Reactive Dual Magnetron Sputtering: A Fast Method for Preparing Stoichiometric Microcrystalline ZnWO4 Thin Films

Abstract

1. Introduction

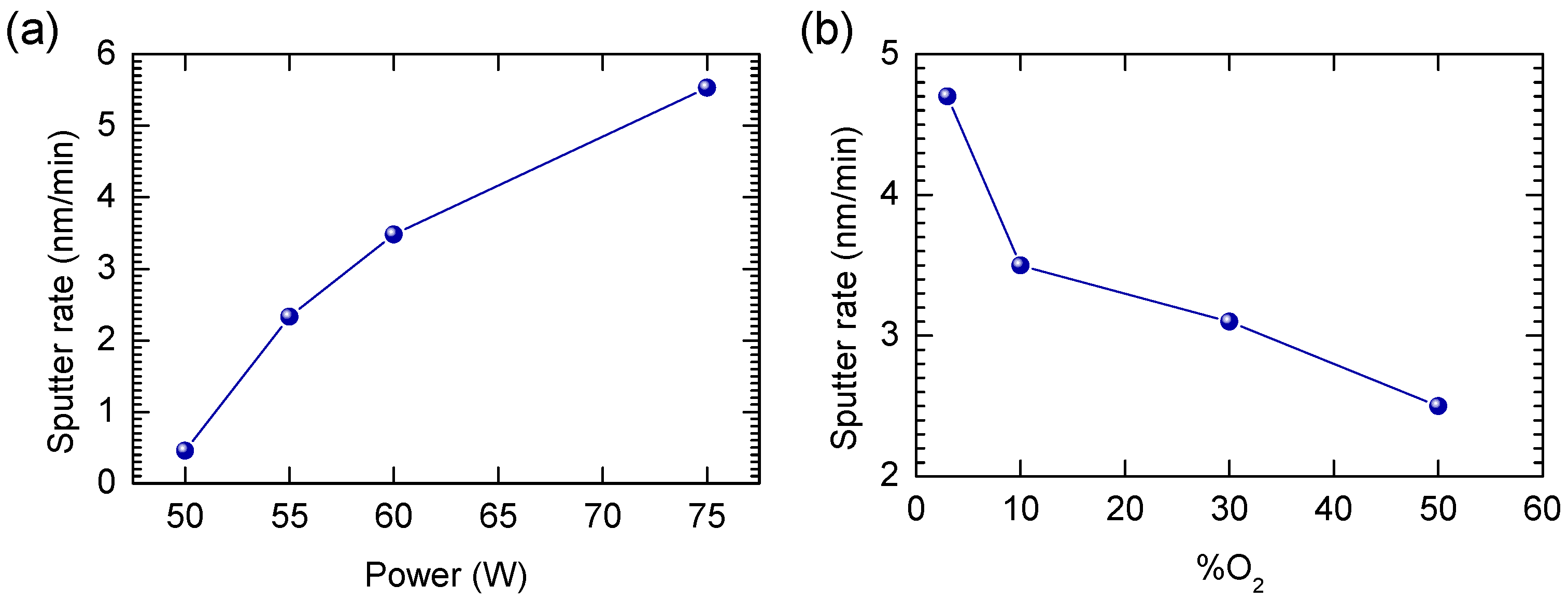

2. Materials and Methods

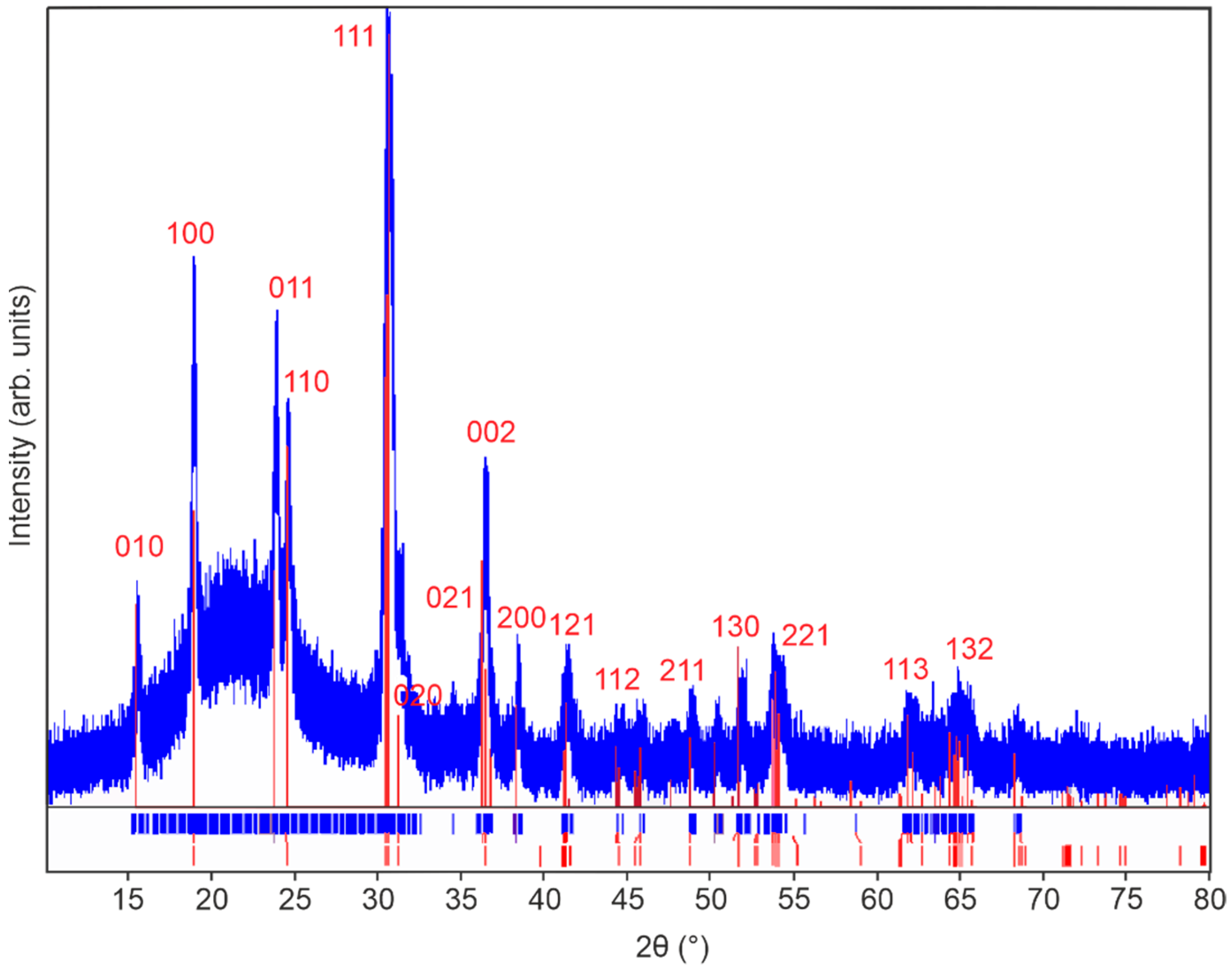

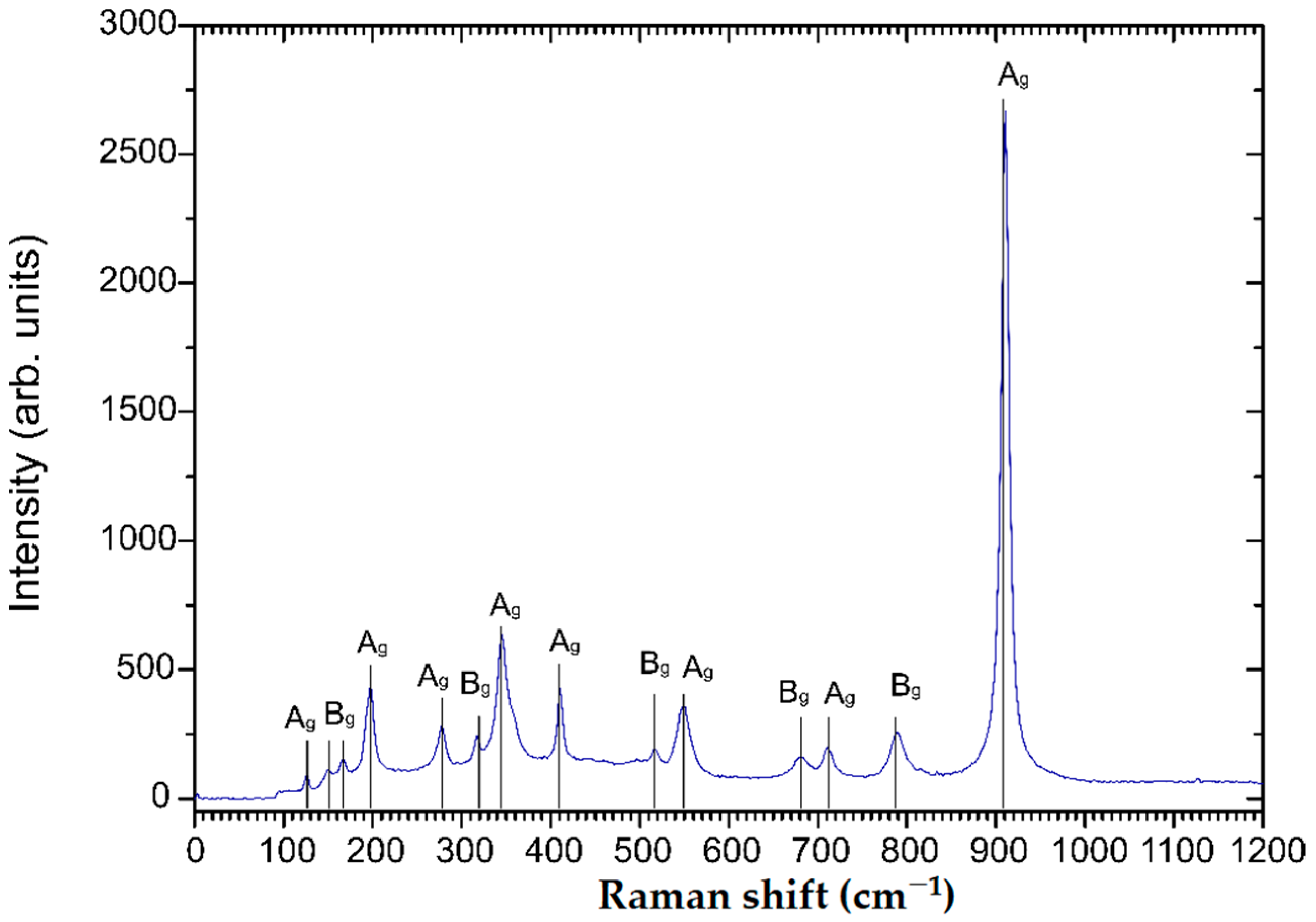

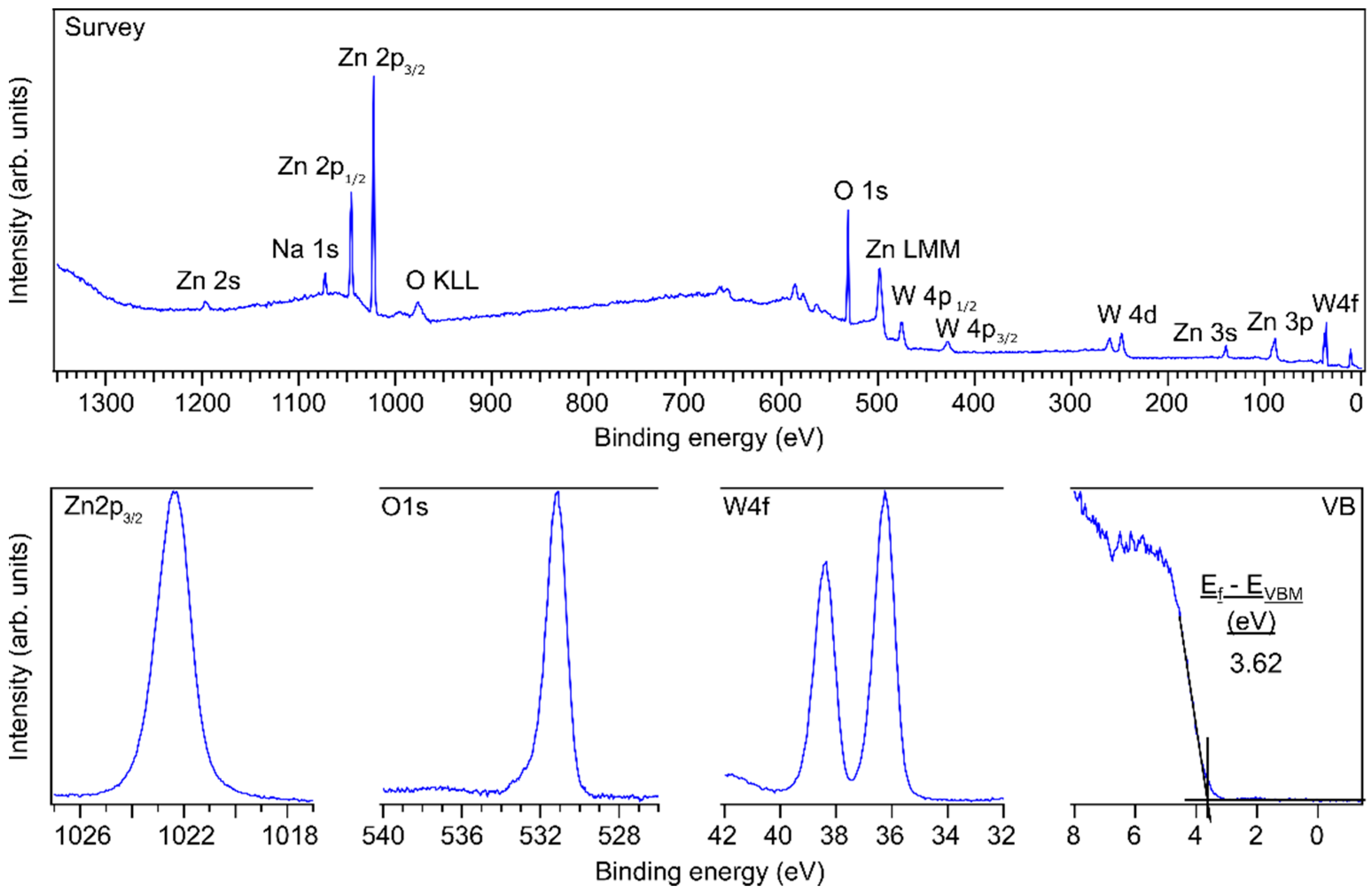

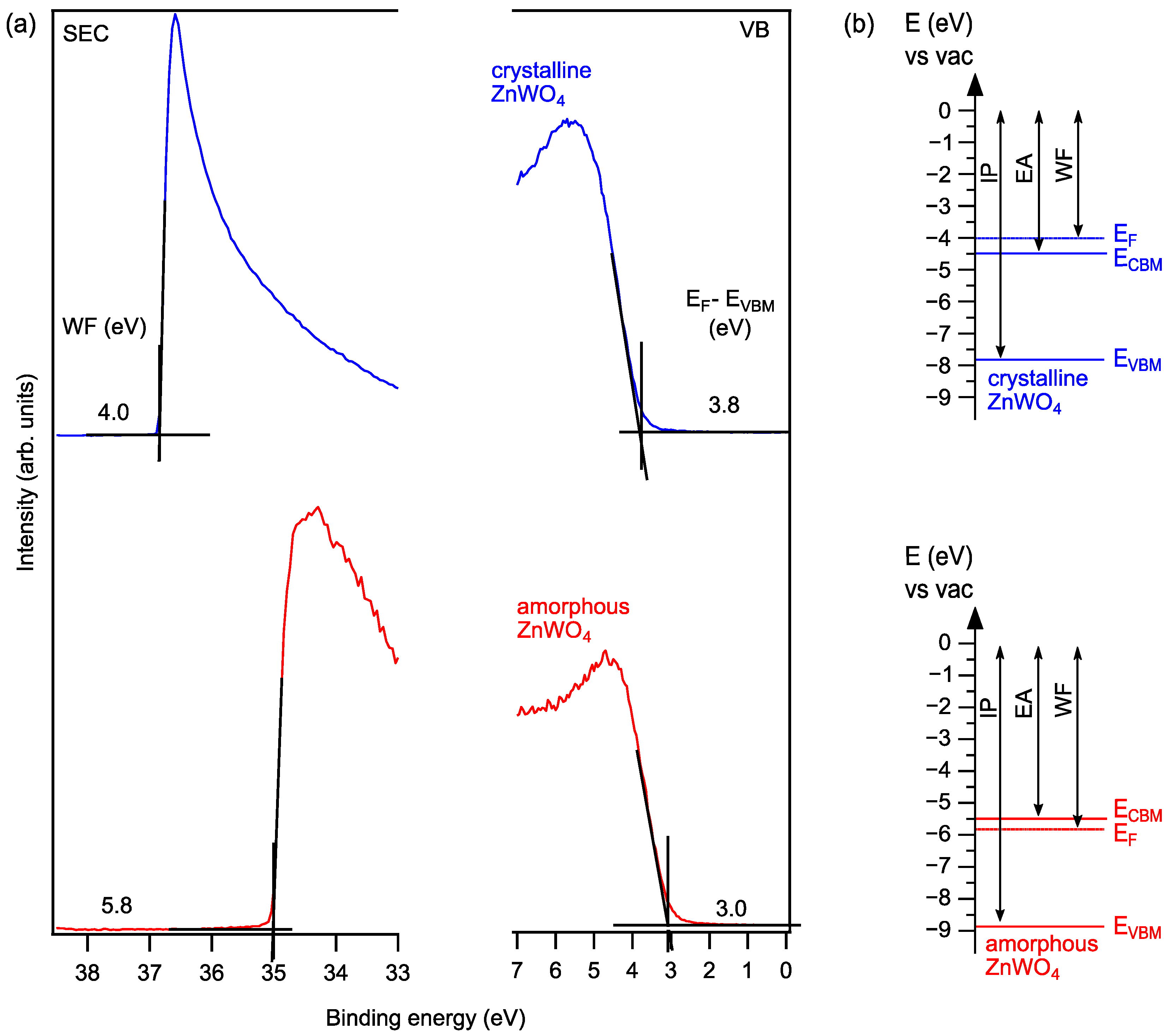

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bai, X.; Wang, L.; Zhu, Y. Visible photocatalytic activity enhancement of ZnWO4 by graphene hybridization. ACS Catal. 2012, 2, 2769–2778. [Google Scholar] [CrossRef]

- Fu, H.; Lin, J.; Zhang, L.; Zhu, Y. Photocatalytic activities of a novel ZnWO4 catalyst prepared by a hydrothermal process. Appl. Catal. A Gen. 2006, 306, 58–67. [Google Scholar] [CrossRef]

- Oi, T.; Takagi, K.; Fukazawa, T. Scintillation study of ZnWO4 single crystals. Appl. Phys. Lett. 1980, 36, 278–279. [Google Scholar] [CrossRef]

- Wen, F.S.; Zhao, X.; Huo, H.; Chen, J.S.; Shu-Lin, E.; Zhang, J.H. Hydrothermal synthesis and photoluminescent properties of ZnWO4 and Eu3+-doped ZnWO4. Mater. Lett. 2002, 55, 152–157. [Google Scholar] [CrossRef]

- Wang, Y.; Liping, L.; Li, G. Solvothermal synthesis, characterization and photocatalytic performance of Zn-rich ZnWO4 nanocrystals. Appl. Surf. Sci. 2017, 393, 159–167. [Google Scholar] [CrossRef]

- Mancheva, M.; Iordanova, R.; Dimitriev, Y. Mechanochemical synthesis of nanocrystalline ZnWO4 at room temperature. J. Alloys Compd. 2011, 509, 15–20. [Google Scholar] [CrossRef]

- Hamrouni, A.; Moussa, N.; Di Paola, A.; Parrino, F.; Houas, A.; Palmisano, L. Characterization and photoactivity of coupled ZnO-ZnWO4 catalysts prepared by a sol-gel method. Appl. Catal. B Environ. 2014, 154–155, 379–385. [Google Scholar] [CrossRef]

- Lou, Z.; Hao, J.; Cocivera, M. Luminescence of ZnWO4 and CdWO4 thin films prepared by spray pyrolysis. J. Lumin. 2002, 99, 349–354. [Google Scholar] [CrossRef]

- Zhao, X.; Yao, W.; Wu, Y.; Zhang, S.; Yang, H.; Zhu, Y. Fabrication and photoelectrochemical properties of porous ZnWO4 film. J. Solid State Chem. 2006, 179, 2562–2570. [Google Scholar] [CrossRef]

- Swann, S. Magnetron sputtering. Phys. Technol. 1988, 19, 67–75. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, Y.; Jin, Y.; Hu, D.; Yuan, C.; Yan, C.; Tang, Q.; Hu, D.; Liu, X. Structure and photoluminescence properties of ZnWO4 film prepared by depositing WO3/ZnO/WO3 heterolayer via magnetron sputtering technique. Opt. Mater. (Amst). 2018, 85, 186–192. [Google Scholar] [CrossRef]

- Yusupov, M.; Saraiva, M.; Depla, D.; Bogaerts, A. Sputter deposition of Mg xAl yO z thin films in a dual-magnetron device: A multi-species Monte Carlo model. New J. Phys. 2012, 14, 073043. [Google Scholar] [CrossRef]

- Trinh, D.H.; Högberg, H.; Andersson, J.M.; Collin, M.; Reineck, I.; Helmersson, U.; Hultman, L. Radio frequency dual magnetron sputtering deposition and characterization of nanocomposite Al2O3–ZrO2 thin films. J. Vac. Sci. Technol. A Vac. Surf. Film. 2006, 24, 309–316. [Google Scholar] [CrossRef]

- Depablos-Rivera, O.; Zeinert, A.; Rodil, S.E. Synthesis and Optical Properties of Different Bismuth Niobate Films Grown by Dual Magnetron Co-Sputtering. Adv. Eng. Mater. 2018, 20, 1800269. [Google Scholar] [CrossRef]

- Michail, G.; Kambylafka, V.; Kortidis, I.; Tsagaraki, K.; Androulidaki, M.; Kiriakidis, G.; Binas, V.; Modreanu, M.; Aperathitis, E. On the growth of transparent conductive oxide ternary alloys Zn–Ir–O (ZIRO) by the means of rf magnetron co-sputtering. Thin Solid Films 2016, 617, 3–8. [Google Scholar] [CrossRef]

- Kang, S.W.; Kim, Y.Y.; Ahn, C.H.; Mohanta, S.K.; Cho, H.K. Growth and characteristics of ternary Zn 1-xMg xO films using magnetron co-sputtering. In Proceedings of the Journal of Materials Science: Materials in Electronics; Springer: Berlin/Heidelberg, Germany, 2008; Volume 19, pp. 755–759. [Google Scholar]

- Wendel, P.; Periyannan, S.; Jaegermann, W.; Klein, A. Polarization dependence of ZnO Schottky barriers revealed by photoelectron spectroscopy. Phys. Rev. Mater. 2020, 4, 084604. [Google Scholar] [CrossRef]

- Shen, Y.; Yamazaki, T.; Liu, Z.; Meng, D.; Kikuta, T.; Nakatani, N. Influence of effective surface area on gas sensing properties of WO3 sputtered thin films. Thin Solid Films 2009, 517, 2069–2072. [Google Scholar] [CrossRef]

- Jaegermann, W.; Kaiser, B.; Ziegler, J.; Klett, J. Interface Engineering of Semiconductor Electrodes for Photoelectrochemical Water Splitting: Application of Surface Characterization with Photoelectron Spectroscopy. In Photoelectrochemical Solar Fuel Production; Springer International Publishing: Cham, Switzerland, 2016; pp. 199–280. [Google Scholar]

- Cremer, R.; Witthaut, M.; Neuschütz, D.; Erkens, G.; Leyendecker, T.; Feldhege, M. Comparative characterization of alumina coatings deposited by RF, DC and pulsed reactive magnetron sputtering. In Proceedings of the Surface and Coatings Technology; Elsevier: Amsterdam, The Netherlands, 1999; Volume 120–121, pp. 213–218. [Google Scholar]

- Li, C.; Wang, D.; Li, Z.; Li, X.; Kawaharamura, T.; Furuta, M. Stoichiometry Control of ZnO Thin Film by Adjusting Working Gas Ratio during Radio Frequency Magnetron Sputtering. J. Mater. 2013, 2013, 1–6. [Google Scholar] [CrossRef]

- Jones, R.E.; Winters, H.F.; Maissel, L.I. Effect of Oxygen on the rf-Sputtering Rate of SiO2. J. Vac. Sci. Technol. 1968, 5, 84–87. [Google Scholar] [CrossRef]

- Wang, M.; Thimont, Y.; Presmanes, L.; Diao, X.; Barnabé, A. The effect of the oxygen ratio control of DC reactive magnetron sputtering on as-deposited non stoichiometric NiO thin films. Appl. Surf. Sci. 2017, 419, 795–801. [Google Scholar] [CrossRef]

- Mitterer, C.; Heuzè, O.; Derflinger, V.H. Substrate and coating damage by arcing during sputtering. Surf. Coat. Technol. 1997, 89, 233–238. [Google Scholar] [CrossRef]

- Pereira, P.F.S.; Gouveia, A.F.; Assis, M.; De Oliveira, R.C.; Pinatti, I.M.; Penha, M.; Gonçalves, R.F.; Gracia, L.; André, J.; Longo, E. ZnWO4 nanocrystals: Synthesis, morphology, photoluminescence and photocatalytic properties †. Phys. Chem. Chem. Phys. 2018, 20, 1923–1937. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Medina, F.D.; Zhou, Y.D.; Zhang, Q.N. Temperature dependence of the polarized Raman spectra of ZnWO4 single crystals. Phys. Rev. B 1992, 45, 10356–10362. [Google Scholar] [CrossRef]

- Yu, C.; Yu, J.C. Sonochemical fabrication, characterization and photocatalytic properties of Ag/ZnWO4 nanorod catalyst. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2009, 164, 16–22. [Google Scholar] [CrossRef]

- You, L.; Cao, Y.; Sun, Y.F.; Sun, P.; Zhang, T.; Du, Y.; Lu, G.Y. Humidity sensing properties of nanocrystalline ZnWO4 with porous structures. Sensors Actuators B Chem. 2012, 161, 799–804. [Google Scholar] [CrossRef]

- Cros, A. Charging effects in X-ray photoelectron spectroscopy. J. Electron. Spectros. Relat. Phenom. 1992, 59, 1–14. [Google Scholar] [CrossRef]

- Battistoni, C.; Mattogno, G.; Paparazzo, E. Quantitative surface analysis by XPS: A comparison among different quantitative approaches. Surf. Interface Anal. 1985, 7, 117–121. [Google Scholar] [CrossRef]

- Heinrich, K.F.J.; Scott, V.D.; Love, G. “Standardless” Quantitative Electron Probe Microanalysis with Energy-Dispersive X-ray Spectrometry: Is It Worth the Risk? Plenum Press: New York, NY, USA, 1995; Volume 67. [Google Scholar]

- Newbury, D.E.; Ritchie, N.W.M. Is scanning electron microscopy/energy dispersive X-ray spectrometry (SEM/EDS) quantitative? Scanning 2013, 35, 141–168. [Google Scholar] [CrossRef]

- Osotsi, M.I.; Macharia, D.K.; Zhu, B.; Wang, Z.; Shen, X.; Liu, Z.; Zhang, L.; Chen, Z. Synthesis of ZnWO4−x nanorods with oxygen vacancy for efficient photocatalytic degradation of tetracycline. Prog. Nat. Sci. Mater. Int. 2018, 28, 408–415. [Google Scholar] [CrossRef]

- Sivaganesh, D.; Saravanakumar, S.; Sivakumar, V.; Rajajeyaganthan, R.; Arunpandian, M.; Nandha Gopal, J.; Thirumalaisamy, T.K. Surfactants-assisted synthesis of ZnWO4 nanostructures: A view on photocatalysis, photoluminescence and electron density distribution analysis. Mater. Charact. 2020, 159, 110035. [Google Scholar] [CrossRef]

- He, H.; Luo, Z.; Tang, Z.Y.; Yu, C. Controllable construction of ZnWO4 nanostructure with enhanced performance for photosensitized Cr(VI) reduction. Appl. Surf. Sci. 2019, 490, 460–468. [Google Scholar] [CrossRef]

| ZnWO4 | Zn 2p3/2 | W 4f | O 1s | Na 1s |

|---|---|---|---|---|

| amorphous | 17% | 17% | 66% | - |

| monoclinic | 31% | 7% | 56% | 6% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hermans, Y.; Mehmood, F.; Lakus-Wollny, K.; Hofmann, J.P.; Mayer, T.; Jaegermann, W. Reactive Dual Magnetron Sputtering: A Fast Method for Preparing Stoichiometric Microcrystalline ZnWO4 Thin Films. Surfaces 2021, 4, 106-114. https://doi.org/10.3390/surfaces4020013

Hermans Y, Mehmood F, Lakus-Wollny K, Hofmann JP, Mayer T, Jaegermann W. Reactive Dual Magnetron Sputtering: A Fast Method for Preparing Stoichiometric Microcrystalline ZnWO4 Thin Films. Surfaces. 2021; 4(2):106-114. https://doi.org/10.3390/surfaces4020013

Chicago/Turabian StyleHermans, Yannick, Faraz Mehmood, Kerstin Lakus-Wollny, Jan P. Hofmann, Thomas Mayer, and Wolfram Jaegermann. 2021. "Reactive Dual Magnetron Sputtering: A Fast Method for Preparing Stoichiometric Microcrystalline ZnWO4 Thin Films" Surfaces 4, no. 2: 106-114. https://doi.org/10.3390/surfaces4020013

APA StyleHermans, Y., Mehmood, F., Lakus-Wollny, K., Hofmann, J. P., Mayer, T., & Jaegermann, W. (2021). Reactive Dual Magnetron Sputtering: A Fast Method for Preparing Stoichiometric Microcrystalline ZnWO4 Thin Films. Surfaces, 4(2), 106-114. https://doi.org/10.3390/surfaces4020013