Vat Photopolymerization of Additively Manufactured Zirconia Ceramic Structures from Slurries of Surface Functionalized Particles: A Critical Review

Abstract

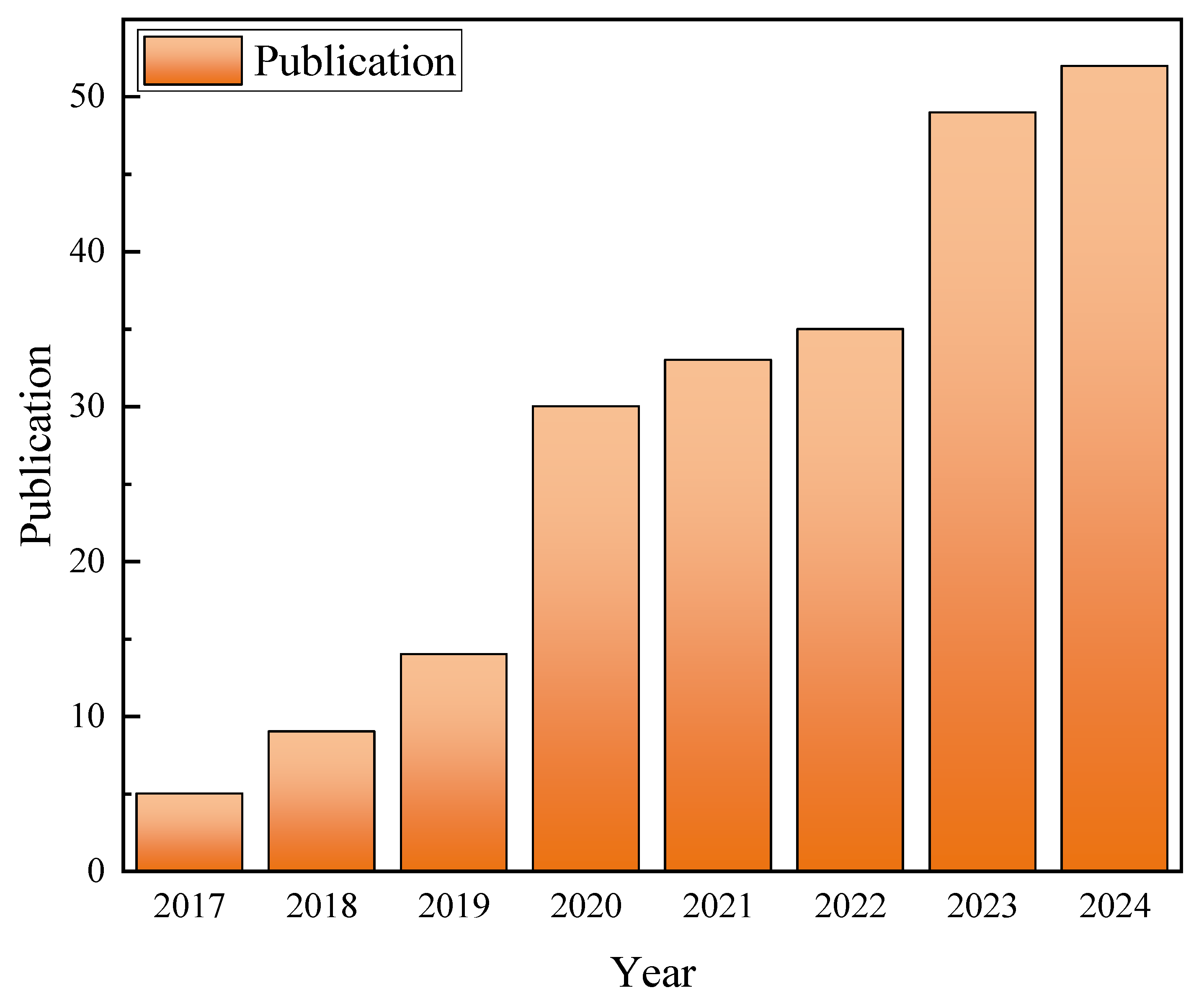

1. Introduction

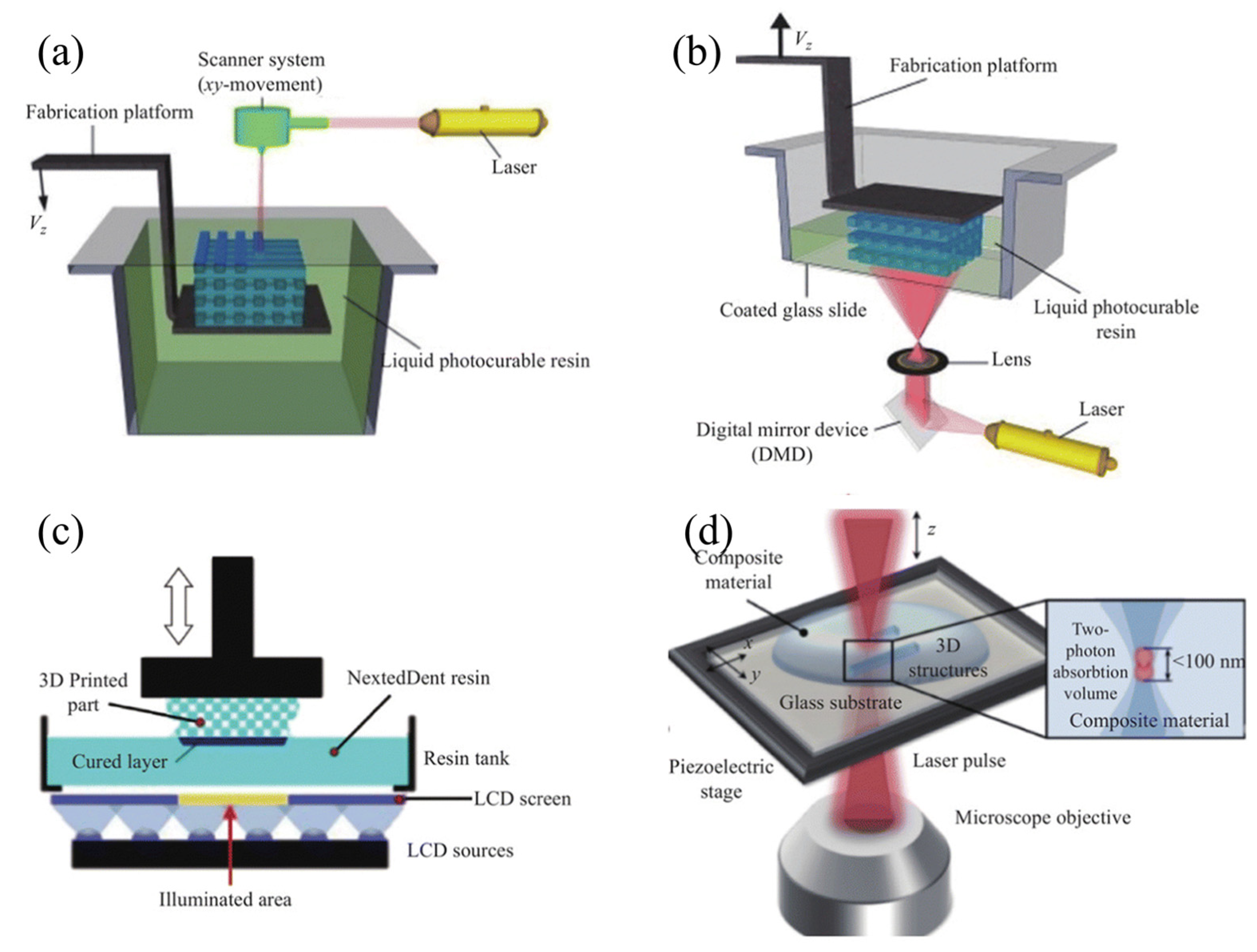

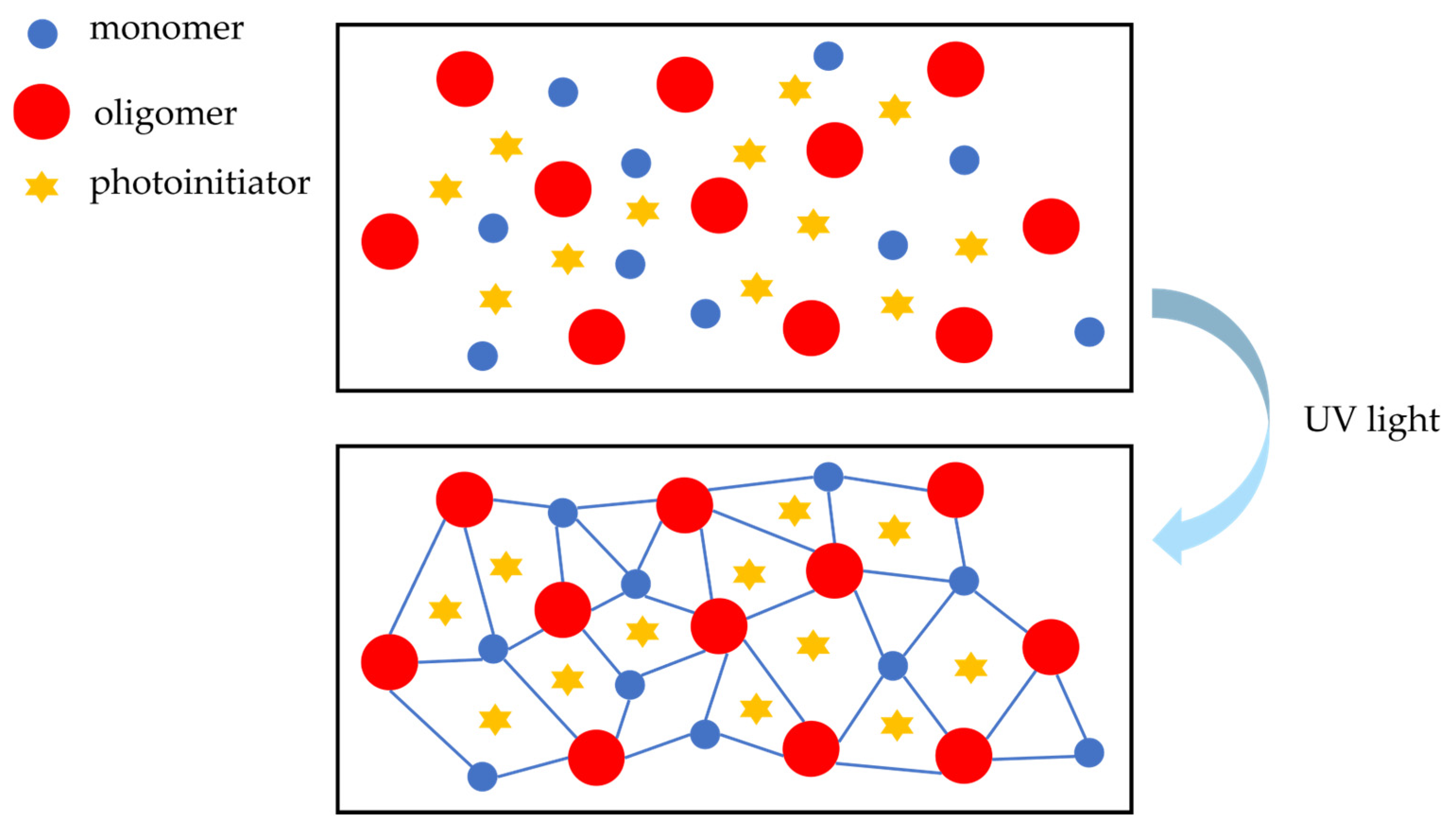

2. Introduction to Vat Photopolymeriztion

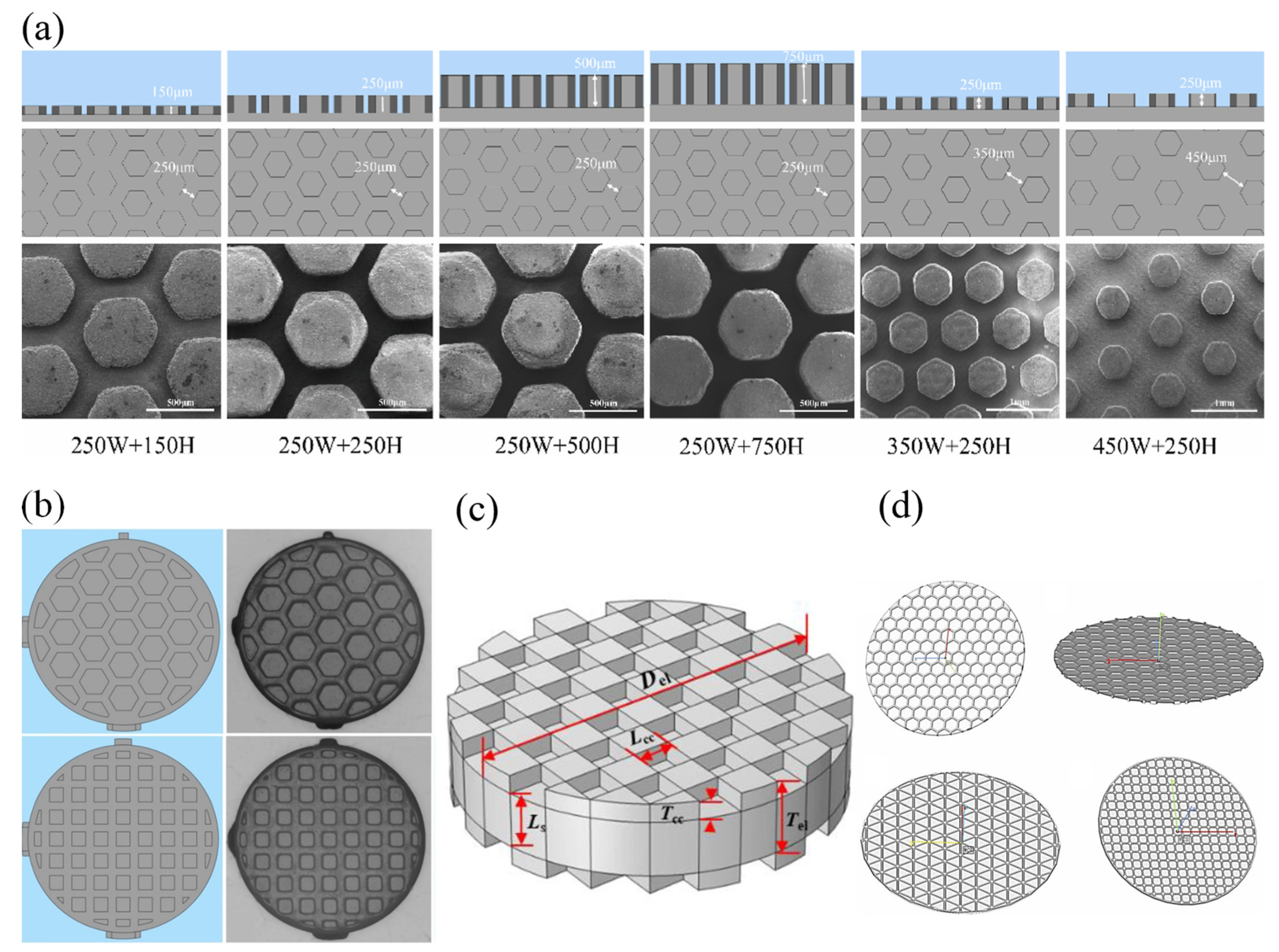

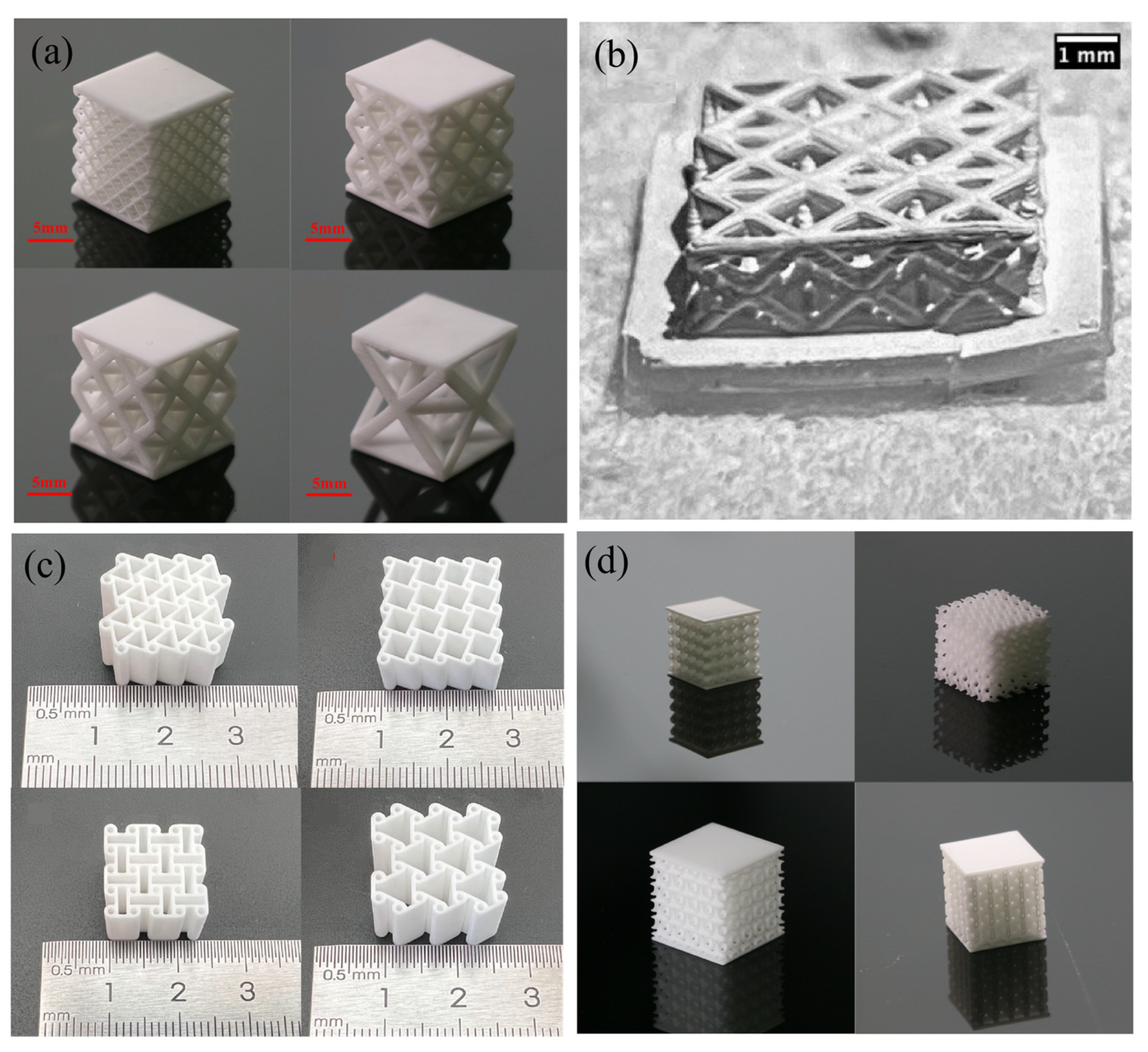

3. Surface Weaving and Topology Design

4. Micro/Nano Structures and Micro/Nano Components

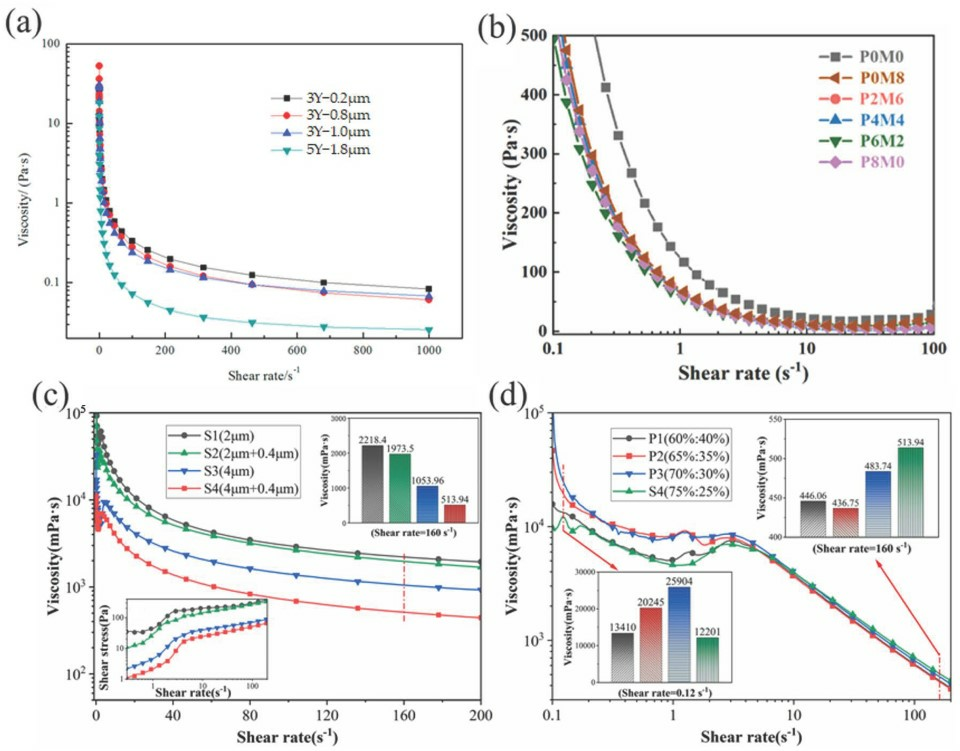

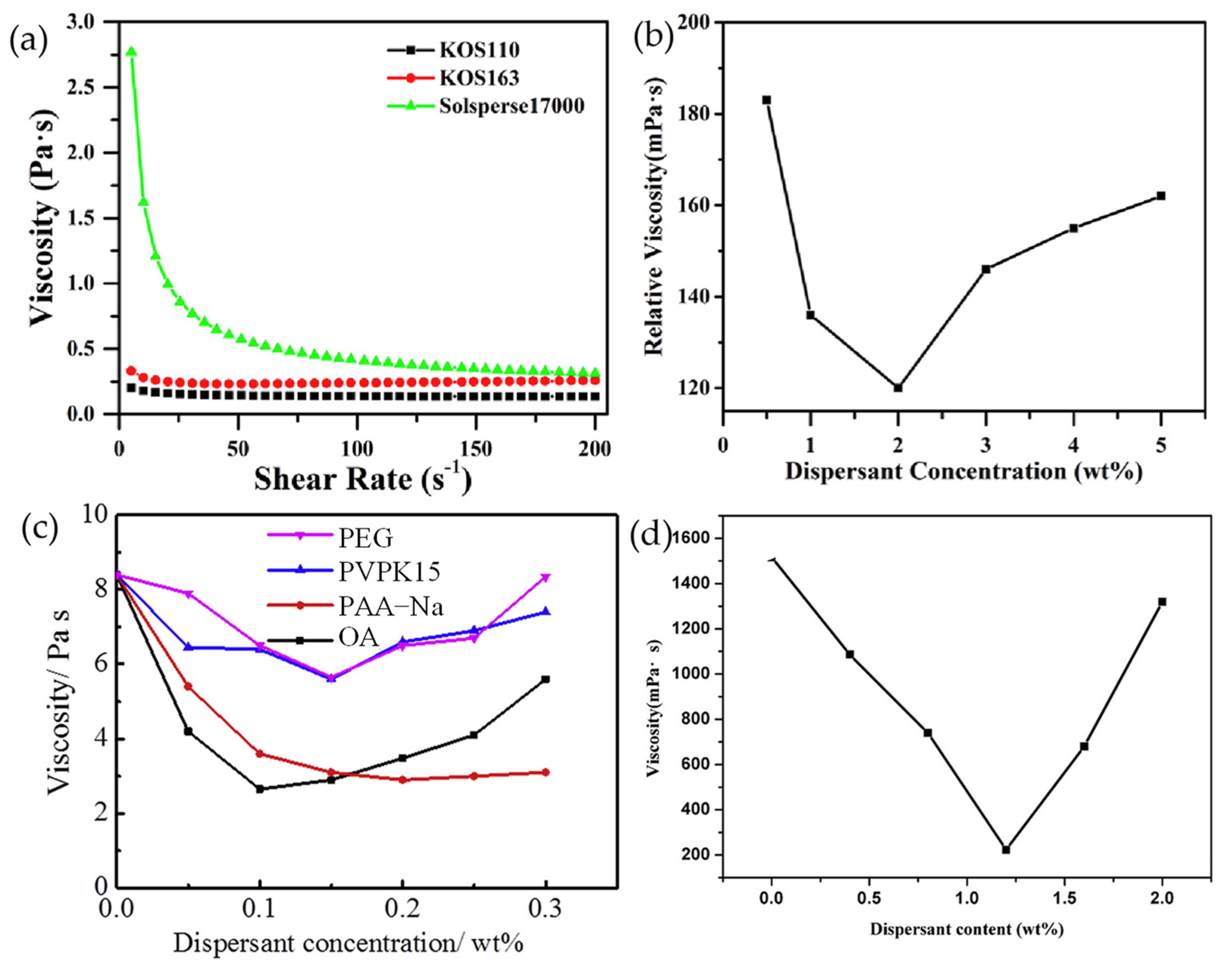

5. Optimization of ZrO2 Ceramic Slurry

5.1. Composition of ZrO2 Ceramic Slurry

5.2. Selection of Ceramic Powders

5.3. Selection of Resins and Dispersants

| Method | Type of Powder | D50 (nm) | Monomer | Dispersant | Cd (μm) | Solid Loading (vol.%) | Viscosity (Pa·s) | Reference |

|---|---|---|---|---|---|---|---|---|

| SLA | 8YSZ | 200 | TMPTA/HDDA (wt.% 1.5:8.5) | Solsperse 41000 (A 100% active polymeric dispersant) | 160 | 43 | 3.6 at 30 s−1 | [99] |

| SLA | 6Yb4ScSZ | 314 | TMPTA | Monofax 4.9vol.% | 125 | 47 | - | [100] |

| SLA | 3YSZ | 40 | HDDA | BYK-111 (A copolymer with an acid group.) | - | 50 | 20–30 at 15.8 s−1 | [132] |

| DLP | ZrO2 | 440 | HDDA | Solsperse 41000 | - | 45 | <3 at 10 s−1 | [133] |

| DLP | 3YSZ | 200 | HDDA/polyethylene glycol diacrylate (PEGDA) | DisperBYK (copolymer containing acid groups) | 50 | 83 wt.% | 1.23 at 100 s−1 | [97] |

| DLP | 3YSZ | 200 | HDDA/TMPTA | Hypermer KD-1 (polyester/polyamine condensation polymer with a cationic head group) | - | 40 | - | [134] |

| DLP | 3Y-TZP | 100–200 | - | BYK-103 (A copolymer solution with affinic filler groups) | - | 40.5/43.6 | 2 at 100 s−1 | [135] |

| DLP | HAP/ZrO2 | - | HDDA/acrylamide morpholine (ACMO)/TMPTA/hyperbranched polyester acrylate 45:35:15:5 | castor oil phosphate (COPE) (a mixed anionic dispersant) | - | 60/3 wt.% | - | [136] |

5.4. ZrO2 Composite Ceramics Slurry

| Materials | D50 (nm) | Cd (μm) | Solid Loading (vol.%) | Viscosity (Pa·s) | Reference |

|---|---|---|---|---|---|

| Ce-TZP 70 vol.%, Al2O3 30 vol.% | - | 75 | 45 | - | [125] |

| 3YSZ 80%, Al2O3 20% | SSA 6.5 m2·g−1 | 92 | 35 | 0.48 at 100 s−1 | [139] |

| Al2O3 85 vol.%, ZrO2 15 vol.% | 1000(Al2O3), 200(ZrO2) | 108 | 47 | 2.82 at 30 s−1 | [111] |

| Al2O3 80 wt.%, 5YSZ 20 wt.% | 780(Al2O3), 230(5YSZ) | - | 45 | 3.45 at 30 s−1 | [142] |

| Al2O3 75 wt.%, 3YSZ 25 wt.% | 400 (Al2O3), 200 (3YSZ) | 45 | 40 | 0.382 at 18.6 s−1 | [143] |

| SiC 85 wt.%, ZrO2 10 wt.%, Al2O3 2.5 wt.%, Y2O3 2.5 wt.% | 3600 (SiC), 300 (ZrO2), 800 (Al2O3), 3300 (Y2O3) | 30 | 40 | - | [140] |

| Si3N4 81 wt.%, ZrO2 10 wt.%, Al2O3 4.5 wt.%, Y2O3 4.5 wt.% | 1660 (Si3N4), 1280 (ZrO2) | 48.5 | - | <2 at 60 s−1 | [141] |

6. Surface Functionalization of ZrO2 Powders

7. Effect of Printing Parameters on the Properties of Zirconia Ceramics

8. Influence of the Debinding and Sintering Processes on Properties of Zirconia Ceramics

8.1. Influence of the Debinding Process on Zirconia Ceramics by VPP

| Materials | Debinding | Sintering | Relative Density (%) | Grain Size (μm) | Mechanical Properties | Reference |

|---|---|---|---|---|---|---|

| ZrO2 (D50 = 440 nm) | 600 °C in air atmosphere, 2 h | 5 °C·min−1, 1600 °C, 2 h | 99.18 | - | Flexural strength 1210 MPa, Fracture toughness 14.10 MPa·m1/2 | [101] |

| ZrO2 | - | 1450 °C, 1.5 h | 99.48 | 0.5 | Vickers hardness 15.11 GPa | [164] |

| 3Y-TZP + ZrO2 | 1000 °C, in air atmosphere, 2 h | 1600 °C, 2 h | 96.40 | - | Flexural strength 306.53 ± 6.03 MPa | [165] |

| 10Sc1YSZ | 1 °C·min−1, in air atmosphere, 800 °C | 1600 °C, 2 h, in air | 96 | 9–11 | Vickers hardness 10.80 GPa | [24] |

| 3YSZ | 0.5 °C·min−1, 600 °C, successively in argon and air atmosphere, 2 h | 5 °C·min−1, 1480 °C, 2 h | 99.60 | 0.39 | Flexural strength 1566 MPa | [166] |

| 3YSZ | 0.83 °C·min−1, 300 °C, 3 h, 380 °C, 3 h, 700 °C, 1 h | 1450 °C, 150 min | 99.95 | 2.64 | Flexural strength 1008.50 MPa | [132] |

8.2. Influence of the Sintering Process on Zirconia Ceramics by VPP

9. The Properties of Zirconia Ceramics and Composite Prepared by VPP

| Fabrication Method | Composition of Starting Powders | Relative Density (%) | Grain Size (μm) | Vickers Hardness (GPa) | Fracture Toughness (MPa·m1/2) | Flexural Strength (MPa) | Reference |

|---|---|---|---|---|---|---|---|

| SLA | Al2O3 80 wt.%, ZrO2 20 wt.% | 99.5 | 1.08 (Al2O3), 0.35 (ZrO2) | 17.76 ± 0.21 | 5.72 ± 0.50 | 530.25 ± 29.5 | [103] |

| SLA | Al2O3 80 wt.%, ZrO2 20 wt.% | 99.7 | 1.07 (Al2O3), 0.34 (ZrO2) | 17.6 | 5.2 | - | [104] |

| SLA | Al2O3 85 vol.%, ZrO2 15 vol.% | - | - | 14.1 | 4.05 | - | [170] |

| SLA | Large-Al2O3 70 vol.%, Fine-Al2O3 15 vol.%, Fine- ZrO2 15 vol.% | 99.4 | 3 (Al2O3) | 19.20 ± 0.89 | 7.4 ± 1.02 | 575 ± 87 | [111] |

| SLA | Al2O3 80 wt.%, ZrO2 (Y2O3 1 wt.%) 20 wt.% | 96.65 | 3.05 ± 1.78 (Al2O3), 1.69 ± 0.68 (ZrO2) | 16.2 | 7.4 | 572.0 | [142] |

| DLP | ZrO2 20 wt.%, MgO 0.5 wt.%, Y2O3 1 wt.%, La2O3 0.25 wt.% | 97.93 | 1.63 ± 0.04 (Al2O3), 1.14 ± 0.02 (ZrO2) | 18.8 | 6.94 | 556.6 | [182] |

| DLP | Al2O3 75 wt.%, 3YSZ 25 wt.% | 99.4 | - | 17.40 | 7.76 | 516.7 | [143] |

| DLP | 3Y-TZP 85 vol.%, α-Al2O3 15 vol.% | 99.6 | 0.61 ± 0.19 (ZrO2), 0.65 ± 0.27 (Al2O3) | 15.36 ± 0.77 | - | 764 ± 136 | [178] |

| DLP | 3YSZ 80 vol.%, Al2O3 20 vol.% (microplatelet:equiaxed = 3:1) | 97.4 ± 0.6 | 0.94 ± 0.11 (ZrO2) | 12.5 | 16.9 ± 0.8 | 539 | [121] |

| DLP | 3YSZ 80 wt.%, Al2O3 20 wt.% | ∼99 | ∼0.18 | - | - | 840 | [133] |

| DLP | SiC 85 wt.%, ZrO2 10 wt.%, Al2O3 2.5 wt.%, Y2O3 2.5 wt.% | 91.1 ± 3.2% | - | 9.76 ± 0.92 | - | 201.5 ± 11.4 | [140] |

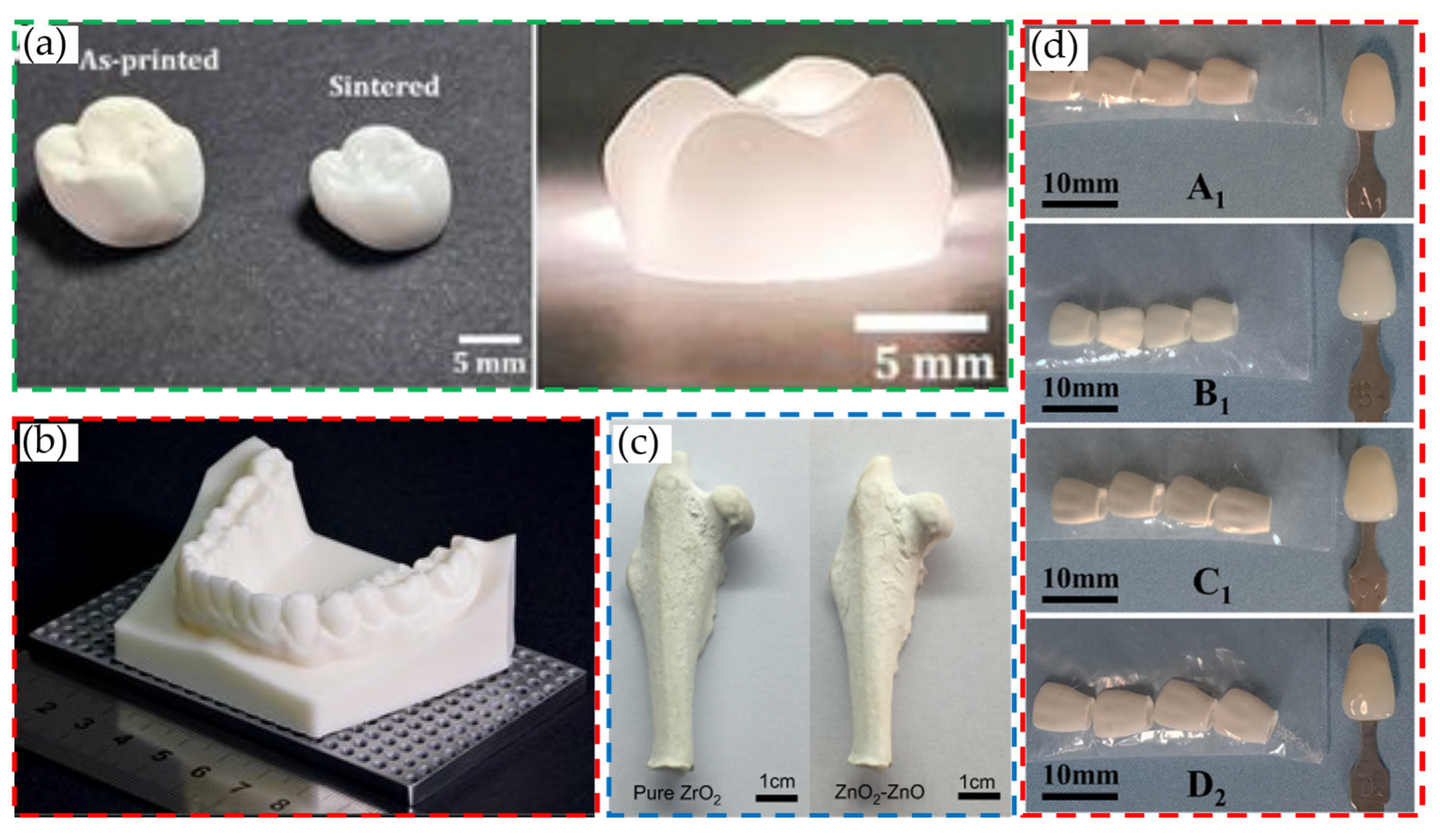

10. Applications of ZrO2 Ceramics by VPP

10.1. Biological Materials

10.2. Solid Oxide Fuel Cell (SOFC) Electrolytes

| Materials | Printing Method | Ionic Conductivity (mS·cm−1) | Geometries (Thickness) | MPDs (mW·cm−2) | Reference |

|---|---|---|---|---|---|

| 3YSZ | SLA | 22 at 900 °C | flat | 100 at 900 °C | [204] |

| honeycomb-like | 110 at 900 °C | ||||

| 8YSZ | SLA | 40 at 850 °C | 3-tube | 230 at 850 °C | [99] |

| 8YSZ | SLA | - | planar (300 μm) | 197.6 at 850 °C | [84] |

| concavo-convex (300 μm) | 288.9 at 850 °C | ||||

| 8YSZ | SLA | 30 at 900 °C | planar (250 μm) | 260 at 900 °C | [6] |

| corrugated (250 μm) | 252 at 850 °C 410 at 900 °C | ||||

| 8YSZ | DLP | - | planar | 114 at 800 °C | [81] |

| honeycomb | 215.4 at 800 °C | ||||

| 8YSZ | DLP | - | ripple-shaped (170 μm) | 197.6 at 800 °C | [206] |

| 8YSZ | DLP | 21.8 at 800 °C | flat | 114.3 at 800 °C | [207] |

| ScSZ | SLA | 35 at 850 °C | planar (265 μm) | 300 at 900 °C | [100] |

| corrugated (265 μm) | 470 at 900 °C |

10.3. Other Applications

11. Conclusions and Prospects

- (1)

- This review firstly summarizes the compositional formulations of zirconia and composites slurry for VPP preparation, and introduces the commonly used resins, dispersants and other slurry compositions. The research on the improvement of slurry properties is summarized, including the selection of powders with moderate particle size, suitable particle size distribution, surface modification of powders, and the regulation of the type and content of resins and dispersants. The smoothness of printing as well as the performance of the components was ensured by improving the interaction between powders and lowering the viscosity while ensuring the solid content. In addition, the performance of the composite powders on the slurry and printed products is summarized, and the slurry components need to be adjusted according to the nature of the material.

- (2)

- In order to further improve the rheological properties of the slurry and make up for the shortcomings in the application of dispersants, the ceramic powders can be surface-functionalized. Surface modification of zirconia powders using surface modifiers such as silane coupling agents reduces the hydrophilicity and improves the dispersion of the powders.

- (3)

- The design of surface weave and topology is an important ring that can take advantage of VPP. Software modeling such as CAD is used to design structures that are difficult to fabricate by conventional manufacturing methods. Surface texturing has a significant improvement on material properties, especially in terms of abrasion resistance and anti-slip. Bionic weaving will be one of the key directions for surface applications. The design of component topology can play a role in reducing component mass and improving mechanical properties. In addition, the influence of printing parameters such as light intensity, layer thickness, and printing angle on print quality is summarized. The printing parameters need to be dynamically regulated in conjunction with the curing properties of ceramic slurries, and the moderate printing parameters are in turn required for their curing properties.

- (4)

- The effects of process parameters on the components during debinding/sintering are summarized. Factors such as mode, atmosphere, temperature, and rate of temperature rise all have a significant impact on debinding/sintering results. The debinding method combining an inert atmosphere with an air environment can well reduce the possibility of defects appearing. Regulate the rate of temperature rise to avoid defects from excessive thermal stress. Select the appropriate temperature to remove organic matter during debinding, and promote the densification process without adversely causing excessive grain growth.

- (5)

- The high degree of liberalization of VPP provides new possibilities for the application of zirconia ceramics. Zirconia itself, with its favorable mechanical properties, high biocompatibility and stabilized electrical properties, has a good potential for applications in biomedicine and electronic energy with the help of VPP. Zirconia dentures, bone repair scaffolds and solid oxide fuel cell electrolytes prepared by VPP have excellent performance.

- (6)

- In the future, zirconia preparation using VPP will develop in line with additive manufacturing and VPP technology. Firstly, the development of 4D printing technology will extend the use of zirconia components to include the time dimension. Secondly, AI technology will be applied to reduce the time cost of research and development by predicting slurry performance. Additionally, combining multiple materials can produce gradient components tailored to specific requirements. Furthermore, high-throughput in situ monitoring technology can be used to adjust process parameters and improve the performance of zirconia prepared by VPP. Finally, attention should be paid to solving the regulatory and scaling issues that arise when applying VPP technology. The difficulties of establishing evaluation standards and mass production brought about by personalization must be overcome.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, K.; He, R.; Xie, C.; Wang, G.; Ding, G.; Wang, M.; Song, W.; Fang, D. Photosensitive ZrO2 suspensions for stereolithography. Ceram. Int. 2019, 45, 12189–12195. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, S.; Zhang, C. Fabrication of ZTA crowns with simultaneously improved isotropy on mechanical property and surface quality by DLP. Int. J. Appl. Ceram. Technol. 2024, 21, 1593–1615. [Google Scholar] [CrossRef]

- Chan, R.N.; Stoner, B.R.; Thompson, J.Y.; Scattergood, R.O.; Piascik, J.R. Fracture toughness improvements of dental ceramic through use of yttria-stabilized zirconia (YSZ) thin-film coatings. Dent. Mater. 2013, 29, 881–887. [Google Scholar] [CrossRef]

- Chen, F.; Zhu, H.; Wu, J.-M.; Chen, S.; Cheng, L.-J.; Shi, Y.-S.; Mo, Y.-C.; Li, C.-H.; Xiao, J. Preparation and biological evaluation of ZrO2 all-ceramic teeth by DLP technology. Ceram. Int. 2020, 46, 11268–11274. [Google Scholar] [CrossRef]

- Li, B.; Jiang, Q.; Meng, D. Evaluation of the trueness and adaptation of zirconia crowns fabricated with stereolithography. Dent. Mater. J. 2023, 42, 441–448. [Google Scholar] [CrossRef] [PubMed]

- Pesce, A.; Hornes, A.; Nunez, M.; Morata, A.; Torrell, M.; Tarancon, A. 3D printing the next generation of enhanced solid oxide fuel and electrolysis cells. J. Mater. Chem. A 2020, 8, 16926–16932. [Google Scholar] [CrossRef]

- Dauletbekova, A.; Zvonarev, S.; Nikiforov, S.; Akilbekov, A.; Shtang, T.; Karavannova, N.; Akylbekova, A.; Ishchenko, A.; Akhmetova-Abdik, G.; Baymukhanov, Z.; et al. Luminescence properties of ZrO2: Ti ceramics irradiated with electrons and high-energy Xe ions. Materials 2024, 17, 1307. [Google Scholar] [CrossRef]

- Yoon, H.-S.; Kwon, S.B.; Nagaraj, A.; Min, S. Investigation of the ductile cutting behavior of monocrystalline yttria-stabilized zirconia during ultra-precision orthogonal cutting. Int. J. Precis. Eng. Manuf. 2019, 20, 1475–1484. [Google Scholar] [CrossRef]

- Aleksandrova, I.; Hristov, T. Modelling and optimizing the tool life of zirconia toughened alumina ceramic cutting tools during turning. In Proceedings of the 7th International Conference on Energy Efficiency and Agricultural Engineering (ee&ae), Ruse, Bulgaria, 12–14 November 2020; IEEE: New York, NY, USA, 2020. [Google Scholar]

- Liu, W.; Wu, H.; Xu, Y.; Lin, L.; Li, Y.; Wu, S. Cutting performance and wear mechanism of zirconia toughened alumina ceramic cutting tools formed by vat photopolymerization-based 3D printing. Ceram. Int. 2023, 49, 23238–23247. [Google Scholar] [CrossRef]

- Spirig, J.V.; Ramamoorthy, R.; Akbar, S.A.; Routbort, J.L.; Singh, D.; Dutta, P.K. High temperature zirconia oxygen sensor with sealed metal/metal oxide internal reference. Sens. Actuators B Chem. 2007, 124, 192–201. [Google Scholar] [CrossRef]

- Bangi, U.K.H.; Bachuwar, V.D.; Park, H.-H. Zirconia coatings as efficient soil moisture sensors for water irrigation. IEEE Sens. J. 2021, 21, 21205–21211. [Google Scholar] [CrossRef]

- Benammar, M. Design and assembly of miniature zirconia oxygen sensors. IEEE Sens. J. 2004, 4, 3–8. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Z.; Huang, J.; Jiang, Y. Zirconia-based solid acid catalysts for biomass conversion. Energy Fuels 2021, 35, 9209–9227. [Google Scholar] [CrossRef]

- Han, Y.; Zhu, J. Surface science studies on the zirconia-based model catalysts. Top. Catal. 2013, 56, 1525–1541. [Google Scholar] [CrossRef]

- Guan, P.; Zhao, Y.; Wu, Y.; Li, W.; Zhang, X.; Gao, X.; Ou, X.; Chai, W.S.; He, Y.; Li, H.N. One-step calcination strategy of 3D printing CuO–ZnO–ZrO2 catalysts for CO2 hydrogenation using digital light processing (DLP). Mater. Today Sustain. 2025, 29, 101086. [Google Scholar] [CrossRef]

- Ouyang, J.-H.; Li, Y.-F.; Zhang, Y.-Z.; Wang, Y.-M.; Wang, Y.-J. High-temperature solid lubricants and self-lubricating composites: A critical review. Lubricants 2022, 10, 177. [Google Scholar] [CrossRef]

- Slifka, A.J.; Filla, B.J.; Phelps, J.M.; Bancke, G.; Berndt, C.C. Thermal conductivity of a zirconia thermal barrier coating. J. Therm. Spray Technol. 1998, 7, 43–46. [Google Scholar] [CrossRef]

- Yi, Z.; Shan, K.; Zhai, F.; Xie, Z.; Li, N.; Mao, Y. Preparation and properties of thermal barrier coating with nanometer alumina coated zirconia. Rare Met. Mater. Eng. 2018, 47, 445. [Google Scholar]

- Rosado, E.; Canas, E.; Recio, P.; Sanchez, E.; Moreno, R. ZrSiO4/ZrO2 thermal barrier coatings produced by suspension plasma spraying. J. Eur. Ceram. Soc. 2024, 44, 460–470. [Google Scholar] [CrossRef]

- Kozlovskiy, A.L.; Konuhova, M.; Borgekov, D.B.; Anatoli, I.P. Study of irradiation temperature effect on radiation-induced polymorphic transformation mechanisms in ZrO2 ceramics. Opt. Mater. 2024, 156, 115994. [Google Scholar] [CrossRef]

- Raj, R.; Singh, G. A review on process prerequisites and biomedical applications of additively manufactured zirconia. Eng. Sci. Technol. Int. J. 2024, 59, 101876. [Google Scholar] [CrossRef]

- Garvie, R.C.; Hannink, R.H.; Pascoe, R.T. Ceramic steel? Nature 1975, 258, 703–704. [Google Scholar] [CrossRef]

- Komissarenko, D.A.; Sokolov, P.S.; Evstigneeva, A.D.; Slyusar, I.; Nartov, A.S.; Volkov, P.A.; Lyskov, N.; Evdokimov, P.; Putlayev, V.; Dosovitsky, A.E. DLP 3D printing of scandia-stabilized zirconia ceramics. J. Eur. Ceram. Soc. 2021, 41, 684–690. [Google Scholar] [CrossRef]

- Wang, L.; Yu, H.; Hao, Z.; Tang, W.; Dou, R. Fabrication of highly translucent yttria-stabilized zirconia ceramics using stereolithography-based additive manufacturing. Ceram. Int. 2023, 49, 17174–17184. [Google Scholar] [CrossRef]

- Sheng, Y.; Wang, L.; Dou, R.; Zhu, F.; Gao, Y. Effects of dopants with varying cationic radii on the mechanical properties and hydrothermal aging stability of dental 3Y-TZP ceramics fabricated via vat photopolymerization. Ceram. Int. 2025, 51, 11857–11870. [Google Scholar] [CrossRef]

- Chevalier, J.; Gremillard, L.; Virkar, A.V.; Clarke, D.R. The tetragonal-monoclinic transformation in zirconia: Lessons learned and future trends. J. Am. Ceram. Soc. 2009, 92, 1901–1920. [Google Scholar] [CrossRef]

- Yousefian, Z.; Dini, G.; Milani, M.; Arastoo, E. Zirconia-doped yttria transparent ceramics via slip casting and sintering. Mater. Chem. Phys. 2021, 273, 125097. [Google Scholar] [CrossRef]

- Gnanasagaran, C.L.; Ramachandran, K.; Jamadon, N.H.; Kumar, V.H.; Muchtar, A.; Pazhani, A.; Ayaz, B. Microstructural and mechanical behaviours of Y-TZP prepared via slip-casting and fused deposition modelling (FDM). Heliyon 2023, 9, e21705. [Google Scholar] [CrossRef]

- Calambás Pulgarin, H.L.; Garrido, L.B.; Albano, M.P. Comparison of different zirconia powders for slip casting of alumina-zirconia ceramics. Adv. Appl. Ceram. Struct. Funct. Bioceram. 2013, 112, 39–45. [Google Scholar] [CrossRef]

- Xin, X.; Lü, Z.; Huang, X.; Sha, X.; Zhang, Y.; Chen, K.; Ai, N.; Zhu, R.; Su, W. Solid oxide fuel cells with dense yttria-stabilized zirconia electrolyte membranes fabricated by a dry pressing process. J. Power Sources 2006, 160, 1221–1224. [Google Scholar] [CrossRef]

- He, Q.; Qin, Y.; Zhan, X.; Zhang, W.; Ye, J. Physicochemical and biological properties of Y-TZP ceramics modified by infiltration with different bioactive glasses for dental implant. Ceram. Int. 2023, 49, 29187–29197. [Google Scholar] [CrossRef]

- Lach, R.; Bućko, M.M.; Haberko, K.; Sitarz, M.; Cholewa-Kowalska, K. From nanometric zirconia powder to transparent polycrystal. J. Eur. Ceram. Soc. 2014, 34, 4321–4326. [Google Scholar] [CrossRef]

- Kim, K.T.; Kim, H.G.; Jang, H.M. Densification behavior and grain growth of zirconia powder compact under high temperature. Int. J. Eng. Sci. 1998, 36, 1295–1312. [Google Scholar] [CrossRef]

- Akimov, G.Y.; Chaika, E.V.; Marinin, G.A. Wear and fracture toughness of partially stabilized zirconia ceramics under dry friction against steel. J. Frict. Wear 2009, 30, 77–79. [Google Scholar] [CrossRef]

- Tan, Q.Q.; Gao, M.; Zhang, Z.T.; Tang, Z.L. Polymerizing mechanism and technical factors optimization of nanometer tetragonal polycrystalline zirconia slurries for the aqueous-gel-tape-casting process. Mater. Sci. Eng. A 2004, 382, 1–7. [Google Scholar] [CrossRef]

- Baquero, T.; Escobar, J.; Frade, J.; Hotza, D. Aqueous tape casting of micro and nano YSZ for SOFC electrolytes. Ceram. Int. 2013, 39, 8279–8285. [Google Scholar] [CrossRef]

- Ghatee, M.; Salihi, H. Electrical and mechanical properties of 25 wt% tetragonal/cubic zirconia based composite thin films prepared by combination of aqueous tape casting and net shape methods. J. Electroceramics 2015, 35, 98–105. [Google Scholar] [CrossRef]

- Liu, R.; Li, Y.; Wang, C.-A.; Tie, S. Fabrication of porous alumina–zirconia ceramics by gel-casting and infiltration methods. Mater. Des. 2014, 63, 1–5. [Google Scholar] [CrossRef]

- Yoshida, M.; Hada, M.; Sakurada, O.; Morita, K. Transparent tetragonal zirconia prepared by sinter forging at 950 °C. J. Eur. Ceram. Soc. 2023, 43, 2051–2056. [Google Scholar] [CrossRef]

- Li, G.; Ren, R. Preparation of YSZ-TZP solid electrolytes by gel-casting technology. J. Environ. Sci. 2011, 23, S170–S172. [Google Scholar] [CrossRef]

- Chen, F.; Wu, J.-M.; Wu, H.-Q.; Chen, Y.; Li, C.-H.; Shi, Y.-S. Microstructure and mechanical properties of 3Y-TZP dental ceramics fabricated by selective laser sintering combined with cold isostatic pressing. Int. J. Lightweight Mater. Manuf. 2018, 1, 239–245. [Google Scholar] [CrossRef]

- Grossin, D.; Montón, A.; Navarrete-Segado, P.; Özmen, E.; Urruth, G.; Maury, F.; Maury, D.; Frances, C.; Tourbin, M.; Lenormand, P.; et al. A review of additive manufacturing of ceramics by powder bed selective laser processing (sintering/melting): Calcium phosphate, silicon carbide, zirconia, alumina, and their composites. Open Ceram. 2021, 5, 100073. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y.; Wiria, F.E.; Tay, B.Y.; Zhao, Z.; Zhao, L.; Tian, Z.; Yang, S. Direct selective laser sintering and melting of ceramics: A review. Rapid Prototyp. J. 2017, 23, 611–623. [Google Scholar] [CrossRef]

- Peng, E.; Wei, X.; Garbe, U.; Yu, D.; Edouard, B.; Liu, A.; Ding, J. Robocasting of dense yttria-stabilized zirconia structures. J. Mater. Sci. 2018, 53, 247–273. [Google Scholar] [CrossRef]

- Shahzad, A.; Lazoglu, I. Direct ink writing (DIW) of structural and functional ceramics: Recent achievements and future challenges. Compos. Part B Eng. 2021, 225, 109249. [Google Scholar] [CrossRef]

- dos Santos, V.I.; Ferey, A.; Chevalier, E.; Fredel, M.C.; Henriques, B.; Gremillard, L. Mechanical evaluation of DIW-printed carbon nanofibers—Alumina-toughened zirconia composites. J. Eur. Ceram. Soc. 2024, 44, 116745. [Google Scholar] [CrossRef]

- Hajjaj, M.S.; Alamoudi, R.A.A.; Babeer, W.A.; Rizg, W.Y.; Basalah, A.A.; Alzahrani, S.J.; Yeslam, H.E. Flexural strength, flexural modulus and microhardness of milled vs. fused deposition modeling printed Zirconia; effect of conventional vs. speed sintering. BMC Oral Health 2024, 24, 38. [Google Scholar] [CrossRef]

- Petit, C.; Meunier, C.; Manceaux, L.; Rivera, H.; Taxil, H. Fused deposition modeling and microwave sintering of 3Y-TZP samples. Open Ceram. 2023, 15, 100378. [Google Scholar] [CrossRef]

- Yang, X.; Guo, J.; Li, Y.; Yang, X. Compressive fracture behavior of zirconia/resin composites prepared by fused deposition modeling combined with vacuum infiltration. Materials 2024, 17, 1989. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Ye, C.; Zhao, H.; Fan, Z.; Wei, Q. Binder jetting yttria stabilised zirconia ceramic with inorganic colloid as a binder. Adv. Appl. Ceram. 2019, 118, 458–465. [Google Scholar] [CrossRef]

- Huang, X.; Zhao, T.; Wang, T.; Li, S.; Wang, G. Binder jetting printing of zirconia structures via grading powder and epoxy binder. Adv. Appl. Ceram. 2022, 121, 231–237. [Google Scholar] [CrossRef]

- Huang, S.; Wu, H.; Jiang, C.; Fu, X.; Liu, Y.; Zhang, J.; He, L.; Yang, P.; Deng, X.; Wu, S. Preparation of high-strength ZrO2 ceramics by binder jetting additive manufacturing and liquid glass infiltration. Ceram. Int. 2024, 50, 44175–44185. [Google Scholar] [CrossRef]

- Fan, Z.; Zhao, Y.; Lu, M.; Huang, H. Yttria stabilized zirconia (YSZ) thin wall structures fabricated using laser engineered net shaping (LENS). Int. J. Adv. Manuf. Technol. 2019, 105, 4491–4498. [Google Scholar] [CrossRef]

- Yan, S.; Wu, D.; Niu, F.; Huang, Y.; Liu, N.; Ma, G. Effect of ultrasonic power on forming quality of nano-sized Al2O3-ZrO2 eutectic ceramic via laser engineered net shaping (LENS). Ceram. Int. 2018, 44, 1120–1126. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, X.; Meng, Q.; Zhang, B.; Qu, Z.; He, R. Failure behavior and mechanism of vat photopolymerization additively manufactured Al2O3 ceramic lattice structures. Addit. Manuf. Front. 2024, 3, 200172. [Google Scholar] [CrossRef]

- Wang, Z.-H.; Zhang, Y.-Z.; Miao, W.-J.; Wu, F.-B.; Wang, S.-Q.; Jia-Hu, O.; Wang, Y.-M.; Zou, Y.-C. Vat photopolymerization-based additive manufacturing of Si3N4 ceramic structures: Printing optimization, debinding/sintering, and applications. Materials 2025, 18, 1556. [Google Scholar] [CrossRef]

- Lu, X.; Liu, G.; Lu, J. Development of ceramic 3D/4D printing in China. Addit. Manuf. Front. 2024, 3, 200158. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Lu, X.; Zhao, Y.; Zhou, Z.; Xu, J.; Yin, J.; Tang, T.; Wang, P.; Yi, S.; et al. 4D additive-subtractive manufacturing of shape memory ceramics. Adv. Mater. 2023, 35, e2302108. [Google Scholar] [CrossRef]

- Wang, F.; Liu, C.; Yang, H.; Wang, H.; Zhang, H.; Zeng, X.; Wang, C.; Zhang, W.; Lv, W.; Zhu, P.; et al. 4D printing of ceramic structures. Addit. Manuf. 2023, 63, 103411. [Google Scholar] [CrossRef]

- Li, Y.; Sheng, P.; Lin, L.; Wang, L.; Lu, D.; Lin, K.; Wu, H.; Wu, S. Vat photopolymerization versus conventional colloidal processing methods in structural ceramics: Progress, challenges, and future perspectives. Addit. Manuf. Front. 2024, 3, 200110. [Google Scholar] [CrossRef]

- Zhao, J.-J.; Zhang, Y.-Z.; Li, J.-H.; Wang, Z.-H.; Miao, W.-J.; Wu, F.-B.; Wang, S.-Q.; Ouyang, J.-H. Additive manufacturing of alumina-based ceramic structures by vat photopolymerization: A review of strategies for improving shaping accuracy and properties. Materials 2025, 18, 2445. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Li, D.; Lian, Q.; Wang, L.; Lu, Z.; Huang, K.; Wang, F.; Liang, Q.; Zhang, H.; Meng, Z.; et al. Additive manufacturing of integrated micro/macro structures driven by diversified functions—30 years of development of additive manufacturing in xi’an jiaotong university. Addit. Manuf. Front. 2024, 3, 200140. [Google Scholar] [CrossRef]

- Brady, G.A.; Halloran, J.W. Stereolithography of ceramic suspensions. Rapid Prototyp. J. 1997, 3, 61–65. [Google Scholar] [CrossRef]

- Nakamoto, T.; Yamaguchi, K.; Abraha, A.P. Consideration on the producing of high aspect ratio micro parts using UV sensitive photopolymer. In Proceedings of the MHS’96 Proceedings of the Seventh International Symposium on Micro Machine and Human Science, Nagoya, Japan, 2–4 October 1996; pp. 53–58. [Google Scholar]

- Hussain, M.I.; Xia, M.; Ren, X.; Ge, C.; Jamil, M.; Gupta, M.K. Digital light processing 3D printing of ceramic materials: A review on basic concept, challenges, and applications. Int. J. Adv. Manuf. Technol. 2024, 130, 3017–3029. [Google Scholar] [CrossRef]

- Subedi, S.; Liu, S.; Wang, W.; Naser Shovon, S.M.A.; Chen, X.; Ware, H.O.T. Multi-material vat photopolymerization 3D printing: A review of mechanisms and applications. Npj Adv. Manuf. 2024, 1, 9. [Google Scholar] [CrossRef]

- Mamatha, S.; Biswas, P.; Johnson, R. Digital light processing of ceramics: An overview on process, materials and challenges. Prog. Addit. Manuf. 2023, 8, 1083–1102. [Google Scholar] [CrossRef]

- Wu, Y.; He, J.; Zhong, K.; Chen, C.; Wang, S.; Zhu, X.; She, X.; Song, Y.; Xu, H. Optimizing the separation process for improved zirconia molding through liquid crystal display 3D printing. Ceram. Int. 2024, 50, 43350–43361. [Google Scholar] [CrossRef]

- Schwarzer, E.; Holtzhausen, S.; Scheithauer, U.; Ortmann, C.; Oberbach, T.; Moritz, T.; Michaelis, A. Process development for additive manufacturing of functionally graded alumina toughened zirconia components intended for medical implant application. J. Eur. Ceram. Soc. 2019, 39, 522–530. [Google Scholar] [CrossRef]

- Tarak, F.; Okoruwa, L.; Ozkan, B.; Sameni, F.; Schaefer, G.; Sabet, E. AI for AM: Machine learning approach to design the base binder formulation for vat-photopolymerisation 3D printing of zirconia ceramics. Virtual Phys. Prototyp. 2025, 20, e2469822. [Google Scholar] [CrossRef]

- Guo, W.; Li, B.; Li, P.; Zhao, L.; You, H.; Long, Y. Review on vat photopolymerization additive manufacturing of bioactive ceramic bone scaffolds. J. Mater. Chem. B 2023, 11, 9572–9596. [Google Scholar] [CrossRef] [PubMed]

- Jian, B.; Li, H.; He, X.; Wang, R.; Yang, H.Y.; Ge, Q. Two-photon polymerization-based 4D printing and its applications. Int. J. Extreme Manuf. 2023, 6, 12001. [Google Scholar] [CrossRef]

- Miao, W.-J.; Wang, S.-Q.; Wang, Z.-H.; Wu, F.-B.; Zhang, Y.-Z.; Ouyang, J.-H.; Wang, Y.-M.; Zou, Y.-C. Additive manufacturing of advanced structural ceramics for tribological applications: Principles, techniques, microstructure and properties. Lubricants 2025, 13, 112. [Google Scholar] [CrossRef]

- Zhang, F.; Zhu, L.; Li, Z.; Wang, S.; Shi, J.; Tang, W.; Li, N.; Yang, J. The recent development of vat photopolymerization: A review. Addit. Manuf. 2021, 48, 102423. [Google Scholar] [CrossRef]

- Mahmood, M.A.; Popescu, A.C. 3D printing at micro-level: Laser-induced forward transfer and two-photon polymerization. Polymers 2021, 13, 2034. [Google Scholar] [CrossRef]

- Meza, L.R.; Greer, J.R. Mechanical characterization of hollow ceramic nanolattices. J. Mater. Sci. 2014, 49, 2496–2508. [Google Scholar] [CrossRef]

- Chai, N.; Yue, Y.; Chen, X.; Zeng, Z.; Li, S.; Wang, X. Isotropic sintering shrinkage of 3D glass-ceramic nanolattices: Backbone preforming and mechanical enhancement. Int. J. Extreme Manuf. 2024, 6, 25003. [Google Scholar] [CrossRef]

- Yin, Y.; Xu, J.; Chen, M. A review on surface texturing of zirconia ceramics for dental applications. Int. J. Adv. Manuf. Technol. 2024, 130, 5109–5135. [Google Scholar] [CrossRef]

- De Mello, C.C.; Bitencourt, S.B.; Dos Santos, D.M.; Pesqueira, A.A.; Pellizzer, E.P.; Goiato, M.C. The effect of surface treatment on shear bond strength between Y-TZP and veneer ceramic: A systematic review and meta-analysis. J. Prosthodont. 2018, 27, 624–635. [Google Scholar] [CrossRef]

- Zhang, X.; Peng, L.; Zhu, C.; Gao, J.; Xing, B.; Yao, Y.; Nian, H.; Zhao, Z. Electrolyte-supported solid oxide fuel cells with ultra-thin honeycomb structure prepared by digital light processing 3D printing technology. Ceram. Int. 2024, 50, 3232–3240. [Google Scholar] [CrossRef]

- Ye, Z.; Zhu, L.; Zhou, T.; Tong, X.; Chen, Z.; Zhou, X.; Huang, S.; Li, Y.; Lin, J.; Wen, C.; et al. Shear bond strength, finite element analysis, flexural strength and accuracy analysis of additively manufactured bio-inspired 3Y-TZP for dental applications. J. Mater. Res. Technol.—JMRT 2024, 29, 4588–4596. [Google Scholar] [CrossRef]

- Dai, K.; Wu, J.; Zhao, Z.; Yu, H.; Zhao, Z.; Gao, B. Surface Texture Designs to Improve the Core-Veneer Bond Strength of Zirconia Restorations Using Digital Light Processing. Materials 2023, 16, 6072. [Google Scholar] [CrossRef]

- Zheng, L.; Xu, R.; Zhang, J.; Yu, F.; Li, C.; Sunarso, J.; Zhang, W.; Meng, X.; Yang, N. Enhanced electrochemical performance by structural design of electrolyte surface combining 3D printing technology with multi-physical modelling. Chem. Eng. J. 2023, 451, 139038. [Google Scholar] [CrossRef]

- Gao, S.; Wang, C.; Xing, B.; Shen, M.; Zhao, W.; Zhao, Z. Experimental investigation on bending behaviour of ZrO2 honeycomb sandwich structures prepared by DLP stereolithography. Thin Walled Struct. 2020, 157, 107099. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, C.; Xing, B.; Shen, M.; Zhao, Z. Mechanical properties of zirconia octet truss structures fabricated by DLP 3D printing. Mater. Res. Express 2020, 7, 085201. [Google Scholar] [CrossRef]

- Pchelintsev, I.; Karamov, R.; Tikhonov, A.; Dubinin, O.; Evlashin, S. Fabrication of hierarchical lattice structures from zirconia stabilized ceramics by micro-SLA 3D printing approach. Ceram. Int. 2023, 49, 29409–29416. [Google Scholar] [CrossRef]

- Chen, L.; Zhou, Z.; Xing, B.; Zhao, Z. Experimental investigation on in-plane compressive behaviour of 2D chiral ceramics. Ceram. Int. 2023, 49, 34415–34430. [Google Scholar] [CrossRef]

- Jiang, C.; Ding, M.; Zhang, J.; Zhu, C.; Qin, W.; Zhao, Z.; Jiao, T. 3D Printed Porous Zirconia Biomaterials based on Triply Periodic Minimal Surfaces Promote Osseointegration In Vitro by Regulating Osteoimmunomodulation and Osteo/Angiogenesis. ACS Appl. Mater. Interfaces 2024, 16, 14548–14560. [Google Scholar] [CrossRef]

- Schwarzer-Fischer, E.; Guenther, A.; Roszeitis, S.; Moritz, T. Combining Zirconia and Titanium Suboxides by Vat Photopolymerization. Materials 2021, 14, 2394. [Google Scholar] [CrossRef]

- Shen, M.; Qin, W.; Xing, B.; Zhao, W.; Gao, S.; Sun, Y.; Jiao, T.; Zhao, Z. Mechanical properties of 3D printed ceramic cellular materials with triply periodic minimal surface architectures. J. Eur. Ceram. Soc. 2021, 41, 1481–1489. [Google Scholar] [CrossRef]

- Liu, S.; Deng, J.; Zhao, H.; Wang, T.; Lu, J.; Ding, B.; Guo, T.; Ritchie, R.O.; Guo, L. Tooth enamel-inspired ceramic coating on metal surface for enhanced mechanical properties and corrosion resistance. Nat. Commun. 2025, 16, 5980. [Google Scholar] [CrossRef] [PubMed]

- Sänger, J.C.; Pauw, B.R.; Riechers, B.; Zocca, A.; Rosalie, J.; Maaß, R.; Sturm, H.; Günster, J. Entering a new dimension in powder processing for advanced ceramics shaping. Adv. Mater. 2023, 35, 2208653. [Google Scholar] [CrossRef]

- Sänger, J.C.; Riechers, B.; Pauw, B.R.; Maaß, R.; Günster, J. Microplastic response of 2PP-printed ceramics. J. Am. Ceram. Soc. 2024, 107, 6636–6645. [Google Scholar] [CrossRef]

- Cao, C.; Liu, J.; Xia, X.; Shen, X.; Qiu, Y.; Kuang, C.; Liu, X. Click chemistry assisted organic-inorganic hybrid photoresist for ultra-fast two-photon lithography. Addit. Manuf. 2022, 51, 102658. [Google Scholar] [CrossRef]

- Desponds, A.; Banyasz, A.; Chateau, D.; Tellal, A.; Venier, A.; Meille, S.; Montagnac, G.; Chevalier, J.; Andraud, C.; Baldeck, P.L.; et al. 3D printing and pyrolysis of optical ZrO2 nanostructures by two-photon lithography: Reduced shrinkage and crystallization mediated by nanoparticles seeds. Small 2021, 17, 2102486. [Google Scholar] [CrossRef] [PubMed]

- de Camargo, I.L.; Morais, M.M.; Fortulan, C.A.; Branciforti, M.C. A review on the rheological behavior and formulations of ceramic suspensions for vat photopolymerization. Ceram. Int. 2021, 47, 11906–11921. [Google Scholar] [CrossRef]

- Lian, Q.; Yang, F.; Xin, H.; Li, D. Oxygen-controlled bottom-up mask-projection stereolithography for ceramic 3D printing. Ceram. Int. 2017, 43, 14956–14961. [Google Scholar] [CrossRef]

- Jia, K.; Zheng, L.; Liu, W.; Zhang, J.; Yu, F.; Meng, X.; Li, C.; Sunarso, J.; Yang, N. A new and simple way to prepare monolithic solid oxide fuel cell stack by stereolithography 3D printing technology using 8 mol% yttria stabilized zirconia photocurable slurry. J. Eur. Ceram. Soc. 2022, 42, 4275–4285. [Google Scholar] [CrossRef]

- Marquez, S.; Anelli, S.; Nunez, M.; Lira, M.; Maria Asensio, A.; Torrell, M.; Tarancon, A. 3D printed electrolyte-supported solid oxide cells based on Ytterbium-doped scandia-stabilized zirconia. J. Phys. Energy 2024, 6, 015016. [Google Scholar] [CrossRef]

- Han, Z.; Liu, S.; Qiu, K.; Liu, J.; Zou, R.; Wang, Y.; Zhao, J.; Liu, F.; Wang, Y.; Li, L. The enhanced ZrO2 produced by DLP via a reliable plasticizer and its dental application. J. Mech. Behav. Biomed. Mater. 2023, 141, 105751. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, G.; Chen, A.; Su, J.; Zhang, Y.; Wang, C.; Yan, C.; Shi, Y. Effect of molecular weight and chemical structure of plasticizer on suspension property, binder removal, and sintered performance for zirconia toughened alumina ceramics fabricated by vat photopolymerization. J. Eur. Ceram. Soc. 2024, 44, 116730. [Google Scholar] [CrossRef]

- Wu, H.; Liu, W.; He, R.; Wu, Z.; Jiang, Q.; Song, X.; Chen, Y.; Cheng, L.; Wu, S. Fabrication of dense zirconia-toughened alumina ceramics through a stereolithography-based additive manufacturing. Ceram. Int. 2017, 43 Pt B, 968–972. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, W.; Wu, H.; Huang, R.; He, R.; Jiang, Q.; Chen, Y.; Ji, X.; Tian, Z.; Wu, S. Research into the mechanical properties, sintering mechanism and microstructure evolution of Al2O3-ZO2 composites fabricated by a stereolithography-based 3D printing method. Mater. Chem. Phys. 2018, 207, 1–10. [Google Scholar] [CrossRef]

- He, R.; Liu, W.; Wu, Z.; An, D.; Huang, M.; Wu, H.; Jiang, Q.; Ji, X.; Wu, S.; Xie, Z. Fabrication of complex-shaped zirconia ceramic parts via a DLP-stereolithography-based 3D printing method. Ceram. Int. 2018, 44, 3412–3416. [Google Scholar] [CrossRef]

- Sokola, P.; Ptacek, P.; Bafti, A.; Panzic, I.; Mandic, V.; Blahut, J.; Kalina, M. Comprehensive study of stereolithography and digital light processing printing of zirconia photosensitive suspensions. Ceramics 2024, 7, 1616–1638. [Google Scholar] [CrossRef]

- Wang, L.; Yu, H.; Hao, Z.; Tang, W.; Dou, R. Investigating the effect of solid loading on microstructure, mechanical properties, and translucency of highly translucent zirconia ceramics prepared via stereolithography-based additive manufacturing. J. Mech. Behav. Biomed. Mater. 2023, 144, 105952. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, Z.; Zhao, L.; Guo, W.; Gao, X. Stability, rheological behaviors, and curing properties of 3Y-ZrO2 and 3Y-ZrO2/GO ceramic suspensions in stereolithography applied for dental implants. Ceram. Int. 2021, 47, 13344–13350. [Google Scholar] [CrossRef]

- Schwentenwein, M.; Homa, J. Additive manufacturing of dense alumina ceramics. Int. J. Appl. Ceram. Technol. 2015, 12, 1–7. [Google Scholar] [CrossRef]

- Krieger, I.M.; Dougherty, T.J. A mechanism for non-newtonian flow in suspensions of rigid spheres. Trans. Soc. Rheol. 1959, 3, 137–152. [Google Scholar] [CrossRef]

- Xing, H.; Zou, B.; Liu, X.; Wang, X.; Chen, Q.; Fu, X.; Li, Y. Effect of particle size distribution on the preparation of ZTA ceramic paste applying for stereolithography 3D printing. Powder Technol. 2020, 359, 314–322. [Google Scholar] [CrossRef]

- Zakeri, S.; Vippola, M.; Levänen, E. A comprehensive review of the photopolymerization of ceramic resins used in stereolithography. Addit. Manuf. 2020, 35, 101177. [Google Scholar] [CrossRef]

- Halloran, J.W.; Tomeckova, V.; Gentry, S.; Das, S.; Cilino, P.; Yuan, D.; Guo, R.; Rudraraju, A.; Shao, P.; Wu, T.; et al. Photopolymerization of powder suspensions for shaping ceramics. J. Eur. Ceram. Soc. 2011, 31, 2613–2619. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, X.; Shang, Y.; Xiong, K.; Xu, Z.; Guo, R.; Cai, S.; Zheng, C. Dense ceramics with complex shape fabricated by 3D printing: A review. J. Adv. Ceram. 2021, 10, 195–218. [Google Scholar] [CrossRef]

- Griffith, M.L.; Halloran, J.W. Scattering of ultraviolet radiation in turbid suspensions. J. Appl. Phys. 1997, 81, 2538–2546. [Google Scholar] [CrossRef]

- Wang, L.; Liu, X.; Wang, G.; Tang, W.; Li, S.; Duan, W.; Dou, R. Partially stabilized zirconia moulds fabricated by stereolithographic additive manufacturing via digital light processing. Mater. Sci. Eng.—Struct. Mater. Prop. Microstruct. Process. 2020, 770, 138537. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, K.; Bourell, D.L.; Chen, F.; Sun, H.; Shi, Y.; Wang, J.; He, M.; Chen, J. Gelcasting of zirconia-based all-ceramic teeth combined with stereolithography. Ceram. Int. 2018, 44, 21556–21563. [Google Scholar] [CrossRef]

- Sun, J.; Binner, J.; Bai, J. Effect of surface treatment on the dispersion of nano zirconia particles in non-aqueous suspensions for stereolithography. J. Eur. Ceram. Soc. 2019, 39, 1660–1667. [Google Scholar] [CrossRef]

- Li, X.-B.; Zhong, H.; Zhang, J.-X.; Duan, Y.-S.; Jiang, D.-L. Effect of Powder Characteristics on the Rheological Performance of Resin-based Zirconia Suspension for Stereolithography. J. Inorg. Mater. 2019, 35, 13. [Google Scholar] [CrossRef]

- Fan, L.; Huang, C.; Liu, H.; Wang, Z.; Xu, L.; Huang, S.; Qu, M.; Xu, Z.; Li, S.; Xu, S. The effect of ZrO2 particle size and solid loading on the rheological properties of highly thixotropic ZrO2 ceramic slurries applied in photopolymerization 3D printing. Ceram. Int. 2025, 51, 6669–6678. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Q.; Han, Z.; Han, Y.; Bi, L.; Zhang, X.; Lu, X.; Zhao, J.; Chu, W.; Li, J.; et al. Towards high strengthening efficiency of equiaxed and platelet-shaped alumina reinforced zirconia ceramics with textured microstructure using DLP-based stereolithography. Ceram. Int. 2024, 50, 2467–2478. [Google Scholar] [CrossRef]

- Khakzad, M.; Sepasi, Z.; Mosadegh, M.; Alsup, Z.; Minary-Jolandan, M. Porous ceramics via vat photopolymerization: Influence of particles relative roundness on porosity in fully sintered ceramics. Ceram. Int. 2025, 51, 19355–19365. [Google Scholar] [CrossRef]

- Zheng, J.; Zhang, H.; Li, X. Effect of ternary particles size distribution on rheology of slurry and microstructure of DLP printed ZTA ceramic. Mater. Chem. Phys. 2021, 269, 124656. [Google Scholar] [CrossRef]

- Bove, A.; Calignano, F.; Galati, M.; Iuliano, L. Photopolymerization of Ceramic Resins by Stereolithography Process: A Review. Appl. Sci. 2022, 12, 3591. [Google Scholar] [CrossRef]

- Cailliet, S.; Roumanie, M.; Croutxe-Barghorn, C.; Bernard-Granger, G.; Laucournet, R. Y-TZP, Ce-TZP and as-synthesized Ce-TZP/Al2O3 materials in the development of high loading rate digital light processing formulations. Ceram. Int. 2021, 47, 3892–3900. [Google Scholar] [CrossRef]

- Inserra, B.; Coppola, B.; Montanaro, L.; Tulliani, J.-M.; Palmero, P. Preparation and characterization of Ce-ZrO2/Al2O3 composites by DLP-based stereolithography. J. Eur. Ceram. Soc. 2023, 43, 2907–2916. [Google Scholar] [CrossRef]

- Kim, J.-H.; Maeng, W.-Y.; Koh, Y.-H.; Kim, H.-E. Digital light processing of zirconia prostheses with high strength and translucency for dental applications. Ceram. Int. 2020, 46, 28211–28218. [Google Scholar] [CrossRef]

- Zhang, J.; Wei, L.; Meng, X.; Yu, F.; Yang, N.; Liu, S. Digital light processing-stereolithography three-dimensional printing of yttria-stabilized zirconia. Ceram. Int. 2020, 46, 8745–8753. [Google Scholar] [CrossRef]

- Jiao, C.; Gu, J.; Cao, Y.; Xie, D.; Liang, H.; Chen, R.; Shi, T.; Shen, L.; Wang, C.; Tian, Z.; et al. Preparation of Al2O3-ZrO2 scaffolds with controllable multi-level pores via digital light processing. J. Eur. Ceram. Soc. 2020, 40, 6087–6094. [Google Scholar] [CrossRef]

- Cao, Y.; Shi, T.; Jiao, C.; Liang, H.; Chen, R.; Tian, Z.; Zou, A.; Yang, Y.; Wei, Z.; Wang, C.; et al. Fabrication and properties of zirconia/hydroxyapatite composite scaffold based on digital light processing. Ceram. Int. 2020, 46, 2300–2308. [Google Scholar] [CrossRef]

- Kim, I.; Kim, S.; Andreu, A.; Kim, J.-H.; Yoon, Y.-J. Influence of dispersant concentration toward enhancing printing precision and surface quality of vat photopolymerization 3D printed ceramics. Addit. Manuf. 2022, 52, 102659. [Google Scholar] [CrossRef]

- Ji, S.H.; Kim, D.S.; Park, M.S.; Yun, J.S. Sintering Process Optimization for 3YSZ Ceramic 3D-Printed Objects Manufactured by Stereolithography. Nanomaterials 2021, 11, 192. [Google Scholar] [CrossRef]

- Borlaf, M.; Szubra, N.; Serra-Capdevila, A.; Kubiak, W.W.; Graule, T. Fabrication of ZrO2 and ATZ materials via UV-LCM-DLP additive manufacturing technology. J. Eur. Ceram. Soc. 2020, 40, 1574–1581. [Google Scholar] [CrossRef]

- Meng, J.; Lian, Q.; Xi, S.; Yi, Y.; Lu, Y.; Wu, G. Crown fit and dimensional accuracy of zirconia fixed crowns based on the digital light processing technology. Ceram. Int. 2022, 48, 17852–17863. [Google Scholar] [CrossRef]

- Coppola, B.; Schmitt, J.; Lacondemine, T.; Tardivat, C.; Montanaro, L.; Palmero, P. Digital light processing stereolithography of zirconia ceramics: Slurry elaboration and orientation-reliant mechanical properties. J. Eur. Ceram. Soc. 2022, 42, 2974–2982. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, D.; Liu, S.; Dong, X.; Li, Y.; Zhang, H.; Yang, Z.; Su, Q.; Huang, W.; Zheng, W.; et al. Zirconia toughened hydroxyapatite biocomposite formed by a DLP 3D printing process for potential bone tissue engineering. Mater. Sci. Eng. C Mater. Biol. Appl. 2019, 105, 110054. [Google Scholar] [CrossRef]

- Komissarenko, D.A.; Sokolov, P.S.; Evstigneeva, A.D.; Shmeleva, I.A.; Dosovitsky, A.E. Rheological and Curing Behavior of Acrylate-Based Suspensions for the DLP 3D Printing of Complex Zirconia Parts. Materials 2018, 11, 2350. [Google Scholar] [CrossRef]

- Sokola, P.; Kalina, M.; Smilek, J.; Ptacek, P.; Krouska, J.; Salamon, D.; Spusta, T. Kinetic stability and rheological properties of photosensitive zirconia suspensions for DLP printing. Ceram. Int. 2023, 49, 18502–18509. [Google Scholar] [CrossRef]

- Thakur, T.; Carretta, M.; Komissarenko, D.; Blugan, G. Advancements in DLP 3D printing: High strength alumina toughened zirconia ceramics for biomedical applications. Open Ceram. 2024, 18, 100601. [Google Scholar] [CrossRef]

- Shi, Z.-A.; Wu, J.-M.; Mao, C.; Fu, L.-X.; Zhang, R.-Z.; Yang, S.-L.; Zhang, J.-X.; Shi, Y.-S. Effect of ZrO2 content on mechanical properties of SiC ceramics prepared based on digital light processing. Ceram. Int. 2024, 50, 44457–44466. [Google Scholar] [CrossRef]

- Mao, G.-X.; Wu, J.-M.; Tian, C.; Liu, C.-L.; Guo, L.; Cai, W.-H.; Zhang, Y.-Z.; Lin, X.; Wang, F.; Xu, H.-S.; et al. ZrO2 reinforced porous Si3N4-based ceramics with improved mechanical properties fabricated via vat photopolymerization (VPP). Addit. Manuf. 2024, 91, 104327. [Google Scholar] [CrossRef]

- Zhu, L.; Xu, Y.; Liu, S.; Chen, H.; Tao, J.; Tong, X.; Li, Y.; Huang, S.; Lin, J.; Wen, C.; et al. Microstructure, mechanical properties, friction and wear performance, and cytotoxicity of additively manufactured zirconia-toughened alumina for dental applications. Compos. Part B Eng. 2023, 250, 110459. [Google Scholar] [CrossRef]

- Zheng, T.; Wang, W.; Sun, J.; Liu, J.; Bai, J. Development and evaluation of Al2O3-ZrO2 composite processed by digital light 3D printing. Ceram. Int. 2020, 46, 8682–8688. [Google Scholar] [CrossRef]

- Qi, S.; Sun, T.; Cui, M.; Li, H.; Chen, Y.; Zhou, T.; Lian, Q.; Shi, C.; Li, D. Digital light processing of rare earth oxide doped natural color zirconia denture for customized aesthetic properties. Open Ceram. 2024, 20, 100670. [Google Scholar] [CrossRef]

- Jang, J.-G.; Kang, J.-H.; Joe, K.-B.; Sakthiabirami, K.; Jang, K.-J.; Jun, M.-J.; Oh, G.-J.; Park, C.; Park, S.-W. Evaluation of Physical Properties of Zirconia Suspension with Added Silane Coupling Agent for Additive Manufacturing Processes. Materials 2022, 15, 1337. [Google Scholar] [CrossRef]

- Reddy, P.K.; Gandhi, P.; Singh, G. Additive manufacturing of yttria-stabilized zirconia using digital light processing: Green density and surface roughness analysis. Ceram. Int. 2024, 50, 22974–22988. [Google Scholar] [CrossRef]

- Fu, X.; Zou, B.; Xing, H.; Li, L.; Li, Y.; Wang, X. Effect of printing strategies on forming accuracy and mechanical properties of ZrO2 parts fabricated by SLA technology. Ceram. Int. 2019, 45, 17630–17637. [Google Scholar] [CrossRef]

- Radomski, K.; Lee, Y.-H.; Lee, S.J.; Yoon, H.-I. Effect of exposure energy dose on lateral resolution and flexural strength of three-dimensionally printed dental zirconia. J. Adv. Prosthodont. 2023, 15, 248–258. [Google Scholar] [CrossRef] [PubMed]

- Conti, L.; Bienenstein, D.; Borlaf, M.; Graule, T. Effects of the Layer Height and Exposure Energy on the Lateral Resolution of Zirconia Parts Printed by Lithography-Based Additive Manufacturing. Materials 2020, 13, 1317. [Google Scholar] [CrossRef]

- Mou, Z.; Zhong, J.; Wang, F.; Alhotan, A.; Zhu, P.; Li, P.; Huang, J. Zirconia crowns manufactured using digital light processing: Effects of build angle and layer thickness on the accuracy. J. Dent. 2024, 151, 105359. [Google Scholar] [CrossRef]

- Xiang, D.; Xu, Y.; Bai, W.; Lin, H. Dental zirconia fabricated by stereolithography: Accuracy, translucency and mechanical properties in different build orientations. Ceram. Int. 2021, 47, 28837–28847. [Google Scholar] [CrossRef]

- Shen, M.; Zhao, W.; Xing, B.; Sing, Y.; Gao, S.; Wang, C.; Zhao, Z. Effects of exposure time and printing angle on the curing characteristics and flexural strength of ceramic samples fabricated via digital light processing. Ceram. Int. 2020, 46, 24379–24384. [Google Scholar] [CrossRef]

- Marsico, C.; Øilo, M.; Kutsch, J.; Kauf, M.; Arola, D. Vat polymerization-printed partially stabilized zirconia: Mechanical properties, reliability and structural defects. Addit. Manuf. 2020, 36, 101450. [Google Scholar] [CrossRef]

- Song, C.; Chen, Y.; Liu, Z.; Li, Y.; Yang, Y.; Yu, J. Rapid and high-accuracy forming of ceramic parts by DLP technology based on optimization of shear stress. J. Eur. Ceram. Soc. 2024, 44, 1748–1760. [Google Scholar] [CrossRef]

- Cho, J.-H.; Yoon, H.-I.; Oh, J.-H.; Kim, D.-H. Effect of maximum support attachment angle on intaglio surface trueness of anatomic contour monolithic prostheses manufactured by digital light processing and zirconia suspension. J. Prosthet. Dent. 2023, 129, 478–485. [Google Scholar] [CrossRef]

- Zhang, G.; Jiang, J.; Wang, H.; Qian, L.; Lan, H. Continuous DLP-based ceramic 3D printing using a composite oxygen-rich film. J. Manuf. Process. 2021, 64, 341–348. [Google Scholar] [CrossRef]

- Liang, H.; Hu, B.; Li, R.; Sun, J.; Wang, Y.; Zhou, P.; Cai, P.; Bai, J. Enhancing mechanical integrity of vat photopolymerization 3D printed hydroxyapatite scaffolds through overcoming peeling defects. J. Eur. Ceram. Soc. 2024, 44, 116642. [Google Scholar] [CrossRef]

- Wang, K.; Qiu, M.; Jiao, C.; Gu, J.; Xie, D.; Wang, C.; Tang, X.; Wei, Z.; Shen, L. Study on defect-free debinding green body of ceramic formed by DLP technology. Ceram. Int. 2020, 46, 2438–2446. [Google Scholar] [CrossRef]

- Zhou, M.; Liu, W.; Wu, H.; Song, X.; Chen, Y.; Cheng, L.; He, F.; Chen, S.; Wu, S. Preparation of a defect-free alumina cutting tool via additive manufacturing based on stereolithography—Optimization of the drying and debinding processes. Ceram. Int. 2016, 42, 11598–11602. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Liu, Y.; Zeng, Q.; Hu, K.; Lu, Z.; Liang, J. Effect of debinding temperature under an argon atmosphere on the microstructure and properties of 3D-printed alumina ceramics. Mater. Charact. 2020, 168, 110548. [Google Scholar] [CrossRef]

- Wang, H.; Shen, F.; Li, Z.; Zhou, B.; Zhao, P.; Wang, W.; Cheng, B.; Yang, J.; Li, B.; Wang, X. Preparation of high-performance ZrO2 bio-ceramics by stereolithography for dental restorations. Ceram. Int. 2023, 49, 28048–28061. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, J.; Pang, X.; Guo, X.; Zhao, Z.; Sunarso, J.; Yu, F.; Meng, X.; Zhang, J.; Yang, N. Integrated micro-tubular SOFC stack supported by a monolithic porous zirconia prepared using 3D printing technology. J. Eur. Ceram. Soc. 2024, 44, 7837–7845. [Google Scholar] [CrossRef]

- Sun, J.; Binner, J.; Bai, J. 3D printing of zirconia via digital light processing: Optimization of slurry and debinding process. J. Eur. Ceram. Soc. 2020, 40, 5837–5844. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, P.; Dong, P.; Zeng, Y.; Chen, J. Investigation on 3D printing ZrO2 implant abutment and its fatigue performance simulation. Ceram. Int. 2021, 47, 1053–1062. [Google Scholar] [CrossRef]

- Zhang, K.; He, R.; Ding, G.; Feng, C.; Song, W.; Fang, D. Digital light processing of 3Y-TZP strengthened ZrO2 ceramics. Mater. Sci. Eng.-Struct. Mater. Prop. Microstruct. Process. 2020, 774, 138768. [Google Scholar] [CrossRef]

- Komissarenko, D.; Roland, S.; Seeber, B.S.M.; Graule, T.; Blugan, G. DLP 3D printing of high strength semi-translucent zirconia ceramics with relatively low-loaded UV-curable formulations. Ceram. Int. 2023, 49, 21008–21016. [Google Scholar] [CrossRef]

- Khalile, N.; Meunier, C.; Petit, C.; Valdivieso, F.; Coppola, B.; Palmero, P. Microwave sintering of dense and lattice 3Y-TZP samples shaped by digital light processing. Ceram. Int. 2023, 49, 7350–7358. [Google Scholar] [CrossRef]

- Wang, L.; Jiao, Y.; Yao, L.; Sheng, Y.; Hao, Z.; Tang, W.; Dou, R. Investigation of mechanical properties and low-temperature degradation of dental 3Y-TZP ceramics fabricated by stereolithography in combination with microwave sintering. J. Mech. Behav. Biomed. Mater. 2023, 148, 106211. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.; She, W.; Li, W.; Cao, Y.; Wang, J. Influence of sintering temperature on the thermal conductivity of digital light processing 3D-printed yttria-stabilized zirconia ceramic. Ceram. Int. 2023, 49, 27514–27525. [Google Scholar] [CrossRef]

- Liu, X.; Zou, B.; Xing, H.; Huang, C. The preparation of ZrO2-Al2O3 composite ceramic by SLA-3D printing and sintering processing. Ceram. Int. 2020, 46, 937–944. [Google Scholar] [CrossRef]

- Goldberg, M.; Obolkina, T.; Smirnov, S.; Protsenko, P.; Titov, D.; Antonova, O.; Konovalov, A.; Kudryavtsev, E.; Sviridova, I.; Kirsanova, V.; et al. The Influence of Co Additive on the Sintering, Mechanical Properties, Cytocompatibility, and Digital Light Processing Based Stereolithography of 3Y-TZP-5Al2O3Ceramics. Materials 2020, 13, 2789. [Google Scholar] [CrossRef]

- Tan, X.; Lu, Y.; Gao, J.; Wang, Z.; Xie, C.; Yu, H. Effect of high-speed sintering on the microstructure, mechanical properties and ageing resistance of stereolithographic additive-manufactured zirconia. Ceram. Int. 2022, 48, 9797–9804. [Google Scholar] [CrossRef]

- Sun, J.; Chen, X.; Wade-Zhu, J.; Binner, J.; Bai, J. A comprehensive study of dense zirconia components fabricated by additive manufacturing. Addit. Manuf. 2021, 43, 101994. [Google Scholar] [CrossRef]

- Revilla-Leon, M.; Methani, M.M.; Morton, D.; Zandinejad, A. Internal and marginal discrepancies associated with stereolithography (SLA) additively manufactured zirconia crowns. J. Prosthet. Dent. 2020, 124, 730–737. [Google Scholar] [CrossRef]

- Zhai, Z.; Qian, C.; Jiao, T.; Xu, C.; Sun, J. Zirconia specimens printed by vat photopolymerization: Mechanical properties, fatigue properties, and fractography analysis. J. Prosthodont.-Implant Esthet. Reconstr. Dent. 2024. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.-S.; Hong, M.-H.; Min, B.-K.; Kim, Y.-K.; Shin, H.-J.; Kwon, T.-Y. Microstructure, Flexural Strength, and Fracture Toughness Comparison between CAD/CAM Milled and 3D-Printed Zirconia Ceramics. Appl. Sci. 2022, 12, 9088. [Google Scholar] [CrossRef]

- Ellakany, P.; Fouda, S.M.; Mahrous, A.A.; AlGhamdi, M.A.; Aly, N.M. Influence of CAD/CAM Milling and 3D-Printing Fabrication Methods on the Mechanical Properties of 3-Unit Interim Fixed Dental Prosthesis after Thermo-Mechanical Aging Process. Polymers 2022, 14, 4103. [Google Scholar] [CrossRef] [PubMed]

- Coppola, B.; Lacondemine, T.; Tardivat, C.; Montanaro, L.; Palmero, P. Designing alumina-zirconia composites by DLP-based stereolithography: Microstructural tailoring and mechanical performances. Ceram. Int. 2021, 47, 13457–13468. [Google Scholar] [CrossRef]

- Zhang, R.-Z.; Huang, Y.-X.; Li, W.-K.; Luo, Y.; Pan, M.-Z.; Wu, J.-M.; Zhang, X.-Y.; Ye, C.-S.; Shi, Y.-S. Second phase strengthening and grain boundary segregation effects on the microstructure and properties of (Ce, Y)-TZP-based ceramics prepared by vat photopolymerization. Addit. Manuf. 2024, 94, 104482. [Google Scholar] [CrossRef]

- Fournier, S.; Chevalier, J.; Baeza, G.P.; Chaput, C.; Louradour, E.; Sainsot, P.; Cavoret, J.; Reveron, H. Ceria-stabilized zirconia-based composites printed by stereolithography: Impact of the processing method on the ductile behaviour and its transformation features. J. Eur. Ceram. Soc. 2023, 43, 2894–2906. [Google Scholar] [CrossRef]

- de Camargo, I.L.; Erbereli, R.; Lovo, J.F.P.; Fortulan, R.; Fortulan, C.A. Digital light processing additive manufacturing of in situ mullite-zirconia composites. J. Eur. Ceram. Soc. 2022, 42, 6025–6032. [Google Scholar] [CrossRef]

- Wei, S.; Han, G.; Zhang, X.; Sun, J.; Wang, W.; Zhang, J.; Zhang, Z.; Zhang, W.; Jingde, Z.; Yang, L.; et al. Preparation of excellent performance ZTA ceramics and complex shaped components using digital light processing 3D printing technology. J. Alloys Compd. 2024, 980, 173640. [Google Scholar] [CrossRef]

- Yao, X.; Moon, S.K.; Bi, G.; Wei, J. A multi-material part design framework in additive manufacturing. Int. J. Adv. Manuf. Technol. 2018, 99, 2111–2119. [Google Scholar] [CrossRef]

- Putra, N.E.; Mirzaali, M.J.; Apachitei, I.; Zhou, J.; Zadpoor, A.A. Multi-material additive manufacturing technologies for Ti-, Mg-, and Fe-based biomaterials for bone substitution. Acta Biomater. 2020, 109, 1–20. [Google Scholar] [CrossRef]

- Jung, J.-M.; Kim, G.-N.; Koh, Y.-H.; Kim, H.-E. Manufacturing and Characterization of Dental Crowns Made of 5-mol% Yttria Stabilized Zirconia by Digital Light Processing. Materials 2023, 16, 1447. [Google Scholar] [CrossRef]

- Lee, H.-B.; Noh, M.-J.; Bae, E.-J.; Lee, W.-S.; Kim, J.-H. Accuracy of zirconia crown manufactured using stereolithography and digital light processing. J. Dent. 2024, 141, 104834. [Google Scholar] [CrossRef] [PubMed]

- Lyu, J.; Yang, X.; Li, Y.; Tan, J.; Liu, X. Dimensional accuracy and clinical adaptation of monolithic zirconia crowns fabricated with the nanoparticle jetting technique. J. Prosthet. Dent. 2024, 132, 985. [Google Scholar] [CrossRef] [PubMed]

- Lian, Q.; Sui, W.; Wu, X.; Yang, F.; Yang, S. Additive manufacturing of ZrO2 ceramic dental bridges by stereolithography. Rapid Prototyp. J. 2018, 24, 114–119. [Google Scholar] [CrossRef]

- He, X.; Reichl, F.-X.; Milz, S.; Michalke, B.; Wu, X.; Sprecher, C.M.; Yang, Y.; Gahlert, M.; Roehling, S.; Kniha, H.; et al. Titanium and zirconium release from titanium- and zirconia implants in mini pig maxillae and their toxicity in vitro. Dent. Mater. 2020, 36, 402–412. [Google Scholar] [CrossRef]

- Branco, A.C.; Colaco, R.; Figueiredo-Pina, C.G.; Serro, A.P. Recent Advances on 3D-Printed Zirconia-Based Dental Materials: A Review. Materials 2023, 16, 1860. [Google Scholar] [CrossRef]

- Luchtenborg, J.; Willems, E.; Zhang, F.; Wesemann, C.; Weiss, F.; Nold, J.; Sun, J.; Sandra, F.; Bai, J.; Reveron, H.; et al. Accuracy of additively manufactured zirconia four-unit fixed dental prostheses fabricated by stereolithography, digital light processing and material jetting compared with subtractive manufacturing. Dent. Mater. 2022, 38, 1459–1469. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, K.; Zuo, Y.; Jin, X.; Yang, J. Effect of inert glass on the physical and mechanical properties of zirconia dental ceramics fabricated by digital light processing. J. Am. Ceram. Soc. 2024, 107, 4689–4704. [Google Scholar] [CrossRef]

- Zhu, Y.; Liu, K.; Deng, J.; Ye, J.; Ai, F.; Ouyang, H.; Wu, T.; Jia, J.; Cheng, X.; Wang, X. 3D printed zirconia ceramic hip joint with precise structure and broad-spectrum antibacterial properties. Int. J. Nanomed. 2019, 14, 5977–5987. [Google Scholar] [CrossRef] [PubMed]

- Wan, L.; Chen, X.; Hu, P.; Wang, L.; Xiong, G.; Gou, Y.; Ai, F. DLP-printed standard tooth -colored ceramic dentures and its biocompatibility study. Ceram. Int. 2024, 50, 19293–19301. [Google Scholar] [CrossRef]

- Mirt, T.; Kocjan, A.; Hofer, A.K.; Schwentenwein, M.; Ivekovic, A.; Bermejo, R.; Jevnikar, P. Effect of airborne particle abrasion and regeneration firing on the strength of 3D-printed 3Y and 5Y zirconia ceramics. Dent. Mater. 2024, 40, 111–117. [Google Scholar] [CrossRef]

- Zhai, Z.; Sun, J. Research on the low-temperature degradation of dental zirconia ceramics fabricated by stereolithography. J. Prosthet. Dent. 2023, 130, 629–638. [Google Scholar] [CrossRef] [PubMed]

- Schiltz, J.; Render, T.; Gatrell, B.A.; Qu, H.; Steiner, C.; McGinn, P.; Schmid, S. Wear behavior of additive manufactured zirconia. In Proceedings of the 48th Sme North American Manufacturing Research Conference, Namrc 48, Cincinnati, OH, USA, 22–26 June 2020; Fratini, L., Ragai, I., Wang, L., Eds.; Elsevier Science BV: Amsterdam, The Netherlands, 2020; Volume 48, pp. 821–827. [Google Scholar]

- Jiao, C.; Xie, D.; He, Z.; Liang, H.; Shen, L.; Yang, Y.; Tian, Z.; Wu, G.; Wang, C. Additive manufacturing of Bio-inspired ceramic bone Scaffolds: Structural Design, mechanical properties and biocompatibility. Mater. Des. 2022, 217, 110610. [Google Scholar] [CrossRef]

- Wu, J.; Li, Z.; Meng, X.; Cheng, B.; Yang, J.; Li, B.; Wang, X. ZrO2-CPS/ZrO2 graded composite ceramics with high osteoinductivity for dental implants fabricated by stereolithography. Ceram. Int. 2025, 51, 21900–21912. [Google Scholar] [CrossRef]

- Coppola, B.; Montanaro, L.; Palmero, P. DLP Fabrication of Zirconia Scaffolds Coated with HA/β-TCP Layer: Role of Scaffold Architecture on Mechanical and Biological Properties. J. Funct. Biomater. 2022, 13, 148. [Google Scholar] [CrossRef]

- He, Z.; Jiao, C.; Zhang, H.; Xie, D.; Ge, M.; Yang, Y.; Wu, G.; Liang, H.; Shen, L.; Wang, C. Fabrication of a zirconia/calcium silicate composite scaffold based on digital light processing. Ceram. Int. 2022, 48, 25923–25932. [Google Scholar] [CrossRef]

- Li, H.; Hu, Y.; Tang, X.; Zhao, Y.; Li, M.; Zhao, Y.; Luo, H.; Lai, Q.; Xing, H. Biomechanical and biological properties of stereolithography-based 3D-printed zirconia interference screws for anterior cruciate ligament reconstruction. Addit. Manuf. Front. 2024, 3, 200135. [Google Scholar] [CrossRef]

- Hernández-Rodríguez, E.M.; Acosta-Mora, P.; Méndez-Ramos, J.; Borges Chinea, E.; Esparza Ferrera, P.; Canales-Vázquez, J.; Núñez, P.; Ruiz-Morales, J.C. Prospective use of the 3D printing technology for the microstructural engineering of Solid Oxide Fuel Cell components. Bol. Soc. Esp. Cerámica Vidr. 2014, 53, 213–216. [Google Scholar] [CrossRef]

- Masciandaro, S.; Torrell, M.; Leone, P.; Tarancón, A. Three-dimensional printed yttria-stabilized zirconia self-supported electrolytes for solid oxide fuel cell applications. J. Eur. Ceram. Soc. 2019, 39, 9–16. [Google Scholar] [CrossRef]

- Wei, L.; Zhang, J.; Yu, F.; Zhang, W.; Meng, X.; Yang, N.; Liu, S. A novel fabrication of yttria-stabilized-zirconia dense electrolyte for solid oxide fuel cells by 3D printing technique. Int. J. Hydrogen Energy 2019, 44, 6182–6191. [Google Scholar] [CrossRef]

- Xing, B.; Yao, Y.; Meng, X.; Zhao, W.; Shen, M.; Gao, S.; Zhao, Z. Self-supported yttria-stabilized zirconia ripple-shaped electrolyte for solid oxide fuel cells application by digital light processing three-dimension printing. Scr. Mater. 2020, 181, 62–65. [Google Scholar] [CrossRef]

- Xing, B.; Cao, C.; Zhao, W.; Shen, M.; Wang, C.; Zhao, Z. Dense 8 mol% yttria-stabilized zirconia electrolyte by DLP stereolithography. J. Eur. Ceram. Soc. 2020, 40, 1418–1423. [Google Scholar] [CrossRef]

- Tang, Z.; Dai, J.; Yu, A.; Li, P.; Liu, C.; Shen, X. 3D-printed zirconia orthodontic brackets: Effect of printing method on dimensional accuracy. Orthod. Craniofac. Res. 2024, 27, 147–154. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Li, Y.F.; Wang, Y.M.; Zhou, Y.; Murakami, T.; Sasaki, S. Microstructure and tribological properties of ZrO2(Y2O3) matrix composites doped with different solid lubricants from room temperature to 800 °C. Wear 2009, 267, 1353–1360. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.-H.; Zhang, Y.-Z.; Zhao, J.-J.; Wang, Z.-H.; Miao, W.-J.; Wu, F.-B.; Wang, S.-Q.; Ouyang, J.-H.; Wang, Y.-M.; Zou, Y.-C. Vat Photopolymerization of Additively Manufactured Zirconia Ceramic Structures from Slurries of Surface Functionalized Particles: A Critical Review. Surfaces 2025, 8, 58. https://doi.org/10.3390/surfaces8030058

Li J-H, Zhang Y-Z, Zhao J-J, Wang Z-H, Miao W-J, Wu F-B, Wang S-Q, Ouyang J-H, Wang Y-M, Zou Y-C. Vat Photopolymerization of Additively Manufactured Zirconia Ceramic Structures from Slurries of Surface Functionalized Particles: A Critical Review. Surfaces. 2025; 8(3):58. https://doi.org/10.3390/surfaces8030058

Chicago/Turabian StyleLi, Jia-Hao, Yun-Zhuo Zhang, Jia-Jun Zhao, Zi-Heng Wang, Wei-Jian Miao, Fan-Bin Wu, Shu-Qi Wang, Jia-Hu Ouyang, Ya-Ming Wang, and Yong-Chun Zou. 2025. "Vat Photopolymerization of Additively Manufactured Zirconia Ceramic Structures from Slurries of Surface Functionalized Particles: A Critical Review" Surfaces 8, no. 3: 58. https://doi.org/10.3390/surfaces8030058

APA StyleLi, J.-H., Zhang, Y.-Z., Zhao, J.-J., Wang, Z.-H., Miao, W.-J., Wu, F.-B., Wang, S.-Q., Ouyang, J.-H., Wang, Y.-M., & Zou, Y.-C. (2025). Vat Photopolymerization of Additively Manufactured Zirconia Ceramic Structures from Slurries of Surface Functionalized Particles: A Critical Review. Surfaces, 8(3), 58. https://doi.org/10.3390/surfaces8030058