Effect of Fluid Flow on the Corrosion Performance of as-Cast and Heat-Treated Nickel Aluminum Bronze Alloy (UNS C95800) in Saline Solution

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Microstructure Studies

2.3. Electrochemical Measurements

3. Results

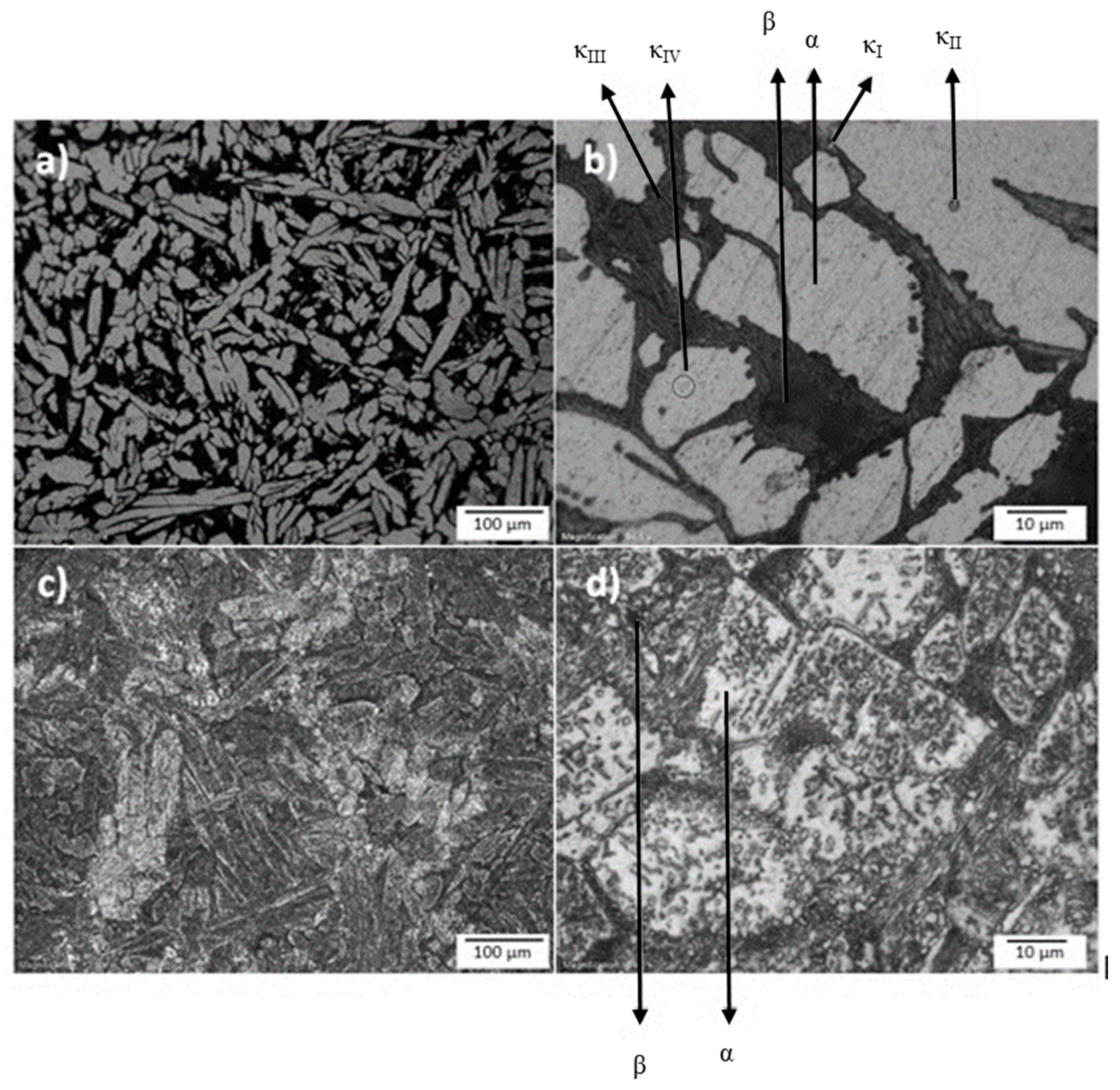

3.1. Microscopic Investigations

3.2. Electrochemical Evaluations

3.2.1. OCP Measurements

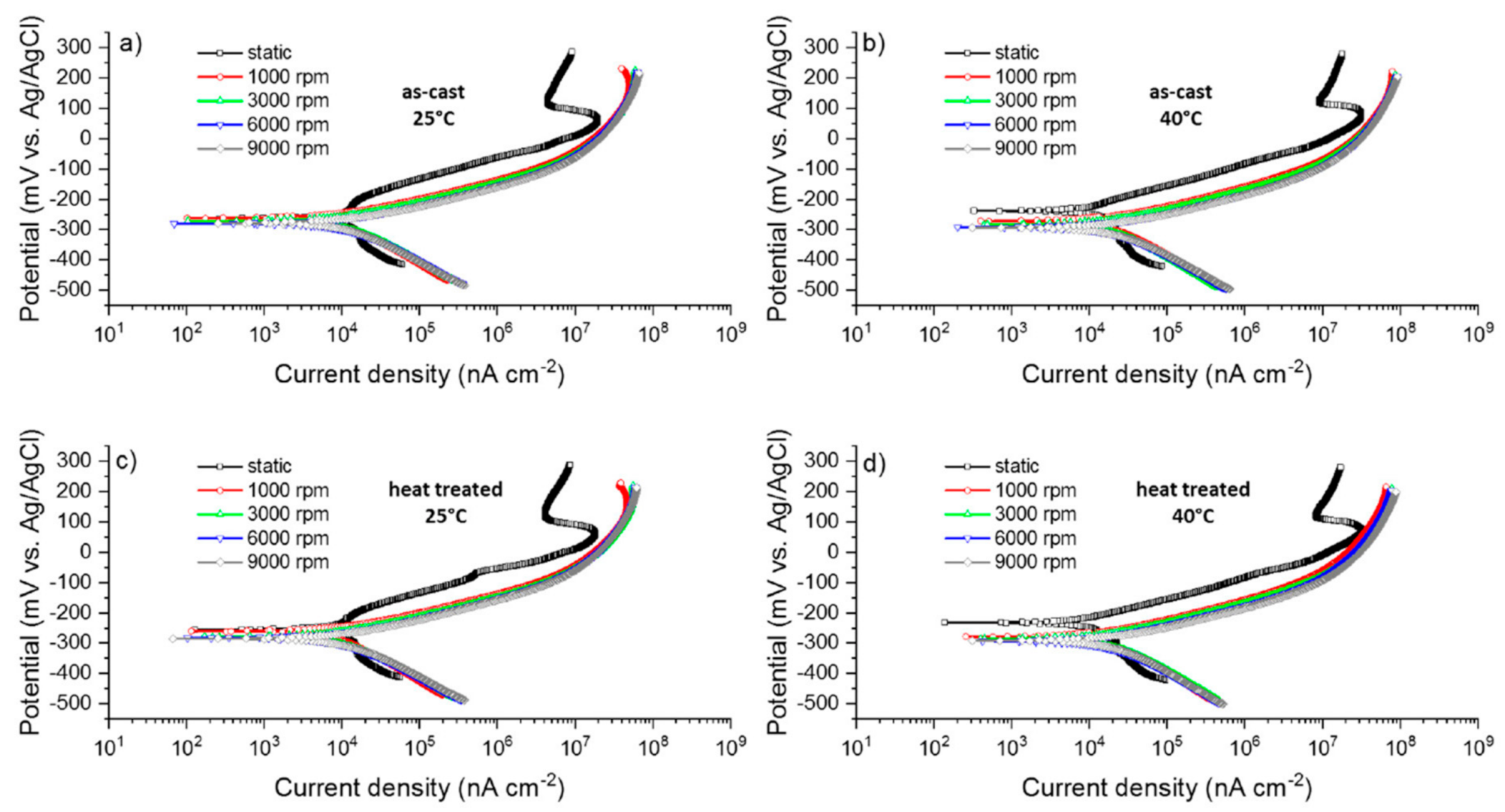

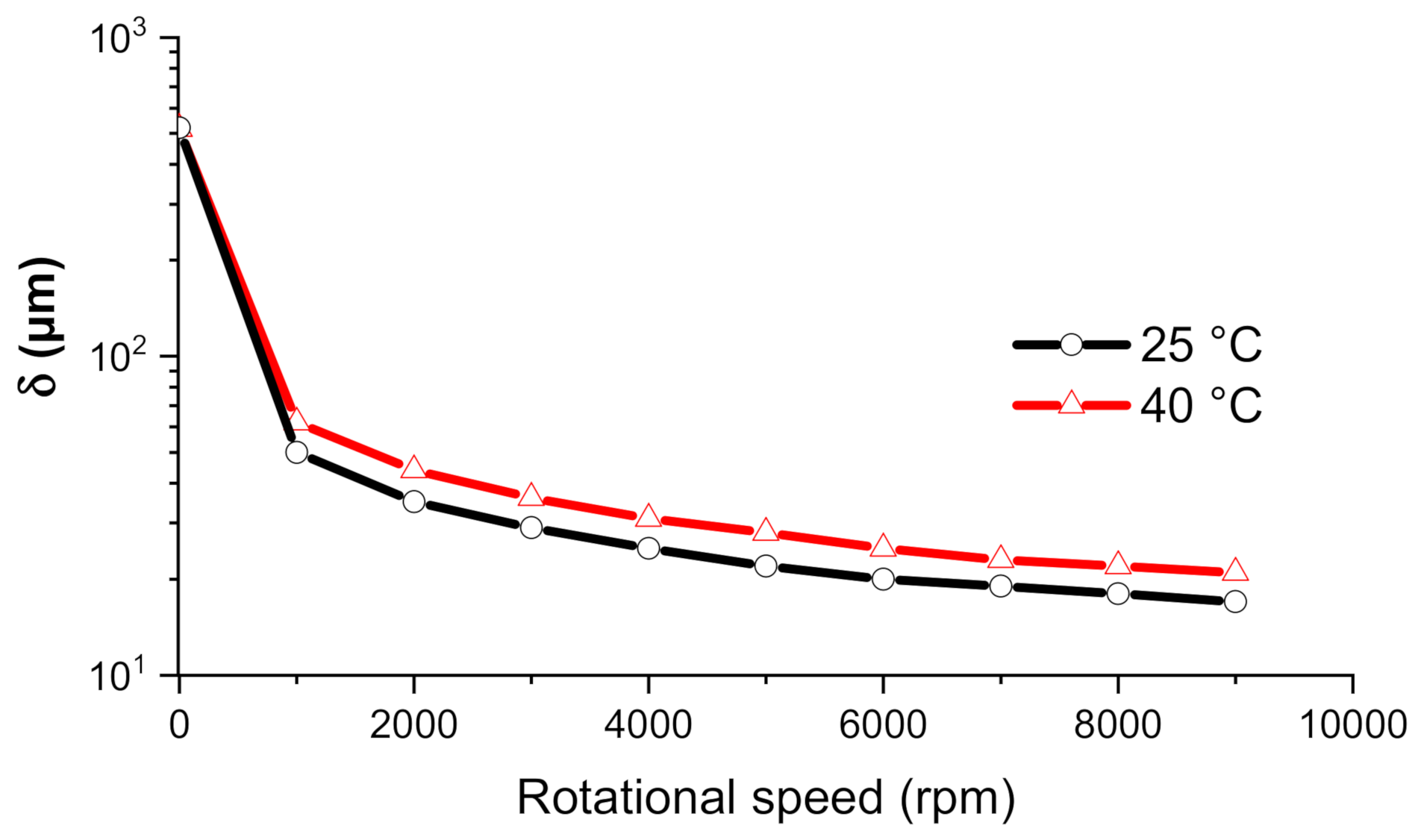

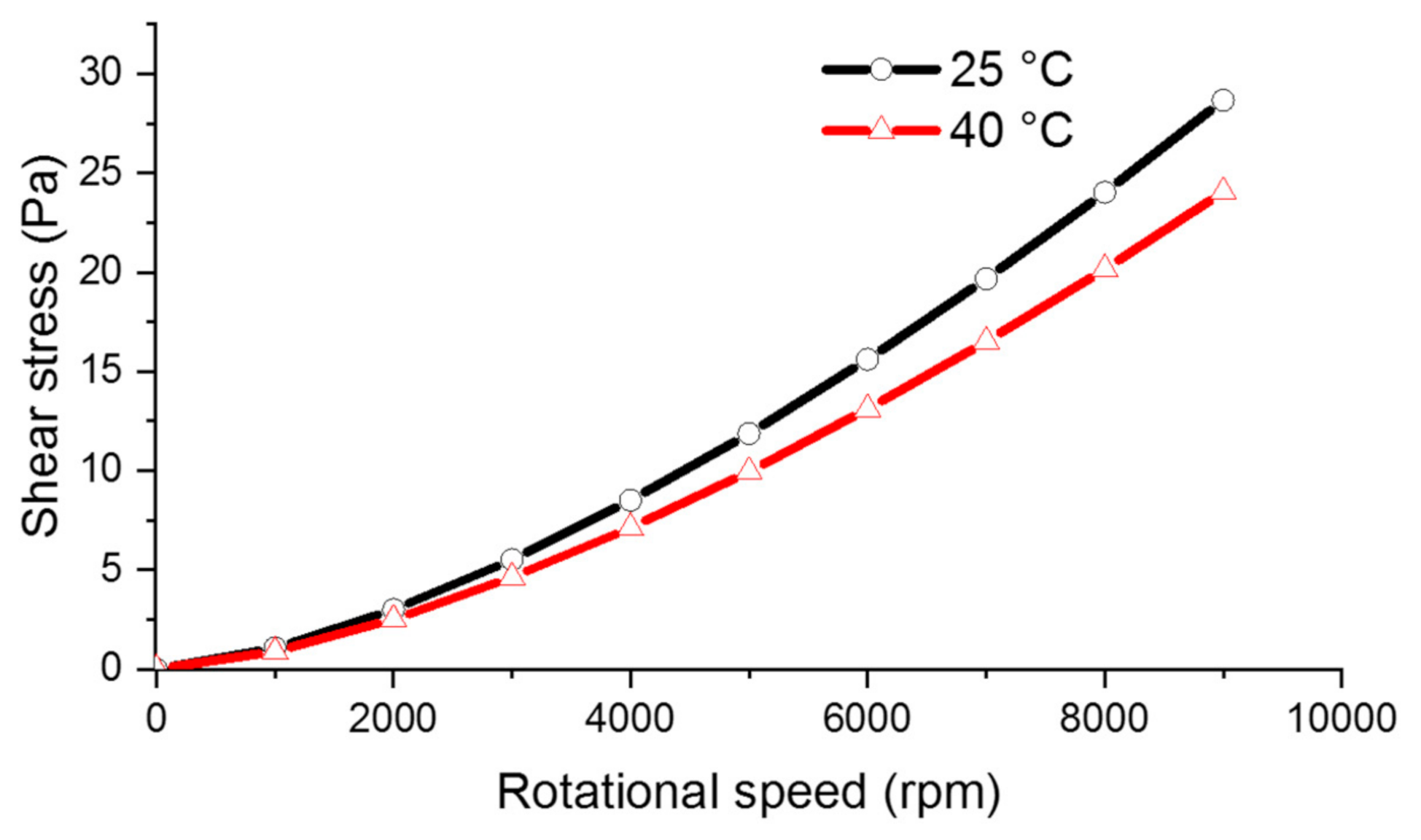

3.2.2. Potentiodynamic Polarization Measurements

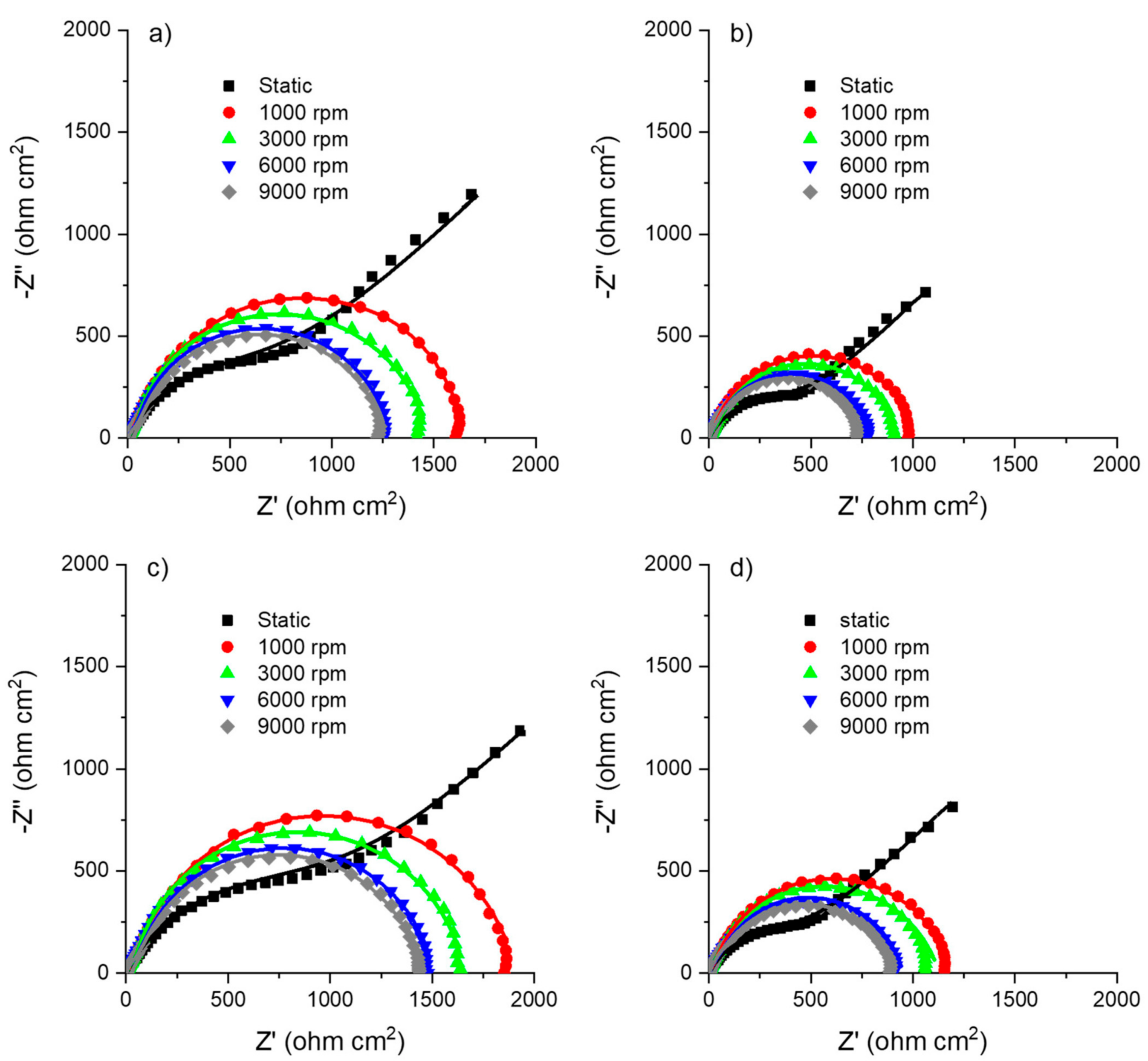

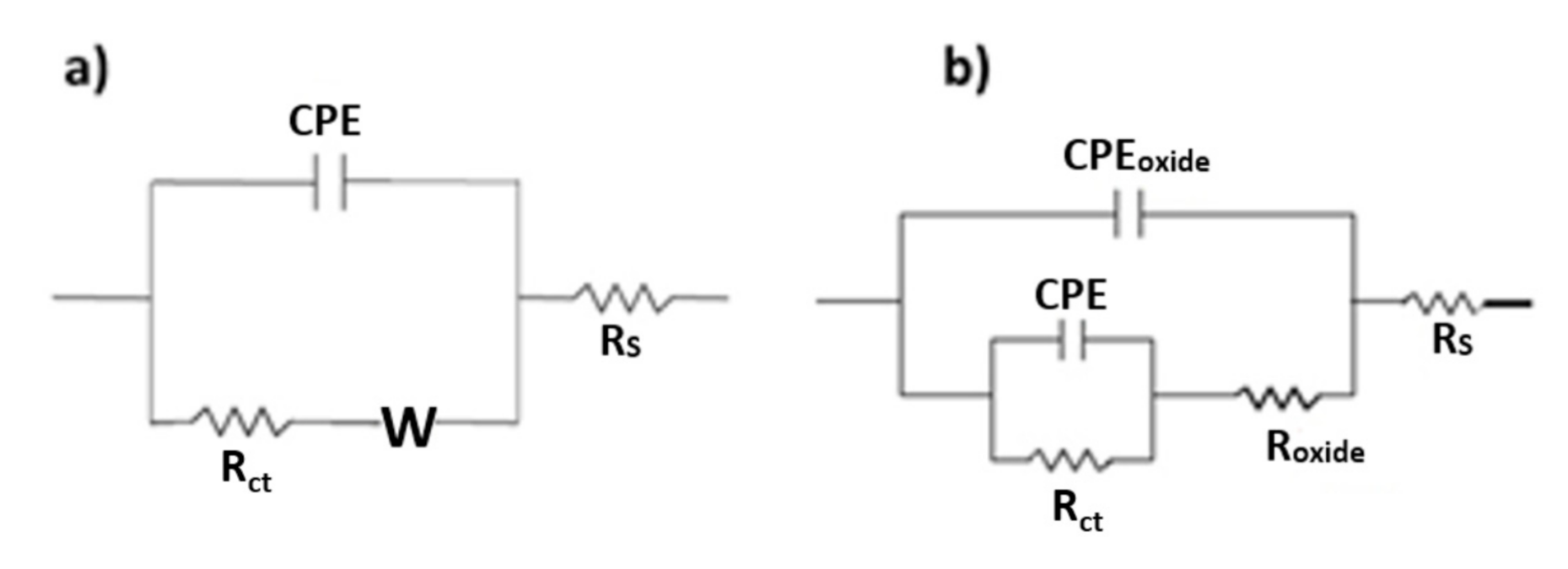

3.2.3. Electrochemical Impedance (EIS) Measurements

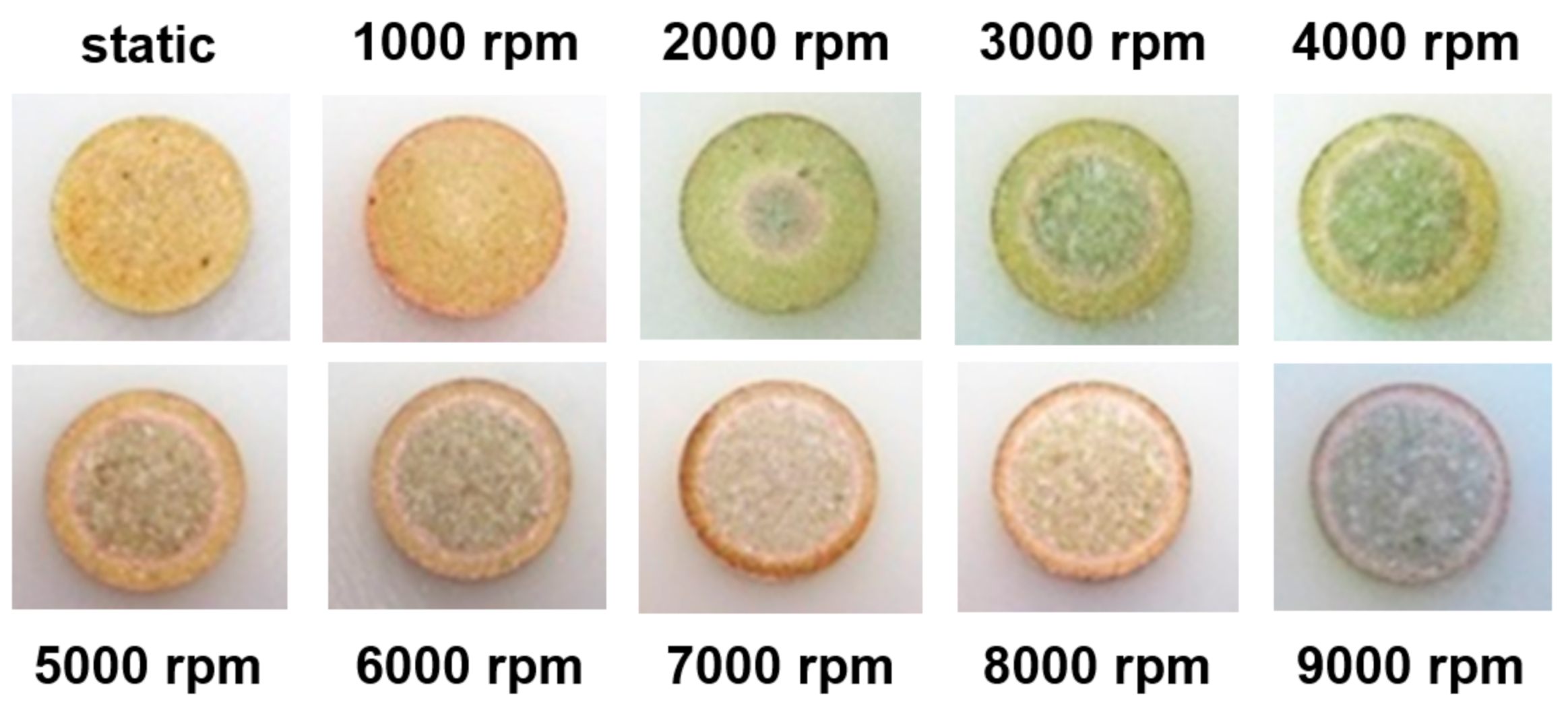

3.3. Macroscopic Optical Observations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wharton, J.A.; Barik, R.C.; Kear, G.; Wood, R.J.K.; Stokes, K.R.; Walsh, F.C. The corrosion of nickel–aluminium bronze in seawater. Corros. Sci. 2005, 47, 3336–3367. [Google Scholar] [CrossRef]

- Tuthill, A. Guidelines for the use of copper alloys in seawater. Mater. Perform. 1987, 26, 12–22. [Google Scholar]

- Hasan, F.; Jahanafrooz, A.; Lorimer, G.W.; Ridley, N. The morphology, crystallography, and chemistry of phases in as-cast nickel-aluminum bronze. Metall. Trans. A 1982, 13, 1337–1345. [Google Scholar] [CrossRef]

- Meigh, H. Cast and Wrought Aluminium Bronzes: Properties, Processes and Structure; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Chen, R.-P.; Liang, Z.Q.; Zhang, W.W.; Zhang, D.T.; Luo, Z.Q.; Li, Y.Y. Effect of heat treatment on microstructure and properties of hot-extruded nickel-aluminum bronze. Trans. Nonferrous Met. Soc. China 2007, 17, 1254–1258. [Google Scholar] [CrossRef]

- Culpan, E.A.; Rose, G. Microstructural characterization of cast nickel aluminium bronze. J. Mater. Sci. 1978, 13, 1647–1657. [Google Scholar] [CrossRef]

- Li, W.S.; Wang, Z.P.; Yang, L.U.; Yong, G.A.O.; Xu, J.L. Preparation, mechanical properties and wear behaviours of novel aluminum bronze for dies. Trans. Nonferrous Met. Soc. China 2006, 16, 607–612. [Google Scholar] [CrossRef]

- Xu, X.; Lv, Y.; Hu, M.; Xiong, D.; Zhang, L.; Wang, L.; Lu, W. Influence of second phases on fatigue crack growth behavior of nickel aluminum bronze. Int. J. Fatigue 2016, 82, 579–587. [Google Scholar] [CrossRef]

- Lenard, D.; Bayley, C.; Noren, B. Electrochemical monitoring of selective phase corrosion of nickel aluminum bronze in seawater. Corrosion 2008, 64, 764–772. [Google Scholar] [CrossRef]

- Oakley, R.S.; Galsworthy, J.C.; Fox, G.S.; Stokes, K.R. 7—Long-term and accelerated corrosion testing methods for cast nickel–aluminium bronzes in seawater. In Corrosion Behaviour and Protection of Copper and Aluminium Alloys in Seawater; Féron, D., Ed.; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2007; pp. 119–127. [Google Scholar]

- Yang, F.; Kang, H.; Guo, E.; Li, R.; Chen, Z.; Zeng, Y.; Wang, T. The role of nickel in mechanical performance and corrosion behaviour of nickel-aluminium bronze in 3.5 wt.% NaCl solution. Corros. Sci. 2018, 139, 333–345. [Google Scholar] [CrossRef]

- Schüssler, A.; Exner, H.E. The corrosion of nickel-aluminium bronzes in seawater—I. Protective layer formation and the passivation mechanism. Corros. Sci. 1993, 34, 1793–1802. [Google Scholar] [CrossRef]

- Song, Q.N.; Zheng, Y.G.; Ni, D.R.; Ma, Z.Y. Characterization of the corrosion product films formed on the as-cast and friction-stir processed Ni-Al bronze in a 3.5wt% NaCl solution. Corrosion 2015, 71, 606–614. [Google Scholar] [CrossRef]

- Levič, B.G. Physicochemical Hydrodynamics; Prentice-Hall: Upper Saddle River, NJ, USA, 1962. [Google Scholar]

- Boto, K.G.; Williams, L.F.G. Rotating disc electrode studies of zinc corrosion. J. Electroanal. Chem. Interfacial Electrochem. 1977, 77, 1–20. [Google Scholar] [CrossRef]

- Kojima, K.; Okamoto, G. A study of corrosion on a rotating iron disk electrode. J. Electroanal. Chem. Interfacial Electrochem. 1975, 62, 231–244. [Google Scholar] [CrossRef]

- Yang, F.; Kang, H.; Chen, Z.; Guo, E.; Zeng, Y.; Wang, W.; Wang, T. Electrochemical corrosion mechanisms of nickel-aluminium bronze with different nickel contents using the rotating disc electrode. Corros. Sci. 2019, 157, 438–449. [Google Scholar] [CrossRef]

- Marco, I.; van der Biest, O. Polarization measurements from a rotating disc electrode for characterization of magnesium corrosion. Corros. Sci. 2016, 102, 384–393. [Google Scholar] [CrossRef]

- de Sanchez, S.R.; Schiffrin, D.J. The use of high speed rotating disc electrodes for the study of erosion-corrosion of copper base alloys in sea water. Corros. Sci. 1988, 28, 141–151. [Google Scholar] [CrossRef]

- Ge, J.; Park, J.; Leong, A.; Zhang, J. In situ electrochemical study of the coexistence of Eu3+ and Eu2+ in molten LiCl-KCl by rotating disc electrode. J. Electrochem. Soc. 2020, 167, 163506. [Google Scholar] [CrossRef]

- ASTM B148-18. Standard Specification for Aluminum-Bronze Sand Castings; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM E407-07. Standard Practice for Microetching Metals and Alloys; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM E562-19e1. Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM E1245-03. Standard Practice for Determining the Inclusion or Second-Phase Constituent Content of Metals by Automatic Image Analysis; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Dharmendra, C.; Hadadzadeh, A.; Amirkhiz, B.S.; Ram, G.J.; Mohammadi, M. Microstructural evolution and mechanical behavior of nickel aluminum bronze Cu-9Al-4Fe-4Ni-1Mn fabricated through wire-arc additive manufacturing. Addit. Manuf. 2019, 30, 100872. [Google Scholar] [CrossRef]

- Han, Z.; Zhao, H. Effect of β martensite transformation on dealuminification behavior of Cu–9Al–2Mn alloy in a marine environment. Mater. Sci. Eng. A 2003, 345, 8–13. [Google Scholar] [CrossRef]

- McCafferty, E. Introduction to Corrosion Science; Springer Science & Business Media: Berlin, Germany, 2010. [Google Scholar]

- Michels, H.T.; Kain, R.M. Effect of Composition and Microstructure on the Seawater Corrosion Resistance of Nickel Aluminum Bronze. In CORROSION 2003; NACE International: San Diego, CA, USA, 2003; p. 17. [Google Scholar]

- Kear, G.; Barker, B.D.; Walsh, F.C. Electrochemical corrosion of unalloyed copper in chloride media—A critical review. Corros. Sci. 2004, 46, 109–135. [Google Scholar] [CrossRef]

- Wharton, J.A.; Stokes, K.R. Analysis of nickel–aluminium bronze crevice solution chemistry using capillary electrophoresis. Electrochem. Commun. 2007, 9, 1035–1040. [Google Scholar] [CrossRef]

- Hosseinpour, S.; Johnson, M. Vibrational spectroscopy in studies of atmospheric corrosion. Materials 2017, 10, 413. [Google Scholar] [CrossRef] [PubMed]

- Tan, K.S.; Wharton, J.A.; Wood, R.J.K. Solid particle erosion–corrosion behaviour of a novel HVOF nickel aluminium bronze coating for marine applications—correlation between mass loss and electrochemical measurements. Wear 2005, 258, 629–640. [Google Scholar] [CrossRef]

- Ghali, E.; Sastri, V.S.; Elboujdaini, M. Corrosion Prevention and Protection: Practical Solutions; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Gonzalez, J.; Real, C.; Hoyos, L.; Miranda, R.; Cervantes, F. Characterization of the hydrodynamics inside a practical cell with a rotating disk electrode. J. Electroanal. Chem. 2011, 651, 150–159. [Google Scholar] [CrossRef]

- O’Sullivan, T.J.; Kannam, S.K.; Chakraborty, D.; Todd, B.D.; Sader, J.E. Viscoelasticity of liquid water investigated using molecular dynamics simulations. Phys. Rev. Fluids 2019, 4, 123302. [Google Scholar] [CrossRef]

- Orazem, M.E.; Tribollet, B. Electrochemical Impedance Spectroscopy; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Bard, A.J.; Faulkner, L.R. Fundamentals and applications. Electrochem. Methods 2001, 2, 580–632. [Google Scholar]

| Cu | Al | Cr | Si | Ni | Fe | Mn | P | Sn | Pb | Zn | S | Co |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Base | 8.79 | 0.007 | 0.08 | 4.50 | 3.70 | 1.00 | 0.02 | 0.02 | <0.01 | 0.05 | 0.01 | <0.01 |

| Parameter | T (°C) | Static | 1000 rpm | 3000 rpm | 6000 rpm | 9000 rpm | Type |

|---|---|---|---|---|---|---|---|

| Ecorr (mV) | 25 | −262 | −264 | −270 | −279 | −278 | as-cast |

| −255 | −260 | −278 | −282 | −284 | heat-treated | ||

| 40 | −237 | −271 | −283 | −291 | −294 | as-cast | |

| −232 | −278 | −285 | −293 | −292 | heat-treated | ||

| icorr (A cm−2) | 25 | 1.74 × 10−6 | 4.95 × 10−6 | 5.06 × 10−6 | 5.23 × 10−6 | 5.57 × 10−6 | as-cast |

| 9.18 × 10−7 | 4.50 × 10−6 | 4.86 × 10−6 | 5.03 × 10−6 | 5.22 × 10−6 | heat-treated | ||

| 40 | 3.37 × 10−6 | 6.61 × 10−6 | 7.45 × 10−6 | 8.44 × 10−6 | 8.97 × 10−6 | as-cast | |

| 1.07 × 10−6 | 5.97 × 10−6 | 6.7 × 10−6 | 7.66 × 10−6 | 8.83 × 10−6 | heat-treated | ||

| Rp (Ω cm2) | 25 | - | 1669.70 | 1646.15 | 1593.94 | 1482.08 | as-cast |

| - | 1968.39 | 1945.78 | 1879.88 | 1739.95 | heat-treated | ||

| 40 | - | 1126.48 | 1056.81 | 936.31 | 887.84 | as-cast | |

| - | 1373.75 | 1177.89 | 1130.01 | 930.42 | heat-treated | ||

| C. Rate (mm year−1) | 25 | 0.02 | 0.05 | 0.05 | 0.05 | 0.06 | as-cast |

| 0.01 | 0.04 | 0.05 | 0.05 | 0.05 | heat-treated | ||

| 40 | 0.03 | 0.07 | 0.07 | 0.08 | 0.09 | as-cast | |

| 0.03 | 0.06 | 0.07 | 0.08 | 0.09 | heat-treated |

| Parameter | T (°C) | Static | 1000 rpm | 3000 rpm | 6000 rpm | 9000 rpm | Type |

|---|---|---|---|---|---|---|---|

| Rs (Ω cm2) | 25 | 3.25 | 3.17 | 3.19 | 3.18 | 3.26 | as-cast |

| 3.01 | 3.15 | 3.25 | 3.12 | 3.01 | heat-treated | ||

| 40 | 2.35 | 2.42 | 2.41 | 2.35 | 2.35 | as-cast | |

| 2.33 | 3.25 | 2.69 | 2.76 | 2.32 | heat-treated | ||

| Roxide (Ω cm2) | 25 | - | 159.81 | 181.11 | 207.20 | 205.06 | as-cast |

| - | 220.25 | 195.76 | 212.54 | 217.33 | heat-treated | ||

| 40 | - | 244.74 | 219.68 | 315.39 | 329.39 | as-cast | |

| - | 203.21 | 302.00 | 334.07 | 363.18 | heat-treated | ||

| Rct (Ω) | 25 | 838.65 | 1507.87 | 1290.50 | 1079.27 | 1053.08 | as-cast |

| 902.16 | 1686.78 | 1460.14 | 1288.93 | 1224.40 | heat-treated | ||

| 40 | 458.85 | 768.47 | 705.95 | 482.22 | 411.30 | as-cast | |

| 494.63 | 984.84 | 743.68 | 614.94 | 533.73 | heat-treated | ||

| Coxide (F) | 25 | - | 6.74 × 10−6 | 6.55 × 10−6 | 5.89 × 10−6 | 6.5 × 10−6 | as-cast |

| - | 5.26 × 10−6 | 6.08 × 10−6 | 5.5 × 10−6 | 5.46 × 10−6 | heat-treated | ||

| 40 | - | 8.64 × 10−6 | 6.4 × 10−6 | 6.42 × 10−6 | 6.5 × 10−6 | as-cast | |

| - | 7.48 × 10−6 | 5.46 × 10−6 | 5.53 × 10−6 | 5.14 × 10−6 | heat-treated | ||

| n1 | 25 | 0.74 | 0.84 | 0.85 | 0.86 | 0.84 | as-cast |

| 0.73 | 0.84 | 0.85 | 0.86 | 0.87 | heat-treated | ||

| 40 | 0.74 | 0.84 | 0.83 | 0.84 | 0.84 | as-cast | |

| 0.73 | 0.83 | 0.84 | 0.83 | 0.84 | heat-treated | ||

| Cdl (F) | 25 | 2.01 × 10−5 | 2.94 × 10−6 | 2.61 × 10−6 | 2.81 × 10−6 | 2.01 × 10−5 | as-cast |

| 2.01 × 10−5 | 2.57 × 10−6 | 3.22 × 10−6 | 4.75 × 10−6 | 2.01 × 10−5 | heat-treated | ||

| 40 | 2.25 × 10−5 | 2.03 × 10−6 | 2.67 × 10−6 | 1.87 × 10−6 | 2.25 × 10−5 | as-cast | |

| 2.22 × 10−5 | 2.47 × 10−6 | 3.61 × 10−6 | 2.47 × 10−6 | 2.22 × 10−5 | heat-treated | ||

| n2 | 25 | - | 0.97 | 0.99 | 0.99 | 0.96 | as-cast |

| - | 0.96 | 0.98 | 0.93 | 0.90 | heat-treated | ||

| 40 | - | 0.99 | 0.97 | 0.99 | 0.99 | as-cast | |

| - | 0.92 | 0.85 | 0.97 | 0.87 | heat-treated |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jafari, H.R.; Davoodi, A.; Hosseinpour, S. Effect of Fluid Flow on the Corrosion Performance of as-Cast and Heat-Treated Nickel Aluminum Bronze Alloy (UNS C95800) in Saline Solution. Corros. Mater. Degrad. 2021, 2, 61-77. https://doi.org/10.3390/cmd2010004

Jafari HR, Davoodi A, Hosseinpour S. Effect of Fluid Flow on the Corrosion Performance of as-Cast and Heat-Treated Nickel Aluminum Bronze Alloy (UNS C95800) in Saline Solution. Corrosion and Materials Degradation. 2021; 2(1):61-77. https://doi.org/10.3390/cmd2010004

Chicago/Turabian StyleJafari, Hamid Reza, Ali Davoodi, and Saman Hosseinpour. 2021. "Effect of Fluid Flow on the Corrosion Performance of as-Cast and Heat-Treated Nickel Aluminum Bronze Alloy (UNS C95800) in Saline Solution" Corrosion and Materials Degradation 2, no. 1: 61-77. https://doi.org/10.3390/cmd2010004

APA StyleJafari, H. R., Davoodi, A., & Hosseinpour, S. (2021). Effect of Fluid Flow on the Corrosion Performance of as-Cast and Heat-Treated Nickel Aluminum Bronze Alloy (UNS C95800) in Saline Solution. Corrosion and Materials Degradation, 2(1), 61-77. https://doi.org/10.3390/cmd2010004