Abstract

The metal injection molding (MIM) manufacturing process has made relevant advances for applications in components with complex geometries, small dimensions, and high production volumes. New technologies such as hot isostatic pressing (HIP), uniform polymer extraction, and sintering with reduced temperature variations improve metallurgical and mechanical properties. However, there are still knowledge gaps in understanding these technologies and the behavior of catalytic low-alloy steels obtained by the MIM process and cyclic applications. This study aims to analyze the behavior of Catamold 100Cr6 steel subjected to quenching and tempering heat treatment in different microhardness ranges and the effect of compressive stresses on the samples obtained by polishing using ceramic microchips. The samples were characterized using optical microscopy, scanning electron microscopy, an EDS microprobe, and X-ray diffraction and subjected to elastic return cycling and an experimental device developed to apply a 19° bending angle. The findings show a significant increase in fatigue life due to the compressive stresses (up to—430 MPa) generated by the reduction in retained austenite and surface plastic microdeformation, indicating the effectiveness of 100Cr6 Catamold steel in cyclic applications.

1. Introduction

Components with complex geometries, small dimensions, and high production volumes have been produced using the metal injection molding (MIM) technology [1]. The MIM process has found wider applications in powder metallurgy [1,2]. This process includes four main stages: preparation of the raw material (feedstock), injection of the parts, removal of the binder (debinding), and sintering [1,2]. Using powders with smaller, spherical particles up to 20 μm in size gives the sintered material greater density [3,4]. This condition significantly favors the metallurgical and mechanical properties of the parts, and in many applications, conditions similar to those of conventional steelmaking processes can be obtained [3,4].

Compared to the conventional powder metallurgy process, the MIM process has the advantage of volumetric injection and linear shrinkage, ensuring less tendency for segregation and dimensional variations [3,4]. Technological advances related to metallurgical aspects such as porosity, carbon segregation, and the heterogeneity of chemical composition have minimized these aspects, which used to be deleterious factors [3,4]. With advances in MIM technology in the catalytic process of extracting polymer binders, positive effects on density, reducing porosity, and the homogeneity of chemical composition have favored obtaining metallurgical and mechanical properties similar to steels obtained by conventional manufacturing processes [4,5]. One of the factors that has contributed to improving the performance of the MIM process is related to advances in feedstock. Initially, atomization was carried out in the water, generating brown resistance in the parts produced due to irregularities. The disadvantages of this process are the low compaction density, resulting in high variation in shrinkage during sintering, and the tendency of irregular injection particles to align slightly, causing anisotropic shrinkage [4,5]. For this reason, the alternative of activating the atomized powders with water and milling them to contribute to more uniform shrinkage was developed, but at a higher cost [4,5]. Another possibility was to atomize the powders with gas, generating a higher compaction density and less need for binding elements, resulting in more uniform shrinkage. The disadvantages of this powder type are its higher price and the lower strength after debinding [4]. Recently, these techniques have shown advances and, together with injection, debinding, and sintering equipment, have contributed to consolidating the MIM manufacturing process for parts with small dimensions, complex geometries, and high production volumes [5].

Research and process applications have taken place since the atomization process of the metal powders, generating morphologies with greater spheronization, which favors bonding with greater surface tension during the chemical and thermal polymer extraction process (debinding) and in the final sintering stage [4,5,6].

In the sintering stage, one of the most important developments has been the use of bath-type furnaces with a rotating heating zone during the process, generating homogeneous temperatures, reducing dimensional variations, and achieving a higher degree of purity in the controlled nitrogen, hydrogen, or argon atmospheres [5,6]. In this way, volumetric contraction tends to occur more efficiently and uniformly, minimizing the presence of deleterious elements such as delta ferrite in stainless steels, which have higher sintering temperatures [6,7,8]. Other improvements, such as controlled cooling after sintering, have also been significant for automotive, aerospace, medical, and security technology [4,5,6,7,8,9]. Low-alloy, medium-carbon, or high-carbon Catamold steels are characterized by good hardenability [10,11]. After applying quenching and tempering heat treatment, it has high mechanical strength limits and yield strength and is used in elements subjected to surface cyclic stresses [11,12,13,14,15,16,17].

The use of MIM components in cyclic applications below the yield strength has long been limited by their anisotropic conditions [3,4,5,6]. However, with the progress made in recent decades and the isotropic behavior obtained with improvements in the raw material (feedstocks) and debiding and sintering equipment, their applications in more severe conditions have been accentuated [4,5,8]. Studies on the application of Catamold steel components to cyclic stresses are little explored in the scientific literature, and their research is restricted to a few institutions with state-of-the-art equipment due to the high cost of the feedstock, equipment, and atmospheres used [4,5,6]. Based on these knowledge gaps related to the application of MIM components in cyclic stresses, this study evaluated the experimental cyclic behavior of Catamold 100Cr6 steel subjected to angular cyclic stresses below the yield strength in the quenched and tempered conditions and subjected to surface compressive microtensions. Catamold 100Cr6 is classified as hypereutectic and a low alloy and has a high yield strength when quenching and tempering at low temperatures [13,14,15].

However, due to its high alloying element content, this steel grade sometimes retains austenite, which reduces its surface microhardness and causes tensile stresses on the surface [10,11]. The retained austenite can transform into martensite under sub-zero, cryogenic, or plastic deformation treatments [16,17]. Phase transformations in steel under non-zero superficial stress produce permanent plastic deformation that preserves the volume, even if the von Mises (macro) stress does not reach the yield strength [18]. In addition, stress influences phase transformations in the presence of retained austenite and martensite. These phenomena are called deformation-induced martensite (MID) [18,19,20]. Mechanical polishing is commonly used for surface finishing and metallographic sample preparation for a wide range of materials. However, polishing causes local deformation and induces residual stress, which affects many surface phenomena. Residual stresses induce changes in the interatomic spacing of crystals in materials, and this phenomenon is verified using the X-ray diffraction (XRD) technique. The position of each diffraction peak is measured at a given point, with the samples’ orientations different from the applied X-ray beam. From this condition, it is possible to determine the spacing in different directions and the related deformations. Tensile or compressive stresses can be obtained from the plastic or elastic deformations on the surface or subsurface of the materials analyzed. This test is highly reliable in polycrystalline materials and is very useful for detecting deformation processes and the diffusion of interstitial elements [21]. The angle of 19° was defined as the optimum angle for the application of the component, correlated with the geometry and cross-sectional area. This approach eliminated the torsion effects, generating tension stresses primarily on the load application side and compression stresses on the opposite side. From the cyclic elastic deformations, cracks were nucleated and propagated until the specimens ruptured. The tests were performed with specimens of the same geometry, only modifying the tempering and rotopolishing conditions and comparing the effects of residual stresses on the number of cycles supported.

Until recently, it has not been possible to quantify the nanoscale depth variation of polishing-induced plastic deformation and the effect of the associated residual stress on cyclic behavior. To improve our understanding of these complex mechanisms, this study seeks to provide new knowledge regarding the importance of isotropic aspects in the behavior of steels obtained by MIM technology. The main conventional steels used as the most severe springbacks are SAE 1070, SAE 5160, and, in some cases, SAE 6150. However, these alloys are not available with catalytic feedstock. Therefore, this study also evaluates the possibility of using Catamold 100Cr6 steel in cyclic applications, considering all the favorable and limiting aspects of the MIM process.

2. Materials and Methods

The Catamold 100Cr6 steel was chosen because it is a low-alloyed hypereutectoid steel with high mechanical and wear resistance. Even though springback is not a relevant characteristic of this class of steel, the study of its application is relevant for applications that may include wear, springback, and fatigue and is of great interest for MIM technology [5,13].

In the first stage of the experiments, Catamold 100Cr6 steel specimens were injected in an Arbur injection molding machine at a pressure of 1400 bar and a mold temperature of 90 °C for 30 s at each injection. Subsequently, the samples were subjected to the debinding process in a Cremer furnace, with nitric acid vapor with a purity level of 99.999% at a temperature of 125 °C for 1 h. The samples were then thermally deburred in a Cremer Model HDH 150/145 oven at a temperature of 650 °C for 60 min in a nitrogen atmosphere.

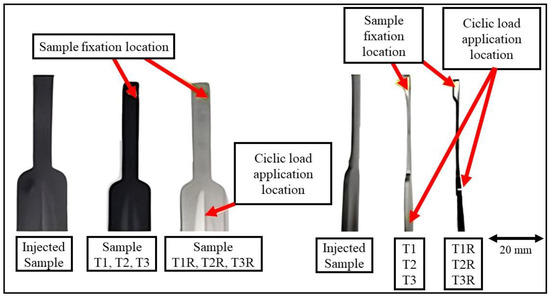

Subsequently, they were sintered in the same furnace for 60 min at a temperature of 1290 °C, with controlled cooling with nitrogen to a temperature of 500 °C. Figure 1 shows the injected samples, sintered with heat treatment and sintered with heat treatment and rotopolished finish with ceramic microchips. The chemical composition of the sintered samples was analyzed using a Foundry—Master Pro, Oxford optical emission spectrometer. The density after sintering was measured using a Quantachrome Ultrapyc 1200 model pycnometer.

Figure 1.

Samples of injected Catamold 100Cr6 steel in conditions T1, T2, T3, T1R, T2R, and T3R.

The heat treatment was carried out in an Ipsen T4 furnace, with austenitization at a temperature of 840 °C, with a carbon potential of 1%, for 30 min, with cooling in oil at a cooling rate of 80 °C/s. Tempering was carried out in a bath furnace with recirculation at a temperature of 180 °C (T1 samples), 200 °C (T2 samples), and 250 °C (T3 samples) for 1 h. Then, parts of the samples were rotopolished with ceramic microchips for 1 h and identified as T1R, T2R, and T3R.

After heat treatment, microstructural analyses were carried out using an Olympus GX 51S optical microscope and a scanning electron microscope (SEM), Jeol JSM—6610 LV, with an EDS microprobe. The microhardness was checked using a Shimadzu HMV 2T microhardness meter with a load of 25 g, and the residual stresses verified by X-ray diffraction (XRD) analyses were carried out directly on the treated surface of the samples without any prior preparation, using Bruker AXS D8 device. Advanced XRD with monochromatic CuKα radiation, a voltage of 40 kV, a current density of 30 mA, and a step size of 0.02° (2θ) per second.

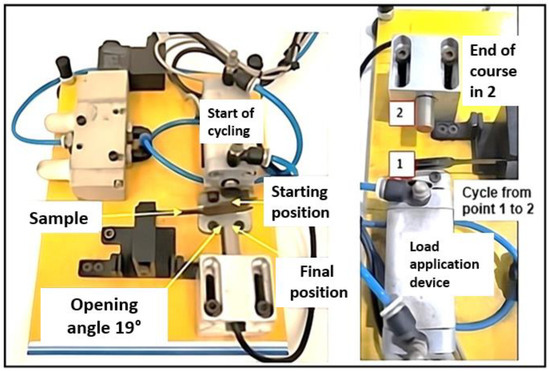

The cyclic behavior related to elastic feedback was evaluated in the device with an application angle of 19°, as shown in Figure 2. The cyclic behavior related to elastic feedback was evaluated in the device with an application angle of 19°, as shown in Figure 2. The bending angle chosen was based on the geometry of the specimens and the limit at which effects such as the morphology of the radii and stress concentrators reached their design limit for the MIM process.

Figure 2.

Device for applying cyclic efforts, with initial (1) and final (2) load application positions.

3. Results and Discussions

3.1. Chemical Analysis

Table 1 shows the chemical composition. The chemical elements are within the specifications of Catamold 100Cr6 steel. No residual elements were detected that could compromise the samples’ performance in the heat treatment or cyclic stresses applied.

Table 1.

Chemical composition of Catamold 100Cr6 steel samples.

The absence of residual chemical elements helps to ensure that hardenability is not affected, minimizing the presence of cracks in quenching and tempering heat treatments [10,11,12,13]. The absence of residual alloying elements in the chemical composition means that the temperatures related to the phase changes in 100Cr6 Catamold steel are uniform during the heat treatment stages. This behavior makes it possible to evaluate better the characteristics of the initial and final plateaus of the martensitic transformation. As the carbon content and alloying elements directly influence the presence of retained austenite, an adequate chemical balance of the steel favors the control of retained austenite [12,13,14,15]. The sample density value detected in the pycnometer analysis was 7.8 g/cm3. This value indicates that the final densification validates the reduction of porosities in the metal injection molding manufacturing process [1,3].

3.2. Microstructural Analysis

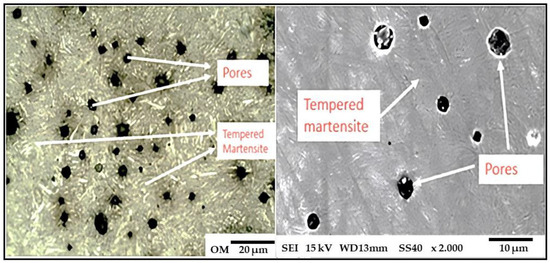

After sintering, the microstructure observed in the samples consists of pearlite and cementite (Figure 3). Their presence is directly related to the low cooling rate applied after sintering [6,7,8,9]. The microstructure of the samples was found to be free of carbon segregation, verifying diffusional phase change mechanisms in the austenitic region [10,11]. After the application of the quenching and tempering heat treatment, the microstructure detected in the sample substrates consisted of finely tempered martensite, retained austenite, and cementite, typical of heating in the intercritical zone between the AC1 and ACm lines of the iron–carbon diagram [12,13].

Figure 3.

Microstructure of Catamold 10Cr6 steel samples after quenching and tempering in optical microscopy and scanning electron microscopy.

Furthermore, the diffusional and instantaneous behavior of martensitic transformation was verified in the samples, but with a reduction in the final temperature of martensitic transformation, generating retained austenite [14,15]. Figure 4 shows the microstructures of the samples after the quenching and tempering cycles. The samples showed the presence of porosity, typical of the MIM process, but with a smaller volume than that found in the literature, as confirmed by their density of over 7.8 g/cm3 measured in a pycnometer [15,16,17]. Even in applications of HIP (High Isostatic Pressure) technology, which significantly increases the density of steels obtained by MIM technology, porosity is inherent to this manufacturing process [15,16,17]. The pores in these materials reduce the effective load area in the tensile test, resulting in lower mechanical strength. Both pores and non-metallic inclusions in conventional steels can be sites of stress concentration and crack nucleation in tensile and fatigue tests, deteriorating the strength and ductility of the materials [3,4].

Figure 4.

Microhardness HV0.25 profile of samples subjected to conditions T1, T2, and T3.

The density observed of the sintered samples showed an average value of 7.9 g/cm3, demonstrating the control of the process concerning the level of porosity. The spherical morphology of the pores is less susceptible to propagation in cyclic applications, as it minimizes the stress concentration [18,19,20,21]. Their fragmentation, reducing their anisotropic aspects, effectively obtains better mechanical properties. Impermeable morphologies are characterized by more refined granulation or mixed grain size, with smaller grains and interconnections between the grains [3].

As mentioned above, the microstructure of the tempered and quenched samples also showed the presence of retained austenite. This microstructure is susceptible to appearing in steels with a high carbon content and alloying elements [15,16,18,20]. In atmospheres with high carbon content and low alloy steels, there are thermodynamic changes in the process, which contribute to the final temperature of the martensitic transformation being reduced to temperatures many times below the ambient temperature [20,21,22,23]. The presence of retained austenite near the surface can cause tensile stresses, reducing fatigue resistance [23,24,25]. However, when subjected to sub-zero, cryogenic, or mechanical treatments, the austenite retained on the surface can be transformed into martensite with compressive stress characteristics [24,25]. Regarding the austenitic grain size, it was found to be refined after the quenching and tempering heat treatment, which is a favorable condition for cyclic applications [3]. The EDS microprobe tests did not detect chemical elements such as silicon, manganese, aluminum, or calcium, which qualitatively refer to the presence of non-metallic micro-inclusions, favorable for better metallurgical properties [3].

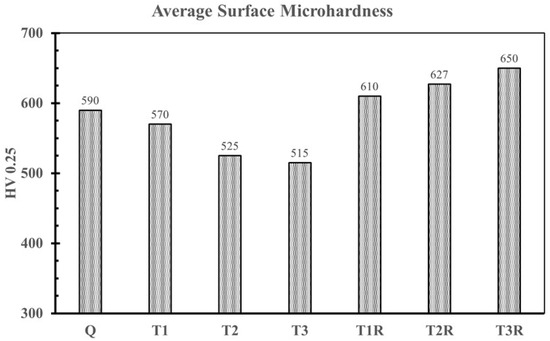

3.3. Vickers Microhardness Behavior

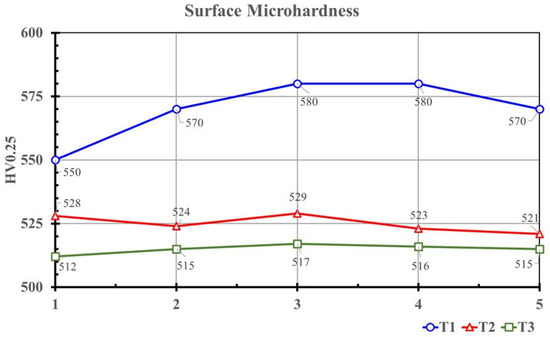

The microhardness analyses helped identify the effect of tempering on the samples and showed the typical behavior of retained austenite. Figure 4 shows the microhardness profiles of the samples under conditions T1, T2, and T3.

After rotopolishing, the surface microhardness was measured. It was observed that the T1R, T2R, and T3R microhardnesses increased and showed higher values than the tempered condition (Q). This effect was intensified by the transformation of the retained austenite on the surface into martensite and by plastic microdeformation near the surface.

The decreasing behavior of the microhardnesses in samples T1, T2, and T3 was due to the increase in the tempering temperatures applied, with no significant effect on transforming austenite into martensite. After rotopolishing, there was an upward trend in the microhardness of samples T1R, T2R, and T3R due to a combination of the transformation of retained austenite into martensite and surface plastic deformation. Plastic deformation behavior was inversely proportional to the tempering temperature due to the greater tendency for discordant movement in samples with higher tempering temperatures [20]. Although carbide precipitation is one of the hardening factors in bearing steels such as Catamold 100Cr6, the initial plastic deformation directly influences the precipitation kinetics. In the metal injection molding process, mechanical forming takes place with the main effect of the feedstock’s polymeric fluidity behavior. This means that the residual stresses generated after quenching and tempering by rotopolishing are not severe enough to dissolve primary carbides [26,27]. The behavior of the average surface microhardness HV0.25 can be seen in Figure 5.

Figure 5.

Average surface microhardness HV0.25 of the samples under different conditions.

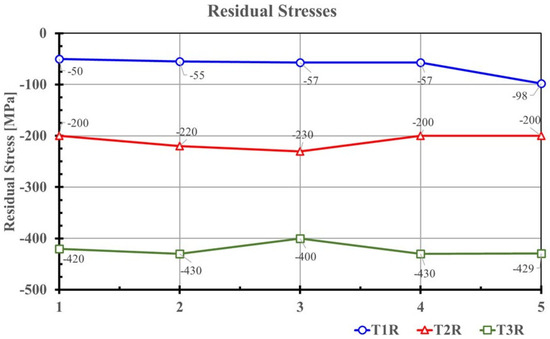

3.4. Residual Stresses

The behavior of the residual stresses in samples T1, T2, and T3 showed values greater than zero (Figure 6), which is not favorable to cyclic stresses [19,20,21]. However, after polishing, all the samples showed compressive stresses, with sample T3R showing the highest compressive residual stresses.

Figure 6.

Residual stresses in the samples after rotopolishing with ceramic microchips.

The TR1 sample suggested lower compressive stress values because its surface had higher microhardness values before rotopolishing, minimizing the effect of plastic microdeformation [20,21]. Evaluating the behavior of the TR2 samples shows that the higher the surface microhardness, the primary mechanism for increasing the compressive residual stresses was associated with the transformation of retained austenite into martensite.

However, in the T3R sample, both mechanisms contributed significantly to the increase in the generation of residual stresses. Figure 6 shows the residual stress profile of the samples. The evolution of residual stress in samples with retained austenite subjected to rotopolishing shows a variation in depth according to the time of application. A significant compressive residual stress value of around 430 MPa can be found near the surface [3]. There are still open questions in the literature about the impact of austenitic grain size and grain interaction on the surface region in conditions free of retained austenite [3]. The XRD technique at low residual stress depths is very effective for MIM components, as the presence of porosity is reduced near the surface. However, at greater depths of stress due to deformation or thermochemical treatments, porosity can be affected, masking compressive or tensile conditions due to random stress concentrators [20].

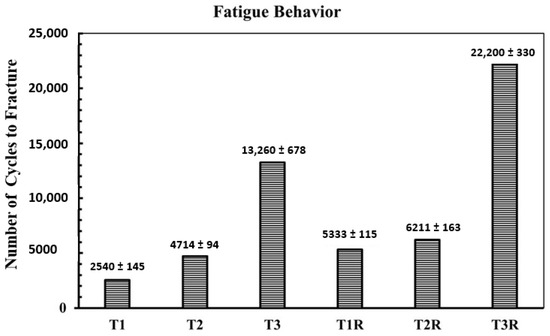

3.5. Cyclic Tests

Figure 7 shows the results obtained from the samples under the different conditions studied.

Figure 7.

The cyclic behavior of the samples studied under different processing conditions.

In the cycling tests, tempered and quenched samples T1, T2, and T3 tended to show an increase in life with a higher tempering temperature. The lower interaction between porosity and the absence of compressive stresses or anisotropies in the substrate corroborates this behavior. In this condition, the best results were obtained at a tempering temperature of 250 °C. After rotopolishing, it was possible to increase the fatigue life of the T1R and T2R samples by more than 5000 cycles. The T3R sample proved the most effective, with its fatigue life exceeding 20,000 cycles. The results show that both the tempering temperature and the compressive microstresses directly influence the application of elastic return cyclic stresses in Catamold 100Cr6 steel obtained by the MIM process [20,24,26].

Observing surface and microstructural deformations in the retained austenite and martensite is ideal for capturing the elastic return behavior at loads below the yield strength and the location of deformations that lead to flaw nucleation and propagation [20].

For example, in Catamold 100Cr6 steels, small phase changes from retained austenite to martensite can increase hardness. Dimensional and thickness property variations significantly impact the springback behavior of steels. They can modify the springback characteristics by generating other classes of residual stress. Strain hardening or phase change models with anisotropic evolution work with the angular variation of anisotropic properties and can predict springback behavior. Edges at right angles favor nucleation and propagation of flaws [22].

A relevant factor verified for the cyclic behavior of the 100Cr6 Catamold steel samples was the absence of non-metallic microinclusions. As has been shown in numerous scientific studies, these are stress concentrators and, together with the presence of porosity, increase the deleterious behavior of this class of steel’s metallurgical and mechanical properties [21]. Another factor favorable to the good behavior of the T3R samples is associated with the appropriate sintering times, generating non-coarse grain sizes and helping crack propagation to occur with reduced kinetics and plastic deformation in the fracture region.

The condition of the sintering furnace with a rotating chamber is an essential factor in homogenizing temperatures and uniform volumetric contraction. The subsequent heat treatment (quenching and tempering) also substantially refined the grains and promoted ductile fracture [22]. The typical necks of Catamold 100Cr6 hypereutectoid steel were distributed heterogeneously within the grains, making this region more favorable in cyclic applications [22,23,24]. The sintered components’ roughness was similar to that found after rotopolishing. This condition is related to the good roughness of the injection mold, where the specimens “copied” the roughness of the mold. In the debinding (chemical and thermal) and sintering stages, the atmospheres used and the quality of the equipment were decisive for these conditions.

4. Conclusions

Based on the results and discussions observed in the research, the following conclusions can be drawn:

- Components produced with MIM Catamold 100Cr6 technology demonstrated the ability to withstand cyclic stresses below the yield limit in quenched and tempered conditions. The applied tempering range presents a relevant factor for cyclic applications with elastic return applied.

- The rotopolishing surface finish with ceramic microchips significantly increased the cyclic fatigue life below the yield point. Compressive residual stresses significantly increased the samples’ behavior in experimental springback applications.

- Samples subjected to T3R conditions showed greater surface microhardness, higher compressive stress levels, and the ability to withstand cycles below the yield limit up to five times greater than T1R and T2R conditions.

The XRD technique demonstrated that surface plastic microdeformations were significant for the performance of the studied samples.

- The effects of surface plastic deformation have a favorable application in quenched and tempered Catamold 100Cr6 steel.

New advances in MIM technology have helped this class of materials be used in items with greater security. For future research, there is interest in studies related to the addition of a higher percentage of silicon in the feedstock of different alloys, enabling the performance of tempering and partitioning heat treatment followed by microdeformations. The condition seeks MIM components with greater fracture toughness and fatigue life with significant increases. Studies on the application of shot peening with components such as glass microspheres or others will also be studied for comparative verification with the application of rotopolishing. A limitation of this research is the need to adjust the parameters according to the geometries and complexities of the samples to be produced.

Author Contributions

Conceptualization, J.L.B.M., I.C.B. and L.V.B.; methodology, J.L.B.M. and L.V.B.; software, J.L.B.M. and validation, J.L.B.M., I.C.B. and L.V.B.; formal analysis, J.L.B.M.; investigation, J.L.B.M., I.C.B. and L.V.B.; resources, J.L.B.M.; data curation, J.L.B.M.; writing—original draft preparation, J.L.B.M., I.C.B. and L.V.B.; writing—review and editing, J.L.B.M., I.C.B. and L.V.B.; visualization, supervision, J.L.B.M. and L.V.B.; project administration, J.L.B.M. and L.V.B.; funding acquisition, J.L.B.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially funded by coordination for the improvement of higher education personnel—Brazil (CAPES), Finance Code 001.

Data Availability Statement

Data is contained within the article.

Acknowledgments

Authors thank the Federal University of Rio Grande—FURG.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hwang, I.S.; So, T.Y.; Lee, D.H.; Shin, C.S. Characterization of Mechanical Properties and Grain Size of Stainless Steel 316L via Metal Powder Injection Molding. Materials 2023, 16, 2144. [Google Scholar] [CrossRef] [PubMed]

- Zhu, B.; Li, D.; Changhai, D.; Wan, Z.; Zhou, Y.; Shu, C.; Luo, F.; Li, Y. Near-spherical micron-porous NiTi alloys with high performances fabricated via metal injection molding. Mater. Sci. Eng. A 2024, 892, 146114. [Google Scholar] [CrossRef]

- Kuo, C.C.; Pan, X.Y. Development of a Rapid Tool for Metal Injection Molding Using Aluminum-Filled Epoxy Resins. Polymers 2023, 15, 3513. [Google Scholar] [CrossRef] [PubMed]

- Enneti, H.K.; Onbattuvelli, V.P.; Gulsoy, O.; Kate, K.H.; Atre, S.V. Powder-binder formulation and compound manufacture in metal injection molding (MIM). In Handbook of Metal Injection Molding; Woodhead Publishing: Cambridge, UK, 2019; pp. 57–88. [Google Scholar]

- Heaney, D. Powders for metal injection molding (MIM). In Handbook of Metal Injection Molding MIM; Series in Metals and Surface Engineering; Woodhead Publishing: Cambridge, UK, 2019; pp. 45–56. [Google Scholar]

- Scheneider, T.H.; Biehl, L.V.; Medeiros, J.L.B.; Souza, D.S. Method for the Determination of Parameters in the Sintering Pross of Mixtures of the Elemental Powders Fe-Cr and Fe-Cr-Ni. Methods X 2019, 6, 1919–1924. [Google Scholar]

- Tochetto, R.; Tochetto, R.; Biehl, L.V.; Medeiros, J.L.B.; Souza, D.S. Evaluation of the Space Holders Technique Applied in Powder Metallurgy Process in the Use of Titanium as Biomaterial. Lat. Am. Appl. Res. 2019, 49, 261–268. [Google Scholar] [CrossRef]

- Da Motta, C.A.O.; De Souza, J.; Martins, V.; Shaeffer, L.; Rossini, E.G.; Biehl, L.V.; Pacheco DA, D.J.; Martins, C.O.D.; Medeiros, J.L.B. Enhancing composite materials through fly ash reinforcement in powder metallurgy. Mater. Chem. Phys. 2023, 307, 128124–128132. [Google Scholar] [CrossRef]

- Suwanpreecha, C.; Manonukul, A. A Review on Material Extrusion Additive Manufacturing of Metal and How It Compares with Metal Injection Moulding. Metals 2022, 12, 429. [Google Scholar] [CrossRef]

- You, H.; Yang, M.; Zhang, Y.; Sisson, R.D., Jr. Austempering and Bainitic Transformation Kinetics of AISI 52100. J. Mater. Eng. Perform. 2024, 33, 4325–4334. [Google Scholar] [CrossRef]

- Kumar, S.; Sigh, S.B. Evolution of microstructure during the “quenching and partitioning (Q&P)” treatment. Materialia 2021, 18, 101135. [Google Scholar]

- Oliveira, M.U.; Biehl, L.V.; Medeiros, J.L.B.; Avellaneda, C.A.O.; Martins, C.O.D.; Souza, J.D.; Sporket, F. Manufacturing Against Corrosion: Increasing Materials Performance by the Combination of Cold Work and Heat Treatment for 6063 Aluminium Alloy. Mater. Sci.-Medzg. 2019, 26, 30–33. [Google Scholar] [CrossRef]

- Erissir, E.; Rarat, O.; Bilir, O.G. Enhancing Wear Resistance of 100Cr6 Bearing Steels by New Heat Treatment Method. Metall. Mater. Trans. A 2022, 53, 850–860. [Google Scholar] [CrossRef]

- Ostermayer, P.; Blinn, B.; Krupp, U.; Beck, T. VHCF behavior and defect tolerance of modified bainitic 100Cr6 with a high retained austenite content. Int. J. Fatigue 2024, 185, 108378. [Google Scholar] [CrossRef]

- Totten, G.E. Steel Heat Treatment: Metallurgy and Technologies; CRC Press: New York, NY, USA, 2006. [Google Scholar]

- Su, Y.; Miao, L.J.; Yu, X.F.; Liu, T.M.; Liu, L.; Liu, J.L. Effect of Isothermal Quenching on Microstructure and Hardness of GCr15 Steel. J. Mark. Res. 2021, 15, 2820–2827. [Google Scholar] [CrossRef]

- ASTM E112; Standard Test Methods for Determining Average Grain Size. ASTM: West Conshohocken, PA, USA, 2021.

- Bevilaqua, L.; Epp, J.; Rocha, A.D.S.; Roelofs, H. Explaining the Abnormal Dilatation Behavior During the Austenite Formation in a Microstructure of a Low-Carbon Low-Alloy Steel Containing Retained Austenite. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2023, 54, 3349–3357. [Google Scholar] [CrossRef]

- Ivaniski, T.M.; Castro, P.J.D.; Rodrigues, D.; Épp, J.; Nunes, R.M.; Rocha, A.D.S. Numerical and Experimental Study of an Industrial Case for Grain Size Evolution in Bainitic Steel in Controlled Hot Forging and its Influence on Mechanical Performance. Mater. Res. 2022, 25, e20210598. [Google Scholar] [CrossRef]

- Marciszko-Wiąckowska, M.; Oponowicz, A.; Baczmański, A.; Braham, C.; Wątroba, M.; Wróbel, M.; Klaus, M.; Genzel, C. A novel approach for nondestructive depth-resolved analysis of residual stress and grain interaction in the near-surface zone applied to an austenitic stainless steel sample subjected to mechanical polishing. Measurement 2022, 194, 111016. [Google Scholar] [CrossRef]

- Gan, W.; Babu, S.S.; Kapustka, N.; Wagoner, R.H. Microstructural Effects on the Springback of Advanced High-Strength Steel. Metall. Mater. Trans. A 2006, 37, 3221–3231. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, E.; Mo, W.; Lv, Y.; Ma, R.; Ye, S.; Wang, X.; Yu, P. On the Microstructures and Fatigue Behaviors of 316L Stainless Steel Metal Injection Molded with Gas- and Water-Atomized Powders. Metals 2018, 8, 893. [Google Scholar] [CrossRef]

- Zavadiuk, S.V.; Loboda, P.I.; Soloviova, T.O.; Trosnicova, I.I.; Karassevska, O.P. Fracture Features of Low-Alloy Steel Produced by Metal Injection Molding. Powder Metall. Met. Ceram. 2021, 59, 11–12. [Google Scholar] [CrossRef]

- Zhang, H.; Ouyang, Z.; Li, L.; Ma, W.; Liu, Y.; Chen, F.; Xiao, X. Numerical Study on Welding Residual Stress Distribution of Corrugated Steel Webs. Metals 2022, 12, 1831. [Google Scholar] [CrossRef]

- Wei, Y.H.; Yu, X.F.; Su, Y.; Shen, X.Y.; Xia, Y.Z.; Yang, W.W. Effect of residual stress and microstructure evolution on size stability of M50 bearing steel. J. Mater. Res. Technol. 2021, 10, 651–661. [Google Scholar] [CrossRef]

- Kumagai, M.; Curd, M.D.; Soyama, H.; Ungár, T.; Ribárik, G.; Withers, P.J. Depth-profiling of residual stress and microstructure for austenitic stainless steel surface treated by cavitation, shot and laser peening. Mater. Sci. Eng. A 2021, 813, 141037. [Google Scholar] [CrossRef]

- Torkamani, H.; Vrček, A.; Larsson, R.; Antti, M.L. Micro-pitting and wear damage characterization of through hardened 100Cr6 and surface induction hardened C56E2 bearing steels. Wear 2022, 492, 204218. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).