An Exploration of SPS Fabrication and the Sliding Wear Properties of γ-TiAl-Ag Self-Lubrication Materials

Abstract

1. Introduction

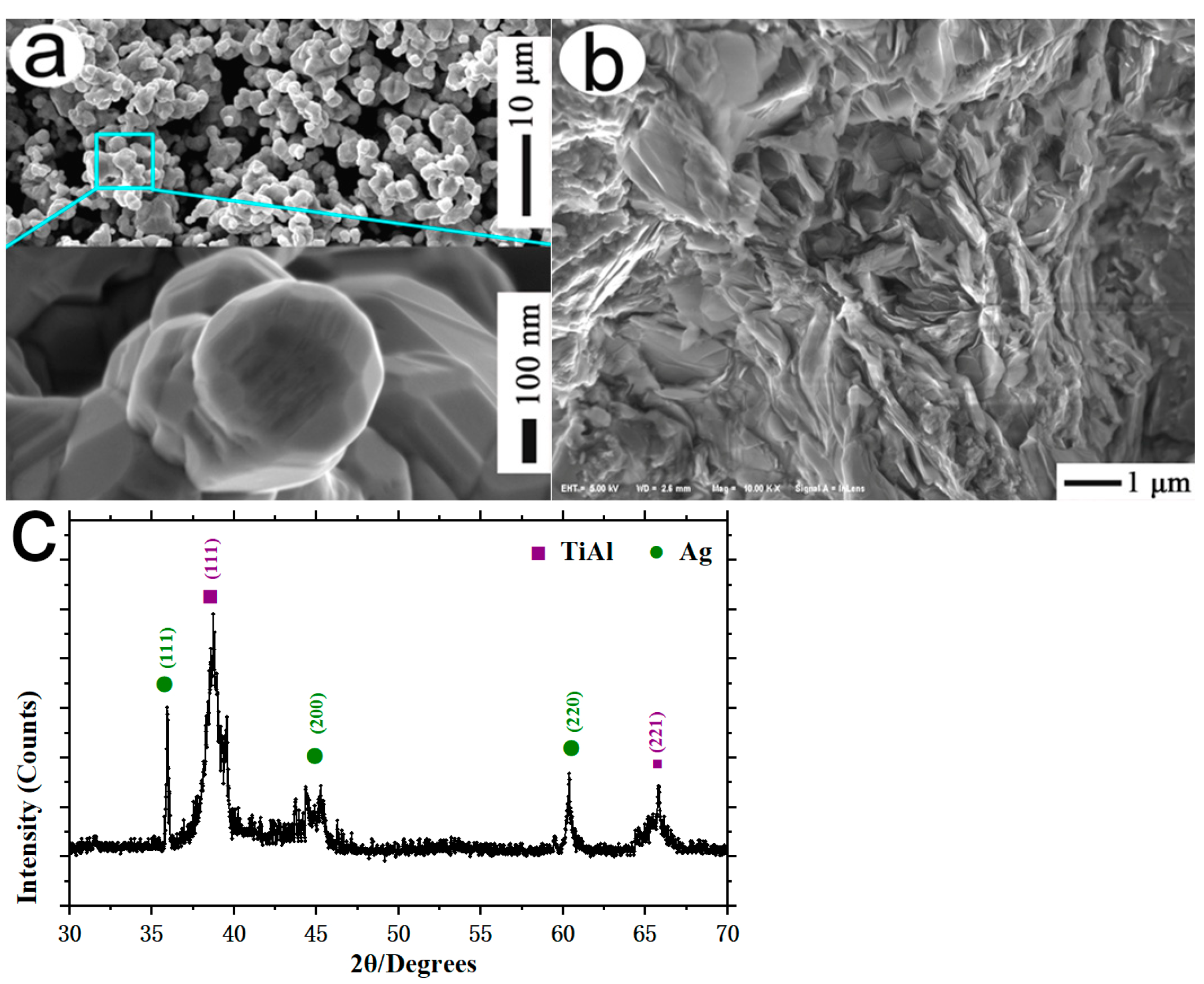

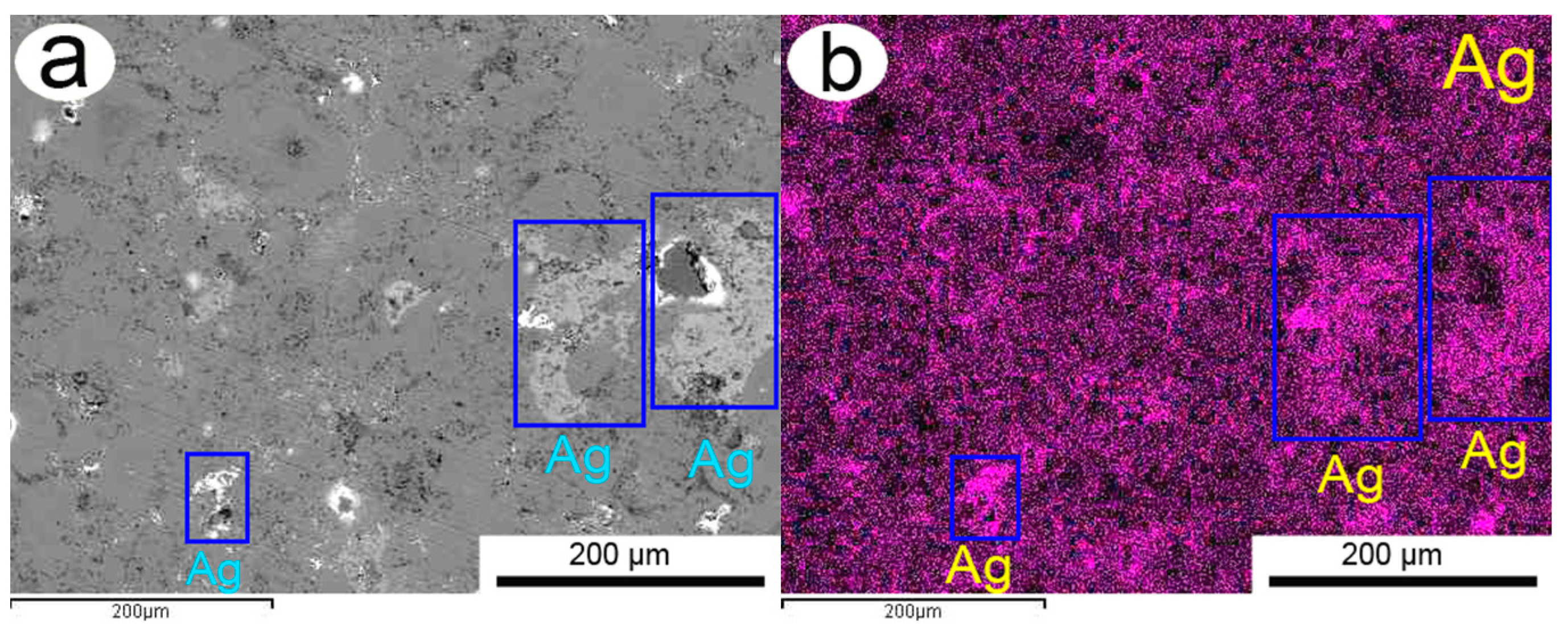

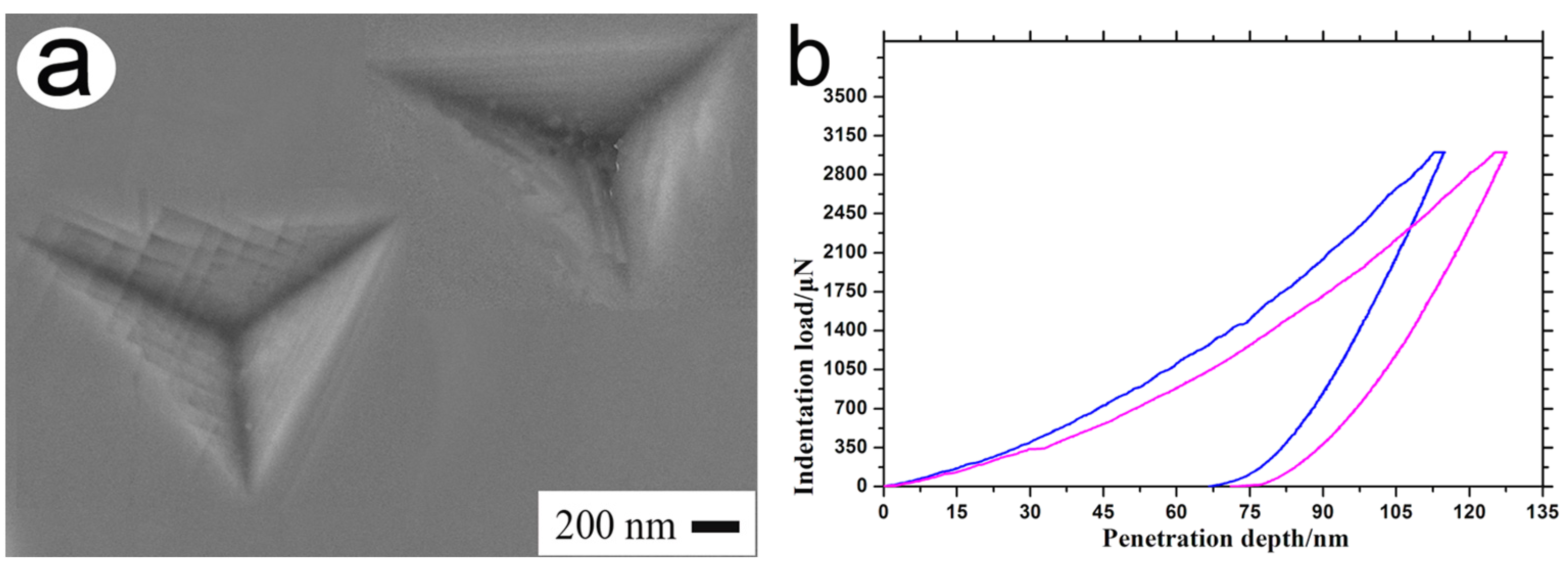

2. Material Preparation and Characterization

Ti + 3Al→TiAl3

3Ti + Al→Ti3Al

TiAl + 2Ti→Ti3Al

TiAl + 2Al→TiAl3

TiAl3 + 2Ti→3TiAl

Ti3Al + 2Al→3TiAl

4Ti + TiAl3→Ti3Al + 2TiAl

4Al + Ti3Al→TiAl3 + 2TiAl

3. Results and Discussion

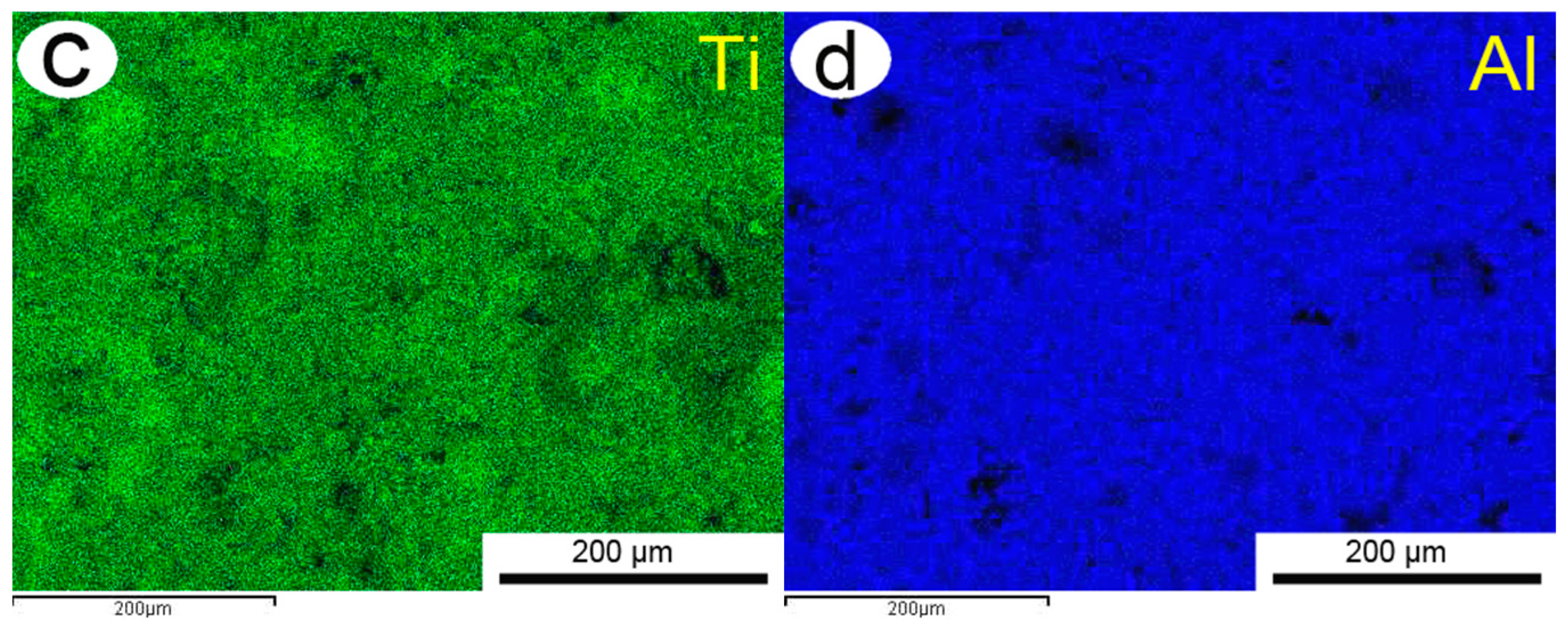

3.1. Analysis of Mechanical Properties

3.2. Friction and Wear Behavior of γ-TiAl-10 wt.% Ag

3.3. Tribology Calculation Model

4. Conclusions

- A large amount of soft silver used in preparing γ-TiAl-10 wt.% Ag samples caused their mechanical properties to be slightly reduced.

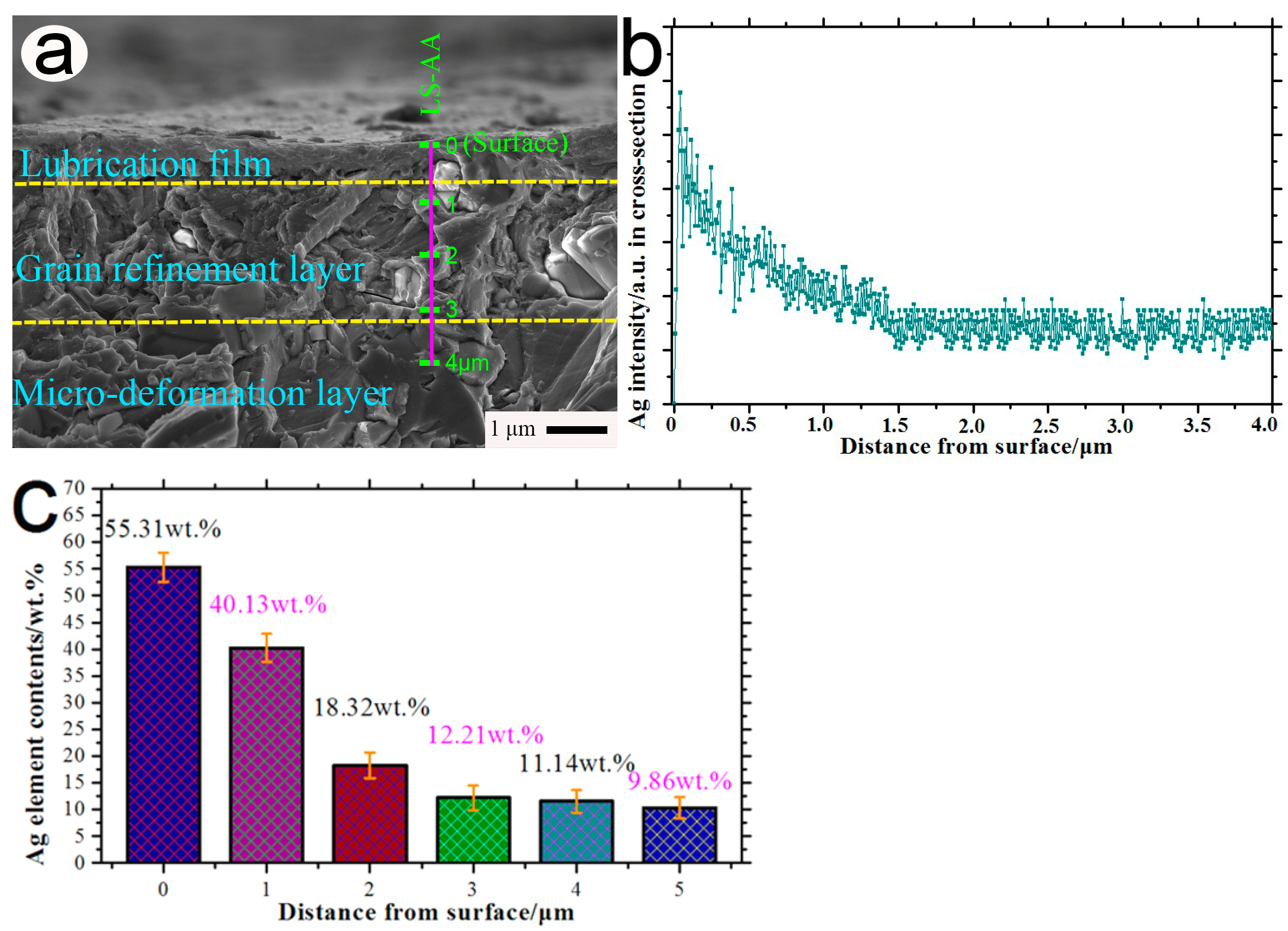

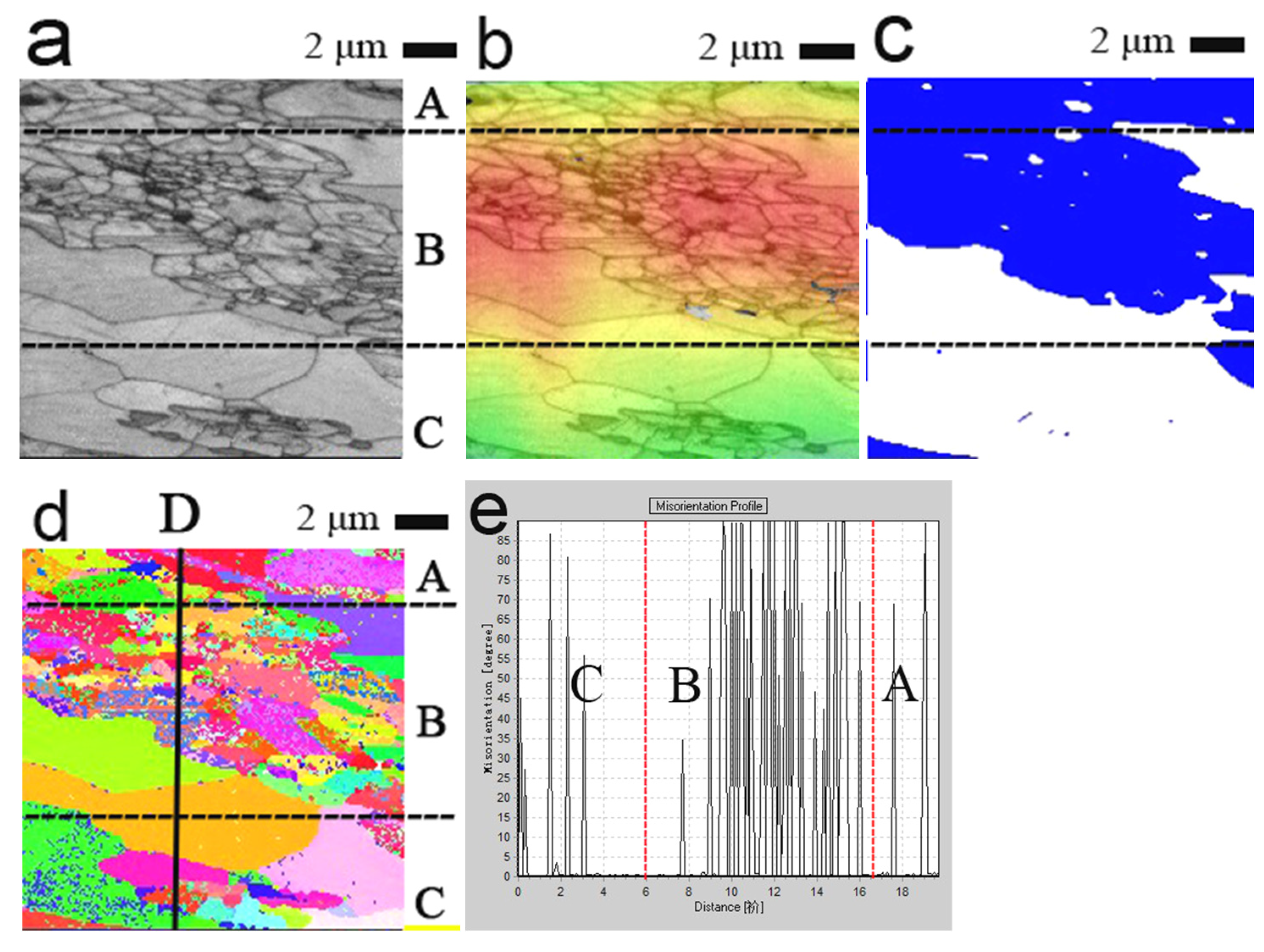

- Because of the low grain strain and small misorientation angle, the silver-rich film was protected from destruction and the lubrication ability was improved, thus leading to the small friction coefficient and wear rate of γ-TiAl-10 wt.% Ag.

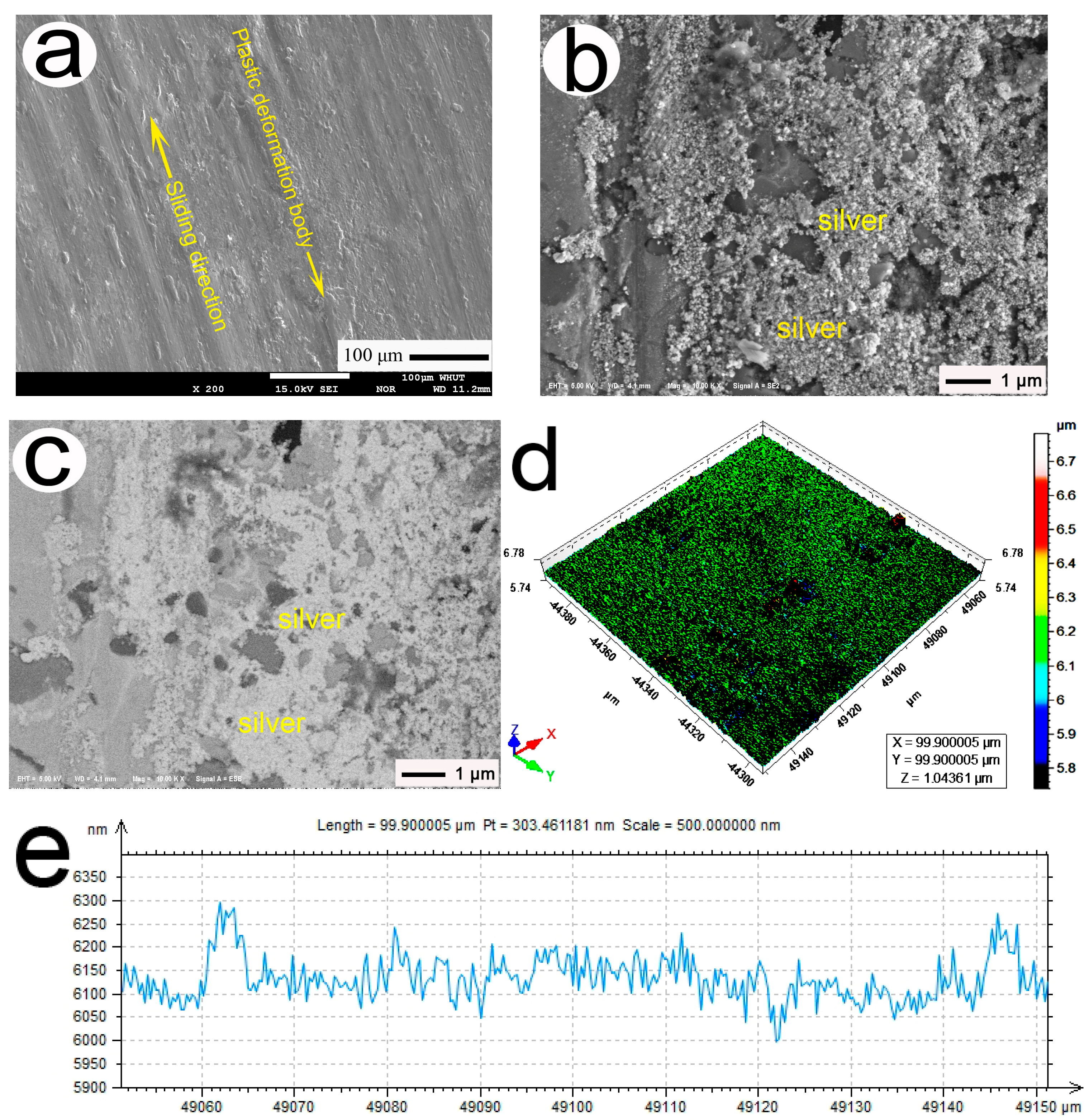

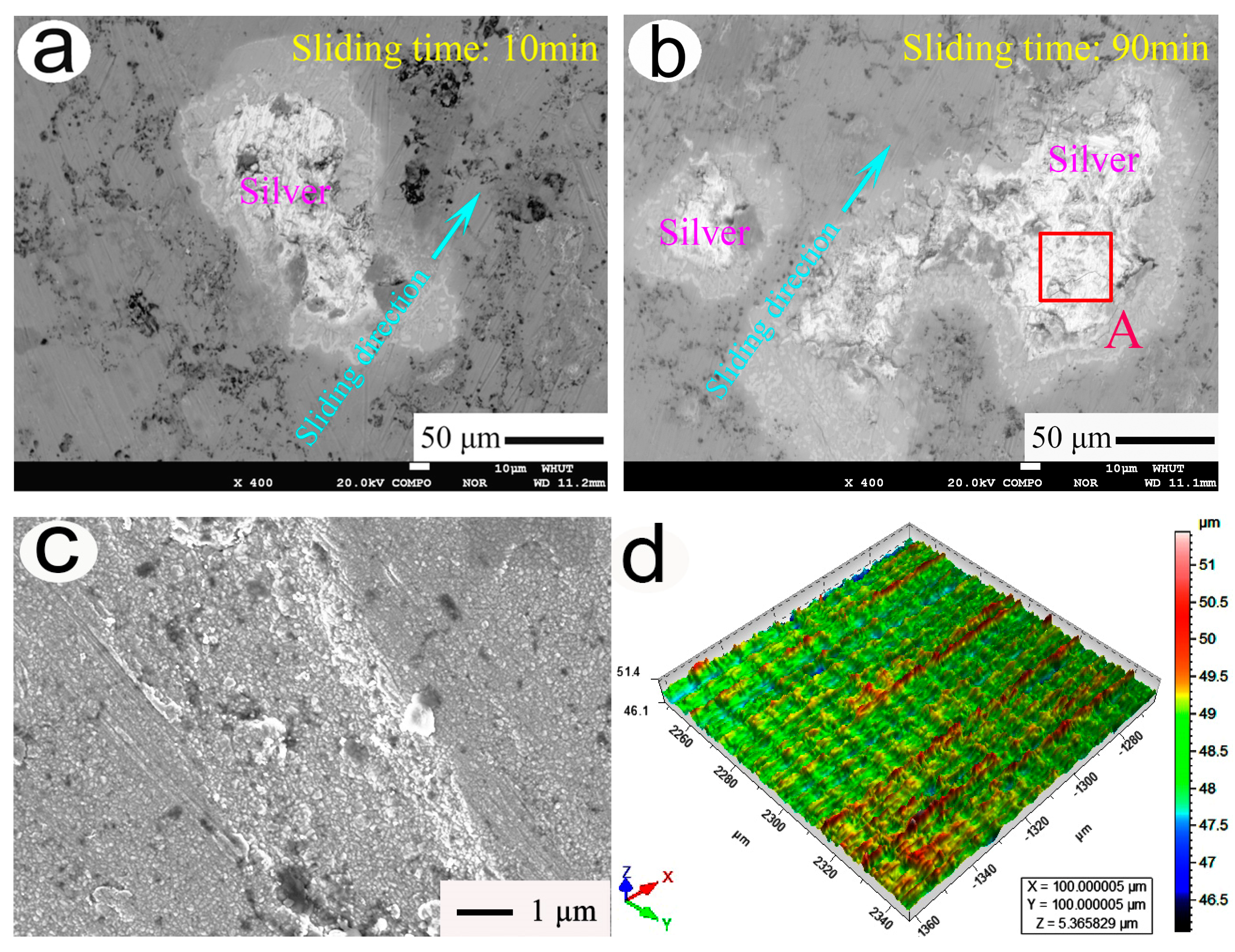

- Massive amounts of silver gradually spread out across the wear scar to increase the Ag distribution area. This resulted in the formation of a silver-rich lubrication film, which was helpful in ensuring the excellent tribological behavior of γ-TiAl-10 wt.% Ag.

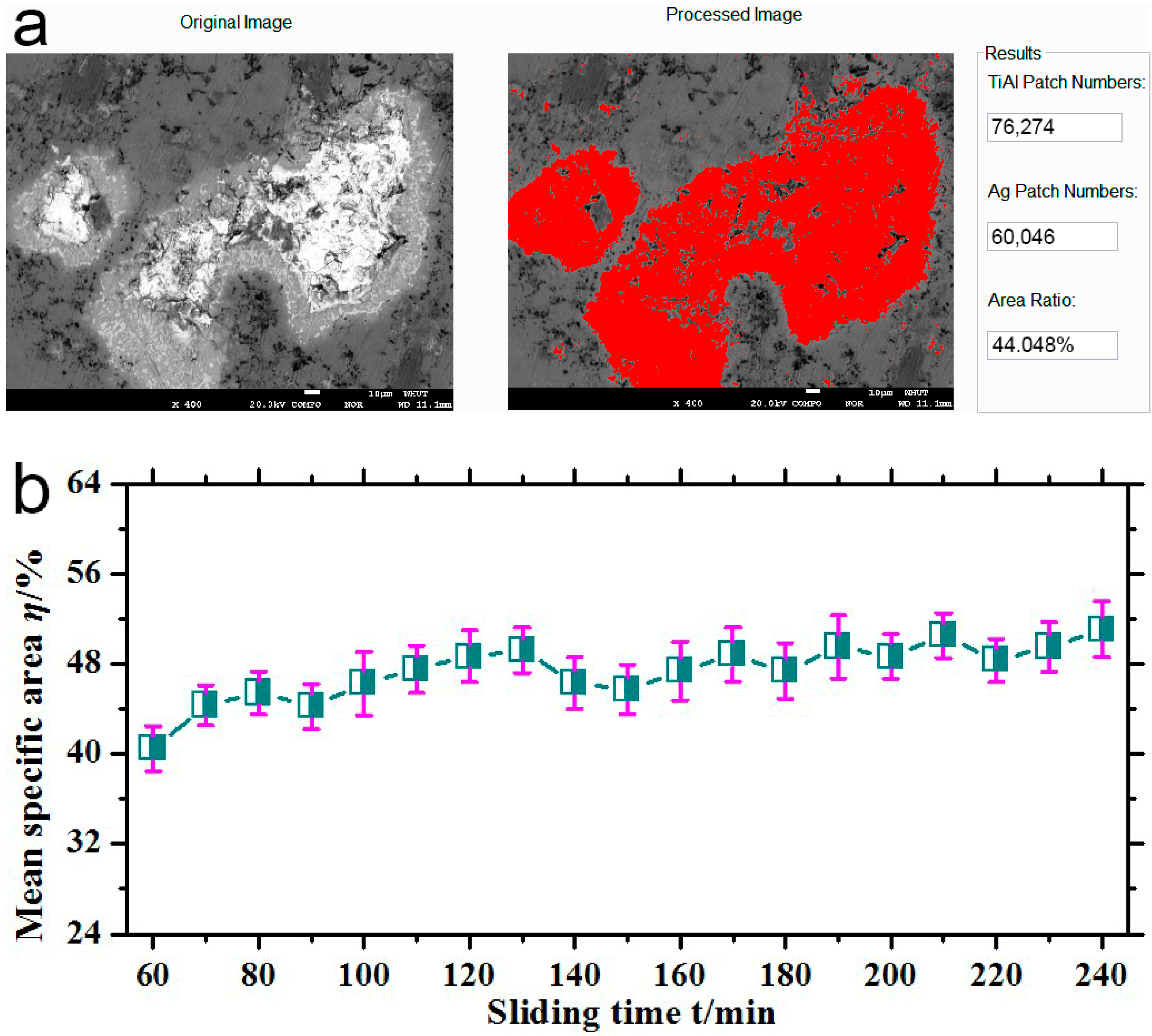

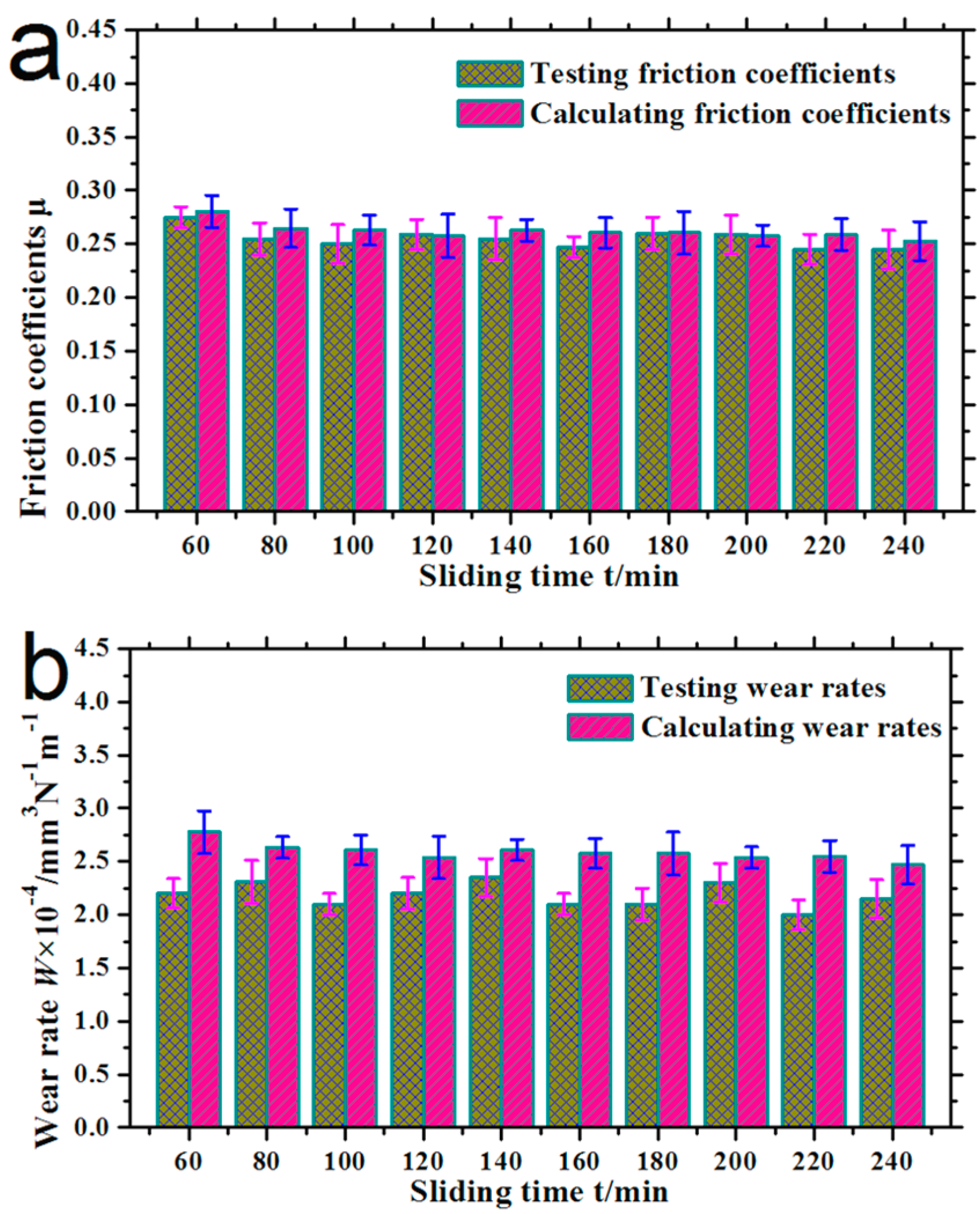

- The K-means method of main component clustering was utilized to establish a theoretical model, and this facilitated the calculation of the distribution area of the silver-enriched lubrication film. It was found that an increase in the silver distribution area improved the friction and wear behavior of γ-TiAl-10 wt.% Ag; subsequently, the specific area η of the silver-rich film was maintained at 44–51%, and a small friction coefficient (almost 0.28) and wear rate (about 2.25 × 10−4 mm3·N−1·m−1) were observed for γ-TiAl-10 wt.% Ag.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, Z.Q.; Chu, L.L.; Yu, M.L.; Guo, W.L.; Zhang, Z.H. Advanced TiAl Based Alloys: From Polycrystals to Polysynthetic Twinned Single Crystals. Adv. Funct. Mater. 2025, 34, 274–279. [Google Scholar] [CrossRef]

- Pan, Y.; Xiao, X. Improving the balance between the strength and ductility of γ-TiAl alloy: An adjustment strategy for alloy doping. Mater. Today Commun. 2025, 42, 111515. [Google Scholar] [CrossRef]

- Zhou, M.; Hu, R.; Li, J.G.; Zhang, K.R.; Luo, X. Microstructure and mechanical properties of heterogeneous double fibers reinforced TiAl composites. J. Manuf. Process. 2025, 136, 291–304. [Google Scholar] [CrossRef]

- Weng, Y.T.; Wang, R.; Sui, X.M.; Song, Z.F.; Wang, K.; Mo, Z.Z.; Yang, F.T.; Huang, X.B. Investigating the microstructure and high-temperature wear resistance of TiAl/WC coating modified via scanning electron beam. Surf. Coat. Technol. 2024, 494, 131479. [Google Scholar] [CrossRef]

- Zhu, D.D.; Yan, J.F.; Wang, Y.P.; Jin, Y.L.; Dong, D.; Wang, X.H.; Ma, T.F.; Zhu, L. Enhancing the mechanical and tribological properties of TiAl alloy by network structured Ti2AlC. J. Mater. Sci. 2024, 59, 5399–5413. [Google Scholar] [CrossRef]

- Tu, L.Q.; Zhang, Y.; Yu, Q.Y.; Wang, X.; Wang, C.R.; Zhang, Z.J.; Huang, L.J.; Geng, L.; Chen, Y.Y. Machinability and tool wear mechanism in the high-speed milling of TiAl alloys with different microstructures. J. Mater. Res. Technol. 2025, 36, 6229–6239. [Google Scholar] [CrossRef]

- Wang, P.J.; Li, X.B.; Peng, B.Y.; Liu, X.G.; Pang, Y.J.; Liu, K. Comparison on Dry Sliding Tribological Behavior Between β-Solidifying γ-TiAl Alloy and 40 CrMo Steel. Rare Met. Mater. Eng. 2024, 53, 2513–2523. [Google Scholar]

- Xu, Z.S.; Zhang, Q.X.; Huang, X.J. An approximate model for the migration of solid lubricant on metal matrix self-lubricating composites. Tribol. Int. 2016, 93, 104–114. [Google Scholar] [CrossRef]

- Yang, K.; Shi, X.L.; Zheng, D.; Zhai, W.Z. Tribological behavior of a TiAl matrix composite containing 10 wt% Ag investigated at four wear stages. RSC Adv. 2015, 5, 77885–77896. [Google Scholar] [CrossRef]

- Shi, X.L.; Xu, Z.S.; Wang, M.; Zhai, W.Z.; Yao, J.; Song, S.Y. Tribological behavior of TiAl matrix self-lubricating composites containing silver from 25 to 800 °C. Wear 2013, 303, 486–494. [Google Scholar] [CrossRef]

- Gonçalves, J.N.C.; Cortez, P.; Carvalho, M.S. K-means clustering combined with principal component analysis for material profiling in automotive supply chains. Eur. J. Ind. Eng. 2021, 15, 273–294. [Google Scholar]

- Korir, E.K. Comparative clustering and visualization of socioeconomic and health indicators: A case of Kenya. Socio-Econ. Plan. Sci. 2024, 95, 101961. [Google Scholar] [CrossRef]

- ASTM Standards G99-95; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 1995.

- Li, X.; Shi, T.; Liu, C. Multifunctional substrate of Al alloy based on general hierarchical micro/nanostructures: Super amphiphobicity and enhanced corrosion resistance. Sci. Rep. 2016, 6, 35940–35951. [Google Scholar] [CrossRef]

- Radmilovic, V.V.; Kacher, J.; Ivanovic, E.R.; Minor, A.M. Multiple twinning and stacking faults in silver dendrites. Cryst. Growth Des. 2016, 16, 467–474. [Google Scholar] [CrossRef]

- Sivasubramanian, R.; Sangaranarayanan, M.V. A facile formation of silver dendrites on indium tin oxide surfaces using electrodeposition and amperometric sensing of hydrazine. Sens. Actuators B Chem. 2015, 213, 92–101. [Google Scholar] [CrossRef]

- Yue, Y.L.; Wu, H.T.; Wu, B.; Wang, Z.J.; Tao, W.H. Thermodynamic and dynamics analysis on the combustion synthesis of TiAl Intermetallic. J. Univ. Jinan 2005, 19, 106–109. (In Chinese) [Google Scholar]

- Xu, Y.; Peng, Y.; Dearn, K.D.; Zheng, X.; Yao, L.; Hu, X. Synergistic lubricating behaviors of graphene and MoS2 dispersed in esterified bio-oil for steel/steel contact. Wear 2015, 342, 297–309. [Google Scholar] [CrossRef]

- Yang, K.; Shi, X.L.; Zou, J.L.; Shen, Q. The study of the preparation and tribological behavior of TiAl matrix composites containing 1 wt% multi-walled carbon nanotubes. RSC Adv. 2016, 6, 29334–29341. [Google Scholar] [CrossRef]

- ASTM B962-08; Standard Test Methods for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle. ASTM International: West Conshohocken, PA, USA, 2008.

- Zhai, W.Z.; Lu, W.L.; Zhang, P. Wear-triggered self-healing nanocrystalline nickel aluminum bronze/Ti3SiC2. Appl. Surf. Sci. 2018, 436, 1038–1049. [Google Scholar] [CrossRef]

- Hartigan, J.A.; Wong, M.A. A K-means clustering algorithm. J. Appl. Stat. 2013, 28, 100–108. [Google Scholar] [CrossRef]

- Zhang, X.; Zong, L.; You, Q. Sampling for nyström extension-based spectral clustering: Incremental perspective and novel analysis. ACM Trans. Knowl. Discov. Data 2016, 11, 1–25. [Google Scholar] [CrossRef]

- Atitey, K. A Novel Prediction Algorithm in Gaussian-Mixture Probability Hypothesis Density Filter for Target Tracking, Image and Graphics; Springer International Publishing: Cham, Switzerland, 2015; pp. 373–393. [Google Scholar]

- Yamamoto, Y.; Ura, A. Influence of interposed wear particles on the wear and friction of silicon carbide in different dry atmospheres. Wear 1992, 154, 141–150. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, N.; Yang, C.; Zhou, S.; Yin, Y.; Zhao, D.; Shi, Y.; Yang, K. An Exploration of SPS Fabrication and the Sliding Wear Properties of γ-TiAl-Ag Self-Lubrication Materials. Surfaces 2025, 8, 45. https://doi.org/10.3390/surfaces8030045

Xiao N, Yang C, Zhou S, Yin Y, Zhao D, Shi Y, Yang K. An Exploration of SPS Fabrication and the Sliding Wear Properties of γ-TiAl-Ag Self-Lubrication Materials. Surfaces. 2025; 8(3):45. https://doi.org/10.3390/surfaces8030045

Chicago/Turabian StyleXiao, Na, Chenglong Yang, Shengfei Zhou, Yuliang Yin, Dian Zhao, Yulong Shi, and Kang Yang. 2025. "An Exploration of SPS Fabrication and the Sliding Wear Properties of γ-TiAl-Ag Self-Lubrication Materials" Surfaces 8, no. 3: 45. https://doi.org/10.3390/surfaces8030045

APA StyleXiao, N., Yang, C., Zhou, S., Yin, Y., Zhao, D., Shi, Y., & Yang, K. (2025). An Exploration of SPS Fabrication and the Sliding Wear Properties of γ-TiAl-Ag Self-Lubrication Materials. Surfaces, 8(3), 45. https://doi.org/10.3390/surfaces8030045