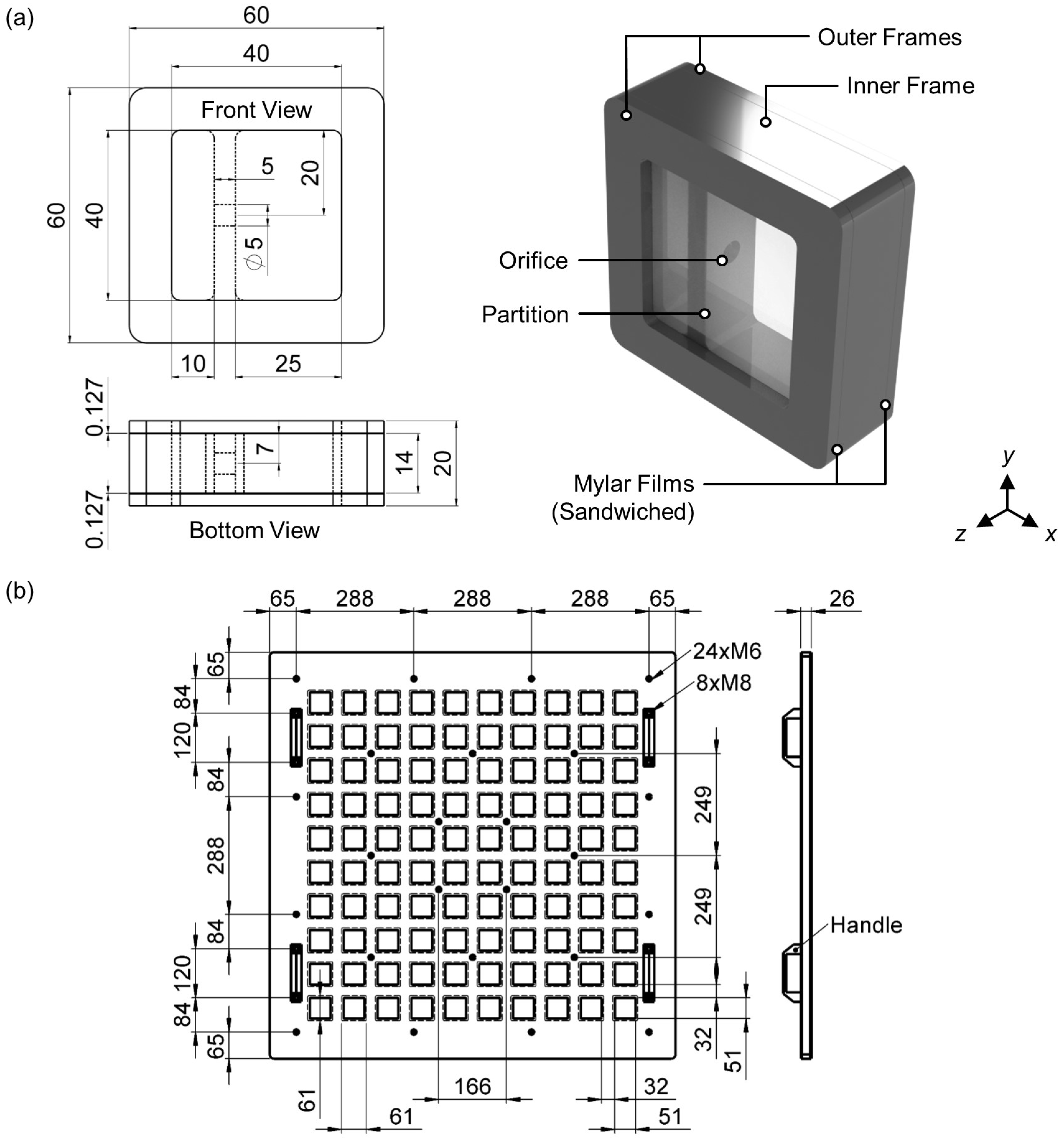

2.1. Meta-Panel Configurations

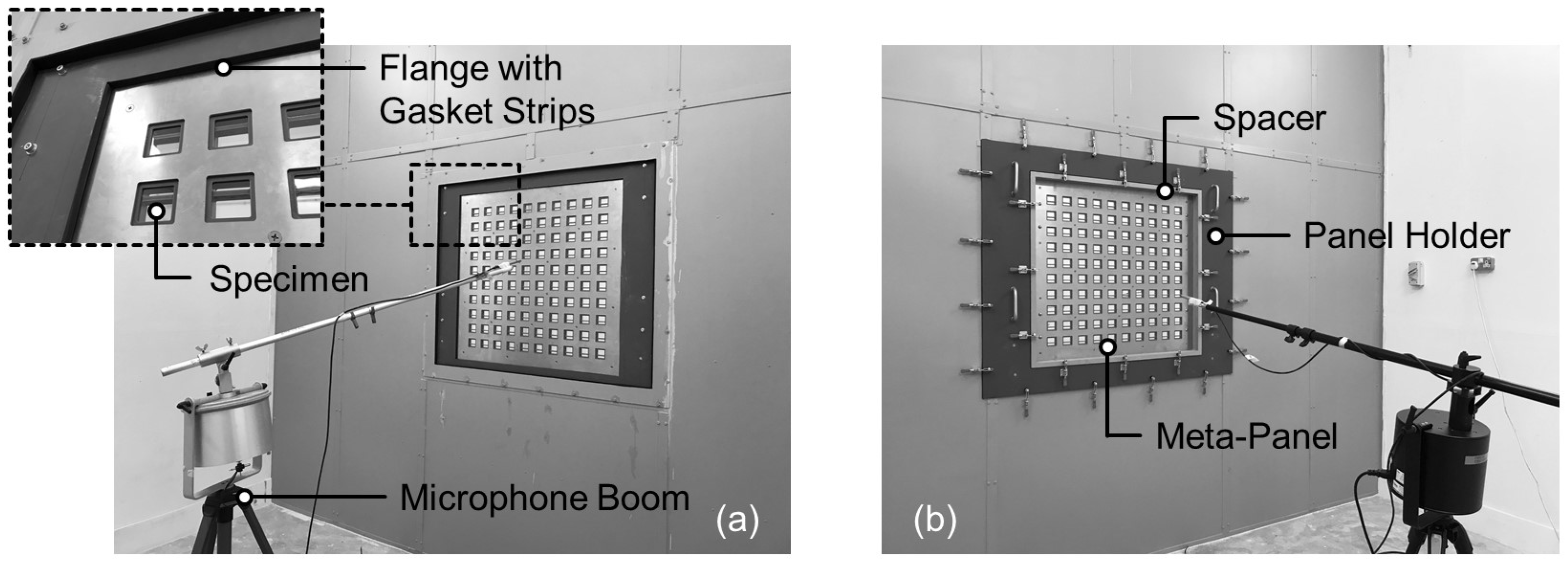

2.2. Experimental Methods

2.2.1. Sound Transmission Class

2.2.2. Outdoor-Indoor Transmission Class

2.2.3. Noise Reduction

3. Results

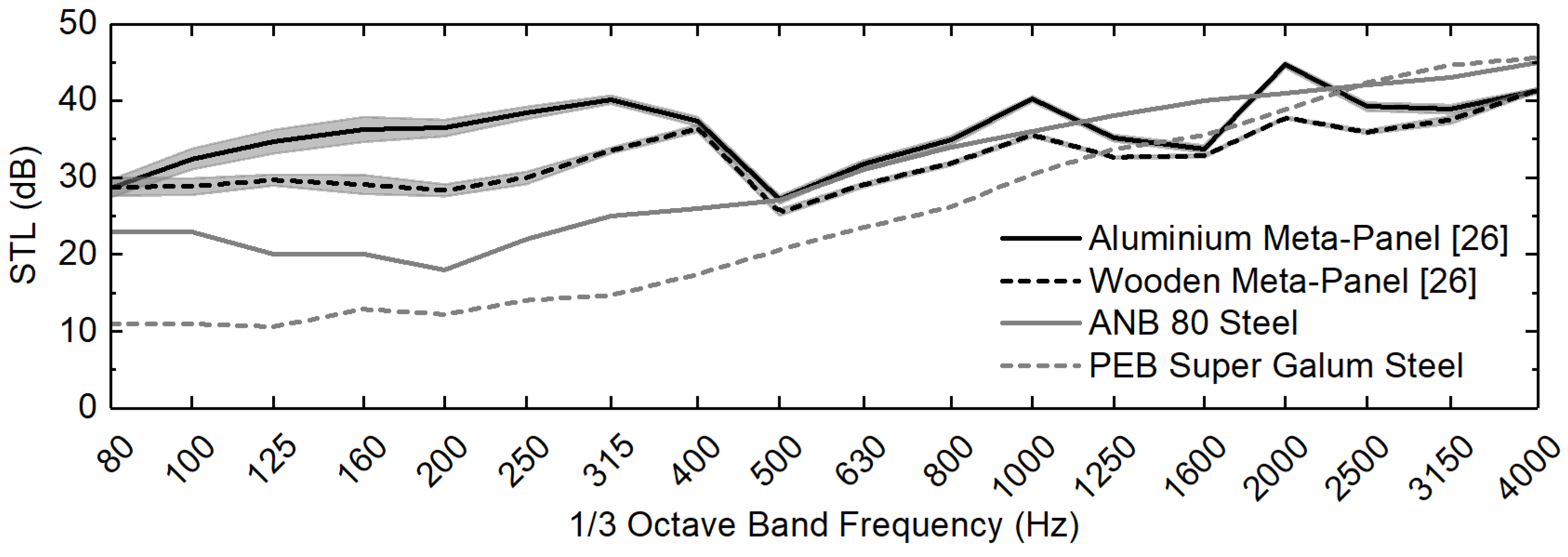

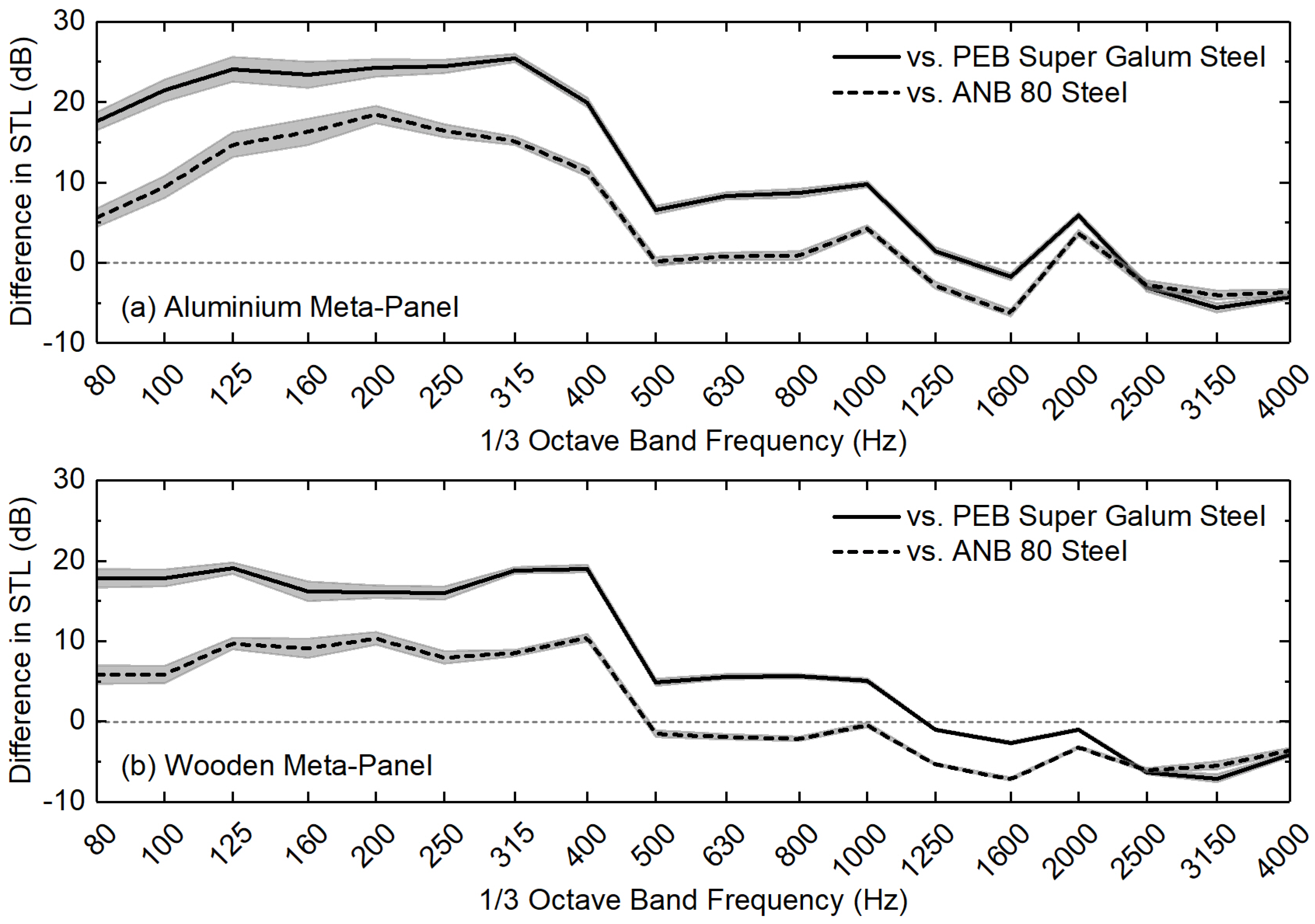

3.1. Comparison with Commercially Available Noise Barriers

3.1.1. Sound Transmission Loss

3.1.2. Sound Transmission Class

3.1.3. Outdoor-Indoor Transmission Class

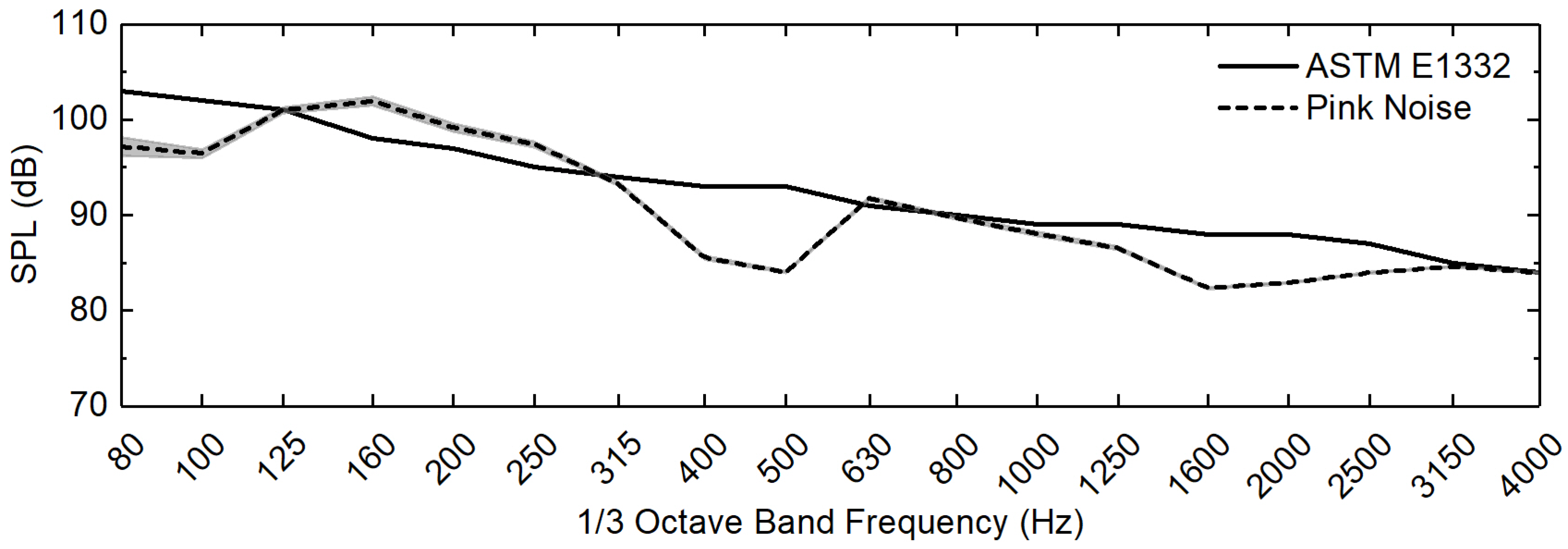

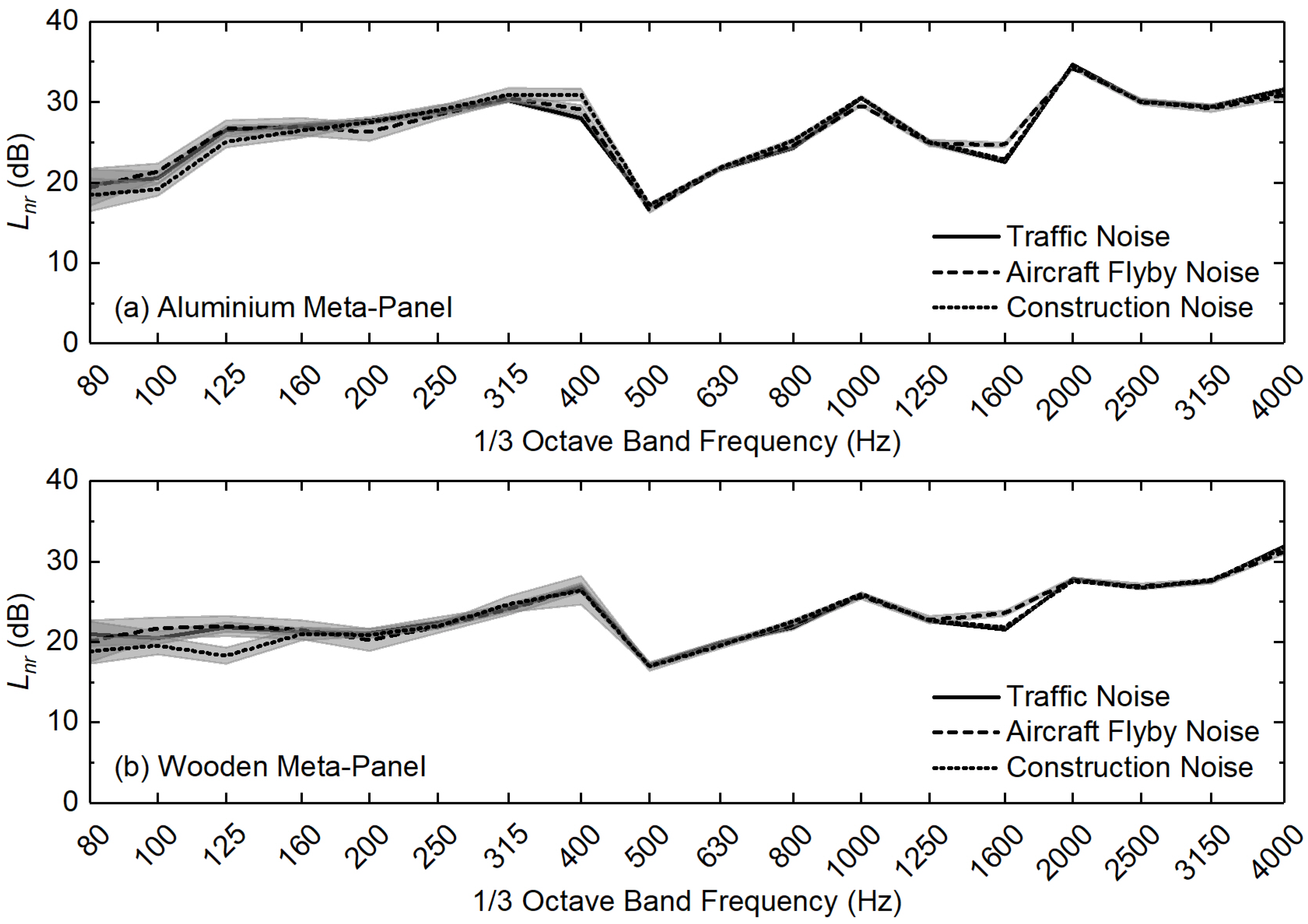

3.2. Acoustical Performance in Different Noise Environments

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| STC | Sound Transmission Class |

| OITC | Outdoor-Indoor Transmission Class |

| STL | Sound Transmission Loss |

| SPL | Sound Pressure Level |

Appendix A. Measured STL Curves of the Noise Barriers

Appendix B. Measured SPL Curves of the Noise Environments

References

- Ang, L.Y.L.; Koh, Y.K.; Lee, H.P. Broadband sound transmission loss of a large-scale membrane-type acoustic metamaterial for low-frequency noise control. Appl. Phys. Lett. 2017, 111, 041903. [Google Scholar] [CrossRef]

- Langfeldt, F.; Kemsies, H.; Gleine, W.; von Estorff, O. Perforated membrane-type acoustic metamaterials. Phys. Lett. A 2017, 381, 1457–1462. [Google Scholar] [CrossRef]

- Mei, J.; Ma, G.; Yang, M.; Yang, Z.; Wen, W.; Sheng, P. Dark acoustic metamaterials as super absorbers for low-frequency sound. Nat. Commun. 2012, 3, 756. [Google Scholar] [CrossRef] [PubMed]

- Naify, C.J.; Chang, C.M.; McKnight, G.; Nutt, S.R. Transmission loss and dynamic response of membrane-type locally resonant acoustic metamaterials. J. Appl. Phys. 2010, 108, 114905. [Google Scholar] [CrossRef]

- Naify, C.J.; Chang, C.M.; McKnight, G.; Scheulen, F.; Nutt, S.R. Membrane-type metamaterials: Transmission loss of multi-celled arrays. J. Appl. Phys. 2011, 109, 104902. [Google Scholar] [CrossRef]

- Naify, C.J.; Chang, C.M.; McKnight, G.; Nutt, S.R. Transmission loss of membrane-type acoustic metamaterials with coaxial ring masses. J. Appl. Phys. 2011, 110, 124903. [Google Scholar] [CrossRef]

- Naify, C.J.; Chang, C.M.; McKnight, G.; Nutt, S.R. Scaling of membrane-type locally resonant acoustic metamaterial arrays. J. Acoust. Soc. Am. 2012, 132, 2784–2792. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, H.; Luo, X.; Huang, Z. Membrane-constrained acoustic metamaterials for low-frequency sound insulation. Appl. Phys. Lett. 2016, 108, 041905. [Google Scholar] [CrossRef]

- Wang, X.; Luo, X.; Zhao, H.; Huang, Z. Acoustic perfect absorption and broadband insulation achieved by double-zero metamaterials. Appl. Phys. Lett. 2018, 112, 021901. [Google Scholar] [CrossRef]

- Yang, Z.; Mei, J.; Yang, M.; Chan, N.H.; Sheng, P. Membrane-type acoustic metamaterial with negative dynamic mass. Phys. Rev. Lett. 2008, 101, 204301. [Google Scholar] [CrossRef]

- Yang, Z.; Dai, H.M.; Chan, N.H.; Ma, G.; Sheng, P. Acoustic metamaterial panels for sound attenuation in the 50–1000 Hz regime. Appl. Phys. Lett. 2010, 96, 041906. [Google Scholar] [CrossRef]

- Yang, M.; Ma, G.; Yang, Z.; Sheng, P. Coupled membranes with doubly negative mass density and bulk modulus. Phys. Rev. Lett. 2013, 110, 134301. [Google Scholar] [CrossRef] [PubMed]

- Sui, N.; Yan, X.; Huang, T.Y.; Xu, J.; Yuan, F.G.; Jing, Y. A lightweight yet sound-proof honeycomb acoustic metamaterial. Appl. Phys. Lett. 2015, 106, 171905. [Google Scholar] [CrossRef]

- Li, S.; Mao, D.; Huang, S.; Wang, X. Enhanced transmission loss in acoustic materials with micro-membranes. Appl. Acoust. 2018, 130, 92–98. [Google Scholar] [CrossRef]

- Huang, T.Y.; Shen, C.; Jing, Y. Membrane- and plate-type acoustic metamaterials. J. Acoust. Soc. Am. 2016, 139, 3240–3250. [Google Scholar] [CrossRef] [PubMed]

- Ma, F.; Huang, M.; Wu, J. Ultrathin lightweight plate-type acoustic metamaterials with positive lumped coupling resonant. J. Appl. Phys. 2017, 121, 015102. [Google Scholar] [CrossRef]

- Ma, F.; Huang, M.; Wu, J. Acoustic metamaterials with synergetic coupling. J. Appl. Phys. 2017, 122, 215102. [Google Scholar] [CrossRef]

- Ma, F.; Huang, M.; Xu, Y.; Wu, J. Bilayer synergetic coupling double negative acoustic metasurface and cloak. Sci. Rep. 2018, 8, 5906. [Google Scholar] [CrossRef]

- Ma, F.; Huang, M.; Xu, Y.; Wu, J. Bilayer plate-type acoustic metamaterials with Willis coupling. J. Appl. Phys. 2018, 123, 035104. [Google Scholar] [CrossRef]

- Varanasi, S.; Bolton, J.S.; Siegmund, T.H. Experiments on the low-frequency barrier characteristics of cellular metamaterial panels in a diffuse sound field. J. Acoust. Soc. Am. 2017, 141, 602–610. [Google Scholar] [CrossRef] [PubMed]

- Ang, L.Y.L.; Koh, Y.K.; Lee, H.P. Plate-type acoustic metamaterial with cavities coupled via an orifice for enhanced sound transmission loss. Appl. Phys. Lett. 2018, 112, 051903. [Google Scholar] [CrossRef]

- Ang, L.Y.L.; Koh, Y.K.; Lee, H.P. A note on the viscous boundary layer in plate-type acoustic metamaterials with an internal tonraum resonator. Appl. Acoust. 2018, 140, 160–166. [Google Scholar] [CrossRef]

- Langfeldt, F.; Wolfgang, G.; von Estorff, O. Enhancing the low-frequency noise reduction of a double wall with membrane-type acoustic metamaterials. In Proceedings of the 45th International Congress and Exposition on Noise Control Engineering (INTER-NOISE 2016), Hamburg, Germany, 21–24 August 2016; Kropp, W., Ed.; Deutsche Gesellschaft Fuer Akustik: Hamburg, Germany, 2016; pp. 3413–3424. [Google Scholar]

- Ma, G.; Fan, X.; Sheng, P.; Fink, M. Shaping reverberating sound fields with an actively tunable metasurface. Proc. Natl. Acad. Sci. USA 2018, 115, 6638–6643. [Google Scholar] [CrossRef] [PubMed]

- Varanasi, S.; Bolton, J.S.; Siegmund, T.H.; Cipra, R.J. The low-frequency performance of metamaterial barriers based on cellular structures. Appl. Acoust. 2013, 74, 485–495. [Google Scholar] [CrossRef]

- Ang, L.Y.L.; Koh, Y.K.; Lee, H.P. Plate-type acoustic metamaterials: Evaluation of a large-scale design adopting modularity for customisable acoustical performance. Appl. Acoust. 2019, 149, 156–170. [Google Scholar] [CrossRef]

- ASTM. ASTM E90-09: Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar] [CrossRef]

- ASTM. ASTM E2235-04: Standard Test Method for Determination of Decay Rates for Use in Sound Insulation Test Methods; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar] [CrossRef]

- ASTM. ASTM E413-10: Classification for Rating Sound Insulation; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar] [CrossRef]

- ASTM. ASTM E1332-16: Standard Classification for Rating Outdoor-Indoor Sound Attenuation; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- Fahy, F.J.; Gardonio, P. Transmission of Sound Through Partitions. In Sound and Structural Vibration: Radiation, Transmission, and Response, 2nd ed.; Academic Press: Cambridge, MA, USA, 2007; Chapter 5; pp. 277–373. [Google Scholar]

| Product Name | Thickness (mm) | Surface Density (kg/m2) |

|---|---|---|

| Aluminium Meta-Panel | 26 | 51.1 |

| Wooden Meta-Panel | 26 | 16.4 |

| ANB 80 Steel * | 80 | 20.0 |

| PEB Super Galum Steel * | 30 | 10.1 |

| Product Name | STC |

|---|---|

| Aluminium Meta-Panel | 36 |

| Wooden Meta-Panel | 33 |

| ANB 80 Steel | 33 |

| PEB Super Galum Steel | 25 |

| Product Name | OITC |

|---|---|

| Aluminium Meta-Panel | 34 |

| Wooden Meta-Panel | 31 |

| ANB 80 Steel | 26 |

| PEB Super Galum Steel | 18 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ang, L.Y.L.; Koh, Y.K.; Lee, H.P. Plate-Type Acoustic Metamaterials: Experimental Evaluation of a Modular Large-Scale Design for Low-Frequency Noise Control. Acoustics 2019, 1, 354-368. https://doi.org/10.3390/acoustics1020019

Ang LYL, Koh YK, Lee HP. Plate-Type Acoustic Metamaterials: Experimental Evaluation of a Modular Large-Scale Design for Low-Frequency Noise Control. Acoustics. 2019; 1(2):354-368. https://doi.org/10.3390/acoustics1020019

Chicago/Turabian StyleAng, Linus Yinn Leng, Yong Khiang Koh, and Heow Pueh Lee. 2019. "Plate-Type Acoustic Metamaterials: Experimental Evaluation of a Modular Large-Scale Design for Low-Frequency Noise Control" Acoustics 1, no. 2: 354-368. https://doi.org/10.3390/acoustics1020019

APA StyleAng, L. Y. L., Koh, Y. K., & Lee, H. P. (2019). Plate-Type Acoustic Metamaterials: Experimental Evaluation of a Modular Large-Scale Design for Low-Frequency Noise Control. Acoustics, 1(2), 354-368. https://doi.org/10.3390/acoustics1020019