Non-Destructive In Situ Investigation of the Study of a Medieval Copper Alloy Door in Canosa di Puglia (Southern Italy)

Abstract

:1. Introduction

2. Materials and Methods

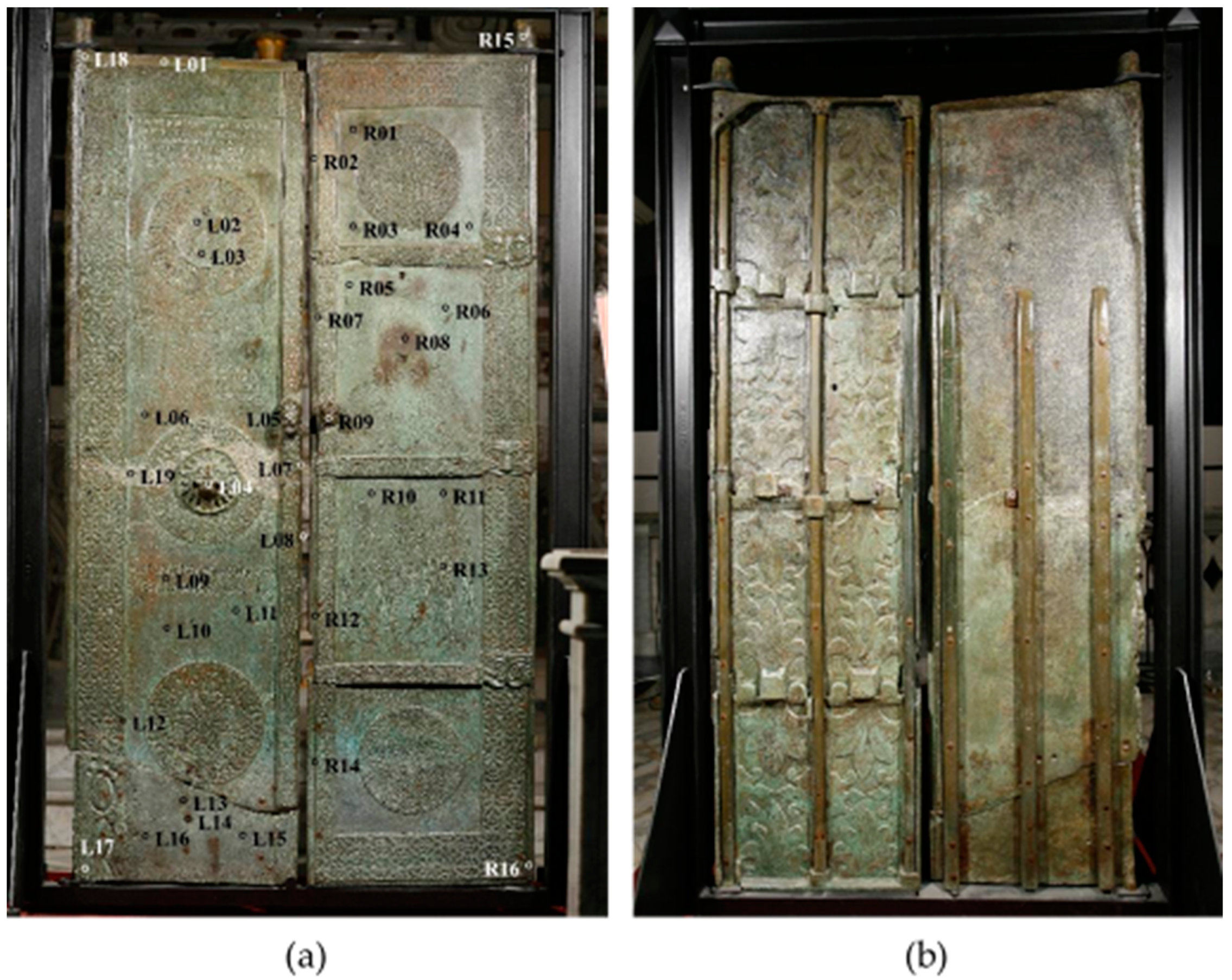

2.1. Description of the Analyzed Door

- Unde boat mundus, quanti fuerit Boamundus:

- Graecia testatur, Syria dunumerat.

- Hanc expugnavit, illam protexit ab hoste;

- hinc rident Graeci, Syria, damna tua.

- Quod Graecus ridet, quod Syrus luget, uterque

- iuste, vera tibi sit, Boamunde, salus.

- Vicit opes regum Boamundus opesque potentum

- et meruit dici nomine iure suo

- intonuit terris. Cui cum succumberet orbis,

- non hominem possum dicere, nolo deum.

- Qui vivens studuit, ut pro Christo moreretur,

- promeruit, quod ei morienti vita daretur.

- Hoc ergo Christi clementia conferat isti,

- militet ut celis suus hic adleta fidelis.

- Intrans cerne fores; videas, quid scribitur; ores,

- ut celo detur Boamundus ibique locetur.

- For this reason, the world resounds of who Boemondo was:

- Greece attests it, Syria enumerates it.

- He conquered this one, he protected that one from the enemy;

- So the Greeks laugh at your damage, O Syria.

- What the Greek laughs at, what the Syrian mourns,

- the one and the other rightly are for you true salvation, O Boemondo.

- Boemondo overcame the power of kings and the work of the mighty men

- and rightly deserved that from his name it was said that he thundered in the lands.

- And, since the world succumbed to him,

- I cannot call him man, but I will not call him God.

- Whoever living endeavoured to die for Christ,

- deserved that the one who was dying should be given life.

- Therefore, may the clemency of Christ grant him this,

- that his faithful athlete may be a soldier in heaven.

- You who enter observe the door;

- see what is written;

- pray that Boemondo may be given to heaven and placed there.

- Sancti Sabini Canusii Rogerius Melfie campanarum fecit has ianuas et candelabrum

2.2. ED-XRF Analysis

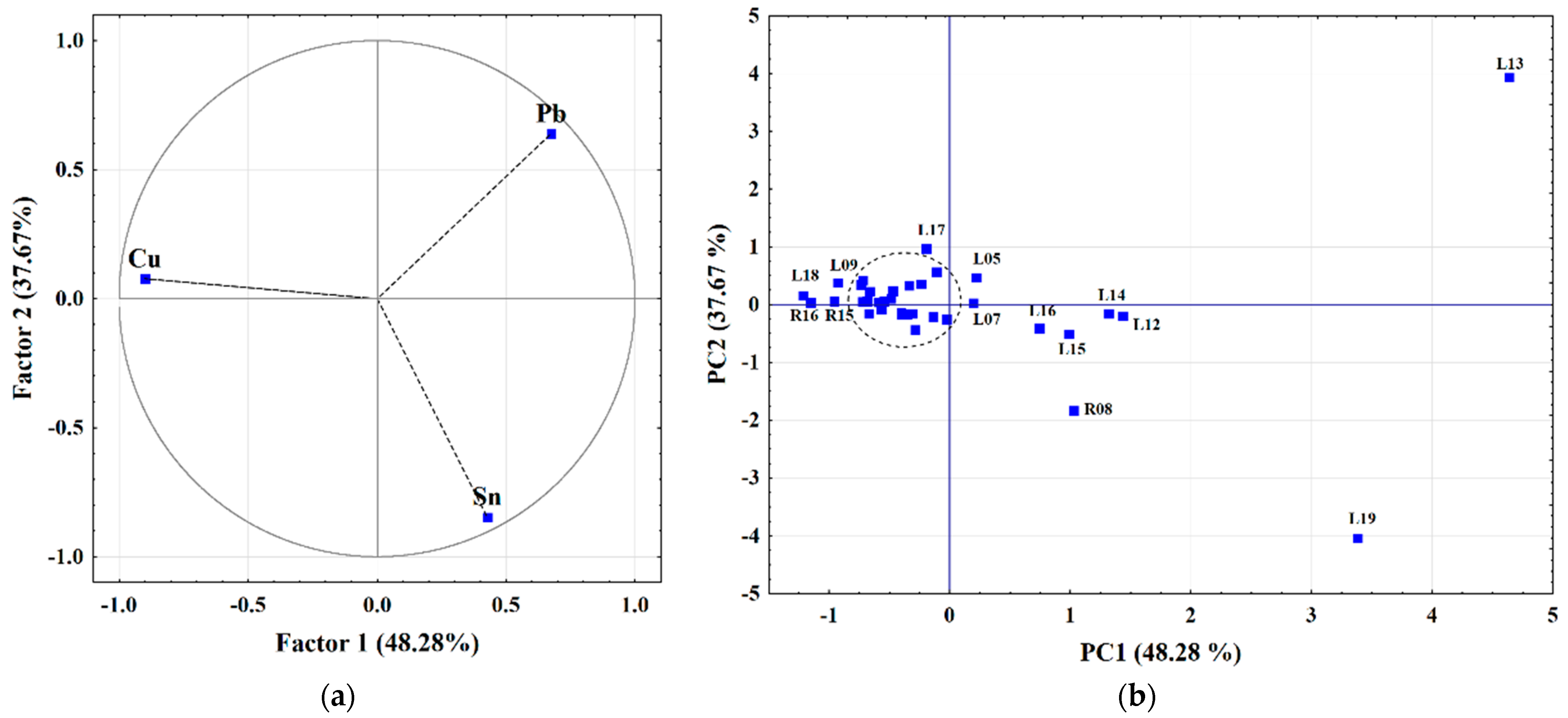

2.3. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Frazer, M.E. Church Doors and the Gates of Paradise: Byzantine Bronze Doors in Italy. Dumbart. Oaks Pap. 1973, 27, 145. [Google Scholar] [CrossRef]

- Alessandrini, G.; Dassù, G.; Pedeferri, P.; Re, G. On the Conservation of the Baptistery Doors in Florence. Stud. Conserv. 1979, 24, 108–124. [Google Scholar] [CrossRef]

- Weinryb, I. The Bronze Object in the Middle Ages; Cambridge University Press: Cambridge, UK, 2016; ISBN 978-1-107-12361-8. [Google Scholar]

- Bloch, H. Origin and Fate of the Bronze Doors of Abbot Desiderius of Monte Cassino. Dumbart. Oaks Pap. 1987, 41, 89. [Google Scholar] [CrossRef]

- Kleinbauer, W.E. A Byzantine Revival: The Inlaid Bronze Doors of Constantinople. Archaeology 1976, 29, 16–29. [Google Scholar]

- Ristovska, N. Medieval Byzantium in the Context of Artistic Interchange between East and West: The Illuminating Example of the Inlaid Brass Door at Saint Paul Outside-TheWalls in Rome. In Discipuli Dona ferentes: Glimpses of Byzantium in Honour of Marlia Mundell Mango; Altripp, M., Hoffman, L.M., Stavrakos, C., Eds.; Studies in Byzantine History and Civilization; Brepols Publishers: Turnhout, Belgium, 2017; Volume 11, pp. 363–445. ISBN 978-2-503-57585-8. [Google Scholar]

- Buccolieri, A.; Castellano, A.; Iacobellis, V.N.; Paladini, F.; Buccolieri, G. ED-XRF Analysis of the Mediaeval Copper-Based Door in Monte Sant’Angelo (Southern Italy). Archaeol. Anthropol. Sci. 2021, 13, 95. [Google Scholar] [CrossRef]

- Di Fazio, M.; Felici, A.C.; Catalli, F.; De Vito, C. Microstructure and Chemical Composition of Roman Orichalcum Coins Emitted after the Monetary Reform of Augustus (23 B.C.). Sci. Rep. 2019, 9, 12668. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Caponetti, E.; Armetta, F.; Martino, D.C.; Saladino, M.L.; Ridolfi, S.; Chirco, G.; Berrettoni, M.; Conti, P.; Bruno, N.; Tusa, S. First Discovery Of Orichalcum Ingots From The Remains Of A 6Th Century Bc Shipwreck Near Gela (Sicily) Seabed. Mediterr. Archaeol. Archaeom. 2017, 17. [Google Scholar] [CrossRef]

- Angelucci, S. Il Rapporto Tra Materia, Tecnica e Forma Nelle Porte Bizantine d’Italia. In Storia Dell’arte Marciana: Sculture, Tesoro, Arazzi: Atti del Convegno Internazionale di Studi, Venezia, 11–14 Ottobre 1994; Polacco, R., Ed.; Marsilio: Venezia, Austria, 1997; ISBN 978-88-317-6852-8. [Google Scholar]

- Matthiae, G. Le Porte Bronzee Bizantine in Italia; Officina Edizione: Roma, Italy, 1971. [Google Scholar]

- Moss, A.A. Niello. Stud. Conserv. 1953, 1, 49–62. [Google Scholar] [CrossRef]

- Craddock, P.T. The Composition of the Copper Alloys Used by the Greek, Etruscan and Roman Civilizations. J. Archaeol. Sci. 1978, 5, 1–16. [Google Scholar] [CrossRef]

- Newman, R.; Dennis, J.R.; Farrell, E. A Technical Note on Niello. J. Am. Inst. Conserv. 1982, 21, 80–85. [Google Scholar] [CrossRef]

- Oddy, W.A.; Bimson, M.; La Niece, S. The Composition of Niello Decoration on Gold, Silver and Bronze in the Antique and Mediaeval Periods. Stud. Conserv. 1983, 28, 29–35. [Google Scholar] [CrossRef]

- Banti, O. La Porta di Bonanno nel Duomo di Pisa e le Porte Bronzee Medioevali Europee: Arte e Tecnologia; Bandecchi & Vivaldi: Pontedera, Italy, 1999; p. 326. [Google Scholar]

- Daniec, J.I. The Bronze Door of The Gniezno Cathedral in Poland. Pol. Rev. 1966, 11, 10–65. [Google Scholar]

- Daniec, J.I. An Enigma: The Medieval Bronze Church Door of Płock in the Cathedral of Novgorod. Pol. Rev. 1991, 36, 21–45. [Google Scholar]

- Cesareo, R.; Sciuti, S.; Marabelli, M. Non-Destructive Analysis of Ancient Bronzes. Stud. Conserv. 1973, 18, 64–80. [Google Scholar] [CrossRef]

- Angelucci, S.; Diana, M.; Ferretti, M.; Sante, G.; Moioli, P.; Palmieri, A. The Byzantine Door in the Basilica of St. Paul Out of the Walls in Rome: Compositional Study of the Alloys and Interpretation of Theresults in View of Its Restoration. In Metal 2001: Proceedings of the International Conference on Metals Conservation; Santiago, Chile, 2–6 April 2001; McLeod, I., Ed.; Western Australian Museum: Welshpool, Australia, 2004; pp. 104–111. ISBN 978-1-920843-17-5. [Google Scholar]

- Cadei, A. La porta del mausoleo di Boemondo a Canosa tra Oriente e Occidente. In Le Porte del Paradiso: Arte e Tecnologia Bizantina tra Italia e Mediterraneo; Iacobini, A., Ed.; Milion; Campisano: Roma, Italy, 2009; ISBN 978-88-88168-43-2. [Google Scholar]

- Osticioli, I.; Mendes, N.F.C.; Porcinai, S.; Cagnini, A.; Castellucci, E. Spectroscopic Analysis of Works of Art Using a Single LIBS and Pulsed Raman Setup. Anal. Bioanal. Chem. 2009, 394, 1033–1041. [Google Scholar] [CrossRef] [PubMed]

- Chiavari, C.; Bernardi, E.; Balbo, A.; Monticelli, C.; Raffo, S.; Bignozzi, M.C.; Martini, C. Atmospheric Corrosion of Fire-Gilded Bronze: Corrosion and Corrosion Protection during Accelerated Ageing Tests. Corros. Sci. 2015, 100, 435–447. [Google Scholar] [CrossRef]

- Delle Donne, F. Le Iscrizioni Del Mausoleo Di Boemondo d’Altavilla a Canosa. In Texts and Studies in Euro-Mediterranean World during XIth-XIIIth Centuries; Centro Europeo di Studi Normanni: Ariano Irpino, Italy, 2012; pp. 7–18. [Google Scholar]

- Mende, U.; Hirmer, A.; Ernstmeier-Hirmer, I. Die Bronzetüren Des Mittelalters, 800–1200; Hirmer: München, Germany, 1983; ISBN 978-3-7774-3530-5. [Google Scholar]

- Pavat, G. Nel Segno di Valcento: Viaggio nel Lazio Meridionale Attraverso le Simbologie Templari e Degli Altri Ordini Monastico-Cavallereschi; Edizioni Belvedere: Latina, Italy, 2010; ISBN 978-88-89504-26-0. [Google Scholar]

- Buccolieri, G.; Buccolieri, A.; Donati, P.; Marabelli, M.; Castellano, A. Portable EDXRF Investigation of the Patinas on the Riace Bronzes. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2015, 343, 101–109. [Google Scholar] [CrossRef]

- Buccolieri, A.; Castellano, A.; Degl’Innocenti, E.; Cesareo, R.; Casciaro, R.; Buccolieri, G. EDXRF Analysis of Gold Jewelry from the Archaeological Museum of Taranto, Italy: EDXRF Analysis of Gold Jewelry. X-ray Spectrom. 2017, 46, 421–426. [Google Scholar] [CrossRef] [Green Version]

- Luciano, G.; Leardi, R.; Letardi, P. Principal Component Analysis of Colour Measurements of Patinas and Coating Systems for Outdoor Bronze Monuments. J. Cult. Herit. 2009, 10, 331–337. [Google Scholar] [CrossRef]

- Capobianco, G.; Sferragatta, A.; Lanteri, L.; Agresti, G.; Bonifazi, G.; Serranti, S.; Pelosi, C. ΜXRF Mapping as a Powerful Technique for Investigating Metal Objects from the Archaeological Site of Ferento (Central Italy). J. Imaging 2020, 6, 59. [Google Scholar] [CrossRef] [PubMed]

- Jolliffe, I.T. Principal Component Analysis, 2nd ed.; Springer Series in Statistics; Springer: New York, NY, USA, 2010; ISBN 978-1-4419-2999-0. [Google Scholar]

| Standard | Cu | Sn | Pb | Zn | Fe |

|---|---|---|---|---|---|

| (% wt) | |||||

| 1 | 73.5 | 2.2 | 12.5 | 4.8 | 0.5 |

| 2 | 65.0 | 4.9 | 8.4 | 7.5 | 1.1 |

| 3 | 58.1 | 8.4 | 5.9 | 12.4 | 2.2 |

| 4 | 51.5 | 10.7 | 3.6 | 18.4 | 2.9 |

| 5 | 48.9 | 11.8 | 2.5 | 21.2 | 3.3 |

| Standard deviation | 0.5 | 0.3 | 0.5 | 0.3 | 0.2 |

| Sample | Description | Cu | Sn | Pb | Zn | Fe | Trace |

|---|---|---|---|---|---|---|---|

| (% wt) | |||||||

| R01 | Alloy | 73.3 | 7.5 | 8.7 | <0.3 | 2.3 | |

| R02 | panel | 71.3 | 10.5 | 10.8 | <0.3 | <0.5 | |

| R03 | alloy | 72.2 | 9.1 | 9.0 | <0.3 | 3.1 | |

| R04 | alloy | 73.3 | 7.3 | 8.0 | <0.3 | 2.3 | |

| R05 | alloy | 71.9 | 8.8 | 6.7 | <0.3 | 3.0 | Ca |

| R06 | panel, green area | 71.0 | 7.7 | 8.8 | <0.3 | 2.3 | Cl |

| R07 | panel | 68.2 | 10.5 | 10.5 | <0.3 | <0.5 | |

| R08 | panel, dark area | 49.7 | 27.4 | 10.2 | <0.3 | <0.5 | |

| R09 | lion protome | 72.7 | 4.5 | 10.4 | 2.3 | <0.5 | |

| R10 | alloy | 71.1 | 8.0 | 9.8 | <0.3 | 1.3 | |

| R11 | alloy | 66.2 | 6.8 | 14.2 | <0.3 | 1.1 | Ca, Cl |

| R12 | panel | 69.2 | 10.5 | 10.2 | <0.3 | <0.5 | |

| R13 | panel, green area | 69.0 | 7.0 | 13.9 | <0.3 | 1.1 | Cl |

| R14 | panel | 70.1 | 10.4 | 10.0 | <0.3 | <0.5 | |

| R15 | top door hinge | 69.4 | 4.3 | 2.4 | 10.4 | 0.7 | |

| R16 | lower door hinge | 75.8 | 4.8 | 2.5 | 11.4 | 0.7 | |

| L01 | alloy | 67.2 | 6.6 | 18.1 | <0.3 | 0.9 | |

| L02 | upper rose window | 68.4 | 7.3 | 9.6 | <0.3 | <0.5 | |

| L03 | upper rose window | 67.3 | 6.2 | 10.2 | <0.3 | <0.5 | |

| L04 | handle (lion) | 70.5 | 5.7 | 8.8 | 2.7 | <0.5 | |

| L05 | lion protome | 63.8 | 8.8 | 20.9 | <0.3 | <0.5 | |

| L06 | alloy | 73.8 | 5.2 | 10.2 | <0.3 | 2.5 | Ca, Cl |

| L07 | edge | 61.4 | 11.1 | 16.2 | <0.3 | <0.5 | |

| L08 | alloy | 64.2 | 12.2 | 12.2 | <0.3 | <0.5 | |

| L09 | alloy, red area | 73.0 | 3.3 | 7.0 | <0.3 | 1.0 | |

| L10 | alloy, green area | 66.5 | 12.2 | 8.0 | <0.3 | 0.5 | Ca, Cl |

| L11 | alloy, green area | 64.7 | 11.2 | 11.0 | <0.3 | 1.1 | Ca, Cl |

| L12 | nail | 2.0 | 5.2 | 3.5 | <0.3 | 82.0 | |

| L13 | closed hole | 1.5 | < 1.0 | 82.5 | <0.3 | <0.5 | |

| L14 | nail | 4.0 | 4.6 | 3.0 | 1.5 | 80.0 | |

| L15 | alloy, near the fracture | 46.8 | 16.8 | 17.4 | 7.8 | 1.8 | |

| L16 | alloy, near the fracture | 49.9 | 15.1 | 15.8 | 7.4 | 3.7 | |

| L17 | lower door hinge | 56.8 | <1.0 | 14.3 | 1.6 | <0.5 | |

| L18 | top door hinge | 76.5 | 3.7 | 2.7 | 13.9 | 0.7 | |

| L19 | center of the fracture | 5.3 | 48.5 | 8.9 | <0.3 | <0.5 | Ca |

| Standard deviation | 0.5 | 0.3 | 0.5 | 0.3 | 0.2 | ||

| Byzantine Door | Cu | Sn | Pb | Zn | Reference |

|---|---|---|---|---|---|

| (% wt) | |||||

| Amalfi (1060 AD) | 62 | Traces | 19 | 17 | [16] |

| Monte Cassino (1066 AD) | 80 | 7 | 3 | 10 | [11] |

| Rome, S. Paul’s outside the Walls (1070 AD) | 73.5 | 0.12 | 8.48 | 17.9 | [11] |

| Monte Sant’Angelo (1076 AD) | 70.2 | 0.8 | 11.2 | 14.2 | [7] |

| Venice, S. Clemente (1080 AD) | 72.4 | 2.2 | 8.6 | 16.8 | [11] |

| Salerno (1085 AD) | 77 | 3.5 | 11 | 4.5 | [16] |

| Venice, central door (1112 AD) | 78 | 5 | 8 | 9 | [11] |

| Canosa di Puglia (1111-1118 AD) | 69.6 | 8.5 | 10.2 | 0.3 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buccolieri, G.; Castellano, A.; Iacobelli, V.N.; Carbone, G.G.; Serra, A.; Calcagnile, L.; Buccolieri, A. Non-Destructive In Situ Investigation of the Study of a Medieval Copper Alloy Door in Canosa di Puglia (Southern Italy). Heritage 2022, 5, 145-156. https://doi.org/10.3390/heritage5010008

Buccolieri G, Castellano A, Iacobelli VN, Carbone GG, Serra A, Calcagnile L, Buccolieri A. Non-Destructive In Situ Investigation of the Study of a Medieval Copper Alloy Door in Canosa di Puglia (Southern Italy). Heritage. 2022; 5(1):145-156. https://doi.org/10.3390/heritage5010008

Chicago/Turabian StyleBuccolieri, Giovanni, Alfredo Castellano, Vito Nicola Iacobelli, Giorgio Giuseppe Carbone, Antonio Serra, Lucio Calcagnile, and Alessandro Buccolieri. 2022. "Non-Destructive In Situ Investigation of the Study of a Medieval Copper Alloy Door in Canosa di Puglia (Southern Italy)" Heritage 5, no. 1: 145-156. https://doi.org/10.3390/heritage5010008

APA StyleBuccolieri, G., Castellano, A., Iacobelli, V. N., Carbone, G. G., Serra, A., Calcagnile, L., & Buccolieri, A. (2022). Non-Destructive In Situ Investigation of the Study of a Medieval Copper Alloy Door in Canosa di Puglia (Southern Italy). Heritage, 5(1), 145-156. https://doi.org/10.3390/heritage5010008