Surfactants for Electrophoretic Deposition of Polyvinylidene Fluoride–Silica Composites

Abstract

1. Introduction

2. Materials and Methods

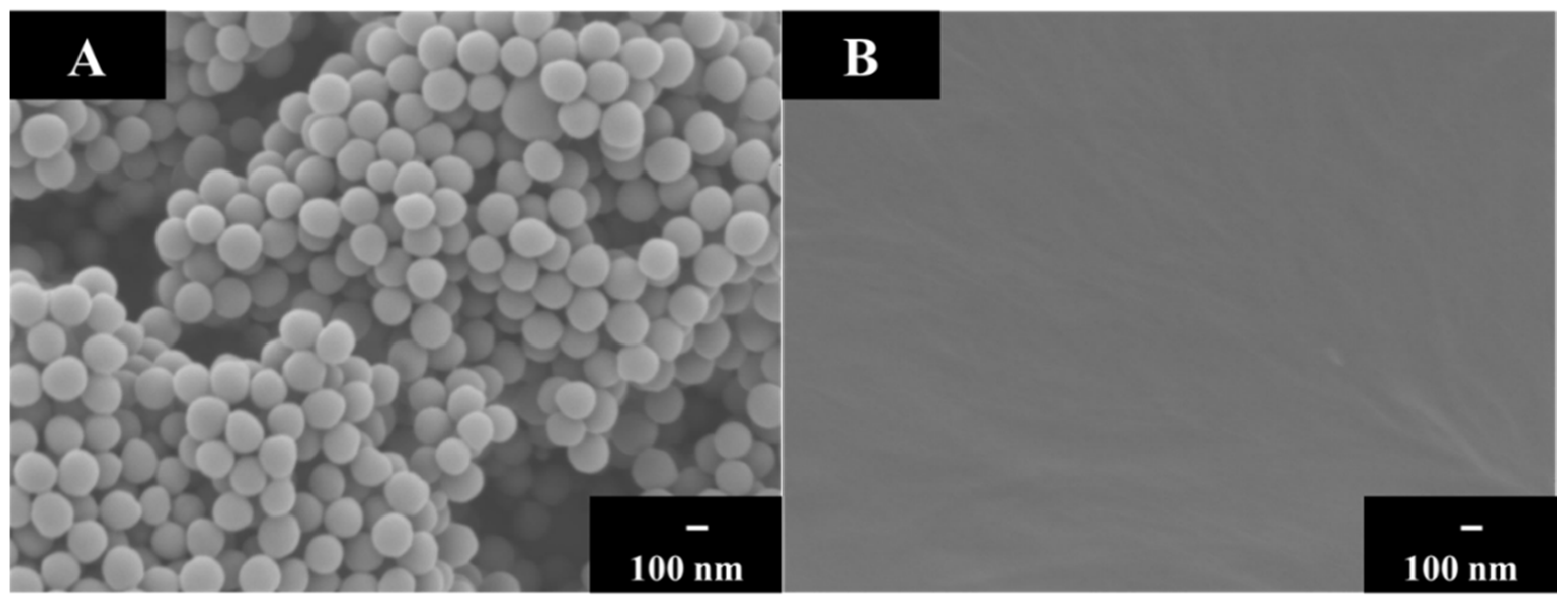

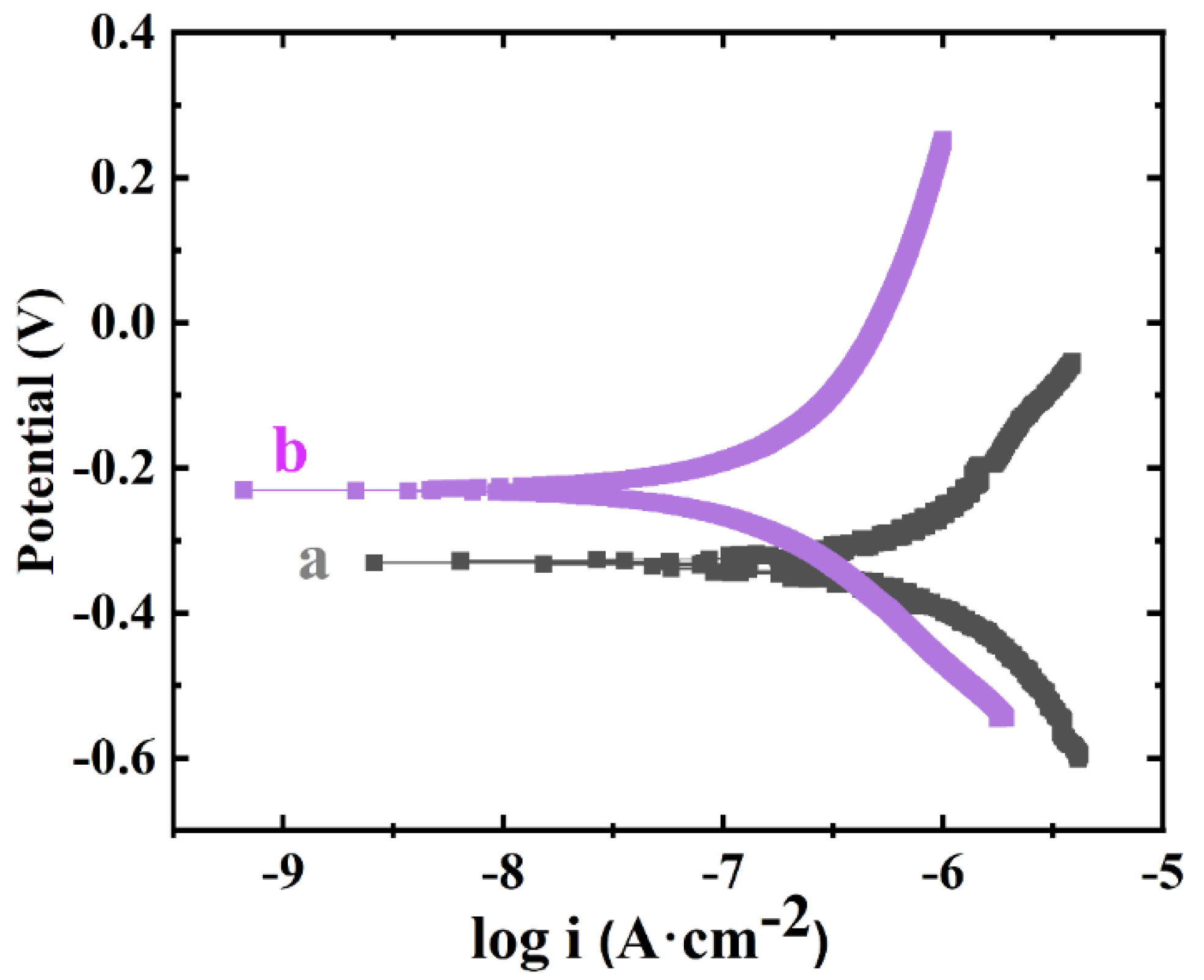

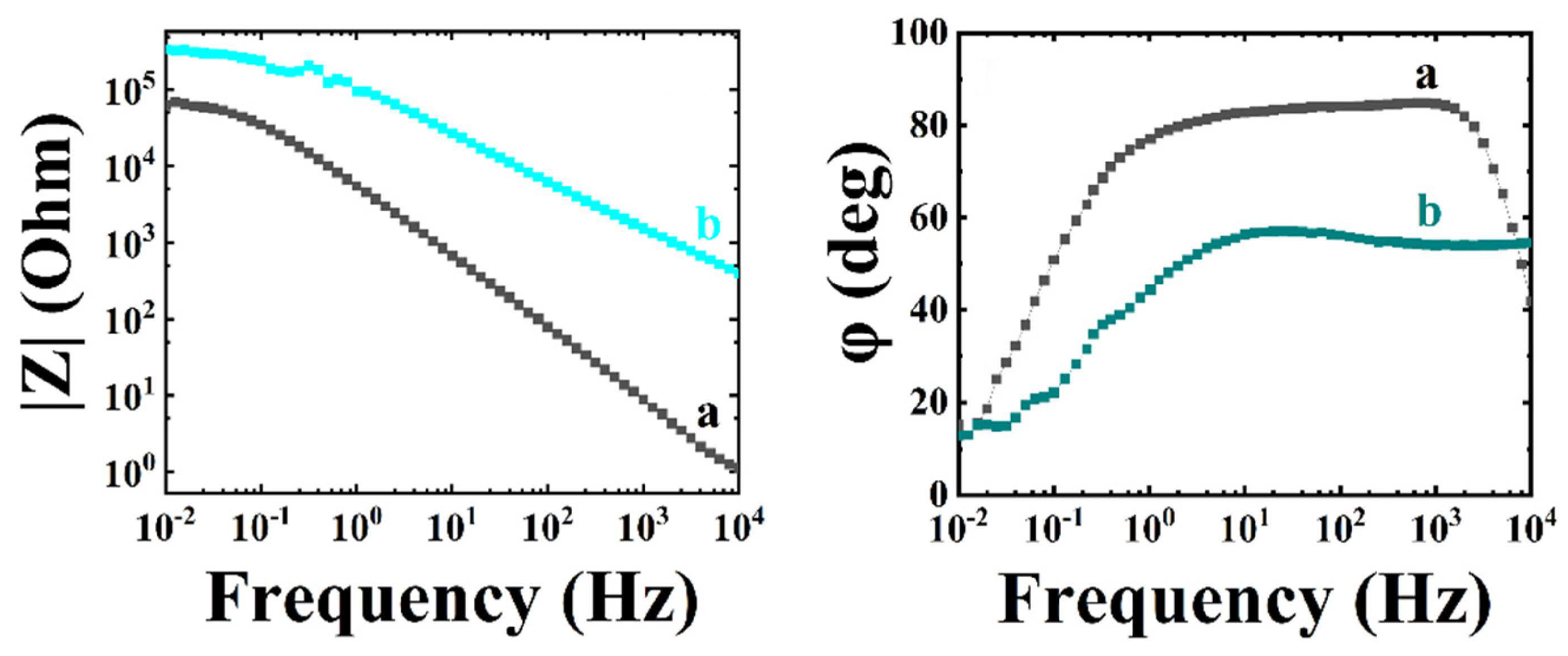

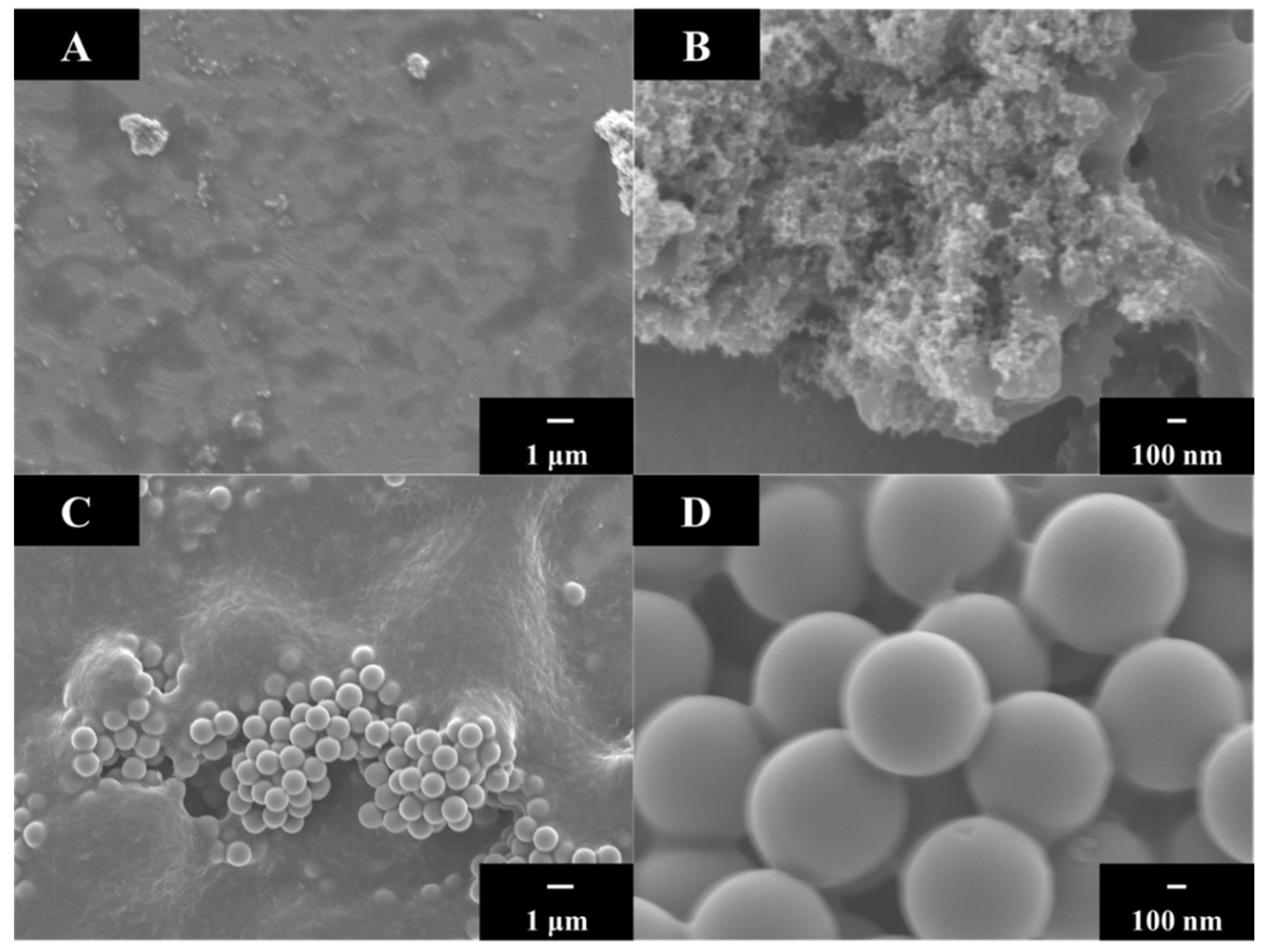

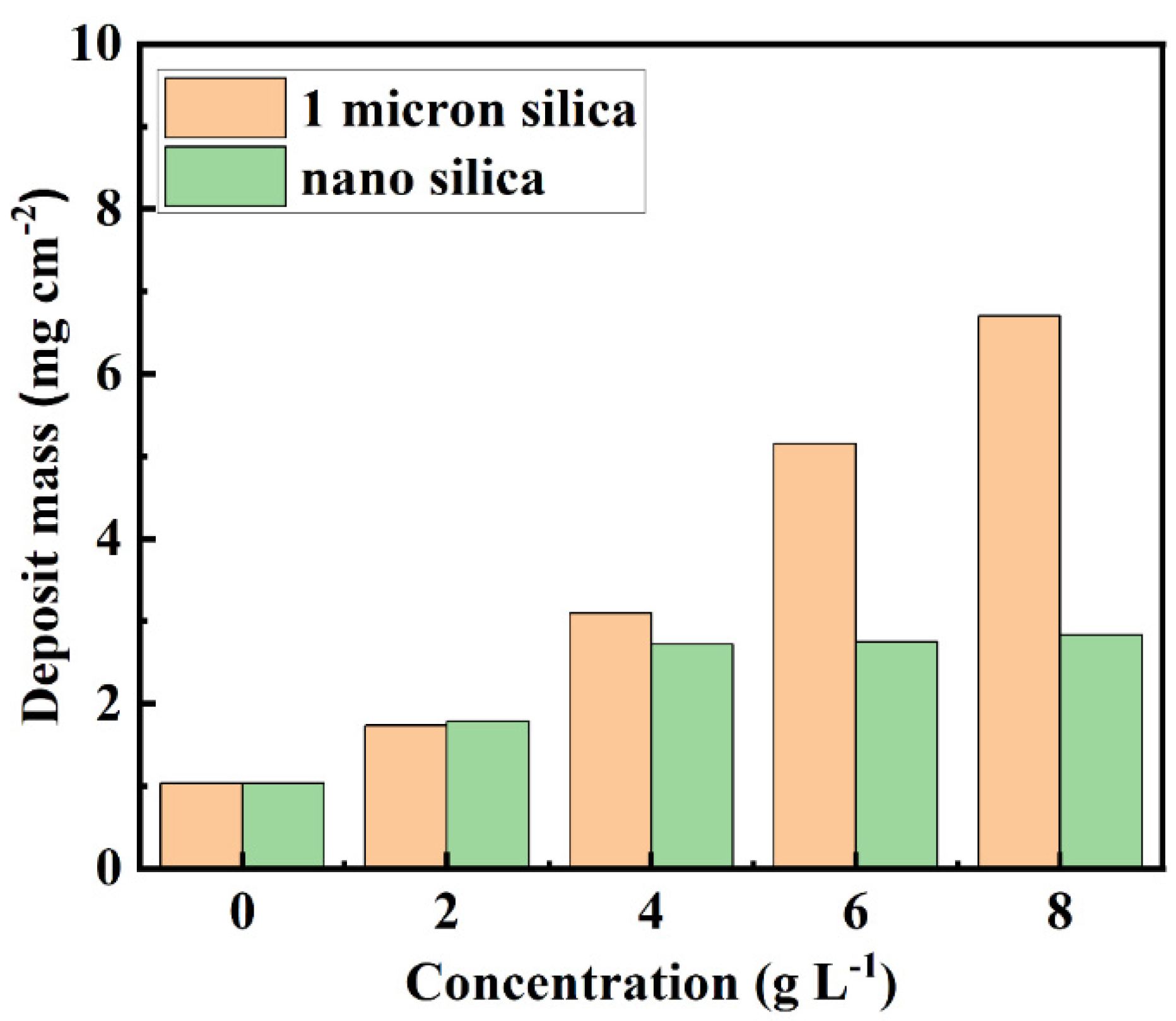

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mishyn, V.; Aspermair, P.; Leroux, Y.; Happy, H.; Knoll, W.; Boukherroub, R.; Szunerits, S. “Click” Chemistry on Gold Electrodes Modified with Reduced Graphene Oxide by Electrophoretic Deposition. Surfaces 2019, 2, 193–204. [Google Scholar] [CrossRef]

- Besra, L.; Liu, M. A review on fundamentals and applications of electrophoretic deposition (EPD). Prog. Mater. Sci. 2007, 52, 1–61. [Google Scholar] [CrossRef]

- Van der Biest, O.O.; Vandeperre, L.J. Electrophoretic deposition of materials. Annu. Rev. Mater. Sci. 1999, 29, 327–352. [Google Scholar] [CrossRef]

- Batool, S.A.; Wadood, A.; Hussain, S.W.; Yasir, M.; Ur Rehman, M.A. A Brief Insight to the Electrophoretic Deposition of PEEK-, Chitosan-, Gelatin-, and Zein-Based Composite Coatings for Biomedical Applications: Recent Developments and Challenges. Surfaces 2021, 4, 205–239. [Google Scholar] [CrossRef]

- Ahmed, Y.; Yasir, M.; Ur Rehman, M.A. Fabrication and Characterization of Zein/Hydroxyapatite Composite Coatings for Biomedical Applications. Surfaces 2020, 3, 237–250. [Google Scholar] [CrossRef]

- Sorkhi, L.; Farrokhi-Rad, M.; Shahrabi, T. Electrophoretic Deposition of Hydroxyapatite–Chitosan–Titania on Stainless Steel 316 L. Surfaces 2019, 2, 458–467. [Google Scholar] [CrossRef]

- Sikkema, R.; Baker, K.; Zhitomirsky, I. Electrophoretic deposition of polymers and proteins for biomedical applications. Adv. Colloid Interface Sci. 2020, 284, 102272. [Google Scholar] [CrossRef]

- Chen, Y.; Ye, R.; Wang, J. Effect of voltage on the mechanical and water resistance properties of zein films by electrophoretic deposition. Food Bioprocess Technol. 2015, 8, 486–491. [Google Scholar] [CrossRef]

- Choudhary, B.; Anwar, S.; Besra, L.; Anwar, S. Electrophoretic deposition studies of Ba (Zr-Ce-Y) O3 ceramic coating. Int. J. Appl. Ceram. Technol. 2019, 16, 1022–1031. [Google Scholar] [CrossRef]

- Dhand, C.; Singh, S.; Arya, S.K.; Datta, M.; Malhotra, B. Cholesterol biosensor based on electrophoretically deposited conducting polymer film derived from nano-structured polyaniline colloidal suspension. Anal. Chim. Acta 2007, 602, 244–251. [Google Scholar] [CrossRef]

- Dange-Delbaere, C.; Buron, C.; Euvrard, M.; Filiâtre, C. Stability and cathodic electrophoretic deposition of polystyrene particles pre-coated with chitosan–alginate multilayer. Colloids Surf. A Physicochem. Eng. Asp. 2016, 493, 1–8. [Google Scholar] [CrossRef]

- Biesheuvel, P.M.; Verweij, H. Theory of cast formation in electrophoretic deposition. J. Am. Ceram. Soc. 1999, 82, 1451–1455. [Google Scholar] [CrossRef]

- De Riccardis, M.F.; Martina, V.; Carbone, D. Study of polymer particles suspensions for electrophoretic deposition. J. Phys. Chem. B 2013, 117, 1592–1599. [Google Scholar] [CrossRef] [PubMed]

- Djošić, M.; Mišković-Stanković, V.B.; Kačarević-Popović, Z.M.; Jokić, B.M.; Bibić, N.; Mitrić, M.; Milonjić, S.K.; Jančić-Heinemann, R.; Stojanović, J. Electrochemical synthesis of nanosized monetite powder and its electrophoretic deposition on titanium. Colloids Surf. A Physicochem. Eng. Asp. 2009, 341, 110–117. [Google Scholar] [CrossRef]

- Zhitomirsky, I.; Petric, A. Electrochemical deposition of yttrium oxide. J. Mater. Chem. 2000, 10, 1215–1218. [Google Scholar] [CrossRef]

- Pang, X.; Zhitomirsky, I.; Niewczas, M. Cathodic electrolytic deposition of zirconia films. Surf. Coat. Technol. 2005, 195, 138–146. [Google Scholar] [CrossRef]

- Ruwoldt, J. A Critical Review of the Physicochemical Properties of Lignosulfonates: Chemical Structure and Behavior in Aqueous Solution, at Surfaces and Interfaces. Surfaces 2020, 3, 622–648. [Google Scholar] [CrossRef]

- Ata, M.; Liu, Y.; Zhitomirsky, I. A review of new methods of surface chemical modification, dispersion and electrophoretic deposition of metal oxide particles. RSC Adv. 2014, 4, 22716–22732. [Google Scholar] [CrossRef]

- Ata, M.S.; Poon, R.; Syed, A.M.; Milne, J.; Zhitomirsky, I. New developments in non-covalent surface modification, dispersion and electrophoretic deposition of carbon nanotubes. Carbon 2018, 130, 584–598. [Google Scholar] [CrossRef]

- Biswas, M.; Raichur, A.M. Electrokinetic and rheological properties of nano zirconia in the presence of rhamnolipid biosurfactant. J. Am. Ceram. Soc. 2008, 91, 3197–3201. [Google Scholar] [CrossRef]

- Alves, A.V.; Tsianou, M.; Alexandridis, P. Fluorinated Surfactant Adsorption on Mineral Surfaces: Implications for PFAS Fate and Transport in the Environment. Surfaces 2020, 3, 516–566. [Google Scholar] [CrossRef]

- Nawwar, M.; Poon, R.; Chen, R.; Sahu, R.P.; Puri, I.K.; Zhitomirsky, I. High areal capacitance of Fe3O4-decorated carbon nanotubes for supercapacitor electrodes. Carbon Energy 2019, 1, 124–133. [Google Scholar] [CrossRef]

- Su, Y.; Zhitomirsky, I. Electrophoretic deposition of graphene, carbon nanotubes and composite films using methyl violet dye as a dispersing agent. Colloids Surf. A Physicochem. Eng. Asp. 2013, 436, 97–103. [Google Scholar] [CrossRef]

- Li, J.; Zhitomirsky, I. Cathodic electrophoretic deposition of manganese dioxide films. Colloids Surf. A Physicochem. Eng. Asp. 2009, 348, 248–253. [Google Scholar] [CrossRef]

- Ghazali, N.; Basirun, W.J.; Mohammed Nor, A.; Johan, M.R. Super-amphiphobic coating system incorporating functionalized nano-Al2O3 in polyvinylidene fluoride (PVDF) with enhanced corrosion resistance. Coatings 2020, 10, 387. [Google Scholar] [CrossRef]

- Pornea, A.M.; Puguan, J.M.C.; Deonikar, V.G.; Kim, H. Fabrication of multifunctional wax infused porous PVDF film with switchable temperature response surface and anti corrosion property. J. Ind. Eng. Chem. 2020, 82, 211–219. [Google Scholar] [CrossRef]

- Kim, Y.H.; Kwon, Y.S.; Shon, M.Y.; Moon, M.J. Corrosion protection performance of PVDF/PMMA-blended coatings by electrochemical impedance method. J. Electrochem. Sci. Technol. 2018, 9, 1–8. [Google Scholar] [CrossRef][Green Version]

- Ribeiro, C.; Costa, C.M.; Correia, D.M.; Nunes-Pereira, J.; Oliveira, J.; Martins, P.; Goncalves, R.; Cardoso, V.F.; Lanceros-Mendez, S. Electroactive poly (vinylidene fluoride)-based structures for advanced applications. Nat. Protoc. 2018, 13, 681. [Google Scholar] [CrossRef]

- Ji-Hun, B.; Seung-Hwan, C. PVDF-based ferroelectric polymers and dielectric elastomers for sensor and actuator applications: A review. Funct. Compos. Struct. 2019, 1, 012003. [Google Scholar]

- Inderherbergh, J. Polyvinylidene fluoride (PVDF) appearance, general properties and processing. Ferroelectrics 1991, 115, 295–302. [Google Scholar] [CrossRef]

- Zhong, J.; Li, W.; Qian, J.; Fu, C.; Chu, H.; Xu, J.; Ran, X.; Nie, W. Modulation of the interfacial architecture enhancing the efficiency and energy density of ferroelectric nanocomposites via the irradiation method. J. Colloid Interface Sci. 2021, 586, 30–38. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.K.; Hernandez, C.; Zuniga, J.P.; Lozano, K.; Mao, Y. Luminescent PVDF nanocomposite films and fibers encapsulated with La 2 Hf 2 O 7: Eu 3+ nanoparticles. SN Appl. Sci. 2020, 2, 1–11. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, X.; Zhang, T.; Bano, S.; Pan, H.; Qi, L.; Zhang, Z.; Yuan, Y. A renewable low-frequency acoustic energy harvesting noise barrier for high-speed railways using a Helmholtz resonator and a PVDF film. Appl. Energy 2018, 230, 52–61. [Google Scholar] [CrossRef]

- Hu, P.; Yan, L.; Zhao, C.; Zhang, Y.; Niu, J. Double-layer structured PVDF nanocomposite film designed for flexible nanogenerator exhibiting enhanced piezoelectric output and mechanical property. Compos. Sci. Technol. 2018, 168, 327–335. [Google Scholar] [CrossRef]

- Park, J.H.; Kurra, N.; AlMadhoun, M.; Odeh, I.N.; Alshareef, H.N. A two-step annealing process for enhancing the ferroelectric properties of poly (vinylidene fluoride)(PVDF) devices. J. Mater. Chem. C 2015, 3, 2366–2370. [Google Scholar] [CrossRef]

- Foster, F.S.; Harasiewicz, K.A.; Sherar, M.D. A history of medical and biological imaging with polyvinylidene fluoride (PVDF) transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2000, 47, 1363–1371. [Google Scholar] [CrossRef]

- Kang, G.-d.; Cao, Y.-m. Application and modification of poly (vinylidene fluoride)(PVDF) membranes—A review. J. Membr. Sci. 2014, 463, 145–165. [Google Scholar] [CrossRef]

- Barbosa, J.C.; Correia, D.M.; Gonçalves, R.; de Zea Bermudez, V.; Silva, M.M.; Lanceros-Mendez, S.; Costa, C.M. Enhanced ionic conductivity in poly(vinylidene fluoride) electrospun separator membranes blended with different ionic liquids for lithium ion batteries. J. Colloid Interface Sci. 2021, 582, 376–386. [Google Scholar] [CrossRef]

- Cui, Y.; Yang, L.; Zheng, J.; Wang, Z.; Li, B.; Yan, Y.; Meng, M. Synergistic interaction of Z-scheme 2D/3D g-C3N4/BiOI heterojunction and porous PVDF membrane for greatly improving the photodegradation efficiency of tetracycline. J. Colloid Interface Sci. 2021, 586, 335–348. [Google Scholar] [CrossRef]

- Wei, N.; Li, Z.; Li, Q.; Yang, E.; Xu, R.; Song, X.; Sun, J.; Dou, C.; Tian, J.; Cui, H. Scalable and low-cost fabrication of hydrophobic PVDF/WS2 porous membrane for highly efficient solar steam generation. J. Colloid Interface Sci. 2021, 588, 369–377. [Google Scholar] [CrossRef]

- Zhao, B.; Hu, J.; Ren, W.; Xu, F.; Wu, X.; Shi, P.; Ye, Z.-G. A new biosensor based on PVDF film for detection of nucleic acids. Ceram. Int. 2015, 41, S602–S606. [Google Scholar] [CrossRef]

- Song, Y.-S.; Yun, Y.; Lee, D.Y.; Kim, B.-Y. Effect of PVDF Concentration and Number of Fiber Lines on Piezoelectric Properties of Polymeric PVDF Biosensors. Fibers Polym. 2021, 22, 1200–1207. [Google Scholar] [CrossRef]

- Hartono, A.; Sanjaya, E.; Ramli, R. Glucose sensing using capacitive biosensor based on polyvinylidene fluoride thin film. Biosensors 2018, 8, 12. [Google Scholar] [CrossRef]

- Häsler, E.; Stein, L.; Harbauer, G. Implantable physiological power supply with PVDF film. Ferroelectrics 1984, 60, 277–282. [Google Scholar] [CrossRef]

- Yu, Y.; Sun, H.; Orbay, H.; Chen, F.; England, C.G.; Cai, W.; Wang, X. Biocompatibility and in vivo operation of implantable mesoporous PVDF-based nanogenerators. Nano Energy 2016, 27, 275–281. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Ding, W.; Liu, J.; Yang, B. Flexible PVDF based piezoelectric nanogenerators. Nano Energy 2020, 78, 105251. [Google Scholar] [CrossRef]

- Houis, S.; Engelhardt, E.; Wurm, F.; Gries, T. Application of polyvinylidene fluoride (PVDF) as a biomaterial in medical textiles. In Medical and Healthcare Textiles; Elsevier: Amsterdam, The Netherlands, 2010; pp. 342–352. [Google Scholar]

- Wang, H.; Klosterhalfen, B.; Müllen, A.; Otto, T.; Dievernich, A.; Jockenhövel, S. Degradation resistance of PVDF mesh in vivo in comparison to PP mesh. J. Mech. Behav. Biomed. Mater. 2021, 119, 104490. [Google Scholar] [CrossRef]

- Haddadi, S.A.; Ghaderi, S.; Amini, M.; Ramazani, S.A. Mechanical and piezoelectric characterizations of electrospun PVDF-nanosilica fibrous scaffolds for biomedical applications. Mater. Today Proc. 2018, 5, 15710–15716. [Google Scholar] [CrossRef]

- Kyeremateng, N.A.; Gukte, D.; Ferch, M.; Buk, J.; Hrebicek, T.; Hahn, R. Preparation of a Self-Supported SiO2 Membrane as a Separator for Lithium-Ion Batteries. Batter. Supercaps 2020, 3, 456–462. [Google Scholar] [CrossRef]

- Prasanna, K.; Subburaj, T.; Jo, Y.N.; Lee, C.W. Optimization of electrophoretic suspension to fabricate Li[Ni1/3Co1/3Mn1/3]O2 based positive electrode for Li-ion batteries. Electrochim. Acta 2013, 95, 295–300. [Google Scholar] [CrossRef]

- Hagberg, J.; Maples, H.A.; Alvim, K.S.; Xu, J.; Johannisson, W.; Bismarck, A.; Zenkert, D.; Lindbergh, G. Lithium iron phosphate coated carbon fiber electrodes for structural lithium ion batteries. Compos. Sci. Technol. 2018, 162, 235–243. [Google Scholar] [CrossRef]

- Ui, K.; OKURA, K.; Koura, N.; Tsumeda, S.; Tamamitsu, K. Fabrication of the electrode for capacitor cell prepared by the electrophoretic deposition method. Electrochemistry 2007, 75, 604–606. [Google Scholar] [CrossRef][Green Version]

- Lau, K.T.; Suan, M.S.M.; Zaimi, M.; Abd Razak, J.; Azam, M.; Mohamad, N. Microstructure and Phase of Poly (Vinyliden Fluoride) Films by Electrophoretic Deposition: Effect of Polymer Dispersion’s Stirring Conditions. J. Adv. Manuf. Technol. (JAMT) 2016, 10, 57–66. [Google Scholar]

- Lau, K.T.; Ab Razak, M.H.R.; Kok, S.L.; Zaimi, M.; Abd Rashid, M.W.; Mohamad, N.; Azam, M.A. Electrophoretic Deposition and Heat Treatment of Steel-Supported PVDF-Graphite Composite Film. In Applied Mechanics and Materials; Trans Tech Publications: Zurich, Switzerland, 2015; pp. 412–416. [Google Scholar]

- Yin, J.; Fukui, T.; Murata, K.; Matsuda, M.; Miyake, M.; Hirabayashi, T.; Yamamuro, S. Fabrication of protective KB/PVdF composite films on stainless steel substrates for PEFCs through electrophoretic deposition. J. Ceram. Soc. Jpn. 2008, 116, 201–204. [Google Scholar] [CrossRef][Green Version]

- Zhao, Q.; Veldhuis, S.; Mathews, R.; Zhitomirsky, I. Influence of chemical structure of bile acid dispersants on electrophoretic deposition of poly (vinylidene fluoride) and composites. Colloids Surf. A Physicochem. Eng. Asp. 2021, 627, 127181. [Google Scholar] [CrossRef]

- Hashiba, M.; Okamoto, H.; Nurishi, Y.; Hiramatsu, K. The zeta-potential measurement for concentrated aqueous suspension by improved electrophoretic mass transport apparatus—application to Al2O3, ZrO3 and SiC suspensions. J. Mater. Sci. 1988, 23, 2893–2896. [Google Scholar] [CrossRef]

- Lee, B.P.; Messersmith, P.B.; Israelachvili, J.N.; Waite, J.H. Mussel-inspired adhesives and coatings. Annu. Rev. Mater. Res. 2011, 41, 99–132. [Google Scholar] [CrossRef]

- Lee, H.; Lee, B.P.; Messersmith, P.B. A reversible wet/dry adhesive inspired by mussels and geckos. Nature 2007, 448, 338–341. [Google Scholar] [CrossRef]

- Xu, N.; Li, Y.; Zheng, T.; Xiao, L.; Liu, Y.; Chen, S.; Zhang, D. A mussel-inspired strategy for CNT/carbon fiber reinforced epoxy composite by hierarchical surface modification. Colloids Surf. A Physicochem. Eng. Asp. 2022, 635, 128085. [Google Scholar] [CrossRef]

- Sun, Y.; Ata, M.; Zhitomirsky, I. Electrophoretic deposition of TiO2 nanoparticles using organic dyes. J. Colloid Interface Sci. 2012, 369, 395–401. [Google Scholar] [CrossRef]

- Sun, Y.; Zhitomirsky, I. Electrophoretic deposition of titanium dioxide using organic acids as charging additives. Mater. Lett. 2012, 73, 190–193. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Y.; Zhitomirsky, I. Dispersing agents for electrophoretic deposition of TiO2 and TiO2–carbon nanotube composites. Colloids Surf. A Physicochem. Eng. Asp. 2013, 418, 131–138. [Google Scholar] [CrossRef]

- Ata, M.; Zhitomirsky, I. Preparation of MnO2 and composites for ultracapacitors. Mater. Manuf. Processes 2013, 28, 1014–1018. [Google Scholar]

- Wu, K.; Wang, Y.; Zhitomirsky, I. Electrophoretic deposition of TiO2 and composite TiO2–MnO2 films using benzoic acid and phenolic molecules as charging additives. J. Colloid Interface Sci. 2010, 352, 371–378. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhitomirsky, I. Bio-inspired catechol chemistry for electrophoretic nanotechnology of oxide films. J. Colloid Interface Sci. 2012, 380, 8–15. [Google Scholar] [CrossRef]

- Sharma, T.; Je, S.-S.; Gill, B.; Zhang, J.X. Patterning piezoelectric thin film PVDF–TrFE based pressure sensor for catheter application. Sens. Actuators A Phys. 2012, 177, 87–92. [Google Scholar] [CrossRef]

- Bhatt, A.S.; Bhat, D.K.; Santosh, M. Crystallinity, conductivity, and magnetic properties of PVDF-Fe3O4 composite films. J. Appl. Polym. Sci. 2011, 119, 968–972. [Google Scholar] [CrossRef]

- Venevtsev, Y.N.; Gagulin, V.V.; Zhitomirsky, I.D. Material science aspects of seignette-magnetism problem. Ferroelectrics 1987, 73, 221–248. [Google Scholar] [CrossRef]

- Luo, H.; Hanagud, S. PVDF film sensor and its applications in damage detection. J. Aerosp. Eng. 1999, 12, 23–30. [Google Scholar] [CrossRef]

- Li, W.; Song, Z.; Zhong, J.; Qian, J.; Tan, Z.; Wu, X.; Chu, H.; Nie, W.; Ran, X. Multilayer-structured transparent MXene/PVDF film with excellent dielectric and energy storage performance. J. Mater. Chem. C 2019, 7, 10371–10378. [Google Scholar] [CrossRef]

- Kobayashi, M.; Tashiro, K.; Tadokoro, H. Molecular vibrations of three crystal forms of poly (vinylidene fluoride). Macromolecules 1975, 8, 158–171. [Google Scholar] [CrossRef]

- Zeng, Z.; Yu, D.; He, Z.; Liu, J.; Xiao, F.-X.; Zhang, Y.; Wang, R.; Bhattacharyya, D.; Tan, T.T.Y. Graphene oxide quantum dots covalently functionalized PVDF membrane with significantly-enhanced bactericidal and antibiofouling performances. Sci. Rep. 2016, 6, 20142. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Zhitomirsky, I. Surfactants for Electrophoretic Deposition of Polyvinylidene Fluoride–Silica Composites. Surfaces 2022, 5, 308-317. https://doi.org/10.3390/surfaces5020022

Wang Z, Zhitomirsky I. Surfactants for Electrophoretic Deposition of Polyvinylidene Fluoride–Silica Composites. Surfaces. 2022; 5(2):308-317. https://doi.org/10.3390/surfaces5020022

Chicago/Turabian StyleWang, Zhengzheng, and Igor Zhitomirsky. 2022. "Surfactants for Electrophoretic Deposition of Polyvinylidene Fluoride–Silica Composites" Surfaces 5, no. 2: 308-317. https://doi.org/10.3390/surfaces5020022

APA StyleWang, Z., & Zhitomirsky, I. (2022). Surfactants for Electrophoretic Deposition of Polyvinylidene Fluoride–Silica Composites. Surfaces, 5(2), 308-317. https://doi.org/10.3390/surfaces5020022