Adjustable Capillary Forces Through Wetting State Changes in Liquid Bridges: Regulation via Trapezoidal Microstructures

Abstract

1. Introduction

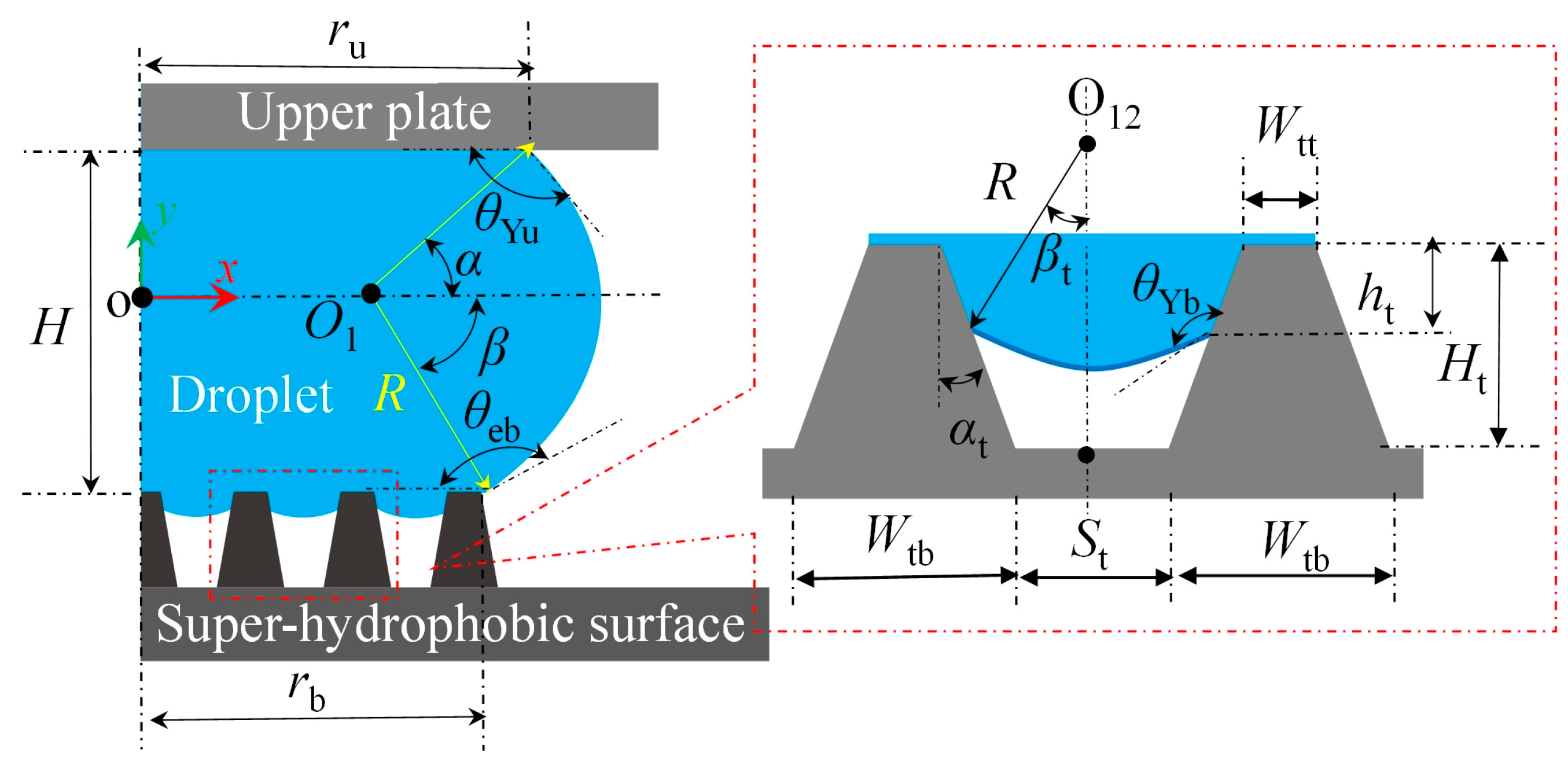

2. Theoretical Model

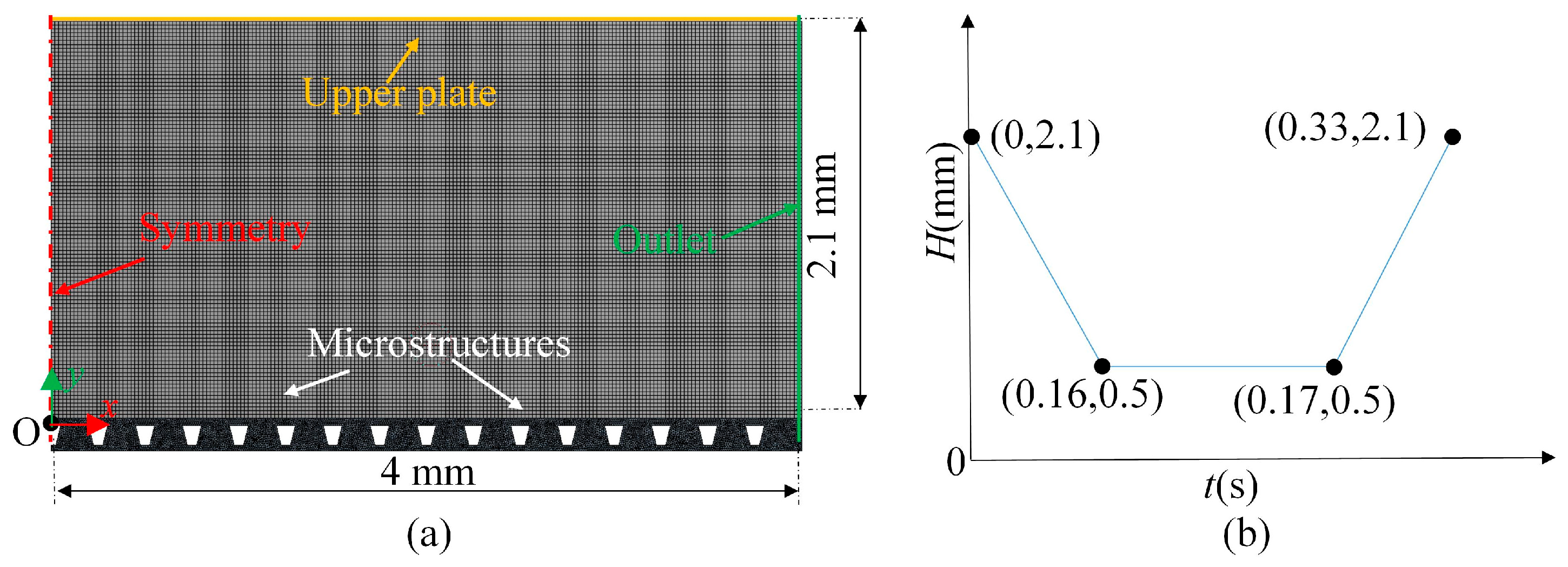

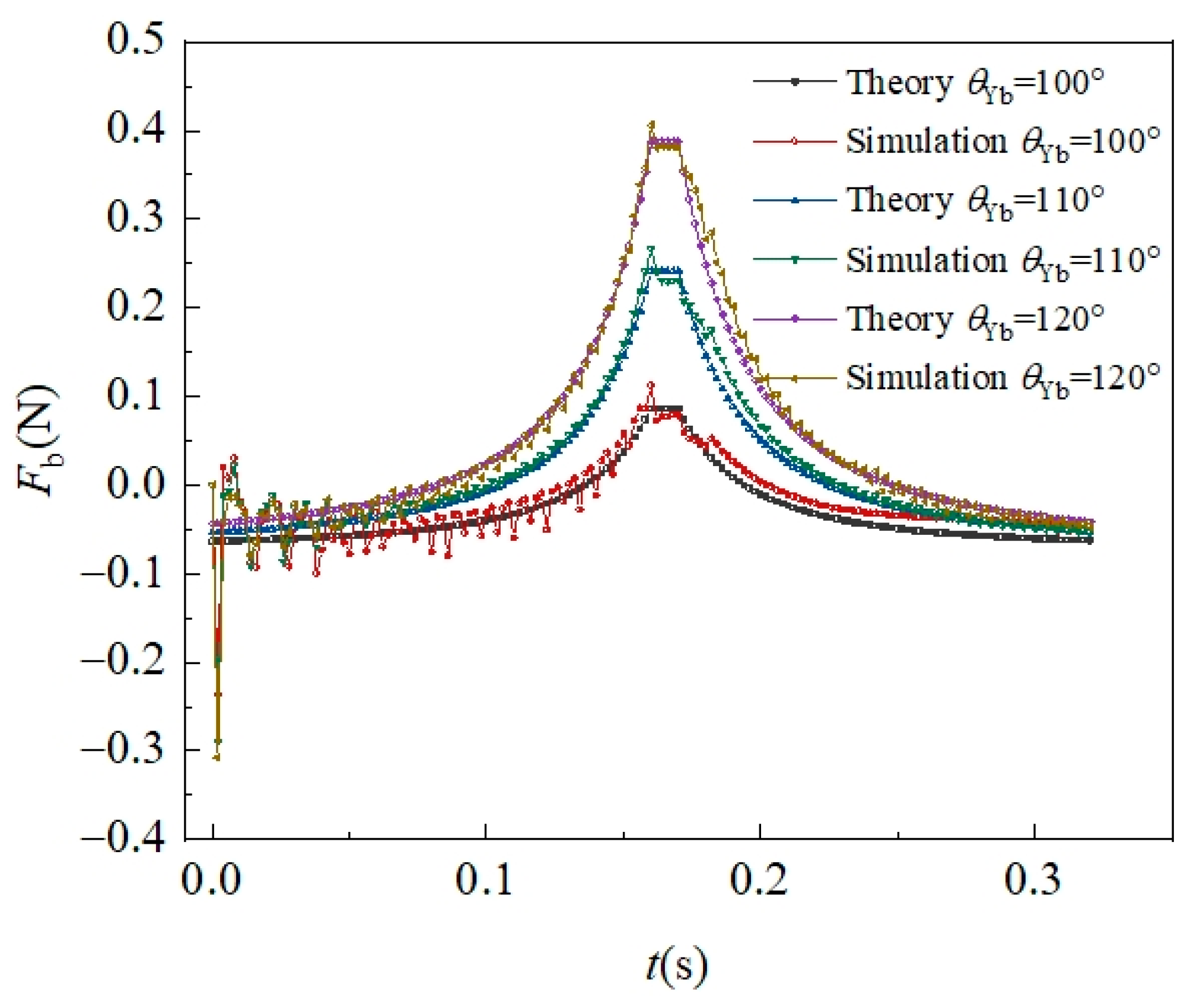

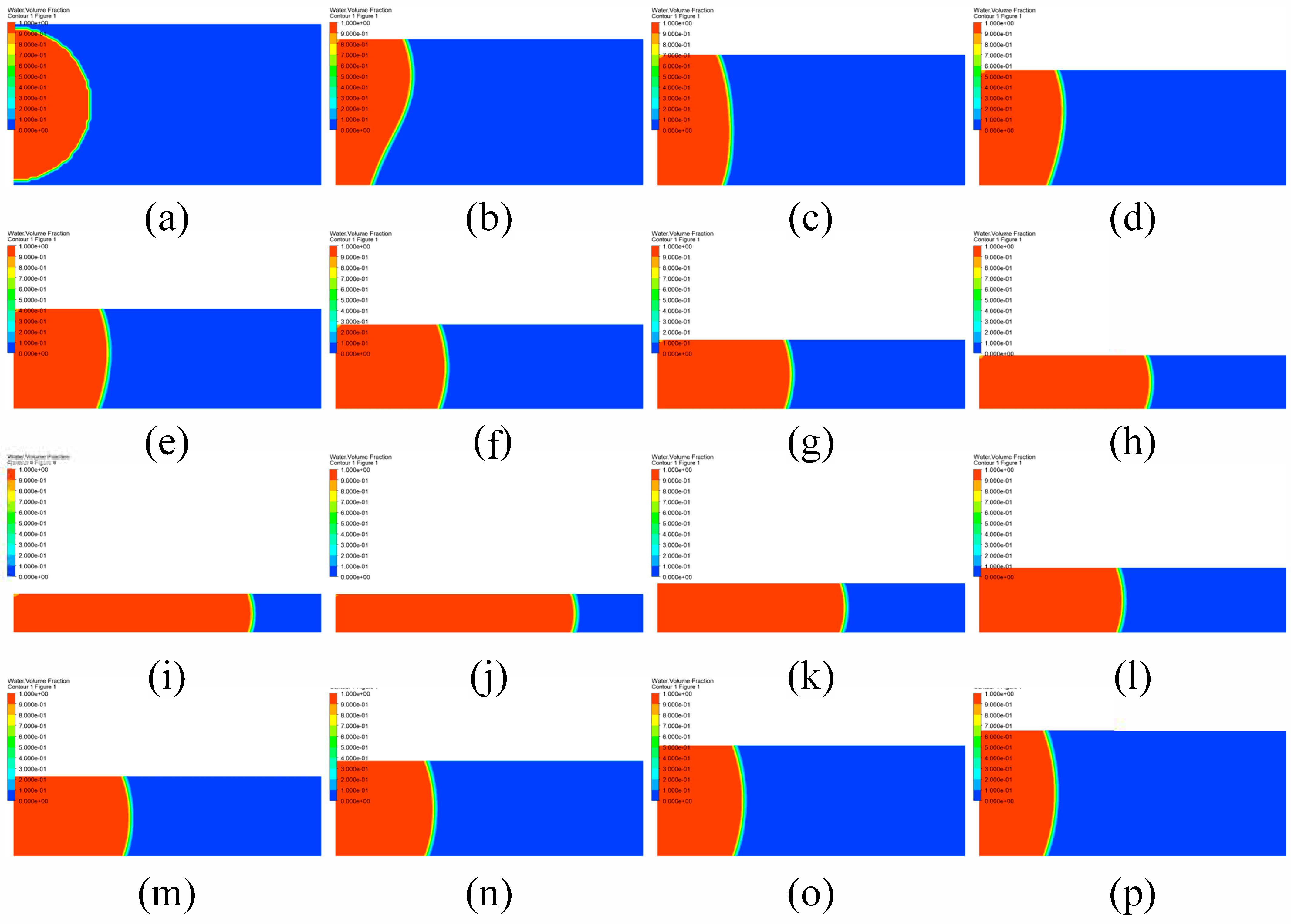

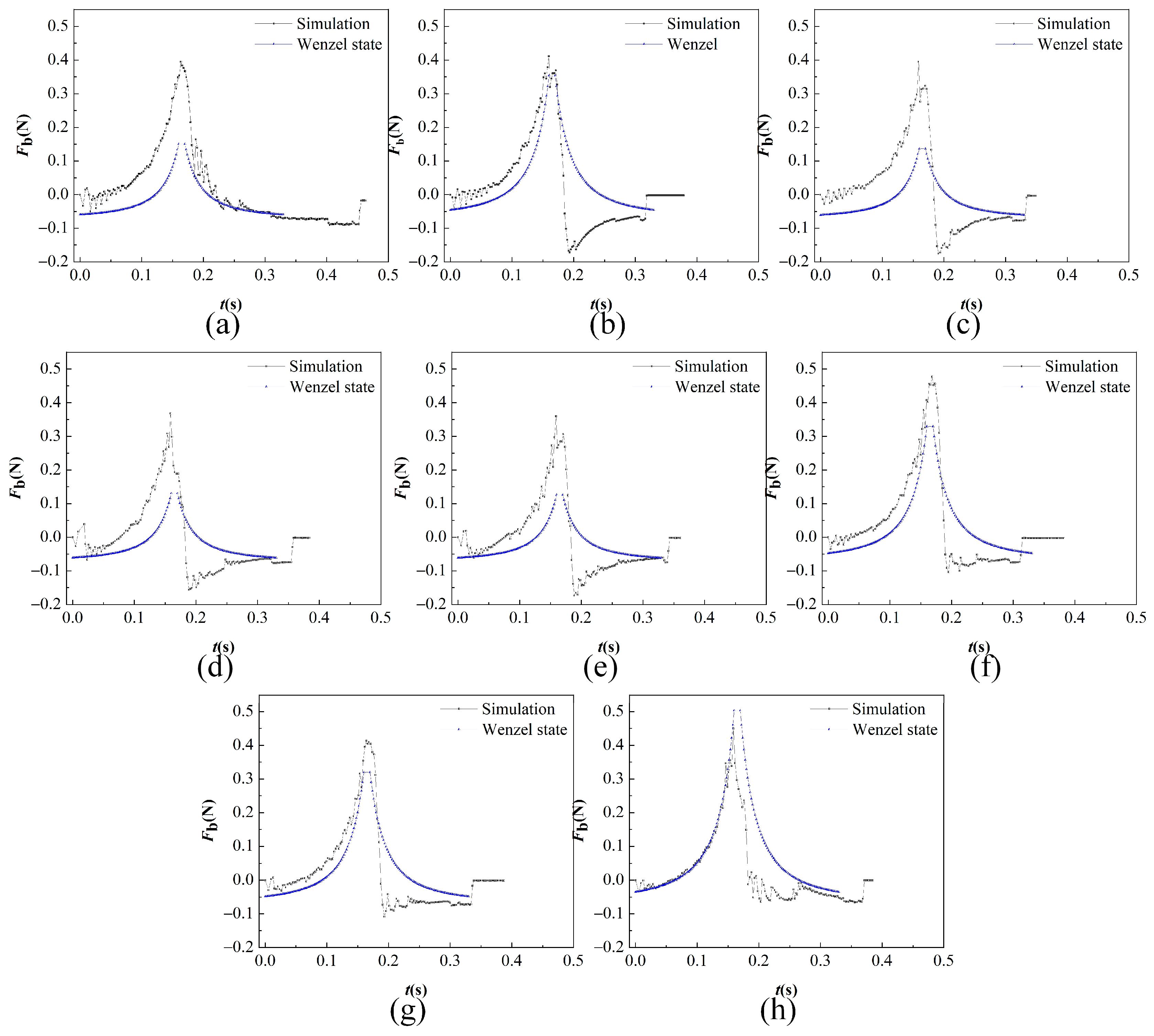

3. Computational Validation of the Capillary Force

4. Results and Discussions

4.1. Influence of Microstructures and Contact Angle on the Capillary Force

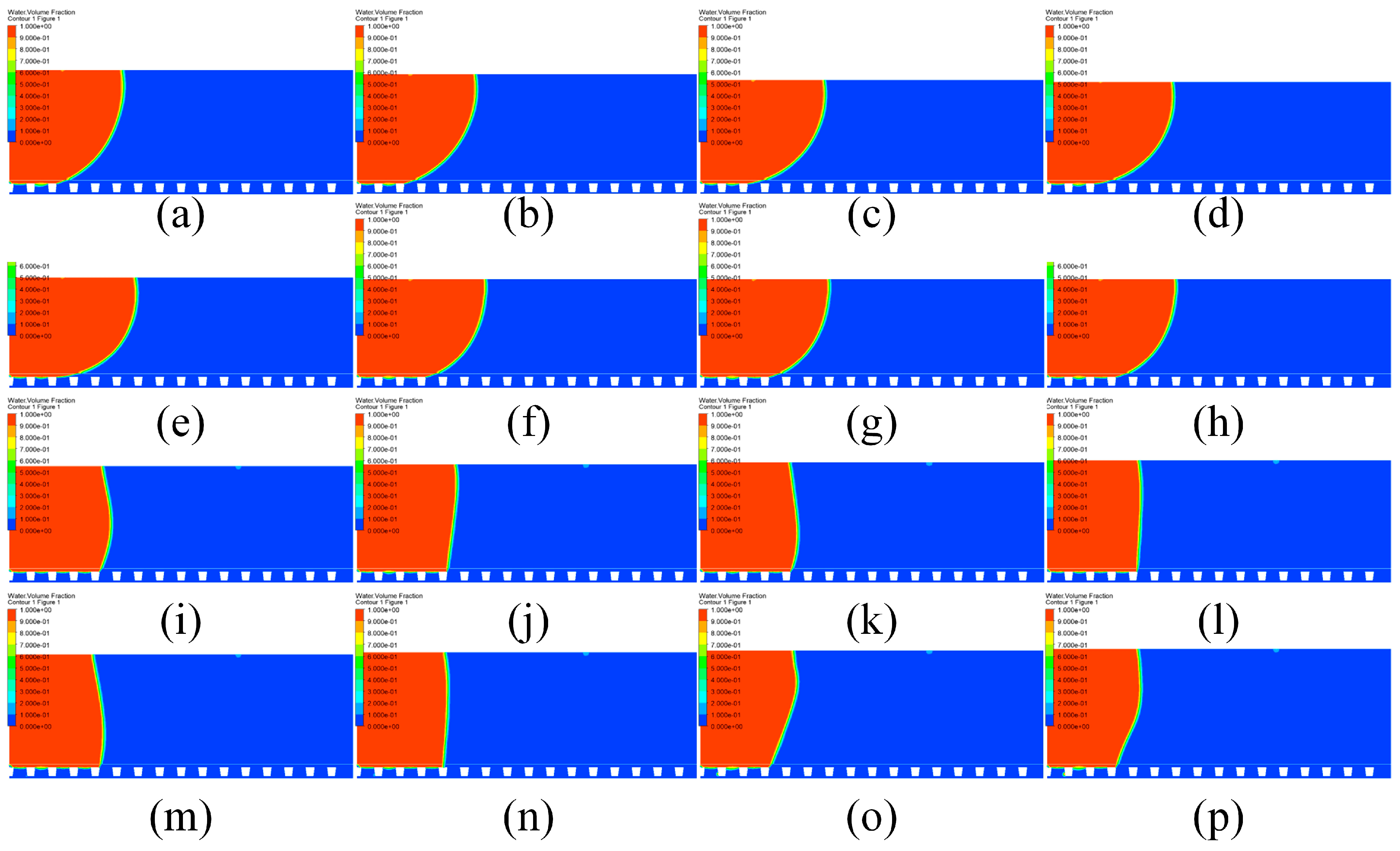

4.1.1. Young State

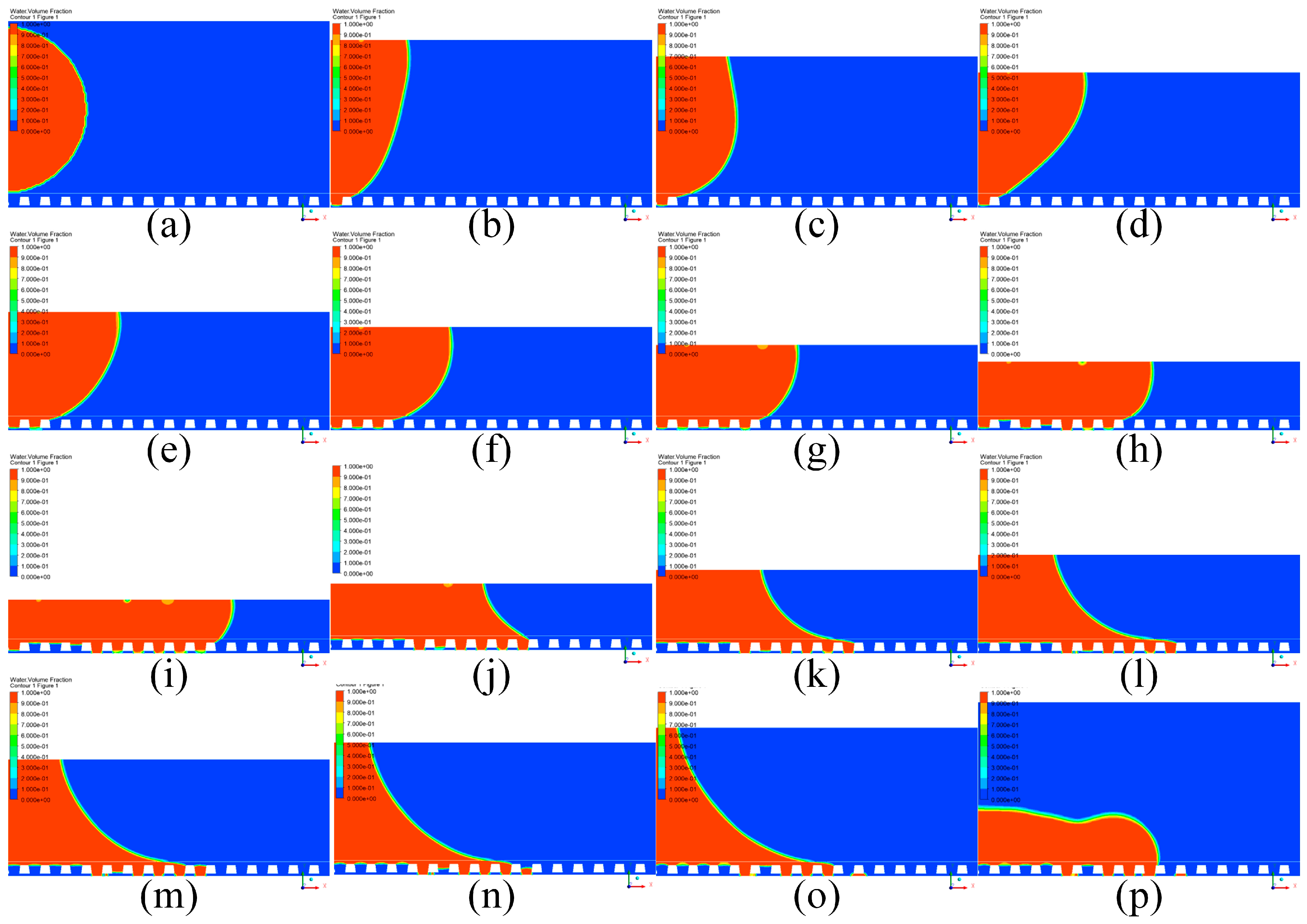

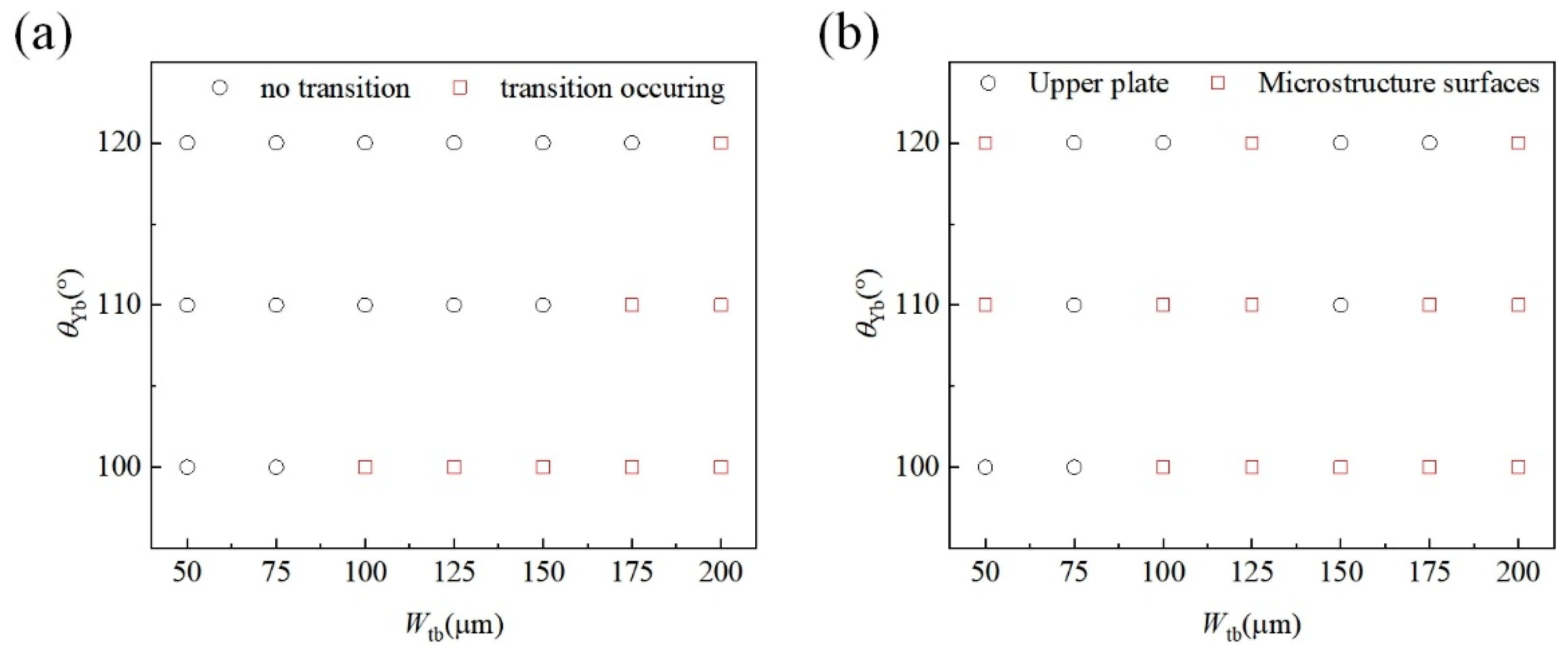

4.1.2. Cassie–Baxter State

4.1.3. Wenzel State

4.2. Influence of Microstructures and Contact Angle on Droplet Transport Performance

5. Conclusions

- (1)

- For hydrophobic surfaces (θYb > 90°), capillary force directionality (tensile/compressive) and magnitude are co-determined by microstructure geometry, θYb, and bridge spacing H: at constant wetting state, force magnitude increases with decreasing H; Increasing H transitions forces from compressive to tensile, crossing a zero-force critical point. These insights can inform the design of microfluidic systems and MEMS devices requiring precise force control.

- (2)

- Decreasing H may trigger Cassie-to-Wenzel wetting transitions on microstructured surfaces. Post-transition, droplets exclusively adhere to microstructured surfaces after rupture. Understanding this transition provides guidance for bioinspired adhesive surfaces and functional coatings.

- (3)

- Microstructures significantly reduce liquid bridge rupture height compared to smooth surfaces, suggesting strategies for optimizing droplet manipulation, sensor sensitivity, and additive manufacturing processes in wet or humid environments.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Peng, Z.; Wang, C.; Chen, S. Effects of surface wettability on gecko adhesion underwater. Colloids Surf. B Biointerfaces 2014, 122, 662–668. [Google Scholar] [CrossRef]

- Li, M.; Shi, L.; Wang, X. Physical mechanisms behind the wet adhesion: From amphibian toe-pad to biomimetics. Colloids Surf. B Biointerfaces 2021, 199, 111531. [Google Scholar] [CrossRef]

- Sun, T.; Liu, Y.; Tian, Y. Bio-inspired controllable adhesion for robotics: Mechanisms, design, and future directions. Robotica 2025, 43, 2751–2781. [Google Scholar] [CrossRef]

- Makrygianni, M.; Margariti, E.; Andritsos, K.; Reppas, D.; Zacharatos, F.; Oikonomidis, N.; Spandonidis, C.; Zergioti, I. High Speed Soldering Using Laser Printing for the Assembly of Electronic Components. J. Laser Micro/Nanoeng. 2020, 15, 204–208. [Google Scholar] [CrossRef]

- Goodband, S.; Kusumaatmaja, H.; Voïtchovsky, K. Development of a setup to characterize capillary liquid bridges between liquid infused surfaces. AIP Adv. 2022, 12, 015120. [Google Scholar] [CrossRef]

- Xiao, Y.; You, Z.; Wang, L.; Du, Z. A critical review of capillary pressure behavior and characterization in fractional-wet reservoirs. Capillarity 2024, 10, 12–21. [Google Scholar] [CrossRef]

- Dejam, M.; Hassanzadeh, H. Formation of liquid bridges between porous matrix blocks. AIChE J. 2011, 57, 286–298. [Google Scholar] [CrossRef]

- Eggers, J.; Sprittles, J.E.; Snoeijer, J.H. Coalescence Dynamics. Annu. Rev. Fluid Mech. 2025, 57, 61–87. [Google Scholar] [CrossRef]

- Zheng, J.; Ge, P.; Bi, W.; Zhao, Y.; Wang, C. Action mechanism of liquid bridge between electroplated diamond wires for ultrathin wafer slicing. Sol. Energy 2022, 231, 343–354. [Google Scholar] [CrossRef]

- Bian, X.; Huang, H.; Chen, L.; Shen, X. Droplet Tweezers Based on the Hydrophilic-Hydrophobic Interface Structure and Their Biological Application. Langmuir 2022, 38, 13522–13531. [Google Scholar] [CrossRef]

- Azizian, P.; Casals-Terré, J.; Ricart, J.; Cabot, J.M. Capillary-driven microfluidics: Impacts of 3D manufacturing on bioanalytical devices. Analyst 2023, 148, 2657–2675. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Wang, W.; Xiang, G.; Jiang, L.; Jiang, X. Capillary-Assisted Confinement Assembly for Advanced Sensor Fabrication: From Superwetting Interfaces to Capillary Bridge Patterning. ACS Nano 2025, 19, 3019–3036. [Google Scholar] [CrossRef]

- Brockmann, P.; Lannert, M.; Ennayar, H.; Cao, Y.; Dong, X.; Zhang, Z.; Brulin, S.; Roisman, I.V.; Hussong, J. Enhancement of interfacial instabilities by solid particles during fast stretching of a liquid suspension bridge. Soft Matter 2025, 21, 6559–6574. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Sun, Y.; Ding, W.; Wang, Z. The formation of liquid bridge in different operating modes of AFM. Sci. China Phys. Mech. Astron. 2016, 59, 694611. [Google Scholar] [CrossRef]

- Wei, Z.; Zhao, Y. Growth of liquid bridge in AFM. J. Phys. D Appl. Phys. 2007, 40, 4368–4375. [Google Scholar] [CrossRef]

- Wang, R.; Lai, T. Comparison of contact time dependence of adhesion force between silica/DLC and silica/graphene interfaces by AFM at different humidities. J. Phys. Conf. Ser. 2024, 2819, 012012. [Google Scholar] [CrossRef]

- Hu, R.; Luo, M.; Liu, T.; Liang, L.; Huang, A.; Trushnikov, D.; Karunakaran, K.P.; Pang, S. Thermal fluid dynamics of liquid bridge transfer in laser wire deposition 3D printing. Sci. Technol. Weld. Join. 2019, 24, 401–411. [Google Scholar] [CrossRef]

- Lee, J.; Lu, Y.; Kashyap, S.; Alarmdari, A.; Emon, M.O.F.; Choi, J.-W. Liquid bridge microstereolithography. Addit. Manuf. 2018, 21, 76–83. [Google Scholar] [CrossRef]

- Zhi, P.; Wu, Y.-C.; Rabczuk, T. Effects of time-varying liquid bridge forces on rheological properties, and resulting extrudability and constructability of three-dimensional printing mortar. Front. Struct. Civ. Eng. 2023, 17, 1295–1309. [Google Scholar] [CrossRef]

- Bagheri, M.; Roy, S.; Pöschel, T. Approximate expressions for the capillary force and the surface area of a liquid bridge between identical spheres. Comput. Part. Mech. 2024, 11, 2179–2190. [Google Scholar] [CrossRef]

- Mu, F.; Su, X. Analysis of liquid bridge between spherical particles. China Particuology 2007, 5, 420–424. [Google Scholar] [CrossRef]

- Willett, C.; Adams, M.; Johnson, S.; Seville, J. Capillary Bridges between Two Spherical Bodies. Langmuir 2000, 16, 9396–9405. [Google Scholar] [CrossRef]

- Nguyen, H.; Millet, O.; Gagneux, G. On the capillary bridge between spherical particles of unequal size: Analytical and experimental approaches. Contin. Mech. Thermodyn. 2018, 31, 225–237. [Google Scholar] [CrossRef]

- Zhao, C.; Kruyt, N.; Millet, O. Capillary bridges between spherical particles under suction control: Rupture distances and capillary forces. Powder Technol. 2020, 360, 622–634. [Google Scholar] [CrossRef]

- Xiao, F.; Jing, J.; Kuang, S.; Yang, L.; Yu, A. Capillary forces on wet particles with a liquid bridge transition from convex to concave. Powder Technol. 2020, 363, 59–73. [Google Scholar] [CrossRef]

- Wu, D.; Zhou, P.; Wang, G.; Zhao, B.; Howes, T.; Chen, W. Modeling of capillary force between particles with unequal contact angle. Powder Technol. 2020, 376, 390–397. [Google Scholar] [CrossRef]

- Wu, D.; Zhou, P.; Zhao, B.; Howes, T.; Wang, G. Liquid redistribution upon the liquid-bridge rupture between two unequal particles with a minimal energy method. Powder Technol. 2019, 354, 165–173. [Google Scholar] [CrossRef]

- Murase, K.; Mochida, T.; Sugama, H. Experimental and numerical studies on liquid bridge formed among three spheres. Granul. Matter 2004, 6, 111–119. [Google Scholar] [CrossRef]

- Murase, K.; Mochida, T.; Sagawa, Y.; Sugama, H. Estimation on the Strength of a Liquid Bridge Adhered to Three Spheres. Adv. Powder Technol. 2008, 19, 349–367. [Google Scholar] [CrossRef]

- Wang, J.; Gallo, E.; François, B.; Gabrieli, F.; Lambert, P. Capillary force and rupture of funicular liquid bridges between three spherical bodies. Powder Technol. 2017, 305, 89–98. [Google Scholar] [CrossRef]

- Teixeira, P.; Teixeira, M. The shape of two-dimensional liquid bridges. J. Phys. Condens. Matter 2020, 32, 034002. [Google Scholar] [CrossRef]

- Chen, H.; Tang, T.; Zhao, H.; Law, K.; Amirfazli, A. How pinning and contact angle hysteresis govern quasi-static liquid drop transfer. Soft Matter 2016, 12, 1998–2008. [Google Scholar] [CrossRef]

- Kwon, S.; Kim, B.; An, S.; Lee, W.; Kwak, H.Y.; Jhe, W. Adhesive force measurement of steady-state water nano-meniscus: Effective surface tension at nanoscale. Sci. Rep. 2018, 8, 8462. [Google Scholar] [CrossRef]

- Yang, L.; Tu, Y.; Fang, H. Modeling the rupture of a capillary liquid bridge between a sphere and plane. Soft Matter 2010, 6, 6178–6182. [Google Scholar] [CrossRef]

- Honschoten, V.; Tas, N.; Elwenspoek, M. The profile of a capillary liquid bridge between solid surfaces. Am. J. Phys. 2010, 78, 277–286. [Google Scholar] [CrossRef]

- Rabinovich, Y.; Esayanur, M.; Moudgil, B. Capillary Forces between Two Spheres with a Fixed Volume Liquid Bridge: Theory and Experiment. Langmuir 2005, 21, 10992–10997. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Li, Q.; Zhao, H.; Zhou, K.; Feng, X. Functional map of biological and biomimetic materials with hierarchical surface structures. RSC Adv. 2015, 5, 66901–66926. [Google Scholar] [CrossRef]

- Butler, M.; Vella, D. Liquid bridge splitting enhances normal capillary adhesion and resistance to shear on rough surfaces. J. Colloid Interface Sci. 2022, 607, 514–529. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, H.; Zhao, C.; Millet, O.; Selvadurai, A. Effects of surface roughness on liquid bridge capillarity and droplet wetting. Powder Technol. 2021, 378, 487–496. [Google Scholar] [CrossRef]

- Matsuoka, H.; Miyamoto, M.; Fukui, S. Effects of surface roughness on characteristics of liquid transfer due to breakage of liquid meniscus bridge. Microsyst. Technol. 2016, 22, 1397–1404. [Google Scholar] [CrossRef]

- Zheng, J.; Streator, J. A liquid bridge between two elastic half-spaces: A theoretical study of interface instability. Tribol. Lett. 2004, 16, 1–9. [Google Scholar] [CrossRef]

- Zhu, M.; Huang, L.; Zhang, B.; Chen, S.; Zhang, H.; Zhang, X.; Li, D.; Yao, Y.; Peng, Z.; Chen, S. Recent progress in optimal design of superhydrophobic surfaces. APL Mater. 2022, 10, 110701–110715. [Google Scholar] [CrossRef]

- Huang, L.; Yao, Y.; Peng, Z.; Zhang, B.C.; Chen, S. One-level microstructure-arrayed hydrophobic surface with low surface adhesion and strong anti-wetting function. J. Phys. Condens. Matter 2021, 33, 505002. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Yao, Y.; Peng, Z.; Zhang, B.; Chen, S. How to achieve a monostable Cassie state on a micropillar-arrayed superhydrophobic surface. J. Phys. Chem. B 2021, 125, 883–894. [Google Scholar] [CrossRef]

- Chen, H.; Amirfazli, A.; Tang, T. Modeling liquid bridge between surfaces with contact angle hysteresis. Langmuir 2013, 29, 3310–3319. [Google Scholar] [CrossRef]

- Chen, J.; Wang, P.; Li, M.; Shen, J.; Howes, T.; Wang, G. Rupture distance and shape of the liquid bridge with rough surface. Miner. Eng. 2021, 167, 106888. [Google Scholar] [CrossRef]

- Rodrigues, M.; Coelho, R.; Teixeira, P. Dynamics of liquid bridges between patterned surfaces. Phys. D Nonlinear Phenom. 2024, 469, 134322. [Google Scholar] [CrossRef]

- Shao, Z.; Ji, R.; Liu, Q. Tree-frog-inspired osmocapillary adhesive bonding to diverse substrates. arXiv 2025, arXiv:2405.05730. [Google Scholar]

- Gao, Y.; Yan, C.; Huang, H.; Yang, T.; Tian, G.; Xiong, D.; Chen, N.; Chu, X.; Zhong, S.; Deng, W.; et al. Microchannel-Confined MXene Based Flexible Piezoresistive Multifunctional Micro-Force Sensor. Adv. Funct. Mater. 2020, 30, 1909603. [Google Scholar] [CrossRef]

- Feng, J.; Qiu, Y.; Jiang, L.; Wu, Y. Long-Range-Ordered Assembly of Micro-/Nanostructures at Superwetting Interfaces. Adv. Mater. 2022, 34, e2106857. [Google Scholar] [CrossRef] [PubMed]

- Zheng, H.; Li, J.; Zhou, Y.; Zhang, C.; Xu, W.; Deng, Y.; Li, J.; Feng, S.; Yi, Z.; Zhou, X.; et al. Electrically switched underwater capillary adhesion. Nat. Commun. 2022, 13, 4584. [Google Scholar] [CrossRef] [PubMed]

- Milne, A.; Amirfazli, A. The Cassie equation: How it is meant to be used. Adv. Colloid Interface Sci. 2012, 170, 48–55. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, D.; Huang, F.; Cai, Z.; Gao, Z. Stretching and rupture of a viscous liquid bridge between two spherical particles. Asia-Pac. J. Chem. Eng. 2020, 16, e2579. [Google Scholar] [CrossRef]

- Gao, S.; Jin, L.; Du, J.; Liu, H. The Liquid-Bridge with Large Gap in Micro Structural Systems. J. Mod. Phys. 2011, 2, 404–415. [Google Scholar] [CrossRef]

- Chen, J.; Shen, J.; Guo, J.; Wang, G. Separation efficiency of liquid–solid undergoing vibration based on breakage of liquid bridge. Particuology 2022, 61, 103–110. [Google Scholar] [CrossRef]

- Dong, L.; Chaudhury, A.; Chaudhury, M. Lateral vibration of a water drop and its motion on a vibrating surface. Eur. Phys. J. E Soft Matter Biol. Phys. 2006, 21, 231–242. [Google Scholar] [CrossRef] [PubMed]

- Endlein, T.; Barnes, W. Wet Adhesion in Tree and Torrent Frogs. In Encyclopedia of Nanotechnology; Springer: Dordrecht, The Netherlands, 2016; pp. 4355–4373. [Google Scholar]

- Tselishchev, Y.; Val’tsifer, V. Influence of the Type of Contact between Particles Joined by a Liquid Bridge on the Capillary Cohesive Forces. Colloid J. 2003, 65, 385–389. [Google Scholar] [CrossRef]

- Li, Y.; Quere, D.; Lv, C.; Zheng, Q. Monostable superrepellent materials. Proc. Natl. Acad. Sci. USA 2017, 114, 3387–3392. [Google Scholar] [CrossRef]

- Fang, W.; Guo, H.; Li, B.; Li, Q.; Feng, X. Revisiting the critical condition for the Cassie–Wenzel transition on micropillar-structured surfaces. Langmuir 2018, 34, 3838–3844. [Google Scholar] [CrossRef]

- Luo, C.; Xiang, M. Existence and stability of an intermediate wetting state on circular micropillars. Microfluid. Nanofluid. 2014, 17, 539–548. [Google Scholar] [CrossRef]

| Wtb (mm) | 0.00 | 0.05 | 0.075 | 0.10 | 0.125 | 0.15 | 0.175 | 0.20 |

|---|---|---|---|---|---|---|---|---|

| θYb = 100° | 6.34 | 3.27 | 2.68 | 3.22 | 1.84 | 2.02 | 2.22 | 2.09 |

| θYb = 110° | 4.50 | 3.83 | 3.41 | 3.76 | 3.43 | 2.86 | 1.80 | 2.04 |

| θYb = 120° | 3.72 | 3.41 | 3.11 | 3.29 | 3.48 | 2.52 | 2.84 | 2.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Chen, X.; Wang, Y.; Lei, G.; Zhao, J.; Li, T.; Huang, L.; Zhang, B. Adjustable Capillary Forces Through Wetting State Changes in Liquid Bridges: Regulation via Trapezoidal Microstructures. Surfaces 2025, 8, 73. https://doi.org/10.3390/surfaces8040073

Liu Y, Chen X, Wang Y, Lei G, Zhao J, Li T, Huang L, Zhang B. Adjustable Capillary Forces Through Wetting State Changes in Liquid Bridges: Regulation via Trapezoidal Microstructures. Surfaces. 2025; 8(4):73. https://doi.org/10.3390/surfaces8040073

Chicago/Turabian StyleLiu, Yanlian, Xueli Chen, Yu Wang, Guannan Lei, Junsheng Zhao, Taiyang Li, Liyang Huang, and Bo Zhang. 2025. "Adjustable Capillary Forces Through Wetting State Changes in Liquid Bridges: Regulation via Trapezoidal Microstructures" Surfaces 8, no. 4: 73. https://doi.org/10.3390/surfaces8040073

APA StyleLiu, Y., Chen, X., Wang, Y., Lei, G., Zhao, J., Li, T., Huang, L., & Zhang, B. (2025). Adjustable Capillary Forces Through Wetting State Changes in Liquid Bridges: Regulation via Trapezoidal Microstructures. Surfaces, 8(4), 73. https://doi.org/10.3390/surfaces8040073