Mortars and Renders: The Case of the Roman Villa Horta da Torre Fronteira, Portugal

Abstract

1. Introduction

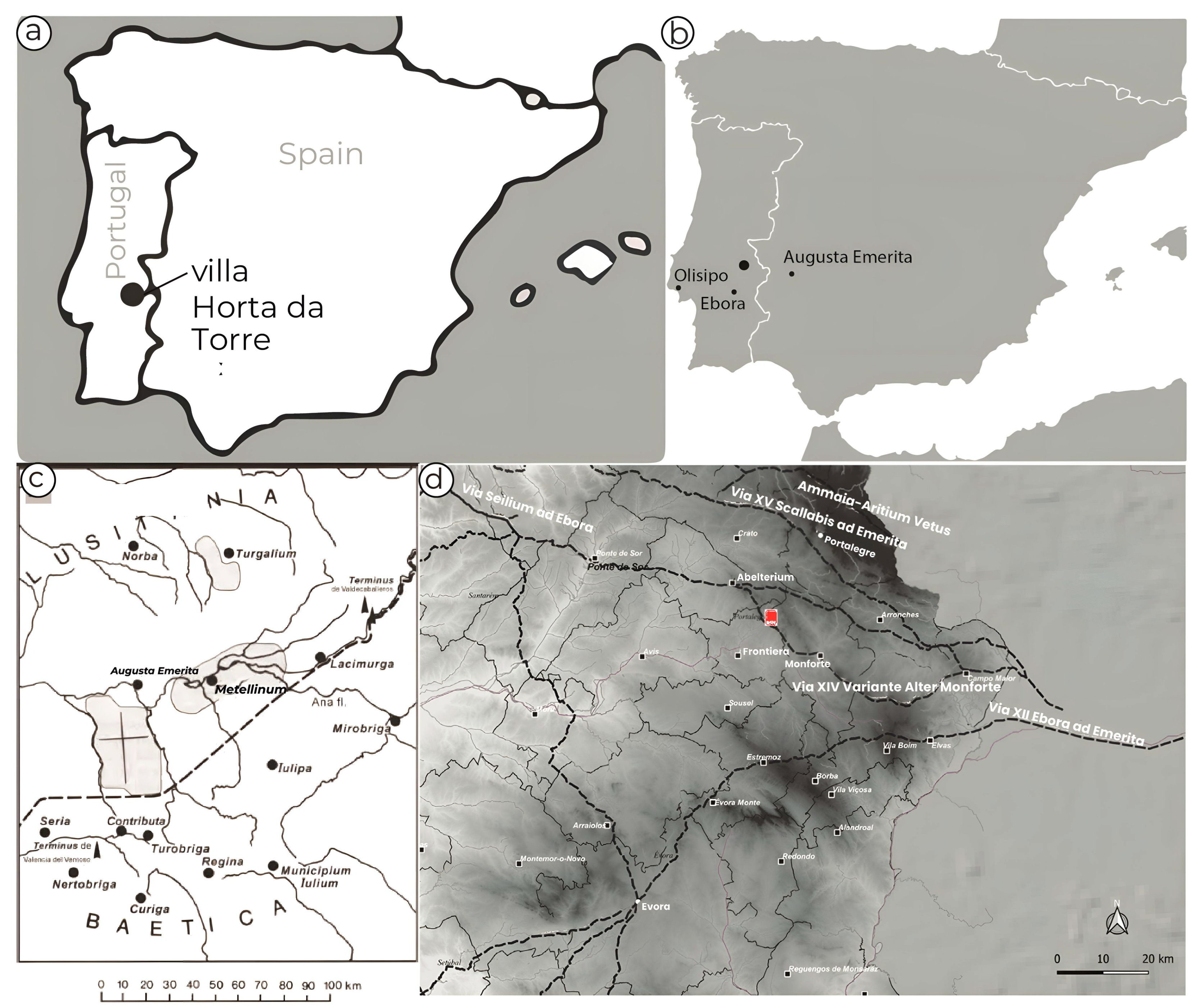

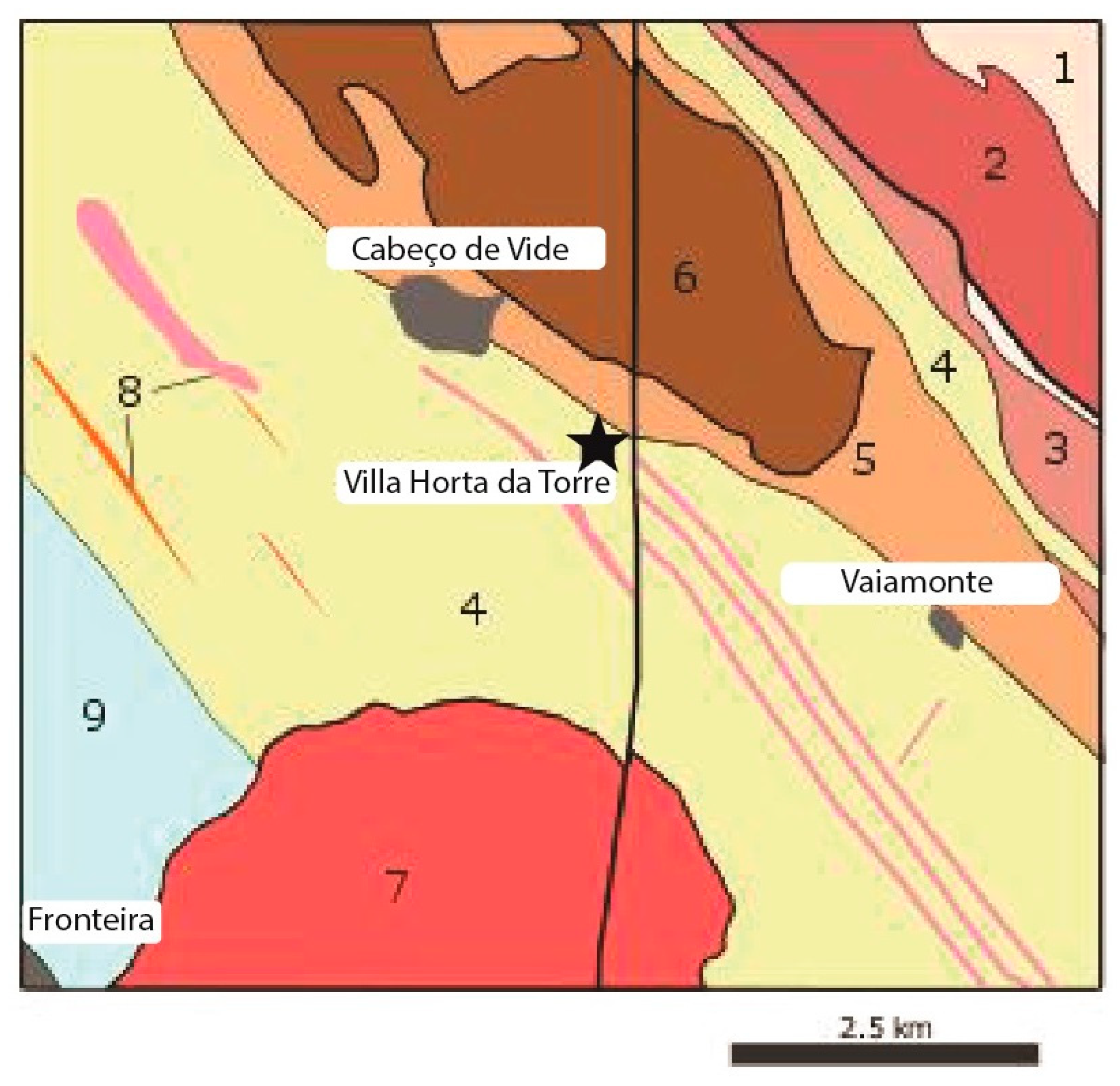

Geological Context

2. Materials and Methods

2.1. Samples

2.2. Sample Preparation

2.3. Instrumental Methods

3. Results

3.1. Macroscopic and Stereomicroscopic Observations

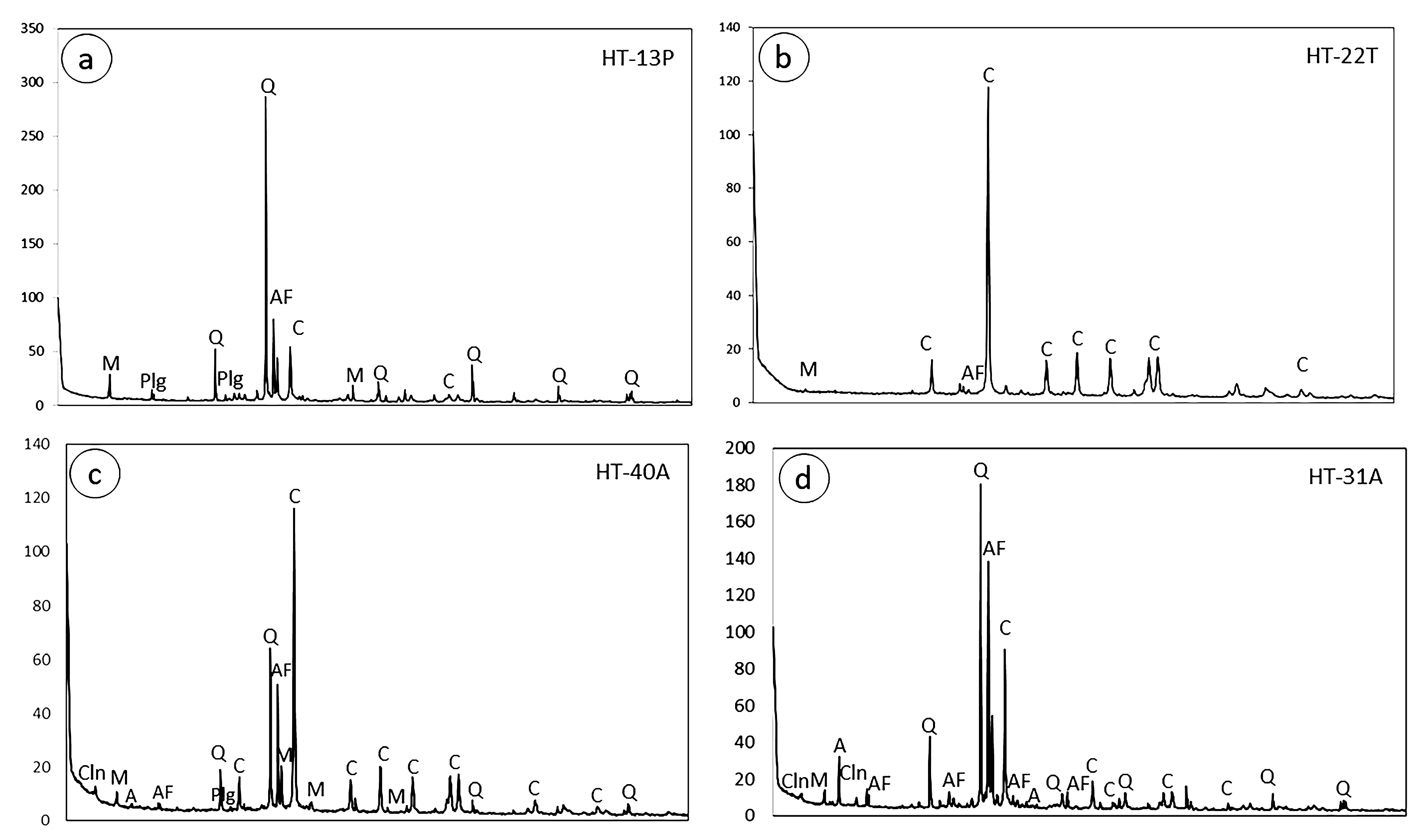

3.2. X-ray Powder Diffraction

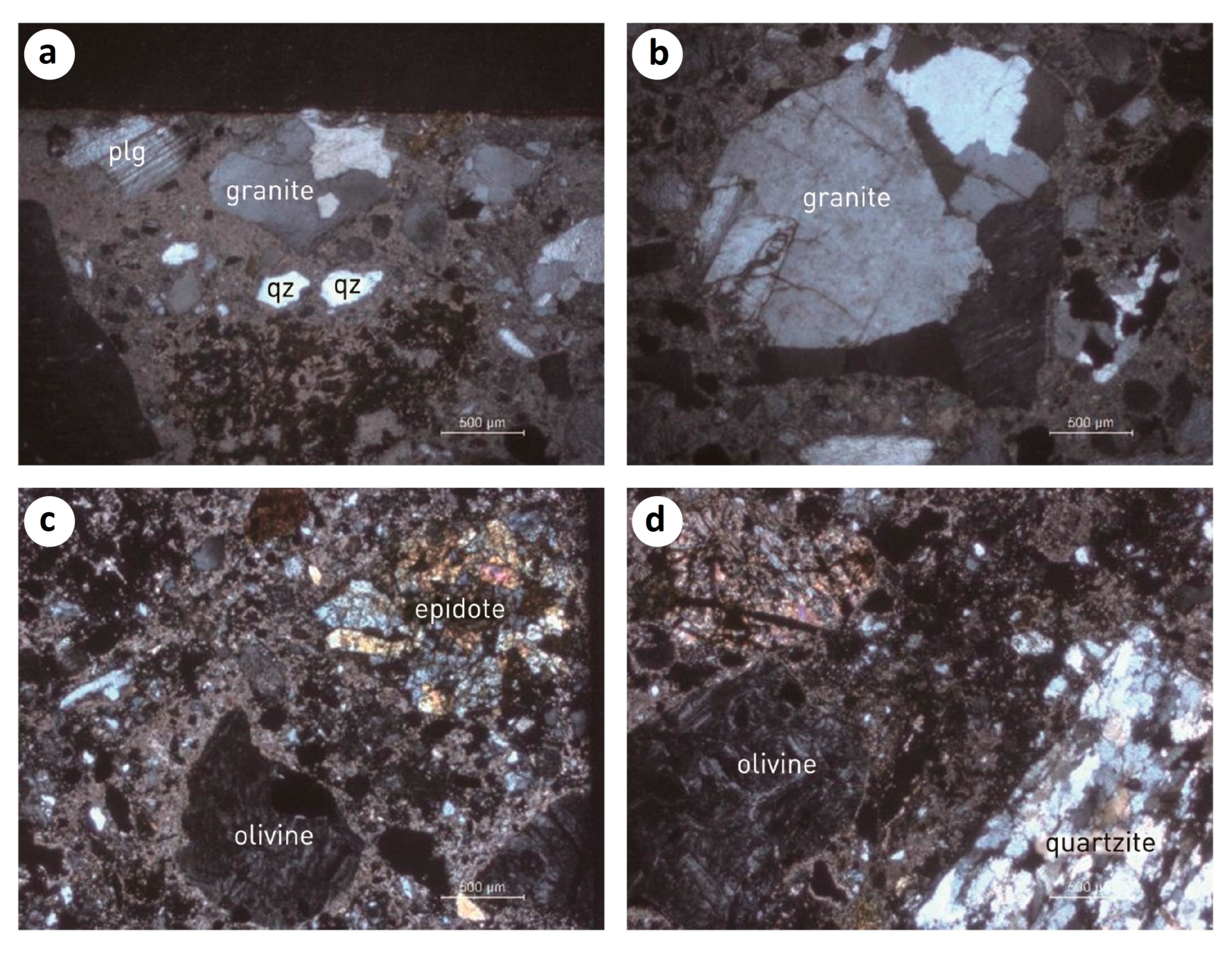

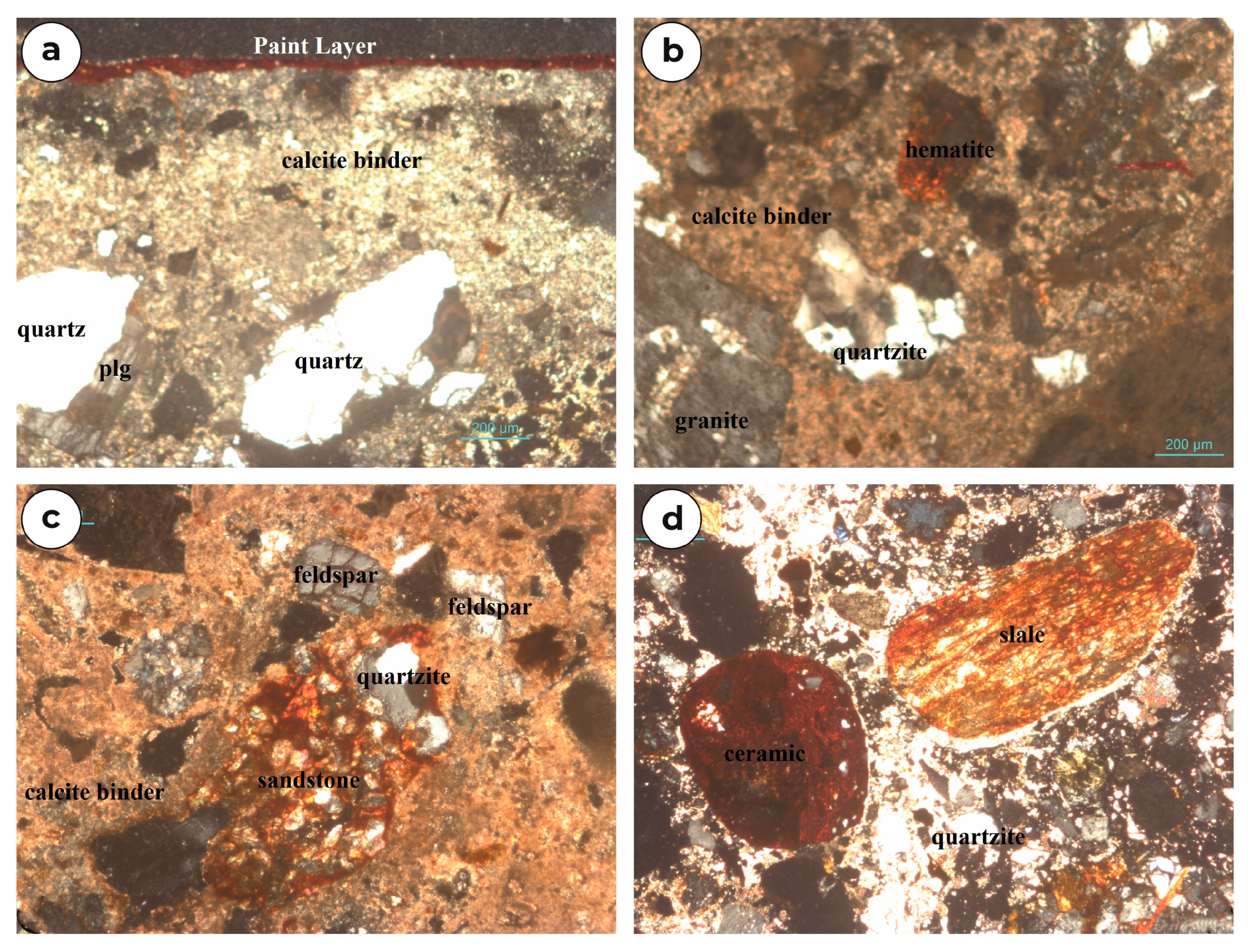

3.3. Microscopic Observation

3.4. Acid Attack and Granulometric Analyses

3.5. Thermal Analysis (TGA/DTA)

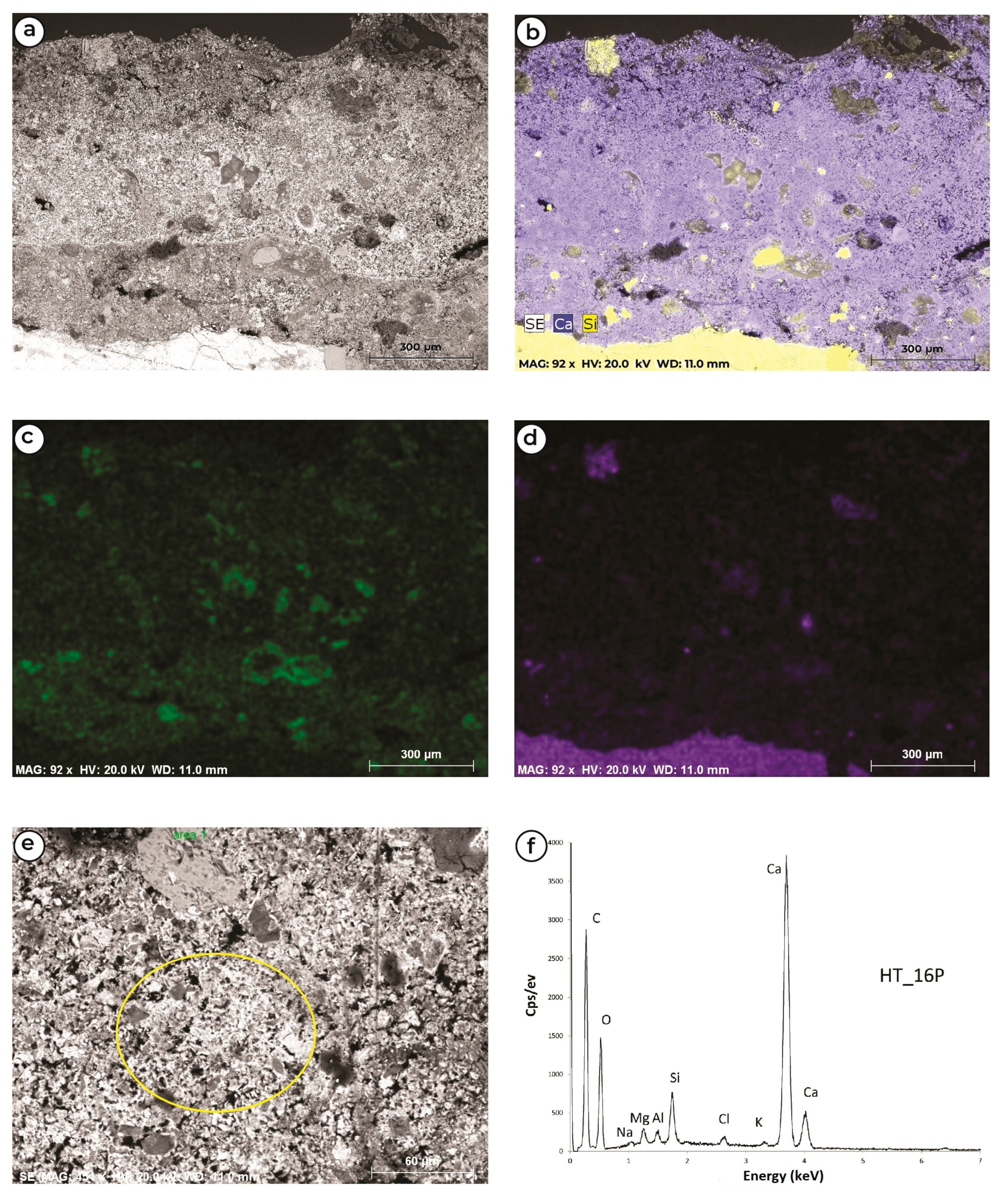

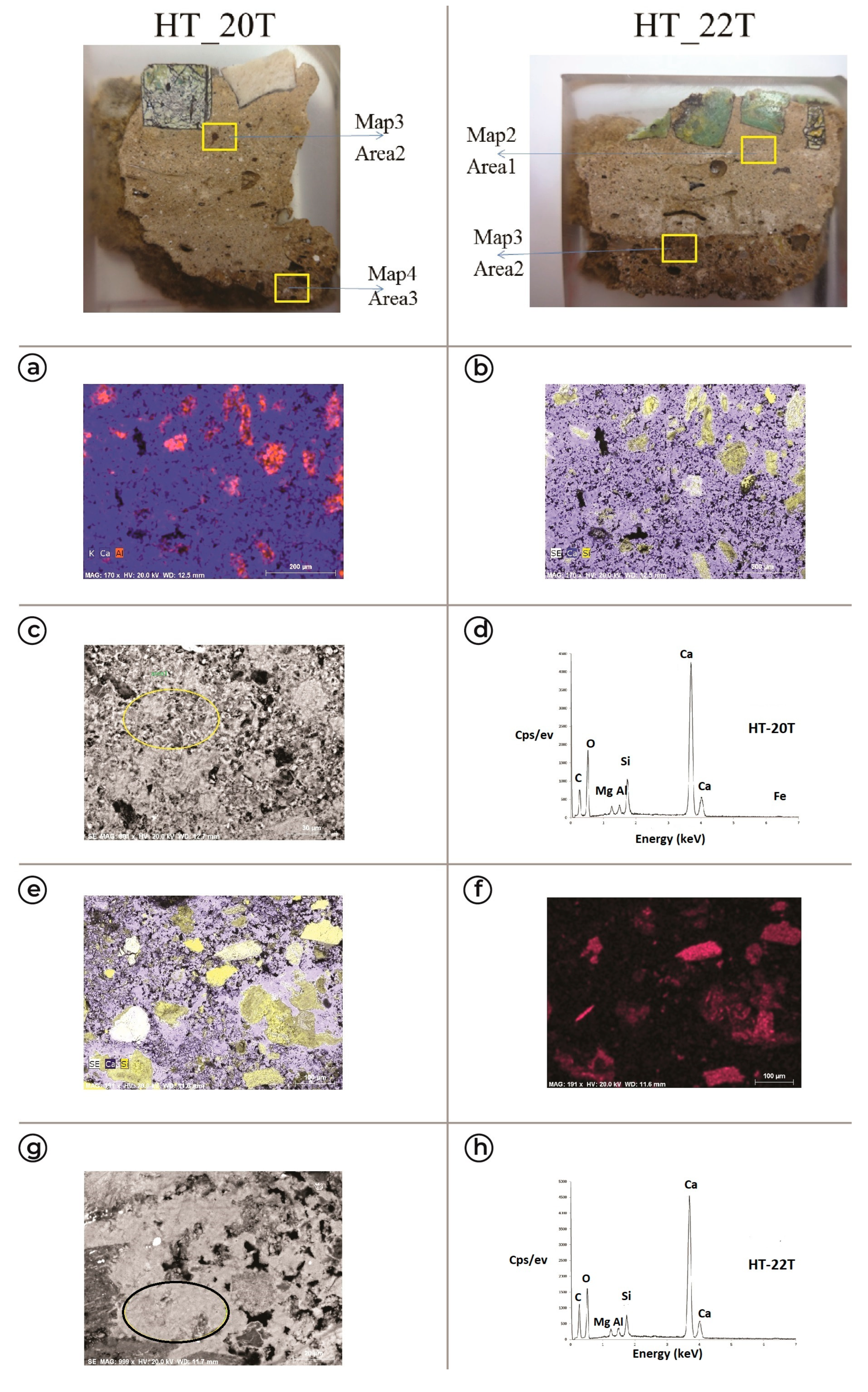

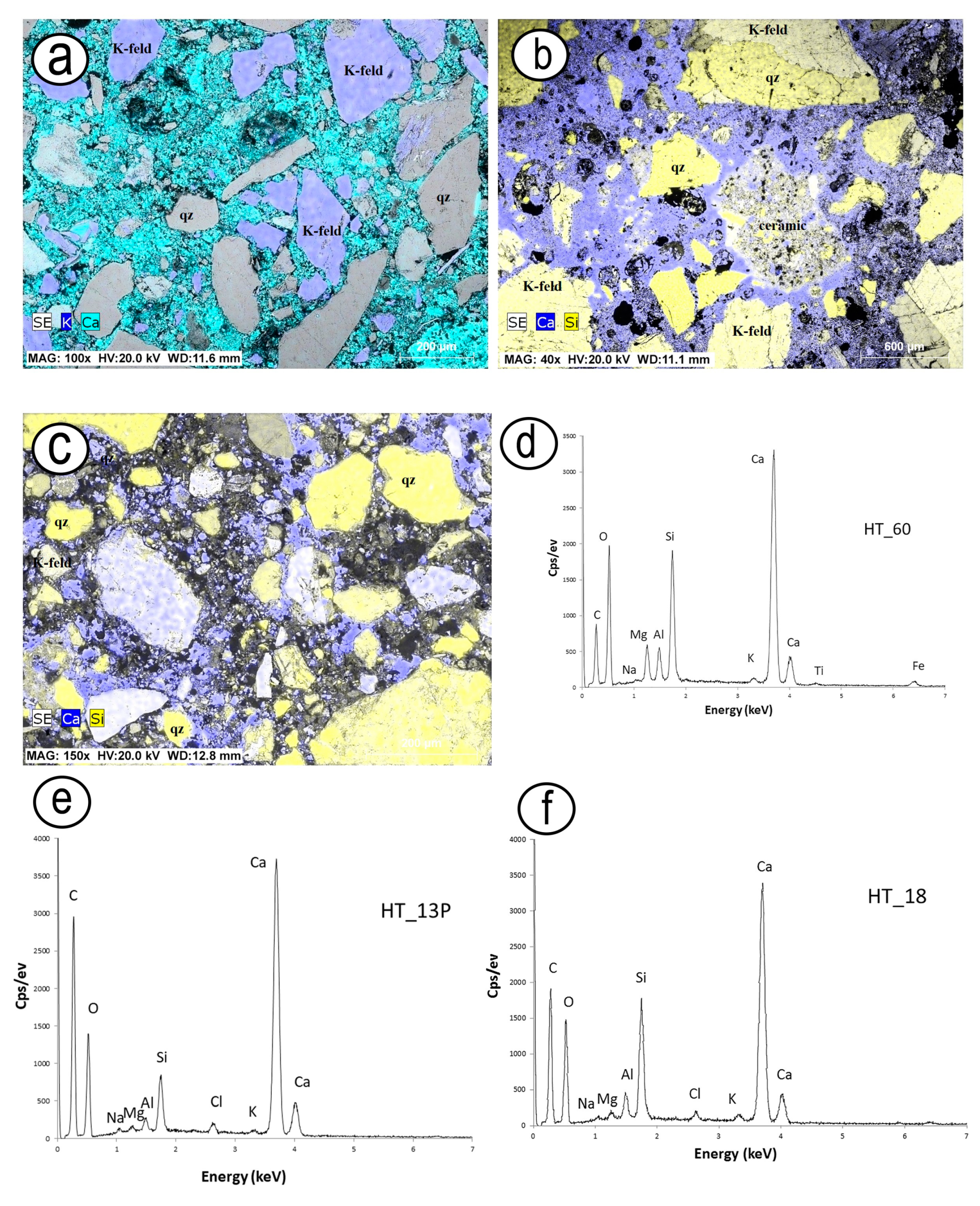

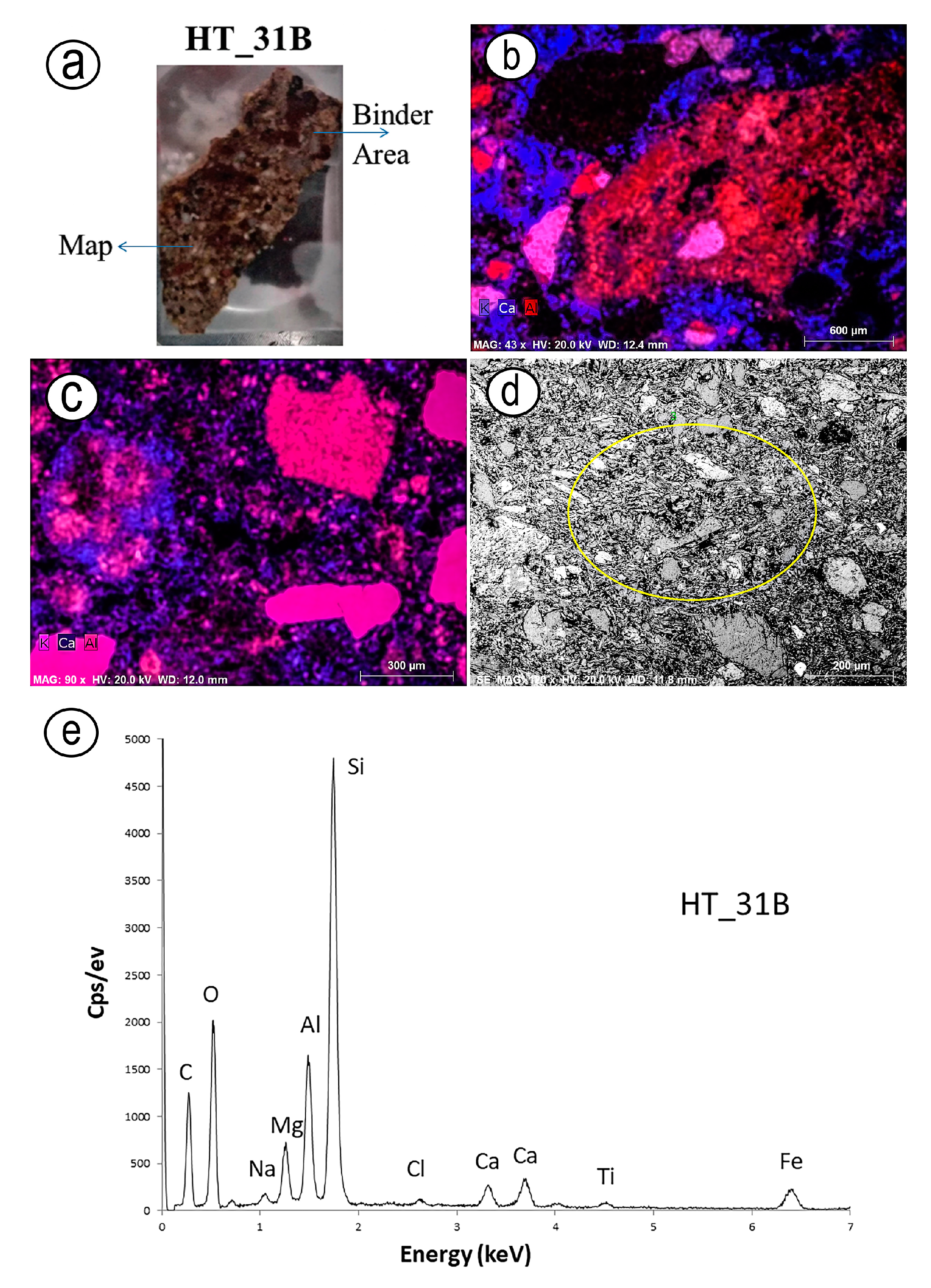

3.6. Variable Pressure Scanning Electron Microscopy with Energy Dispersive X-ray Spectroscopy

4. Discussion

4.1. Production Technology

4.2. Raw Materials and Provenance

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Artioli, G.; Secco, M.; Addis, A. The Vitruvian legacy: Mortars and binders before and after the Roman world. In EMU Notes Mineralogy; Mineralogical Society of Great Britain and Ireland: London, UK, 2019; Volume 20, pp. 151–202. [Google Scholar] [CrossRef]

- Lancaster, L.C. Mortars and plasters—How mortars were made. The literary sources. Archaeol. Anthropol. Sci. 2021, 13, 192. [Google Scholar] [CrossRef]

- Torraca, G. Lectures on Materials Science for Architectural Conservation; Getty Institute: Los Angeles, CA, USA, 2009. [Google Scholar]

- Lugli, G. La Tecnica Edilizia Romana: Con Particolare Riguardo a Roma e Lazio; G. Bardi: Firenze, Italy, 1957. [Google Scholar]

- Ventolà, L.; Vendrell, M.; Giraldez, P.; Merino, L. Traditional organic additives improve lime mortars: New old 20 materials for restoration and building natural stone fabrics. Constr. Build. Mater. 2011, 25, 3313–3318. [Google Scholar] [CrossRef]

- Von Landsberg, D. History of quicklime production and use from early times to the industrial revolution. ZKG Int. Ed. B 1992, 45, 269–273. [Google Scholar]

- Curulli, A.; Montesperelli, G.; Ronca, S.; Cavalagli, N.; Ubertini, F.; Padeletti, G.; Vecchio Ciprioti, S. A multidisciplinary approach to the mortars characterization from the Town Walls of Gubbio (Perugia, Italy). J. Therm. Anal. Calorim. 2020, 142, 1721–1737. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Bisbikou, K. Investigation of the technology of historic mortars. J. Cult. Herit. 2000, 1, 45–58. [Google Scholar] [CrossRef]

- Rua, H. The Ten Books on Architecture by Vitruvius; IST: Lisbon, Portugal, 1998. [Google Scholar]

- Hobbs, L.W.; Siddall, R. Cementitious materials of the ancient world. In Building Roma Aeterna: Current Research on Roman Mortar and Concrete, Proceedings of the Conference, Helsinki, Finland, 27–29 March 2008; Ringbom, Å., Hohlfelder, R.L., Eds.; Commentationes Humanarum Litterarum; Societas Scientiarum Fennica: Helsinki, Finland, 2011; Volume 128, pp. 34–58. [Google Scholar]

- Ergenç, D.; Fort, R. Multi-technical characterization of Roman mortars from Complutum, Spain. Measurement 2019, 147, 106876. [Google Scholar] [CrossRef]

- Silva, A.S.; Adriano, P.; Magalhães, A.; Pires, J.; Carvalho, A.; Cruz, A.J.; Candeias, A. Characterization of historical mortars from Alentejo’s religious buildings. Int. J. Archit. Herit. 2010, 4, 138–154. [Google Scholar] [CrossRef]

- Esposito, D.; Conte, A.M.; Corda, L.; Giorgi, E. An interdisciplinary approach for the historical and technical characterization of medieval and modern mortars. Conserv. Sci. Cult. Herit. 2020, 20, 197–212. [Google Scholar]

- Carneiro, A. Adapting to change in rural Lusitania: Zooarchaeological records in the Horta da Torre Roman villa (Portugal). Eur. J. Post Class. Archaeol. 2020, 10, 247–278. [Google Scholar]

- Edmondson, J. A Tale of Two Colonies: Augusta Emerita (Mérida) and Metellinum (Medellín) in Roman Lusitania. In Roman Colonies in the First Century of their Foundation; Torrossa Online Digital Bookstore: Oxford, UK, 2011; pp. 32–54. [Google Scholar]

- Myers, P.J. Developing Identities within Roman Iberia: Hybridity, Urbanism, and Economics in Southern Iberia in the Second and First Centuries BC. Doctoral Dissertation, University of Birmingham: Birmingham, UK, 2016. [Google Scholar]

- Oliveira, R.J.; Neves, S.; Caldeira, B.; Borges, J.F.; Teixidó, T. Desenvolvimento de Metodologias eficazes de Prospeção Geofísica Aplicadas a diferentes Ambientes Arqueológicos: O Caso de Horta da Torre (resultados preliminares). In Workshop de Ciências da Terra e do Espaço; Universidade de Évora: Évora, Portugal, 2015. [Google Scholar] [CrossRef]

- Carneiro, A. O Final Das Villae na Lusitânia Romana. O Exemplo da Horta da Torre (Fronteira); URBS REGIA: Toledo, Spain, 2017. [Google Scholar]

- Carneiro, A. Lugares, Tempos e Pessoas. Povoamento Rural Romano no Alto Alentejo; Humanitas Supplementum no; Imprensa da Universidade de Coimbra: Coimbra, Portugal, 2014. [Google Scholar]

- Cardoso, I.; Macedo, M.F.; Vermeulen, F.; Corsi, C.; Santos Silva, A.; Rosado, L.; Mirao, J. A Multidisciplinary Approach to the Study of Archaeological Mortars from the Town of Ammaia in the Roman Province of Lusitania (Portugal). Archaeometry 2014, 56, 1–24. [Google Scholar] [CrossRef]

- Velosa, A.L.; Coroado, J.; Veiga MD, R.; Rocha, F. Characterisation of Roman mortars from Conímbriga with respects to their repair. Mater. Charact. 2007, 58, 1208–1216. [Google Scholar] [CrossRef]

- Callebaut, K.; Elsen, J.; Van Balen, K.; Viaene, W. Nineteenth century hydraulic restoration mortars in the Saint Michael’s Church (Leuven, Belgium): Natural hydraulic lime or cement? Cem. Concr. Res. 2001, 31, 397–403. [Google Scholar] [CrossRef]

- Paiva, H.; Silva, L.M.; Labrincha, J.A.; Ferreira, V.M. Effects of a water-retaining agent on the rheological behavior of a single-coat render mortar. Cem. Concr. Res. 2006, 36, 1257–1262. [Google Scholar] [CrossRef]

- Grilo, J.; Faria, P.; Veiga, R.; Silva, A.S.; Silva, V.; Velosa, A. New natural hydraulic lime mortars–physical and microstructural properties in different curing conditions. Constr. Build. Mater. 2014, 54, 378–384. [Google Scholar] [CrossRef]

- Secco, M.; Dilaria, S.; Addis, A.; Bonetto, J.; Artioli, G.; Salvadori, M. The Evolution of the Vitruvian Recipes over 500 Years of Floor-Making Techniques: The Case Studies of the Domus delle Bestie Ferite and the Domus di Tito Macro (Aquileia, Italy). Archaeometry 2018, 60, 185–206. [Google Scholar] [CrossRef]

- Moore, R.E. A newly observed stratum in Roman floor mosaics. Am. J. Archaeol. 1968, 72, 57–68. [Google Scholar] [CrossRef]

- Ponce-Antón, G.; Zuluaga, M.C.; Ortega, L.A.; Agirre Mauleon, J. Petrographic and chemical–mineralogical characterization of mortars from the cistern at Amaiur castle (Navarre, Spain). Minerals 2020, 10, 311. [Google Scholar] [CrossRef]

- Montana, G. Ceramic raw materials: How to recognize them and locate the supply basins—Mineralogy, petrography. Archaeol. Anthropol. Sci. 2020, 12, 175. [Google Scholar] [CrossRef]

- Elsen, J.; Van Balen, K.; Mertens, G. Hydraulicity in historic lime mortars: A review. Hist. Mortars 2012, 7, 125–139. [Google Scholar]

- Bruni, S.; Cariati, F.; Fermo, P.; Pozzi, A.; Toniolo, L. Characterization of ancient magnesian mortars coming from 4 northern Italy. Thermochim. Acta 1998, 321, 161–165. [Google Scholar] [CrossRef]

- Elsen, J. Microscopy of historic mortars—A review. Cem. Concr. Res. 2006, 36, 1416–1424. [Google Scholar] [CrossRef]

- Margalha, G.; Veiga, R.; Silva, A.S.; De Brito, J. Traditional methods of mortar preparation: The hot lime mix methods. Cem. Concr. Compos. 2011, 33, 796–804. [Google Scholar] [CrossRef]

- Silva, A.S.; Cruz, T.; Paiva, M.J.; Candeias, A.; Adriano, P.; Schiavon, N.; Mirão JA, P. Mineralogical and chemical characterizations of historical mortars from military fortifications in Lisbon harbour (Portugal). Environ. Earth Sci. 2011, 63, 1641–1650. [Google Scholar] [CrossRef]

- Baragona, A.J.; Zanier, K.; Frankova, D.; Anghelone, M.; Weber, J. ARchaeometric analysis of mortars from the roman villa rustica at skolarice (Slovenia). Ann. Anal. ZA Istrske Mediter. Stud. Ser. Hist. Et Sociol. 2022, 32, 499–522. [Google Scholar]

- Moropoulou, A.; Bakolas, A.; Bisbikou, K. Characterization of ancient, byzantine and later historic mortars by thermal and X-ray diffraction techniques. Thermochim. Acta 1995, 269, 779–795. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Moundoulas, P.; Aggelakopoulou, E.; Anagnostopoulou, S. Strength development and lime reaction in mortars for repairing historic masonries. Cem. Concr. Compos. 2005, 27, 289–294. [Google Scholar] [CrossRef]

- Moropoulou, A.; Polikreti, K.; Bakolas, A.; Michailidis, P. Correlation of physicochemical and mechanical properties of historical mortars and classification by multivariate statistics. Cem. Concr. Res. 2003, 33, 891–898. [Google Scholar] [CrossRef]

- Maravelaki-Kalaitzaki, P.; Bakolas, A.; Moropoulou, A. Physico-chemical study of Cretan ancient mortars. Cem. Concr. Res. 2003, 33, 651–661. [Google Scholar] [CrossRef]

- Bakolas, A.; Biscontin, G.; Moropoulou, A.; Zendri, E. Characterization of structural byzantine mortars by thermogravimetric analyses. Thermochim. Acta 1998, 321, 151–160. [Google Scholar] [CrossRef]

- Robert, F.; Colina, H. The influence of aggregates on the mechanical characteristics of concrete exposed to fire. Mag. Concr. Res. 2009, 61, 311–321. [Google Scholar] [CrossRef]

- Jedrzejewska, H. Old mortars in Poland: A new method of investigation. Stud. Conserv. 1960, 5, 132–138. [Google Scholar] [CrossRef]

- Casadio, F.; Chiari, G.; Simon, S. Evaluation of binder/aggregate ratios in archaeological lime mortars with carbonate aggregate: A comparative assessment of chemical, mechanical and microscopic approaches. Archaeometry 2005, 47, 671–689. [Google Scholar] [CrossRef]

- Borsoi, G.; Silva, A.S.; Menezes, P.; Candeias, A.; Mirão, J. Analytical characterization of ancient mortars from the archaeological roman site of Pisões (Beja, Portugal). Constr. Build. Mater. 2019, 204, 597–608. [Google Scholar] [CrossRef]

- Dilaria, S.; Secco, M.; Ghiotto, A.R.; Furlan, G.; Giovanardi, T.; Zorzi, F.; Bonetto, J. Early exploitation of Neapolitan pozzolan (pulvis puteolana) in the Roman theatre of Aquileia, Northern Italy. Sci. Rep. 2023, 13, 4110. [Google Scholar] [CrossRef] [PubMed]

- Dilaria, S.; Secco, M.; Rubinich, M.; Bonetto, J.; Miriello, D.; Barca, D.; Artioli, G. High-performing mortar-based materials from the late imperial baths of Aquileia: An outstanding example of Roman building tradition in Northern Italy. Geoarchaeology 2022, 37, 637–657. [Google Scholar] [CrossRef]

- Coutelas, A. L’hydraulicité des mortiers antiques, entre préconçus et réalité: L’exemple des mortiers de tuileau et autres matériaux de Gaule romaine. Mortiers et Hydraulique en Mediterranée Antique; Presses universitaires de Provence: Provence, France, 2019; pp. 17–30. [Google Scholar]

- Daniele, D.; Corrado, G. Marmo e calcite spatica di vena: Termini di un equivoco sull’intonaco vitruviano. In Annali della Scuola Normale Superiore di Pisa. Classe di Lettere e Filosofia; Scuola Normale Superiore: Pisa, Italy, 1996; Volume 1, pp. 541–548. [Google Scholar]

- Dilaria, S.; Sebastiani, L.; Salvadori, M.; Secco, M.; Flaviana, O.; Artioli, G. Caratteristiche dei pigmenti e dei tectoria ad Aquileia: Un approccio archeometrico per lo studio di frammenti di intonaco provenienti da scavi di contesti residenziali aquileiesi (II sec. aC-V sec. dC). In La Peinture Murale Antique: Méthodes et Apports d’une Approche Technique; Edizioni Quasar: Rome, Italy, 2021; pp. 125–148. [Google Scholar]

- Lanzón, M.; Madrid-Balanza, M.J.; Martínez-Peris, I.; García-Vera, V.E.; Navarro-Moreno, D. Roman wall paintings from the Roman Forum district of Carthago Nova: Characterisation of mortars and pigments. Constr. Build. Mater. 2023, 408, 133543. [Google Scholar] [CrossRef]

- Akyol, A.A. Material Characterization of Ancient Mural Paintings and Related Base Materials: A Case Study of Zeugma Archaeological Area. Ph.D. Thesis, Middle East Technical University, Ankara, Turkey, 2009. [Google Scholar]

- Carneiro, A.M.S.P. (Departamento História/Laboratório de Arqueologia, Universidade de Évora, Évora, Portugal). Personal communication, 2018.

- Fulford, M.; Jean-Pierre, A. Roman Building: Materials and techniques; Routledge: London, UK, 2005. [Google Scholar]

- Bernard, E.; Nguyen, H.; Kawashima, S.; Lothenbach, B.; Manzano, H.; Provis, J.; Scott, A.; Unluer, C.; Winnefeld, F.; Kinnunen, P. MgO-based cements–Current status and opportunities. RILEM Tech. Lett. 2023, 8, 65–78. [Google Scholar] [CrossRef]

- Pahlavan, P. Conservation and Restoration of Historic Mortars and Masonry Structures; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Dilaria, S.; Secco, M.; Bonetto, J.; Ricci, G.; Artioli, G. Making Ancient Mortars Hydraulic. How to Parametrize Type and Crystallinity of Reaction Products in Different Recipes. In Historic Mortars International Conference; Springer Nature: Cham, Switzerland, 2022. [Google Scholar]

- Gonçalves, F.; Fernandes, A.P. Carta Geológica de Portugal na Escala de 1: 50 000: Notícia Explicativa da Folha, 32-B: Portalegre; Universitat de Barcelona: Bareselona, Spain, 1973. [Google Scholar]

- Ditta, A. Conservation of Architectural Heritage: Characterization and Provenance of Roman Mortars. Master’s Thesis, University of Évora, Évora, Portugal, 2017. [Google Scholar]

| Group | Sample | Location | Stratigraphy | Description |

|---|---|---|---|---|

| Group 1 (Painting mortars with chromatic layer) | HT-13P | Peristylium |  | The surface is painted dark red on a white lime base. It is less porous with varying stone aggregate sizes of light gray color. Pieces of terracotta and ‘cocciopesto’ (crushed ceramics) are also present as aggregate. |

| HT-16P | Peristylium |  | The top surface is painted red on the thin white lime base. It is less porous with uniform aggregate size (i.e., stones of very light gray in color). | |

| Group 2 (Preparative mortars for wall mosaic tesserae) | HT-20T | From Ceiling above the Stibadium |  | Colorful mosaics are embedded into the top surface, and a few pieces are embedded in the mortar bed. The second layer of mortar is compact, light gray in color, and has a lower proportion of aggregate. The third layer is dark gray/brown in color with bigger and more stone aggregates. Other pieces of the sample are thicker and have less porosity but a uniform lime bed. |

| HT-22T | Triclinum Southwest Wall |  | The top layer of the colorful mosaic is embedded in a hard, light gray lime bed, working as a base for the mosaics. This layer of mortar is compact, porous, and homogenous. The third layer is non-porous with dark gray stone aggregates. | |

| Group 3 (Filling mortars in between wall and marble cladding) | HT-31B | Narrow Southern Wall |  | It is porous and light gray in color, with big lime lumps present in the mortar. Stone and ceramic/terracotta aggregates of various sizes and shapes are present. |

| HT-40A | Wider Northern Wall |  | The sample is more porous and lighter gray in color, with a homogenous lime matrix. Stone aggregates of various sizes with some pieces of red ceramics/terracotta are present. It consists of big lime lumps as well. | |

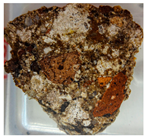

| Group 4 (mortars for stone masonry) | HT-18 | Inner Apse |  | The sample is porous and light and dark gray in color. Stone aggregates and lime lumps of various sizes are visible. |

| HT-19 | Outer Apse |  | It is porous, light gray in color, and has stone aggregates of various sizes. One piece of the sample is a hard stone that is different from the other two samples. The sample contains small lime lumps as well. | |

| HT-31A | Narrow Southern Wall |  | It is porous and light gray in color, with lithic aggregates of various sizes and sand particles. | |

| HT-40B | Wider Northern Wall |  | It is less porous and dark gray in color, with a homogenous composition. Stone aggregates of uniform sizes are embedded in the lime matrix. | |

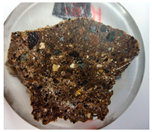

| HT-60 | Wall of the Water Tank |  | It has almost uniform porosity and is dark gray in color, with small lime lumps and stone aggregates of various sizes. It has high compression strength. It looks different from the other samples. |

| Group | Sample | Fraction | Quartz | Calcite | Alkaline Feldspars | Plagioclase | Pyroxene | Micas | Clinochlore | Vermiculite | Amphibole | Hematite | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G-1 (Painting mortar) | HT-13P | G.F | +++++ | + | ++ | +++ | ++ | - | + | +++ | - | - | ± | - | |

| HT-16P | G.F | +++++ | + | - | ++++ | ++ | - | + | + | + | Tr | - | Tr | ||

| G-2 (Preparation mortar for mosaic tesserae from wall) | HT-20T | G.F.2 | + | +++++ + | - | + | Tr | - | ± | + | Tr | - | - | - | |

| HT-22T | G.F.2 | Tr | +++++ ++++++ | - | + | Tr | - | Tr | Tr | Tr | - | - | - | ||

| G.F.3 | Tr | ++++++ +++++ | ± | ++ | Tr | - | + | + | Tr | - | - | - | |||

| G-3 (Filling mortar for marble clad) | HT-31B | G.F | ++++ | +++++ +++ | - | + | + | - | Tr | ++ | - | - | tr | - | |

| HT-40A | G.F | ++ | ++++ | ++ | +++ | ± | - | ± | +++ | Tr | - | Tr | - | ||

| G-4 (Masonry mortars for joining stone) | HT-18 | G.F | +++++ | +++ | + | ++++ | ++++ | - | ± | ++ | ± | - | - | - | |

| HT-19 | G.F | ++++++ | +++ | - | ++++ | ++ | - | + | ± | ++ | ± | - | - | Tr | |

| HT-31A | G.F | +++ | ++++ | ++++ | +++++ | ± | - | + | ± | Tr | ± | ±hrn. | ± | ||

| HT-40B | G.F | ++++ | ++ | - | ++++++ | ++ | - | Tr | + | Tr | - | Tr | - | ||

| HT-60 | G.F | ++++ | ++ | - | - | ++ | - | Tr Py. | ++ | + | + | - | ++++ | + |

| Sample Name | Insoluble Residue (%) | Grain or Particle Size Distribution of Insoluble Residue/% | |||||||

|---|---|---|---|---|---|---|---|---|---|

| >4 mm | 4–2 mm | 2–1 mm | 1–0.5 mm | 0.5–0.25 mm | 0.25–0.125 mm | 0.125–0.63 mm | <0.63 mm | ||

| Fine Gravel | Very Fine Gravel | Very Coarse Sand | Coarse Sand | Medium Sand | Fine Sand | Very Fine Sand | Silt | ||

| HT-13P | 72.54 | 1.35 | 14.87 | 22.57 | 17.57 | 14.46 | 12.84 | 10.27 | 5.40 |

| HT-16P | 60.70 | 1.36 | 20.75 | 37.66 | 18.91 | 10.26 | 5.69 | 3.44 | 1.20 |

| HT-20T2 | 12.47 | 0 | 0 | 0 | 0 | 19.84 | 40.48 | 31.75 | 6.35 |

| HT-22T2 | 15.71 | 0 | 0 | 0 | 36.65 | 19.88 | 22.36 | 19.26 | 0.62 |

| HT-20T3 | 49.22 | 9.66 | 14.84 | 24.8 | 21.81 | 14.14 | 7.97 | 5.08 | 2.09 |

| HT-22T3 | 55.94 | 4.7 | 17.77 | 21.6 | 18.64 | 15.33 | 10.45 | 7.67 | 1.92 |

| HT-31B | 56.93 | 9.5 | 16.41 | 23.66 | 17.44 | 14.51 | 8.98 | 5.87 | 2.59 |

| HT-40A | 47.13 | 15.13 | 17.86 | 20.17 | 17.65 | 13.45 | 9.24 | 5.25 | 2.10 |

| HT-18 | 64.92 | 7.17 | 25.18 | 32.36 | 18.16 | 9.22 | 4.98 | 2.34 | 0.88 |

| HT-19 | 75.69 | 7.96 | 18.41 | 23.89 | 17.36 | 14.23 | 9.92 | 5.09 | 1.96 |

| HT-31A | 70.48 | 0 | 23.42 | 30.58 | 19.15 | 11.16 | 8.26 | 5.23 | 1.93 |

| HT-40B | 63.81 | 6.49 | 24.65 | 33.54 | 24.57 | 6.03 | 2.55 | 1.46 | 0.70 |

| HT-60 | 72.08 | 17.2 | 11.07 | 12.62 | 14.78 | 13.97 | 14.04 | 11.47 | 5.33 |

| Group | Sample | Temperature Range (°C) and Weight Loss (%) | CaCO3 Content | CO2/H2O * | Binder: Aggregate | ||

|---|---|---|---|---|---|---|---|

| 40–200 °C | 200–600 °C | 600–900 °C | |||||

| G-1 Wall Painting Mortars | HT-13P | 0.6 | 1.43 | 8.87 | 20.2 | 6.20 | 1:4 |

| HT-16P | 0.93 | 2.45 | 12.69 | 28.9 | 5.18 | 1:2.46 | |

| G-2 Preparation Mortars for Wall Tesserae | HT-20T-2 | 2.26 | 3.98 | 31.19 | 70.9 | 7.84 | 1:0.41 |

| HT-20T-3 | 0.58 | 2.43 | 15.38 | 35.0 | 6.33 | 1:1.86 | |

| HT-22T-2 | 1.59 | 3.87 | 31.08 | 70.7 | 8.03 | 1:0.41 | |

| G-3 Filling Mortars for Marble Skirting | HT-31B | 1.25 | 2.30 | 12.63 | 28.7 | 5.49 | 1:2.48 |

| HT-40A | 1.44 | 3.35 | 20.88 | 47.5 | 6.23 | 1:1.1 | |

| G-4 Mortars for Stone Masonry | HT-18 | 0.85 | 2.10 | 11.6 | 26.4 | 5.52 | 1:2.79 |

| HT-19 | 1.59 | 2.30 | 11.59 | 26.4 | 5.04 | 1:2.79 | |

| HT-31A | 0.38 | 1.85 | 11.82 | 26.9 | 6.38 | 1:2.72 | |

| HT-40B | 0.4 | 2.03 | 14.8 | 33.6 | 7.29 | 1:1.98 | |

| HT-60 | 1.83 | 3.14 | 8.07 | 18.3 | 2.57 | 1:4.46 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ditta, A.; Carneiro, A.; Galacho, C.; Moita, P. Mortars and Renders: The Case of the Roman Villa Horta da Torre Fronteira, Portugal. Heritage 2024, 7, 1589-1617. https://doi.org/10.3390/heritage7030076

Ditta A, Carneiro A, Galacho C, Moita P. Mortars and Renders: The Case of the Roman Villa Horta da Torre Fronteira, Portugal. Heritage. 2024; 7(3):1589-1617. https://doi.org/10.3390/heritage7030076

Chicago/Turabian StyleDitta, A., André Carneiro, Cristina Galacho, and Patrícia Moita. 2024. "Mortars and Renders: The Case of the Roman Villa Horta da Torre Fronteira, Portugal" Heritage 7, no. 3: 1589-1617. https://doi.org/10.3390/heritage7030076

APA StyleDitta, A., Carneiro, A., Galacho, C., & Moita, P. (2024). Mortars and Renders: The Case of the Roman Villa Horta da Torre Fronteira, Portugal. Heritage, 7(3), 1589-1617. https://doi.org/10.3390/heritage7030076