Conservation of Earthen Bricks in Architecture: An Experimental Campaign to Test Different Treatments on Vernacular Built Heritage

Abstract

:1. Introduction

2. Materials and Methods

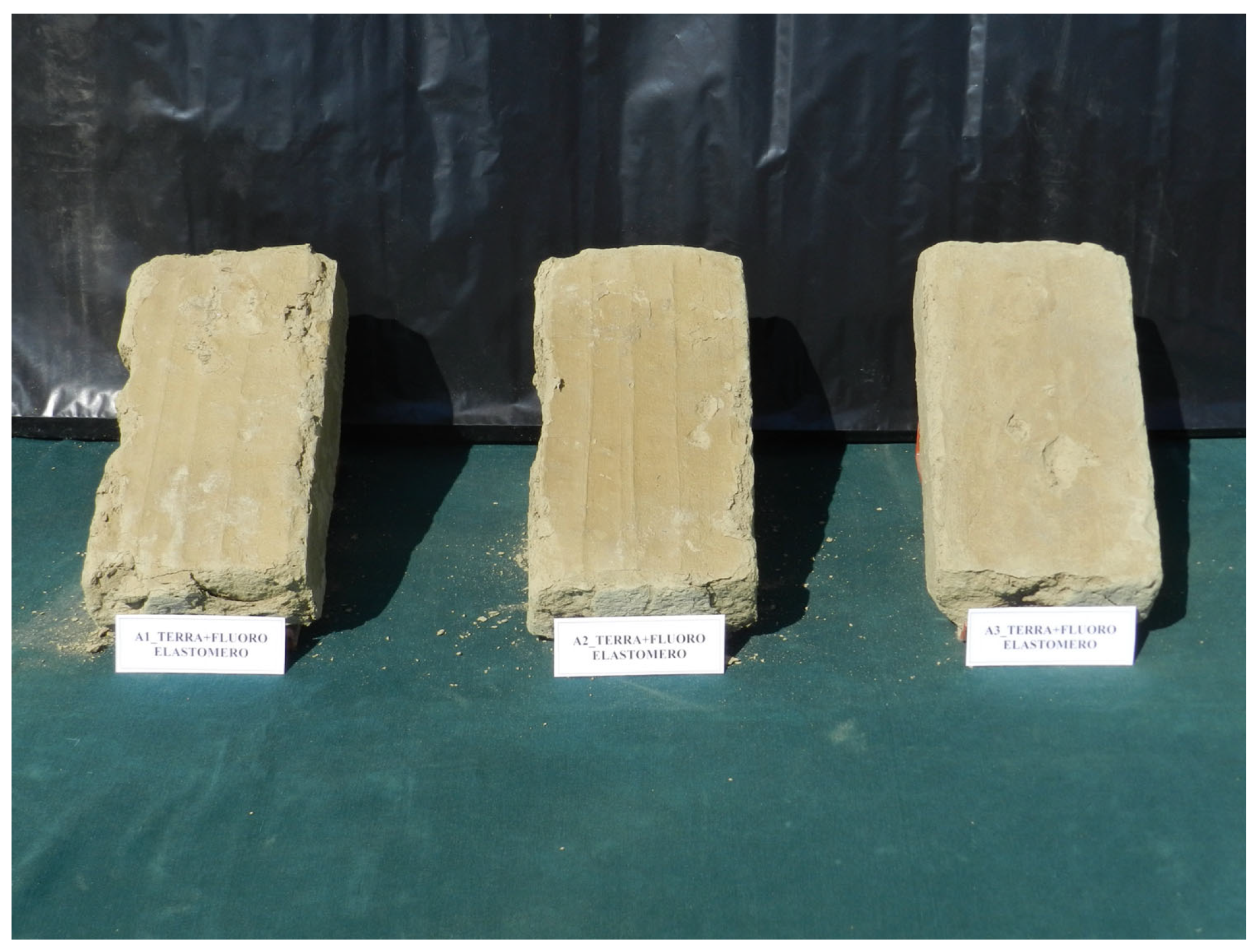

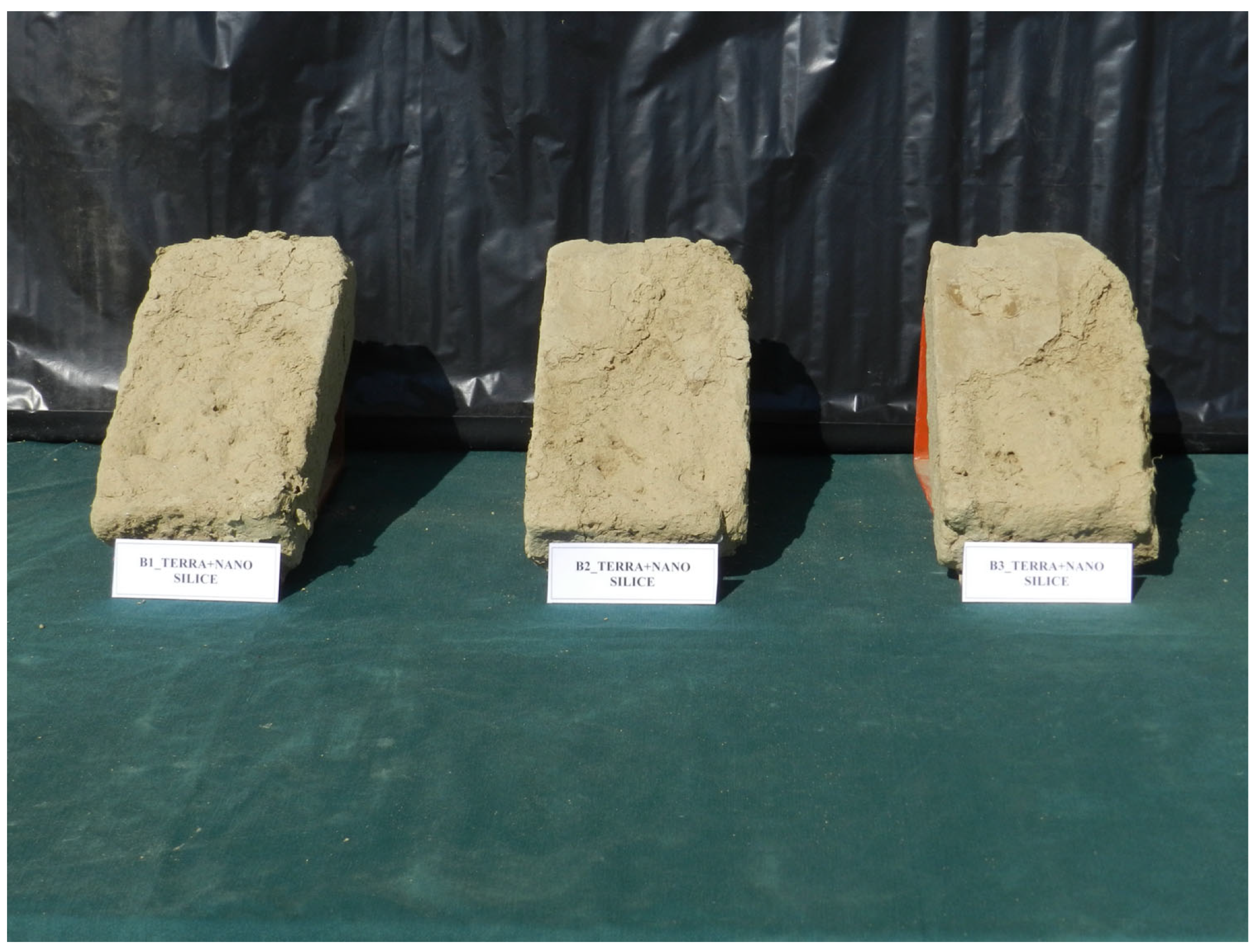

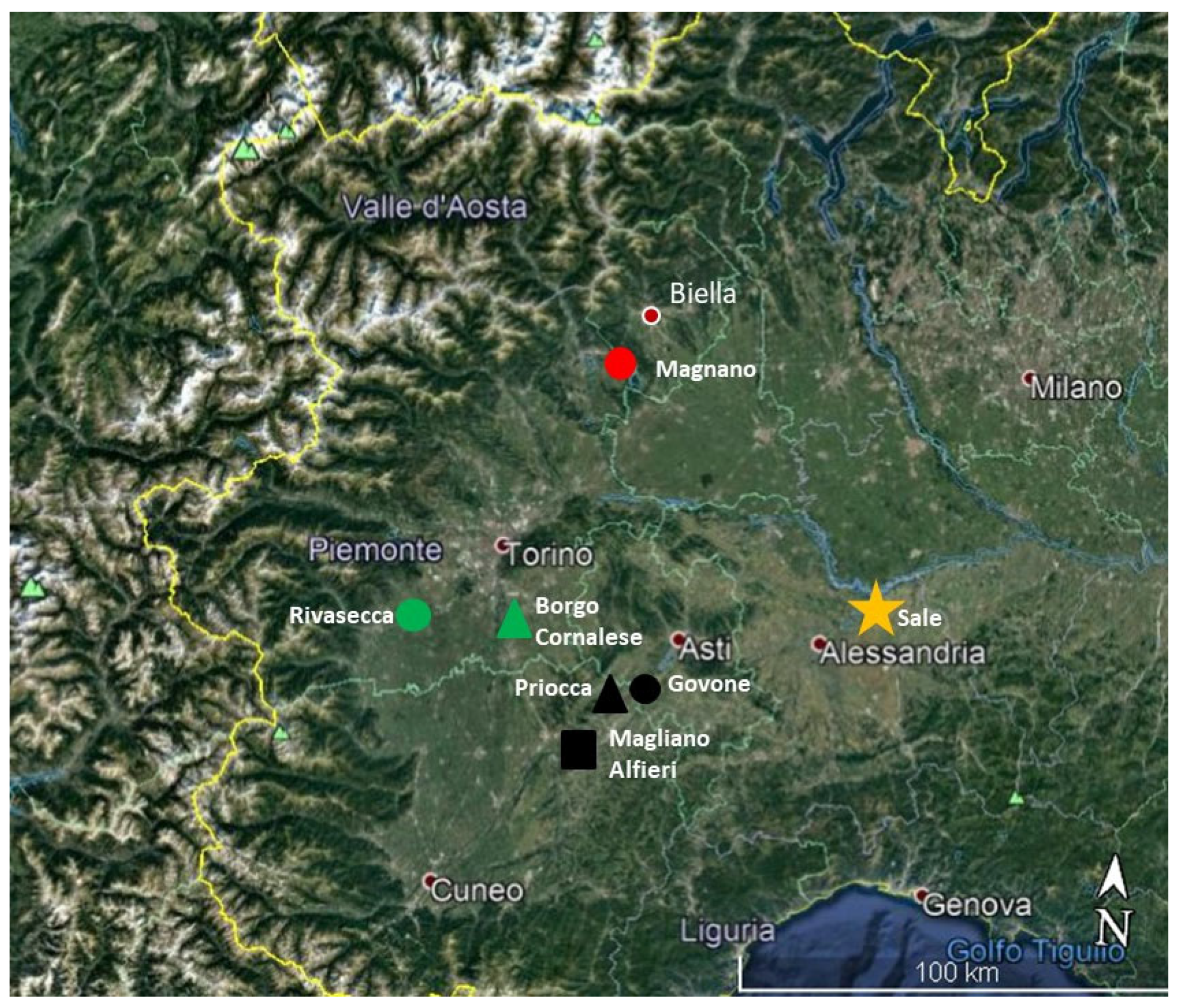

2.1. Earthen Bricks

2.2. Treatments

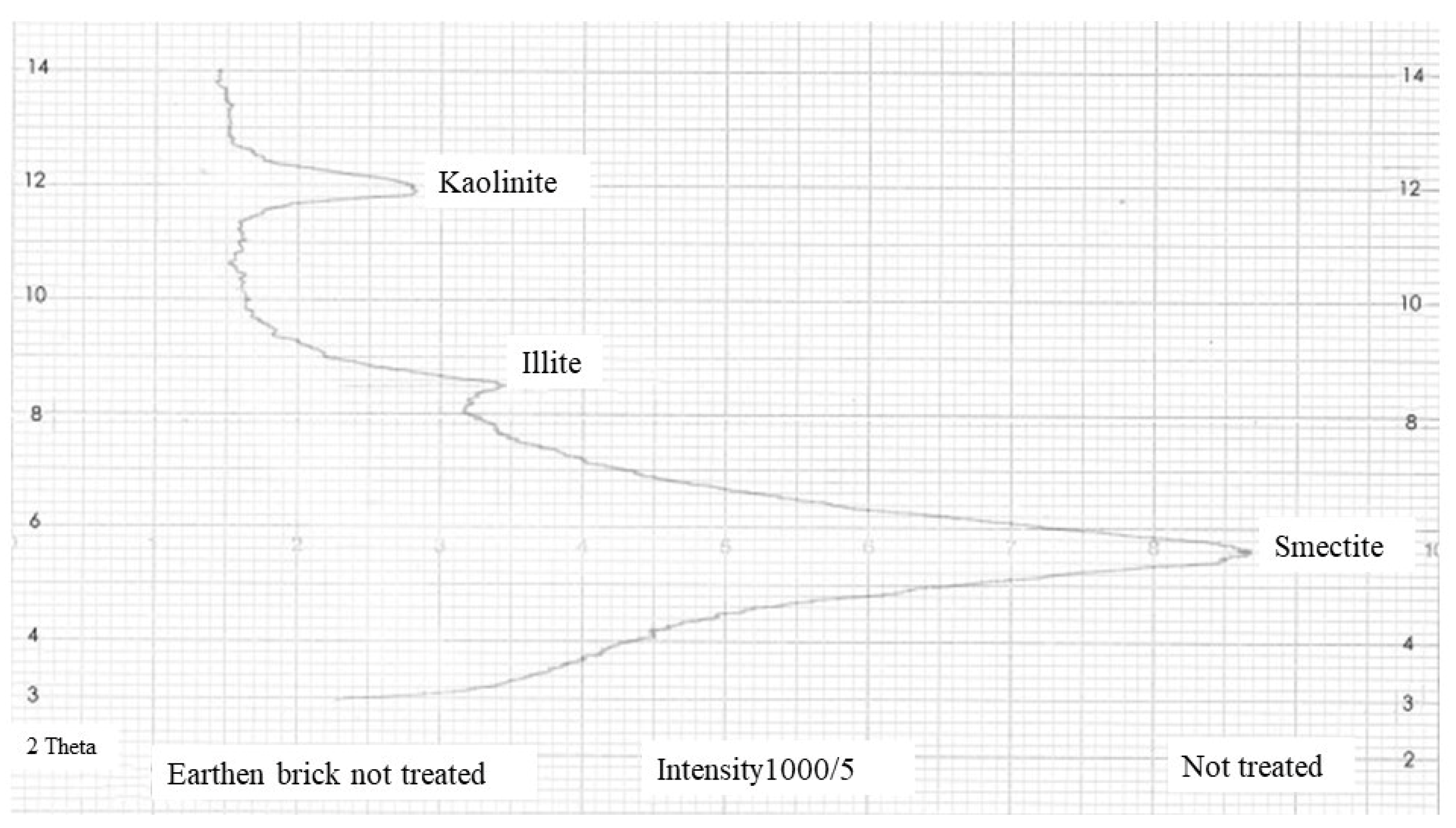

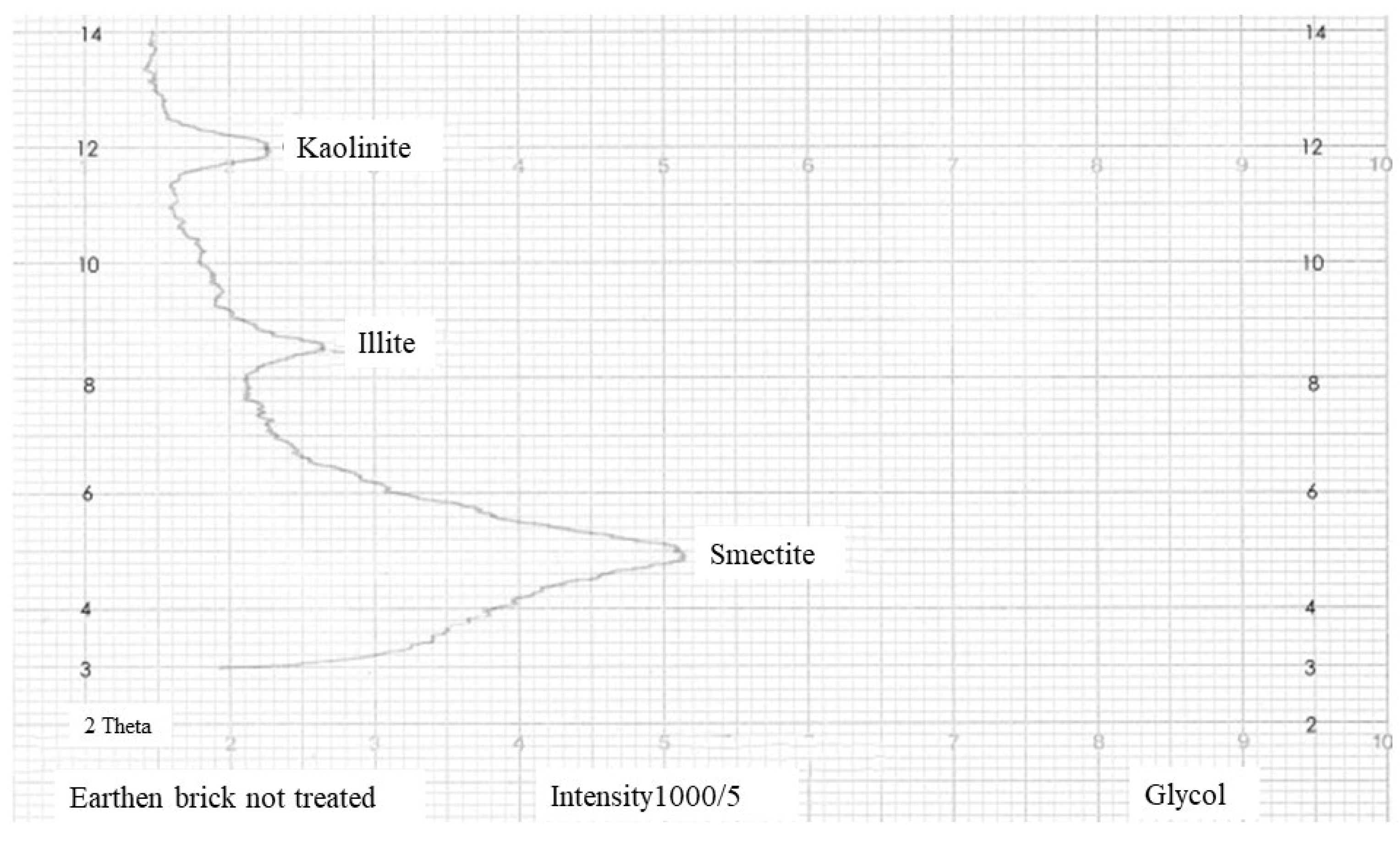

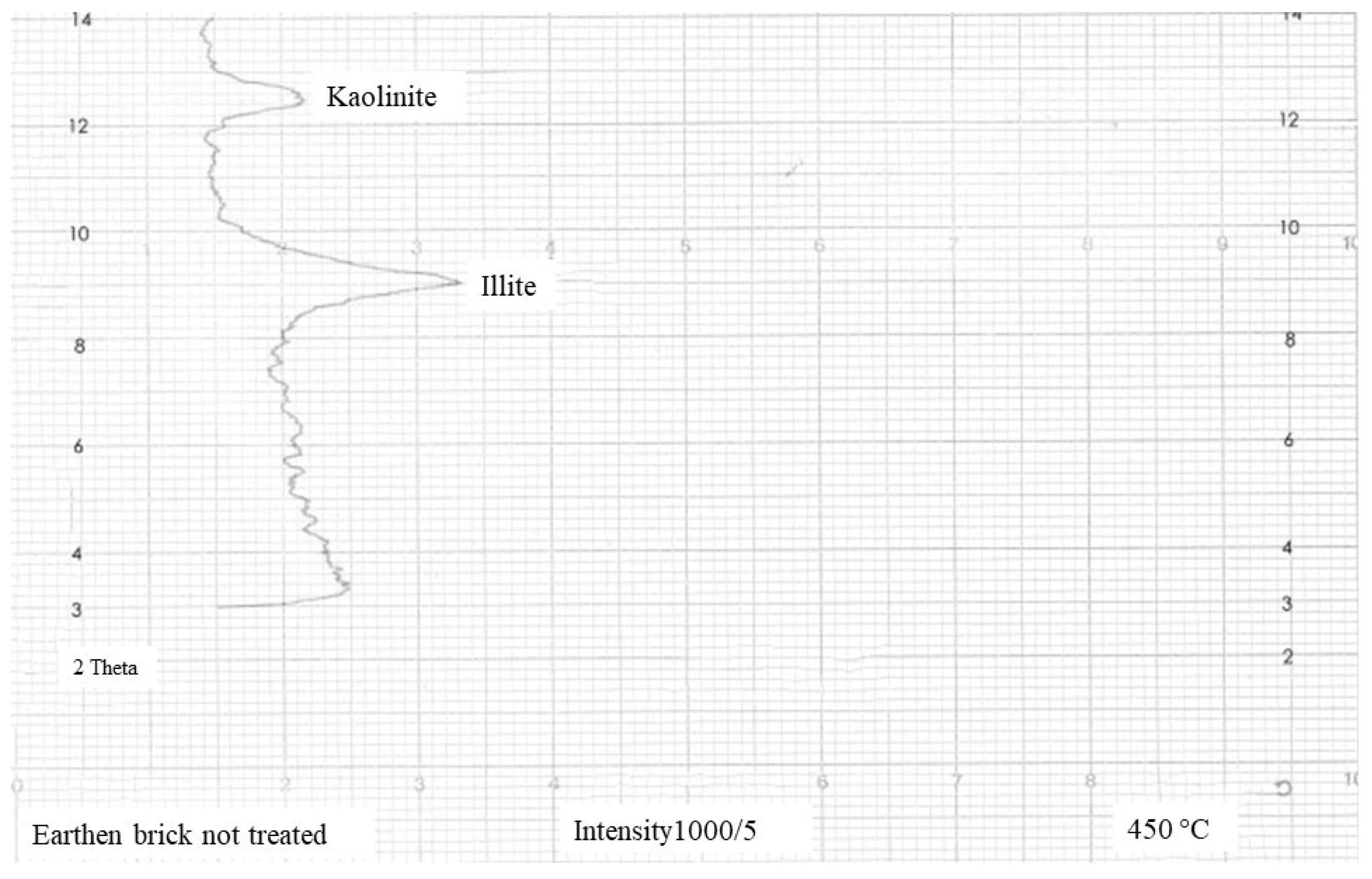

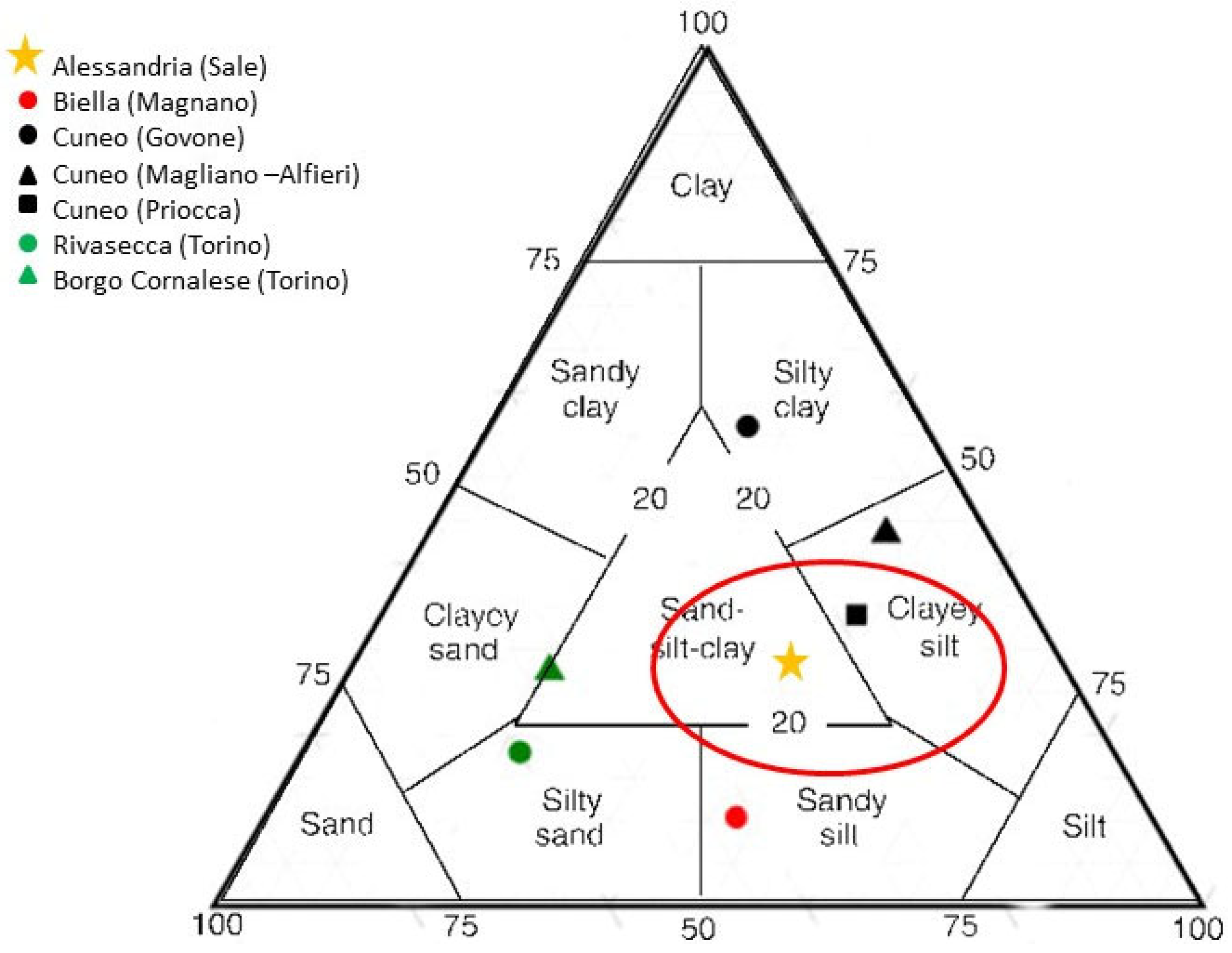

2.3. Grain Size Distribution and Mineralogical Composition

2.4. Water Surface Erosion Test

2.5. Karsten Test

2.6. Static Contact Angle Test

2.7. DRMS Test

2.8. Wet Cup Test

2.9. Colour Test

- ΔL* = (L* before treatment − L* after treatment);

- Δa* = (a* before treatment − a* after treatment);

- Δb* = (b* before treatment − b* after treatment).

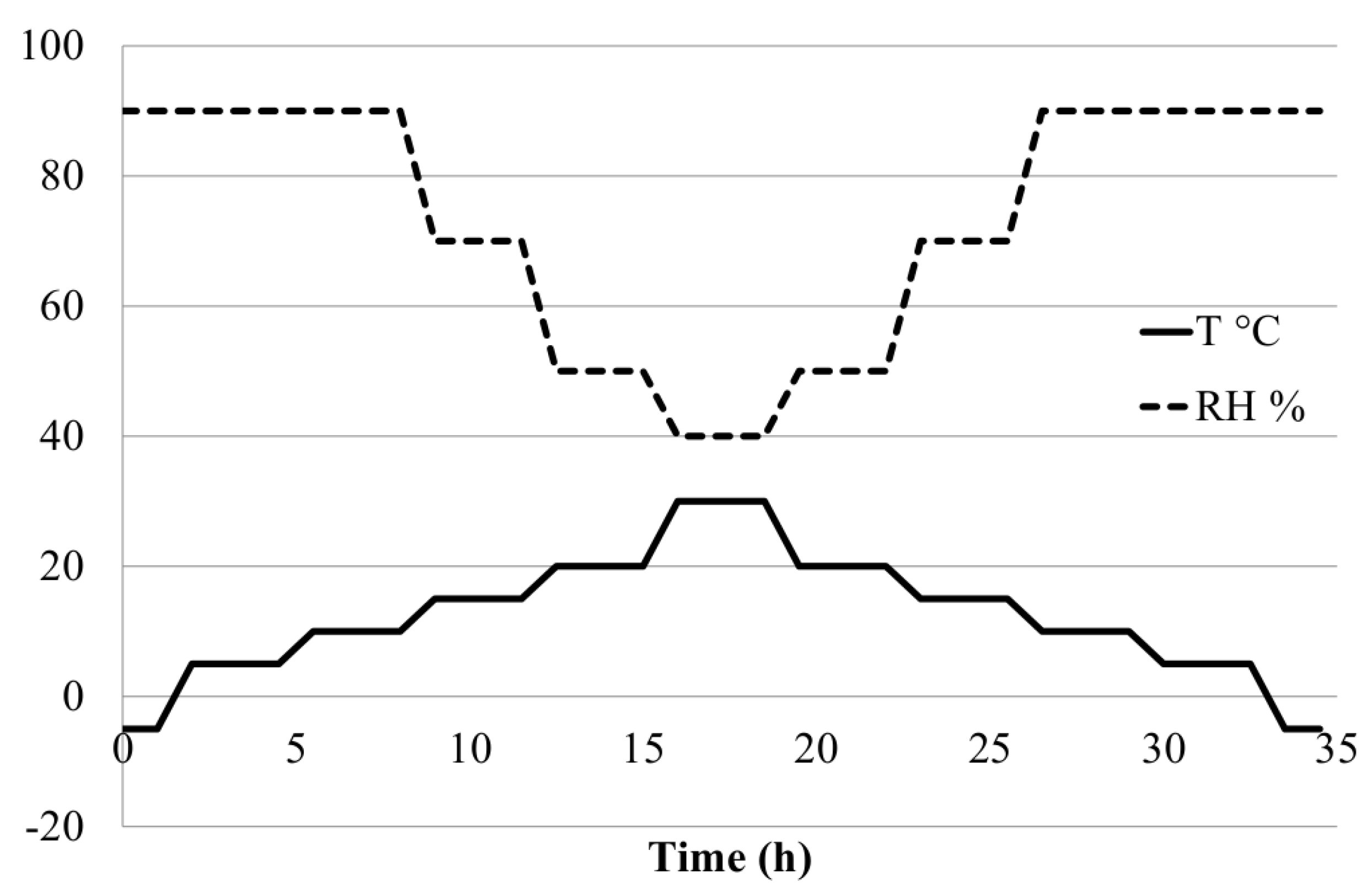

2.10. Durability Test

3. Results

3.1. Material Characterization

3.2. Evaluation of the Performance of the Treated Earthen Bricks

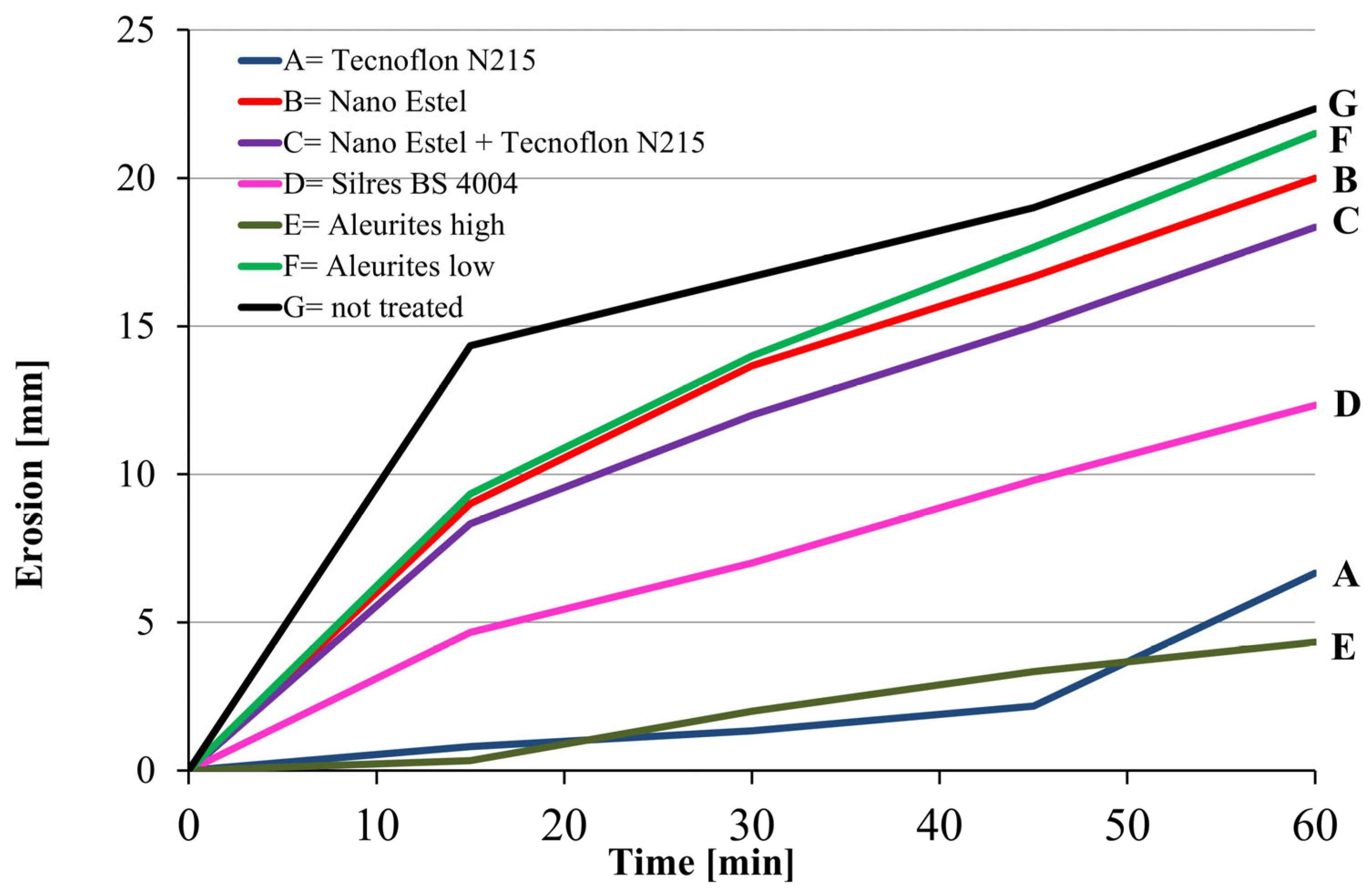

3.2.1. Geelong and Spray Test

- -

- All of the treatments except Nano Estel (B) and Aleurites low (F) improved the resistance to the spray erosion of the not treated brick;

- -

- All of the bricks including the untreated ones and excluded those treated with Tecnoflon N215 (A) and Aleurites high (E) showed an erosion rate higher in the first 15 min, according to a lower cohesion of the surface layer of the bricks (possibly induced by the cleaning made before the treatments);

- -

- The bricks treated with Tecnoflon N215 and Aleurites high showed a very low erosion rate in the first 45 and 15 min, respectively. However, the erosion rate grew very slowly even afterwards, and they generally had a higher resistance to all of the other treatments. In the case of these two treatments, the erosion at the end of the test reached about 5 mm.

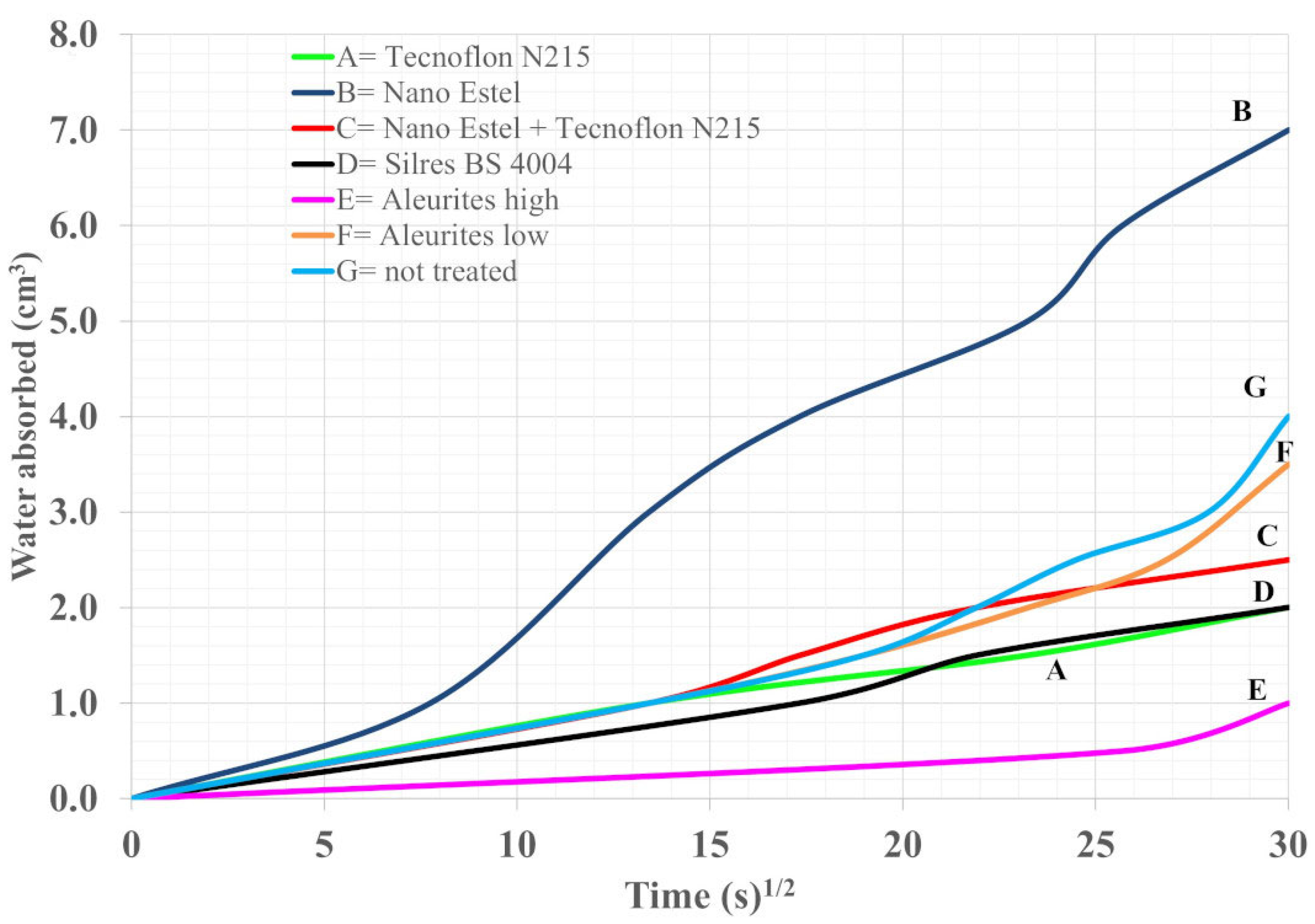

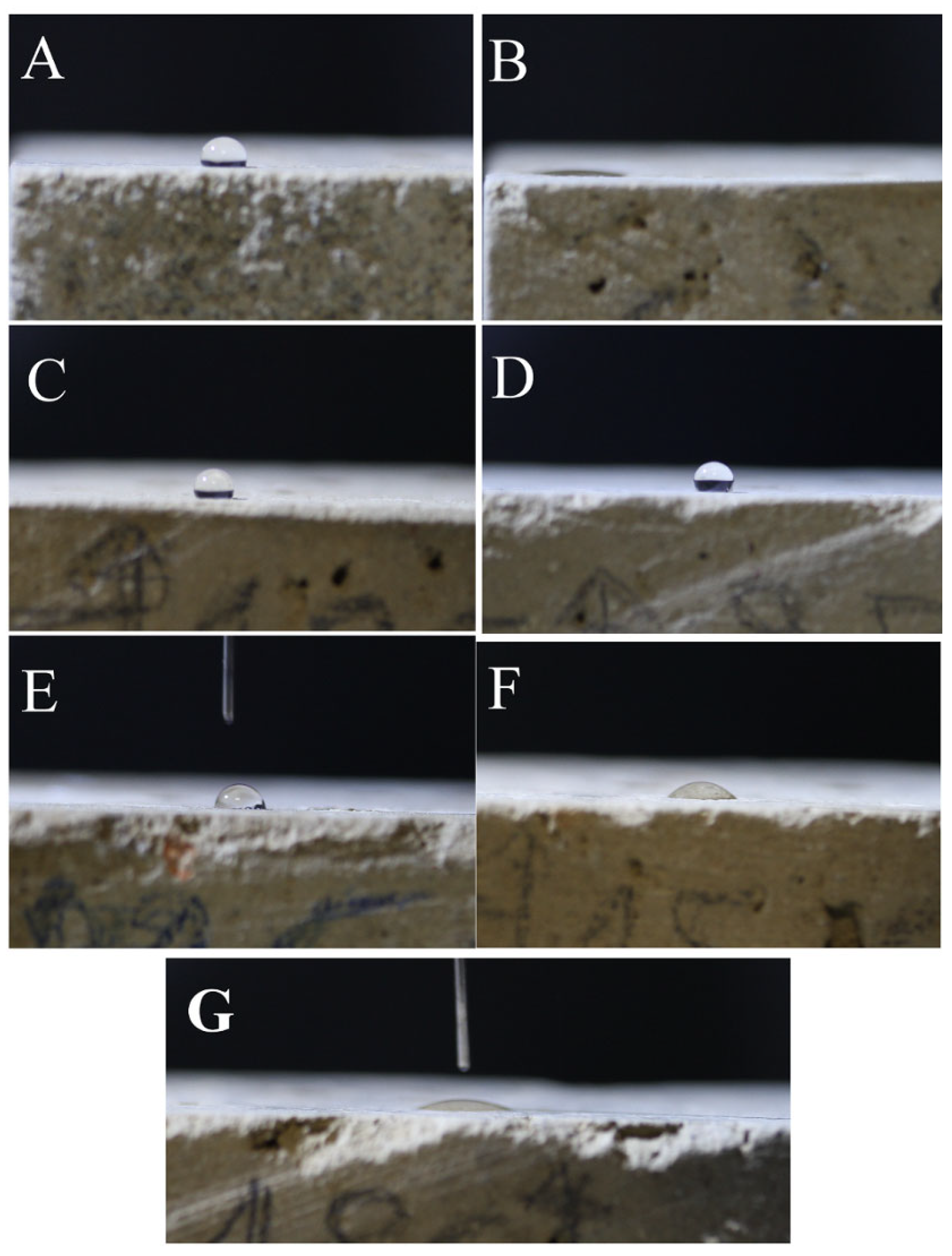

3.2.2. Karsten Test and Static Contact Angle Test

- -

- At the end of the test, only the brick treated with Aleurites high (E) absorbed an amount of water lower than the not treated brick (G). Moreover, brick E began to absorb water 10 min after the beginning of the test, demonstrating that the treatment significantly decreased the water absorption;

- -

- Earthen brick B (Nano Estel) showed the worst results compared to the not treated brick (G). It absorbed the maximum amount of water (i.e., 7 cm3) and began to absorb from the first minute. This result is not unexpected for two reasons: nano silica is a consolidating but not a protective product, and second, it is applied in an aqueous solvent. The aqueous solvent could have caused partial melting of the earth with a reorganization of the matter that favoured the creation of a porous network more accessible to liquid water [47];

- -

- Bricks A, C, and F began to absorb water like an untreated brick (G) (i.e., after 3 min), but while bricks A and C moderately reduced the water absorption to the untreated earthen brick (G), brick F reached a value of water absorption similar to that of the not treated brick G;

- -

- Earthen brick D began to absorb water after 6 min, showing that the treatment decreased water absorption. Nevertheless, at the end of the test, the amount of absorbed water was similar to that of A and C, even if lower than the untreated brick.

3.2.3. Wet Cup Test

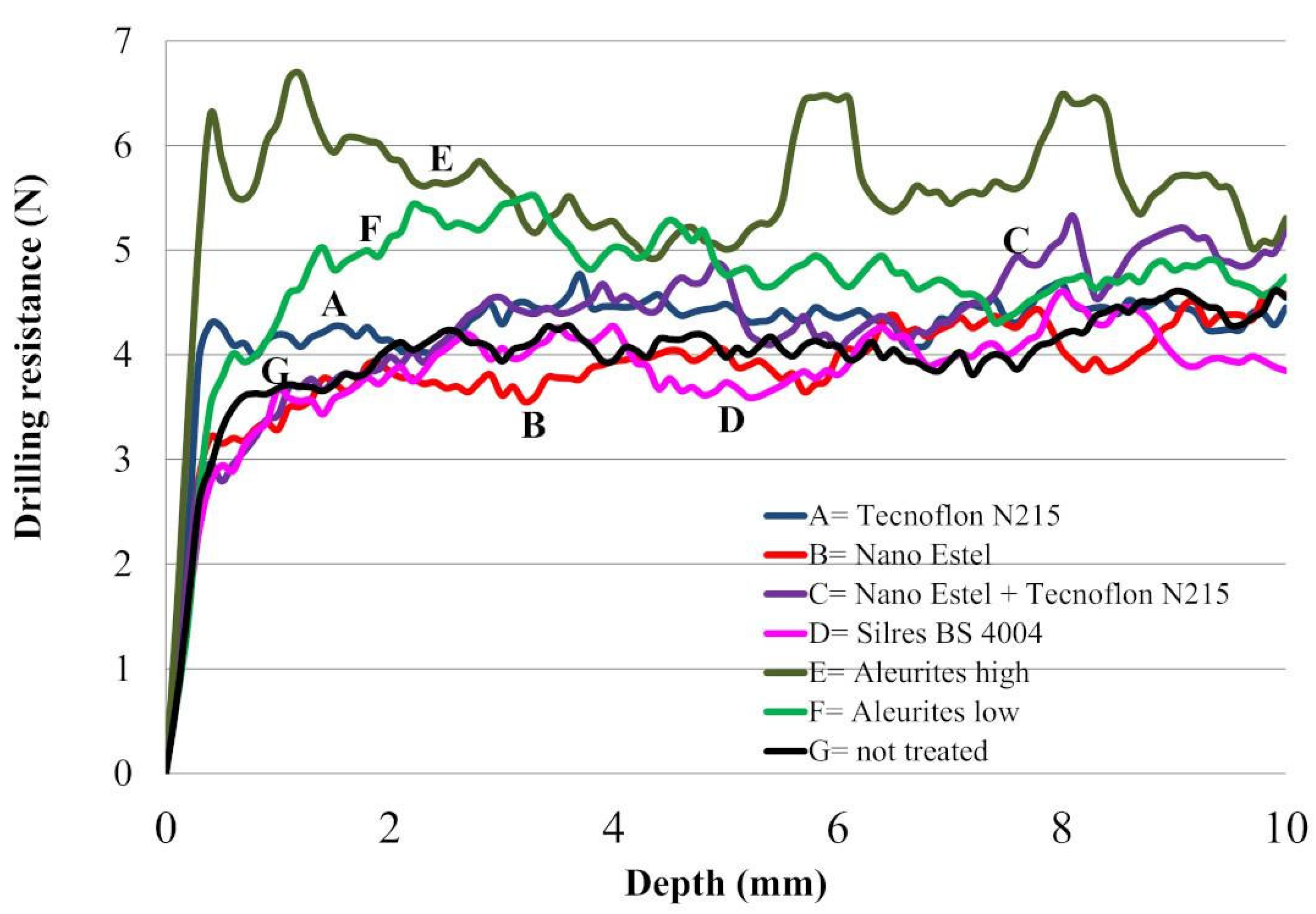

3.2.4. DRMS Test

- -

- For all treatments, there were no relevant differences between the values of the drilling resistance calculated in the two depth ranges (0.3–2 mm and 2–10 mm) (Table 9). This suggests that there is no superficial crust due to a surface concentration of the product. This hypothesis was also confirmed by the drilling profiles shown in Figure 17;

- -

- Only the two treatments with Aleurites oil, low (F) and high (E), showed an increase in the drilling resistance (Table 9) that was more evident in the case of the high concentration treatment, especially in the first few millimetres (Figure 17). This suggests a higher concentration of the product on the surface with the formation of a harder layer. However, it can be seen that the drilling resistance profile for both concentrations of the Aleurites treatment had higher values than that of the untreated one throughout the depth range. This would indicate that the product, through its porosity-filling action, also induced an increase in the surface cohesion of the earthen brick;

- -

- The treatments with a consolation action based on Nano Estel (B) alone and Nano Estel + Tecnoflon N215(C) did not seem to have induced an increase in the drilling resistance compared to the untreated sample (G); this considered both the average value (Table 9) and the trends of the drilling profiles (Figure 17).

3.2.5. Colour Test

- -

- Earthen bricks treated with Tecnoflon N215, Nano Estel, Nano Estel + Tecnoflon N215, and Aleurites oil high showed a decrease in brightness (L*) and an increase in the a* (redder) and b* (more yellow) parameters. Therefore, the earthen bricks were darker brown than before the treatment;

- -

- Earthen bricks treated with Silres BS 4004 showed an increase in brightness (L*) and in a* (redder) and b* (more yellow) parameters. Therefore, for the treatment with Silres BS 4004, the earthen bricks were slightly lighter brown than before the treatment;

- -

- Regarding the earthen bricks treated with the Aleurites oil low concentration, their colour remained almost unchanged, resulting in the variation ΔE < 3.

3.2.6. Durability Test

4. Discussion

- -

- Tecnoflon N215 (A) showed good behaviour in the tests in both the resistance to the erosive action of the water and in the evaluation of the hydrophobic properties, guaranteeing excellent characteristics of permeability to water vapour. However, a change in colour was evident (ΔE > 5). The drilling resistance also did not show a significant increase in the first millimetre excluding the formation of a hard crust;

- -

- Nano Estel (B) showed poor results concerning the resistance to water erosion, water absorption, hydrophobicity, and drilling resistance. The poor result of the drilling resistance test in this case was not expected since the product is a consolidating agent. The main causes could be related to the difficult penetration of the nanoparticles inside the porosity of the material due to the application method (spraying); a low percentage of the applied product that is therefore unable to provide cohesion back to the material; and a negative action of the aqueous solvent on the earthy material that caused it to disintegrate. This last hypothesis seems confirmed by the water vapour permeability test performed on brick samples on which solvents were applied (see Table 7) [54]. It was observed that, in general, the solvents, polar and nonpolar (water > acetone > isopropanol > limonene) [56], interacted with the earth material, in particular with the clay fraction, triggering absorption/desorption phenomena (swelling/contraction), particularly in expandable lattice minerals such as smectite and vermiculite [57,58,59]. The result is a reorganisation of the structure and probably a lower “compactness” of the material. A role can also be played by the rate of evaporation of the solvent, namely, how long the material remains wet (solvent vapour pressure increasing: limonene > water > isopropanol > acetone) [55,56,57]. The colour variation was not relevant;

- -

- The combined product Nano Estel + Tecnoflon N215 (C) showed promising results with respect to water absorption and hydrophobic tests, and is connected to the presence of a fluoelastomer in the mixture, which can preserve the permeability to water vapour. As in the case of Nano Estel alone, the resistance to water vapour transmission was decreased, probably due to the disaggregation power of the solvent or to experimental error/data dispersion. As for the resistance to both the action of water by spray and the Geelong tests and to drilling, no positive effects were observed. It was positively assessed that the drilling resistance did not show significant increases in the first millimetre excluding the formation of a hard crust. The colour changed perceptibly, that is ΔE > 3;

- -

- Silres BS 4004 (D) showed a behaviour similar to that of Tecnoflon N215 with excellent results both for the tests of resistance to the erosive action of water and for the hydrophobic properties, guaranteeing the excellent characteristics of water vapour permeability with a change in colour below that perceptible to the naked eye (ΔE < 3). The resistance to the transmission of water vapour was decreased, and also, in this case, the reason can be attributed to the action of the solvent or to experimental error/data dispersion. The drilling resistance did not show significant increases in the first millimetre excluding the formation of a hard crust;

- -

- Aleurites high (E) showed excellent results concerning the action against water ingress and the increase in the surface hydrophobicity. Unfortunately, the DRMS test seemed to indicate the formation of a surface hard layer, although such ‘hardening’ was also observed within the brick up to the investigated depth (10 mm). In agreement with the presence of this harder layer, there were also the very poor results of the water vapour permeability test, where it seems that the product caused occlusion of the pores. A possible reason is the product application as supplied by the seller, without dilution, which is therefore of a higher concentration with respect to the others. Additionally, the results of the colour tests were very poor;

- -

- Aleurites low (F) seems to have occluded the material’s pores with an increase in the resistance to the water vapour transmission. There was a slight increase in the drilling resistance, showing that the treatment did not induce the formation of a hard surface layer in this concentration in the first millimetres but did not even confer the characteristics of protection against water, as evidenced by the tests of resistance to erosion, water absorption, and surface hydrophobicity, with results similar to those of the untreated brick. There were small colour changes but considering all of the performances, the treatment did not induce positive effects.

5. Conclusions

- -

- Application by brush could guarantee a good distribution of the product, but the best results were obtained by spraying because the “mechanical” interaction between the earth’s surface and the brush, which could cause the removal of material from the surface, is avoided;

- -

- The type of solvent is undoubtedly a critical parameter when the material to be protected is earth. Indeed, a water solvent should be preferred for lower toxicity, but water has a bad effect on the earthen material, especially in the presence of swelling clay minerals. Therefore, solvents with low polarity and high vapour pressure should be used. However, the action of the solvent on the earthen material would need to be investigated with even more in-depth experimentation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mattone, M. Earthen Architectures: History, Typologies and Construction Techniques. In Past and Present of the Earthen Architectures in China and Italy; CNR Edizioni: Roma, Italy, 2021; pp. 11–22. ISBN 9788880804703. [Google Scholar]

- Minke, G. Building with Earth: Design and Technology of a Sustainable Architecture, 4th ed.; Birkhauser: Basel, Switzerland, 2021; ISBN 9783035622539. [Google Scholar]

- Costi de Castrillo, M.; Philokyprou, M.; Ioannou, I. Comparison of adobes from pre-history to date. J. Archaeol. Sci. Rep. 2017, 12, 437–448. [Google Scholar] [CrossRef]

- Guillaud, H.; Houben, H.; Dethier, J. Traité de Construction en Terre; Parenthèses Editions: Marseille, France, 2015; ISBN 9782863641613. [Google Scholar]

- Steen, A.; Steen, B.; Komatsu, E. Built by Hand: Vernacular Buildings around the World; Gibbs Smith Publishers: Layton, UT, USA, 2003; ISBN 9781586852375. [Google Scholar]

- Mecca, S. From disregard to innovation. In Earth/Lands. Earthen Architecture of Southen Italy; Mecca, S., Boti Briccoli, S., Forlani, M.C., Germanà, M., Eds.; Edizioni ETS: Firenze, Italy, 2011; pp. 89–95. ISBN 9788846721464. Available online: https://issuu.com/dida-unifi/docs/earth-lands (accessed on 18 January 2023).

- Frenda, A. Earthen architecture in the agricultural heritage system: Sustainable development, restoration, and continuity of tradition. J. Mater. Environ. Sci. 2016, 7, 3614–3622. [Google Scholar]

- Baglioni, E.; Rovero, L.; Tonietti, U. Drâa valley earthen architecture: Construction techniques, pathology and intervention criteria. J. Mater. Environ. Sci. 2016, 7, 3499–3508. [Google Scholar]

- Mileto, C.; Vegas, F.; Llatas, C.; Soust-Verdaguer, B. A Sustainable Approach for the Refurbishment Process of Vernacular Heritage: The Sesga House Case Study (Valencia, Spain). Sustainability 2021, 13, 9800. [Google Scholar] [CrossRef]

- Achenza, M. Historical Earthen Architectures in Italy. In Past and Present of the Earthen Architectures in China and Italy; CNR Edizioni: Roma, Italy, 2021; pp. 39–56. ISBN 978 88 8080 470 3. [Google Scholar]

- Aloiz, E.M. New Investigations into a Historic Treatment: The Efficacy of Gelatin as an Adhesive for Earthen Finishes at Mesa Verde National Park. Master’s Thesis, University of Pennsylvania, Philadelphia, PA, USA, 2011. [Google Scholar]

- Eires, R.; Camões, A.; Jalali, S. Ancient Materials and Techniques to Improve the Earthen Building Durability. Key Eng. Mater. 2014, 634, 357–366. [Google Scholar] [CrossRef]

- Gomes, M.I.; Goncalves, T.D.; Faria, P. Earth-based repair mortars: Experimental analysis with different binders and natural fibers. In Rammed Earth Conservation, Proceedings of the RESTAPIA 2012, Valencia, Spain, 21–23 June 2012; Mileto, C., Vegas, F., Cristini, V., Eds.; Taylor & Francis Group: London, UK, 2012; pp. 661–668. [Google Scholar]

- Mattone, M.; Ibnoussina, M.; Rescic, S.; Fratini, F.; Magrini, D.; Mecchi, A.M.; Nocairi, M. Stabilization of earthen plasters: Exchange of knowledge and experiences between Italy and Morocco. J. Mater. Environ. Sci. 2016, 7, 3647–3655. [Google Scholar]

- Mattone, M.; Rescic, S.; Fratini, F.; Manganelli Del Fa, R. Experimentation of Earth-Gypsum Plasters for the Conservation of Earthen Constructions. Int. J. Archit. Herit. 2017, 11, 763–772. [Google Scholar] [CrossRef]

- Stazi, F.; Nacci, A.; Tittarelli, F.; Pasqualini, E.; Munafò, P. An experimental study on earthen plasters for earthen building protection: The effect of different admixtures and surface treatments. J. Cult. Herit. 2016, 17, 27–41. [Google Scholar] [CrossRef]

- Ferron, A. The Consolidation of Earthen Surface Finishes: A Study of Disaggregating Plasters at Mesa Verde National Park. Master’s Thesis, University of Pennsylvania, Philadelphia, PA, USA, 2007. [Google Scholar]

- Ferron, A.; Matero, F.G. A Comparative Study of Ethyl-silicate-based Consolidants on Earthen Finishes. J. Am. Inst. Conserv. 2011, 50, 49–72. [Google Scholar] [CrossRef]

- Pacheco, G.; Pozzi-Escot, D.; Cappai, M.; Malpartida, S.; Petrick, S. Productos orgánicos para la conservación de pintura mural. In Proceedings of the XII World Congress on Earthen Architecture Terra 2016, Lyon, France, 11–14 July 2016; Craterre: Villefontaine, France, 2016; pp. 133–137, ISBN 9791096446117. [Google Scholar]

- Li, Z.; Zhao, L.; Sun, M. Deterioration of earthen sites and consolidation with PS material along Silk Road of China. Chin. J. Rock Mech. Eng. 2009, 28, 1047–1054. [Google Scholar]

- Chiari, G. Chemical surface treatments and capping techniques of earthen structures: A long-term evaluation. In Proceedings of the 6th International Conference on the Conservation of Earthen Architecture, Las Cruces, NM, USA, 14–19 October 1990; Agnew, N., Taylor, M., Balderrama, A.A., Houben, H., Grimstad, K., Eds.; The Getty Conservation Institute: Los Angeles, CA, USA, 1990; pp. 267–273. [Google Scholar]

- Bourgès, A.; Colas, E.; Vissac, A.; Fontaine, L.; Anger, R.; Gandreau, D.; Joffroy, T. Similarities and differences in evaluation methods for stone or Earthen surfaces. In Proceedings of the International Conference on Conservation of Stone and Earthen Architectural Heritage, Gongju, Republic of Korea, 20–23 May 2014; pp. 165–171. [Google Scholar]

- Elert, K.; Sebastian, E.; Valverde, I.; Rodriguez-Navarro, C. Alkaline treatment of clay minerals from the Alhambra Formation: Implications for the conservation of earthen architecture. Appl. Clay Sci. 2008, 39, 122–132. [Google Scholar] [CrossRef]

- Elert, K.; Pardo, E.S.; Rodriguez-Navarro, C. Alkaline activation as an alternative method for the consolidation of earthen architecture. J. Cult. Herit. 2015, 16, 461–469. [Google Scholar] [CrossRef]

- Elert, K.; Bel-Anzué, P.; Monasterio-Guillot, L.; Pardo, S. Performance of alkaline activation for the consolidation of earthen architecture. J. Cult. Herit. 2019, 39, 93–102. [Google Scholar] [CrossRef]

- Lohnas, D.E. Evaluating the effectiveness of calcium hydroxide nanoparticle dispersions for the consolidation of painted earthen architectural surfaces. Master’s Thesis, University of California, Los Angeles, CA, USA, 2012. [Google Scholar]

- Lanzón, M.; Madrid, J.A.; Martínez-Arredondo, A.; Mónaco, S. Use of diluted Ca(OH)2 suspensions and their transformation into nanostructured CaCO3 coatings: A case study in strengthening heritage materials (stucco, adobe and stone). Appl. Surf. Sci. 2017, 424, 20–27. [Google Scholar] [CrossRef]

- Camerini, R.; Chelazzi, D.; Giorgi, R.; Baglioni, P. Hybrid nano-composites for the consolidation of earthen masonry. J. Colloid Interface Sci. 2019, 539, 504–515. [Google Scholar] [CrossRef]

- Mattone, M. Prevenire il degrado: La protezione delle costruzioni in terra cruda. In Proceedings of the XXVI Convegno Internazionale Scienza e Beni Culturali-Pensare la Prevenzione, Bressanone, Italy, 13–16 July 2010; Arcadia Ricerche: Venice, Italy, 2010; pp. 141–150, ISBN 978-88-95409-14-6. [Google Scholar]

- European Standards EN 15802: 2009; Conservation of Cultural Property—Test Methods—Determination of Static Contact Angle. UNI: Milan, Italy, 2009.

- European Standards EN 16581:2014; Conservation of Cultural Heritage—Urface Protection for Porous Inorganic Materials—Laboratory Test Methods for the Evaluation of the Performance of Water Repellent Products. UNI: Milan, Italy, 2014.

- European Standards EN 15803:2010; Conservation of Cultural Property—Test Methods—Determination of Water Vapour Permeability (δp). UNI: Milan, Italy, 2010.

- European Standards EN 15886:2010; Conservation of Cultural Property—Test Methods—Colour Measurement of Surfaces. UNI: Milan, Italy, 2010.

- NZS 4298-D; Materials and Workmanship for Earth Buildings, Appendix D. Standards New Zealand: Wellington, New Zealand, 1998.

- NZS 4298-E; Materials and Workmanship for Earth Buildings, Appendix E. Standards New Zealand: Wellington, New Zealand, 1998.

- Camaiti, M.; Benvenuti, E.; Paciulli, L. Formulati a base di poliammidi parzialmente fluorurate e fluoroelastomeri per la protezione e il consolidamento di manufatti lapidei. Arkos Sci. Restauro 2011, 28, 29–33. [Google Scholar]

- Banchelli, A.; Fratini, F.; Germani, M.; Malesani, P.; Manganelli Del Fa, C. The sandstones of the Florentine historic buildings: Individuation of the marker and determination of the supply quarries of the rocks used in some Florentine monuments. Sci. Technol. Cult. Herit. 1997, 6, 13–22. [Google Scholar]

- The Australian Earth Building Handbook; Standards Australia International: Sydney, Australia, 2002.

- SAZS 724; Rammed Earth Structures. Standards Association of Zimbabwe: Harare, Zimbabwe, 2001.

- EN 16302: 2013; Conservation of Cultural Property—Test Methods—Measurement of Water Absorption by Pipe Method. UNI: Milan, Italy, 2013.

- Papamichos, E.; Papanicolopolus, S.A.; Larsen, I.; Alnæ, L.; Rescic, S. Method for in situ, quasi non-destructive diagnosis of mechanical properties and damage of natural building stones. In Proceedings of the Gulf Rock 2004, the 6th North America Rock Mechanics Symposium, Houston, TX, USA, 5–9 June 2004; p. ARMA-04-583. [Google Scholar]

- Valentini, E.; Benincasa, A.; Tiano, P.; Fratini, F.; Rescic, S. On Site Drilling Resistance Profiles of Natural Stones. In Proceedings of the International Workshop In Situ Monitoring of Monumental Sufaces, Florence, Italy, 27–29 October 2008; pp. 195–204. [Google Scholar]

- Rescic, S.; Fratini, F.; Tiano, P. Onsite evaluation of the mechanical properties of Maastricht limestone and their relationship with the physical characteristics. Geol. Soc. Lond. Spec. Publ. 2010, 331, 203–207. [Google Scholar] [CrossRef]

- Rescic, S.; Mattone, M.; Fratini, F.; Luvidi, L. Earthen Plasters Stabilized through Sustainable Additives: An Experimental Campaign. Sustainability 2021, 13, 1090. [Google Scholar] [CrossRef]

- Snethlage, R. Stone Conservation. In Stone in Architecture, 5th ed.; Siegesmund, S., Snethlage, R., Eds.; Springer: Berlin, Germany, 2014; pp. 512–520. [Google Scholar]

- Delgado Rodrigues, J.; Grossi, A. Indicators and ratings for the compatibility assessment of conservation actions. J. Cult. Herit. 2007, 8, 32–34. [Google Scholar] [CrossRef]

- CIELAB. Commission Internationale de l’Eclairage; Wien CIE: Vienna, Austria, 1976. [Google Scholar]

- ASTM D4141/D4141M; Standard Practice for Conducting Black Box and Solar Concentrating Exposures of Coatings. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D559/D559M; Standard Test Methods for Wetting and Drying Compacted Soil-Cement Mixtures. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D560/D560M; Standard Test Methods for Freezing and Thawing Compacted Soil-Cement Mixtures. ASTM International: West Conshohocken, PA, USA, 2015.

- RILEM. Internal Damage of Concrete Due to Frost Action. In Final Recommendation Test Methods of Frost Resistance of Concrete: CIF-Test: Capillary Suction, Internal Damage, and Freeze Thaw Test—Reference Method and Alternative Methods A and B in RILEM TC 176-IDC (2004); RILEM Publications: Champs-sur-Marne, France, 2004. [Google Scholar]

- Houben, H.; Guillaud, H. Traité de Construction en Terre de CRATerre; Parenthèse Editions: Marseille, France, 1989. [Google Scholar]

- Mattone, M.; Fratini, F.; Rescic, S.; Rovero, L. Analysis of the earthen architectural heritage in Piedmont (northern Italy): Typologies, construction techniques and materials. Rev. Grem. 2021, 7, 41–52. [Google Scholar]

- Bourgès, A.; Tiennot, M.; Mertz, J.D.; Liégey, A.; Bouquillon, A. Review of earthen materials consolidation with ethyl silicate. In Proceedings of the 22th World Congress on Earthen Architecture, TERRA, Lyon, France, 11–14 July 2016; pp. 104–107. [Google Scholar]

- Barsottelli, M.; Fratini, F.; Giorgetti, G.; Manganelli Del Fa, C. Microfabric and alteration in the Carrara marble: A preliminary study. Sci. Technol. Cult. Herit. 1998, 7, 109–120. [Google Scholar]

- Sadek, P.C. The HPLC Solvent Guide, 2nd ed.; Wiley-Interscience: New York, NY, USA, 2002; 644p, ISBN 0-471-41138-8. [Google Scholar]

- Madsen, F.T.; Müller-Vonmoos, M. The swelling behaviour of clays. Appl. Clay Sci. 1989, 4, 143–156. [Google Scholar] [CrossRef]

- Houben, H.; Guillaud, H. Earth Construction: A Comprehensive Guide; Practical Action Publishing: Rugby, UK, 1994; 376p, ISBN 10: 185339193X. [Google Scholar]

- Rodriguez-Navarro, C.; Sebastian, E.; Doehne, E.; Ginell, W.S. The role of sepiolite-palygorskite in the decay of ancient Egyptian limestone sculptures. Clays Clay Miner. 1996, 46, 414–422. [Google Scholar] [CrossRef]

| Test | Sample Size in cm | Number of Samples for Each Treatment | Number of Tests for Each Sample |

|---|---|---|---|

| Spray | 26 × 13.5 × 6.5 | 3 | 1 |

| Geelong | 26 × 13.5 × 6.5 | 3 | 3 |

| Karsten | 26 × 13.5 × 6.5 | 3 | 3 |

| Colour | 5 × 5 × 2 | 12 | 3 |

| Water vapour permeability | 5 × 5 × 2 | 3 | 1 |

| Static contact angle | 5 × 5 × 2 | 3 | 10 |

| DRMS | 5 × 5 × 2 | 3 | 3 |

| Ageing | 5 × 5 × 2 | 3 | 1 |

| Treatment | Brick | Original Concentration (% w/w) | Applied Concentration (% w/w) | Solvent | Amount Applied (L/m2) | Method of Application |

|---|---|---|---|---|---|---|

| Tecnoflon N215 | A | 3 | 1 | Acetone | 2.20 | Spray |

| Nano Estel | B | 30 | 1 | Water | 1.28 | Spray |

| Nano Estel+N215 * | C | 1.5% Nano Estel +0.5% N215 * | 1.5% Nano Estel +0.5% N215 * | Acetone/water | 1.92 | Spray |

| Silres BS 4004 | D | 50 | 1 | Isopropanol | 2.00 | Spray |

| Aleurites high | E | 37 | 37 | - | 2.12 | Brush |

| Aleurites low | F | 37 | 1 | Limonene | 2.12 | Brush |

| Not treated | G | - | - | - | - | - |

| Depth of Erosion D [mm] | Erodibility Index |

|---|---|

| 0 < D < 5 | 2 (no erosion) |

| 5 ≤ D < 10 | 3 |

| 10 ≤ D < 15 | 4 |

| D ≥ 15 | 5 (fail) |

| Depth of the Erosion D [mm/h] | Erodibility Index |

|---|---|

| 0 < D < 20 | 1 |

| 20 ≤ D < 50 | 2 |

| 50 ≤ D < 90 | 3 |

| 90 ≤ D < 120 | 4 |

| D ≥ 120 | 5 (fail) |

| Brick | Depth of Erosion (mm) | Index |

|---|---|---|

| Tecnoflon N215 | 0 | 2 |

| Nano Estel | 8.23 ± 0.20 | 3 |

| Nano Estel + Tecnoflon N215 | 8.00 ± 0.20 | 3 |

| Silres BS 4004 | 0.16 ± 0.10 | 2 |

| Aleurites high | 0 | 2 |

| Aleurites low | 4.00 ± 0.15 | 2 |

| Not treated | 5.34 ± 0.15 | 3 |

| Treatment | Contact Angle Ɵ° | Water Absorption Speed |

|---|---|---|

| Tecnoflon N215 | 110 ± 5 | Very slow |

| Nano Estel | 10 ± 2 | Very fast |

| Nano Estel + Tecnoflon | 120 ± 5 | Very slow |

| Silres BS 4004 | 125 ± 5 | Very slow |

| Aleurites high | 93 ± 3 | Slow |

| Aleurites low | 40 ± 3 | Medium slow |

| Not treated | 20 ± 3 | Fast |

| Parameter | Brick | ||||||

|---|---|---|---|---|---|---|---|

| Tecnoflon N215 | Nano Estel | Nano Estel + Tecnoflon N215 | Silres BS 4004 | Aleurites High | Aleurites Low | Not Treated | |

| μ (-) | 9.0 ± 0.1 | 8.8 ± 0.1 | 8.7 ± 0.1 | 8.7 ± 0.1 | 14.2 ± 0.1 | 11.7 ± 0.1 | 9.1 ± 0.1 |

| Δμ (%) | −0.9 | −3.4 | −4.6 | −4.3 | 28.3 | 56.5 | - |

| Parameter | Solvent | |||

|---|---|---|---|---|

| Water | Acetone | Isopropanol | Limonene | |

| μ (-) | 8.8 ± 0.1 | 9.0 ± 0.1 | 8.9 ± 0.1 | 9.1 ± 0.1 |

| Δμ (%) | 3.3 | 2.2 | 1.1 | 0 |

| Treatment | Drilling Resistance (N) | ||

|---|---|---|---|

| Depth Range (mm) | |||

| 0.3–10 | 0.3–2 | 2–10 | |

| Tecnoflon N215 | 4.35 ± 0.36 | 4.17 ± 0.34 | 4.38 ± 0.49 |

| Nano Estel | 3.94 ± 0.68 | 3.52 ± 0.35 | 4.03 ± 0.83 |

| Nano Estel + Tecnoflon | 4.38 ± 0.65 | 3.51 ± 0.45 | 4.56 ± 0.53 |

| Silres BS 4004 | 3.91 ± 0.61 | 3.44 ± 0.43 | 4.01 ± 0.59 |

| Aleurites high | 5.66 ± 0.71 | 6.05 ± 0.75 | 5.58 ± 0.37 |

| Aleurites low | 4.50 ± 0.74 | 4.82 ± 0.94 | 4.89 ± 0.96 |

| not treated | 3.66 ± 0.36 | 4.07 ± 0.49 | 4.15 ± 0.58 |

| Treatment | ΔL* | Δa* | Δb* | ΔE* |

|---|---|---|---|---|

| Tecnoflon N215 | 2.56 ± 1.69 | −1.35 ± 0.22 | −5.10 ± 0.58 | 6.00 ± 1.00 |

| Nano Estel | 4.16 ± 2.89 | −0.98 ± 0.45 | −3.06 ± 1.46 | 5.70± 2.30 |

| Nano Estel + Tecnoflon N215 | 5.51 ± 1.22 | −1.35 ± 0.21 | −4.17 ± 0.64 | 7.10 ± 1.20 |

| Silres BS 4004 | −4.07 ± 1.92 | −0.32 ± 0.16 | −1.78 ± 0.57 | 4.50 ± 1.90 |

| Aleurites high | 13.92 ± 3.73 | −2.28 ± 0.33 | 5.51 ± 1.22 | 14.90 ± 3.10 |

| Aleurites low | −2.04 ± 1.17 | −0.24 ± 0.03 | −0.65 ± 1.03 | 2.60± 1.50 |

| Brick | Colorimetric Results | Contact Angle Result | Weight Results | ||||

|---|---|---|---|---|---|---|---|

| ΔL* | Δa* | Δb* | ΔE* | Contact Angle Ɵ° Before | Contact Angle Ɵ° After | # Weight Loss (%) | |

| Tecnoflon N215 | 0.64 ± 0.74 | −0.32 ± 0.20 | −0.94 ± 0.50 | 1.25 ± 0.77 | 110 ± 5 | 108 ± 5 | 0.29 ± 0.10 |

| Nano Estel | 0.15 ± 0.41 | 0.00 ± 0.07 | 0.04 ± 0.17 | 0.37 ± 0.18 | 10 ± 2 | 10 ± 4 | 0.35 ± 0.12 |

| Nano Estel + Tecnoflon N215 | 0.10 ± 0.09 | −0.03 ± 0.00 | −0.23 ± 0.08 | 0.26 ± 0.11 | 120 ± 5 | 118 ± 6 | 0.43 ± 0.12 |

| Silres BS 4004 | −0.15 ± 0.15 | −0.03 ± 0.11 | −0.07 ± 0.39 | 0.37 ± 0.17 | 125 ± 5 | 115 ± 7 | 0.42 ± 012 |

| Aleurites high | −4.54 ± 2.54 | 0.58 ± 0.19 | −0.97 ± 1.57 | 4.78 ± 2.75 | 93 ± 3 | 90 ± 3 | 0.31 ± 0.10 |

| Aleurites low | −1.22 ± 0.50 | −0.13 ± 0.05 | −0.68 ± 0.28 | 1.40 ± 0.57 | 40 ± 3 | 37 ± 5 | 0.34 ± 0.10 |

| not treated | −2.03 ± 0.08 | −0.20 ± 0.07 | −1.13 ± 0.16 | 2.33 ± 0.04 | 20 ± 3 | 10 ± 3 | 0.30 ± 0.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rescic, S.; Mattone, M.; Fratini, F.; Luvidi, L. Conservation of Earthen Bricks in Architecture: An Experimental Campaign to Test Different Treatments on Vernacular Built Heritage. Heritage 2023, 6, 1541-1566. https://doi.org/10.3390/heritage6020083

Rescic S, Mattone M, Fratini F, Luvidi L. Conservation of Earthen Bricks in Architecture: An Experimental Campaign to Test Different Treatments on Vernacular Built Heritage. Heritage. 2023; 6(2):1541-1566. https://doi.org/10.3390/heritage6020083

Chicago/Turabian StyleRescic, Silvia, Manuela Mattone, Fabio Fratini, and Loredana Luvidi. 2023. "Conservation of Earthen Bricks in Architecture: An Experimental Campaign to Test Different Treatments on Vernacular Built Heritage" Heritage 6, no. 2: 1541-1566. https://doi.org/10.3390/heritage6020083

APA StyleRescic, S., Mattone, M., Fratini, F., & Luvidi, L. (2023). Conservation of Earthen Bricks in Architecture: An Experimental Campaign to Test Different Treatments on Vernacular Built Heritage. Heritage, 6(2), 1541-1566. https://doi.org/10.3390/heritage6020083