Graphical Reconstruction of the Lost Paper Mill at Locks 11–12 of the Canal de Castilla

Abstract

1. Introduction

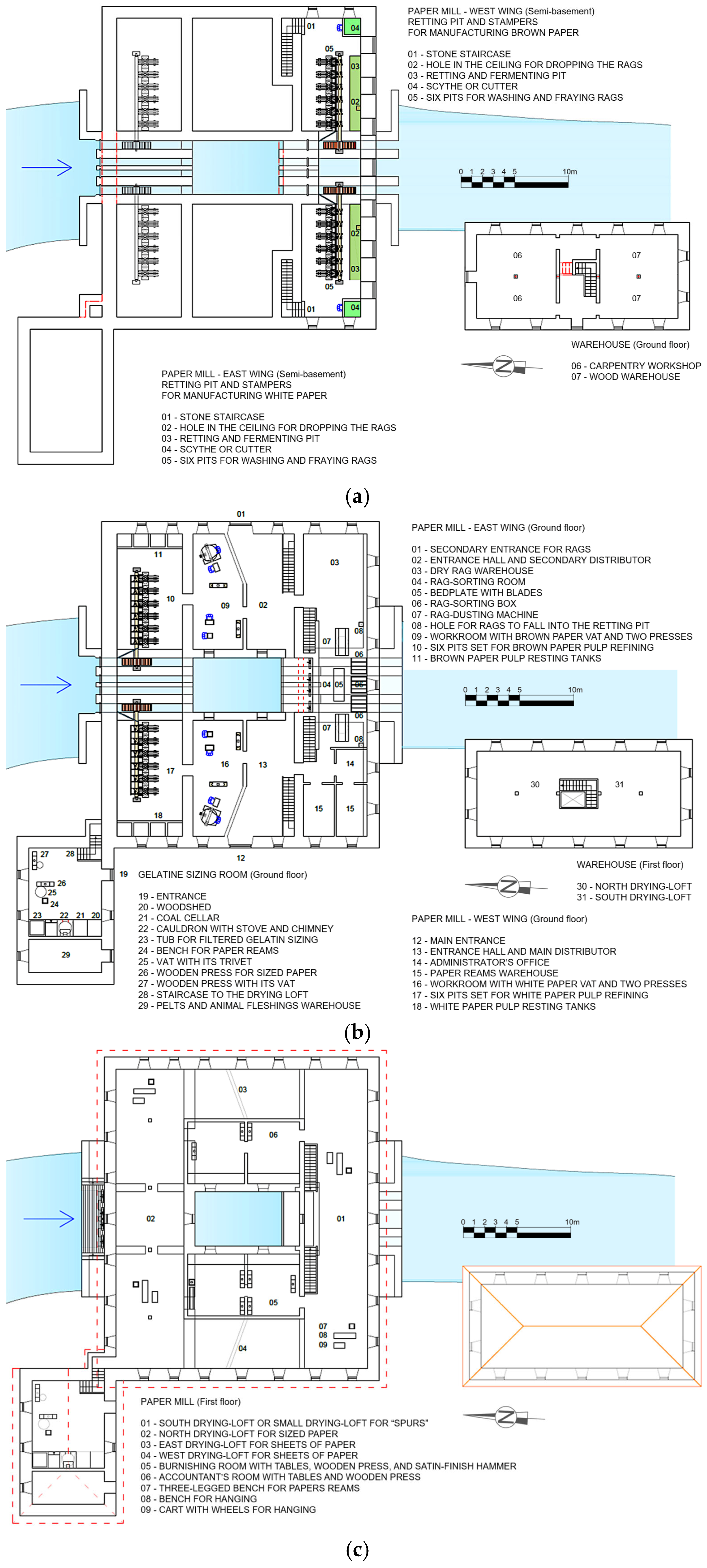

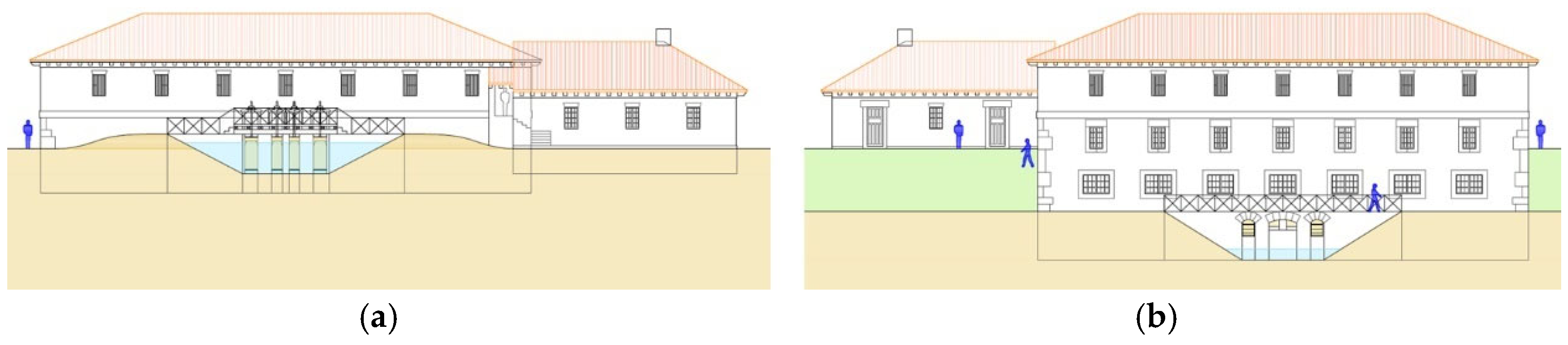

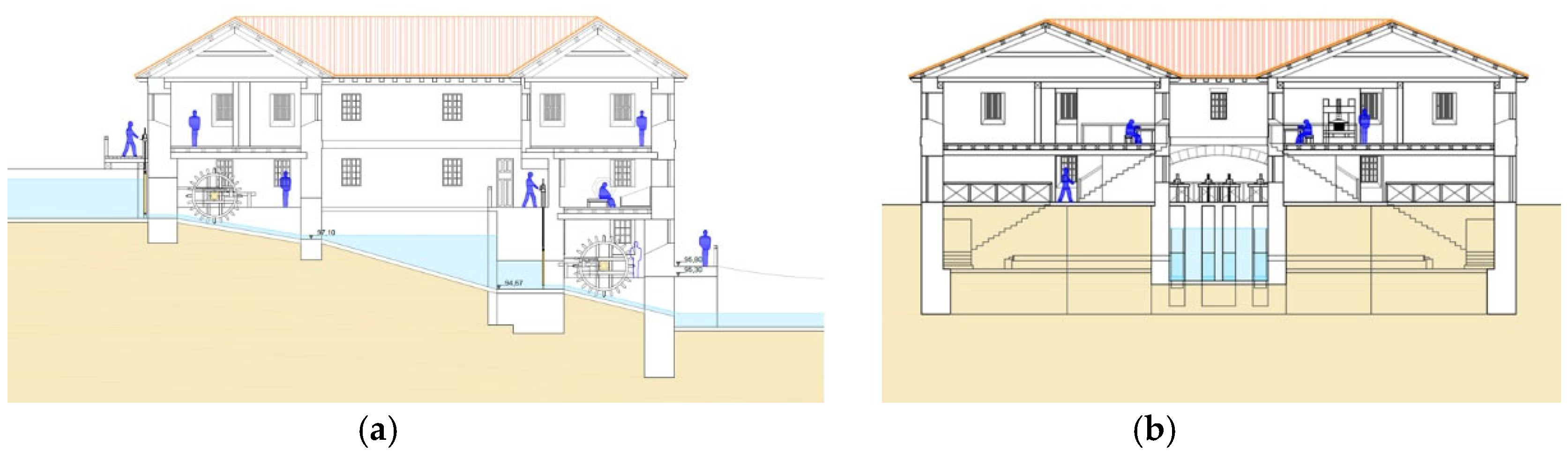

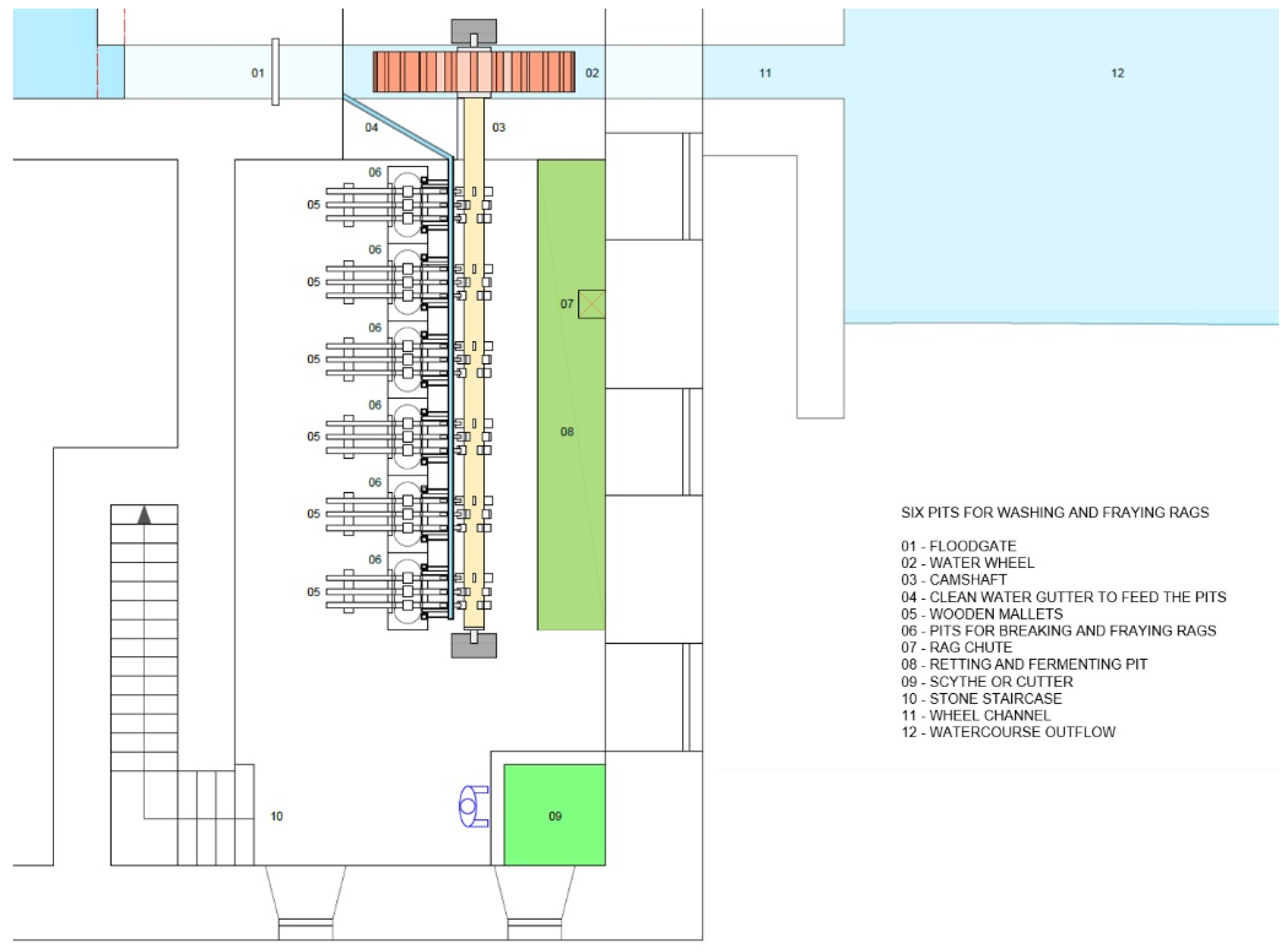

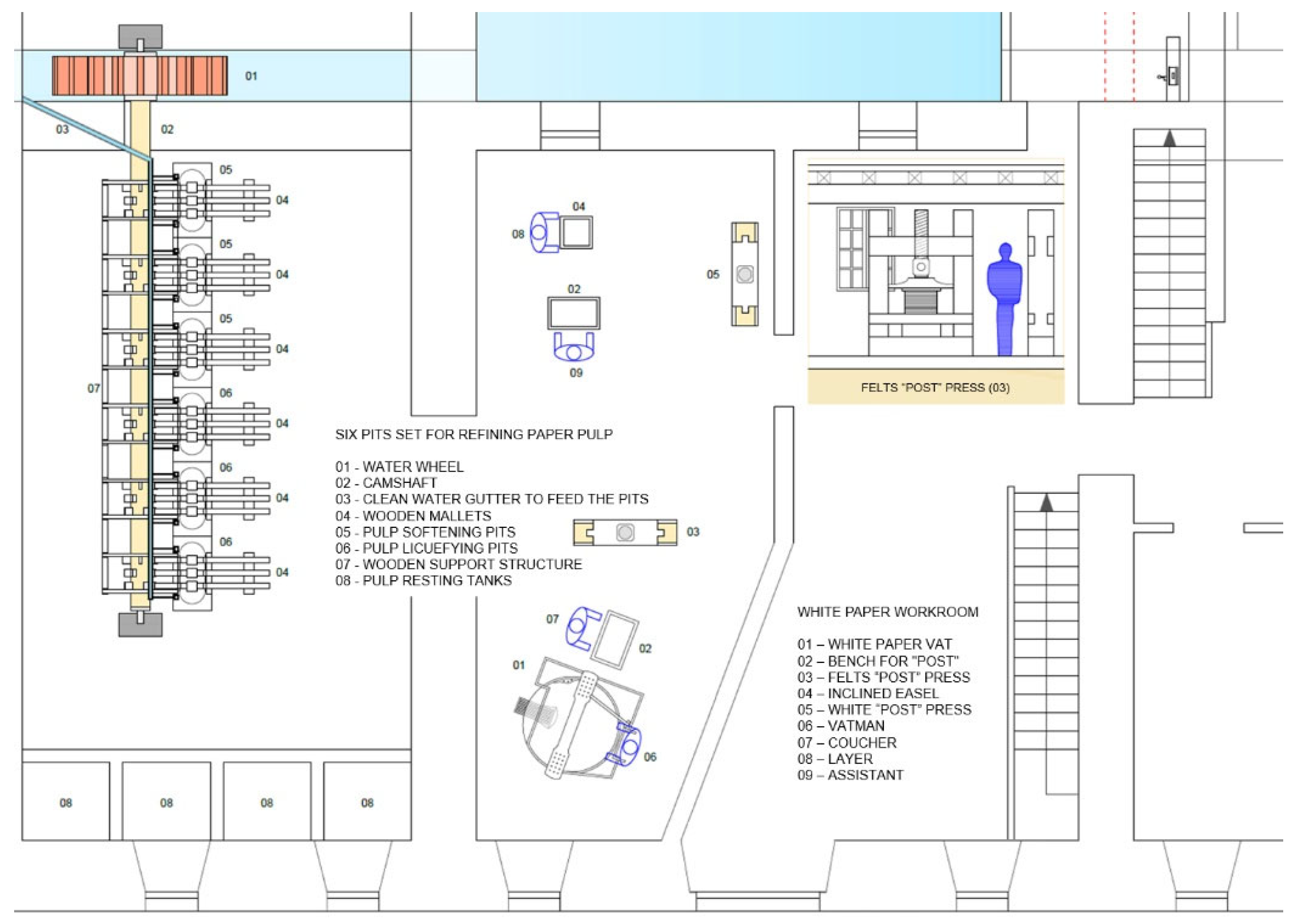

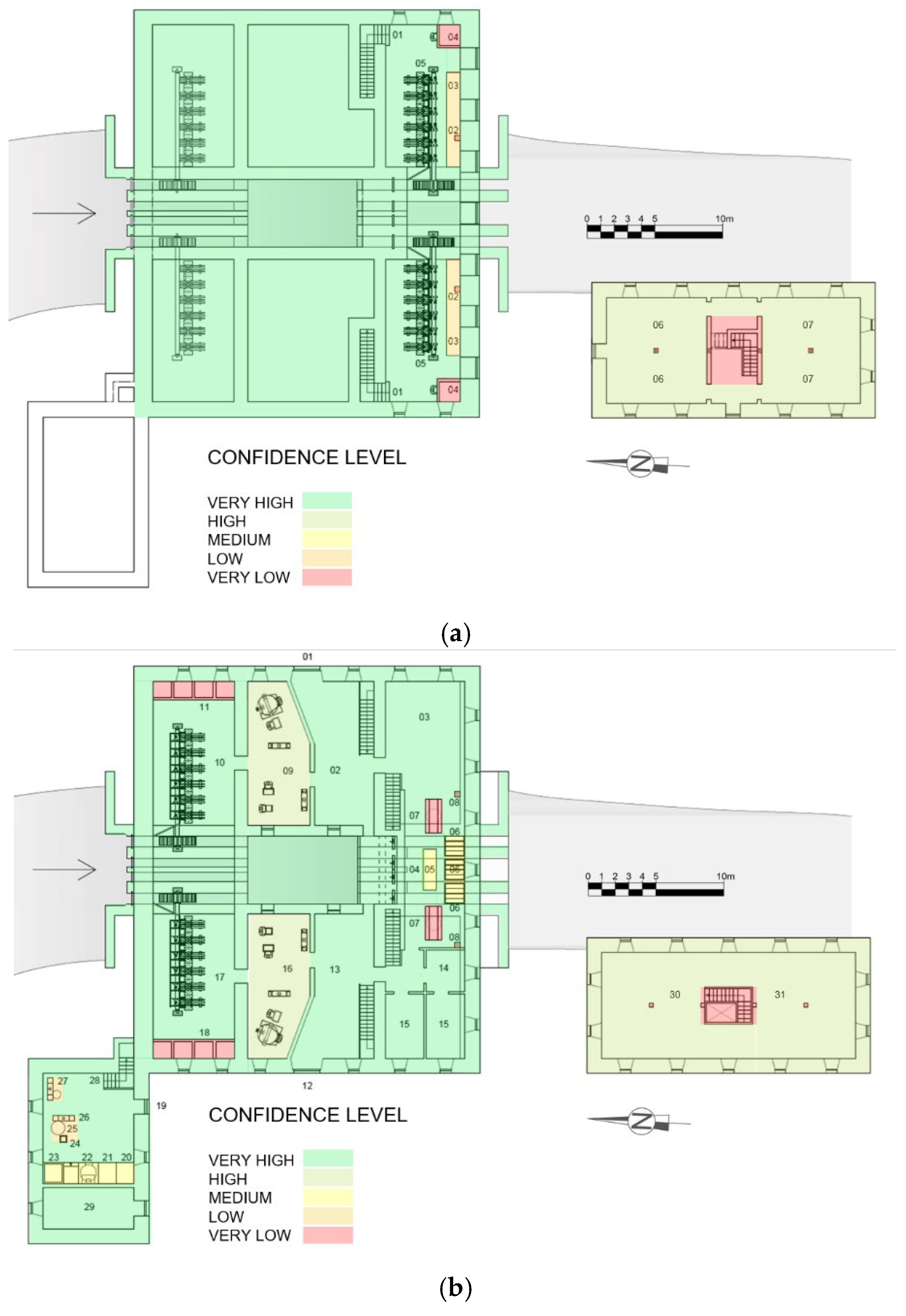

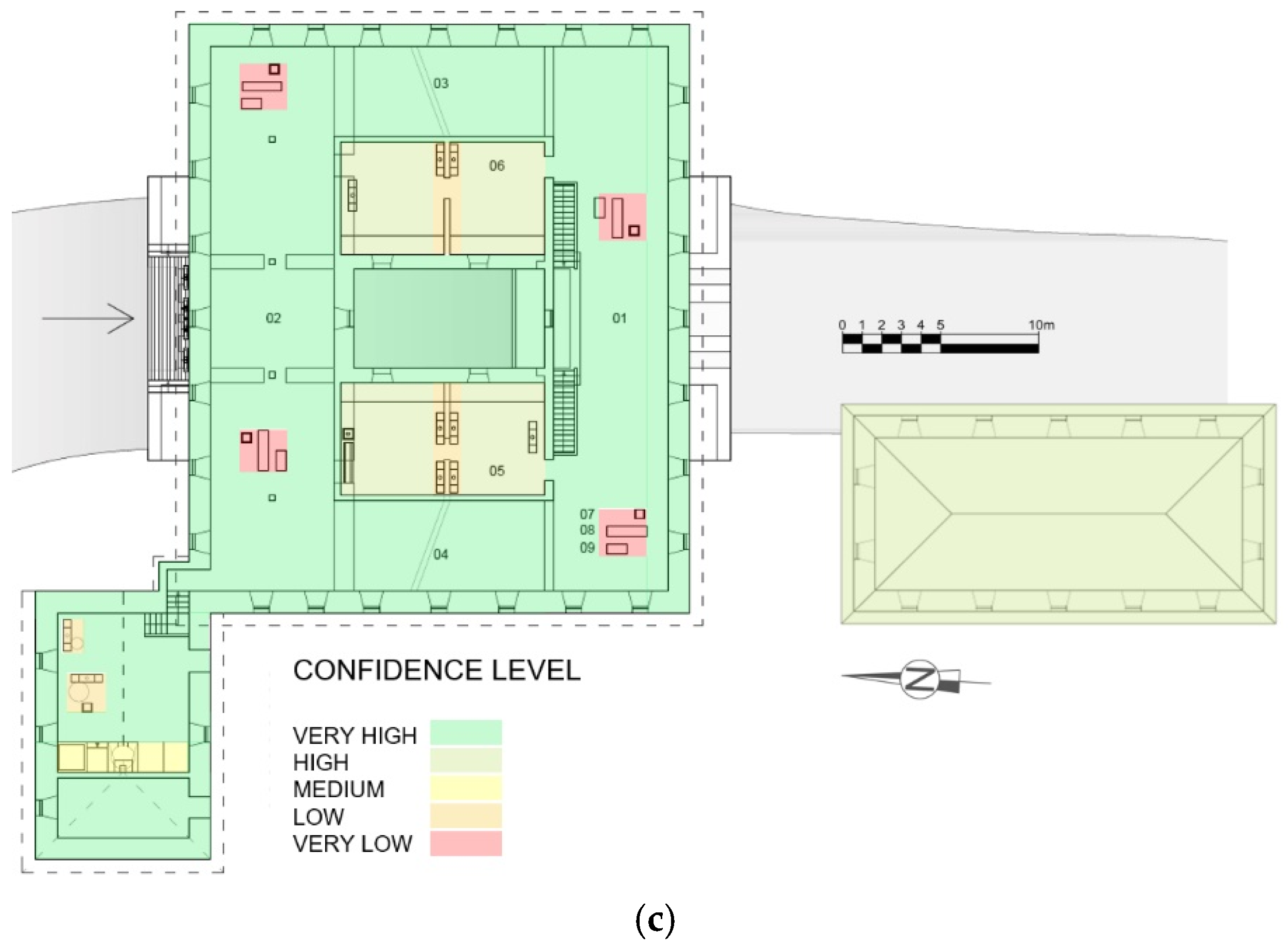

- To understand the comprehensive functioning of the paper mill: This entails analysing its buildings, construction materials, machinery, and operational processes, as well as producing the necessary architectural drawings (plans, elevations, and sections). Such a study will enable a full understanding of the papermaking process, facilitate comparisons with other paper mills, and provide contextualization for the industrial elements that are still preserved within this manufacturing complex.

- To analyse the distinguishing features of this paper mill: Unlike traditional paper mills, which replicated medieval patterns and were typically located alongside river dams, this facility was established next to an artificial watercourse, where hydraulic drops were generated using navigation locks.

- The creation of a realistic three-dimensional (3D) model of the factory and its virtual reconstruction using CAD techniques, in line with the objectives outlined in the “Seville Principles” [66] on virtual archaeology, which reference the London Charter [67] concerning computer-based visualization of cultural heritage.

- The development of virtual reality applications that promote user interaction with the model, thereby facilitating a better understanding of its operation and allowing each element or system to be identified by name and by the materials from which it was made.

- The creation of an immersive augmented reality experience that enables access to the virtual model of the paper mill located at Locks 11–12.

- The ultimate aim of this project is the interpretation of the existing remains for educational and recreational purposes (cultural tourism). Furthermore, the implementation of these technologies would contribute to the preservation of the Canal de Castilla, as the knowledge and transmission of the memory of labour associated with any industrial site fosters appreciation and emotional connection—key drivers of its conservation.

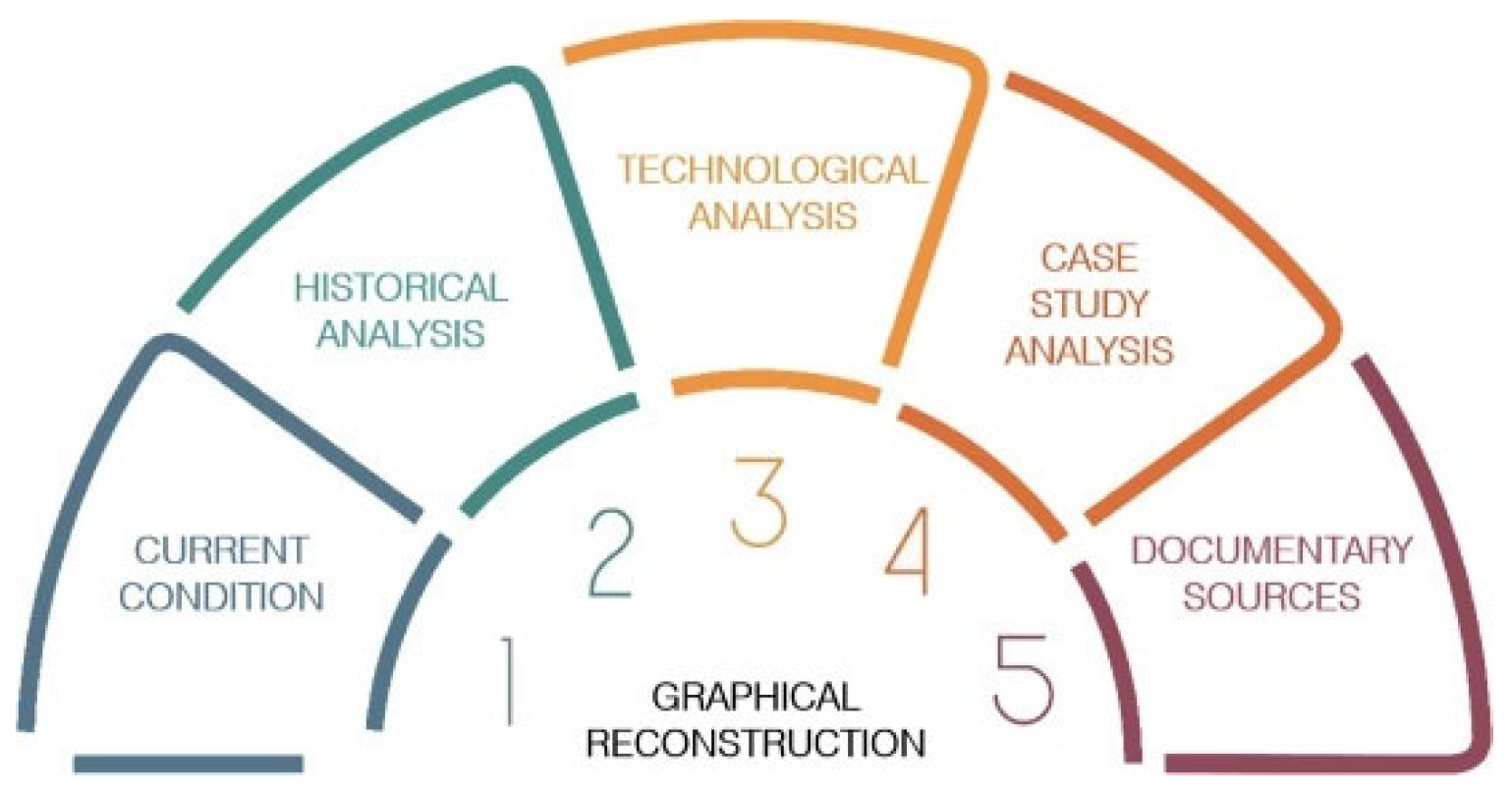

2. Materials and Methods

2.1. Materials

2.1.1. Current Condition and Recent Visual Documentation

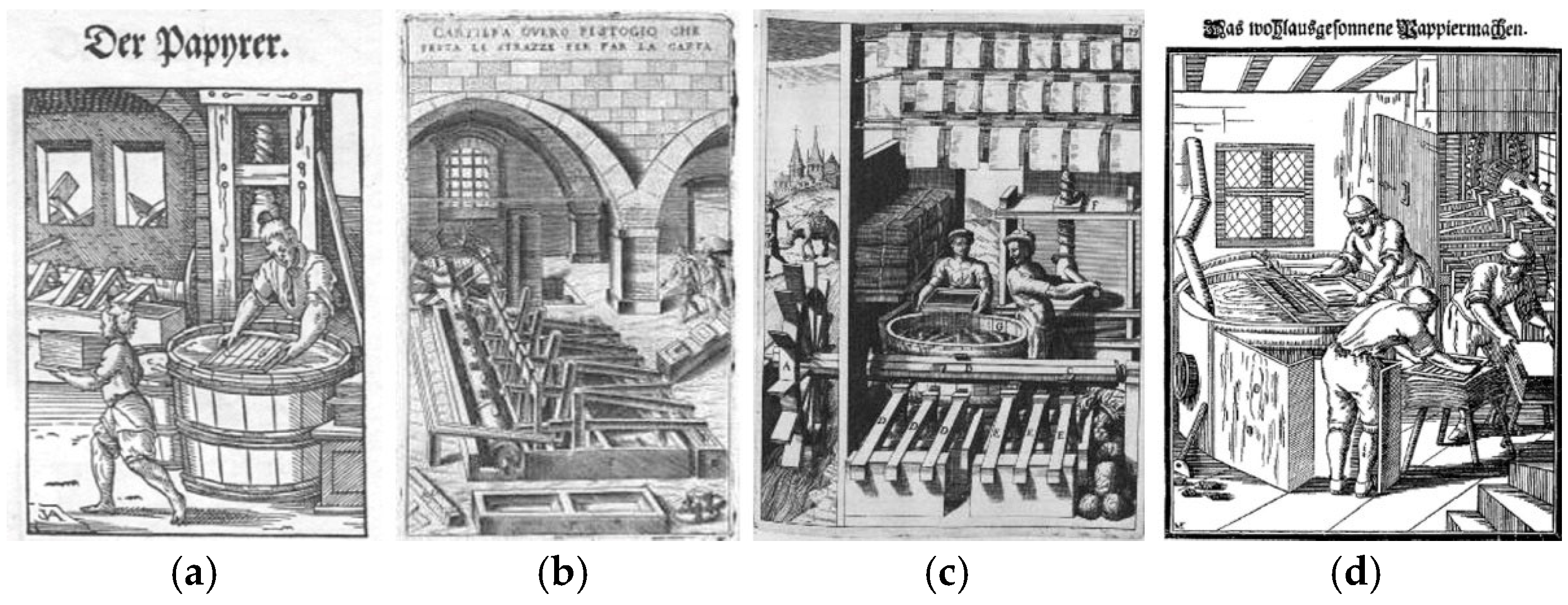

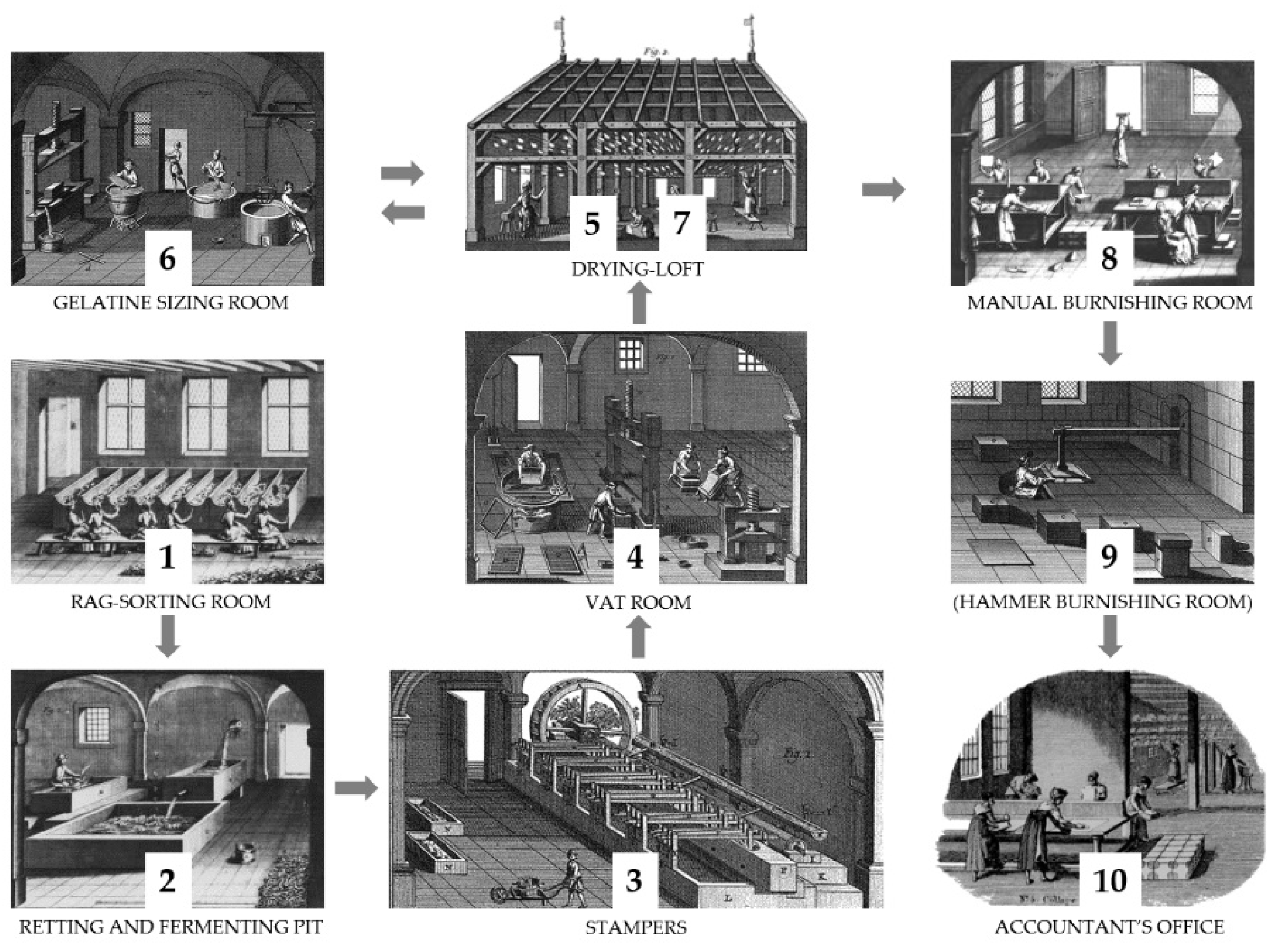

2.1.2. History of the Papermaking Process

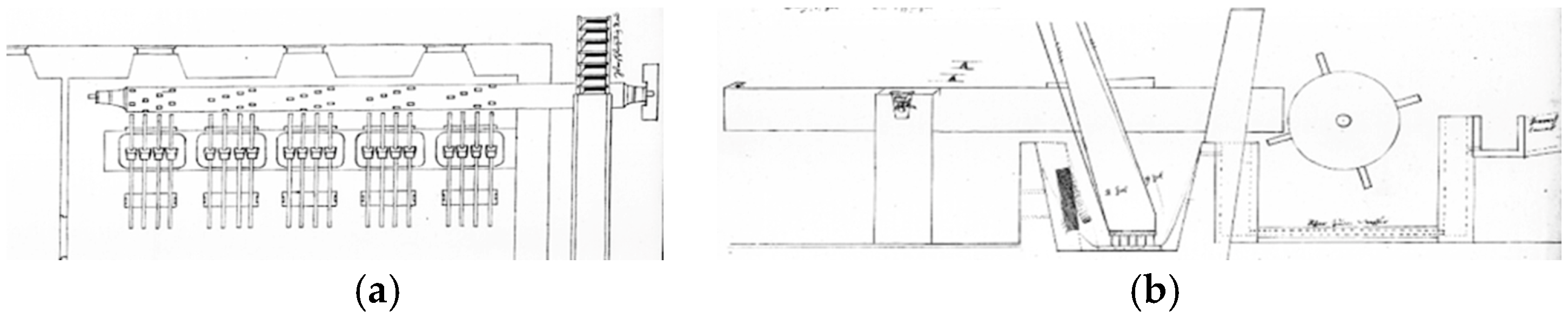

2.1.3. Mechanics and Technology of Papermaking Mills

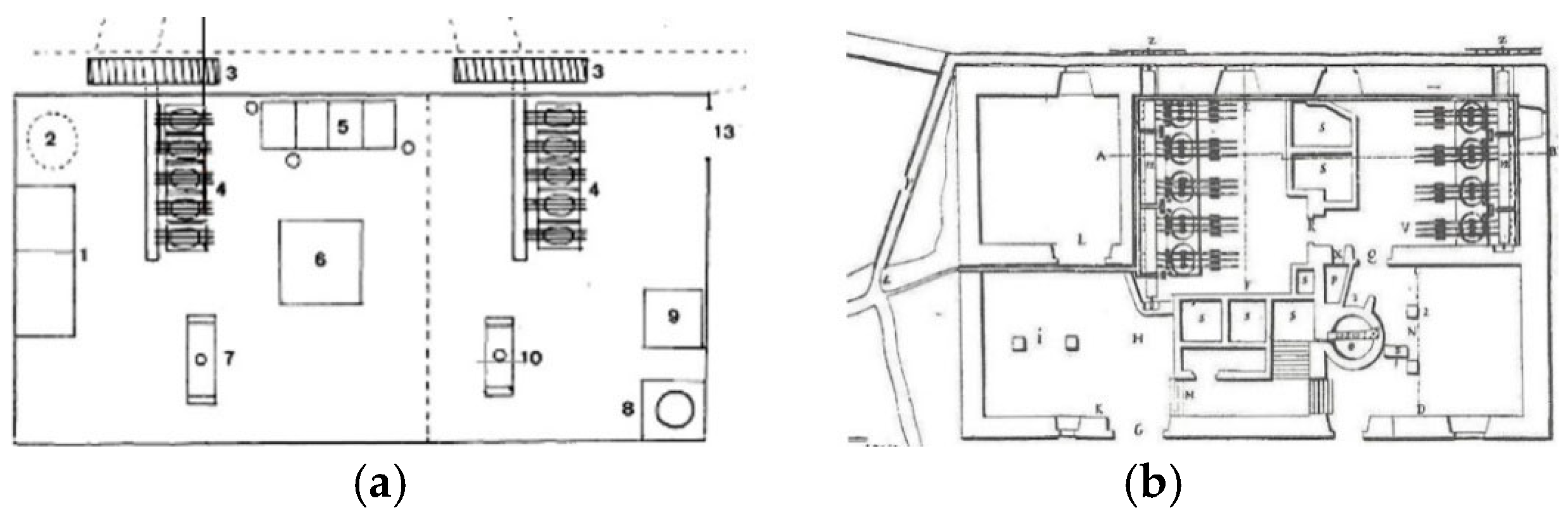

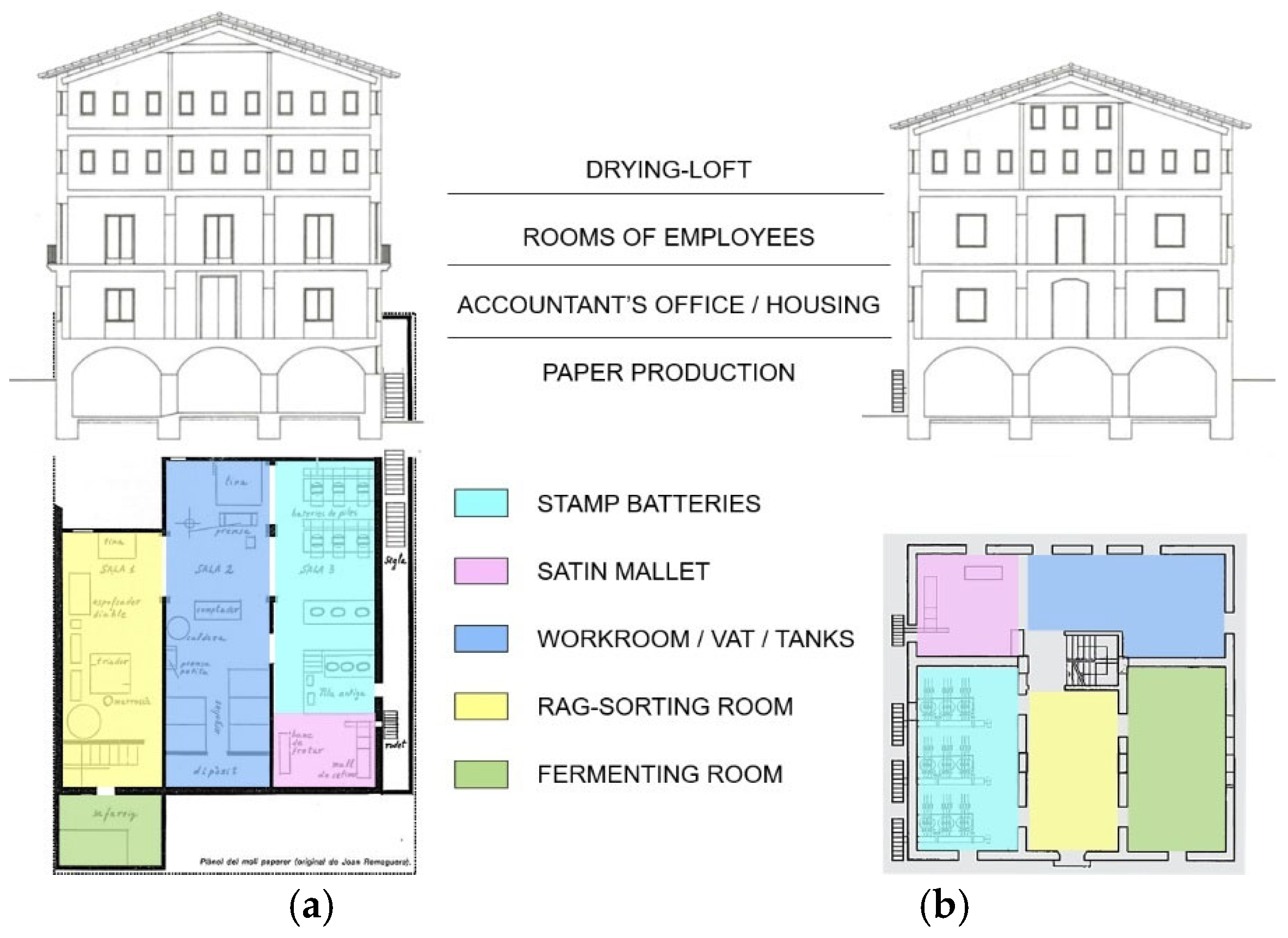

2.1.4. Examples of Paper Mills

2.1.5. Documentary Sources

2.2. Methods

3. Results

4. Discussion

5. Conclusions

- The complete recovery of the layout of the vanished paper mill.

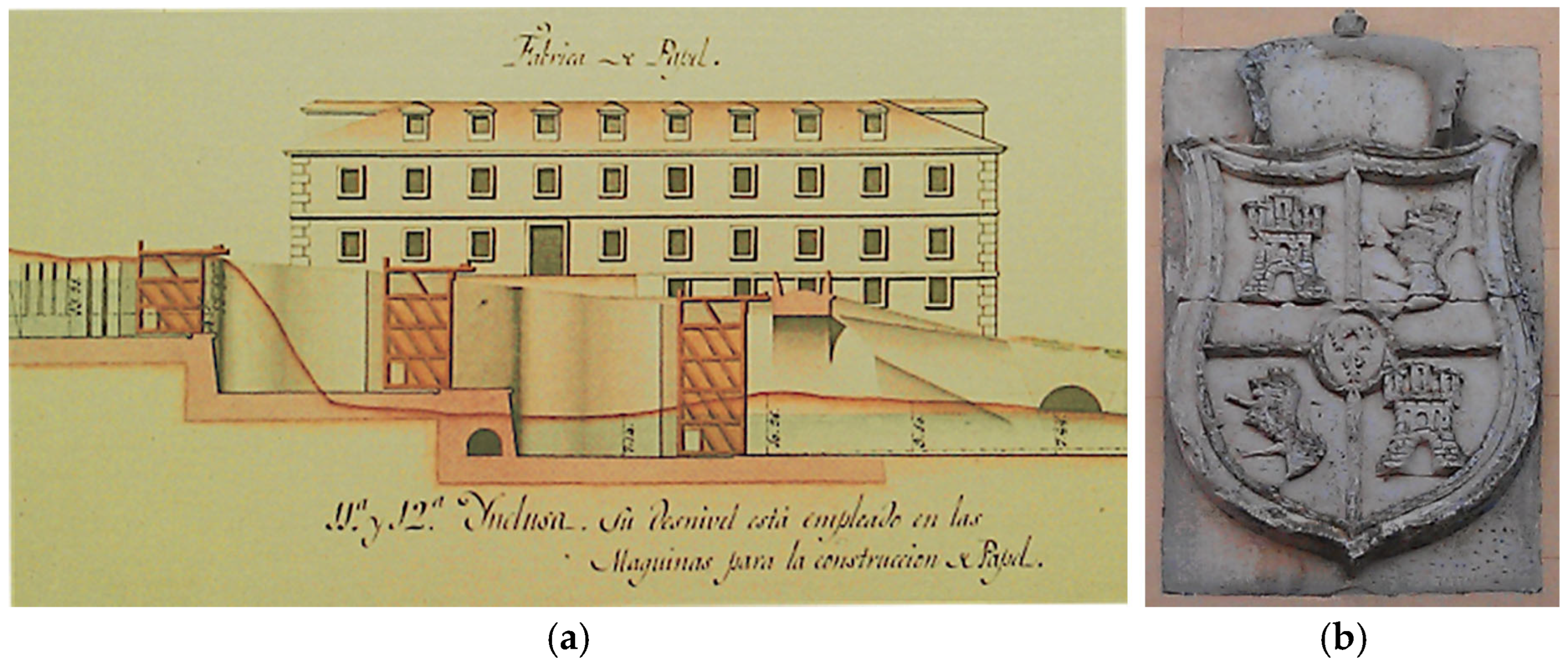

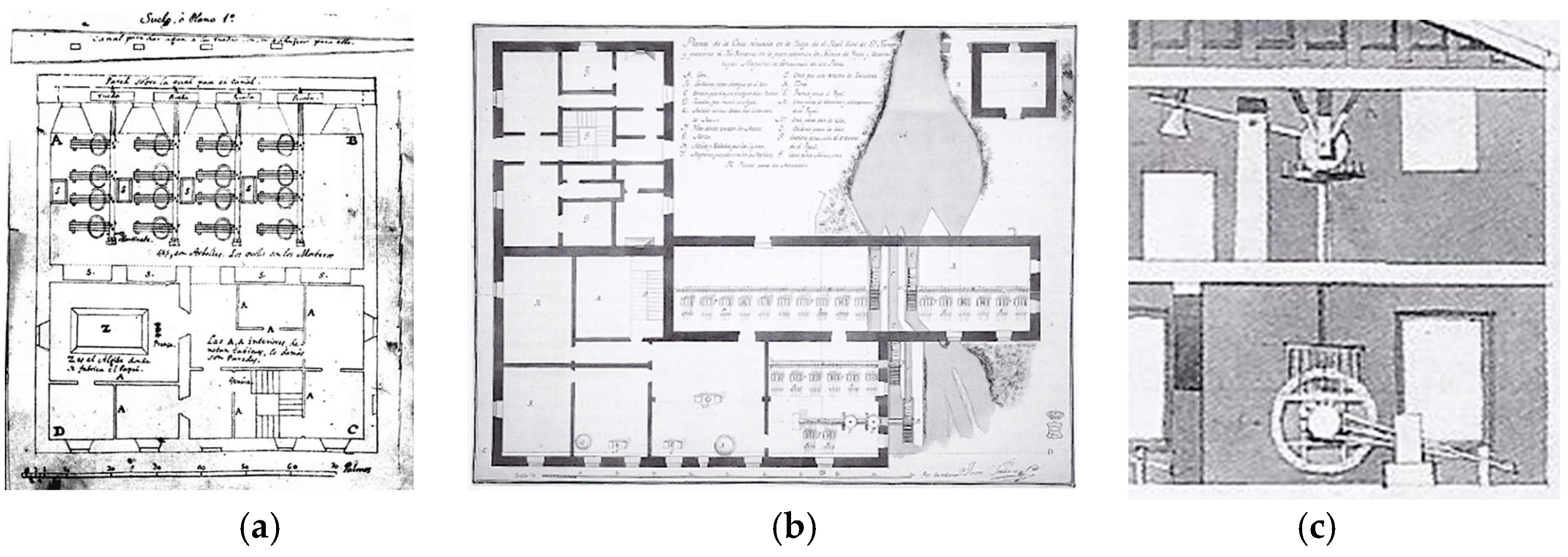

- The west elevation depicted by Homar in 1808 [48] (Figure 1a) does not accurately reflect reality. The drawing shows a significantly longer building, with dormer windows, lacking a coat of arms, and with the culvert incorrectly positioned. This image appears to have been deliberately exaggerated by the author, possibly to draw the attention of high-ranking officials to a declining Royal Paper Mill to which he had devoted nearly half of his life. The dimensions and appearance of this idealized representation do not match those found in other documents or in later depictions, such as the one included in the 1853 transformation project [107].

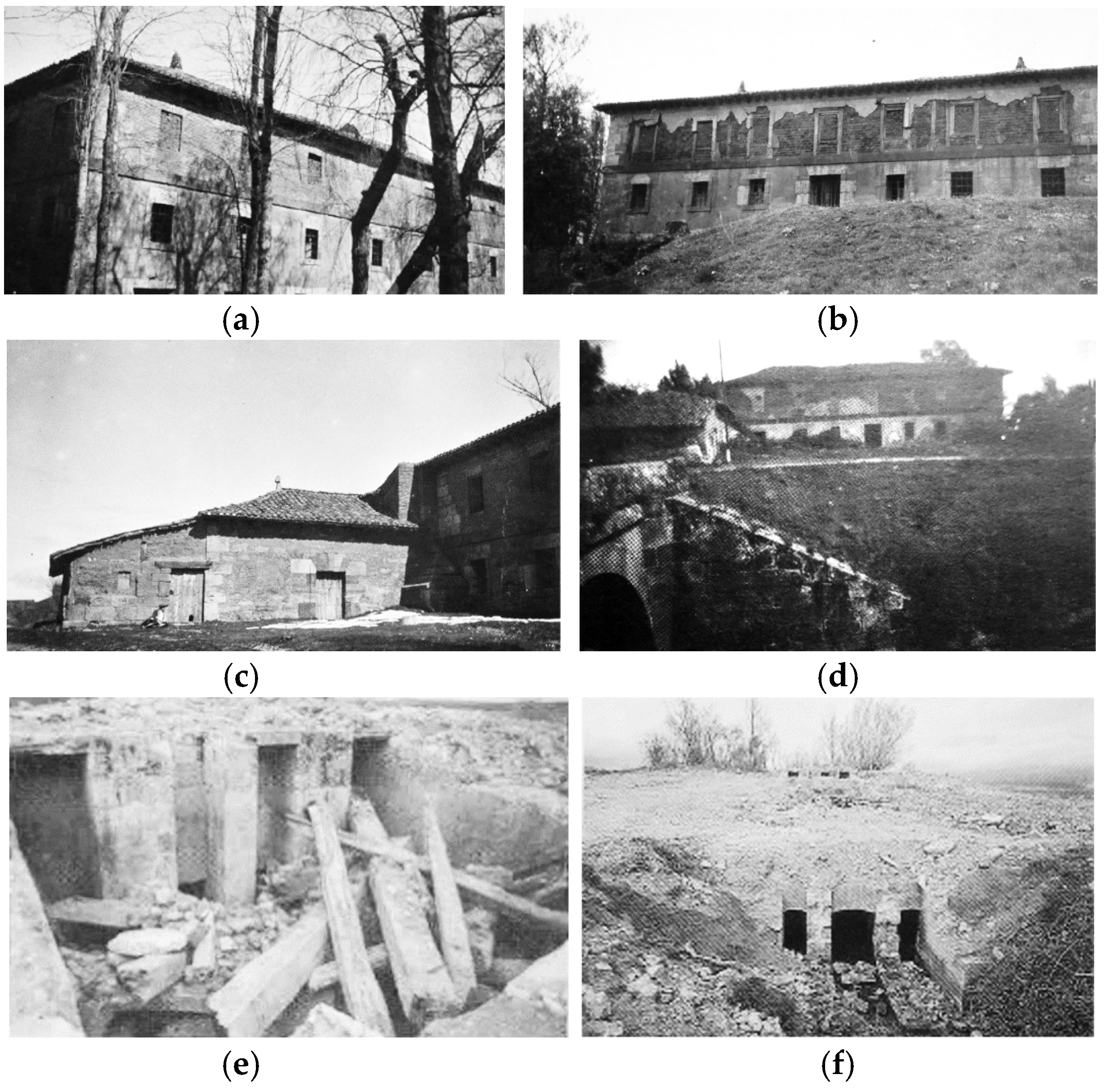

- The photograph from 1920 to 1930, published in Helguera’s 1992 work [48] (p. 37), has been incorrectly attributed to this mill. It corresponds to the third mill, built in 1922 over the fulling mill at Locks 22–23–24 in Calahorra de Ribas.

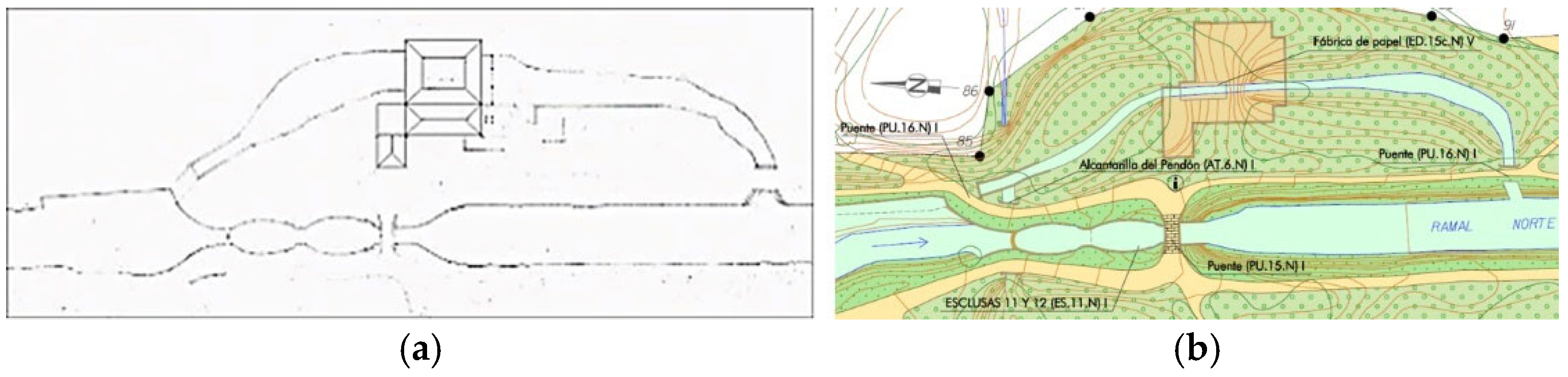

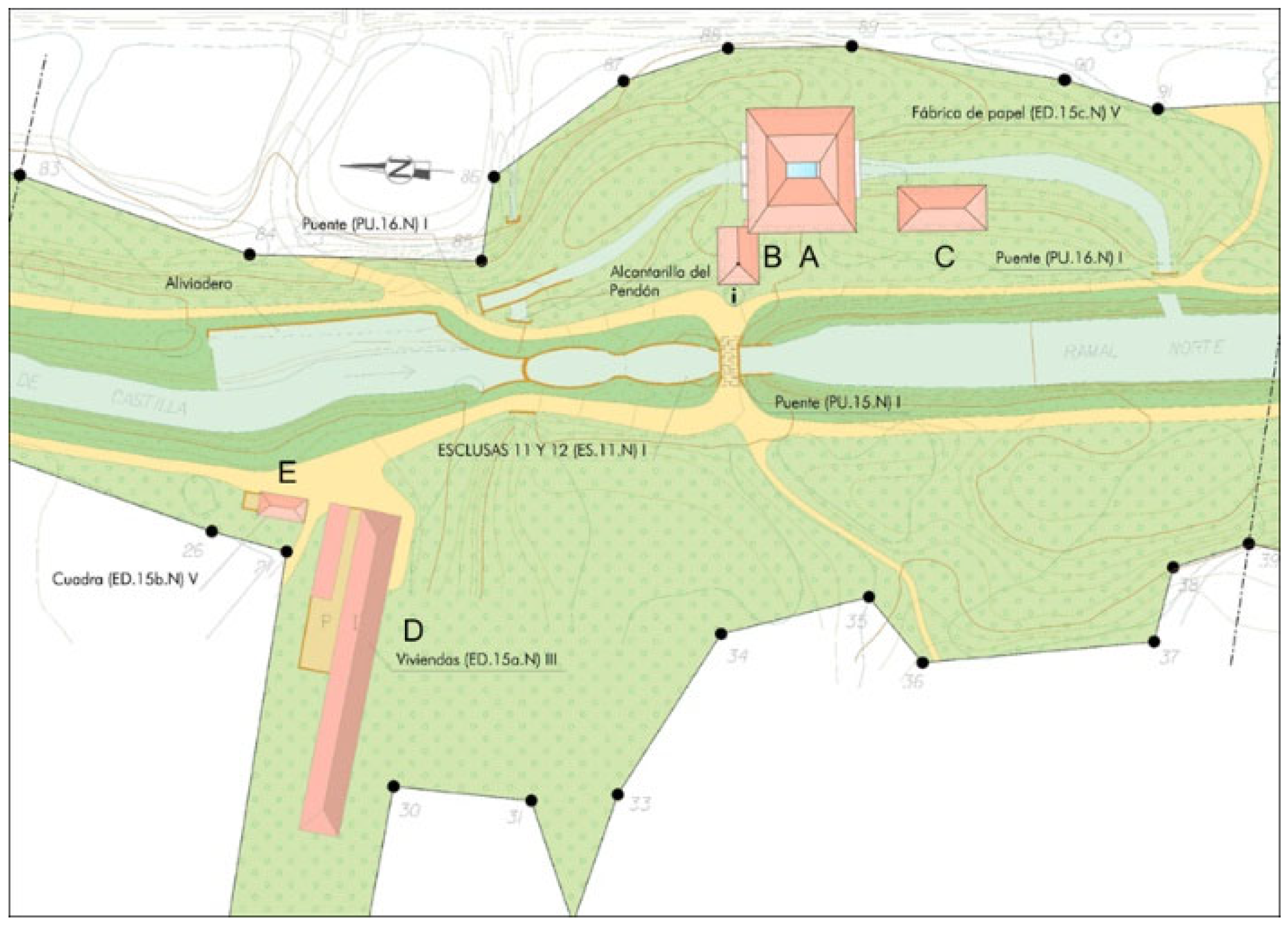

- The location plan included in the 2001 Regional Plan for the Canal de Castilla [71] (Figure 5b)—a regulatory document governing any intervention in the Canal—shows an incomplete configuration of the mill. Likely based on the barely visible remains of the foundations, this plan depicts a layout of the main building that does not correspond to the original floor plan of the mill.

- 2.

- The identification of distinctive features in this mill reveals the following key innovations that were incorporated into its design:

- Diversification of buildings: The mill consisted of several specialized structures with different functions, including a residential area for employees.

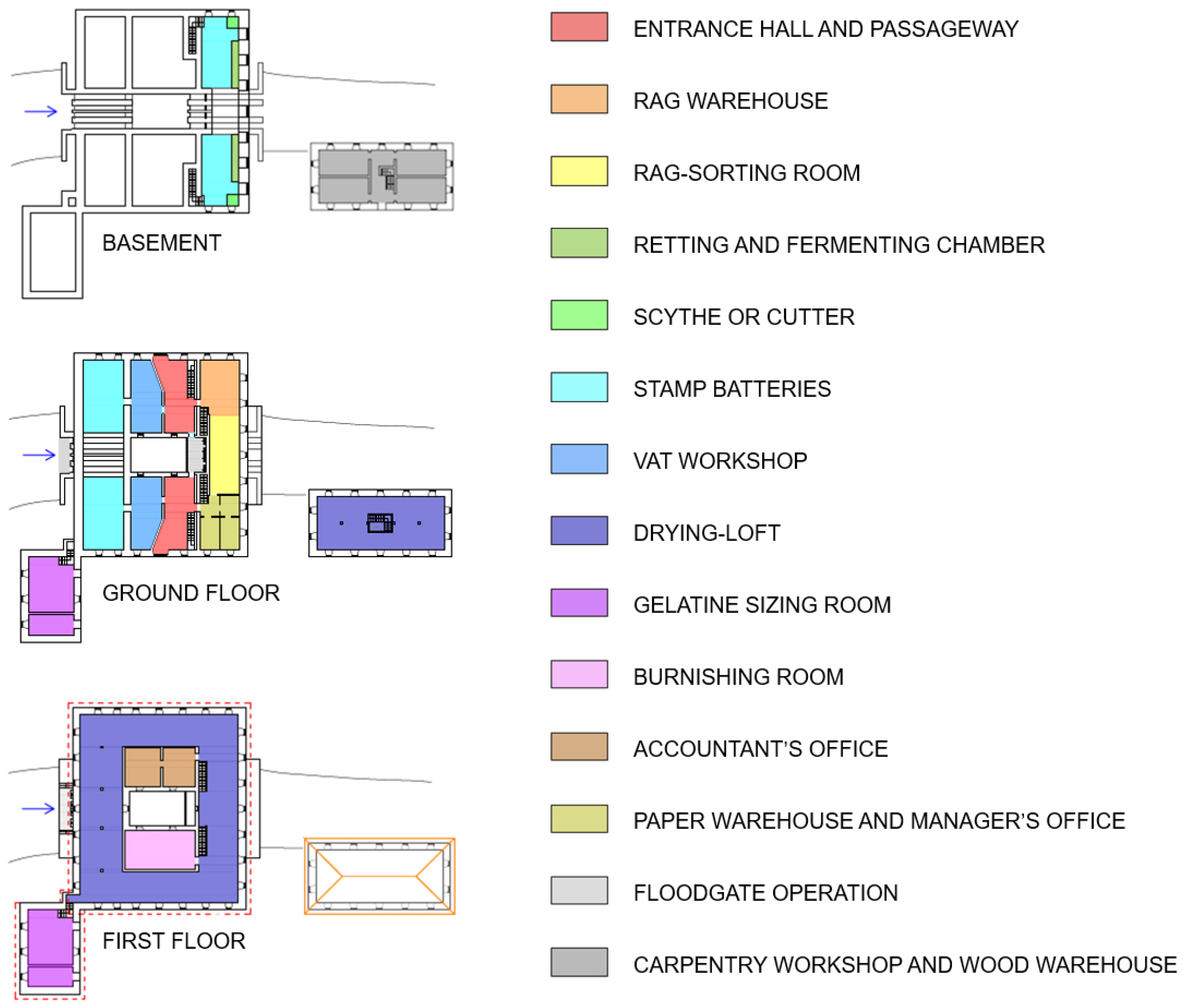

- Configuration of the main building: Designed as a symmetrical bridge mill over the diversion channel, the main building integrated two pairs of internal waterwheels arranged on two levels.

- Rationalization of spaces and workflows: The organization of labour aimed to improve the production process. This new approach marked the beginning of the transition from early guild workshops to the modern factories of the 19th century, already embedded in an industrial production context.

- Improvements in environmental conditions: Enhancements were made to ventilation, lighting, and fire safety, as fires were commonly caused by the stove located in the sizing office.

- Strategic location of the rag-sorting room: Positioned strategically, it facilitated the division of the paper-making process into two independent circuits.

- 3.

- The establishment of connections between this mill and other Royal manufactories.

5.1. Limitations of the Work

5.2. Future Work

- Identification of new sources and data: Old photographs, drawings, oral histories, records, private archives, etc.

- Conducting archaeological studies: Excavation of the foundations and other remains hidden by vegetation to verify their locations, elevations, and dimensions. Once the vegetation is removed, techniques such as traditional surveying, laser scanning, and UAV photogrammetry may be employed. Implementation of measures to conserve and enhance the remains of the facility.

- 3D digitization of the site: Three-dimensional reconstruction of the material remains within their context.

- Creation of hyper-realistic 3D models: Visualization and documentation of the paper mill using photorealism and immersive virtual reality (VR) technologies. The virtual reality model of the building and its machinery can be used to demonstrate the manufacturing process and interact with its elements for the purposes of educational and scientific dissemination.

- Enhancement of the Canal de Castilla’s tourism resources: Installation of informational panels near the paper mill, incorporating interactive augmented reality (AR) and mixed reality (MR) features.

- Creation of 3D physical models, both individual machines and the entire system, to improve data interpretation and facilitate its dissemination.

- Further exploration of the papermaking process in terms of Intangible Cultural Heritage.

- Expansion of the study to other industrial sites along the Canal de Castilla: Documentation and dissemination of its rich industrial heritage.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AGCHD | General Archive of the Confederación Hidrográfica del Duero |

| AHCC | Historical Archive of the Canal de Castilla |

| CAD | Computer-Aided Design |

| CDF | Documentary Collection of Factories |

| FACC | Administrative Collection of the Canal de Castilla |

| TICCIH | The International Committee for the Conservation of the Industrial Heritage |

| PCC | Projects for the Canal de Castilla |

References

- Cipolla, C.M. Before the Industrial Revolution: European Society and Economy 1000–1700, 3rd ed.; Routledge: London, UK, 2004. [Google Scholar] [CrossRef]

- Crompton, G.W. Canals and the Industrial Revolution. J. Transp. Hist. 1993, 14, 93–110. [Google Scholar] [CrossRef]

- Pérez Sarrión, G. La política de construcción de canales. Una aproximación. In Técnica e Ingeniería en España, Vol. II, El Siglo de las Luces. De la ingeniería a la Nueva Navegación; Silva Suárez, M., Ed.; Institución Fernando el Católico: Zaragoza, Spain, 2005; pp. 429–468. [Google Scholar]

- Muller, J.; Sánchez Taramas, M. Tratado de fortificación, ó Arte de construir los edificios militares, y civiles. In Tomo Segundo; Thomas Piferrer: Barcelona, Spain, 1769. [Google Scholar]

- Larruga, E. Memorias políticas y económicas sobre los frutos, comercio, fábricas y minas de España. In Tomo XXXII; Antonio Espinosa: Madrid, Spain, 1794; p. 254. [Google Scholar]

- Benito Arranz, J. El Canal de Castilla (memoria descriptiva). Vol. II.; In Colección Academia Nueva; Publicaciones del Departamento Provincial de Seminarios del FET y de las JONS: Valladolid, Spain, 1957. [Google Scholar]

- Ulloa, F. Detalle del Plano y Proyecto General de el Canal de Navegación y Riego que da Principio en el Estrecho de Nogales…. [Detail of the Plan and General Project of the Navigation and Irrigation Canal Beginning at the Strait of Nogales…] Archivo General Militar de Madrid (AGMM), Cart., Sign. ESP-07/10, 1760. Biblioteca Virtual de Defensa > Plano y Proyecto General de el [sic] Canal de Navegación... (Fragment Reproduced in Helguera Quijada, J.; García Tapia, N.; Molinero Hernando, F. El Canal de Castilla, 1st ed.; Junta de Castilla y León: Valladolid, Spain, 1988; p. 53. [Google Scholar]

- Ulloa, F. Plano y perfil de las dos inclusas unidas construidas en el barranco de Olmos. Detalle del Plano general de los proyectos de los Canales de Castilla la Vieja con las porciones que ya estaban abiertas y las que faltan de abrir para su conclusión [Plan and Profile of the Two Connected Locks Built in the Barranco de Olmos. Detail from the General Plan of the Projects for the Canals of Old Castile, Including the Sections Already Opened and Those Yet to Be Completed]. Archivo General Militar de Madrid (AGMM), Cart., sign. ESP-07/11, 1775.

- Homar, J. (attributed). Detalle del “Plano general del proyecto ejecutado y por ejecutar de los Canales de Castilla que comprende desde Olea a la ciudad de Segovia y así mismo el nuevo que le une desde Quintanilla de las Torres á Golmir, distante un quarto de legua de la villa de Reynosa” [Detail of the “General Plan of the Executed and Planned Project of the Canals of Castile, Covering from Olea to the City of Segovia, Including the New Section Connecting Quintanilla de las Torres to Golmir, a Quarter League from the Town of Reynosa”]. Archivo General del Ministerio de Fomento (AGMF), Map, ref. OH-7, 179.

- Jovellanos, G.M. Expedición al canal de Campos. In Diarios (Memorias Íntimas) 1790–1801; Instituto de Jovellanos, Ed.; Instituto de Jovellanos: Gijón, Spain, 1915; pp. 38–57. [Google Scholar]

- Geijo-Barrientos, J.M.; Zulueta, P. El Canal de Castilla: Molinos, fábricas y otros artefactos. COIIM Rev. inf. Col. Ing. Ind. Madr. 2010, 47, 22–32. [Google Scholar]

- De la Cruz Macho, F.J. De espaldas al río. La incidencia del ferrocarril en la expansión urbana de la ciudad de Palencia. Publ. Inst. Tello Téllez Men. 2010, 81, 231–250. [Google Scholar]

- Domínguez Aparicio, J. Un proyecto ferroviario fallido: El trazado de la línea Alar-Palencia por Carrión. Publ. Inst. Tello Téllez Men. 2023, 93, 179–191. [Google Scholar]

- López Linage, J. El Canal de Castilla: El recuerdo de un sueño ilustrado. Publ. Inst. Tello Téllez Men. 1985, 52, 153–171. [Google Scholar]

- Moreno Lázaro, J. La Industria Harinera en Castilla la Vieja y León, 1778–1913. Ph.D. Thesis, Universidad de Valladolid, Valladolid, Spain, 1997. [Google Scholar]

- Moreno Lázaro, J. La harinería castellana y el capitalismo agrario en el tránsito a la industrialización: 1788–1868. Hist. Agrar. Rev. Agric. Hist. Rural 2002, 27, 165–190. [Google Scholar]

- Moreno Lázaro, J. Protección arancelaria, distorsiones de mercado y beneficios extraordinarios: La producción de harinas en Castilla la Vieja, 1820–1841. Rev. Hist. Econ. 1995, XIII, 227–250. [Google Scholar]

- Guerra Garrido, R. El Canal de Castilla: Un Plan regional; Junta de Castilla y León, Consejería de Fomento, Ministerio de Fomento: Salamanca, Spain, 2004; Volume 2, pp. 60–492.

- Soria Cáceres, C.H.; Andrés López, G. El estudio del patrimonio industrial en España: Cincuenta años de análisis sobre el legado de la industrialización contemporánea (1972–2022). Cuad. Geogr. Univ. Granada 2023, 62, 208–232. [Google Scholar] [CrossRef]

- Tagil, N. Letter from Nizhny Tagil on Industrial Heritage. In Proceedings of the The International Council of Monuments and Sites (ICOMOS)/The International Committee for the Conservation of the Industrial Heritage Conference, Paris, France, 15 May 2003. [Google Scholar]

- ICOMOS; TICCIH. Joint Principles for the Conservation of Industrial Heritage Sites, Structures, Areas and Landscapes. In Proceedings of the 17th ICOMOS General Assembly, Paris, France, 27 November–2 December 2011; Available online: https://whc.unesco.org/uploads/activities/documents/activity-646-1.pdf (accessed on 15 May 2025).

- Benito del Pozo, P. Territorio, paisaje y herencia industrial: Debates y acciones en el contexto europeo. Doc. d’Anàl. Geogr. 2012, 58, 443–457. [Google Scholar] [CrossRef]

- Decreto 154/1991 de 13 de Junio, por el que se Declara Bien de Interés Cultural con Categoría de Conjunto Histórico a Favor del Canal de Castilla [Decree 154/1991 of June 13, Declaring the Canal de Castilla a Site of Cultural Interest in the Category of Historic Ensemble]. Available online: https://www.boe.es/diario_boe/txt.php?id=BOE-A-1991-20732 (accessed on 15 May 2025).

- Biel Ibáñez, M.P.; Cueto Alonso, G.J. 100 Elementos de Patrimonio Industrial en España; TICCIH España, CICEES, IPCE: Gijón, Spain, 2012; Available online: https://dialnet.unirioja.es/servlet/libro?codigo=507149 (accessed on 15 May 2025).

- Instituto del Patrimonio Cultural de España, Ministerio de Educación, Cultura y Deporte. Plan Nacional de Patrimonio Industrial. Actualización. 2016. Available online: https://oibc.oei.es/uploads/attachments/172/patrimonio_industrial.pdf (accessed on 15 May 2025).

- Sun, L.; Fan, X. Research Hotspots and Future Trends in Canal-Related Industrial Buildings. Sustainability 2024, 16, 5208. [Google Scholar] [CrossRef]

- Guerra Garrido, R. El Canal de Castilla: Un Plan regional; Junta de Castilla y León, Consejería de Fomento, Ministerio de Fomento: Salamanca, Spain, 2004; Volume 1, pp. 51–124.

- Bellido Blanco, A. Aproximación al Patrimonio Industrial de la Tierra de Campos palentina. Publ. Inst. Tello Téllez Men. 2006, 77, 263–293. [Google Scholar]

- Alario Trigueros, M. El paisaje patrimonial del Canal de Castilla. In Paisajes Patrimoniales de España. Significado y Valor del Patrimonio Territorial Español, 1st ed.; Molinero, F., Tort, J., Eds.; Ministerio de Agricultura, Pesca y Alimentación-Ministerio para la Transición Ecológica: Madrid, Spain, 2018; Volume 1, pp. 1050–1065. [Google Scholar]

- Ausín Íñigo, M. Desarrollo Artístico del Molino del Canal de Castilla en el Punto de Viñalta: 1800–1995; Diputación Provincial de Palencia: Palencia, Spain, 1995; pp. 705–714. [Google Scholar]

- Represa Fernández, M.F.; Helguera Quijada, J. La evolución del primer espacio industrial en Valladolid: La dársena y el derrame del Canal de Castilla (1836–1975). An. Estud. Econ. Empres. 1992, 7, 321–352. [Google Scholar]

- Represa Fernández, M.F.; López Linage, J. Arqueología Industrial: Un batán del siglo XVIII. Rev. Arqueol. 1987, 69, 17–24. [Google Scholar]

- Represa Fernández, M.F. Estudio arqueológico del molino de corteza de un batán de curtidos del siglo XVIII. In Proceedings of the XVI Simposio Internacional ICOHTEC, Madrid, Spain, 5–9 September 1988. [Google Scholar]

- Represa Fernández, M.F. Propuesta de conservación del batán de antes y cueros del Canal de Castilla (Palencia). In Proceedings of the Congreso sobre Conservación y Desarrollo de los Recursos del Canal de Castilla, Palencia, Spain, 1990; pp. 249–261. [Google Scholar]

- Rodríguez Pérez, Á.M.; Rodríguez, C.A.; Olmo Rodríguez, L.; Caparros Mancera, J.J. Revitalizing the Canal de Castilla: A Community Approach to Sustainable Hydropower Assessed through Fuzzy Logic. Appl. Sci. 2024, 14, 1828. [Google Scholar] [CrossRef]

- Martín Roda, E.M.; Fernández Portela, J. Recovery of Industrial and Natural Heritage as a Resource for Developing Tourism in the Castille Canal Municipalities. Cuad. Tur. 2023, 51, 255–279. [Google Scholar] [CrossRef]

- Hortelano Mínguez, L.A.; Mansvelt Beck, J. Is heritage tourism a panacea for rural decline? A comparative study of the Camino de Santiago and the Canal de Castilla in Spain. J. Herit. Tour. 2023, 18, 224–242. [Google Scholar] [CrossRef]

- Pardo Abad, C.J.; Fernández Portela, J. El Canal de Castilla: Recurso patrimonial del agua y perspectivas de uso e innovación turística. Cuad. Tur. 2022, 50, 229–256. [Google Scholar] [CrossRef]

- Geijo-Barrientos, J.M.; Zulueta Pérez, P.; Sánchez Lite, A. Methodological approach to point out the value of the industrial heritage. A case study:“The mallet from Alar del Rey”. In Proceedings of the 25th International Congress on Project Management and Engineering, Alcoi, Spain, 6 July 2021; pp. 6–9. [Google Scholar]

- Geijo-Barrientos, J.M.; Sanchez-Lite, A.; Zulueta, P.; Sampaio, A.Z. Study of an “Artefact” of the Castilla Canal: Reconstruction of the Missing Machinery. Machines 2022, 10, 239. [Google Scholar] [CrossRef]

- Fernández Martín, J.J.; Revilla Casado, J.; San José Alonso, J.I. El Agua y la Fábrica de Harinas en Torno al Canal de Castilla en Medina de Rioseco; Junta de Castilla y León, Consejería de Cultura y Turismo: Valladolid, Spain, 2011. Available online: https://bibliotecadigital.jcyl.es/jcyl/i18n/catalogo_imagenes/grupo.cmd?path=10111444 (accessed on 15 May 2025).

- Mozo, J. Oficios de Dn Juan Mozo Mozo de la Torre Dirigidos a Dn Diego de Gardoqui Informando Sobre los Artefactos del Canal [Official Letters from Don Juan Mozo Mozo de la Torre to Don Diego de Gardoqui Reporting on the Canal’s Machinery]; Confederación Hidrográfica del Duero, AGCHD, FACC, AHCC (18th Century, Ref. C-0001-09): Valladolid, Spain, 1792–1800. [Google Scholar]

- Nadal, J. Atlas de la Industrialización en España 1750–2000; Editorial Crítica: Barcelona, Spain, 2003. [Google Scholar]

- Obligación Que Otorga Juan Millán en Favor de, S.M. por el Abasto del Molino de Papel [Obligation Granted by Juan Millán in Favor of His Majesty for the Supply of the Paper Mill]; Confederación Hidrográfica del Duero, AGCHD, FACC, AHCC (18th Century, Ref. C-0006-22): Palencia, Spain, 1793.

- Gazeta de Madrid; Imprenta Real: Madrid, Spain, 1791; Nº 85; pp. 785–787.

- Alonso, J.L. Rutas Para Descubrir: El Canal de Castilla; Ámbito Ediciones: Valladolid, Spain, 2000. [Google Scholar]

- Miñano, S. Diccionario Geográfico-Estadístico de España y Portugal, Tomo VI; Imprenta de Pierart-Peralta: Madrid, Spain, 1827. [Google Scholar]

- Homar, J.; Helguera, J. El Canal de Castilla: Cartografía de un Proyecto Ilustrado; CEHOPU, CEDEX, Ministerio de Obras Públicas y Transportes: Madrid, Spain, 1992.

- Ceccarelli, M.; Cocconcelli, M. Italian Historical Developments of Teaching and Museum Valorization of Mechanism Models. Machines 2022, 10, 628. [Google Scholar] [CrossRef]

- Rojas-Sola, J.I.; del Río-Cidoncha, G.; Coronil-García, Á. Industrial Archaeology Applied to the Study of an Ancient Harvesting Machine: Three-Dimensional Modelling and Virtual Reconstruction. Agriculture 2020, 10, 322. [Google Scholar] [CrossRef]

- Hain, V.; Ganobjak, M. Forgotten industrial heritage in virtual reality case study: Old power plant in Piest’any, Slovakia. Presence-Virtual Augment. Real. 2017, 26, 355–365. [Google Scholar] [CrossRef]

- Rojas-Sola, J.I.; Barranco-Molina, J.C. Engineering Drawing Applied to the Study of the Design of a Two-Cylinder Entablature Steam Engine with Parallel Motion Crosshead. Symmetry 2024, 16, 578. [Google Scholar] [CrossRef]

- Rojas-Sola, J.I.; De la Morena-De la Fuente, E. Agustín de Betancourt’s Double-Acting Steam Engine: Analysis through Computer-Aided Engineering. Appl. Sci. 2018, 8, 2309. [Google Scholar] [CrossRef]

- Rojas-Sola, J.I.; Barranco-Molina, J.C. Study of the Mechanical Behavior of a Single-Cylinder Horizontal Steam Engine with a Crosshead Trunk Guide through the Finite-Element Method. Appl. Sci. 2024, 14, 5878. [Google Scholar] [CrossRef]

- Rojas-Sola, J.I.; Gutiérrez-Antúnez, J.F. Analysis of the Design of Henry Muncaster’s Two-Cylinder Compound Vertical Steam Engine with Speed Control. Appl. Sci. 2023, 13, 9150. [Google Scholar] [CrossRef]

- Rojas-Sola, J.I.; Barranco-Molina, J.C. Technical Feasibility of a Two-Cylinder Entablature Steam Engine with a Parallel Motion Crosshead: An Analysis from Mechanical Engineering. Appl. Sci. 2024, 14, 6597. [Google Scholar] [CrossRef]

- Forte, M.; Siliotti, A. Virtual Archaeology: Re-Creating Ancient Worlds; H.N. Abrams: New York, NY, USA, 1997. [Google Scholar]

- Forte, M. About virtual archaeology: Disorders, cognitive interactions and virtuality. Archeol. Calc. 2000, 11, 273–300. [Google Scholar]

- Forte, M. Cyber-archaeology: Notes on the simulation of the past. Virtual Archaeol. Rev. 2011, 2, 7–18. [Google Scholar] [CrossRef]

- Martens, B.; Peter, H. Die Zerstörten Synagogen Wiens; Mandelbaum Verlag: Vienna, Austria, 2009. [Google Scholar]

- Martens, B.; Peter, H. Virtual reconstruction of synagogues: Systematic maintenance of modeling data. In Proceedings of the 20th International Conference on Education and Research in Computer Aided Architectural Design in Europe, Warsaw, Poland, 9 September 2002. [Google Scholar]

- Martens, B.; Peter, H.; Spera, D.; Hanak-Lettner, W. Wiener Synagogen: Ein Memory; Jüdisches Museum Wien: Vienna, Austria, 2016. [Google Scholar]

- Martens, B.; Peter, H. Virtual reconstruction of Viennese synagogues: Sustainable 3D models. In Proceedings of the Computer Aided Architectural Design Conference, Tübingen, Germany, 2003; Available online: https://ub01.uni-tuebingen.de/xmlui/bitstream/handle/10900/60607/CD42_Martens_Peter_CAA_2003.pdf (accessed on 13 June 2025).

- Rabanal Yus, A. Las Reales Fundiciones Españolas del Siglo XVIII, 1st ed.; Servicio de Publicaciones del Estado Mayor del Ejército: Madrid, Spain, 1990. [Google Scholar]

- Rabanal Yus, A. Arquitectura de las Reales Fábricas Españolas en el siglo XVIII. In Jornadas Sobre Las Reales Fábricas (2002. La Granja de San Ildefonso); Fundación Centro Nacional del Vidrio: Segovia, Spain, 2004; pp. 265–298. [Google Scholar]

- Principles of Seville. Available online: http://smartheritage.com/wp-content/uploads/2016/06/PRINCIPIOS-DE-SEVILLA.pdf (accessed on 15 May 2025).

- London Charter. Available online: http://www.londoncharter.org (accessed on 15 May 2025).

- General Archive of the Confederación Hidrográfica del Duero (AGCHD), Documentary Collection of Factories (CDF), refs. CDF, RN-075-1, RN-075-2 and RN-077: Valladolid, Spain.

- Alonso Ortega, J.L. El Canal de Castilla: Actualidad de una obra de la Ilustración; Diputación Provincial de Palencia: Palencia, Spain, 1990. [Google Scholar]

- Fernández Muñoz, Á.L.; Helguera Quijada, J.; García Tapia, N. El Canal de Castilla. Catálogo de la Exposición: Marzo-Abril 1986; Junta de Castilla y León, Consejería de Cultura y Bienestar Social: Valladolid, Spain, 1986; p. 224. [Google Scholar]

- Junta de Castilla y León. Plan Regional del Canal de Castilla. Electronic Planning Archive. 2001. Available online: https://servicios.jcyl.es/PlanPublica/openDocuIndice.do;jsessionid=6892cbd065fa190e9310108f47c3094ce2e8aed2bd4e7681bb45c3d1756c2dbb.e3mTb3qQb3aPe34Kc390?cDocId=285729 (accessed on 15 May 2025).

- Asenjo Martínez, J.L. Desde la prehistoria del papel hasta la fábrica de Játiva. Rev. Investig. Téc. Pap. 1975, 46, 941–951. [Google Scholar]

- Emery, O. Introducción del papel en Europa. Rev. Investig. Téc. Pap. 1966, 8, 283–289. [Google Scholar]

- González Burgos, F.R. Papel a mano, papel continuo: Su elaboración a lo largo de la historia. Rev. Investig. Téc. Pap. 2001, 147, 69–97. [Google Scholar]

- Gutiérrez Poch, M. Trabajo y materias primas en una manufactura preindustrial: El papel. Rev. Hist. Ind. 1993, 4, 147–157. [Google Scholar]

- Hidalgo Brinquis, M.C. La fabricación del papel en España e Hispanoamérica en el siglo XVII. In V Jornadas Científicas Sobre Documentación de Castilla e Indias en el Siglo XVII; Universidad Complutense de Madrid: Madrid, Spain, 2006; pp. 207–223. [Google Scholar]

- León Portillo, R. Tendedoras de mañir y espito. Rev. Investig. Téc. Pap. 1986, 87, 34–47. [Google Scholar]

- González Tascón, I. Fábricas Hidráulicas Españolas; Centro de Estudios y Experimentación de Obras Públicas (CEDEX), Biblioteca CEHOPU: Madrid, Spain, 1987. [Google Scholar]

- Hidalgo Brinquis, M.C. Breve historia de la fabricación del papel en España y sus filigranas. In Cabeza de Buey y Sirena. La Historia del Papel y las Filigranas Desde el Medievo Hasta la Modernidad, 4th ed.; Bernstein Project, Ed.; Bernstein Project: Stuttgart, Germany; Valencia, Spain, 2011; pp. 18–28. [Google Scholar]

- Sachs, H.; Amman, J. Das Ständebuch; Sigmund Feyerabent: Frankfurt am Mayn, Germany, 1568. [Google Scholar]

- Zonca, V. Novo Teatro di Machine e Edificci; P. Bertelli: Padova, Italy, 1607. [Google Scholar]

- Böckler, G.A. Theatrum Machinarum Novum; P. Principis: Cologne, Germany, 1662. [Google Scholar]

- Porcelius, E. Curioser Spiegel, worinnen der ganze Lebenslauf des Menschen von der Kindheit bis zum Alter zu sehen. In Figuren Mit Ganz Neuen Erklärungen; J.A. Endter: Nuremberg, Germany, 1689. [Google Scholar]

- La Lande, J. Art de Faire le Papier; Saillant et Nyon: Paris, France, 1761. [Google Scholar]

- Diderot, D. Recueil de planches sur les sciences, les arts libéraux et les arts méchaniques: Avec leur explication. In Quatrieme Livraison; Briasson: Paris, France, 1767. [Google Scholar]

- Hemart, M. Galerie industrielle, ou application des produits de la nature aux arts et métiers. In Leur Origine, Leurs Progrès et Leur Perfectionnement; Alexis Eymery: Paris, France, 1822. [Google Scholar]

- Sturm, L.C. Vollständige Mühlen-Baukunst; Verlag Jeremias Wolff: Augsburg, Germany, 1718. [Google Scholar]

- Barrett, T.D.; Pickwoad, N. Early European Papers; Institute of Paper Conservation: Worcestershire, UK, 1989. [Google Scholar]

- Explicación de Cada Uno de los Planos, Que Representan un Molino, o Fábrica de Papel, Juntamente Con Las Noticias Que Conducen a Su Manutención [Explanation of Each of the Plans Representing a Mill or Paper Factory, Along with Information Relevant to its Maintenance]; Archivo General de Navarra (A.G.N. Hosp. Gral. tít. 6, fajo 1, caja 1, núm. 4): Navarra, Spain, 1754.

- Relazión, y construcción del Molino Papelero, situado en el termino de Sn Pedro de Riudevitlles, del Corregimito de Villafranca del Panadés, en el Principado de Cathaluña [Account and construction of the paper mill located in the district of San Pedro de Riudevitlles, in the jurisdiction of Villafranca del Panadés, Principality of Catalonia]. In Libro de Varios Planos y Máquinas; Fundació Cultural Manuel Rocamora: Barcelona, Spain, 1760.

- Marcos Bermejo, M.T. El funcionamiento de los molinos papeleros tradicionales: Los molinos de Cuenca. Rev. Investig. Téc. Pap. 1995, 124, 273–291. [Google Scholar]

- León Portillo, R. El molino de las toesas en Sant Pere de Riudebitlles. Rev. Investig. Téc. Pap. 1991, 108, 299–321. [Google Scholar]

- Munné Sellarés, L. Els Molins Paperers. Origen, Arquitectura, Funció i Evolució (Comarca de Capellades, 1700–1950). Doctoral Thesis, Universitat de Barcelona, Barcelona, Spain, 2015. Available online: https://diazdemiranda.com/tesis-doctoral-de-lourdes-munne-los-molinos-papeleros/ (accessed on 4 July 2024).

- Munné Sellarés, L. Els molins paperers a la comarca de l’Anoia. Introducció al seu estudi. Misc. Aqualatensia 1983, 3, 185–214. [Google Scholar]

- Lloret Ortínez, T. Els molins paperers de l’Anoia al segle XVIII: Entre el mas i la fàbrica. Misc. Aqualatensia 2006, 12, 143–184. [Google Scholar]

- García Serrano, R. El molino de papel del hospital general de Pamplona. Cuad. Etnol. Etnogr. Navar. 1974, 6, 7–21. [Google Scholar]

- Hidalgo Brinquis, M.C. La Real Fábrica de papel de San Fernando. Rev. R. Sitios 1995, 125, 9–16. [Google Scholar]

- Homar, J. Official Letters Sent by Juan de Homar, Chief Engineer of the Royal Canals, to the Secretary of the Treasury, Don Diego María de Gardoqui; Confederación Hidrográfica del Duero, AGCHD, FACC, AHCC (18th Century, Ref. C-0001-09): Valladolid, Spain, 1792. [Google Scholar]

- Homar, J. Memoria de Edificios, Máquinas, Tierras y Huertas Que Tiene la Real Hacienda en Los Canales de Castilla la Vieja [Report on Buildings, Machinery, Land, and Orchards Owned by the Royal Treasury Along the Canals of Old Castile]; Confederación Hidrográfica del Duero, AGCHD, FACC, AHCC (18th Century, Ref. C-0077-1): Valladolid, Spain, 1800. [Google Scholar]

- Arriete, A.; Mendizábal, A. Valoración de Los Artefactos de la Línea del Canal Pertenecientes al Estado Por Los Señores Peritos, Númº 3º [Assessment of Canal Line Artifacts Belonging to the State by the Expert Surveyors, No. 3]; Confederación Hidrográfica del Duero, AGCHD, FACC, AHCC (19th–20th Century, Ref. C-0034-08): Valladolid, Spain, 1828. [Google Scholar]

- Arriete, A.; Mendizábal, A. Valoración de Los Artefactos de la Línea del Canal Pertenecientes al Estado Por Los Señores Peritos, Númº 3º [Assessment of Canal Line Artifacts Belonging to the State by the Expert Surveyors, No. 3]; Confederación Hidrográfica del Duero, AGCHD, FACC, AHCC (19th–20th Century, Ref. C-0034-08): Valladolid, Spain, 1842. [Google Scholar]

- Ynventario General Que la Empresa Antigua del Canal de Castilla Presenta a la Compañía Anónima del Mismo Para la Toma de Posesiones de Dicho Canal [General Inventory Presented by the Former Canal de Castilla Company to the Joint-Stock Company for the Transfer of Possession of the Canal]; Confederación Hidrográfica del Duero, AGCHD, FACC, AHCC (19th–20th Century, Ref. L-3): Valladolid, Spain, 1851.

- Ynventario General Descriptivo y Valorado de Los Artefactos Que Existen Construidos Sobre el Canal de Castilla [General Descriptive and Valued Inventory of the Artifacts Built Along the Canal de Castilla]; Confederación Hidrográfica del Duero, AGCHD, FACC, AHCC (19th–20th Century, Ref. C-0079-01): Valladolid, Spain, 1906.

- Saiz, F.J. Proyecto de Transformación de la Fábrica de Papel de la 11ª y 12ª Esclusas Para la Elaboración de Harinas [Project for the Conversion of the Paper Mill at the 11th and 12th Locks for Flour Production]; Confederación Hidrográfica del Duero, AGCHD, FACC, PCC (19th–20th Century, Ref. P-551): Valladolid, Spain, 1853. [Google Scholar]

- Planos Generales de Fábricas [General Factory Plans]; Confederación Hidrográfica del Duero, AGCHD, FACC, AHCC (19th–20th Century Plans and Drawings, Ref. 076): Valladolid, Spain, 1863.

- Alonso, L. Fábrica de Papel en las Esclusas 11 y 12 del Ramal del Norte [Paper Mill at Locks 11 and 12 of the Northern Branch]; Confederación Hidrográfica del Duero, AGCHD, FCC, AHCC (19th–20th Century Plans and Drawings, Ref. 147): Valladolid, Spain, 1901. [Google Scholar]

- Fungairiño, E. Proyecto de Obras Para el Aprovechamiento Industrial de Los Saltos de Las Esclusas 11 y 12 del Canal de Castilla [Project for Industrial Use of the Waterfalls at Locks 11 and 12 of the Canal de Castilla]; Confederación Hidrográfica del Duero, AGCHD, FACC, PCC (Ref. C-2176, Pyto-2598): Valladolid, Spain, 1921. [Google Scholar]

- Fungairiño, E. Aprovechamiento Industrial de Los Saltos de Las Esclusas 11 y 12 del Canal de Castilla; Medición General y Datos Para la Liquidación [Industrial Use of the Waterfalls at Locks 11 and 12 of the Canal de Castilla; General Measurement and Data for Settlement]; Confederación Hidrográfica del Duero, AGCHD, FCC, PCC (Ref. C-2153, Pyto-2506): Valladolid, Spain, 1921. [Google Scholar]

- Gaceta de Madrid; Imprenta Real: Madrid, Spain, 1829; p. 104, Nº 26, 28 de febrero de 1829, BOE.es—Documento de Gazeta.

- Gaceta de Madrid; Imprenta Nacional: Madrid, Spain, 1847; p. 4, Nº 4494, 3 de enero de 1847, BOE.es—Documento de Gazeta.

- Madoz, P. Diccionario Geográfico-Estadístico-Histórico de España y sus posesiones de ultramar. In Imprenta del Diccionario Geográfico-Estadístico-Histórico de D; Pascual Madoz: Madrid, Spain, 1849; Tomo XII; p. 257. [Google Scholar]

- Sánchez García, J.L. El Canal de Castilla y la fabricación de papel. In VI Congreso Nacional de Historia del Papel en España: Actas; Conselleria de Cultura, Educació i Esport: Valencia, Spain, 2005; pp. 503–510. [Google Scholar]

- Sáez Hidalgo, I. El Canal de Castilla. In Una Ruta con Mucha Historia, 2nd ed.; Ediciones Desnivel S.L.: Madrid, Spain, 2018. [Google Scholar]

- Guerra Garrido, R. Castilla en Canal, 1st ed.; Ediciones Cálamo: Palencia, Spain, 2016. [Google Scholar]

- Gutiérrez Pérez, E. El Canal. El sueño ilustrado y sus pueblos ribereños. In Navegando por Palencia, Burgos y Valladolid, 2nd ed.; Aruz Ediciones: Palencia, Spain, 2023. [Google Scholar]

- Gastón Guirao, C.; Rovira Llobera, T. El proyecto moderno. In Pautas de investigación, 1st ed.; Universitat Politècnica de Catalunya Ediciones: Barcelona, Spain, 2007. [Google Scholar]

- Kensek, K.M. Colour-coded confidence in reconstruction plans [Conference paper]. In Proceedings of the Acadia Conference 2002, Halifax, NS, Canada, 14–16 June 2002. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geijo-Barrientos, J.M.; Sánchez-Lite, A.; Romero, V.J.; Fuentes-Bargues, J.L. Graphical Reconstruction of the Lost Paper Mill at Locks 11–12 of the Canal de Castilla. Heritage 2025, 8, 231. https://doi.org/10.3390/heritage8060231

Geijo-Barrientos JM, Sánchez-Lite A, Romero VJ, Fuentes-Bargues JL. Graphical Reconstruction of the Lost Paper Mill at Locks 11–12 of the Canal de Castilla. Heritage. 2025; 8(6):231. https://doi.org/10.3390/heritage8060231

Chicago/Turabian StyleGeijo-Barrientos, José M, Alberto Sánchez-Lite, Victor Julio Romero, and Jose Luis Fuentes-Bargues. 2025. "Graphical Reconstruction of the Lost Paper Mill at Locks 11–12 of the Canal de Castilla" Heritage 8, no. 6: 231. https://doi.org/10.3390/heritage8060231

APA StyleGeijo-Barrientos, J. M., Sánchez-Lite, A., Romero, V. J., & Fuentes-Bargues, J. L. (2025). Graphical Reconstruction of the Lost Paper Mill at Locks 11–12 of the Canal de Castilla. Heritage, 8(6), 231. https://doi.org/10.3390/heritage8060231