The Susceptibility to Salt Fog Degradation of Stone Cladding Materials: A Laboratory Case Study on Two Limestones from Portugal

Abstract

1. Introduction

2. Materials and Methods

- Specimens were washed with demineralized water and dried at a temperature of 70 ± 5 °C until constant mass (m0) was reached.

- Salt spray cycles comprised 4 h of saline spray followed by 8 h of drying at 35 ± 5 °C. Salt solution (NaCl) concentration was 100 ± 10 g/l.

- Every 15 cycles, the specimens were checked for visual macro and micro inspections. Every 15 cycles, specimens were washed with running and demineralized water; then they were dried (climate chamber at 60 °C after 24 h) and then weighed.

3. Results and Discussion

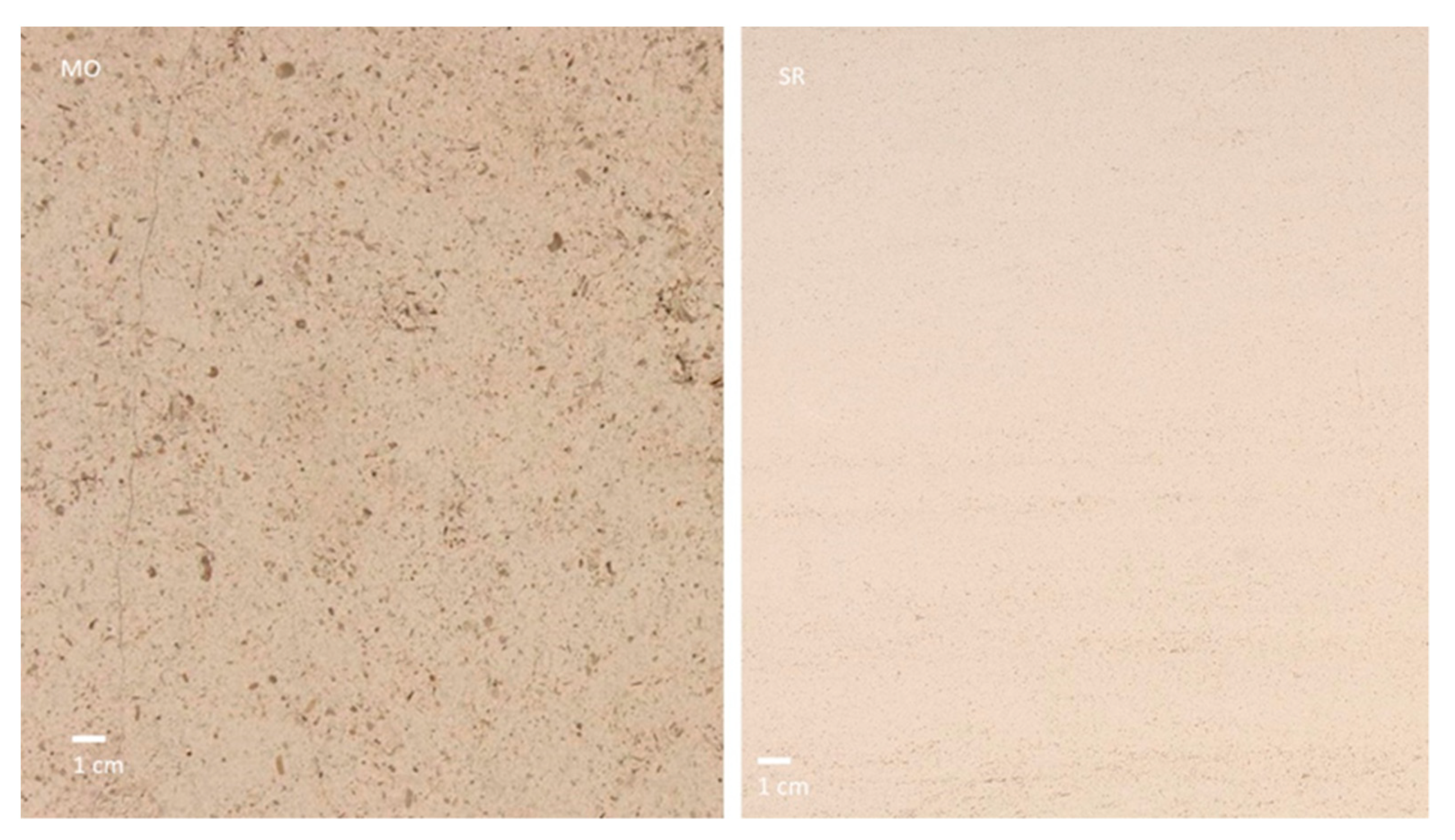

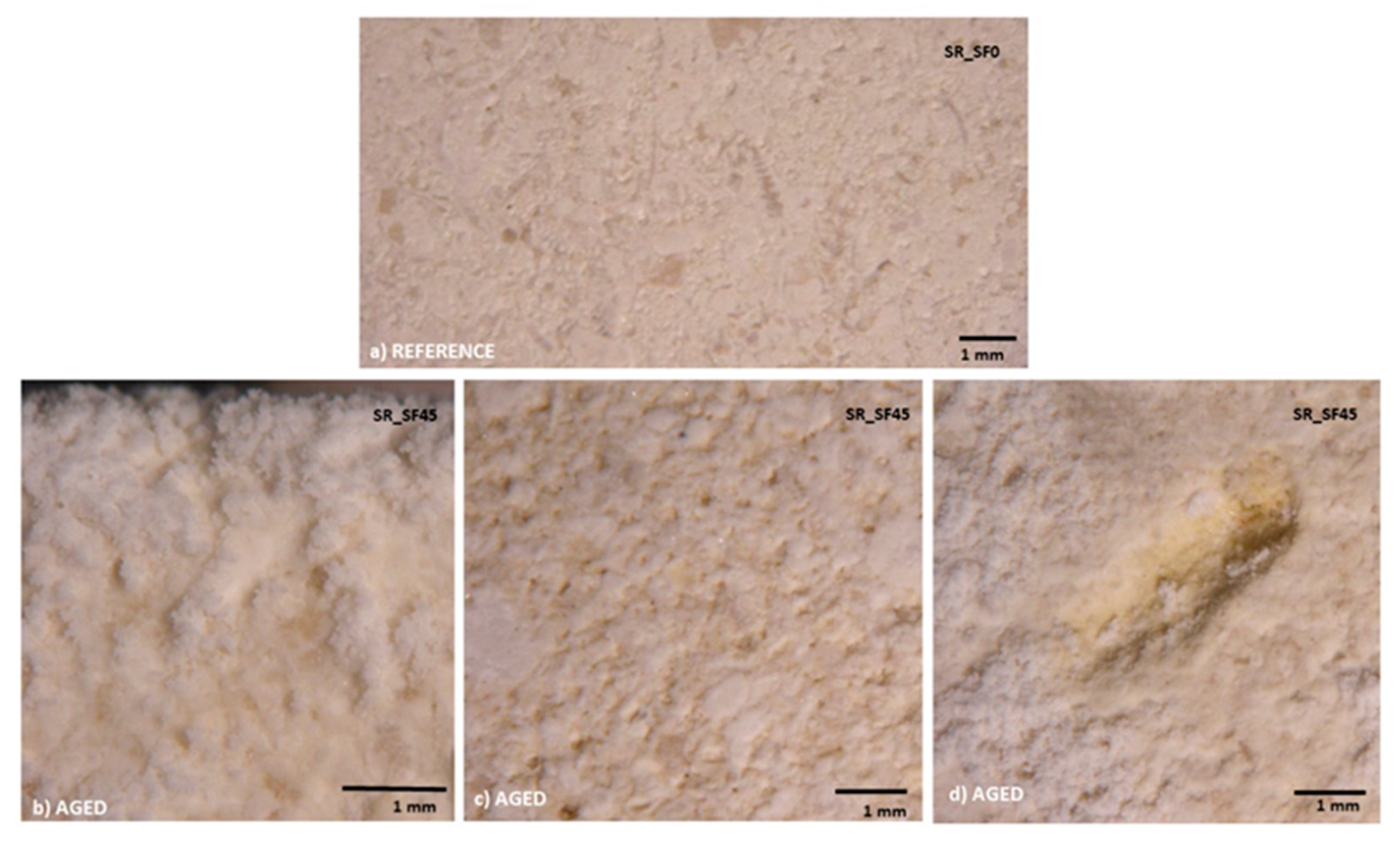

3.1. Microscopic Analysis

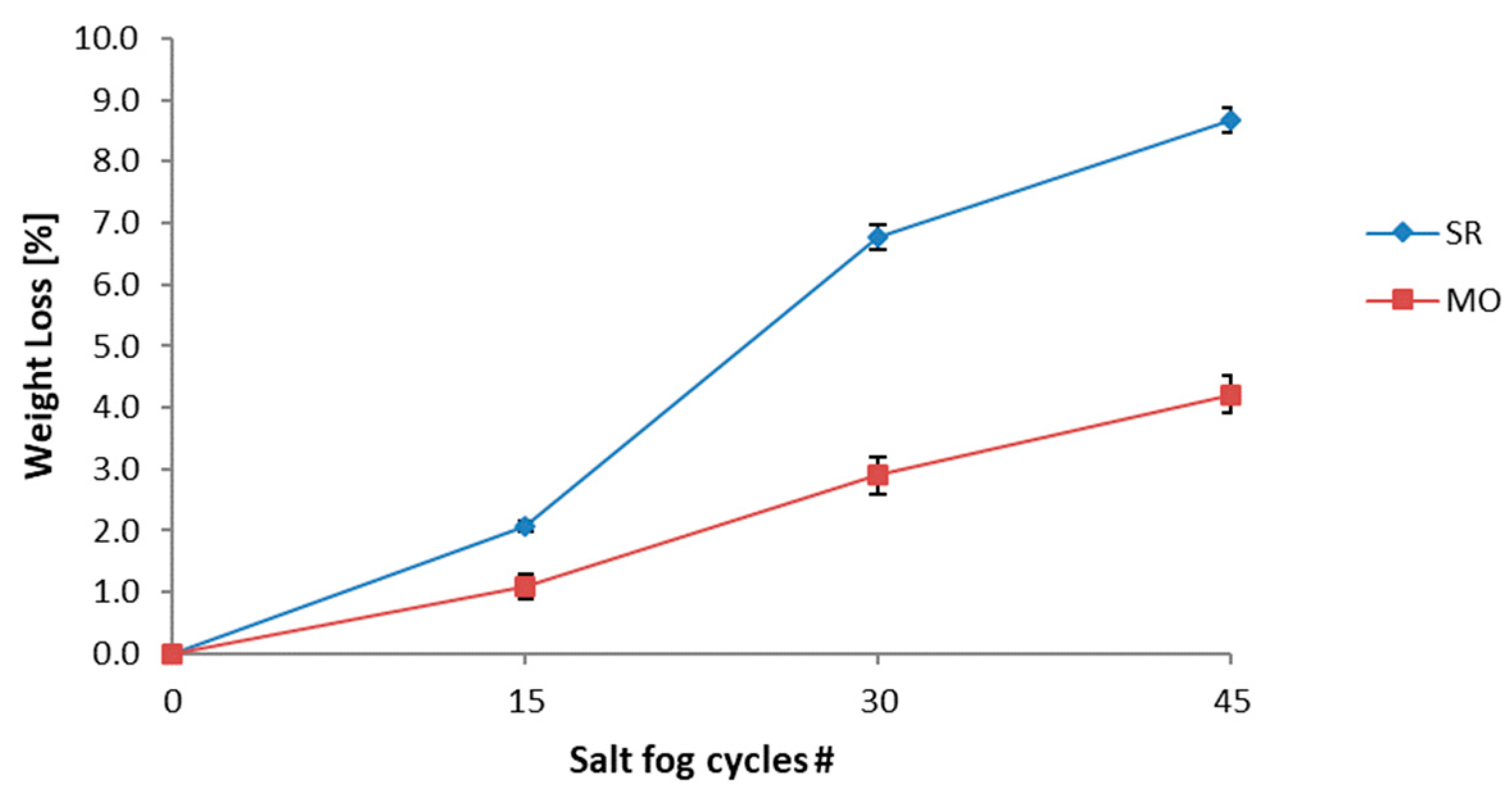

3.2. Weight Loss Assessment

3.3. Flexural Strength

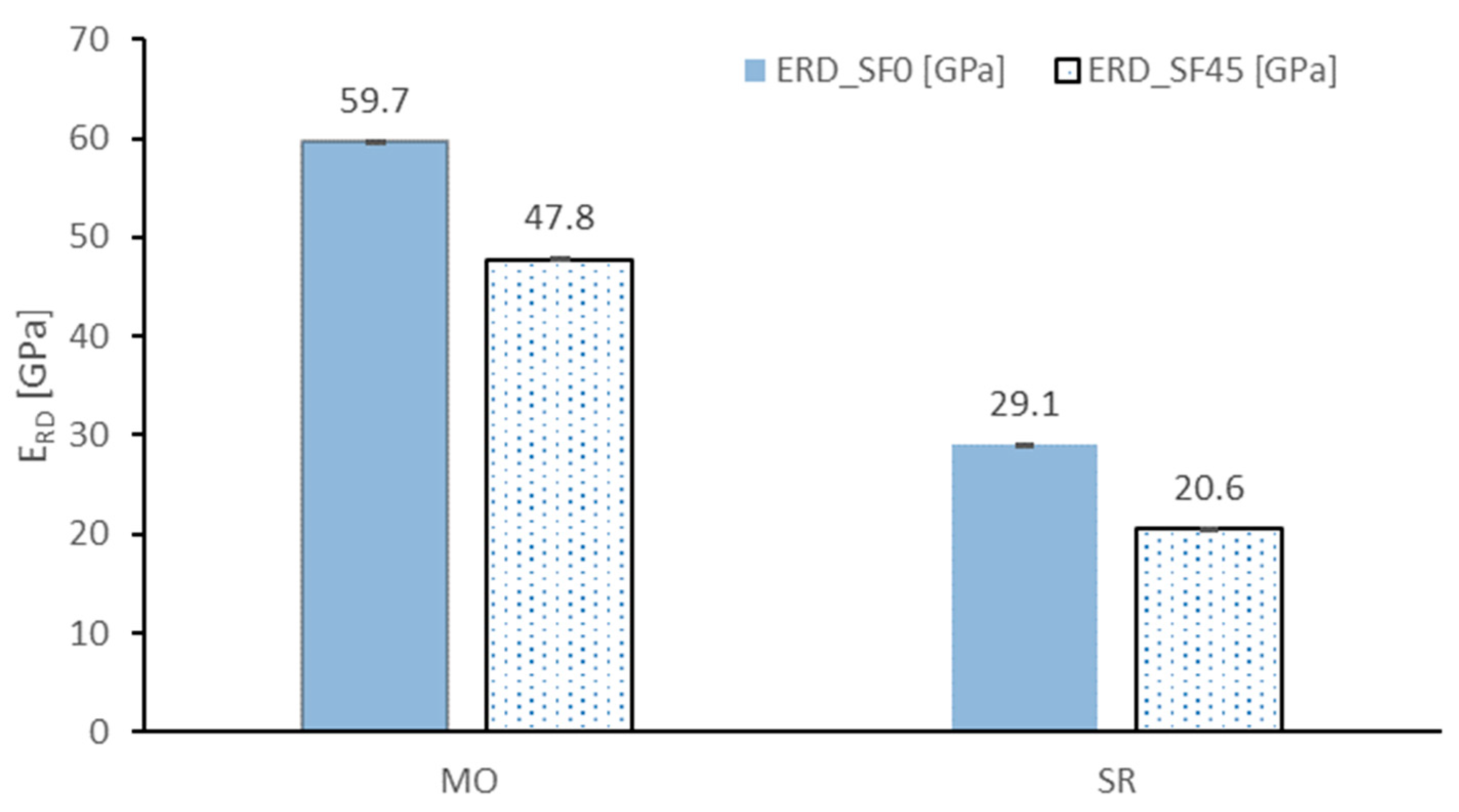

3.4. Elastic Modulus—Through Flexural Resonance Method

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Molina, E.; Cultrone, G.; Sebastián, E.; Alonso, F.J. Evaluation of stone durability using a combination of ultrasound, mechanical and accelerated aging tests. J. Geophys. Eng. 2013, 10, 035003. [Google Scholar] [CrossRef]

- Sitzia, F.; Lisci, C.; Mirão, J. The interaction between rainwater and polished building stones for flooring and cladding—Implications in architecture. J. Build. Eng. 2022, 52, 104495. [Google Scholar] [CrossRef]

- Pires, V.; Rosa, L.G.; Dionísio, A. Implications of exposure to high temperatures for stone cladding requirements of three Portuguese granites regarding the use of dowel-hole anchoring systems. Constr. Build. Mater. 2014, 64, 440–450. [Google Scholar] [CrossRef]

- Pires, V.; Silva, Z.S.G.; Simão, J.A.R.; Galhano, C.; Amaral, P.M. “Bianco di Asiago” limestone pavement—Degradation and alteration study. Constr. Build. Mater. 2010, 24, 686–694. [Google Scholar] [CrossRef]

- Sitzia, F.; Lisci, C.; Mirão, J. Building pathology and environment: Weathering and decay of stone construction materials subjected to a Csa mediterranean climate laboratory simulation. Constr. Build. Mater. 2021, 300, 124311. [Google Scholar] [CrossRef]

- Simão, J.; Ruiz-Agudo, E.; Rodriguez-Navarro, C. Effects of particulate matter from gasoline and diesel vehicle exhaust emissions on silicate stones sulfation. Atmos. Environ. 2006, 40, 6905–6917. [Google Scholar] [CrossRef]

- Pires, V.; Amaral, P.M.; Simão, J.A.R.; Galhano, C. Experimental procedure for studying the degradation and alteration of limestone slabs applied on exterior cladding. Environ. Earth Sci. 2022, 81, 59. [Google Scholar] [CrossRef]

- Mousavi, S.; Silva, A.; de Brito, J.; Ekhlassi, A.; Hosseini, S.B. Degradation Assessment of Natural Stone Claddings over Their Service Life: Comparison between Tehran (Iran) and Lisbon (Portugal). Buildings 2021, 11, 438. [Google Scholar] [CrossRef]

- Gutiérrez, J.; Mas, Á.; Gil, E.; Galvañ, V. Clay-related damage in rainscreen walls built with natural stone coverings. Constr. Build. Mater. 2012, 29, 357–367. [Google Scholar] [CrossRef]

- Neto, N.; de Brito, J. Validation of an inspection and diagnosis system for anomalies in natural stone cladding (NSC). Constr. Build. Mater. 2012, 30, 224–236. [Google Scholar] [CrossRef]

- Silva, Z.C.G.; Simão, J.A.R.; Sá, M.; Leal, N. Rock Finishing and Response to Salt Fog Atmosphere. Key Eng. Mater. 2013, 548, 275–286. [Google Scholar] [CrossRef]

- Cardell, C.; Delalieux, F.; Roumpopoulos, K.; Moropoulou, A.; Auger, F.; Van Grieken, R. Salt-induced decay in calcareous stone monuments and buildings in a marine environment in SW France. Constr. Build. Mater. 2003, 17, 165–179. [Google Scholar] [CrossRef]

- Ludovico-Marques, M.; Chastre, C. Effect of salt crystallization ageing on the compressive behavior of sandstone blocks in historical buildings. Eng. Fail. Anal. 2012, 26, 247–257. [Google Scholar] [CrossRef]

- Benavente, D. Role of pore structure in salt crystallisation in unsaturated porous stone. J. Cryst. Growth. 2004, 260, 532–544. [Google Scholar] [CrossRef]

- Alves, C.; Figueiredo, C.A.M.; Sanjurjo-Sánchez, J.; Hernández, A.C. Salt Weathering of Natural Stone: A Review of Comparative Laboratory Studies. Heritage 2021, 4, 1554–1565. [Google Scholar] [CrossRef]

- Silva, Z.S.G.; Simão, J.A.R. The role of salt fog on alteration of dimension stone. Constr. Build. Mater. 2009, 23, 3321–3327. [Google Scholar] [CrossRef]

- EN 14147:2003; Natural Stone Test Methods—Determination of Resistance to Ageing by Salt Mist. European Committee for Standardization: Brussels, Belgium, 2003.

- Cultrone, G.; Sebastián, E. Laboratory simulation showing the influence of salt efflorescence on the weathering of composite building materials. Environ. Geol. 2008, 56, 729–740. [Google Scholar] [CrossRef]

- Alves, C.; Figueiredo, C.; Maurício, A.; Braga, M.A.S.; Aires-Barros, L. Limestones under salt decay tests: Assessment of pore network-dependent durability predictors. Environ. Earth Sci. 2011, 63, 1511–1527. [Google Scholar] [CrossRef]

- Alves, C.; Figueiredo, C.; Maurício, A. A Study of Salt Weathering Cycles Impact on Limestones. Procedia Earth Planet. Sci. 2017, 17, 316–319. [Google Scholar] [CrossRef]

- Benavente, D.; Cueto, N.; Martínez-Martínez, J.; del Cura, M.A.G.; Cañaveras, J.C. The influence of petrophysical properties on the salt weathering of porous building rocks. Environ. Geol. 2007, 52, 215–224. [Google Scholar] [CrossRef]

- Al-Omari, A.; Beck, K.; Brunetaud, X.; Al-Mukhtar, M. Assessment the stones compatibility based on salt weathering tests. ZANCO J. PURE Appl. Sci. 2019, 31, 75–83. [Google Scholar] [CrossRef]

- Angeli, M.; Bigas, J.-P.; Benavente, D.; Menéndez, B.; Hébert, R.; David, C. Salt crystallization in pores: Quantification and estimation of damage. Environ. Geol. 2007, 52, 205–213. [Google Scholar] [CrossRef]

- Benavente, D.; García del Cura, M.; Bernabéu, A.; Ordóñez, S. Quantification of salt weathering in porous stones using an experimental continuous partial immersion method. Eng. Geol. 2001, 59, 313–325. [Google Scholar] [CrossRef]

- Chabas, A.; Jeannette, D. Weathering of marbles and granites in marine environment: Petrophysical properties and special role of atmospheric salts. Environ. Geol. 2001, 40, 359–368. [Google Scholar] [CrossRef]

- Winkler, H.; Singer, P. Crystallization Pressure of Salts in Stone and Concrete. GSA Bull. 1972, 83, 3509–3514. [Google Scholar] [CrossRef]

- Pires, V.; Amaral, P.M.; Rosa, L.G.; Camposinhos, R.S. Slate flexural and anchorage strength considerations in cladding design. Constr. Build. Mater. 2011, 25, 3966–3971. [Google Scholar] [CrossRef]

- Amaral, P.M.; Fernandes, J.C.; Pires, V.; Rosa, L.G. Ornamental stones. In Materials for Construction and Civil Engineering; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Camposinhos, R.S.; Camposinhos, R.P.A. Dimension stone design—Kerf anchorage in limestone and marble. Proc. Inst. Civ. Eng. Constr. Mater. 2012, 165, 161–175. [Google Scholar] [CrossRef]

- Pires, V.; Pacheco, A.; Infante, V.; Amaral, P.M.; Rosa, L.G. Finite element model development applied to portuguese granites for contact analysis of two dowel fixing conditions used in cladding. Key Eng. Mater. 2013, 548, 255–266. [Google Scholar] [CrossRef]

- Lewis, M.D. Modern Stone Cladding, Design and Installation of Exterior Dimension Stone Systems; ASTM International: West Conshohocken, PA, USA, 1995. [Google Scholar] [CrossRef]

- Carvalho, J.M.F.; Carvalho, C.I.; Lisboa, J.V.; Moura, A.C.; Machado Leite, M. Portuguese ornamental stones. Geonovas 2013, 26, 15–22. [Google Scholar]

- Moura, A.C. Mármores e Calcários Ornamentais de Portugal; Gestão de artes Gráficas SA.: Amadora, Portugal, 2007. [Google Scholar]

- EN 13161:2008; Natural Stone Test Methods—Determination of Flexural Strength under Constant Moment. European Committee for Standardization: Brussels, Belgium, 2008.

- EN 14146:2004; Natural Stone Test Methods—Determination of the Dynamic Modulus of Elasticity (by Measuring the Fundamental Resonance Frequency. European Committee for Standardization: Brussels, Belgium, 2004.

- EN 1936:2006; Natural Stone Test Method. Determination of Real Density and Apparent Density, and of Total and Open Porosity. European Committee for Standardization: Brussels, Belgium, 2006.

- EN 13755:2008; Natural Stone Test Methods—Determination of Water Absorption at Atmospheric Pressure. European Committee for Standardization: Brussels, Belgium, 2008.

- ASTM C615/C615M-18e1; Standard Specification for Granite Dimension Stone. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- Cardell, C.; Rivas, T.; Mosquera, M.J.; Birginie, J.M.; Moropoulou, A.; Prieto, B.; Silva, B.; Van Grieken, R. Patterns of damage in igneous and sedimentary rocks under conditions simulating sea-salt weathering. Earth Surf. Process. Landf. 2003, 28, 1–14. [Google Scholar] [CrossRef]

- ICOMOS-ISCS. Illustrated Glossary on Stone Deterioration Patterns; ICOMOS International Scientific Committee for Stone (ISCS): Champigny/Marne, France, 2008. [Google Scholar]

- Morillas, H.; de Mendonça Filho, F.F.; Derluyn, H.; Maguregui, M.; Grégoire, D.; Madariaga, J.M. Decay processes in buildings close to the sea induced by marine aerosol: Salt depositions inside construction materials. Sci. Total Environ. 2020, 721, 137687. [Google Scholar] [CrossRef] [PubMed]

- Molina, E.; Cultrone, G.; Sebastián, E.; Alonso, F.J.; Carrizo, L.; Gisbert, J.; Buj, O. The pore system of sedimentary rocks as a key factor in the durability of building materials. Eng. Geol. 2011, 118, 110–121. [Google Scholar] [CrossRef]

- Zezza, F.; Macrì, F. Marine aerosol and stone decay. Sci. Total Environ. 1995, 167, 123–143. [Google Scholar] [CrossRef]

- Pinto, A.C.R. Manual da Pedra Natural para Arquitectura, 1st ed.; DGGE: Lisbon, Portugal, 2006. [Google Scholar]

- Coussy, O. Deformation and stress from in-pore drying-induced crystallization of salt. J. Mech. Phys. Solids. 2006, 54, 1517–1547. [Google Scholar] [CrossRef]

| Initial Physical–Mechanical Characterization | MO | SR |

|---|---|---|

| Flexural strength (under constant moment|σ4p SF0 (MPa) | 10.1 ± 0.8 | 7.4 ± 0.8 |

| CV (%) | 8 | 10 |

| Elastic modulus (through dynamic resonance frequency method|ERD SF0 (MPa) | 59.7 ± 2 | 29.1 ± 5 |

| CV (%) | 3 | 17 |

| Apparent density|ρa (kg/m3) | 2463 ± 12 | 2098 ± 24 |

| CV (%) | 0.5 | 1 |

| Open Porosity|P0 (%) | 5.9 ± 0.1 | 17.4 ± 2.2 |

| CV [%] | 2.2 | 12.4 |

| Volume of open pores|V0 (mL) | 7.6 ± 0.2 | 22.0 ± 2.7 |

| CV (%) | 3 | 12 |

| Water absorption at atmospheric pressure|Watm (%) | 1.8 ± 0.1 | 5.1 ± 0.4 |

| CV (%) | 6 | 8 |

| Flexural Strength under Constant Moment | MO | SR |

|---|---|---|

| σ4p SF0 (MPa) | 10.1 ± 0.8 | 7.4 ± 0.8 |

| CV (%) | 8 | 10 |

| σ4p SF45 (MPa) | 7.4 ± 0.4 | 5.1 ± 1.2 |

| CV (%) | 5 | 23 |

| Δ (%) | −27 | −32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pires, V.; Rosa, L.G.; Amaral, P.M.; Simão, J.A.R. The Susceptibility to Salt Fog Degradation of Stone Cladding Materials: A Laboratory Case Study on Two Limestones from Portugal. Heritage 2023, 6, 492-504. https://doi.org/10.3390/heritage6010026

Pires V, Rosa LG, Amaral PM, Simão JAR. The Susceptibility to Salt Fog Degradation of Stone Cladding Materials: A Laboratory Case Study on Two Limestones from Portugal. Heritage. 2023; 6(1):492-504. https://doi.org/10.3390/heritage6010026

Chicago/Turabian StylePires, Vera, Luis G. Rosa, Pedro M. Amaral, and Joaquim A. R. Simão. 2023. "The Susceptibility to Salt Fog Degradation of Stone Cladding Materials: A Laboratory Case Study on Two Limestones from Portugal" Heritage 6, no. 1: 492-504. https://doi.org/10.3390/heritage6010026

APA StylePires, V., Rosa, L. G., Amaral, P. M., & Simão, J. A. R. (2023). The Susceptibility to Salt Fog Degradation of Stone Cladding Materials: A Laboratory Case Study on Two Limestones from Portugal. Heritage, 6(1), 492-504. https://doi.org/10.3390/heritage6010026