Likely Technology Making the Ancient Cham Bricks Lightweight, Carvable, and Durable for Constructing Big Engraved Towers Lasting Thousands of Years: A Case Study of the Po Nagar Towers, Nhatrang, Vietnam

Abstract

1. Introduction

2. Experimental

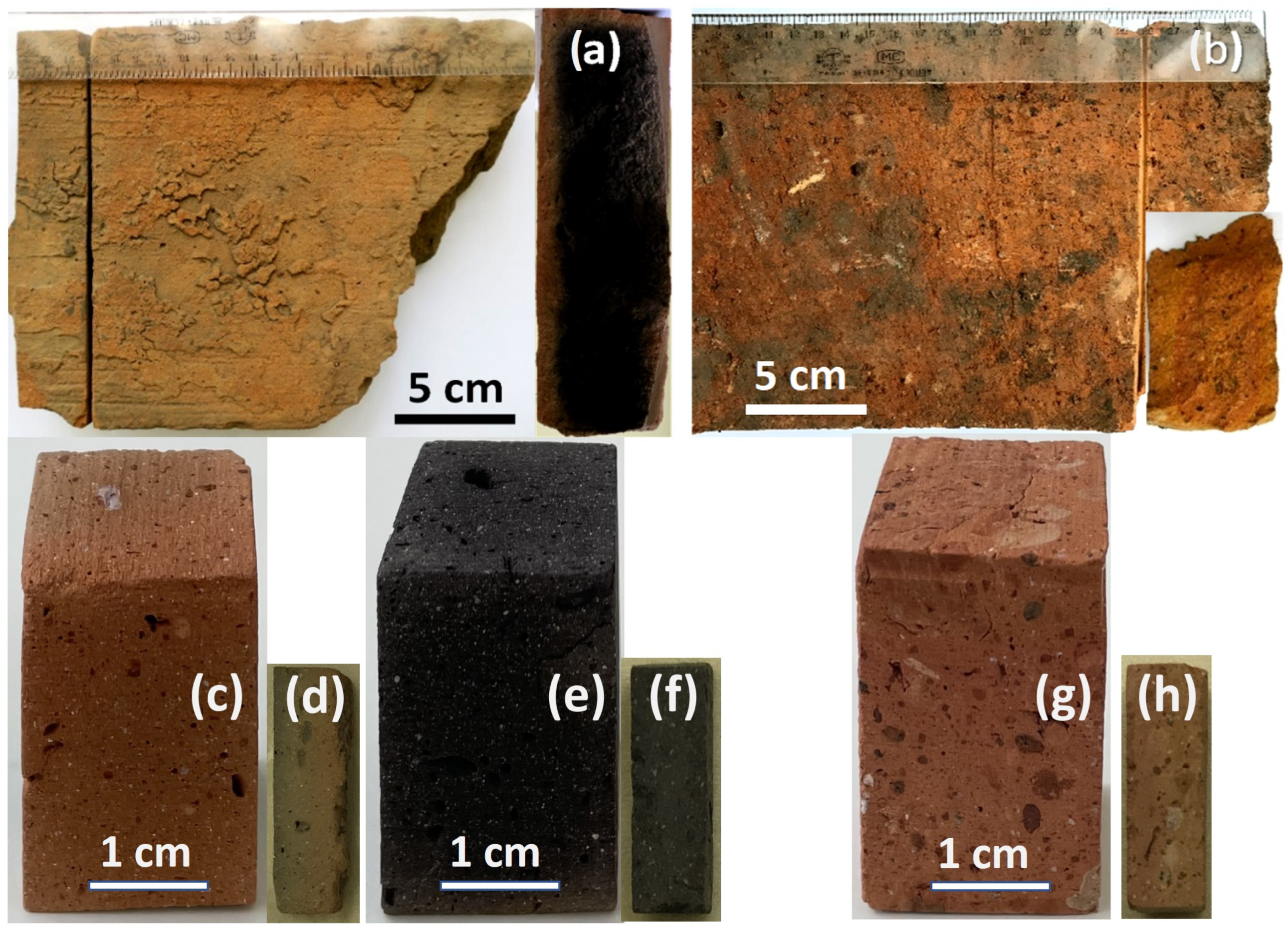

2.1. Bricks and Samples

2.2. Characterization Techniques

3. Results

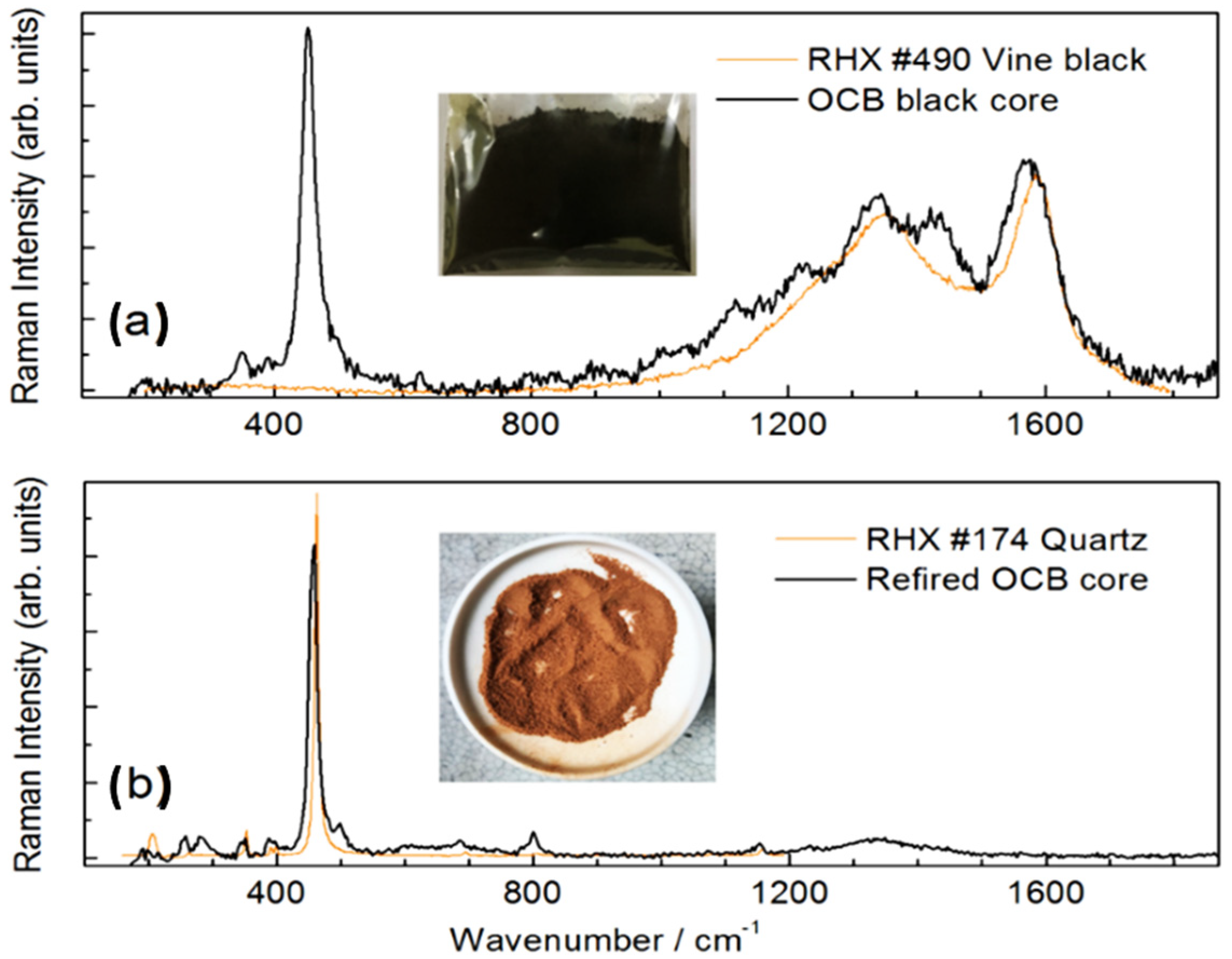

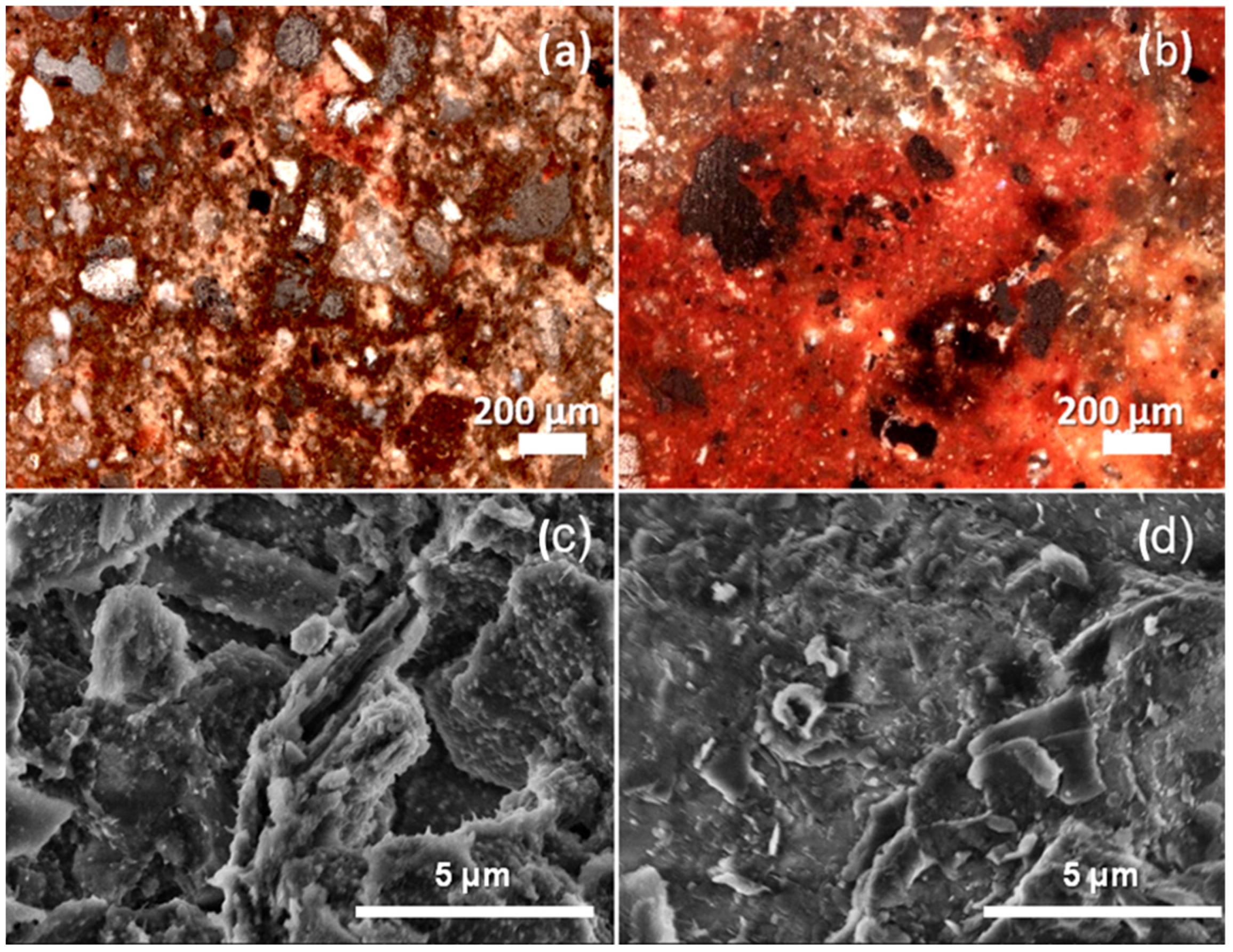

3.1. Black Core of OCB and Morphology

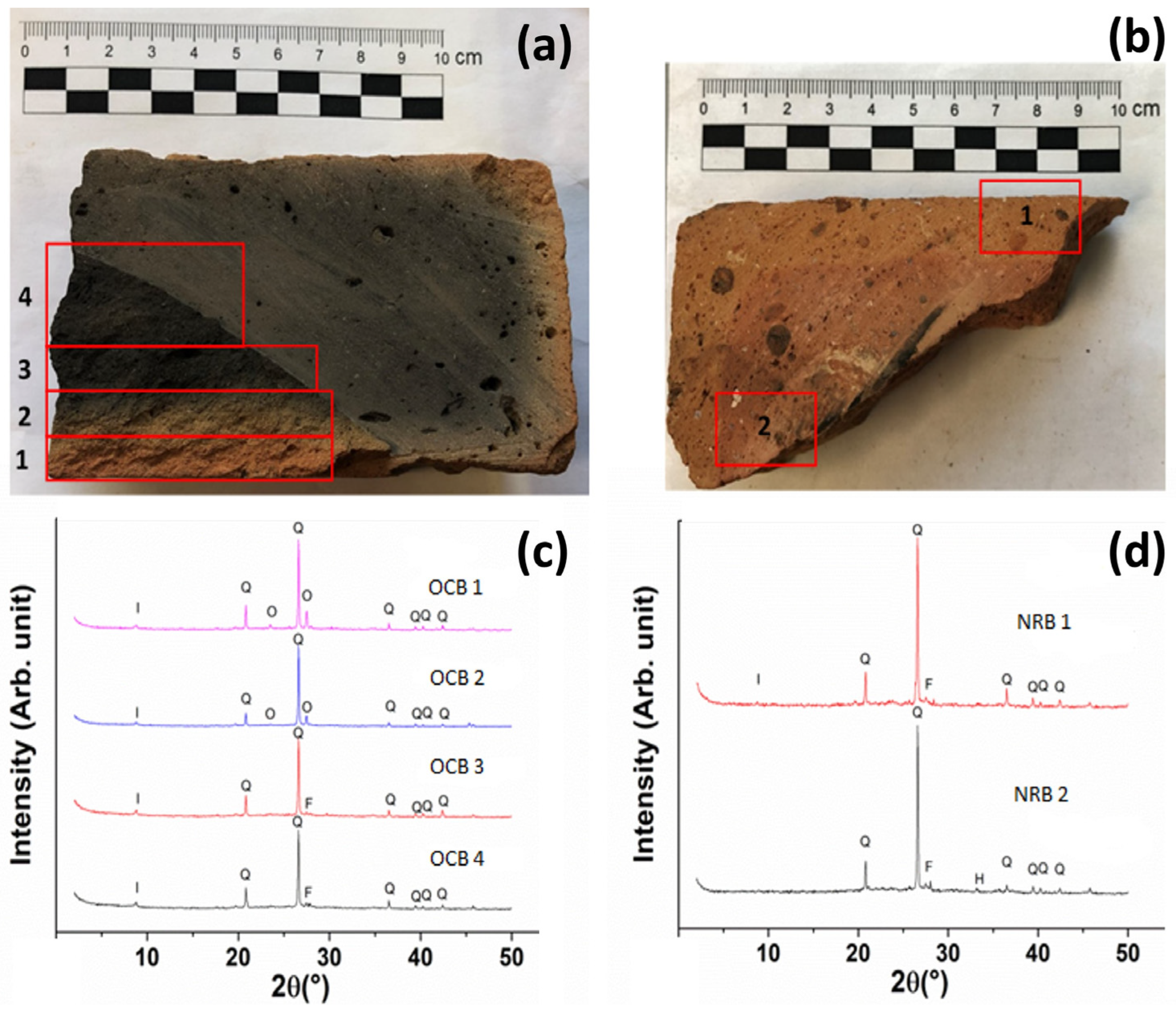

3.2. Compositions and Structural Phases

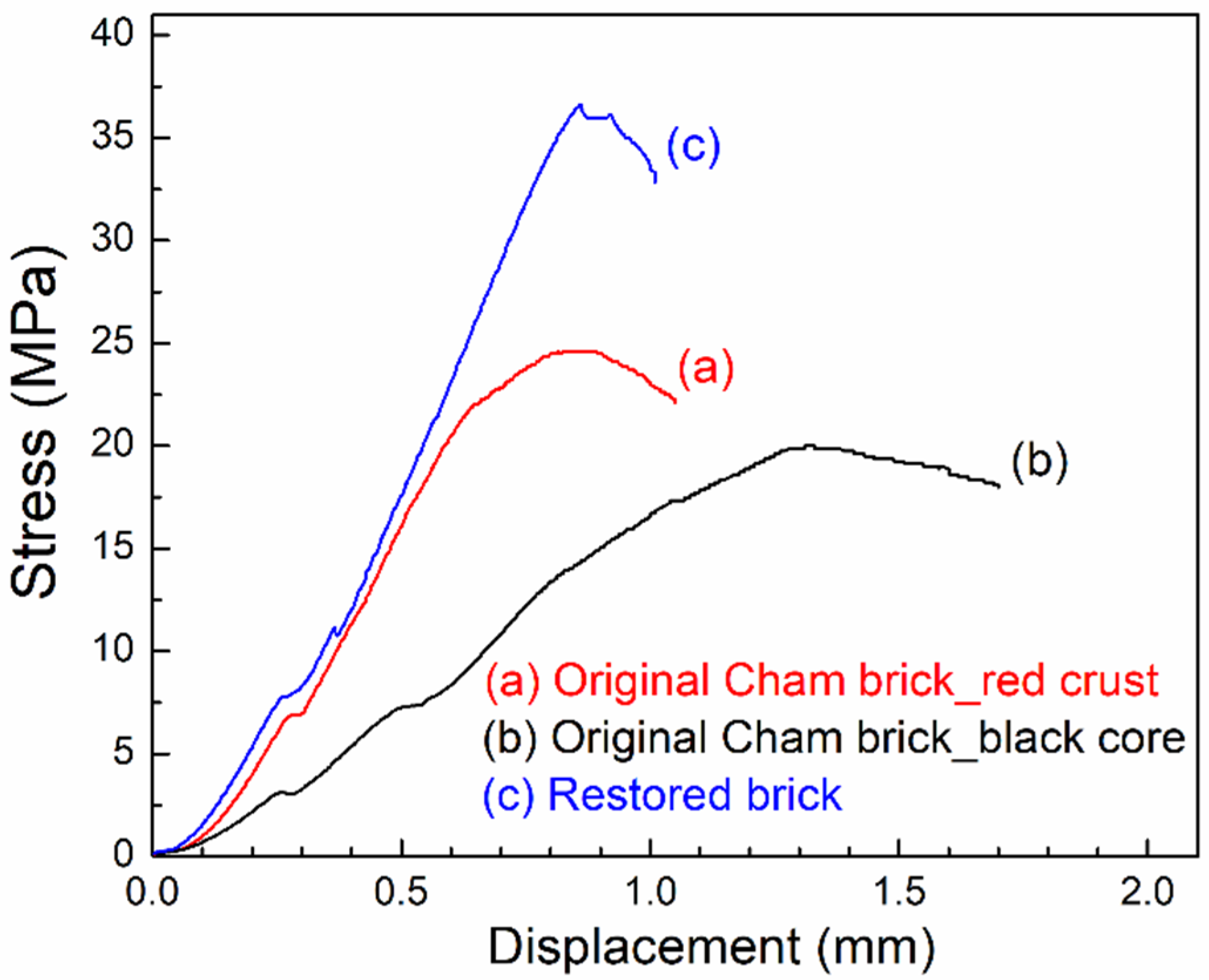

3.3. Open Porosity, the Rate of Water Sorption, Mechanical and Physical Properties

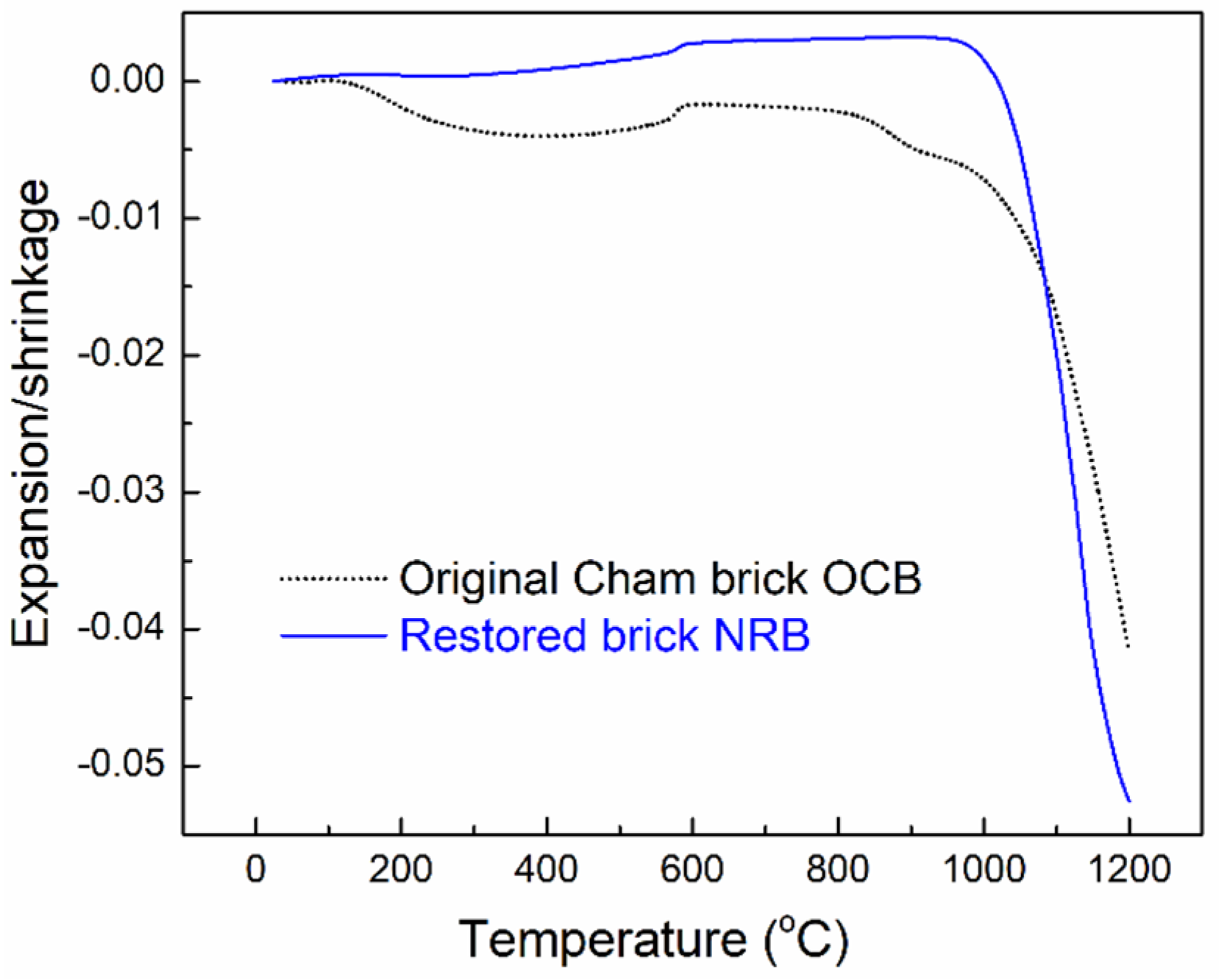

3.4. Firing Process

4. Discussion: Likely Technology for Making Original Cham Bricks

- (1)

- The raw materials were locally mined clay and sand and charcoal powder derived from rice husks or straws. All starting materials must be ground fairly fine and well mixed together. The charcoal/clay ratio could be 10–15 wt% for making OCBs that have light mass densities ranging 1.3–1.6 kg/dm3 and high open porosities.

- (2)

- The moderate firing temperature of bricks was between 800 °C and below 1000 °C, with a relatively long duration cycle to provide the conditions for efficient solid-state reaction, to ensure that the brick had adequate strength and open porosity.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dung, N.T.K.; Huong, P.L. The Phung Nguyen culture. In Khao Co Hoc Viet Nam (Viet Nam Archaeology, in Vietnamese); Tan, H.V., Ed.; The Social Publisher: Hanoi, Vietnam, 1999; Volume II, pp. 11–63. [Google Scholar]

- Young, C.M.; Dupoizat, M.F.; Lane, E.W. (Eds.) Vietnamese Ceramic; Southeast Asian Ceramic Society/Oxford University Press: Oxford, UK, 1982. [Google Scholar]

- Phan, H.L. Vietnam Social Sciences 2017. Volume 1, pp. 33–82. Available online: https://www.researchgate.net/publication/379630909_Likely_technology_to_make_the_ancient_Cham_bricks_lightweight_sculptable_and_durable_for_constructing_big_engraved_towers_lasting_thousands_of_years_the_Po_Nagar_Towers_Thap_Ba_Nhatrang_Vietnam/fulltext/66115ccc2034097c54f9e1a4/Likely-technology-to-make-the-ancient-Cham-bricks-lightweight-sculptable-and-durable-for-constructing-big-engraved-towers-lasting-thousands-of-years-the-Po-Nagar-Towers-Thap-Ba-Nhatrang-Vietnam.pdf (accessed on 6 February 2025).

- Ha, N.T.T.; Noppe, C. La culture de Dông Son. In Arts du Viet Nam; Noppe, C., Hubert, J.F., Eds.; La Renaissance Livre: Brussel, Belgium, 2002; pp. 17–37. [Google Scholar]

- Hong, N.S. Relics of the pre-Sa Huynh culture. In Khao Co Hoc Viet Nam (Viet Nam Archaeology, in Vietnamese); Tan, H.V., Ed.; The Social Publisher: Hanoi, Vietnam, 1999; Volume II, pp. 11–336. [Google Scholar]

- Colomban, P.; Doan, N.K.; Nguyen, Q.L.; Roche, C.; Sagon, G. Sa Huynh and Cham potteries: Microstructure and likely processing. J. Cult. Herit. 2004, 5, 149–155. [Google Scholar] [CrossRef]

- Stern, P. L’art du Champa (Ancien Annam) et Son Évolution; Adrien-Maisonneuve: Paris, France, 1942. [Google Scholar]

- Tran, K.P. Chapter 14—The preservation and management of the monuments of Champa in central Vietnam: The example of My Son sanctuary, a World Cultural Heritage site. In Rethinking Cultural Resource Management in Southeast Asia: Preservation, Development, and Neglect; Miksic, J.N., Goh, G.Y., O’Connor, S., Eds.; Cambridge University Press: Cambridge, UK, 2012; pp. 235–256. [Google Scholar] [CrossRef]

- Reena, M.; Le, T.H. Chapter 2—Cultural Linkages. In India-Vietnam relations; Dynamics of Asian Development; Springer: Singapore, 2021; pp. 25–44. [Google Scholar] [CrossRef]

- Tedeschi, C.; Binda, L.; Condoleo, P. Proceedings of the 2nd Conference on Historic Mortars—HMC 2010 and RILEM TC 203-RHM Final Workshop 2000; Válek, J., Groot, C., Hughes, J.J., Eds.; Rilem Publications: Bagneux, France, 2010; pp. 1189–1198. [Google Scholar]

- Le, T.V. Report (in Vietnamese) of the International Cooperation Project under the Vietnam-Italy Protocol on Empirical Research on Construction Materials and Techniques of Cham Architecture at My Son Relic Site; Ministry of Culture, Sports and Tourism of Vietnam: Hanoi, Vietnam, 2018. [Google Scholar]

- Available online: https://bomanhatrang.com/po-nagar-cham-towers/ (accessed on 6 February 2025).

- Landoni, A.M. Proceedings of the On-site Workshop on Technical Process of Restoring Cham Towers in My Son, My Son, December 2018; National Culture Publishing House: Hanoi, Vietnam, 2018; pp. 16–27. ISBN 978-604-70-2421-6. [Google Scholar]

- Shimoda, I.; So, S.; Chan, V. Damage Assessment and Guidelines for Restoration Methods of Ancient Brick Structures at Sambor Prei Kuk, Cambodia. Int. J. Archit. Herit. 2021, 16, 1366–1381. [Google Scholar] [CrossRef]

- Available online: https://vr360.com.vn/projects/ponagar-nhatrang/ (accessed on 6 February 2025).

- Nguyen, Q.M. Report on the Dating of Ancient Ceramics Using 14C, Research Project of the Institute of Archaeology; Vietnam Academy of Social Sciences: Hanoi, Vietnam, 2002. [Google Scholar]

- Tran, B.V. Report (in Vietnamese) of the National Research Project on the Construction Techniques of Cham Towers to Serve for the Restoration and Promotion of the Relic Value; Ministry of Construction of Vietnam: Hanoi, Vietnam, 2004. [Google Scholar]

- Abdrakhimov, V.Z.; Abdrakhimova, E.S. Chemical-Elemental, Phase Compositions and Porosity Structure of Ceramic Samples from Cham Tower (Vietnam) More Than 1000 Y/O. Glass Ceram. 2018, 75, 154–159. [Google Scholar] [CrossRef]

- Nguyen, Q.L.; Thanh, N.T.; Colomban, P. Reliability of Raman microspectroscopy in analyzing ancient ceramics: The case of ancient Vietnamese porcelain and celadon glazes. J. Raman Spectrosc. 2002, 33, 287–294. [Google Scholar] [CrossRef]

- Nguyen, Q.L.; Colomban, P. Applications of Modern Analysis Techniques in Searching back Ancient Art Ceramic Technologies. J. Anal. Sci. Technol. 2011, 2, A78–A83. [Google Scholar]

- Lee, G.; Park, J.; Lee, C.H.; Lee, S.M.; Lee, K. Mechanical and Structural Investigation of Traditional Masonry Systems with Diverse Types of Bricks and Hydrated Lime Mortars. Int. J. Architect. Herit. 2023, 18, 871–893. [Google Scholar] [CrossRef]

- Benjatham, E.M.; Agua, F.; Fort, R.; Alvarez de Buergo, M.; Conde, J.F.; Garcia-Heras, M. Effect of manufacturing methods on the decay of ceramic materials: A case study of bricks in modern architecture of Madrid (Spain). Appl. Clay Sci. 2017, 135, 136–149. [Google Scholar] [CrossRef]

- Sukkaneewat, B.; Petchwattana, N.; Sanetuntikul, J. Lightweight fired clay brick production for archeological heritage site maintenance application. J. Mater. Struct. 2023, 56, 111. [Google Scholar] [CrossRef]

- Pérez-Villarejo, L.; Eliche-Quesada, D.; Martín-Pascual, J.; Martín-Morales, M.; Zamorano, M. Comparative study of the use of different biomass from olive grove in the manufacture of sustainable ceramic lightweight bricks. Constr. Build. Mater. 2020, 231, 117103. [Google Scholar] [CrossRef]

- Sutas, J.; Mana, A.; Pitak, L. Effect of Rice Husk and Rice Husk Ash to Properties of Bricks. Procedia Eng. 2012, 32, 1061–1067. [Google Scholar] [CrossRef]

- Muñoz Velasco, P.; Mendívil, M.A.; Morales, M.P.; Muñoz, L. Eco-fired clay bricks made by adding spent coffee grounds: A sustainable way to improve buildings insulation. Mater. Struct. 2016, 49, 641–650. [Google Scholar] [CrossRef]

- Pérez-Monserrat, E.M.; Maritan, L.; Garbin, E.; Cultrone, G. Production technologies of ancient bricks from Padua, Italy: Changing colors and resistance over time. Minerals 2021, 11, 744. [Google Scholar] [CrossRef]

- Jouenne, C.A. Traité de Céramique et Matériaux Minéraux; Editions Septima: Paris, France, 2001. [Google Scholar]

- De Bonis, A.; Cultrone, G.; Grifa, C.; Langella, A.; Leone, A.P.; Mercurio, M.; Morra, V. Different shades of red: The complexity of mineralogical and physic-chemical factors influencing the colour of ceramics. Ceram. Int. 2017, 43, 8065–8074. [Google Scholar] [CrossRef]

- Maritan, L.; Nodari, L.; Mazzoli, C.; Milano, A.; Russo, U. Influence of firing conditions on ceramic products: Experimental study on clay rich in organic matter. Appl. Clay Sci. 2006, 31, 1–15. [Google Scholar] [CrossRef]

- Nodari, L.; Maritan, L.; Mazzoli, C.; Russo, U. Sandwich structures in Etruscan-Padan type pottery. Appl. Clay Sci. 2004, 27, 119–128. [Google Scholar] [CrossRef]

- Yang, F.; Antonietti, M. Artificial Humic Acids: Sustainable Materials against Climate Change. Adv. Sci. 2020, 7, 1902992. [Google Scholar] [CrossRef]

- Gliozzo, E. How to reconstruct the firing process. Archaeol. Anthropol. Sci. 2020, 12, 260. [Google Scholar] [CrossRef]

- Ballirano, P.; De Vito, C.; Medeghini, L.; Mignardi, S.; Ferrini, V.; Matthiae, P.; Bersani, D.; Lottici, P. A combined use of optical microscopy, X-ray powder diffraction and micro-Raman spectroscopy for the characterization of ancient ceramic from Ebla (Syria). Ceram. Int. 2014, 40, 16409–16419. [Google Scholar] [CrossRef]

- Froment, F.; Tournié, A.; Colomban, P. Raman identification of natural red to yellow pigments: Ochre and iron-containing ores. J. Raman Spectrosc. 2008, 39, 560–568. [Google Scholar] [CrossRef]

- Gunasekaran, S.; Anbalagan, G.; Pandi, S. Raman and infrared spectra of carbonates of calcite structure. J. Raman Spectrosc. 2006, 37, 892–899. [Google Scholar] [CrossRef]

- Colomban, P.; Kırmızı, B.; Simsek Franci, G. Cobalt and Associated Impurities in Blue (and Green) Glass, Glaze and Enamel: Relationships between Raw Materials, Processing, Composition, Phases and International Trade. Minerals 2021, 11, 633. [Google Scholar] [CrossRef]

- TCVN 6355-2:2009; Vietnam Standard on Compressive Strength of Building Bricks. Vietnam Certification Centre: Hanoi, Vietnam, 2009.

- Levin, E.M.; Robbins, C.; McMurdie, H.F.; Reser, M.K. Phase Diagrams for Ceramists; The American Ceramic Society: Colombus, OH, USA, 1964. [Google Scholar]

- Nguyen, Q.L.; Thuy, U.T.D.; Hoi, P.V.; Loan, N.T. Methods of Materials Preparation and Firing to Make Porous, Hard, and Sculptable Bricks for Use in Restoration of Cham Towers and Construction of Sculptures, Monuments. Patent #41303, 5 September 2024. [Google Scholar]

- Lawanwadeekul, S.; Otsuru, T.; Tomiku, R.; Nishiguchi, H. Thermal-acoustic clay brick production with added charcoal for use in Thailand. Constr. Build. Mater. 2020, 255, 119376. [Google Scholar] [CrossRef]

| Sample | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | TiO2 | MnO | ZnO | C |

|---|---|---|---|---|---|---|---|---|---|---|

| 1. Reddish crust OCB (XRF) | 58.6 | 25.0 | 7.8 | 1.6 | 1.5 | 3.9 | 1.2 | 0.13 | 0.02 | n.m |

| 2. Reddish crust OCB (EDX) | 60.3 | 31.4 | 3.3 | 0.6 | 1.1 | 2.6 | 0.4 | 0.12 | 0.12 | low |

| 3. Crust NRB (EDX) | 58.9 | 23.5 | 8.9 | 1.2 | 2.2 | 3.6 | 1.3 | 0.14 | 0.02 | low |

| 4. Black core OCB (XRF) | 61.5 | 22.8 | 7.0 | 1.7 | 1.9 | 3.8 | 1.0 | 0.08 | 0.02 | n.m |

| 5. Black core OCB (EDX) | 58.3 | 24.9 | 2.5 | 0.8 | 0.6 | 2.2 | 1.9 | 0.03 | 0.06 | 8.7 |

| 6. Fired core OCB (EDX) | 61.9 | 22.9 | 6.3 | 1.7 | 2.0 | 3.8 | 1.1 | 0.08 | 0.02 | low |

| Sample | Open Porosity (%) | Mass Density (kg/dm3) | Compressive Failure Strength (MPa) |

|---|---|---|---|

| Reddish crust OCB | 18–25 | 1.30–1.60 | 23–25 |

| Black core OCB | 18–25 | 1.32–1.61 | 20–22 |

| NRB | 7–14 | 1.80–1.83 | 36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loan, N.T.; Thuy, U.T.D.; Duong, L.V.; Huong, T.T.T.; Toan, B.T.; Saladino, M.L.; Armetta, F.; Colomban, P.; Hreniak, D.; Liem, N.Q. Likely Technology Making the Ancient Cham Bricks Lightweight, Carvable, and Durable for Constructing Big Engraved Towers Lasting Thousands of Years: A Case Study of the Po Nagar Towers, Nhatrang, Vietnam. Heritage 2025, 8, 173. https://doi.org/10.3390/heritage8050173

Loan NT, Thuy UTD, Duong LV, Huong TTT, Toan BT, Saladino ML, Armetta F, Colomban P, Hreniak D, Liem NQ. Likely Technology Making the Ancient Cham Bricks Lightweight, Carvable, and Durable for Constructing Big Engraved Towers Lasting Thousands of Years: A Case Study of the Po Nagar Towers, Nhatrang, Vietnam. Heritage. 2025; 8(5):173. https://doi.org/10.3390/heritage8050173

Chicago/Turabian StyleLoan, Nguyen Thu, Ung Thi Dieu Thuy, Luong Van Duong, Tran Thi Thu Huong, Ba Trung Toan, Maria Luisa Saladino, Francesco Armetta, Philippe Colomban, Dariusz Hreniak, and Nguyen Quang Liem. 2025. "Likely Technology Making the Ancient Cham Bricks Lightweight, Carvable, and Durable for Constructing Big Engraved Towers Lasting Thousands of Years: A Case Study of the Po Nagar Towers, Nhatrang, Vietnam" Heritage 8, no. 5: 173. https://doi.org/10.3390/heritage8050173

APA StyleLoan, N. T., Thuy, U. T. D., Duong, L. V., Huong, T. T. T., Toan, B. T., Saladino, M. L., Armetta, F., Colomban, P., Hreniak, D., & Liem, N. Q. (2025). Likely Technology Making the Ancient Cham Bricks Lightweight, Carvable, and Durable for Constructing Big Engraved Towers Lasting Thousands of Years: A Case Study of the Po Nagar Towers, Nhatrang, Vietnam. Heritage, 8(5), 173. https://doi.org/10.3390/heritage8050173