Non-Destructive Testing of Dalle de Verre Windows by Fernand Léger and Alexandre Cingria in Switzerland

Abstract

:1. Introduction

- Corrosion of rebars due to carbonation of the cement paste and loss of passivation

- Formation of expansive phases due to chemical reactions between the cement paste and the aggregate (most prominently the alkali-silica reaction)

- Chemical reactions between the cement paste and the glass sometimes leading to a nearly complete decomposition of the glass pieces

- Environmental impact such as freeze-thaw cycles also leading to cracks and spalling of the mortar

- Structural problems and mechanical stress

- Damage related to the manufacture of the dalles de verre, such as drying shrinkage cracks and uncovered rebars.

2. Questions and Aims

- Existence and position of rebar

- Concrete cover of rebar

- Thickness of the dalle de verre structures

- Corrosion of rebar

- Existence and location of micro-cracks and other damages

- Material properties, such as humidity and carbonation

3. Investigated Dalle de Verre Glazings

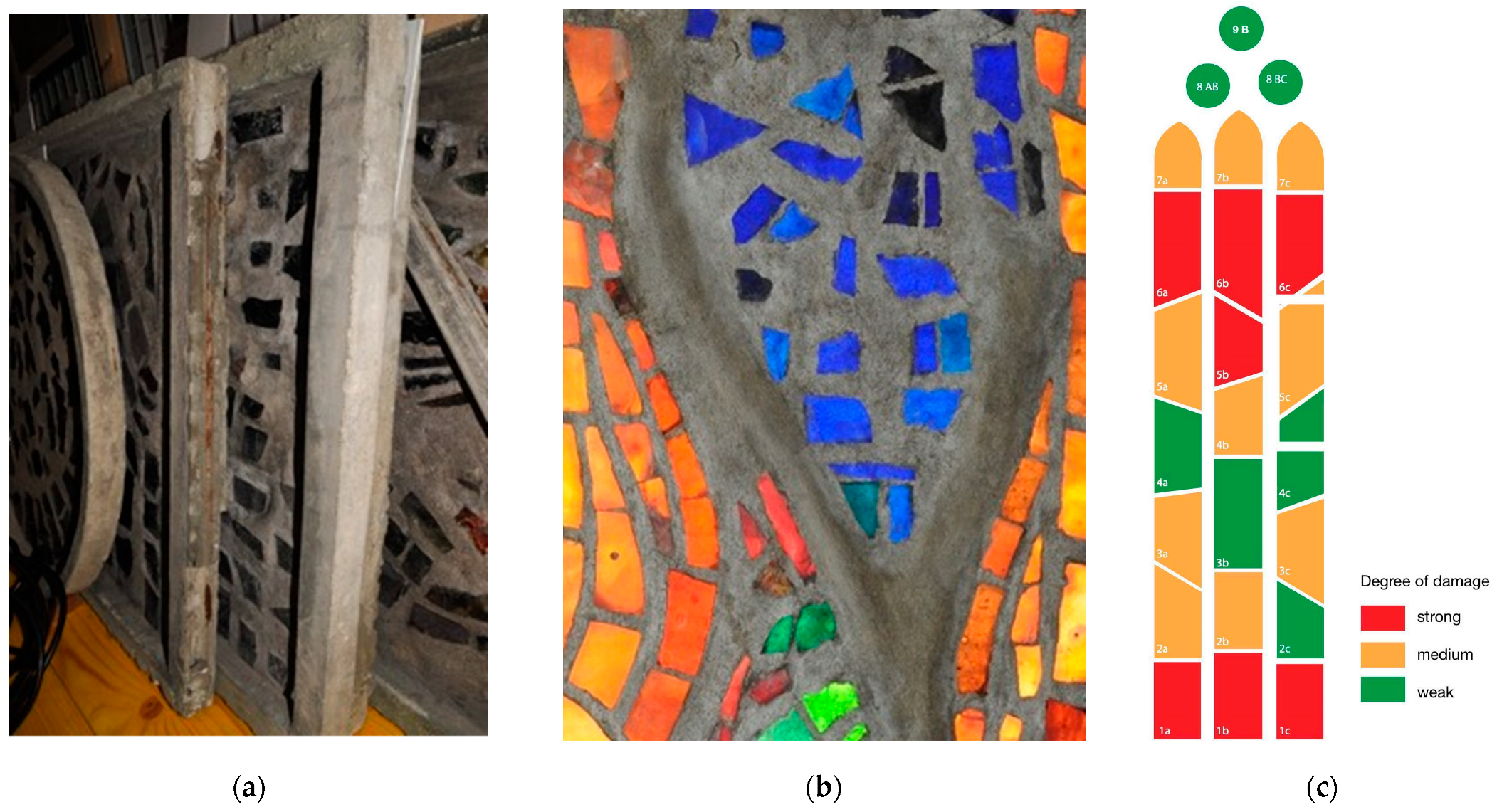

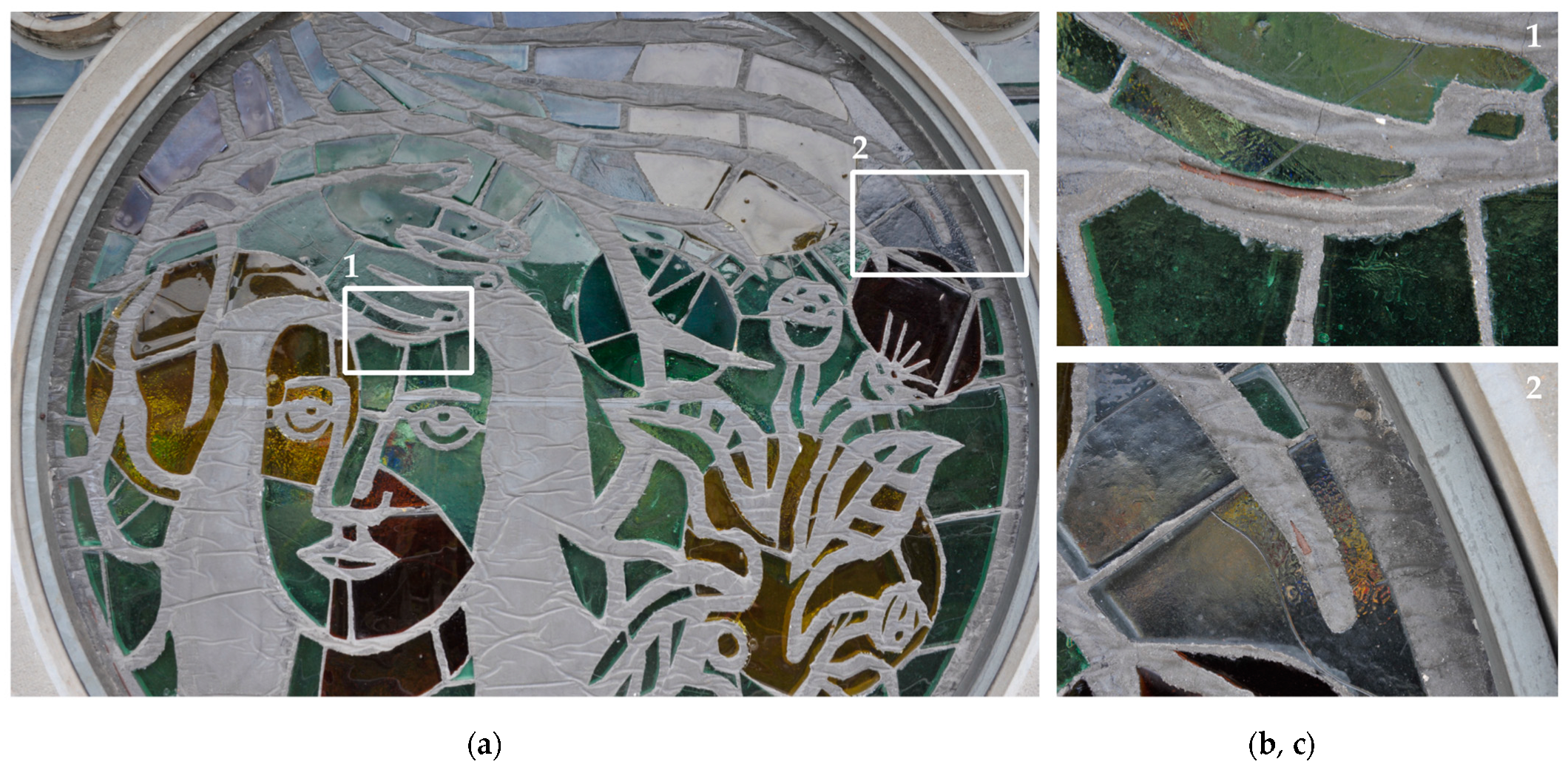

3.1. Fribourg

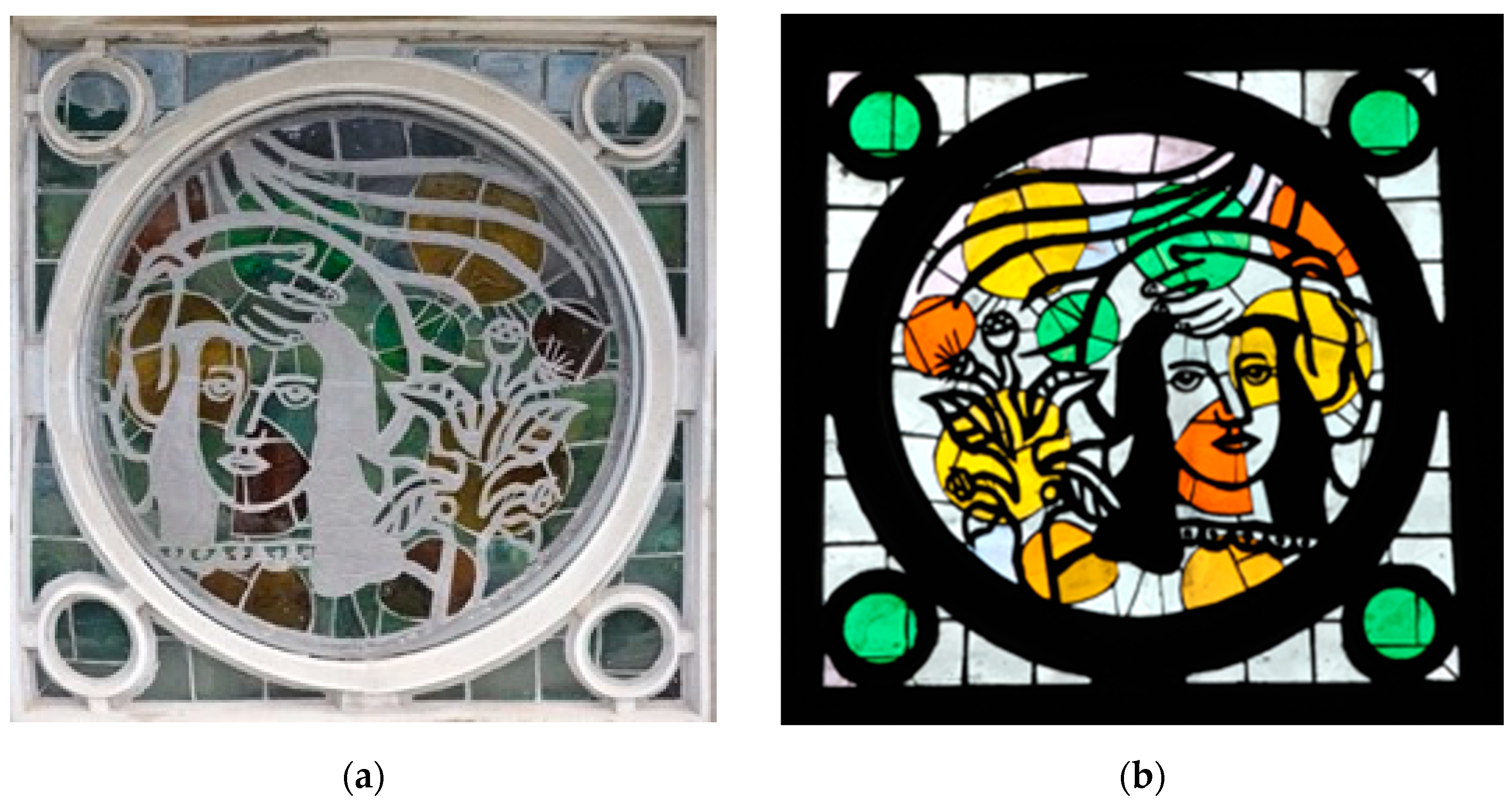

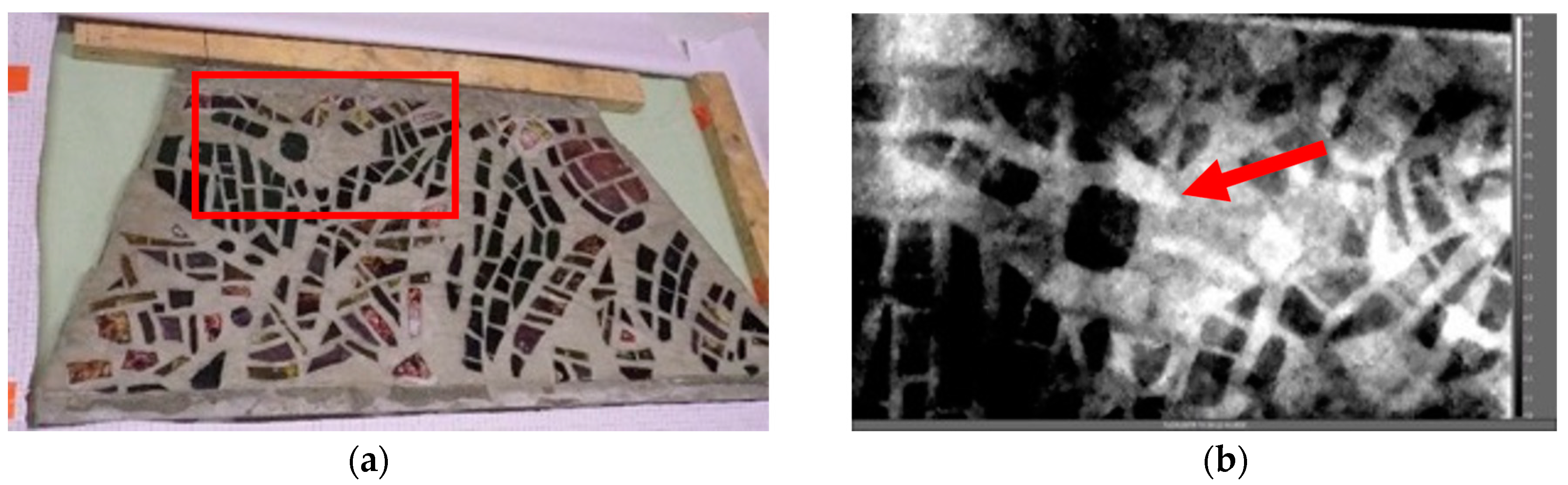

3.2. Saint-Germain d’Auxerre at Courfaivre

4. Methods

4.1. Magnet

4.2. Induction

4.3. Electrical Resistivity

4.4. Ground Penetrating Radar

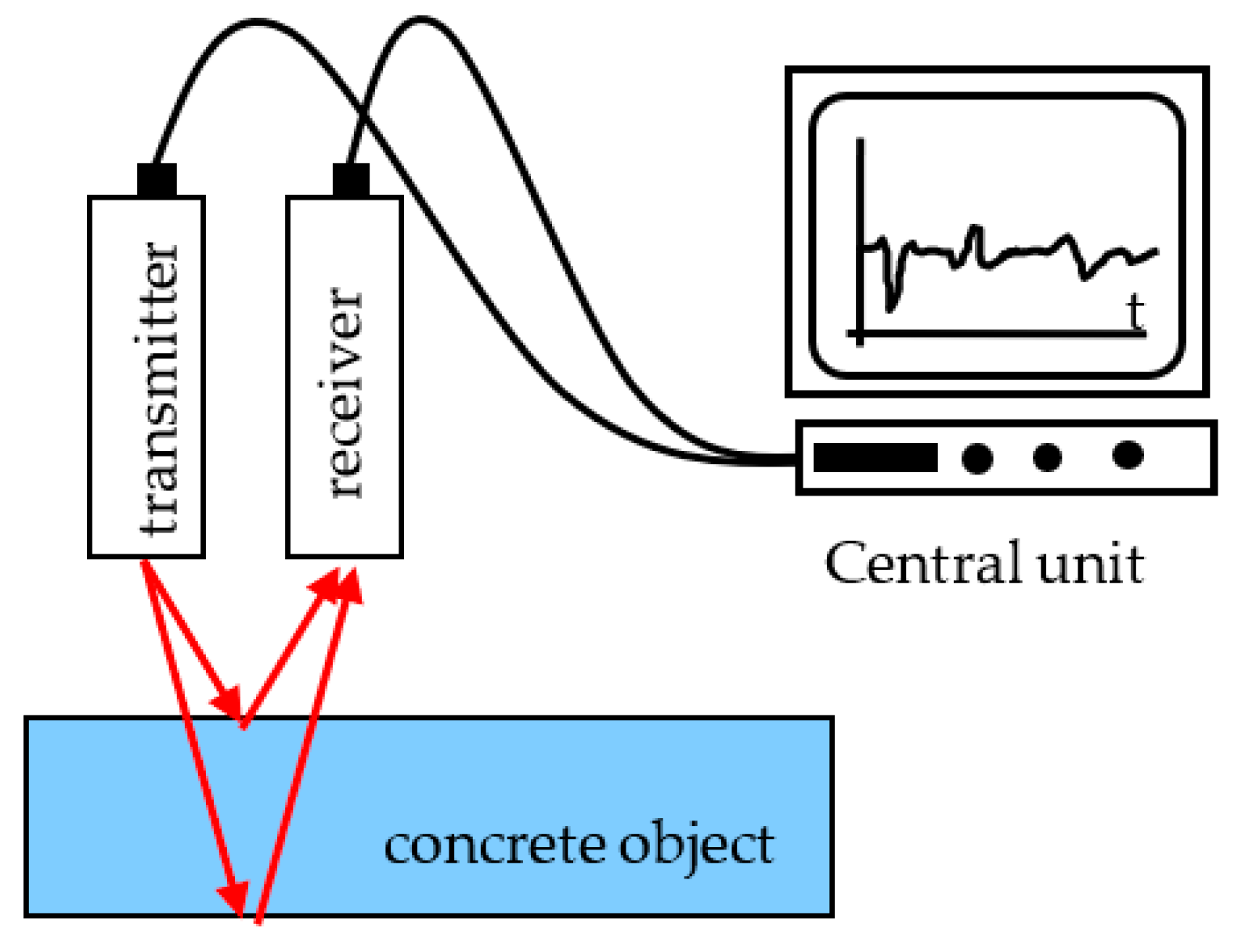

4.5. Ultrasonics

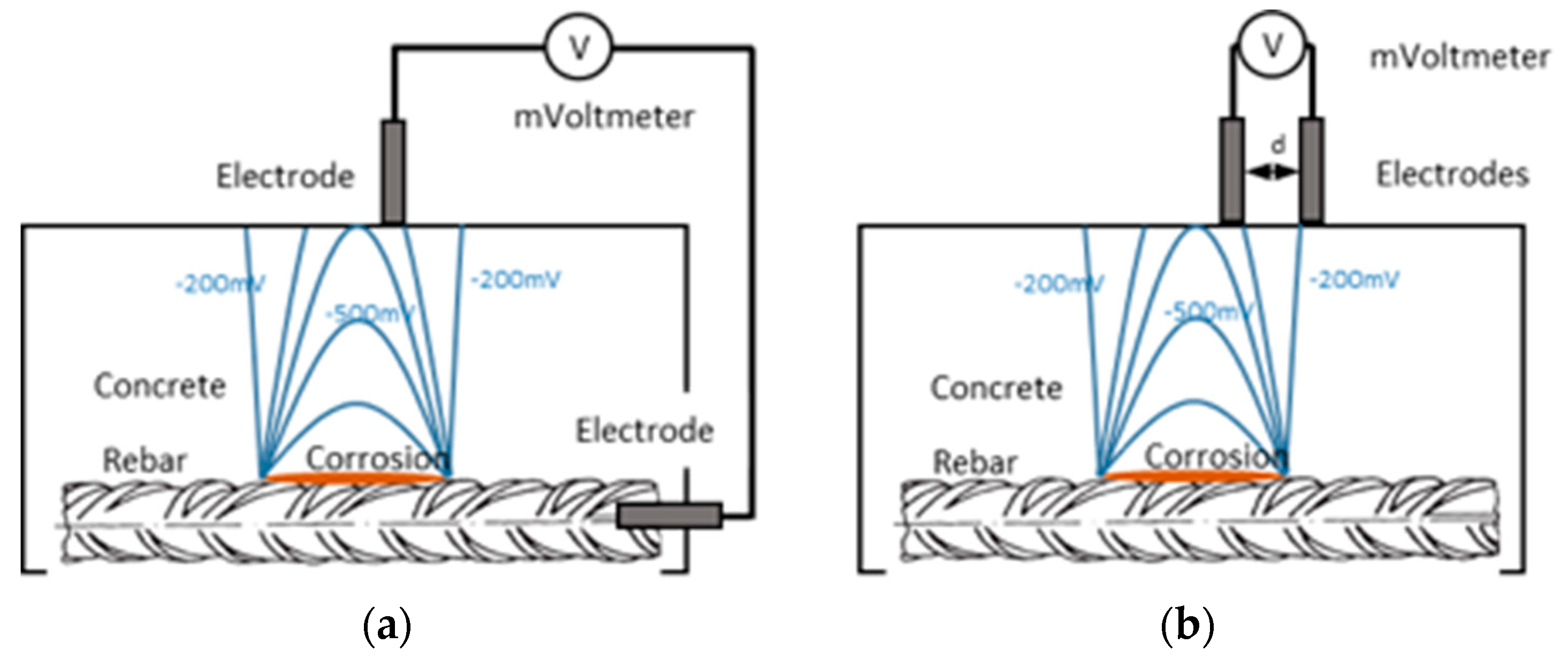

4.6. Half-Cell Potential

4.7. Thermography

5. Results and Discussion

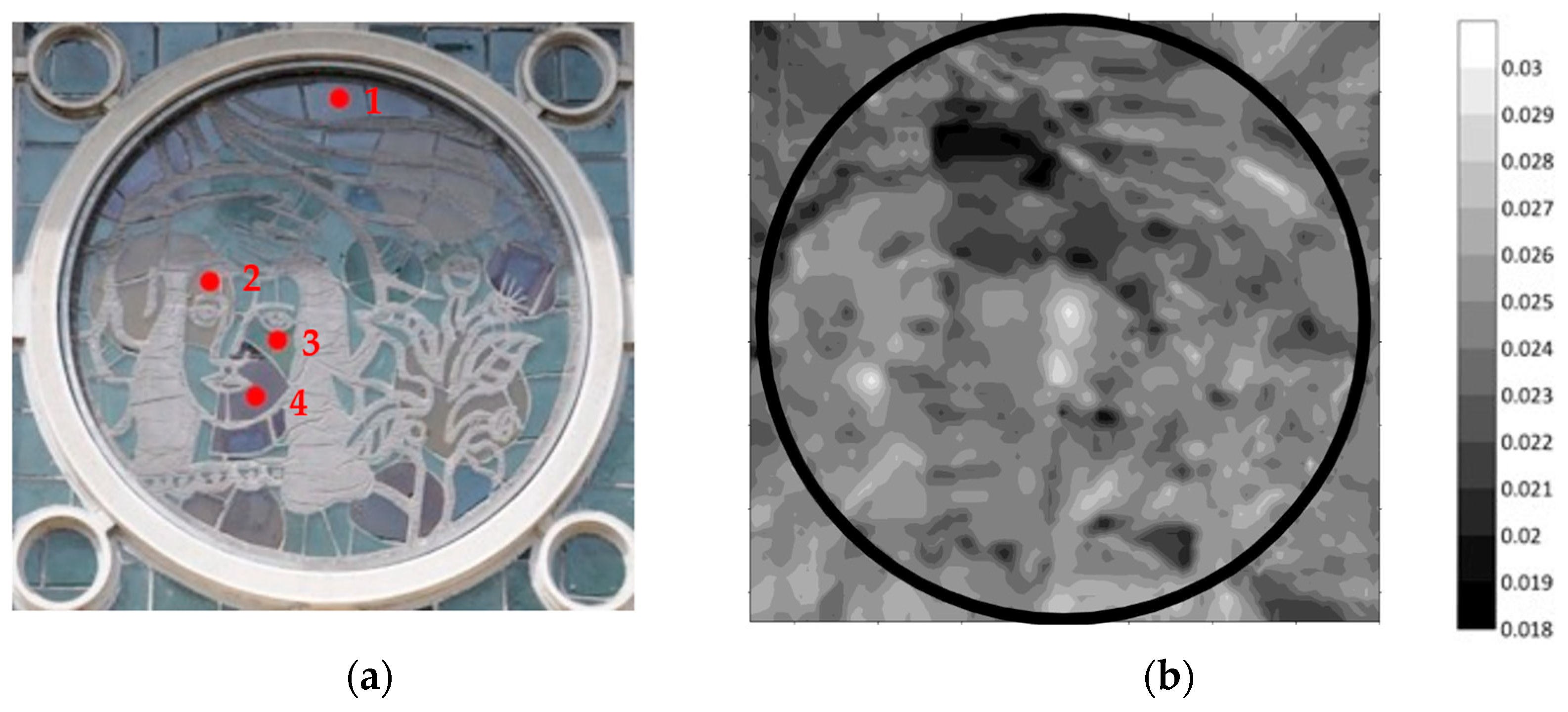

5.1. Existence and Position of Rebar

5.2. Concrete Cover of Rebar

5.3. Thickness of the Dalle de Verre Panels

5.4. Rebar Corrosion

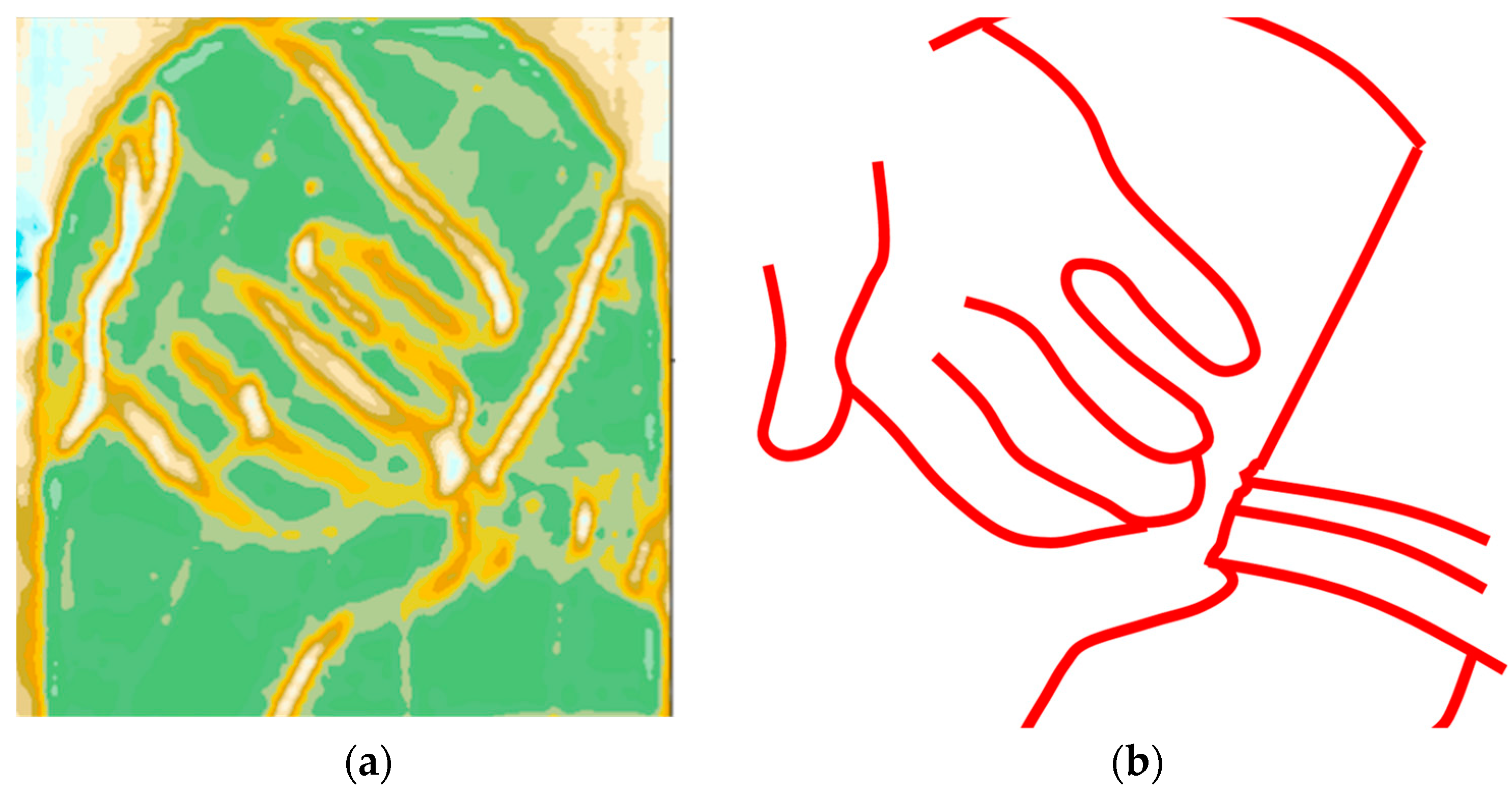

5.5. Existence and Location of Cracks and Other Damages

5.6. Material Properties, Such as Humidity or Carbonation

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Method | Equipment (Model, Producer) | Type of Measurement | Type of Data | Information Obtained | Approx. Cost of Equipment | Remarks on Method, Handling, Knowledge Required, Data Representation, etc. |

|---|---|---|---|---|---|---|

| Magnet | Unknown | Spot analysis, on outside surface | Analog data (rebar positions on paper) | Magnetic attraction, position of rebar | 10 € | Inexpensive and fast, easy handling, no prior technical knowledge required, no digital representation of data |

| Induction, manual | Proceq Profometer5+ | Line scan, on outside surface | Digital display and data recording | Position and/or concrete cover of rebar | 5–10 k€ | Fast and comparatively inexpensive, easy handling, little technical experience required, limited precision due to large size of sensor |

| Induction, automated | Hilti PS200 | Area scan, on outside surface | Digital data recording, 2D data processing and display | Position and/or concrete cover of rebar | 10–15 k€ | Fast and straightforward, easy handling, comparatively expensive, some technical experience required, digital data representation |

| GPR | Hardware: GSSI SIR30 radar unit and model 623000XT antenna. Software: REFLEXW, Sandmeier Scientific | Wide range of options, in this paper area or line scan on surface | Digital data recording, 3D data processing and representation | Position of rebar, depth of concrete cover, thickness of dalle de verre, material inhomogeneities (humid areas, fissures, etc.) | 5–50 k€ | Versatile (multiple uses), but expensive and time-consuming, good technical experience required, digital data representation in full 3D |

| Ultrasonics | TT-10, TIME Group Inc., Beijing, China | Spot analysis in reflection mode on outside surface (glass) | Digital display, no data recording | Thickness of dalle de verre | 1 k€ | Fast and comparatively inexpensive, easy handling, some technical experience required, no digital data representation, contact fluid required |

| Electrical resistivity | Proceq Resipod | Spot analysis, on outside surface; setup with four electrodes at fixed distances | Digital display | Changes in electrical resistivity, position of rebar, information on degree of carbonation and humidity | 3–5 k€ | Fast and comparatively inexpensive, handling tricky, technical experience required, no digital data representation, method unsuitable, if cement fully carbonated |

| Half-cell potential electrodes | Copper sulphate electrodes and voltmeter | Spot analysis, on outside surface (non-destructive setup) | Digital display | Voltage between two points, information on corrosion of rebar | 1 k€ | Inexpensive, but time-consuming, handling tricky, technical experience required, surface has to be moistened to create contact, values provide information on probability of corrosion of rebar |

| Thermography camera | Hardware: FLIR T640BX Software: FLIR ResearchIR | 2D scans surface temperatures, repeated measurements (e.g. 1 scan/minute) | Digital data recording and processing (2D false colour images) | Differences in relative surface temperatures, information on material inhomogeneities (humid areas, fissures, etc.) | 30–70 k€ | Active (active heating of object) thermography provides better results than passive thermography (no active heating); active approach difficult to apply for in-situ measurements |

References

- Labouret, A. (A)—Windows, Particularly Stained Glass Windows for Churches and Other Buildings of Reinforced Concrete, and a Process for Their Production, Submitted by in 1933. Patent No. FR756065. Available online: https://www.epo.org/searching-for-patents/technical/espacenet.html (accessed on 26 October 2022).

- Loire, N. Les vitraux en dalle de verre en France, des origines à 1940; Décors Muraux. Hist. De L’art 1989, 8, 40–56. [Google Scholar] [CrossRef]

- Noverraz, C.; Sauterel, V.; Wolf, S. De béton et de verre. La dalle de verre et ses premières utilisations en Suisse. Monum. Vaud. 2021, 11, 50–59. [Google Scholar]

- Barrat, R. A Vous de Choisir Votre Avenir: Cimenteur Verrier, RTS, Broadcast on 11 April 1964. Available online: https://www.rts.ch/archives/tv/jeunesse/a-vous-de-choisir-votre-avenir/7519078-cimenteur-verrier.html (accessed on 26 October 2022).

- Marie-Victoire, É.; Bouichou, M.; Congar, T.; Blanchard, R. Concrete cultural heritage in France—Inventory and State of Conservation. In Concrete Repair, Rehabilitation and Retroftting III; Dehn, F., Beushausen Hans, D., Alexander, M., Moyo, P., Eds.; CRC Press: London, UK, 2016; pp. 343–350. [Google Scholar]

- Breysse, D. Non-Destructive Assessment of Concrete Structures: Reliability and Limits of Single and Combined Techniques; Springer: Berlin, Germany, 2012. [Google Scholar]

- Bertolini, L.; Carsana, M.; Gastaldi, M.; Lollini, F.; Redaelli, E. Corrosion assessment and restoration strategies of reinforced concrete buildings of the cultural heritage. Mater. Corros. 2010, 62, 146–154. [Google Scholar] [CrossRef]

- Hugenschmidt, J. Ground penetrating radar for the evaluation of reinforced concrete structures. In Non-destructive evaluation of reinforced concrete structures. Non-Destructive Testing Methods; Maierhofer, C., Reinhardt, H.-W., Dobmann, G., Eds.; CRC Press: Boston, MA, USA, 2010; pp. 317–333. [Google Scholar]

- Cuzange, L.; Loisel, C.; Marie-Victoire, É.; Faure, W. Conserver les dalles de verre: Un nouveau défi interdisciplinaire pour le vingt et unième siècle. In The Art of Collaboration Stained-Glass Conservation in the Twenty-First Century; Shepard, M.B., Pilosi, L., Strobl, S., Eds.; Harvey Miller Publications: London, UK, 2010; pp. 176–182. [Google Scholar]

- Golobardes, S.M. Vitralls de Ciment—Vitralls de Ciment—Avaluació d’un Sistema de Conservació Preventiva al Baptisteri de la Parròquia Verge de la Pau (Barcelona). Master’s Thesis, University of Barcelona, Barcelona, Spain, 2021. Available online: https://diposit.ub.edu/dspace/handle/2445/181444 (accessed on 9 August 2023).

- De Vis, K.; Caen, J.; Janssens, K.; Jacobs, P. The consolidation of cracks and fissures in dalle de verre. Assessment of selected adhesives. In Recent Advances in Glass, Stained Glass and Ceramics Conservation 2012; Roemich, H., Van Lookeren, C.K., Eds.; Spa Uitgevers: Zwolle, The Netherlands, 2013; pp. 43–52. [Google Scholar]

- Pepi, R.M.; Buchner, L.N.; Gembinski, C. Conservation of Dalle de Verre at the New York Hall of Science, APT Bulletin. J. Preserv. Technol. 2012, 45, 3–12. [Google Scholar]

- Ünal, M.; Kühne, H.-C. Repair and restoration of Dalle de Verre concrete windows. In Concrete Repair, Rehabilitation and Retroftting III; Dehn, F., Beushausen, H.-D., Alexander, M., Moyo, P., Eds.; CRC Press: London, UK, 2012; pp. 343–350. [Google Scholar]

- Sander, C.; Kühne, H.-C.; Ünal, M.; Kleine, M.; Köhler, A.; Kriesten, V. Betondickglasfenster. Schadensmechanismen und Instandsetzungsprinzipien zur Erhaltung. Restauro 2011, 117, 48–53. [Google Scholar]

- Wolf, S.; Hugenschmidt, J.; Gosselin, C. La dalle de verre: Évaluation de méthodes non invasives pour le diagnostic des oeuvres menaces. In Stained Glass Conservation: Preserving Identity, Proceedings of the 11th Forum for the Conservation and Technology of Historic Stained Glass, Girona, Barcelona, 7–9th July 2022; Cañellas, S., Brown, S., Eds.; Corpus Vitrearum Catalunya: Barcelona, Spain, 2022; pp. 144–150. [Google Scholar]

- Wolf, S.; Dumont, A. Dalle de Verre en Suisse. 2021. Available online: www.vitrosearch.ch (accessed on 2 November 2022).

- Zacharias, N.; Palamara, E.; Kordali, R.; Muros, V. Archeological glass corrosion studies: Composition, environment and content. Sci. Cult. 2020, 6, 53–67. [Google Scholar]

- Vitrocentre Romont. Available online: https://vitrosearch.ch/de/objects/2674436 (accessed on 9 January 2023).

- Rudaz, P. Église des Cordeliers: Pas de résurrection en vue pour la Pentecôte. Pro Fribg. 1997, 116, 10–15. [Google Scholar]

- Vitrocentre Romont. Available online: https://vitrosearch.ch/de/objects/2674496 (accessed on 9 January 2023).

- Bueche, J. Die Kirche von Courfaivre und ihre Bildfenster. Cementbulletin 1957, 25, 1–10. [Google Scholar]

- Vitrocentre Romont. Available online: https://vitrosearch.ch/de/objects/2674613 (accessed on 9 January 2023).

- Vitrocentre Romont. Available online: https://vitrosearch.ch/de/objects/2675388 (accessed on 9 January 2023).

- Lataste, J.F. Electrical resistivity measurement. In Non-Destructive Assessment of Concrete Structures: Reliability and Limits of Single and Combined Techniques, State-of-the-Art Report of the RILEM Technical Committee 207-INR; Breysse, D., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 77–85. [Google Scholar]

- Lataste, J.-F. Electrical resistivity for the evaluation of reinforced concrete structures. In Non-Destructive Evaluation of Concrete Structures, Vol.2: Non-Destructive Testing Methods; Maierhofer, C., Reinhardt, H.-W., Dobmann, G., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2010; pp. 243–270. [Google Scholar]

- Daniels, D.G. Ground Penetrating Radar, 2nd ed.; IEE The Institution of Electrical Engineers: London, UK, 2004. [Google Scholar]

- Carrick, U.E. Ground Penetrating Radar—Theory and Practice, 1st ed.; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Hugenschmidt, J. Ground-Penetrating Radar. In Non-Destructive Assessment of Concrete Structures: Reliability and Limits of Single and Combined Techniques, State-of-the-Art Report of the RILEM Technical Committee 207-INR; Breysse, D., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 63–70. [Google Scholar]

- Hugenschmidt, J.; Loser, R. Detection of chlorides and moisture in concrete structures with Ground penetrating radar. Mater. Struct. 2008, 41, 785–792. [Google Scholar] [CrossRef]

- Schickert, M.; Krause, M. Ultrasonic techniques for the evaluation of reinforced concrete structures. In Non-Destructive Evaluation of Concrete Structures, Vol.2: Non-Destructive Testing Methods; Maierhofer, C., Reinhardt, H.-W., Dobmann, G., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2010; pp. 490–526. [Google Scholar]

- Garnier, V. Ultrasounds through transmission. In Non-Destructive Assessment of Concrete Structures: Reliability and Limits of Single and Combined Techniques, State-of-the-Art Report of the RILEM Technical Committee 207-INR; Breysse, D., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 17–26. [Google Scholar]

- Krause, M.; Mielentz, F. Ultrasonic Echo. In Non-Destructive Assessment of Concrete Structures: Reliability and Limits of Single and Combined Techniques, State-of-the-Art Report of the RILEM Technical Committee 207-INR; Breysse, D., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 27–38. [Google Scholar]

- Andrade, C.; Martinez, I. Techniques for measuring the corrosion rate (polarization resistance) and the corrosion potential of reinforced concrete structures. In Non-Destructive Evaluation of Concrete Structures, Vol.2: Non-Destructive Testing Methods; Maierhofe, C., Reinhardt, H.-W., Dobmann, G., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2010; pp. 284–313. [Google Scholar]

- Defer, D.; Maierhofer, C. Infrared thermography. In Non-Destructive Assessment of Concrete Structures: Reliability and Limits of Single and Combined Techniques, State-of-the-Art Report of the RILEM Technical Committee 207-INR; Breysse, D., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 85–97. [Google Scholar]

- Maierhofer, C.; Roellig, M.; Schlichting, J. Active thermography for the evaluation of reinforced concrete structures. In Non-Destructive Evaluation of Concrete Structures, Vol.2: Non-Destructive Testing Methods; Maierhofer, C., Reinhardt, H.-W., Dobmann, G., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2010; pp. 370–399. [Google Scholar]

| Position | Ultrasonics (Thickness in m) | GPR (Thickness in m) |

|---|---|---|

| 1 | 0.0247 | 0.024–0.025 |

| 2 | 0.0268 | 0.025–0.026 |

| 3 | 0.0254 | 0.024–0.025 |

| 4 | 0.0241 | 0.023–0.024 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hugenschmidt, J.; Wolf, S.; Gosselin, C. Non-Destructive Testing of Dalle de Verre Windows by Fernand Léger and Alexandre Cingria in Switzerland. Heritage 2023, 6, 6311-6327. https://doi.org/10.3390/heritage6090330

Hugenschmidt J, Wolf S, Gosselin C. Non-Destructive Testing of Dalle de Verre Windows by Fernand Léger and Alexandre Cingria in Switzerland. Heritage. 2023; 6(9):6311-6327. https://doi.org/10.3390/heritage6090330

Chicago/Turabian StyleHugenschmidt, Johannes, Sophie Wolf, and Christophe Gosselin. 2023. "Non-Destructive Testing of Dalle de Verre Windows by Fernand Léger and Alexandre Cingria in Switzerland" Heritage 6, no. 9: 6311-6327. https://doi.org/10.3390/heritage6090330

APA StyleHugenschmidt, J., Wolf, S., & Gosselin, C. (2023). Non-Destructive Testing of Dalle de Verre Windows by Fernand Léger and Alexandre Cingria in Switzerland. Heritage, 6(9), 6311-6327. https://doi.org/10.3390/heritage6090330