Abstract

The preservation of natural stone heritage is still a major challenge for the scientific community. This topic assumes a greater importance since it impacts economic and socio-cultural values. Recent research has indicated that water action and microorganism activity are among the major contributors to the deterioration of this material. Despite the emergence of new protective solutions in the market, some constraints still need to be overcome. This study aims to contribute to unveiling the effectiveness of innovative commercial coatings on the preservation of natural stone frequently used in built heritage. Four different commercial coatings are assessed regarding their compatibility with the substrata and effectiveness against UV radiation, water action, and microbial development under accelerated ageing. The protective solutions are tested on five different Portuguese lithotypes, including carbonate and silicate-based stones. Colour change is measured to assess compatibility, while profilometric change of the stones’ surface and antimicrobial potential are evaluated to determine their effectiveness. Our research demonstrates that the solution that exhibits the greatest compatibility and effectiveness potential is composed of modified silanes and siloxanes derivatives.

1. Introduction

Stone deterioration is a phenomenon that strongly impacts its aesthetics and, consequently, its value as a natural construction material. This issue becomes increasingly important as stones are used in the construction of historic buildings and in the production of artefacts, and their deterioration may hinder the preservation of important heritage assets.

Intrinsic stone factors [1,2,3], such as their chemical and mineralogical composition (e.g., calcium carbonate, which is highly susceptible to reactions with acid solutions, the presence of sulphide-based minerals, etc.) and their physical properties (e.g., porosity, commercial finishing), play a key role in the deterioration of natural stone. However, extrinsic factors [4,5,6,7,8,9] such as the presence of water and soluble salts, and the action of microorganisms, are considered to be major inducers of deterioration phenomena occurring in these materials. A considerable number of recent studies have provided a more comprehensive overview of stone deterioration mechanisms [10,11,12,13], the understanding of which is critical to trigger new avenues of research targeting the preservation and safeguarding of both historic and contemporary constructions. However, like any other natural material, natural stone has an unpredictable deterioration pattern. Commercial companies dealing with natural stone are, therefore, permanently seeking to develop new effective solutions to increase their competitiveness by providing robust and long-term certification of the durability of the material; while conservators-restorers struggle to pursue effective solutions to preserve historic buildings and artefacts, and guarantee their integrity for future generations.

The most conventional methods used over the last few decades to preserve natural stone present several post-application constraints [14,15,16]. The recently developed innovative hybrid products, on the other hand, exhibit promising potential for their application in the preservation of natural stone [7,17,18,19]. However, the long-term effectiveness of these innovative solutions remains poorly explored. In fact, many criteria must be met for the successful application of protective coatings in natural stone, such as good adhesion and durability, the reduction of water penetration, transparency, and resistance to microbial development. Innovative compounds, such as modified silanes and siloxanes, as well as inorganic nano-oxides to act as photocatalysts (e.g., titanium dioxide), have been incorporated in the composition of recently created solutions [20,21], also known as smart hybrid coatings. Smart hybrid coatings are advanced materials that combine different functionalities [20] within a single coating layer. These coatings are designed to respond to specific stimuli or environmental conditions, exhibiting adaptive behaviour that can lead to enhanced performance, durability, and functionality. Smart hybrid coatings are often composed of a combination of materials, which can include polymers, nanoparticles, silica, epoxy, and organic-inorganic hybrids [22]. These compounds enable the introduction of hydrophobic, self-cleaning, and antimicrobial properties [23], making them suitable for the preservation of natural stone used both in contemporaneous projects and in heritage assets. Moreover, the mechanisms they induce, which may involve breaking down organic matter, dirt, and pollutants, and preventing the absorption of moisture [24], can limit the conditions that support microbial growth. Nanostructured compounds, such as nanoparticles of silver, zinc oxide, magnesium oxide, or copper have also shown potential in imparting biocidal properties [25] to coatings since these nanoparticles release ions that have antimicrobial properties. However, it is essential to keep in mind that the effectiveness of these protective treatments can vary based on factors such as the type of stone and its physical characteristics, the environment it is exposed to, and the specific formulation of the coating.

This work aims to assess four innovative commercial solutions with potential use for the preservation of natural stone, establishing their compatibility and effectiveness against the action of UV radiation, water, and the action of microorganisms on five Portuguese lithotypes. For this purpose, colour alteration, changes in surface profilometry, and antimicrobial properties were evaluated on the stones using non-destructive and non-invasive methods. The results generated new prospects that will be employed as guidelines for future research of novel eco-friendly and cost-effective solutions.

2. Materials and Methods

Four innovative commercial coatings were assessed in this work, three of them kindly provided by Fakolith (coating 1—Fakolith FK-7; coating 2—Fakolith FK3 PLUS N; coating 4—Fakolith FK-7 NanoTane) and a fourth by a second company that would like to remain anonymous. A deep insight into the four coatings’ substrata compatibility, effectiveness, and antimicrobial potential was performed. These coatings were selected based on the emergence of new and promising products on the market targeted at natural stone preservation. The manufacturers provided their composition, main properties, and application guidelines, all of which can be found in Table 1.

Table 1.

Composition, antimicrobial properties, dilution, and application guidelines recommended by the manufacturers for the coatings used in this study.

The coatings were applied on five different Portuguese lithotypes, including two limestones (Azul Mónica—lithotype A, Branco Real—lithotype B), two marbles (Rosa JPL—lithotype C, Golden Brown—lithotype D), and one slate (Ardósia de Valongo—lithotype E). Their chemical composition, open porosity, and macroscopic appearance are presented in Table 2. The selection of the stones was based on their current high demand for construction purposes and their presence in built and non-built heritage.

Table 2.

Description of the lithotypes used to assess coatings’ compatibility, effectiveness, and antimicrobial potential.

2.1. Experimental Setup and Preparation of the Stone Mock-Ups

The compatibility of the coatings with the substrata and their effectiveness against UV radiation and water action were assessed in two moments, after the coatings’ application and after ageing the treated mock-ups. The antimicrobial potential of the coatings against six microbial strains was individually assessed using the disk diffusion test, and also on treated and inoculated mock-ups after ageing.

The natural stone mock-ups (1.5 × 1.5 × 1.5 cm) were prepared with a DISPLAN-TS (Struers, Copenhagen, Dennmark) precision saw. The mock-ups used to assess the antimicrobial activity were sterilized at 110 °C for 25 min to be able to control the further development of the inoculated cells.

2.2. Preparation of the Cells’ Suspensions

Six distinct microbial strains were selected to assess the antimicrobial potential of the coatings, including two bacteria, three fungi, and one yeast. Except for the yeast, all microorganisms were previously obtained and isolated from natural stone exposed outdoors and exhibiting aesthetic alterations [23], and were previously characterized and sequenced (Table 3). Some of these strains are well known to act as biodeteriogenic agents and have been extensively associated with the colonization of stone-constructed buildings and artefacts [4,13,26,27,28].

Table 3.

Characterization of the microbial isolates used to evaluate the antimicrobial potential of the coatings.

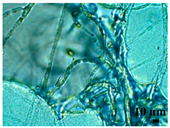

Fresh cultures were prepared in slants using the Nutrient Agar (NA, Oxoid, UK) culture medium (peptone, beef extract, yeast extract, and sodium chlorine) for bacteria growth for 2 days at 30 °C, the Malt Extract Agar (MEA, VWR, Radnor, PA, USA) culture medium (malt extract, glucose, and peptone) for fungi growth for 4 days at 28 °C, and the Yeast extract-Peptone-Dextrose (YPD, HIMEDIA, Einhausen, Germany) culture medium (peptone, yeast extract, and dextrose) for yeast growth for 2 days at 30 °C. After the growth procedure, the cells were placed in a sterilized physiological saline medium (Merck, Darmstadt, Germany) (0.9% w/v). The concentration of each cell suspension was set as 1 × 107 cells/mL. Cell counting was supported by a Neubauer chamber and an optical microscope BA310 (Motic, Hong Kong, China) for fungi and yeast, and by a densitometer DEN-1B (Biosan, Riga, Latvia) for bacteria.

2.3. Compatibility of the Coatings and Their Effectiveness against UV Radiation and Water Action

The compatibility of the coatings with the substrata and their effectiveness against UV radiation and water action were assessed through the determination of the colour change and the evaluation of the structural alteration present in the mock-ups, respectively. These physical characteristics were recorded on the mock-ups at three different stages: (t0) before the application of the coatings, (t1) after the application of the coatings and drying according to the application guides described in Table 1, and (t2) after the accelerated ageing of the mock-ups for 15 days. The assays were performed in duplicate.

The colour was established using a CheckPlusII (DataColor, Lucerne, Switzerland) portable spectrophotometer with a measuring aperture of 5 mm, by determining the parameters of the CIELAB colour space. The total difference in colour (ΔE*) was calculated in each mock-up using the formula ΔE* = ((ΔL)2 + (Δa)2 + (Δb)2)1/2. ΔE* values were determined after the application of the coatings [ΔE*1 (t1 − t0)] and after the ageing of the coated mock-ups [ΔE*2 (t2 − t1)].

The resistance of the protective coatings was determined using a digital microscope (HR-5000E, Hirox, Tokyo, Japan) and a scanning electron microscope (S-3700N, Hitachi, Tokyo, Japan) equipped with 3D surface micro-reconstruction software. The scanning electron microscope was operated at a 20 kV accelerating voltage and a 40 Pa chamber pressure. The 3D surface micro-reconstructions were performed using the four quadrants of the backscattered electron (BSE) detector without any sample preparation step. The 3D models were built and processed using the software MountainsMap®7 (Digital Surf, Besançon, France) to obtain individual surface profiles.

The mock-ups were aged using a QUV-Accelerated Weathering Tester (Q-Lab, Westlake, OH, USA) following ASTM G154 standard conditions: 30 cycles, where each cycle was composed of 8 h of UV radiation (at 60 °C), followed by 15 min of water spray and 3 h and 45 min of condensation (at 50 °C). One mock-up of each lithotype was aged without any coating application to function as a control for the experiment.

2.4. Antimicrobial Potential of the Coatings

2.4.1. Assessing the Antimicrobial Potential Using the Disk Diffusion Method

The disk diffusion method was performed following the Committee on Clinical Laboratory Standard Guidelines [29]. First, 100 µL of each cell suspension, previously prepared as described in Section 2.2., was used to uniformly inoculate MEA, NA, and YPD agar plates. Sterile filter paper disks (ø = 6.5 mm) (VWR, Radnor, PA, USA) were placed on the previous inoculated media by slight pressing and then impregnated with 25 µL of each coating solution. Three different concentrations of the coatings were assessed, using the recommended dilutions of application by the manufacturers. The assay was performed in triplicate for each concentration. Sterile water was used as a negative control. The plates were then incubated for 72 h at 30 °C (for bacteria and yeast development) and 28 °C (for fungi development). After the incubation period, the inhibition zones were measured using a ruler with 1 mm of resolution.

2.4.2. Assessing the Antimicrobial Potential on Stone Mock-Ups

An amount of 1 mL from each cell suspension, previously prepared as described in Section 2.2., was pooled in one single solution composed of all six microbial strains. A new set of mock-ups was assembled and the autoclave was sterilized (110 °C for 25 min) before the application of the coatings was performed following the manufacturer’s guidelines in Table 1. After the drying procedure (Table 1), each mock-up was inoculated with 100 µL of the solution containing the six different microbial cells. The mock-ups were then placed in a Fitoclima 600 (Aralab, Sintra, Portugal) climatic chamber for 30 days at a constant temperature of 28 °C and a relative humidity of 90%. One mock-up of each lithotype was incubated without cell inoculation to function as a control for the experiment. Photographic recording was performed using the digital microscope referred to in Section 2.3. before (t0) and after (t1) the incubation.

3. Results and Discussion

This study considered the major factors that trigger and contribute to the overall deterioration processes occurring on natural stone. The major achievements obtained constitute an important contribution to correlating the chemical composition of coatings that are currently used for stone protection with their effectiveness. Hydrophobic and biocidal properties, and also compatibility with different stone substrata, were assessed in four innovative commercial coatings.

3.1. Compatibility of the Coatings and Their Effectiveness against Water Action and UV Radiation

To constitute effective methodologies for the preservation of heritage assets, commercial coatings have to follow restricted conservation requirements, where colour is considered a major characteristic to be maintained.

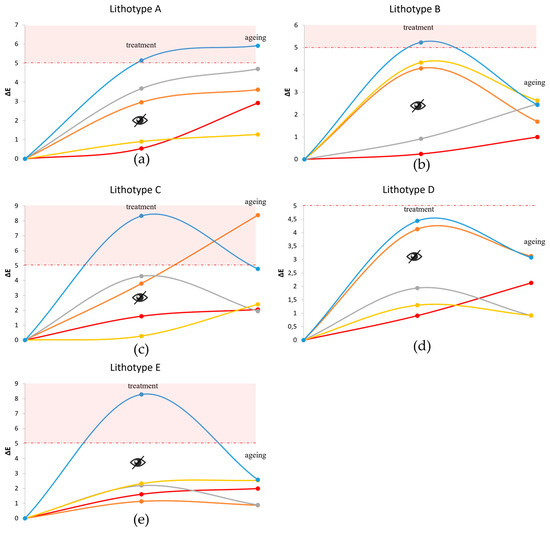

To study the influence of the protective coatings on the colour integrity of the natural stone lithotypes, the total difference in colour (∆E*) was determined after the treatment of the stone mock-ups and after their controlled ageing. It should be noted that, except for coating 4, ∆E* values generally remain below 5 (Figure 1). As ∆E* > 5 is considered to be the acceptance threshold of colour change when dealing with the conservation and restoration of historic buildings [30], this illustrates the good compatibility of the other three protectives with the selected stones. Coating 4 (composed of modified silanes and siloxanes and C6 fluorinated compounds, with polyurethane) was, therefore, the protective that induced the highest colour variation in the mock-ups after their treatment. On the other hand, coating 3 (an aqueous suspension of TiO2 dispersed in an acrylic polymer) revealed the greatest potential to maintain the original colour of the mock-ups in this step, exhibiting greater compatibility with the selected lithotypes.

Figure 1.

Visual representation of the colour alteration of the mock-ups after their treatment and ageing. (a) lithotype A (limestone); (b) lithotype B (limestone); (c) lithotype C (marble); (d) lithotype D (marble); (e) lithotype E (slate). ( ) not coated; (

) not coated; ( ) coating 1 (microemulsion based on modified silanes and siloxanes); (

) coating 1 (microemulsion based on modified silanes and siloxanes); ( ) coating 2 (microemulsion based on nanosilanes, siloxanes, and C6 fluorinated compounds); (

) coating 2 (microemulsion based on nanosilanes, siloxanes, and C6 fluorinated compounds); ( ) coating 3 (aqueous suspension of TiO2 dispersed in an acrylic polymer); (

) coating 3 (aqueous suspension of TiO2 dispersed in an acrylic polymer); ( ) coating 4 (waterproofing based on modified silanes and siloxanes and C6 fluorinated compounds, with polyurethane).

) coating 4 (waterproofing based on modified silanes and siloxanes and C6 fluorinated compounds, with polyurethane).

) not coated; (

) not coated; ( ) coating 1 (microemulsion based on modified silanes and siloxanes); (

) coating 1 (microemulsion based on modified silanes and siloxanes); ( ) coating 2 (microemulsion based on nanosilanes, siloxanes, and C6 fluorinated compounds); (

) coating 2 (microemulsion based on nanosilanes, siloxanes, and C6 fluorinated compounds); ( ) coating 3 (aqueous suspension of TiO2 dispersed in an acrylic polymer); (

) coating 3 (aqueous suspension of TiO2 dispersed in an acrylic polymer); ( ) coating 4 (waterproofing based on modified silanes and siloxanes and C6 fluorinated compounds, with polyurethane).

) coating 4 (waterproofing based on modified silanes and siloxanes and C6 fluorinated compounds, with polyurethane).

After ageing, the colour of the mock-ups generally changed, most likely due to the effects of the ageing process itself, since it is known that UV radiation and moisture have a key role in changing the colour patterns of natural stone [31,32]. The results obtained for the non-treated mock-ups validate this hypothesis. Nevertheless, coating 3 revealed the greatest potential to retard this deleterious effect and preserve the original colour of the lithotypes exposed to atmospheric conditions for a longer period.

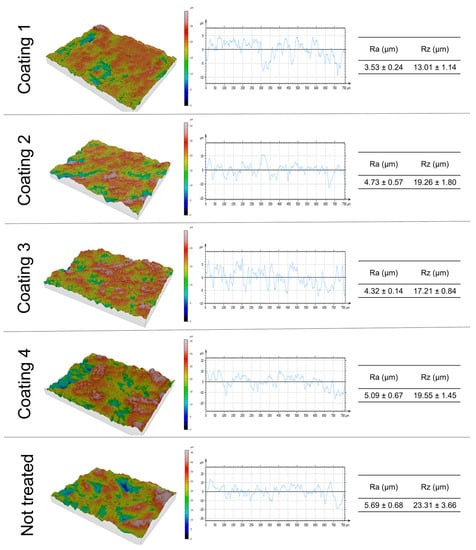

The effectiveness of the coatings against UV radiation and water action was assessed by building a profile of the stone mock-ups’ surface and measuring the roughness parameters Ra and Rz. The profiles were obtained in two mock-ups of each lithotype, using 3D surface micro-reconstruction, which enabled the evaluation of the photodegradation and dissolution processes that occurred on the coated surface of the stones and were enhanced by accelerated ageing. Considering the deterioration processes, in this specific study, lower surface irregularities (lower Ra and Rz values) were taken as higher effectiveness of the coatings. This serves as a significant marker for the study, as all mock-ups were subjected to similar physical preparation, resulting in uniform flat surfaces across all studied mock-ups. The results obtained demonstrated that the most effective protectives were coating 1 (microemulsion based on modified silanes and siloxanes) and coating 3, both presenting the lowest Ra and Rz values. A representative example of the 3D models, profilometry results, and Ra and Rz values obtained with different protective coatings is shown in Figure 2. These results sustain the growing general interest in hybrid organic-inorganic coatings as a potential new effective class for material preservation. These solutions derive from the combination of different building blocks, which lead to multifunctional properties [7,33,34,35,36,37], including hydrophobicity and photostability.

Figure 2.

Determination of the roughness parameters after accelerated ageing of the mock-ups of lithotype C, using 3D surface micro-reconstructions. Mean and standard deviation values were obtained after nine measurements on each mock-up.

On the other hand, coatings 2 (microemulsion based on nanosilanes, siloxanes, and C6 fluorinated compounds) and 4 exhibited the lowest potential to effectively preserve the tested lithotypes, presenting higher Ra and Rz values. These coatings have fluorinated compounds in their composition, which have been indicated and applied as water repellents for stone conservation since the 1980s [38]. However, some studies have recently pointed out that the treatment efficacy using these compounds dramatically decreases with time [39]. Our findings are in agreement with the aforementioned studies, which revealed that the components of these fluorinated solutions and their chemical bonds are more vulnerable to photo and oxidative degradation promoted by high UV radiation and temperature [40]. Moreover, coating 4 has polyurethane in its composition, which, in addition to its hydrophobic properties, is suitable for resistance under humid environments and not for direct contact with water [41]. The untreated stone mock-ups revealed the highest Ra and Rz values, which naturally result from greater exposure of the stone matrixes to the deterioration agents.

3.2. Antimicrobial Potential on Agar Plates

One of the methods adopted for the determination of the antimicrobial potential of the coatings was the disk diffusion test. The inhibition of growth was evaluated using three different coatings concentrations and microbial strains that typically colonize natural stone substrata under a Mediterranean climate. The inhibition zone measurements for the selected microorganisms (Table 4) demonstrate that coating 2 is the protective that exhibits greater antimicrobial potential. In this solution, the antimicrobial potential is probably achieved due to the incorporation of fluorinated compounds into its composition, which are known to possess antimicrobial and anti-biofilm capacities [42].

Table 4.

Measurement of the zone of inhibition (in mm) of the microorganisms’ growth, using different concentrations of the coatings. The different dilutions used were selected according to the manufacturers’ recommendations for the application of each protective.

Coating 1 exhibited strong antibacterial activity, since the observable inhibition zones were greater for bacterial strains. Coatings 3 did not present significant inhibition of growth for the microorganisms under study, most likely due to their high hydrophobic and photostability properties, indicating greater effectiveness for protection against water action and UV radiation and lower resistance to microorganism growth. The presence of TiO2 nanoparticles in this protective could lead us to assume this solution has high antimicrobial potential [43,44], but that has not been confirmed against the selected strains. This suggests that these nanoparticles may have a photocatalytic function [45,46], but specific experiments are required to confirm this hypothesis. On the other hand, coating 4 combined its limited effectiveness against water and UV radiation with a low resistance to microbial growth. The different nature of the C6 fluorinated compounds, which incorporate coatings 2 and 4, are likely paramount to explain the differences in the results obtained for these two protectives.

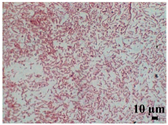

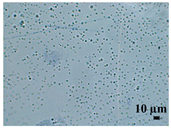

3.3. Antimicrobial Potential on Stone Mock-Ups

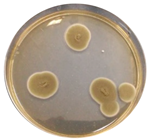

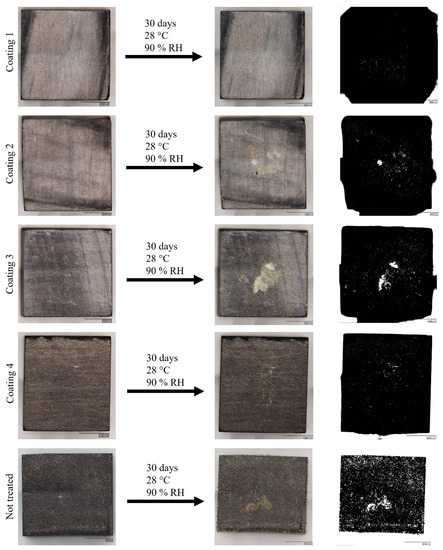

The study of the antimicrobial properties of the protective coatings also encompassed their assessment on natural stone mock-ups to mimic authentic conditions as closely as possible. For this purpose, two treated mock-ups of the selected lithotypes were inoculated with a mixture containing the six microbial colonizers and incubated for 30 days at constant temperature and relative humidity levels. In general, the microemulsion based on modified silanes and siloxanes (coating 1) presented higher effectiveness in the treatment of the stone mock-ups against the colonization of the selected microbial strains, which is indicative of the greatest antimicrobial potential under natural conditions of application. On the other hand, the aqueous suspension of TiO2 dispersed in an acrylic polymer (coating 3) was the solution that presented the lowest antimicrobial potential, corroborating the results obtained on the disk diffusion test. Figure 3 shows exemplificative data obtained in this section, revealing the different protective effects of the coatings against microbial development when applied to stone substrata. A visual representation of the antimicrobial effect of the more effective coating (coating 1) and least effective coating (coating 3) can be found in the Supplementary Materials. The non-treated stone mock-ups were naturally the most susceptible to microbial development, validating the results obtained.

Figure 3.

Visual representation of the antimicrobial effects of the four coatings applied on lithotype E (slate). The images on the right side were included to highlight the microbial growth on the stones; white areas represent the microbial colonies. The scale bars represent 5.0 mm.

The different results obtained in the assessment of the antimicrobial potential of the coatings may be associated with the interaction of the solutions with the substrata at the moment of their application and drying. Since each stone lithotype has distinct chemical and physical characteristics, intrinsic factors such as chemical nature, porosity, and roughness may contribute to divergent absorption patterns of the coating [47,48,49,50]. Furthermore, the viscosity of the coatings may play a key role in this step. Consequently, more absorption suggests more resistance to endolithic colonization, while less absorption will imply more resistance to epilithic colonization. Only epilithic colonization was considered in this study. An overall assessment of microbial colonization on stone mock-ups (including endolithic) will be considered in future research to better establish the biocidal properties of each protective under authentic circumstances.

4. Conclusions

Natural stone is an attractive material in many aspects, which has led mankind to use it for building and artistic purposes over time. With the mission to preserve built and non-built heritage assets for the next generations, researchers are channelling efforts to develop new effective and sustainable solutions to eliminate or mitigate stone deterioration. This study intends to contribute to reaching this goal, unveiling the real effects of some innovative commercial protective coatings that may be employed on natural stone. As such, four different commercial coatings were applied on five Portuguese lithotypes and assessed regarding their compatibility with the substrata and effectiveness against UV radiation, water action, and microbial development under accelerated ageing.

The results obtained regarding the alteration of the lithotypes’ natural colour patterns revealed that all of the coatings studied, except for coating 4, exhibited good compatibility with the selected substrata. However, coating 3 was the protective that revealed the greatest capacity to maintain the original colour of the stones after the treatment and ageing steps. In addition to the good resistance against UV radiation and water action provided by all the solutions, coatings 1 and 3 were the protectives that revealed the greatest capacity to preserve the stones’ integrity after controlled ageing. On the other hand, coating 2 was the protective with greater antimicrobial potential using disk diffusion on agar plates. However, when applied to stone, coating 1 was the protective that provided the greatest resistance to microbial growth. Therefore, considering the experiments performed in this study, the components of coating 1 (modified silanes and siloxanes) demonstrated greater potential to mitigate the deleterious effects promoted by the deterioration agents tested.

The inclusion of stones with different chemical and mineralogical compositions (e.g., granites), the measurement of contact angles and permeability alterations, and an overall biocolonization assessment through metabolic activity studies will also be considered in the future to obtain a more well-rounded perspective on the compatibility and effectiveness of these coatings in natural stone protection.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/heritage6090331/s1, Figure S1: Visual representation of the antimicrobial effect of the most effective coating (coating 1) applied on the five lithotypes. The scale bars represent 5.0 mm; Figure S2: Visual representation of the antimicrobial effect of the least effective coating (coating 3) applied on the five lithotypes. The scale bars represent 5.0 mm.

Author Contributions

Conceptualization: L.D., A.T.C., J.M. and P.B.; Methodology: L.D., R.N., A.T.C., J.M. and P.B.; Validation: L.D. and P.B.; Formal analysis: L.D., R.N. and P.B.; Investigation: L.D., R.N. and P.B.; Resources: A.T.C., J.M. and P.B.; Writing—original draft preparation: L.D.; Writing—review and editing: L.D., M.C., A.T.C., J.M. and P.B.; Visualization: L.D. and R.N.; Supervision: L.D., A.T.C. and P.B.; Project administration: L.D., A.T.C. and P.B.; Funding acquisition: J.M. and P.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Fundação para a Ciência e Tecnologia (FCT) under the projects Eco-STONEPROTEC—Eco-friendly superhydrophobic hybrid coatings for STONE PROTECtion (EXPL/CTA-GEO/0609/2021) and UIDB/04449/2020 and UIDP/04449/2020. The APC was funded by FCT under the project Eco-STONEPROTEC—Eco-friendly superhydrophobic hybrid coatings for STONE PROTECtion (EXPL/CTA-GEO/0609/2021).

Data Availability Statement

The data presented in this study and not contained within the article, or the Supplementary Materials, they are available on request from the corresponding author.

Acknowledgments

The authors would like to thank the anonymous companies that kindly provided commercial coatings samples in order to conduct the present study. We also acknowledge, particularly Fakolith for their collaboration and for providing their commercial products to run the study herein presented.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nasri, F.; Boumezbeur, A.; Benavente, D. Influence of the petrophysical and durability properties of carbonate rocks on the deterioration of historic constructions in Tebessa (northeastern Algeria). Bull. Eng. Geol. Env. 2019, 78, 3969–3981. [Google Scholar] [CrossRef]

- Padilla-Ceniceros, R.; Pacheco-Martínez, J.; López-Doncel, R.A.; Orenday-Tapia, E.E. Rock deterioration in the masonry walls of the Cathedral Basilica of Aguascalientes, Mexico. Rev. Mex. Cienc. Geol. 2017, 34, 138–149. [Google Scholar] [CrossRef]

- Dias, L.; Rosado, T.; Candeias, A.; Mirão, J.; Caldeira, A.T. A change in composition, a change in colour: The case of limestone sculptures from the Portuguese National Museum of Ancient Art. J. Cult. Herit. 2020, 42, 255–262. [Google Scholar] [CrossRef]

- Rosado, T.; Dias, L.; Lança, M.; Nogueira, C.; Santos, R.; Martins, M.R.; Candeias, A.; Mirão, J.; Caldeira, A.T. Assessment of microbiota present on a Portuguese historical stone convent using high-throughput sequencing approaches. MicrobiologyOpen 2020, 9, e1030. [Google Scholar] [CrossRef]

- Ershad-Langroudi, A.; Fadaei, H.; Ahmadi, K. Application of polymer coatings and nanoparticles in consolidation and hydrophobic treatment of stone monuments. Iran. Polym. J. 2019, 28, 1–19. [Google Scholar] [CrossRef]

- Ortega-Morales, O.; Montero-Muñoz, J.L.; Baptista Neto, J.A.; Beech, I.B.; Sunner, J.; Gaylarde, C. Deterioration and microbial colonization of cultural heritage stone buildings in polluted and unpolluted tropical and subtropical climates: A meta-analysis. Int. Biodeterior. Biodegrad. 2019, 143, 104734. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M. Novel Attribute of Organic–Inorganic Hybrid Coatings for Protection and Preservation of Materials (Stone and Wood) Belonging to Cultural Heritage. Coat 2018, 8, 319. [Google Scholar] [CrossRef]

- Kanellopoulou, D.G.; Koutsoukos, P.G. Kinetics of Dissolution of Monument Building Materials. In 10th International Symposium on the Conservation of Monuments in the Mediterranean Basin: Natural and Anthropogenic Hazards and Sustainable Preservation; Koui, M., Zezza, F., Kouis, D., Eds.; Springer: Cham, Switzerland, 2018; pp. 339–346. [Google Scholar] [CrossRef]

- Cappelletti, G.; Fermo, P. 15—Hydrophobic and superhydrophobic coatings for limestone and marble conservation. In Smart Composite Coatings and Membranes; Montemor, M.F., Ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 421–452. [Google Scholar] [CrossRef]

- Alves, C.; Figueiredo, C.A.M.; Sanjurjo-Sánchez, J.; Hernández, A.C. Salt weathering of natural stone: A review of comparative laboratory studies. Heritage 2021, 4, 1554–1565. [Google Scholar] [CrossRef]

- Raju, K.; Ravindhar, S. Detailed review on natural stone materials in architecture. Mater. Today Proc. 2021, 45, 6341–6347. [Google Scholar] [CrossRef]

- Schroer, L.; Boon, N.; De Kock, T.; Cnudde, V. The capabilities of bacteria and archaea to alter natural building stones—A review. Int. Biodeterior. Biodegrad. 2021, 165, 105329. [Google Scholar] [CrossRef]

- Pinheiro, A.C.; Mesquita, N.; Trovão, J.; Soares, F.; Tiago, I.; Coelho, C.; Paiva de Carvalho, H.; Gil, F.; Catarino, L.; Piñar, G.; et al. Limestone biodeterioration: A review on the Portuguese cultural heritage scenario. J. Cult. Herit. 2019, 36, 275–285. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Q.; Liu, T.; Zhang, B. The preservation damage of hydrophobic polymer coating materials in conservation of stone relics. Prog. Org. Coat. 2013, 76, 1127–1134. [Google Scholar] [CrossRef]

- Ema, N.P.; Álvarez de Buergo, M. Adverse effects arising from conservation treatments on archaeological sites: Theory, practice and review. Coalition 2013, 24, 14–23. [Google Scholar]

- Delgado-Rodrigues, J. Stone patina: A controversial concept of relevant importance in conservation. In Proceedings of the International Seminar Theory and Practice in Conservation: A Tribute to Cesare Brandi, Lisbon, Portugal, 4–5 May 2006; LNEC: Lisbon, Portugal, 2006; Volume 1, pp. 163–174. [Google Scholar]

- Corcione, C.E.; Striani, R.; Capone, C.; Molfetta, M.; Vendetta, S.; Frigione, M. Preliminary study of the application of a novel hydrophobic photo-polymerizable nano-structured coating on concrete substrates. Prog. Org. Coat. 2018, 121, 182–189. [Google Scholar] [CrossRef]

- Raneri, S.; Barone, G.; Mazzoleni, P.; Alfieri, I.; Bergamonti, L.; De Kock, T.; Cnudde, V.; Lottici, P.P.; Lorenzi, A.; Predieri, G.; et al. Efficiency assessment of hybrid coatings for natural building stones: Advanced and multi-scale laboratory investigation. Constr. Build. Mater. 2018, 180, 412–424. [Google Scholar] [CrossRef]

- Colangiuli, D.; Lettieri, M.; Masieri, M.; Calia, A. Field study in an urban environment of simultaneous self-cleaning and hydrophobic nanosized TiO2-based coatings on stone for the protection of building surface. Sci. Total Environ. 2019, 650, 2919–2930. [Google Scholar] [CrossRef]

- Cappelleti, G.; Fermo, P.; Camiloni, M. Smart hybrid coatings for natural stones conservation. Prog. Org. Coat. 2015, 78, 511–516. [Google Scholar] [CrossRef]

- Kapridaki, C.; Maravelaki-Kalaitzaki, P. TiO2-SiO2-PDMS nano-composite hydrophobic coating with self-cleaning properties for marble protection. Prog. Org. Coat. 2013, 76, 400–410. [Google Scholar] [CrossRef]

- Berdimurodov, E.; Berdimuradov, K.; Eliboev, I.; Kholikov, A.; Akbarov, K.; Umirov, N.; Borikhonov, B. Chapter 12: Smart-hybrid nanomaterials in corrosion prevention. In Corrosion Prevention Nanoscience: Nanoengineering Materials and Technologies; Tukhlievich, B.E., Verma, C., Eds.; De Gruyter: Berlin, Germany; Boston, MA, USA, 2023; pp. 181–194. [Google Scholar] [CrossRef]

- Sierra-Fernandez, A.; Gomez-Villalba, L.; Rabanal, M.; Fort, R. New nanomaterials for applications in conservation and restoration of stony materials: A review. Mater. Construcción 2017, 67, 107. [Google Scholar] [CrossRef]

- Luna, M.; Mosquera, M.J.; Vidal, H.; Gatica, J.M. Au-TiO2/SiO2 photocatalysts for building materials: Self-cleaning and de-polluting performance. Build. Environ. 2019, 164, 106347. [Google Scholar] [CrossRef]

- Franco-Castillo, I.; Hierro, L.; de la Fuente, J.; Seral-Ascaso, A.; Mitchell, S.G. Perspectives for antimicrobial nanomaterials in cultural heritage conservation. Chem 2021, 7, 629–669. [Google Scholar] [CrossRef]

- Dias, L.; Rosado, T.; Coelho, A.; Barrulas, P.; Lopes, L.; Moita, P.; Candeias, A.; Mirão, J.; Caldeira, A.T. Natural limestone discolouration triggered by microbial activity—A contribution. AIMS Microbiol. 2018, 4, 594–607. [Google Scholar] [CrossRef] [PubMed]

- Miller, A.Z.; Laiz, L.; Gonzalez, J.M.; Dionísio, A.; Macedo, M.F.; Saiz-Jimenez, C. Reproducing stone monument photosynthetic-based colonization under laboratory conditions. Sci. Total Environ. 2008, 405, 278–285. [Google Scholar] [CrossRef]

- Cappitelli, F.; Principi, P.; Pedrazzani, R.; Toniolo, L.; Sorlini, C. Bacterial and fungal deterioration of the Milan Cathedral marble treated with protective synthetic resins. Sci. Total Environ. 2007, 385, 172–181. [Google Scholar] [CrossRef] [PubMed]

- M02-A11; Performance Standards for Antimicrobial Disk Susceptibility Tests: Approved Standard, 11th ed. Clinical and Laboratory Standards Institute (CLSI): Wayne, PA, USA, 2012.

- Munafò, P.; Battista Goffredo, G.; Quagliarini, E. TiO2-based nanocoatings for preserving architectural stone surfaces: An overview. Constr. Build. Mater. 2015, 84, 201–218. [Google Scholar] [CrossRef]

- Lisci, C.; Sitzia, F.; Pires, V.; Mirão, J. Building stones durability by UVA radiation, moisture and spray accelerated weathering. J. Build. Pathol. Rehabil. 2022, 7, e60. [Google Scholar] [CrossRef]

- Careddu, N.; Graziella, M. The effects of solar UV radiation on the gloss values of polished stone surfaces. Constr. Build. Mater. 2013, 49, 828–834. [Google Scholar] [CrossRef]

- Jia, Z.; Hong, R. Anticorrosive and photocatalytic properties research of epoxy-silica organic-inorganic coating. Colloids Surf. A Physicochem. Eng. Asp. 2021, 622, 126647. [Google Scholar] [CrossRef]

- Al Zoubi, W.; Prisla Kamil, M.; Fatimah, S.; Nashrah, N.; Gun Ko, Y. Recent advances in hybrid organic-inorganic materials with spatial architecture for state-of-the-art applications. Prog. Mater. Sci. 2020, 112, 100663. [Google Scholar] [CrossRef]

- El-Bashir, S.M.; Yahia, I.S.; Al-Harbi, F.; Elburaih, H.; Al-Faifi, F.; Aldosari, N.A. Improving photostability and efficiency of polymeric luminescent solar concentrations by PMMA/MgO nanohybrid coatings. Int. J. Green Energy 2017, 14, 270–278. [Google Scholar] [CrossRef]

- Kumar, D.; Wu, X.; Fu, Q.; Chye Ho, J.W.; Kanhere, P.D.; Li, L.; Chen, Z. Development of durable self-cleaning coatings using organic-inorganic hybrid sol-gel method. Appl. Surf. Sci. 2015, 344, 205–212. [Google Scholar] [CrossRef]

- Sadat-Shojai, M.; Ershad-Langroudi, A. Polymeric coatings for protection of historic monuments: Opportunities and challenges. J. Appl. Polym. Sci. 2009, 112, 2535–2551. [Google Scholar] [CrossRef]

- Piacenti, F.; Camaiti, M. Synthesis and characterization of fluorinated polyetheric amides. J. Fluor. Chem. 1994, 68, 227–235. [Google Scholar] [CrossRef]

- Cao, Y.; Salvini, A.; Camaiti, M. Oligoamide grafted with perfluoropolyether blocks: A potential protective coating for stone materials. Prog. Org. Coat. 2017, 111, 164–174. [Google Scholar] [CrossRef]

- Gao, J.; Li, C.; Lv, Z.; Wang, R.; Wu, D.; Li, X. Correlation between the surface ageing of acrylic polyurethane coatings and environmental factors. Prog. Org. Coat. 2019, 132, 362–369. [Google Scholar] [CrossRef]

- Zhang, S.F.; Wang, R.M.; He, Y.F.; Song, P.F.; Wu, Z.M. Waterborne polyurethane-acrylic copolymers crosslinked core-shell nanoparticles for humidity-sensitive coatings. Prog. Org. Coat. 2013, 76, 729–735. [Google Scholar] [CrossRef]

- Alshammari, N.A.H.; Bakhotmah, D.A. Synthesis, reactivity, antimicrobial, and anti-biofilm evaluation of fluorinated 4-amino-3-mercapto-1,2,4-triazin-5(4H)-one and their derivatives. Phosphorus Sulfur. Silicon Relat. Elem. 2022, 198, 385–396. [Google Scholar] [CrossRef]

- Ahmad, W.; Jaiswal, K.K.; Soni, S. Green synthesis of titanium dioxide (TiO2) nanoparticles by using Mentha arvensis leaves extract and its antimicrobial properties. Inorg. Nano-Met. Chem. 2020, 50, 1032–1038. [Google Scholar] [CrossRef]

- Subhapriya, S.; Gomathipriya, P. Green synthesis of titanium dioxide (TiO2) nanoparticles by Trigonella foenum-graecum extract and its antimicrobial properties. Microb. Pathog. 2018, 116, 215–220. [Google Scholar] [CrossRef]

- Calia, A.; Lettieri, M.; Masieri, M.; Pal, S.; Licciulli, A.; Arima, V. Limestones coated with photocatalytic TiO2 to enhance building surface with self-cleaning and depolluting abilities. J. Clean. Prod. 2017, 165, 1036–1047. [Google Scholar] [CrossRef]

- Calia, A.; Lettieri, M.; Masieri, M. Durability assessment of nanostructured TiO2 coatings applied on limestones to enhance building surface with self-cleaning ability. Build. Environ. 2016, 110, 1–10. [Google Scholar] [CrossRef]

- Matteucci, E.; Scarcella, A.V.; Croveri, P.; Marengo, A.; Borghi, A.; Benelli, C.; Hamdan, O.; Favero-Longo, S.E. Lichens and other lithobionts on the carbonate rock surfaces of the heritage site of the tomb of Lazarus (Palestinian territories): Diversity, biodeterioration and control issues in a semi-arid environment. Ann. Microbiol. 2019, 69, 1033–1046. [Google Scholar] [CrossRef]

- Quagliarini, E.; Graziani, L.; Diso, D.; Licciulli, A.; D’Orazio, M. Is nano-TiO2 alone an effective strategy for the maintenance of stones in Cultural Heritage? J. Cult. Herit. 2018, 30, 81–91. [Google Scholar] [CrossRef]

- de los Ríos, A.; Pérez-Ortega, S.; Wierzchos, J.; Ascaso, C. Differential effects of biocide treatments on saxicolous communities: Case study of the Segovia cathedral cloister (Spain). Int. Biodeter. Biodegr. 2012, 67, 64–72. [Google Scholar] [CrossRef]

- Cámara, B.; de los Ríos, A.; Urizal, M.; Álvarez de Buergo, M.; Varas, M.J.; Fort, R.; Ascaso, C. Characterizing the microbial colonization of a dolostone quarry: Implications for stone biodeterioration and response to biocide treatments. Microb. Ecol. 2011, 62, 299–312. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).