Design and Assessment of Pastes for the Reattachment of Fractured Porous Stones

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Used in the Current Investigation

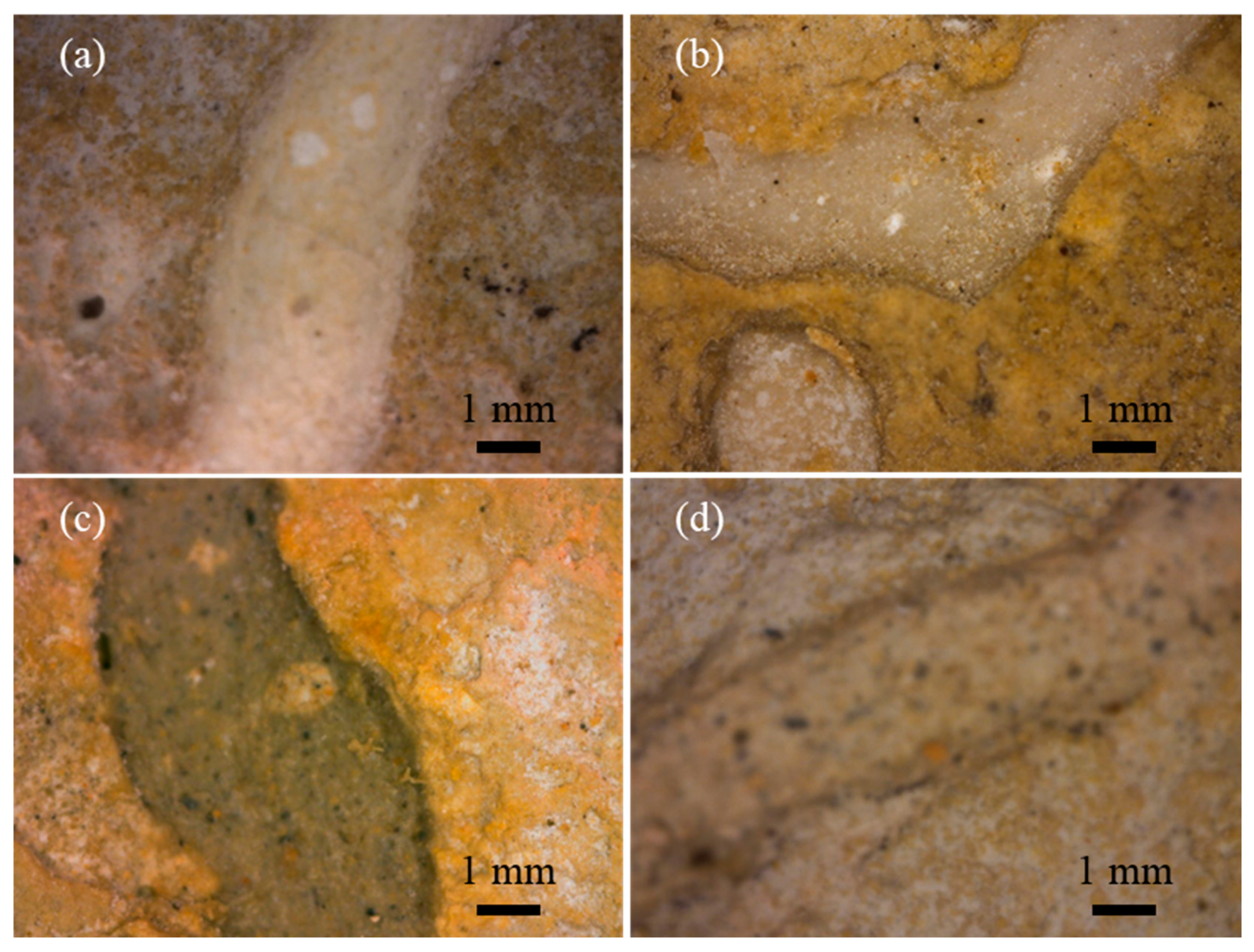

2.1.1. Raw Materials

2.1.2. Paste Mix Design, Mixing and Curing

2.1.3. Other Materials Used in the Investigation

2.2. Paste Examination and Assessment Methods and Techniques

2.2.1. In-Lab Paste Examination Techniques

- -

- Determination of bulk density: The bulk density of the specimens was determined by dividing the mass of each specimen (after drying) by the volume of the specimen (as calculated by its dimensions). Bulk density was determined at 12 months’ curing in accordance with EN 1936 [50]. Measurements were conducted on three specimens for each mix. Bulk density, in addition to its importance as a building material characteristic, was also used for the estimation of the dynamic modulus of elasticity for each material through the ultrasonic pulse velocity measurements, as presented below.

- -

- The characteristics of capillary rise coefficient, porosity accessible to water through capillary pores and water absorption through capillarity capacity percentage were determined in accordance with EN 15801 [51]. Tests were conducted on three specimens for each mix at 12 months curing.

- -

- -

- Compressive strength tests: Specimens were subjected to uniaxial compression in accordance with EN1015-11 [46]. Tests were conducted at 1, 3, 6, 12 and 30 months’ age on three specimens for each mix and age using a ToniTechnik DKD-K-23301 (loading rate: 0.01 KN/s).

- -

- Ultrasonic pulse velocity measurements and estimation of dynamic modulus of elasticity: Measurements were conducted at 12 months’ age (three specimens for each mix) using a CNS Farnell-Pundit 6 (transducers frequency: 54 KHz; probe diameter: 20 mm) in accordance with ASTM-C597-16 [53]. The measurements were conducted on the flat surfaces (upper top surface, lower bottom surface) of the cylindrical specimens using a direct method (transmitter on one surface and receiver on opposite surface). The following formula was applied for the estimation of the dynamic elasticity modulus:

2.2.2. Paste/Ancient Stone Compatibility Evaluation Criteria

- The bulk density of the adhesive/anchoring material should be equal to or lower than that of the ancient stone;

- The porosity of the repair material should be equal to or higher than that of the ancient stone in order for the adhesive/anchoring material to play the role of a sacrificial material in terms of water uptake. The same applies for water absorption capacity;

- The capillary rise coefficient of the repair material should be as close as possible to that of the ancient stone in order to neither increase water uptake nor cause water to preferentially transfer to the ancient material;

- The mechanical strength of the repair material must be as close as possible to or lower than that of the ancient material in order for the repair material, and not the ancient material, to fail under compression; this applies to compressive strength and ultrasonic pulse velocity.

2.2.3. In Situ Paste Evaluation Techniques

3. Results and Discussion

3.1. In Lab Assessment of Paste Mix Designs

3.1.1. Determination of Physical Properties and Hygric Behavior During Setting and Hardening

Bulk Density Determination

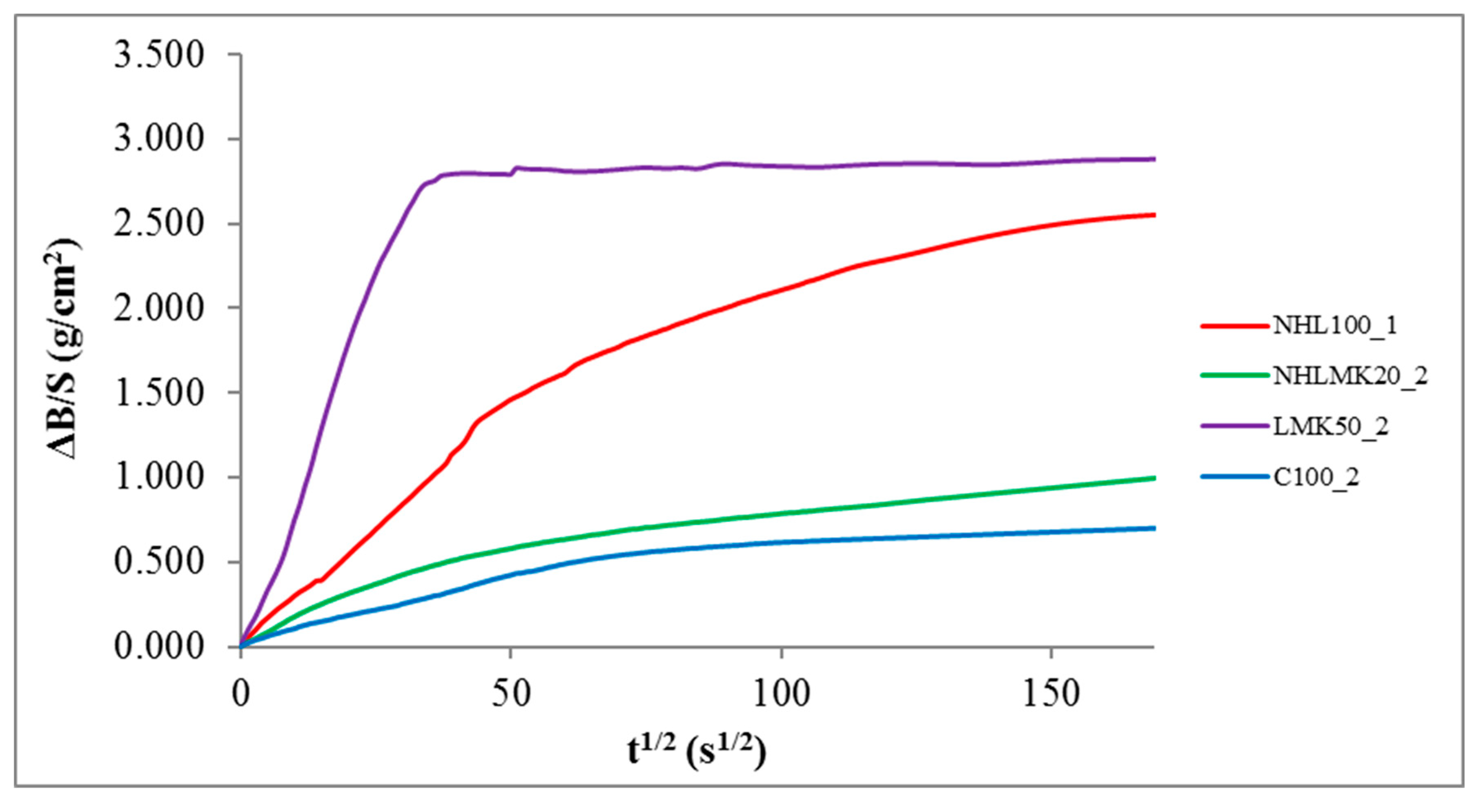

Capillary Rise Coefficient, Porosity Accessible to Water Through Capillary Pores and Water Absorption Through Capillarity Capacity Percentage

Total Water Immersion Results

3.1.2. Determination of Mechanical Properties During Setting and Hardening

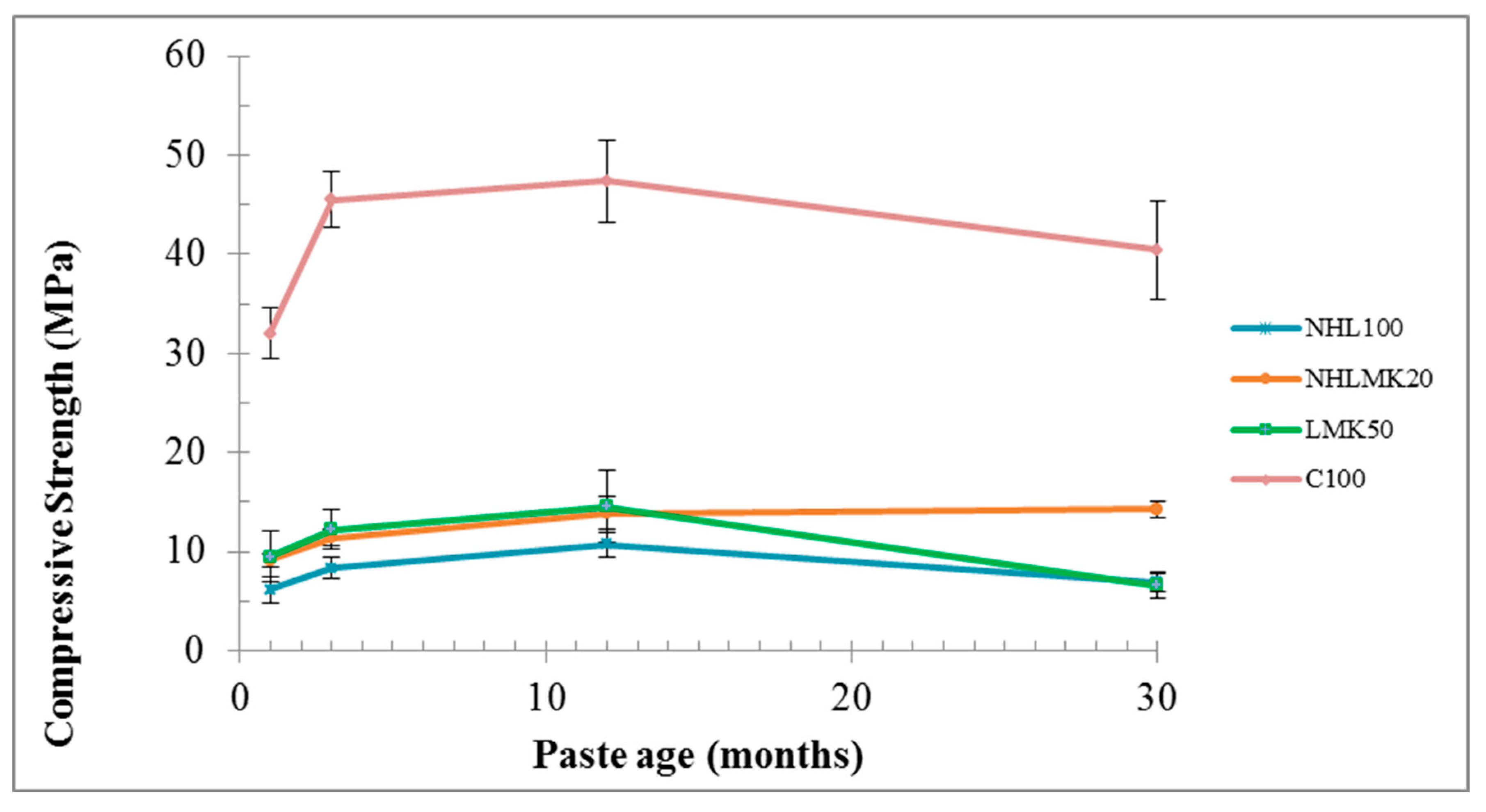

Compressive Strength

Ultrasonic Pulse Velocity and Dynamic Modulus of Elasticity

3.2. Compatibility Evaluation of Pastes with Ancient Porous Stone

3.3. On-Site Pilot Application and Assessment

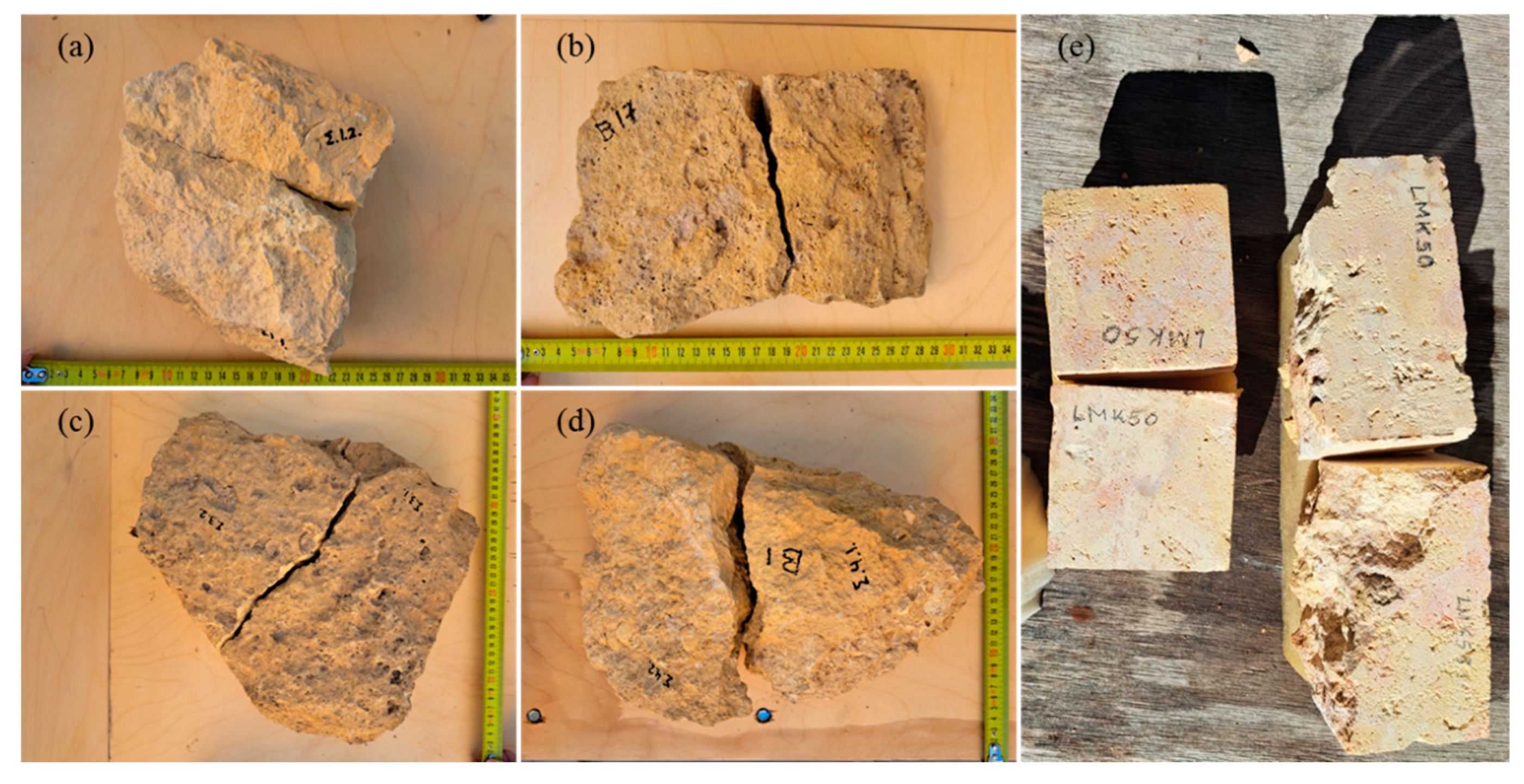

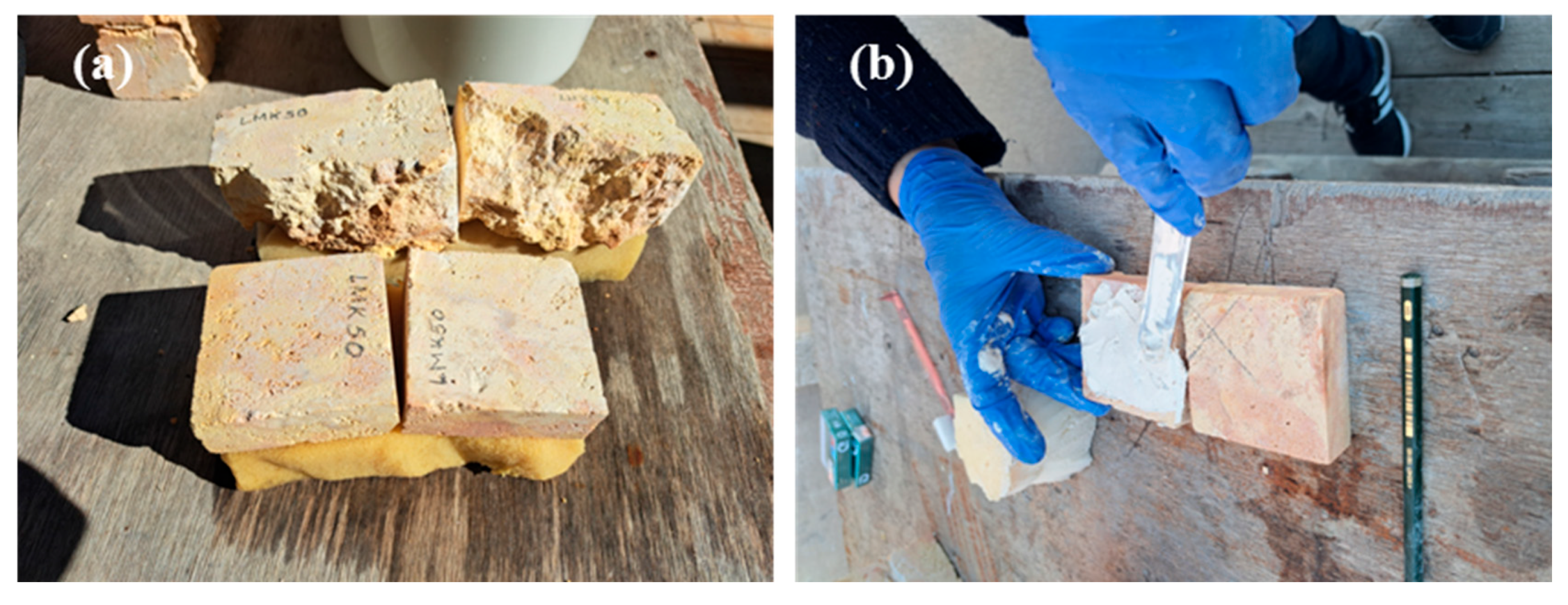

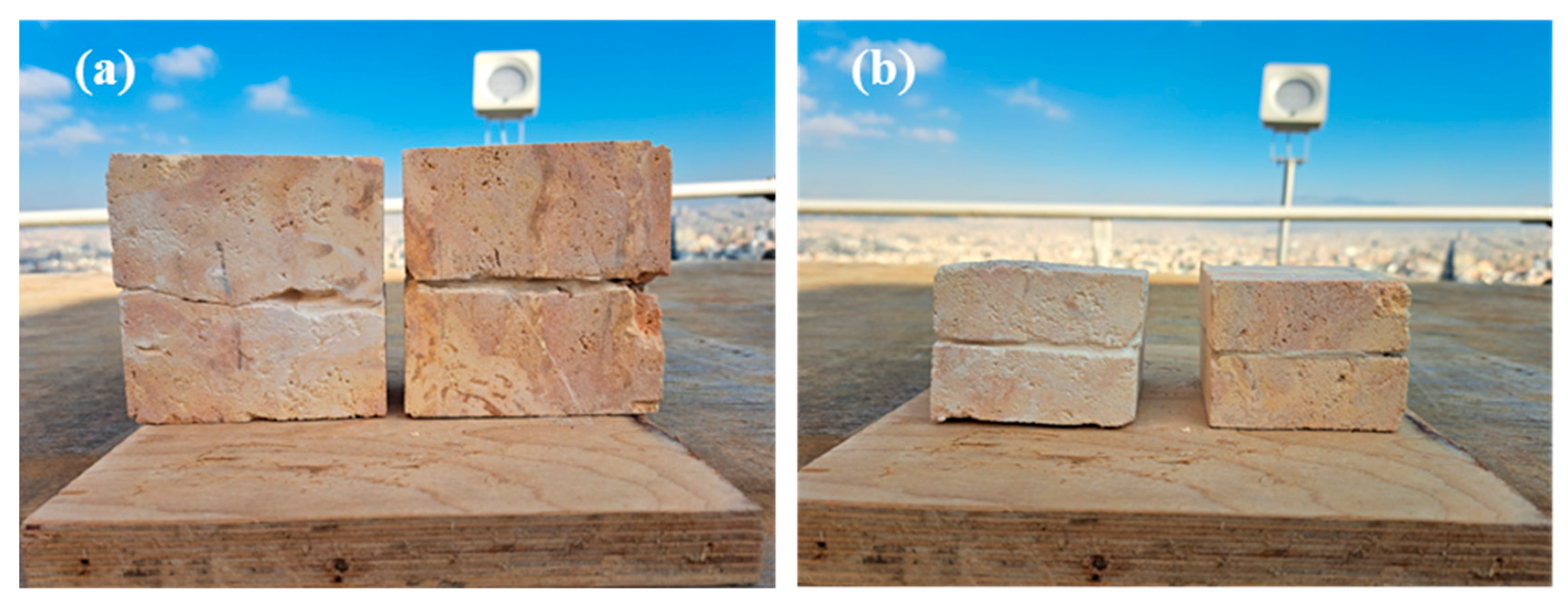

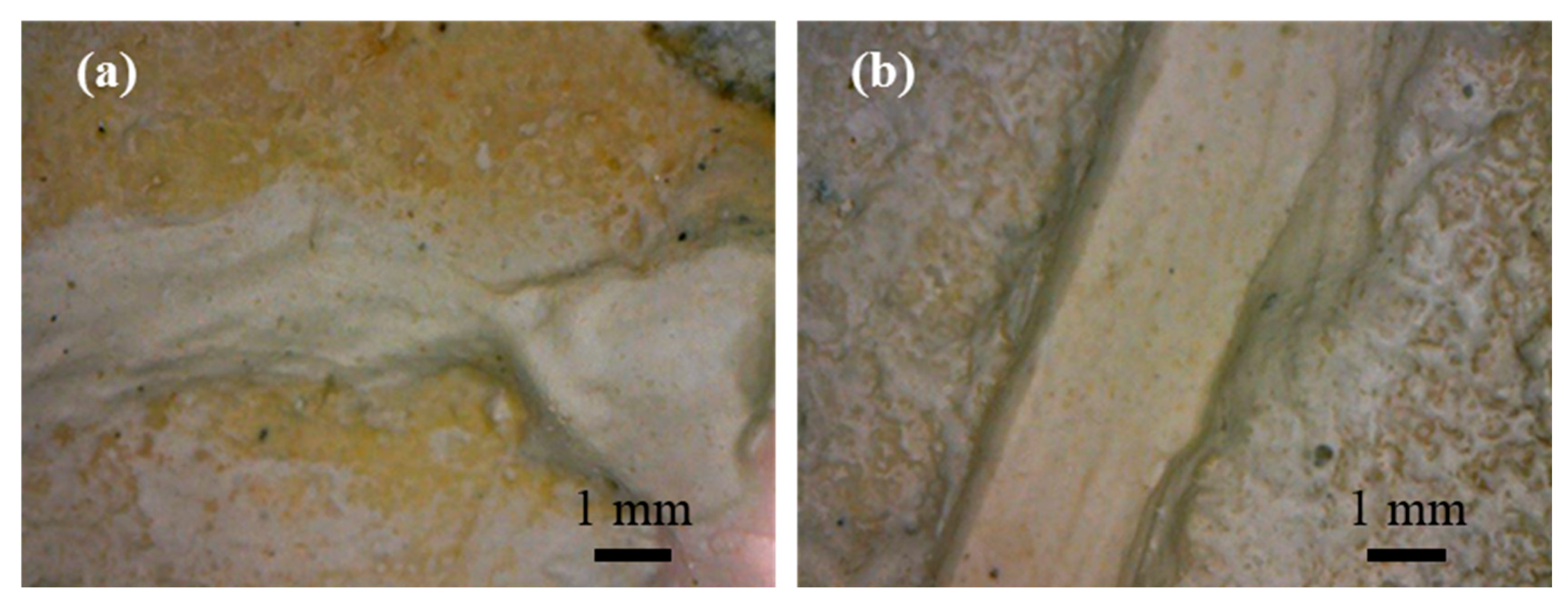

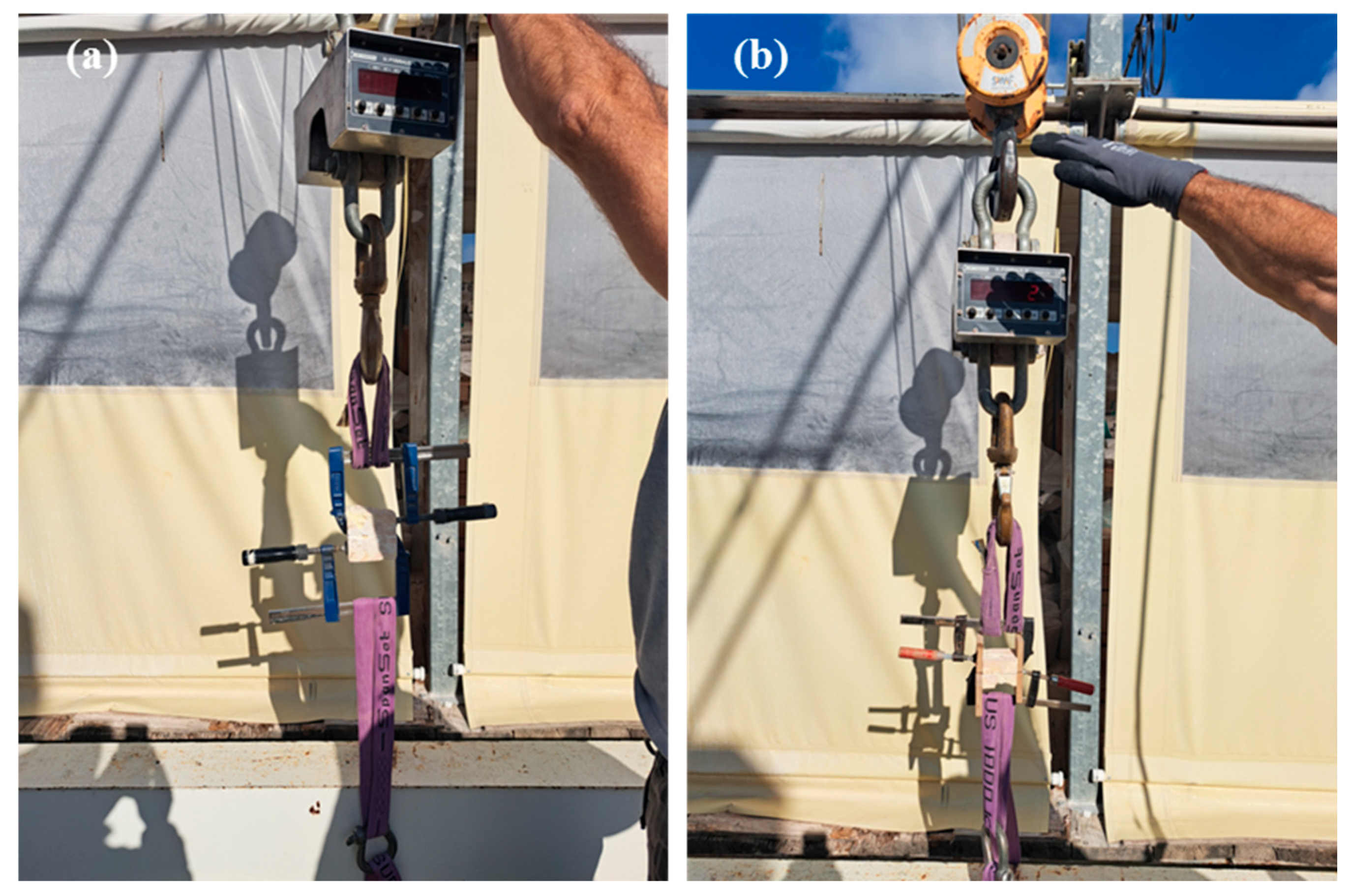

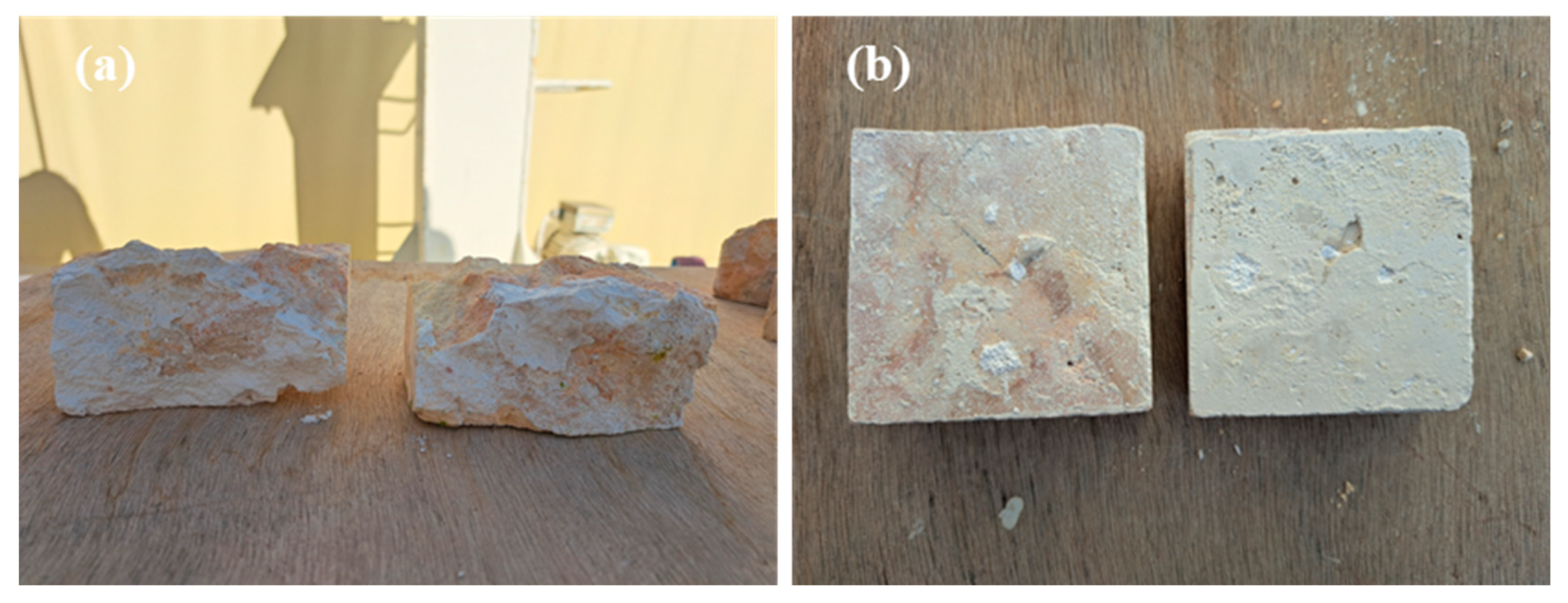

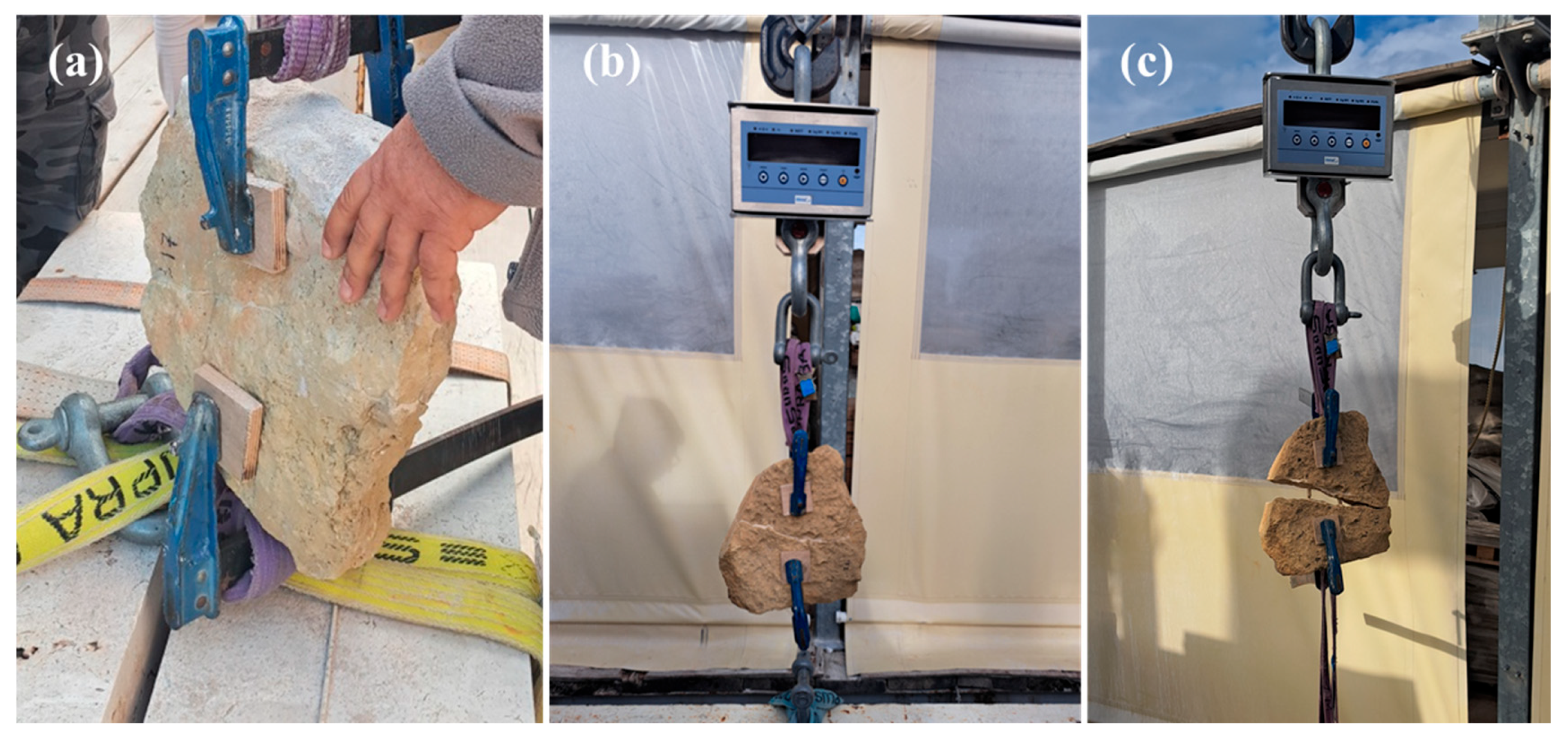

3.3.1. Reattachment Without Titanium Pins—Small Fragments

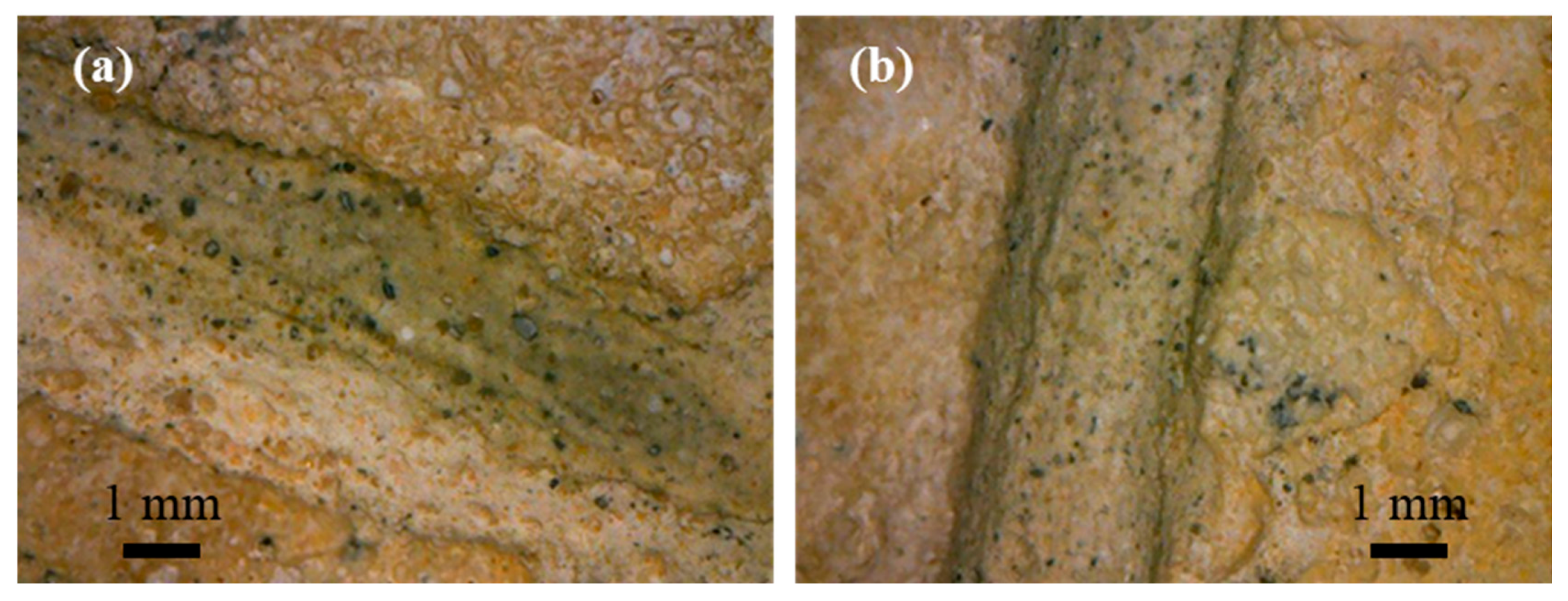

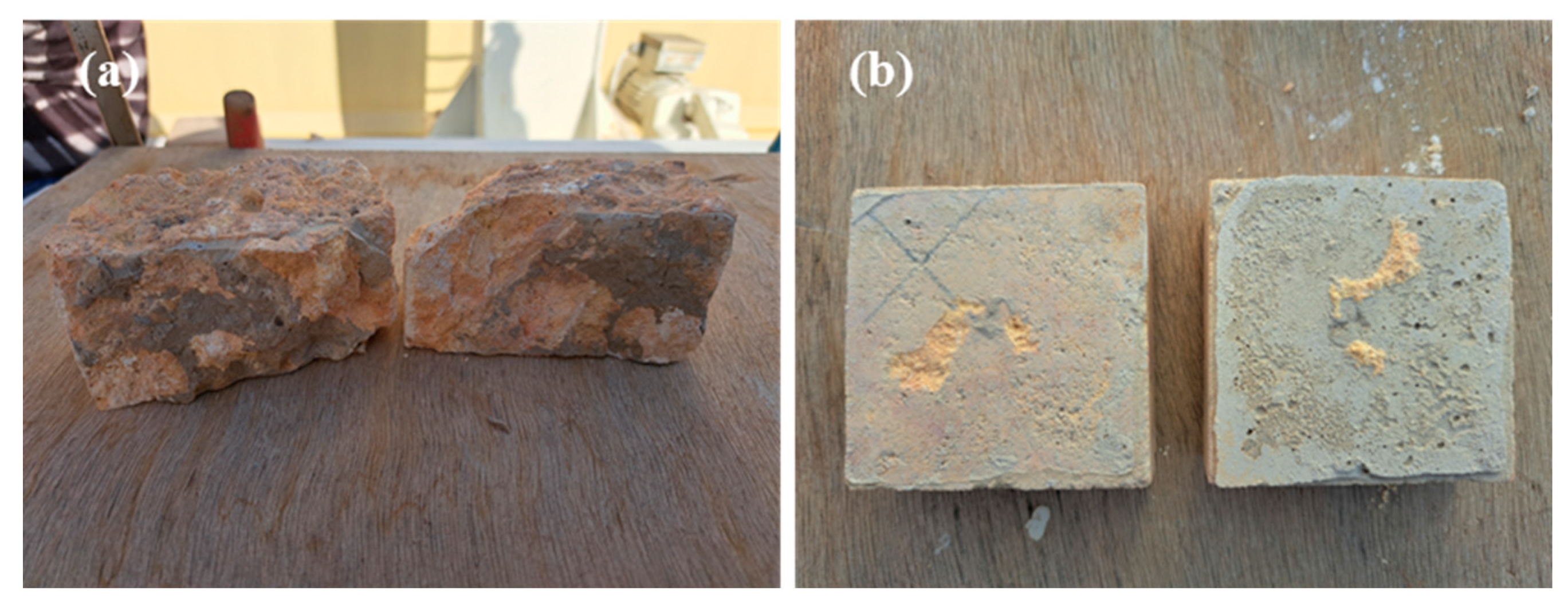

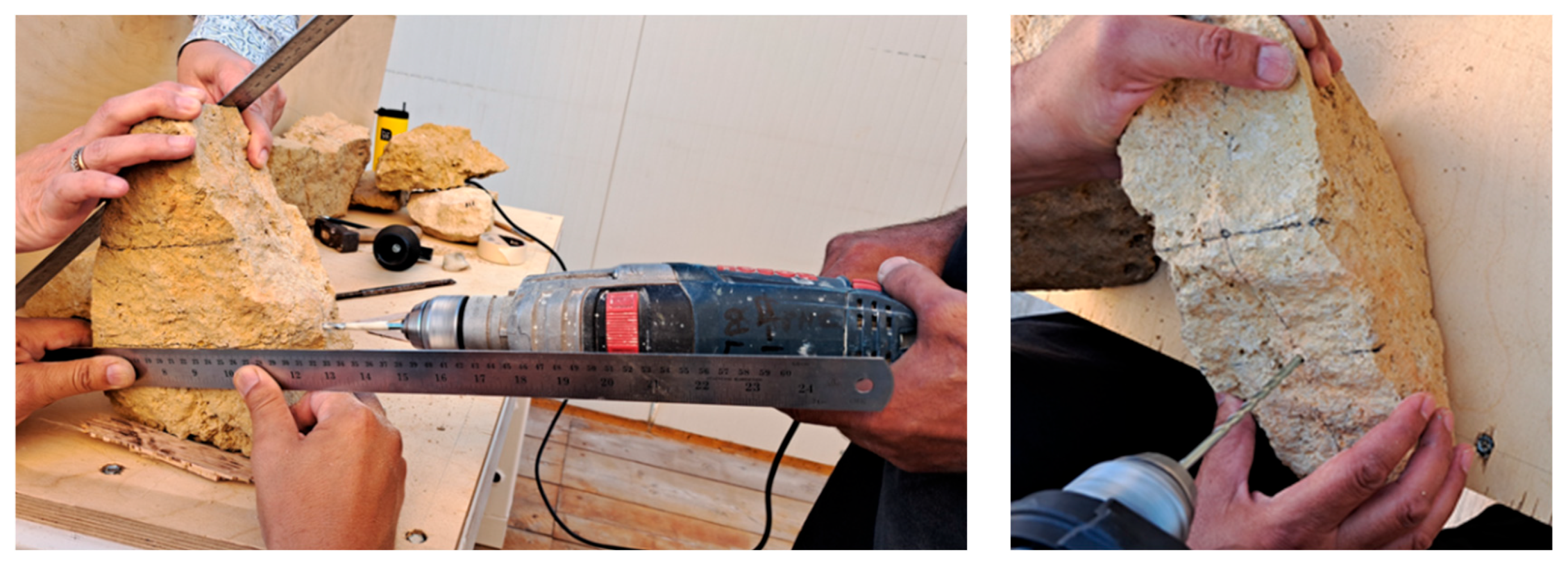

3.3.2. Reattachment with Titanium Pins—Medium Fragments

3.4. Discussion Regarding the Results of the Applied Methodological Approach in Relation to the Literature

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Christou, P.; Elliotis, M. Construction and retrofit methods of stone masonry structures in Cyprus. Open Constr. Build. Technol. J. 2016, 10, 246–258. [Google Scholar] [CrossRef]

- Di Benedetto, C.; Cappelletti, P.; Favaro, M.; Graziano, S.F.; Langella, A.; Calcaterra, D.; Colella, A. Porosity as key factor in the durability of two historical building stones: Neapolitan Yellow Tuff and Vicenza Stone. Eng. Geol. 2015, 193, 310–319. [Google Scholar] [CrossRef]

- Caner-Saltık, E.N. Atmospheric weathering of historic monuments and their related conservation issues. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 149, p. 01009. [Google Scholar]

- Dermentzopoulos, T.; Mimides, T.; Davi, E.; Kazas, S.; Perraki, T.; Sachpazis, K. Building stones of ancient monuments in Attica: An. Int. J. Rock Mech. Min. Sci. 2005, 42, 619–628. [Google Scholar]

- El-Gohary, M.A. Environmental impacts: Weathering factors, mechanism and forms affected the stone decaying in Petra. J. Afr. Earth Sci. 2017, 135, 204–212. [Google Scholar] [CrossRef]

- Aalil, I.; Beck, K.; Brunetaud, X.; Cherkaoui, K.; Chaaba, A.; Al-Mukhtar, M. Deterioration analysis of building calcarenite stone in the House of Venus in the archaeological site of Volubilis (Morocco). Constr. Build. Mater. 2016, 125, 1127–1141. [Google Scholar] [CrossRef]

- Steiger, M.; Charola, A.E.; Sterflinger, K. Weathering and deterioration. Stone Archit. Prop. Durab. 2011, 227–316. [Google Scholar] [CrossRef]

- Bugani, S.; Camaiti, M.; Morselli, L.; Van de Casteele, E.; Cloetens, P.; Janssens, K. X-ray computed tomography as a non-destructive tool for stone conservation. In Proceedings of the 9th International Conference on Non-Destructive Investigations and Microanalysis for the Diagnostics and Conservation of Cultural and Environmental Heritage, Jerusalem, Israel, 25–30 May 2008. [Google Scholar]

- Eslami, J.; Walbert, C.; Beaucour, A.L.; Bourges, A.; Noumowe, A. Influence of physical and mechanical properties on the durability of limestone subjected to freeze-thaw cycles. Constr. Build. Mater. 2018, 162, 420–429. [Google Scholar] [CrossRef]

- Huang, S.; Yu, S.; Ye, Y.; Ye, Z.; Cheng, A. Pore structure change and physico-mechanical properties deterioration of sandstone suffering freeze-thaw actions. Constr. Build. Mater. 2022, 330, 127200. [Google Scholar] [CrossRef]

- Charola, A.E. Salts in the deterioration of porous materials: An overview. J. Am. Inst. Conserv. 2000, 39, 327–343. [Google Scholar] [CrossRef]

- Galanaki, N.; Delegou, E.; Bris, T.; Moropoulou, A. Accelerated ageing tests of sodium chloride for the evaluation of stones durability to salt crystallization: A comparative study of selected restoration lithotypes. Dev. Built Environ. 2022, 11, 100081. [Google Scholar] [CrossRef]

- Li, Y.H.; Gu, J.D. A more accurate definition of water characteristics in stone materials for an improved understanding and effective protection of cultural heritage from biodeterioration. Int. Biodeterior. Biodegrad. 2022, 166, 105338. [Google Scholar] [CrossRef]

- Fitzner, B.; Heinrichs, K. Damage diagnosis at stone monuments-weathering forms, damage categories and damage indices. Acta-Univ. Carol. Geol. 2001, 1, 12–13. [Google Scholar]

- Rosewitz, J.; Muir, C.; Riccardelli, C.; Rahbar, N.; Wheeler, G. A multimodal study of pinning selection for restoration of a historic statue. Mater. Des. 2016, 98, 294–304. [Google Scholar] [CrossRef]

- Amstock, J.S. Handbook of Adhesives and Sealants in Construction; McGraw-Hill: New York, NY, USA, 2001. [Google Scholar]

- Riccardelli, C.; Morris, M.; Wheeler, G.; Soultanian, J.; Becker, L.; Street, R. The treatment of Tullio Lombardo’s Adam: A new approach to the conservation of monumental marble sculpture. Metrop. Mus. J. 2014, 49, 48–116. [Google Scholar] [CrossRef]

- Maravelaki-Kalaitzaki, P.; Agioutantis, Z.; Lionakis, E.; Stavroulaki, M.; Perdikatsis, V. Physico-chemical and mechanical characterization of hydraulic mortars containing nano-titania for restoration applications. Cem. Concr. Compos. 2013, 36, 33–41. [Google Scholar] [CrossRef]

- Aggelakopoulou, E.; Adami, C.E.; Tsimereki, A.; Vintzileou, E.; Eleftheriou, V. Adhesive materials for the conservation interventions in the acropolis monuments. In Protection of Historical Constructions: Proceedings of PROHITECH; Springer International Publishing: Cham, Switzerland, 2021; Volume 4, pp. 804–815. [Google Scholar]

- Apostolopoulou, M.; Keramidas, V.; Galanaki, N.; Kalofonou, M.; Skoula, C.; Karoglou, M.; Delegou, E.T.; Mouzakis, C.; Bakolas, A.; Moropoulou, A.; et al. A study on the historical materials of the Apollo Pythios Temple in Rhodes and the evaluation of potential restoration materials. Heritage 2019, 2, 988–1022. [Google Scholar] [CrossRef]

- Botas, S.; Veiga, R.; Velosa, A. Air lime mortars for conservation of historic tiles: Bond strength of new mortars to old tiles. Constr. Build. Mater. 2017, 145, 426–434. [Google Scholar] [CrossRef]

- Trinkley, M. Suitability of Pins & Epoxy—CONSERVATION TALK. Ags Q. 2011, 35, 23–25. [Google Scholar]

- Skoulikidis, T.; Vassiliou, P. Corrosion and conservation of building materials of monuments; the Acropolis case. Corros. Rev. 1999, 17, 295–332. [Google Scholar] [CrossRef]

- Riccardelli, C.; Wheeler, G.; Muir, C.; Scherer, G.; Vocaturo, J. An examination of pinning materials for marble sculpture. AIC Objects Spec. Group Postprints 2010, 17, 95–112. [Google Scholar]

- Podany, J.; Risser, E.; Sanchez, E. Never Forever: Assembly of sculpture guided by the demands of disassembly. In Holding it All Together: Ancient and Modern Approaches to Joining, Repair and Consolidation; Ambers, J., Higgitt, C., Harrison, L., Saunders, D., Eds.; Archetype Publications Ltd.: London, UK, 2009; pp. 134–142. [Google Scholar]

- Drinia, H.; Tripolitsiotou, F.; Cheila, T.; Zafeiropoulos, G. The geosites of the sacred rock of acropolis (UNESCO world heritage, athens, greece): Cultural and geological heritage integrated. Geosciences 2022, 12, 330. [Google Scholar] [CrossRef]

- Manidaki, V. The circuit wall of the Acropolis: Documentary works and studies. Acropolis Restor. News 2006, 6, 23–26. Available online: https://www.ysma.gr/en/open-access/publications/newsletter/ (accessed on 30 December 2024).

- Ksinopoulou, E.; Aggelakopoulou, E.; Eleftheriou, V. Investigation of a suitable porous stone for the restoration work on the Acropolis circuit wall. Constr. Build. Mater. 2022, 335, 127522. [Google Scholar] [CrossRef]

- Psarropoulos, P.; Kapogianni, E.; Kalogeras, I.; Michalopoulou, D.; Eleftheriou, V.; Dimopoulos, G.; Sakellariou, M. Seismic response of the Circuit Wall of the Acropolis of Athens: Recordings versus numerical simulations. Soil Dyn. Earthq. Eng. 2018, 113, 309–316. [Google Scholar] [CrossRef]

- Theoulakis, P.; Bardanis, M. The stone of Piraeus at the monuments of the Acropolis of Athens. In Proceedings of the 9th International Congress on Deterioration and Conservation of Stone; Elsevier Science BV: Amsterdam, The Netherlands, 2000; pp. 255–263. [Google Scholar]

- Bouras, C.; Iōannidou, M.; Jenkins, I.D. (Eds.) Acropolis Restored; British Museum: London, UK, 2012. [Google Scholar]

- EN 459-1:2015; Building Lime. Part 1: Definitions, Specifications and Conformity Criteria; CEN: Brussels, Belgium, 2015.

- Zhang, D.; Zhao, J.; Wang, D.; Xu, C.; Zhai, M.; Ma, X. Comparative study on the properties of three hydraulic lime mortar systems: Natural hydraulic lime mortar, cement-aerial lime-based mortar and slag-aerial lime-based mortar. Constr. Build. Mater. 2018, 186, 42–52. [Google Scholar] [CrossRef]

- De Nardi, C.; Brito de Carvalho Bello, C.; Ferrara, L.; Cecchi, A. Self-healing lime mortars: An asset for restoration of heritage buildings. In Proceedings of the International Conference on Sustainable Materials, Systems and Structures, Rovinj, Croatia, 20–22 March 2019; Volume 128, pp. 652–659. [Google Scholar]

- Apostolopoulou, M.; Asteris, P.G.; Armaghani, D.J.; Douvika, M.G.; Lourenço, P.B.; Cavaleri, L.; Bakolas, A.; Moropoulou, A. Mapping and holistic design of natural hydraulic lime mortars. Cem. Concr. Res. 2020, 136, 106167. [Google Scholar] [CrossRef]

- EN 197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Commitee for Standardisation (CEN): Brussels, Belgium, 2011.

- Arizzi, A.; Cultrone, G. Negative Effects of the Use of White Portland Cement as Additive to Aerial Lime Mortars Set at Atmospheric Conditions: A Chemical, Mineralogical and Physical-Mechanical Investigation; Rivera, S.M., Diaz, A.L.P., Eds.; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2011; pp. 231–243. [Google Scholar]

- Figueiredo, C.; Ball, R.; Lawrence, R. Is EN459-1 fit for purpose in the context of conservation? In Proceedings of the 36th Cement and Concrete Science Conference, Cardiff, UK, 5 September 2016; p. 9. [Google Scholar]

- Aggelakopoulou, E.; Bakolas, A.; Moropoulou, A. Lime putty versus hydrated lime powder: Physicochemical and mechanical characteristics of lime based mortars. Constr. Build. Mater. 2019, 225, 633–641. [Google Scholar] [CrossRef]

- Aggelakopoulou, E.; Bakolas, A.; Moropoulou, A. Properties of lime–metakolin mortars for the restoration of historic masonries. Appl. Clay Sci. 2011, 53, 15–19. [Google Scholar] [CrossRef]

- Gameiro, A.; Silva, A.S.; Faria, P.; Grilo, J.; Branco, T.; Veiga, R.; Velosa, A. Physical and chemical assessment of lime–metakaolin mortars: Influence of binder: Aggregate ratio. Cem. Concr. Compos. 2014, 45, 264–271. [Google Scholar] [CrossRef]

- Vejmelková, E.; Keppert, M.; Keršner, Z.; Rovnaníková, P.; Černý, R. Mechanical, fracture-mechanical, hydric, thermal, and durability properties of lime-metakaolin plasters for renovation of historical buildings. Constr. Build. Mater. 2012, 31, 22–28. [Google Scholar] [CrossRef]

- Grilo, J.; Silva, A.S.; Faria, P.; Gameiro, A.; Veiga, R.; Velosa, A. Mechanical and mineralogical properties of natural hydraulic lime-metakaolin mortars in different curing conditions. Constr. Build. Mater. 2014, 51, 287–294. [Google Scholar] [CrossRef]

- Grilo, J.; Faria, P.; Veiga, R.; Silva, A.S.; Silva, V.; Velosa, A. New natural hydraulic lime mortars–physical and microstructural properties in different curing conditions. Constr. Build. Mater. 2014, 54, 378–384. [Google Scholar] [CrossRef]

- Sáez-Pérez, M.P.; Brümmer, M.; Durán-Suárez, J.A. Effect of the state of conservation of the hemp used in geopolymer and hydraulic lime concretes. Constr. Build. Mater. 2021, 285, 122853. [Google Scholar] [CrossRef]

- EN 1015-11; Methods of Test for Mortar for Masonry—Part 11. Determination of Flexural and Compressive Strength of Hardened Mortars; European Commitee for Standardisation (CEN): Brussels, Belgium, 2007.

- Haile, F.; Adkins, J.; Corradi, M. A Review of the Use of Titanium for Reinforcement of Masonry Structures. Materials 2022, 15, 4561. [Google Scholar] [CrossRef]

- Papadopoulos, K.; Vintzileou, E. New titanium connectors for the columns capitals of the classical temple of Apollo Epikourios. Int. J. Archit. Herit. 2016, 10, 749–765. [Google Scholar] [CrossRef]

- Zambas, C.; Ioannidou, M.; Papanikolaou, A. The use of titanium reinforcement for the restoration of marble architectural members of the Acropolis monuments. Stud. Conserv. 1986, 31 (Suppl. S1), 138–141. [Google Scholar] [CrossRef]

- ΕΝ 1936; Natural Stone Test Methods. Determination of Real Density and Apparent Density, and of Total and Open Porosity; European Committee for Standardisation: Brussels, Belgium, 2006.

- EN 15801; Conservation of Cultural Property-Test Methods-Determination of Water Absorption by Capillarity. European Committee for Standardisation: Brussels, Belgium, 2010.

- EN 13755; Natural Stone Test Methods. Determination of Water Absorption at Atmospheric Pressure; European Committee for Standardisation (CEN): Brussels, Belgium, 2008.

- ASTM C597-16; Standard Test Method for Pulse Velocity through Concrete. American Society for Testing Materials: Philadelphia, PA, USA, 2016.

- Boothby, T.E.; Rosson, B.T. Elasto-plastic Hardening and Shakedown of Masonry Arch Joints. Meccanica 1999, 34, 71–84. [Google Scholar] [CrossRef]

- Groot, C.J.W.P.; Bartos, P.J.M.; Hughes, J.J. Characterisation of old mortars with respect to their repair. In Proceedings of the 12th International Brick/Block Masonry Conference, Madrid, Spain, 25–28 June 2000; Volume 2, pp. 815–827. [Google Scholar]

- Van Balen, K.; Papayianni, I.; Van Hees, R.; Binda, L.; Waldum, A. Introduction to requirements for and functions and properties of repair mortars. Mater. Struct. 2005, 38, 781–785. [Google Scholar] [CrossRef]

- Bakolas, A.; Aggelakopoulou, E.; Moropoulou, A.; Anagnostopoulou, S. Evaluation of pozzolanic activity and physicomechanical characteristics in metakaolin-lime pastes. J. Therm. Anal. Calorim. 2006, 84, 157–163. [Google Scholar] [CrossRef]

- Richardson, I.G. The nature of the hydration products in hardened cement pastes. Cem. Concr. Compos. 2000, 22, 97–113. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, D.; Zhao, J.; Wang, Y.; Liu, Z.; Ma, X. Assessment of the thermal and microstructural properties of metakaolin-air lime based materials at an early age. Appl. Clay Sci. 2020, 191, 105619. [Google Scholar] [CrossRef]

- Çelik, M.Y.; Sert, M. An assessment of capillary water absorption changes related to the different salt solutions and their concentrations ratios in the Döğer tuff (Afyonkarahisar-Turkey) used as building stone of cultural heritages. J. Build. Eng. 2021, 35, 102102. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Moundoulas, P.; Michailidis, P. Evaluation of the compatibility between repair mortars and building materials in historic structures by the control of the microstructure of cement-based systems. Conc. Sci. Engineer. 2002, 2, 191–195. [Google Scholar]

- Amenta, M.; Karatasios, I.; Maravelaki-Kalaitzaki, P.; Kilikoglou, V. The role of aggregate characteristics on the performance optimization of high hydraulicity restoration mortars. Constr. Build. Mater. 2017, 153, 527–534. [Google Scholar] [CrossRef]

- Charola, A.E.; Wendler, E. An overview of the water-porous building materials interactions. Restor. Build. Monum. 2015, 21, 55–65. [Google Scholar] [CrossRef]

- Stogia, M.E.; Dimou, A.E.; Kourkoulis, S.K.; Alexopoulos, N.D. Study of different binders for restoration applications. Procedia Struct. Integr. 2022, 41, 744–751. [Google Scholar] [CrossRef]

- Gameiro, A.; Silva, A.S.; Veiga, R.; Velosa, A. Hydration products of lime–metakaolin pastes at ambient temperature with ageing. Thermochim. Acta 2012, 535, 36–41. [Google Scholar] [CrossRef]

- Cachim, P.; Velosa, A.L.; Rocha, F. Effect of Portuguese metakaolin on hydraulic lime concrete using different curing conditions. Constr. Build. Mater. 2010, 24, 71–78. [Google Scholar] [CrossRef]

- Columbu, S.; Usai, M.; Rispoli, C.; Fancello, D. Lime and Cement Plasters from 20th Century Buildings: Raw Materials and Relations between Mineralogical–Petrographic Characteristics and Chemical–Physical Compatibility with the Limestone Substrate. Minerals 2022, 12, 226. [Google Scholar] [CrossRef]

- Olaniyan, S.A. Pore structure as a determinant of flexibility in sustainable lime-cement mortar composites. Eur. J. Eng. Technol. Res. 2021, 6, 113–122. [Google Scholar] [CrossRef]

- Murphy III, W.F.; Roberts, J.N.; Yale, D.; Winkler, K.W. Centimeter scale heterogeneities and microstratifaction in sedimentary rocks. Geophys. Res. Lett. 1984, 11, 697–700. [Google Scholar] [CrossRef]

- Heritage, E. Practical Building Conservation; Ashgate: Chesterfield, UK, 2011. [Google Scholar]

| Oxides | Chemical Composition (%) | |||

|---|---|---|---|---|

| NHL | L | MK | C | |

| SiO2 | 10.83 | 0.17 | 51.70 | 21.91 |

| Al2O3 | 3.74 | 0.18 | 40.60 | 3.58 |

| Fe2O3 | 1.88 | 0.07 | 0.64 | 0.24 |

| CaO | 55.29 | 70.06 | 1.67 | 66.43 |

| MgO | 2.50 | 2.35 | 1.10 | |

| MnO | 0.02 | - | - | - |

| SO3 | 1.82 | 0.77 | 0.10 | 3.39 |

| K2O | 0.92 | - | 2.31 | 0.43 |

| Na2O | 0.18 | - | 0.04 | |

| TiO2 | 0.24 | - | 0.21 | |

| Cl | - | - | - | 0.03 |

| P2O5 | 0.05 | - | - | 0.04 |

| Cr2O3 | - | - | - | 0.02 |

| SrO | - | - | - | |

| LOI | 19.91 | 25.60 | 1.19 | 2.58 |

| Mortar/Paste Mix | Mix Design (% per Weight) | W/T | |||

|---|---|---|---|---|---|

| NHL | L | MK | C | ||

| NHL100 | 100 | 0.42 | |||

| NHLMK20 | 80 | 20 | 0.48 | ||

| LMK50 | 50 | 50 | 0.70 | ||

| C100 | 100 | 0.40 | |||

| Paste Mix | Bulk Density (g/cm3) | |

|---|---|---|

| Average | St. Dev. | |

| NHL100 | 1.37 | 0.00 |

| NHLMK20 | 1.34 | 0.01 |

| LMK50 | 1.07 | 0.01 |

| C100 | 1.76 | 0.02 |

| Paste Mix | C.R.C. * (mg/(cm2s1/2)) | Pcap ** (%) | W.A.C.cap *** (%) | |||

|---|---|---|---|---|---|---|

| Average | St.Dev. | Average | St. Dev. | Average | St. Dev. | |

| NHL100 | 29.9 | 0.6 | 46.0 | 0.3 | 33.1 | 0.3 |

| NHLMK20 | 11.0 | 0.9 | 22.1 | 1.3 | 15.9 | 0.8 |

| LMK50 | 125.9 | 8.3 | 51.7 | 0.7 | 47.9 | 0.9 |

| C100 | 6.2 | 1.8 | 14.8 | 1.3 | 8.3 | 0.7 |

| Paste Mix | Porosity * (%) | Water Absorption Capacity * (%) | ||

|---|---|---|---|---|

| Average | St. Dev. | Average | St. Dev. | |

| NHL100 | 46.4 | 0.4 | 33.4 | 0.3 |

| NHLMK20 | 40.8 | 0.3 | 29.5 | 0.1 |

| LMK50 | 51.9 | 0.7 | 48.1 | 0.9 |

| C100 | 23.8 | 0.2 | 13.4 | 0.3 |

| Paste Mix | Ultrasonic Pulse Velocity (m/s) | Dynamic Modulus of Elasticity (GPa) | ||

|---|---|---|---|---|

| Average | St. Dev. | Average | St. Dev. | |

| NHL100 | 2755 | 177 | 8.7 | 1 |

| NHLMK20 | 2260 | 186 | 5.8 | 0.9 |

| LMK50 | 2293 | 115 | 4.7 | 0.5 |

| C100 | 3905 | 101 | 21.4 | 1.1 |

| Material | Bulk Density (g/cm3) | Porosity (%) * | W.A.C. (%) | C.R.C. (mg/(cm2s1/2)) | Fc ** (MPa) | U.P.V. (m/s) | |

|---|---|---|---|---|---|---|---|

| Piraeus stone | Min | 1.8 | 4.6 | 1.6 | 1.4 | 12.80 | 2401 |

| Max | 2.5 | 29.2 | 16.4 | 43.9 | 34.10 | 4567 | |

| NHL100 | 1.4 | 46.4 | 33.4 | 29.9 | 10.73 | 2755 | |

| NHLMK20 | 1.3 | 40.8 | 29.5 | 11.0 | 13.90 | 2260 | |

| LMK50 | 1.1 | 51.9 | 48.1 | 125.9 | 14.50 | 2293 | |

| C100 | 1.8 | 23.8 | 13.4 | 6.2 | 47.36 | 3905 | |

| Paste Mix | Fractured Stone System | Prominent Pins | Hidden Pins | Pin Diameter | Pin Length |

|---|---|---|---|---|---|

| LMK50 | Sr1 | N.A. | N.A. | N.A. | N.A. |

| LMK50 | Ss1 | N.A. | N.A. | N.A. | N.A. |

| LMK50 | S1 | X | 3 mm | 11.5 cm | |

| LMK50 | S3 | X | 3 mm | 18 cm | |

| NHLMK20 | Sr2 | N.A. | N.A. | N.A. | N.A. |

| NHLMK20 | Ss2 | N.A. | N.A. | N.A. | N.A. |

| NHLMK20 | S2 | X | 3 mm | 11 cm | |

| NHLMK20 | S4 | X | 3 mm | 21.5 cm |

| Adhesive and Anchoring Material | Fragment System | Maximum Applied Weight (kg) | Reattached Surface (cm2) | Force (N) | Direct Tension (MPa) | Manner of Detachment |

|---|---|---|---|---|---|---|

| LMK50 | Sr1 | 32 | 55.00 | 313.92 | 0.06 | Rupture of the paste No damage to the ancient stone |

| Ss1 | 10 | 42.25 | 38.10 | 0.02 | Rupture of the paste No damage to the ancient stone | |

| NHLMK20 | Sr2 | 250 | 48.00 | 2452.5 | 0.51 | Rupture of the paste No damage to the ancient stone fragments |

| Ss2 | 46 | 46.24 | 451.26 | 0.10 | Rupture of the paste No damage to the ancient stone |

| Adhesive and Anchoring Material | Fragment System | Maximum Applied Weight (kg) | Reattached Surface (cm2) | Force (N) | Direct Tension (MPa) | Manner of Detachment |

|---|---|---|---|---|---|---|

| LMK50 | S1 | 90 | 108.94 | 883 | 0.08 | Rupture of the paste No damage to the ancient stone |

| S3 | 680 | 378.87 | 6374 | 0.17 | Rupture of the paste No damage to the ancient stone | |

| NHLMK20 | S2 | 300 | 78.96 | 2942 | 0.37 | Rupture of the paste No damage to the ancient stone |

| S4 | 340 | 198.94 | 3334 | 0.17 | Rupture of the paste No damage to the ancient stone fragments |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Apostolopoulou, M.; Ksinopoulou, E.; Aggelakopoulou, E.; Tsimereki, A.; Bakolas, A.; Maravelaki, P.-N. Design and Assessment of Pastes for the Reattachment of Fractured Porous Stones. Heritage 2025, 8, 97. https://doi.org/10.3390/heritage8030097

Apostolopoulou M, Ksinopoulou E, Aggelakopoulou E, Tsimereki A, Bakolas A, Maravelaki P-N. Design and Assessment of Pastes for the Reattachment of Fractured Porous Stones. Heritage. 2025; 8(3):97. https://doi.org/10.3390/heritage8030097

Chicago/Turabian StyleApostolopoulou, Maria, Evangelia Ksinopoulou, Eleni Aggelakopoulou, Anthi Tsimereki, Asterios Bakolas, and Pagona-Noni Maravelaki. 2025. "Design and Assessment of Pastes for the Reattachment of Fractured Porous Stones" Heritage 8, no. 3: 97. https://doi.org/10.3390/heritage8030097

APA StyleApostolopoulou, M., Ksinopoulou, E., Aggelakopoulou, E., Tsimereki, A., Bakolas, A., & Maravelaki, P.-N. (2025). Design and Assessment of Pastes for the Reattachment of Fractured Porous Stones. Heritage, 8(3), 97. https://doi.org/10.3390/heritage8030097