Life Cycle Impact Assessment (LCIA) of Materials in Painting Conservation: A Pilot Protocol for Evaluating Environmental Impact in Cultural Heritage

Abstract

1. Introduction

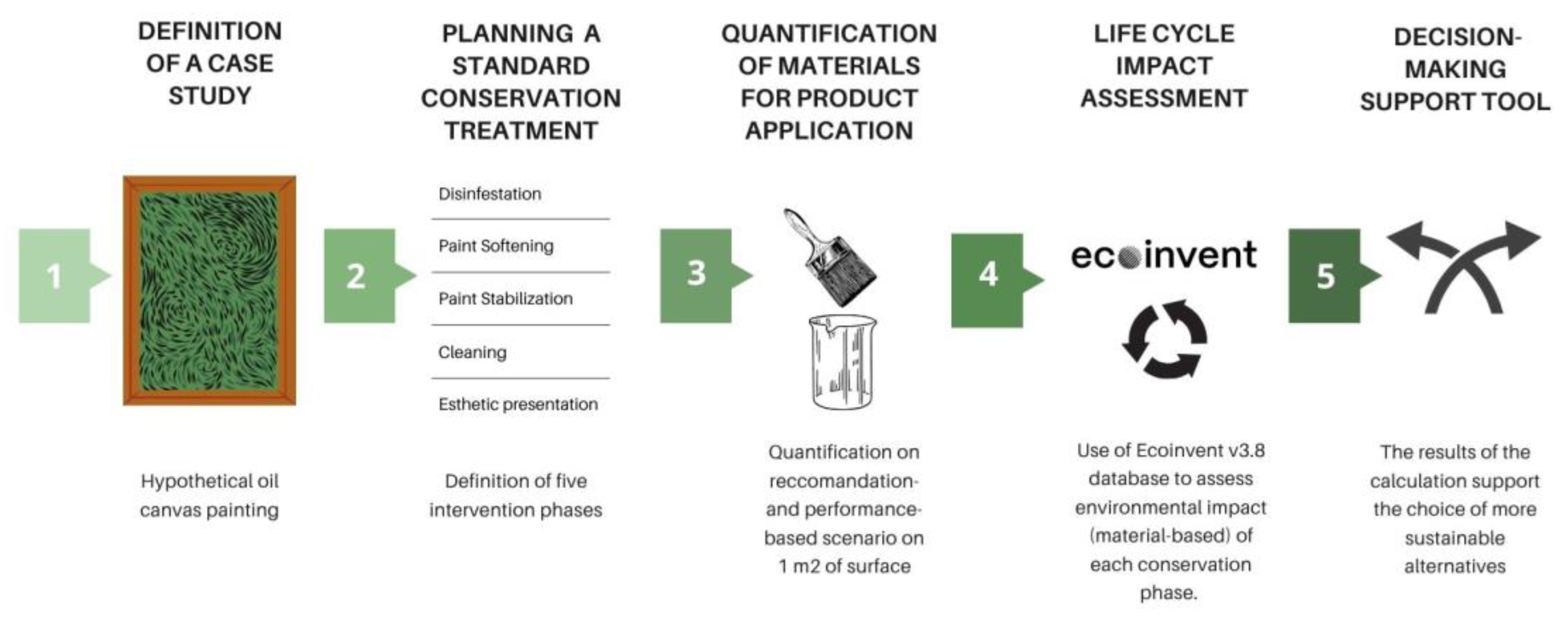

2. Materials and Methods

2.1. Experimental Design

2.2. Life Cycle Inventory Dataset

- Climate Change: Global Warming Potential (GWP100), expressed in kg CO2-equivalent.

- Freshwater Ecotoxicity: Comparative Toxic Unit for Ecosystems (CTUe), based on USEtox v2.0.

- Human Toxicity (Carcinogenic and Non-Carcinogenic): Comparative Toxic Unit for Humans (CTUh), also from USEtox.

- Water Consumption: Deprivation-weighted consumption (m3 world), calculated using the AWARE method.

- Hazardous Waste Generation (Landfilling): Measured in kg of waste, based on disposal and classification data.

2.3. Case Study: A Treatment Hypothesis

2.4. LCIA Calculation

- (a)

- Climate Change was quantified using GWP100, expressed in kg CO2-equivalent, according to IPCC guidelines and implemented in EF v3.0 for compatibility with standard environmental assessments [45].

- (b)

- (c)

- (d)

- Water Consumption was evaluated using the AWARE method, which considers water scarcity and regional availability, expressed in m3 of water deprived (user deprivation potential) [50].

- (e)

- Hazardous Waste Generation was measured in kg of hazardous waste generated, as defined in the LCI models, which include both direct emissions and treatment processes [51].

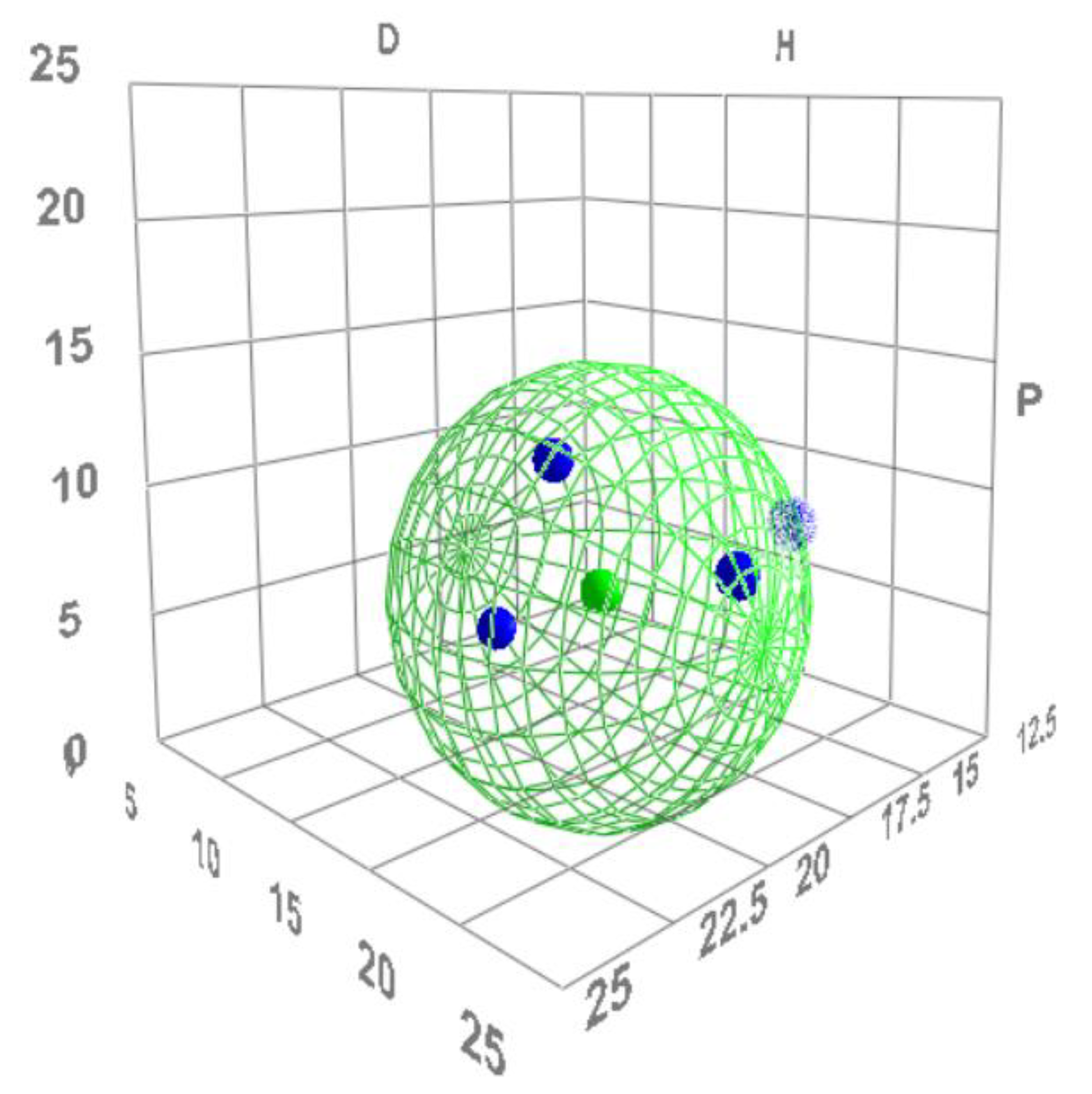

2.5. Methodology Validation

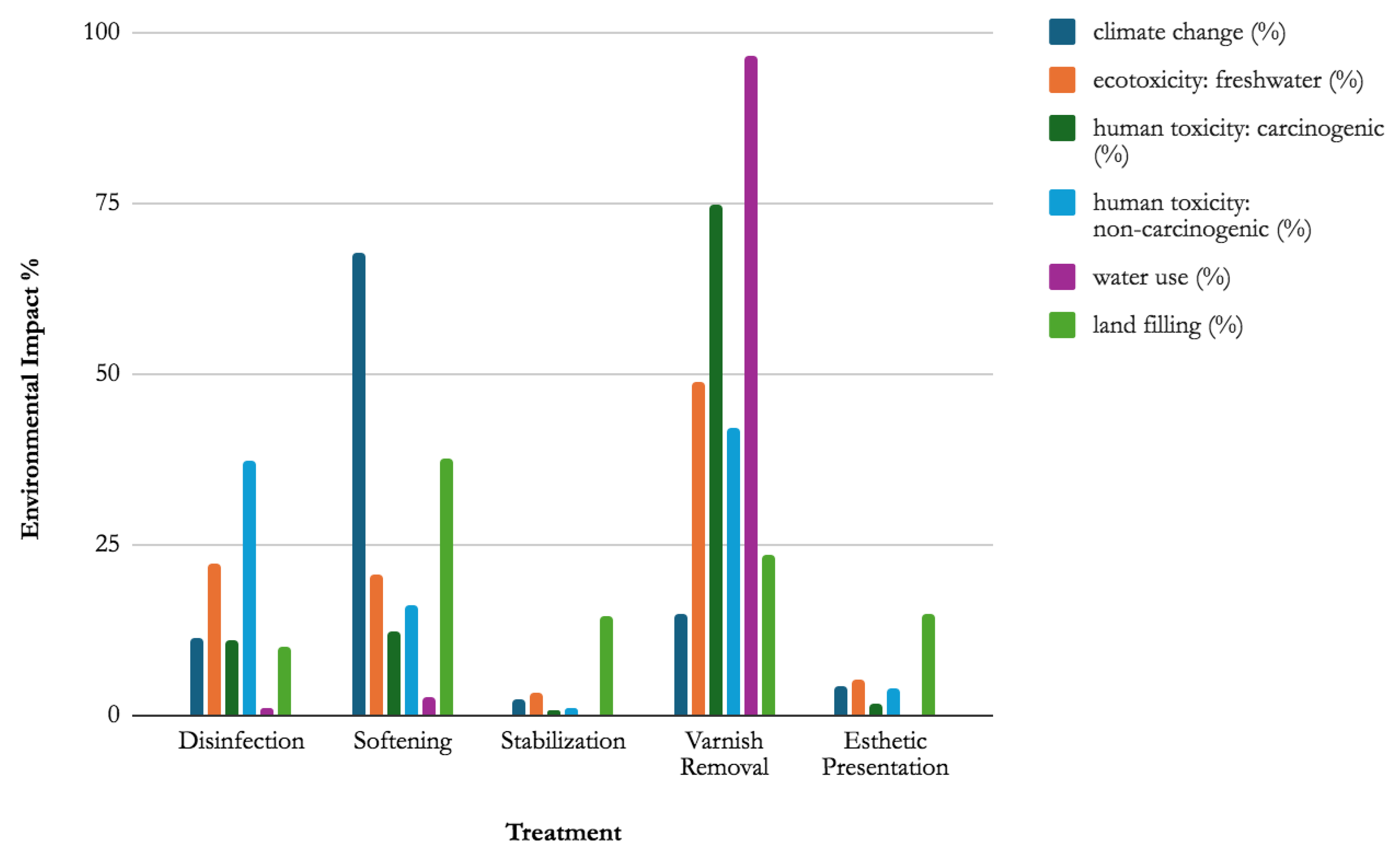

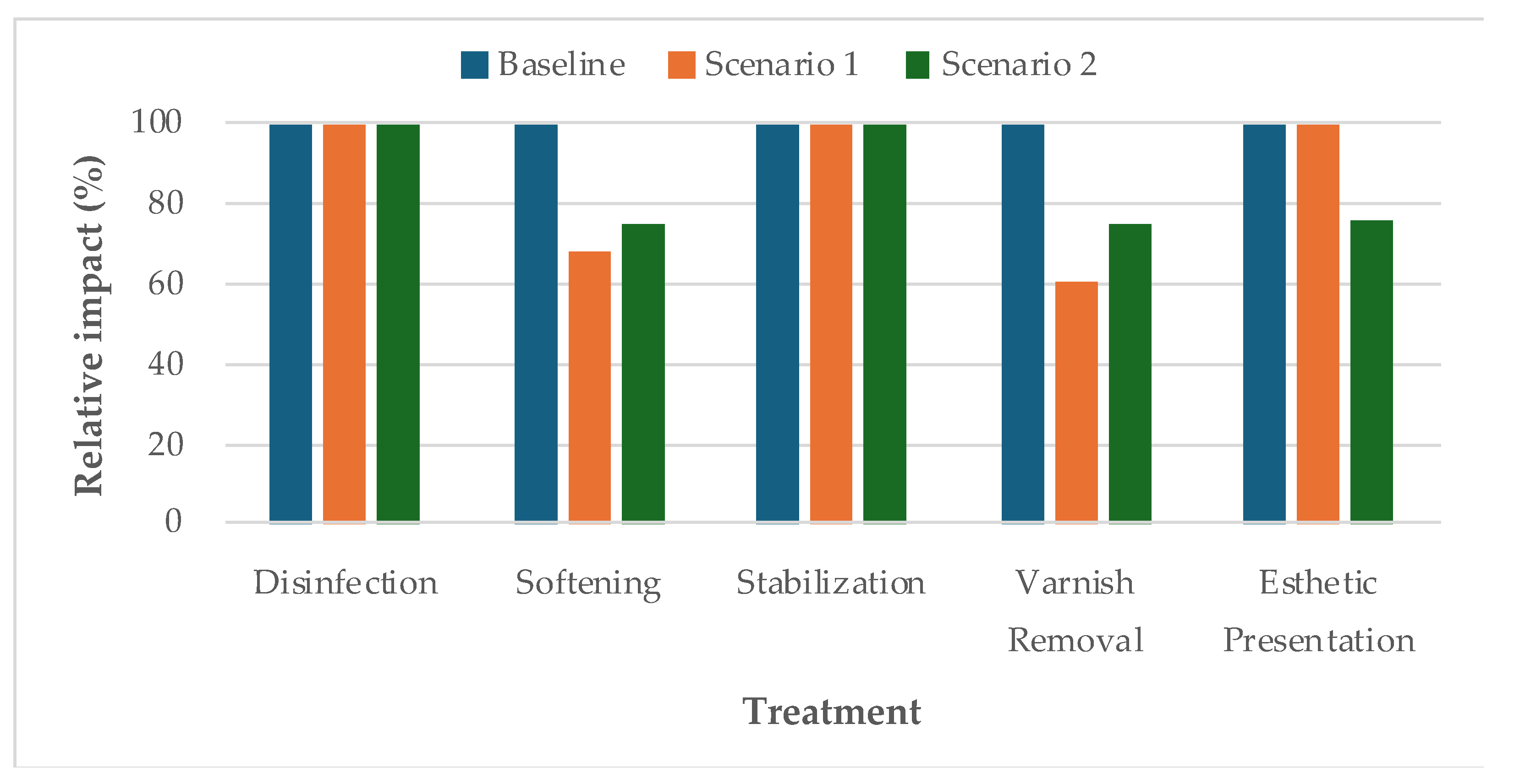

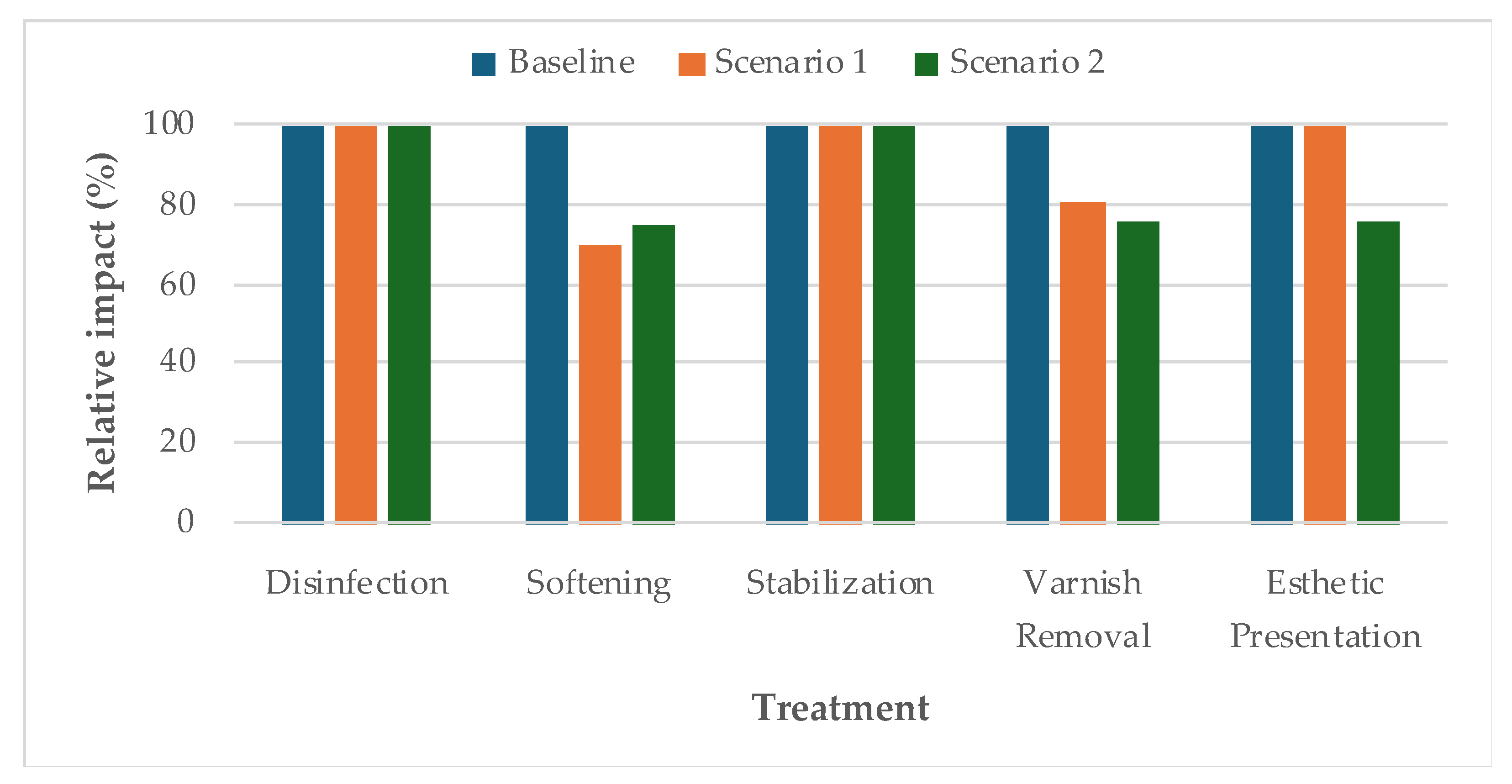

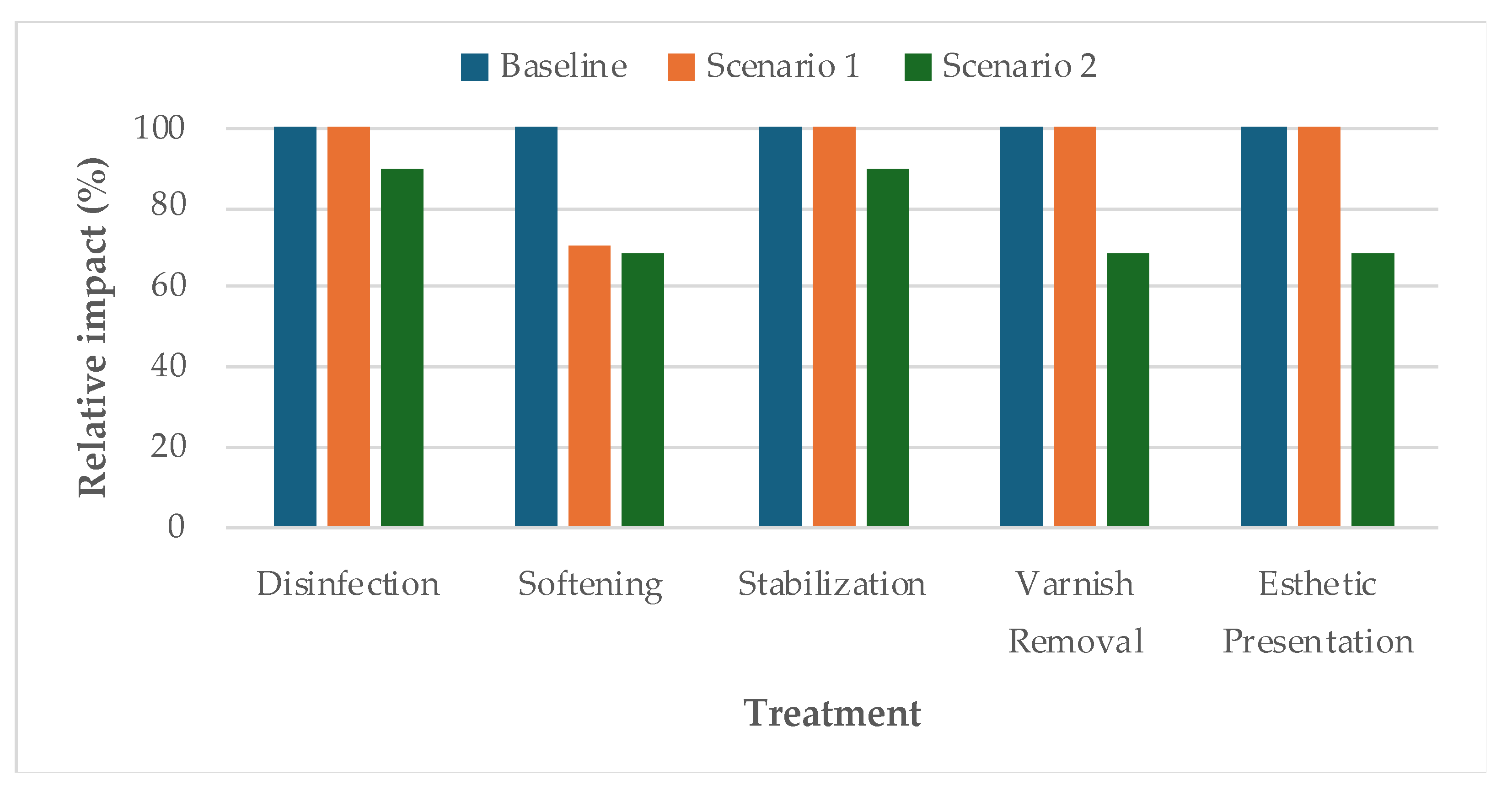

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LCIA | Life Cycle Impact Assessment |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| EF | Environmental Footprint |

| GWP100 | Global Warming Potential |

| CTUe | Comparative Toxic Unit for Ecosystems |

| CTUh | Comparative Toxic Unit for Humans |

| RED | Relative Energy Difference |

| MEK | Methyl Ethyl Ketone |

| FAMEs | fatty acid methyl esters |

| DES | Deep Eutectic Solvents |

| NADES | Natural Deep Eutectic Solvents |

| ILs | Ionic Liquids |

References

- Marzano, M.; Castellini, M. Cultural Heritage and Sustainability: What Is the State of the Art? A Systematic Literature Review. Sinergie Ital. J. Manag. 2024, 42, 61–89. [Google Scholar] [CrossRef]

- Pinheiro, C.; Beaumont, A.; Cardinali, F.; Marra, A.; Molinari, D.; Fife, G.; Wagner, J.; Galacho, C.; Southwick, C. Access to Sustainability in Conservation-Restoration Practices. Sustainability 2024, 16, 7675. [Google Scholar] [CrossRef]

- De Silva, M.; Henderson, J. Sustainability in Conservation Practice. J. Inst. Conserv. 2011, 34, 5–15. [Google Scholar] [CrossRef]

- Chelazzi, D.; Poggi, G.; Baglioni, P. The GREENART Project: Environmentally Friendly and Low Impact Materials for the Conservation of Cultural Heritage. Stud. Conserv. 2024, 69, 25–34. [Google Scholar] [CrossRef]

- Zaratti, C.; Marinelli, L.; Colasanti, I.A.; Barbaccia, F.I.; Aureli, H.; Prestileo, F.; De Caro, T.; La Russa, M.F.; Macchia, A. Evaluation of Fatty Acid Methyl Esters (FAME) as a Green Alternative to Common Solvents in Conservation Treatments. Appl. Sci. 2024, 14, 1970. [Google Scholar] [CrossRef]

- Paolino, B.; Sorrentino, M.C.; Pacifico, S. Greener Solutions for Biodeterioration of Organic-Media Cultural Heritage: Where Are We? Herit. Sci. 2024, 12, 334. [Google Scholar] [CrossRef]

- Macchia, A.; Zaratti, C.; Biribicchi, C.; Colasanti, I.A.; Barbaccia, F.I.; Favero, G. Evaluation of Green Solvents’ Applicability for Chromatic Reintegration of Polychrome Artworks. Heritage 2023, 6, 3353–3364. [Google Scholar] [CrossRef]

- Macchia, A.; Valentini, F.; Colasanti, I.A.; Zaratti, C. Prediction of Green Solvent Applicability in Cultural Heritage Using Hansen Solubility Parameters, Cremonesi Method and Integrated Toxicity Index. Sustainability 2025, 17, 2944. [Google Scholar] [CrossRef]

- Nowak, P.M. What Does It Mean That “Something Is Green”? The Fundamentals of a Unified Greenness Theory. Green. Chem. 2023, 25, 4625–4640. [Google Scholar] [CrossRef]

- Del Curto, D.; Turrina, A. Towards a Reasoned Glossary of Green Conservation: A Semantic Review of Green-Oriented Terms in the Field of Cultural Heritage. Sustainability 2023, 15, 12104. [Google Scholar] [CrossRef]

- Nocca, F. The Role of Cultural Heritage in Sustainable Development: Multidimensional Indicators as Decision-Making Tool. Sustainability 2017, 9, 1882. [Google Scholar] [CrossRef]

- Nunberg, S.; Sanchez, S.A.; Eckelman, M.J. Sustainability Tools in Cultural Heritage: Life Cycle Assessment Examining Crates for Heritage Objects. J. Am. Inst. Conserv. 2025, 64, 17–29. [Google Scholar] [CrossRef]

- Muñoz, I. LCA in Green Chemistry: A New Subject Area and Call for Papers. Int. J. Life Cycle Assess. 2012, 17, 517–519. [Google Scholar] [CrossRef]

- Curran, M.A. Life Cycle Assessment: A Review of the Methodology and Its Application to Sustainability. Curr. Opin. Chem. Eng. 2013, 2, 273–277. [Google Scholar] [CrossRef]

- Jourdaine, M.; Loubet, P.; Sonnemann, G.; Trébucq, S. The ABC-LCA Method for the Integration of Activity-based Costing and Life Cycle Assessment. Bus. Strat. Environ. 2021, 30, 1735–1750. [Google Scholar] [CrossRef]

- Birat, J.-P. MFA vs. LCA, Particularly as Environment Management Methods in Industry: An Opinion. Matériaux Tech. 2020, 108, 503. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. Life Cycle Assessment of Construction Materials: Methodologies, Applications and Future Directions for Sustainable Decision-Making. Case Stud. Constr. Mater. 2023, 19, e02326. [Google Scholar] [CrossRef]

- Herrero, C.C.; Laso, J.; Cristóbal, J.; Fullana-i-Palmer, P.; Albertí, J.; Fullana, M.; Herrero, Á.; Margallo, M.; Aldaco, R. Tourism under a Life Cycle Thinking Approach: A Review of Perspectives and New Challenges for the Tourism Sector in the Last Decades. Sci. Total Environ. 2022, 845, 157261. [Google Scholar] [CrossRef]

- Campos, C.; Gallego, M.; Villanueva, P.; Laso, J.; Dias, A.C.; Quinteiro, P.; Oliveira, S.; Albertí, J.; Fullana-i-Palmer, P.; Mélon, L.; et al. Life Cycle Assessment to Address the Environmental Impacts of Tourism in a Spanish Tourist Destination: The Case of Rias Baixas (Galicia) Holidays. Sci. Total Environ. 2023, 896, 166242. [Google Scholar] [CrossRef]

- Settembre Blundo, D.; Ferrari, A.M.; Pini, M.; Riccardi, M.P.; García, J.F.; Fernández Del Hoyo, A.P. The Life Cycle Approach as an Innovative Methodology for the Recovery and Restoration of Cultural Heritage. J. Cult. Herit. Manag. Sustain. Dev. 2014, 4, 133–148. [Google Scholar] [CrossRef]

- Blundo, D.S.; Ferrari, A.M.; del Hoyo, A.F.; Riccardi, M.P.; Muiña, F.E.G. Improving Sustainable Cultural Heritage Restoration Work through Life Cycle Assessment Based Model. J. Cult. Herit. 2018, 32, 221–231. [Google Scholar] [CrossRef]

- Gravagnuolo, A.; Angrisano, M.; Nativo, M. Evaluation of Environmental Impacts of Historic Buildings Conservation through Life Cycle Assessment in a Circular Economy Perspective. Aestimum 2020, 241–272. [Google Scholar] [CrossRef]

- Serrano, T.; Kampmann, T.; Ryberg, M.W. Comparative Life-Cycle Assessment of Restoration and Renovation of a Traditional Danish Farmer House. Build. Environ. 2022, 219, 109174. [Google Scholar] [CrossRef]

- Foster, G. Circular Economy Strategies for Adaptive Reuse of Cultural Heritage Buildings to Reduce Environmental Impacts. Resour. Conserv. Recycl. 2020, 152, 104507. [Google Scholar] [CrossRef]

- Mohaddes Khorassani, S.; Ferrari, A.M.; Pini, M.; Settembre Blundo, D.; García Muiña, F.E.; García, J.F. Environmental and Social Impact Assessment of Cultural Heritage Restoration and Its Application to the Uncastillo Fortress. Int. J. Life Cycle Assess. 2019, 24, 1297–1318. [Google Scholar] [CrossRef]

- Sabzi, J.; Esfahani, M.R.; Ozbakkaloglu, T.; Gholampour, A.; Masoodi, A.R. Rehabilitation of Reinforced Concrete Beam: Sustainable Restoration Mortar with Waste Materials. Case Stud. Constr. Mater. 2024, 20, e02827. [Google Scholar] [CrossRef]

- Ferrari, A.; Pini, M.; Neri, P.; Bondioli, F. Nano-TiO2 Coatings for Limestone: Which Sustainability for Cultural Heritage? Coatings 2015, 5, 232–245. [Google Scholar] [CrossRef]

- Pozzo, A.D.; Masi, G.; Sassoni, E.; Tugnoli, A. Life Cycle Assessment of Stone Consolidants for Conservation of Cultural Heritage. Build. Environ. 2024, 249, 111153. [Google Scholar] [CrossRef]

- Opher, T.; Duhamel, M.; Posen, I.D.; Panesar, D.K.; Brugmann, R.; Roy, A.; Zizzo, R.; Sequeira, L.; Anvari, A.; MacLean, H.L. Life Cycle GHG Assessment of a Building Restoration: Case Study of a Heritage Industrial Building in Toronto, Canada. J. Clean. Prod. 2021, 279, 123819. [Google Scholar] [CrossRef]

- Tate-Harte, A.; Thickett, D. Calculating the Carbon Footprint of Interventive and Preventive Conservation at English Heritage, UK. Stud. Conserv. 2024, 69, 323–332. [Google Scholar] [CrossRef]

- UNI 11897:2023; Conservazione del Patrimonio Culturale—Linee Guida per L’applicazione dei Criteri Generali di Qualità Negli Interventi di Conservazione e Restauro dei Beni Culturali. Ente Italiano di Normazione (UNI): Via Sannio, Italy, 2023.

- Elnaggar, A. Nine Principles of Green Heritage Science: Life Cycle Assessment as a Tool Enabling Green Transformation. Herit. Sci. 2024, 12, 7. [Google Scholar] [CrossRef]

- ISO 14040:2006/Amd 1:2020; Environmental Management-Life Cycle Assessment-Principles and Framework. ISO: Geneva, Switzerland, 2020.

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The New International Standards for Life Cycle Assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organisation for Standardisation (ISO): Geneva, Switzerland, 2006.

- Pranjić, A.M.; Ranogajec, J.; Škrlep, L.; Škapin, A.S.; Vučetić, S.; Rebec, K.M.; Turk, J. Life Cycle Assessment of Novel Consolidants and a Photocatalytic Suspension for the Conservation of the Immovable Cultural Heritage. J. Clean. Prod. 2018, 181, 293–308. [Google Scholar] [CrossRef]

- Turk, J.; Pranjić, A.M.; Tomasin, P.; Škrlep, L.; Antelo, J.; Favaro, M.; Škapin, A.S.; Bernardi, A.; Ranogajec, J.; Chiurato, M. Environmental Performance of Three Innovative Calcium Carbonate-Based Consolidants Used in the Field of Built Cultural Heritage. Int. J. Life Cycle Assess. 2017, 22, 1329–1338. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Hawileh, R.A.; Bahurudeen, A.; Jyothsna, G.; Sofi, A.; Shanmugam, V.; Thomas, B.S. A Comprehensive Review on the Use of Natural Fibers in Cement/Geopolymer Concrete: A Step towards Sustainability. Case Stud. Constr. Mater. 2023, 19, e02244. [Google Scholar] [CrossRef]

- Cappitelli, F.; Cattò, C.; Villa, F. The Control of Cultural Heritage Microbial Deterioration. Microorganisms 2020, 8, 1542. [Google Scholar] [CrossRef] [PubMed]

- Michalski, S.W. A Physical Model of the Consolidation Process, Particularly of Paintings (with Errata). In Proceedings of the Scientific Methods to Evaluate Their Effectiveness: Proceedings of the CESMAR7 Conference, Milan, Italy, 10–11 November 2006; Il Prato: Milan, Italy, 2008; pp. 23–47. [Google Scholar]

- Bridarolli, A.; Nualart-Torroja, A.; Chevalier, A.; Odlyha, M.; Bozec, L. Systematic Mechanical Assessment of Consolidants for Canvas Reinforcement under Controlled Environment. Herit. Sci. 2020, 8, 52. [Google Scholar] [CrossRef]

- Ploeger, R.; McGlinchey, C.W.; De La Rie, E.R. Original and Reformulated BEVA® 371: Composition and Assessment as a Consolidant for Painted Surfaces. Stud. Conserv. 2015, 60, 217–226. [Google Scholar] [CrossRef]

- Cremonesi, P.; Signorini, E. Un Approccio Alla Pulitura dei Dipinti Mobili; I talenti; II Prato: Padova, Italy, 2012; ISBN 978-88-6336-191. [Google Scholar]

- Cremonesi, P. L’uso dei Solventi Organici Nella Pulitura di Opere Policrome; I talenti; II Prato: Padova, Italy, 2004. [Google Scholar]

- Fazio, S.; Biganzioli, F.; Sala, S.; Zampori, L.; Diaconu, E.; De Laurentiis, V.; European Commission (Eds.) Supporting Information to the Characterisation Factors of Recommended EF Life Cycle Impact Assessment Methods: Version 2, from ILCD to EF 3.0; Publications Office: Luxembourg, 2018; ISBN 978-92-79-98584-3. [Google Scholar]

- Jimenez-Gonzalez, C. Life Cycle Considerations of Solvents. Curr. Opin. Green. Sustain. Chem. 2019, 18, 66–71. [Google Scholar] [CrossRef]

- Shibin, K.T.; Gunasekaran, A.; Papadopoulos, T.; Dubey, R.; Mishra, D. Sustainable Consumption and Production: Need, Challenges and Further Research Directions. Int. J. Process Manag. Benchmarking 2016, 6, 447. [Google Scholar] [CrossRef]

- Egemose, C.W.; Bastien, D.; Fretté, X.; Birkved, M.; Sohn, J.L. Human Toxicological Impacts in Life Cycle Assessment of Circular Economy of the Built Environment: A Case Study of Denmark. Buildings 2022, 12, 130. [Google Scholar] [CrossRef]

- Fantke, P.; Huijbregts, M.; van de Meent, D.; Margni, M.; Jolliet, O.; Rosenbaum, R.K.; McKone, T.E.; Hauschild, M. USEtox 2.0 Manual–UNEP/SETAC; USEtox® Team: Copenhagen, Denmark, 2017. [Google Scholar]

- Boulay, A.-M.; Motoshita, M.; Pfister, S.; Bulle, C.; Muñoz, I.; Franceschini, H.; Margni, M. Analysis of Water Use Impact Assessment Methods (Part A): Evaluation of Modeling Choices Based on a Quantitative Comparison of Scarcity and Human Health Indicators. Int. J. Life Cycle Assess. 2015, 20, 139–160. [Google Scholar] [CrossRef]

- Czekała, W.; Drozdowski, J.; Łabiak, P. Modern Technologies for Waste Management: A Review. Appl. Sci. 2023, 13, 8847. [Google Scholar] [CrossRef]

- Silberman, J.; Taylor, A. Carbamate Toxicity. In StatPearls; StatPearls Publishing: Treasure Island, FL, USA, 2024. [Google Scholar]

- Nasrabadi, M.; Nazarian, M.; Darroudi, M.; Marouzi, S.; Harifi-Mood, M.S.; Samarghandian, S.; Farkhondeh, T. Carbamate Compounds Induced Toxic Effects by Affecting Nrf2 Signaling Pathways. Toxicol. Rep. 2024, 12, 148–157. [Google Scholar] [CrossRef]

- Melchiorre, M.; Melchiorre, C.; Moracci, M.; Somma, P.I.; Markiewicz, M.; Stolte, S.; Cerruti, P.; Ruffo, F.; Carpentieri, A. Lactic Acid-Based Compounds as Green Alternative Solvents for Cultural Heritage: Application on Canvas Painting Restoration. J. Cult. Herit. 2025, 73, 206–214. [Google Scholar] [CrossRef]

- Pacheco, M.F.; Pereira, A.I.; Branco, L.C.; Parola, A.J. Varnish Removal from Paintings Using Ionic Liquids. J. Mater. Chem. A 2013, 1, 7016. [Google Scholar] [CrossRef]

- Melchiorre, C.; Melchiorre, M.; Marra, M.; Rizzo, E.; Fatigati, G.; Rossi, P.; Cerruti, P.; Improta, I.; Amoresano, A.; Marino, G.; et al. Green Solvents and Restoration: Application of Biomass-Derived Solvents in Cleaning Procedures. J. Cult. Herit. 2023, 62, 3–12. [Google Scholar] [CrossRef]

- Cremonesi, P. L’ambiente Acquoso per Il Trattamento di Manufatti Artistici; II Prato: Padova, Italy, 2019. [Google Scholar]

| Intervention Phase | Treatment | Product | Application Method | Quantity (L/kg) |

|---|---|---|---|---|

| Disinfection | Anti-fungal biocidal treatment | Thio-carbamates-based product | The product is applied on the back of the painting by brush | 0.3 L/0.3 kg |

| Consolidation | Softening of the support and pictorial layers | Methyl Ethyl Ketone (MEK) | Exposure to solvent vapor. The cotton wool is soaked in MEK and placed inside a PET container, positioned close to the painting, and the chamber is sealed to promote the softening of artwork materials | 10 L/8 kg |

| Stabilization: Re-adherence of detached paint layers and strengthening of the canvas support | Ethylene vinyl acetate copolymer in White Spirit 10% v/v | The product is applied locally to the front of the painting to reattach paint layer flakes and to the back of the canvas with a brush | EVA: 0.08 L/0.07 kg White Spirit: 0.72 L/0.58 kg | |

| Cleaning | Varnish removal | White Spirit and Ethanol mixture (6:4) | The varnish removal is carried out after solubilization tests by cotton swab | Ethanol: 0.32 L/0.12 kg White Spirit: 0.48 L/0.5 kg |

| Esthetic presentation | Infilling | Retouching using acrylic varnish, isopropyl alcohol, and pigment. Acrylic varnish in White Spirit as final protective layer (20% v/v) | Calcium sulfate-based stucco and retouching with a mixture of diluted acrylic paint in isopropyl alcohol and powdered pigments, followed by a final coating with acrylic varnish and White Spirit. | Acrylic Varnish: 0.16 L/0.19 kg White Spirit: 0.64 L/0.51 kg isopropyl alcohol: 0.06 L/0.04 kg |

| Retouching | ||||

| Final varnishing |

| Solvent | δD (Dispersion) | δP (Polarity) | δH (Hydrogen Bonding) |

|---|---|---|---|

| White Spirit | 15.8 | 0.1 | 0.2 |

| 2-Propanol (Isopropyl alcohol) | 15.8 | 6.1 | 16.4 |

| Methyl Ethyl Ketone (MEK) | 16.0 | 9.0 | 5.1 |

| Ethanol | 15.8 | 8.8 | 19.4 |

| White Spirit/Ethanol (6:4) | 15.8 | 3.58 | 7.88 |

| Treatment | Composition | Volume/ Weight (Kg/L) | Reference Unit (kg) | Global Warming Potential (GWP100) kg CO2-Eq | Comparative Toxic Unit for Ecosystems (CTUe) | Comparative Toxic Unit for Human (CTUh) | Comparative Toxic Unit for Human (CTUh) | User Deprivation Potential (Deprivation-Weighted Water Consumption) m3 | Hazardous Waste kg |

|---|---|---|---|---|---|---|---|---|---|

| Disinfection | [Thio]carbamate- compound | 0.77 kg/L | Market Impact of 0.23 kg | 2.4043867 | 130.53512 | 3.42 × 10−9 | 2.25 × 10−7 | 2.73012484 | 3.84 × 10−5 |

| Softening | Methyl ethyl ketone | 0.80 kg/L | Production Impact of 8 kg | 14.5234864 | 120.413832 | 3.84 × 10−9 | 9.63 × 10−8 | 8.4615296 | 1.46 × 10−4 |

| Stabilization | Ethylene vinyl acetate copolymer | 0.94 kg/L | Market Impact of 0.07 kg | 0.1644955 | 1.555401375 | 4.83 × 10−11 | 1.44 × 10−9 | 0.11532021 | 1.19 × 10−6 |

| White Spirit | 0.80 kg/L | Market Impact of 0.58 kg | 0.3136060 | 17.10590868 | 1.75 × 10−10 | 5.11× 10−9 | 0.0494005691 | 5.56 × 10−5 | |

| Tot | 0.4781015 | 18.66131006 | 2.24 × 10−10 | 6.56 × 10−9 | 0.1647207791 | 5.68 × 10−5 | |||

| Varnish Removal | Ethanol, without water, in 99.7% solution state, from fermentation | 0.78 kg/L | Market Impact of 0.32 kg | −0.4964941 | 79.5505888 | 2.50 × 10−9 | 7.16 × 10−8 | 2.02816592 | 7.26 × 10−6 |

| White Spirit | 0.80 kg/L | Market Impact of 0.48 kg | 0.2595360 | 14.15661408 | 1.45 × 10−10 | 4.23 × 10−9 | 0.0408832296 | 4.61 × 10−5 | |

| Cottonseed and cotton fibre production | Market Impact of 0.5 kg | 3.4062356 | 193.1773609 | 2.08 × 10−8 | 1.78 × 10−7 | 326.8067266 | 3.79 × 10−5 | ||

| Tot | 3.1692774 | 286.8845637 | 2.35 × 10−8 | 2.54 × 10−7 | 328.8757757 | 9.13 × 10−5 | |||

| Esthetic Presentation | White Spirit | 0.80 kg/L | Market Impact of 0.51 kg | 0.2757570 | 15.04140246 | 1.54 × 10−10 | 4.49 × 10−9 | 0.04343843145 | 4.89 × 10−5 |

| Isopropanol | 0.78 kg/L | Market Impact of 0.04 kg | 0.0813205 | 0.50914308 | 2.13 × 10−11 | 5.05 × 10−10 | 0.0259783324 | 6.56 × 10−7 | |

| Acrylic varnish production, product in 87.5% solution state | 1.18 kg/L | Market Impact of 0.19 kg | 0.5124259 | 15.3696554 | 0.0000000 | 0.0000000 | 0.3007678 | 0.0000083 | |

| Tot | 0.8695034 | 30.9202009 | 0.0000000 | 0.0000000 | 0.3701846 | 0.0000579 | |||

| TOT | 21.4447554 | 587.4150267 | 3.15 × 10−8 | 6.05 × 10−7 | 340.6023355 | 3.90 × 10−4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paolino, B.; Prestileo, F.; Carnazza, P.; Sacco, F.; Strozzi, A.; Congeduti, A.; Macchia, A. Life Cycle Impact Assessment (LCIA) of Materials in Painting Conservation: A Pilot Protocol for Evaluating Environmental Impact in Cultural Heritage. Heritage 2025, 8, 212. https://doi.org/10.3390/heritage8060212

Paolino B, Prestileo F, Carnazza P, Sacco F, Strozzi A, Congeduti A, Macchia A. Life Cycle Impact Assessment (LCIA) of Materials in Painting Conservation: A Pilot Protocol for Evaluating Environmental Impact in Cultural Heritage. Heritage. 2025; 8(6):212. https://doi.org/10.3390/heritage8060212

Chicago/Turabian StylePaolino, Benedetta, Fernanda Prestileo, Paola Carnazza, Federica Sacco, Alessia Strozzi, Alberta Congeduti, and Andrea Macchia. 2025. "Life Cycle Impact Assessment (LCIA) of Materials in Painting Conservation: A Pilot Protocol for Evaluating Environmental Impact in Cultural Heritage" Heritage 8, no. 6: 212. https://doi.org/10.3390/heritage8060212

APA StylePaolino, B., Prestileo, F., Carnazza, P., Sacco, F., Strozzi, A., Congeduti, A., & Macchia, A. (2025). Life Cycle Impact Assessment (LCIA) of Materials in Painting Conservation: A Pilot Protocol for Evaluating Environmental Impact in Cultural Heritage. Heritage, 8(6), 212. https://doi.org/10.3390/heritage8060212