The Grouting Process as an Innovative Tool for the Assessment of the State of Preservation and Internal Features of the Holy Aedicule of the Holy Sepulchre

Abstract

:1. Introduction

2. Materials and Methods

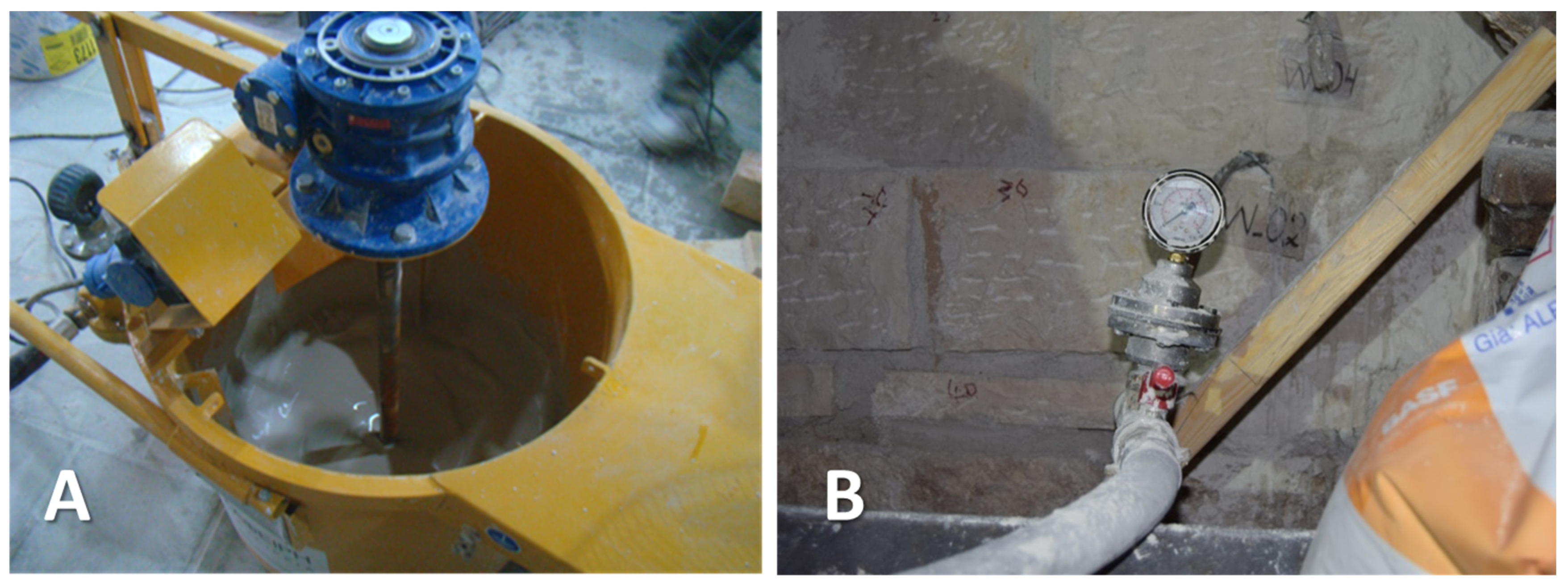

2.1. Grouting Material

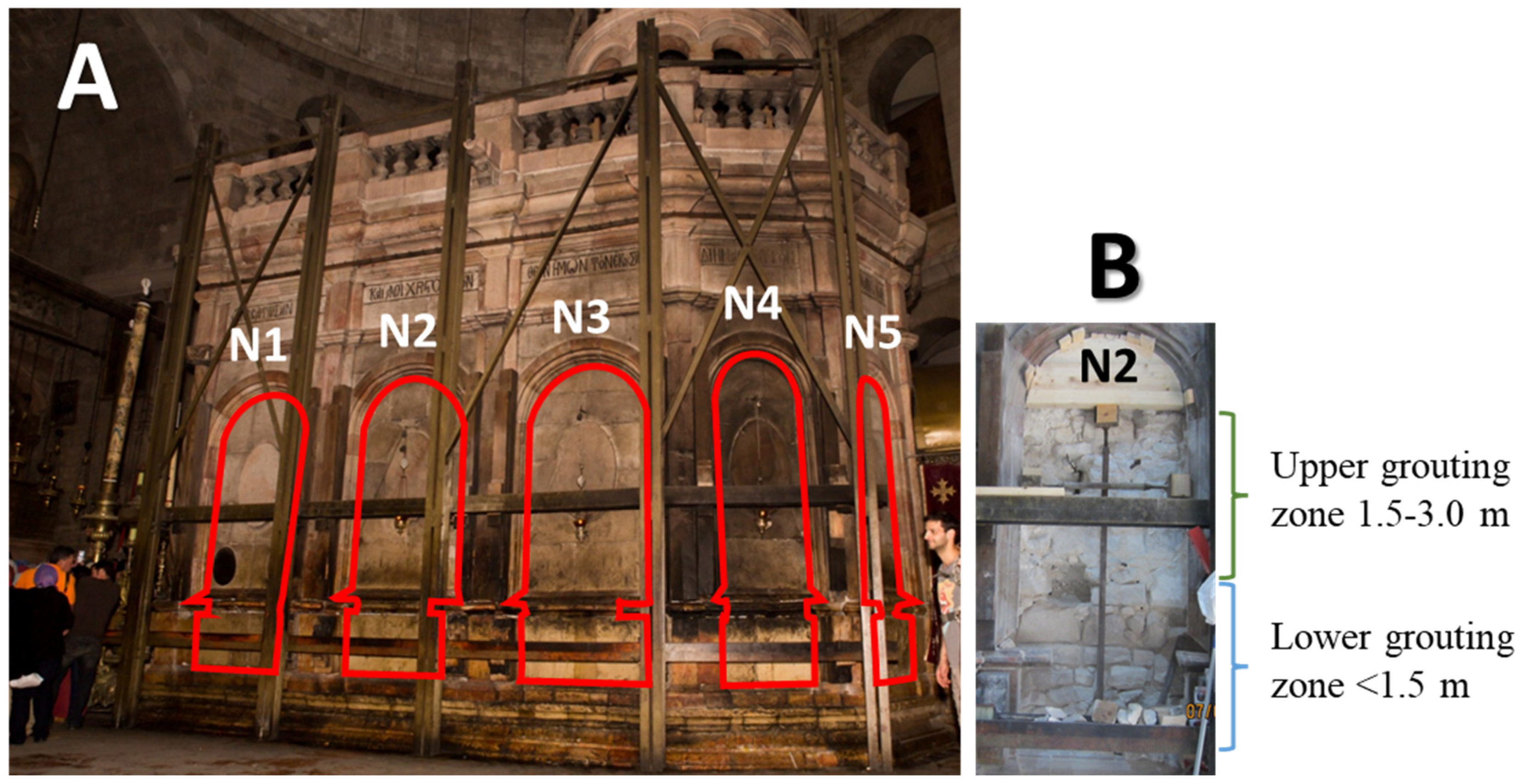

2.2. Grouting Procedure

2.3. Applied Techniques

3. Results and Discussion

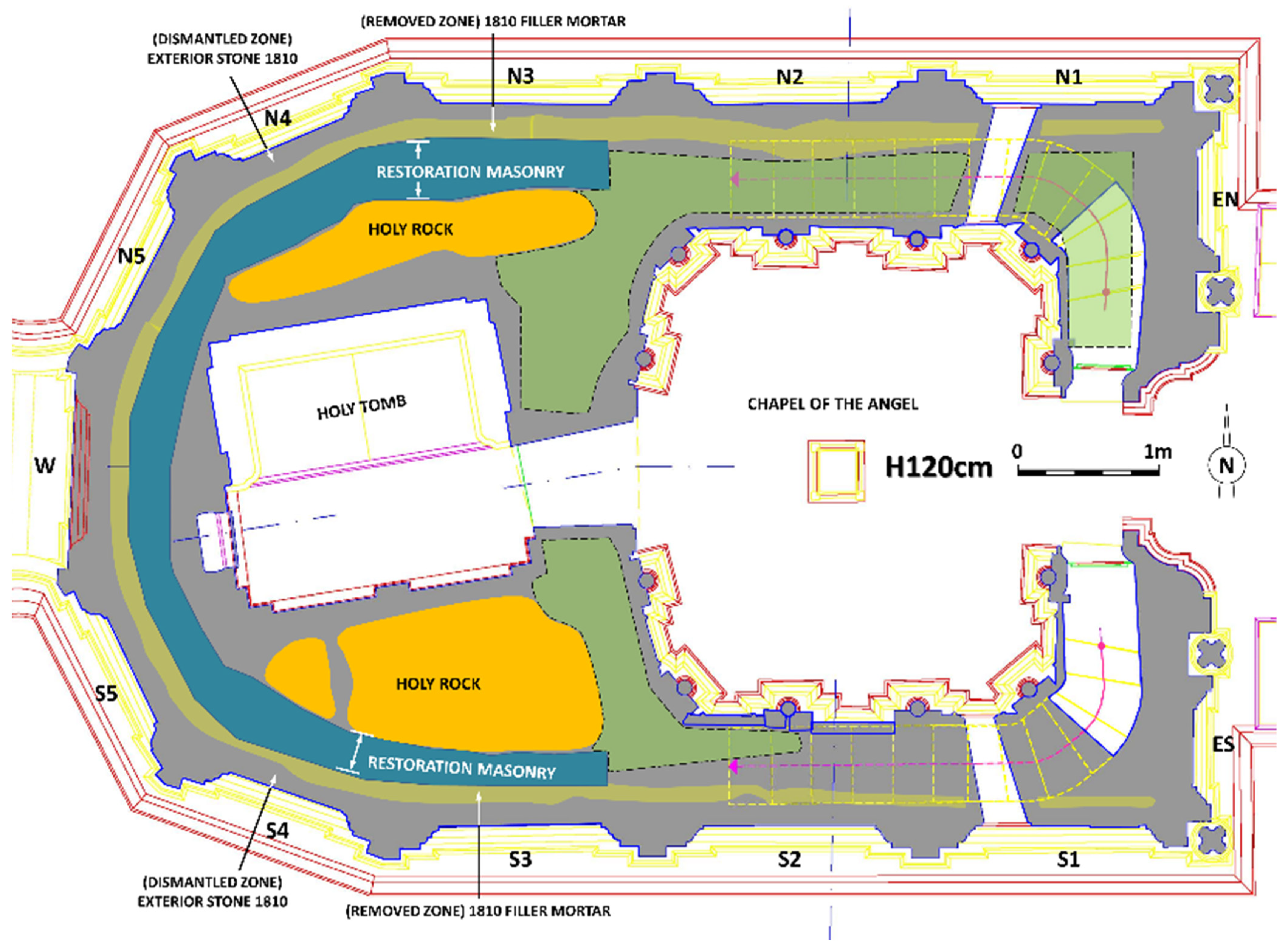

3.1. Analysis of Detailed Grouting Data

3.1.1. Analysis of Grouting Data per Panel Area and Zone

3.1.2. Analysis of Grouting Data per Grout Injection Tube

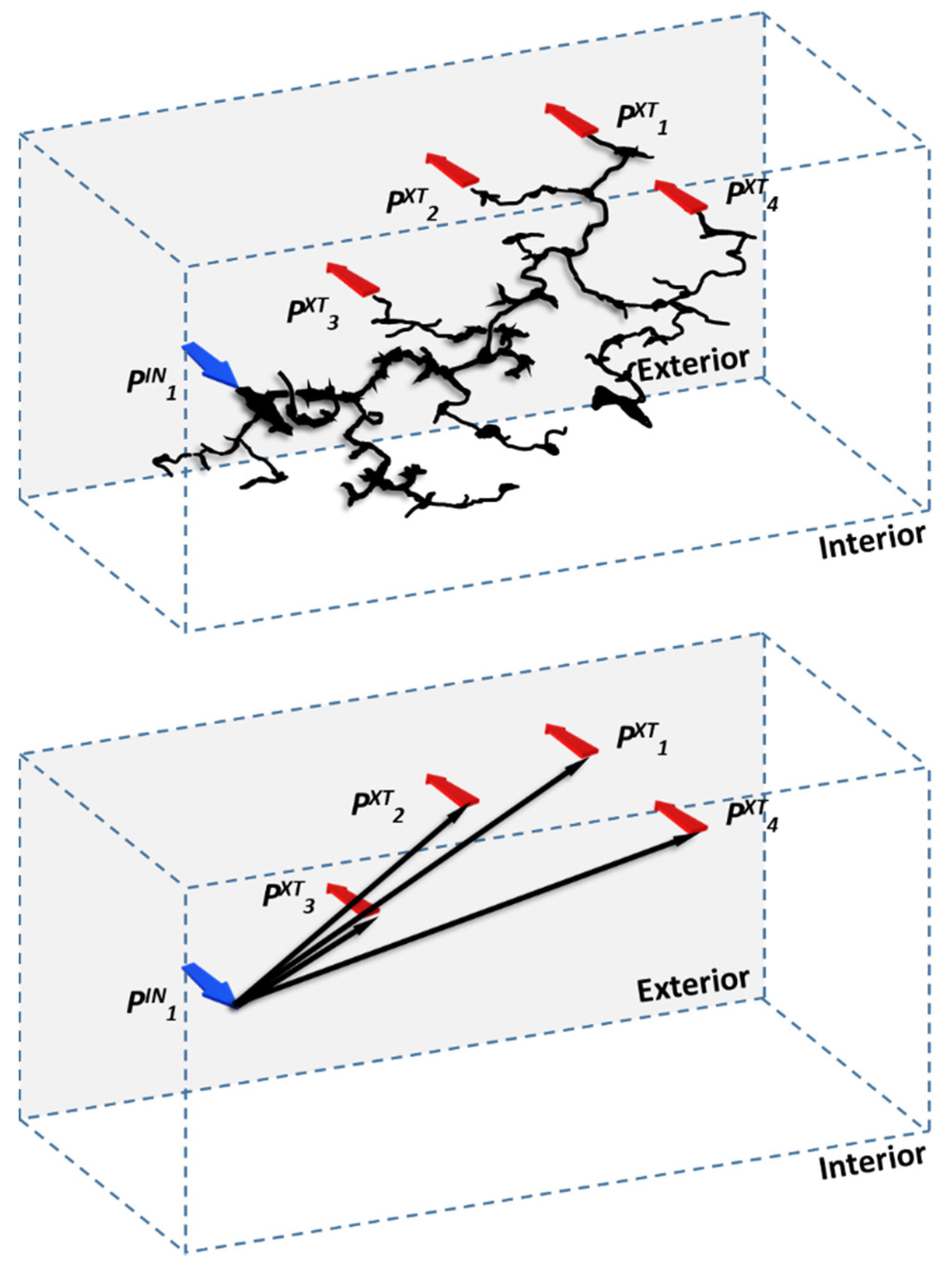

3.1.3. Analysis of Grouting Tube Interconnectivity

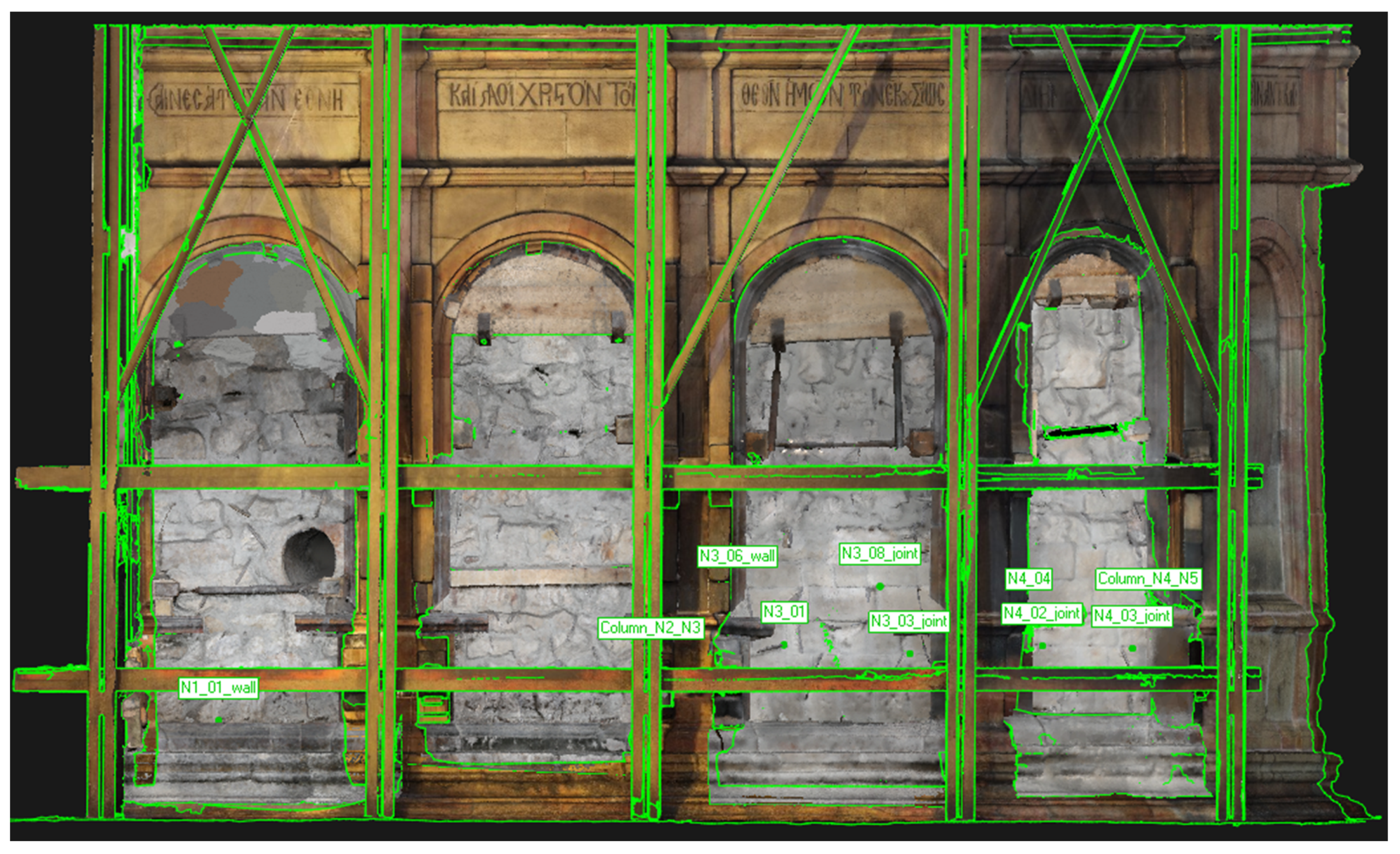

3.2. Correlation of Geospatial and Grouting Data

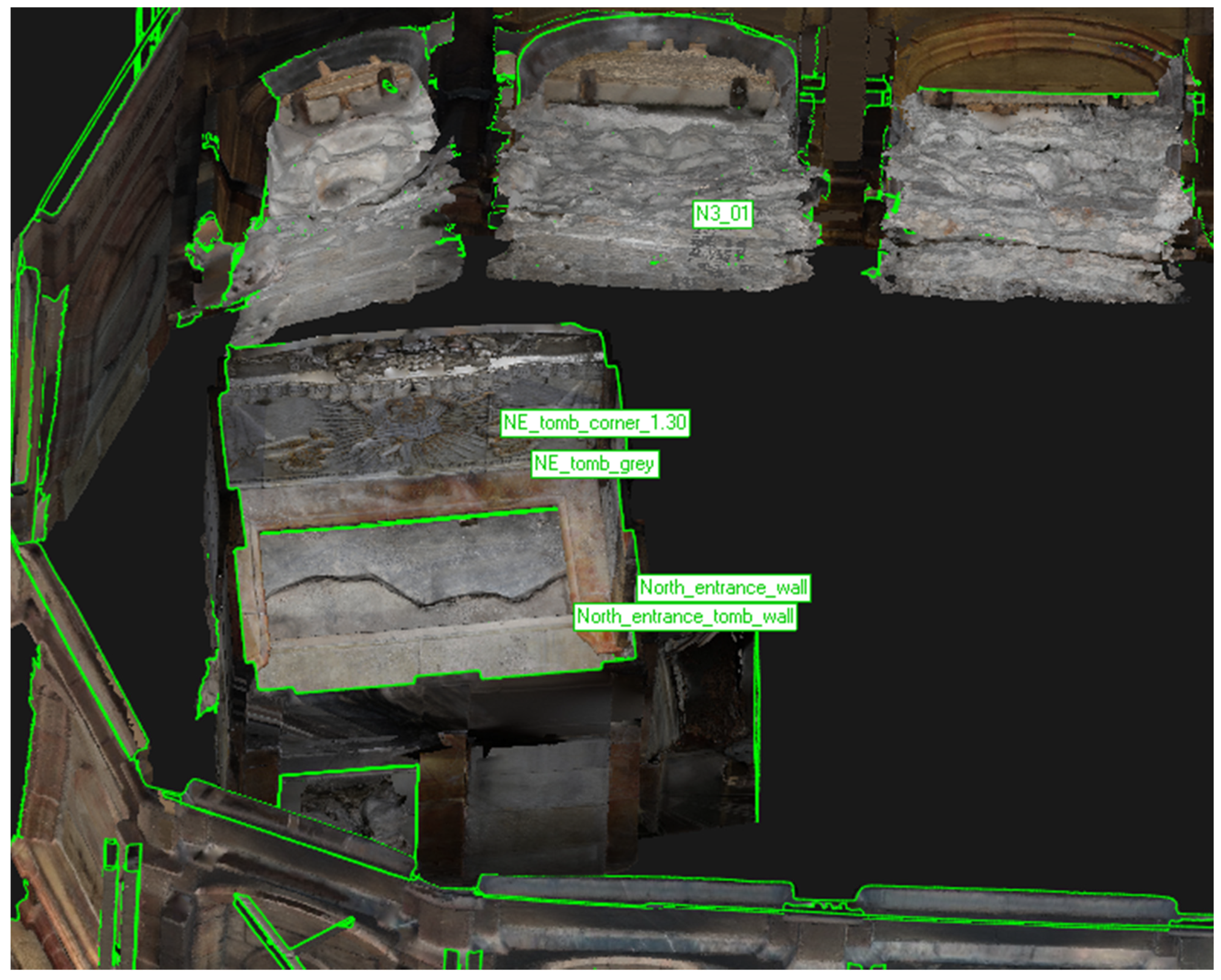

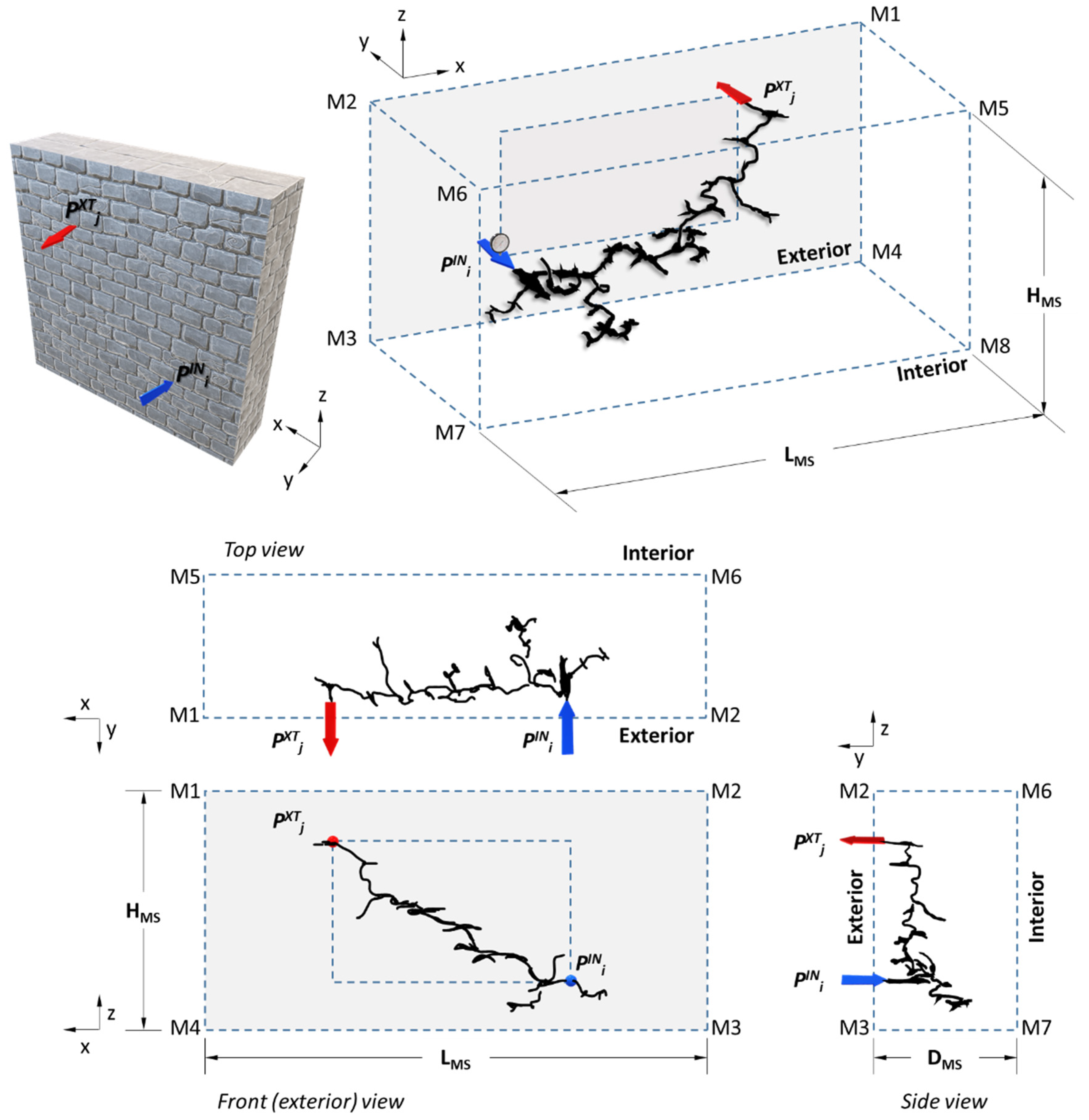

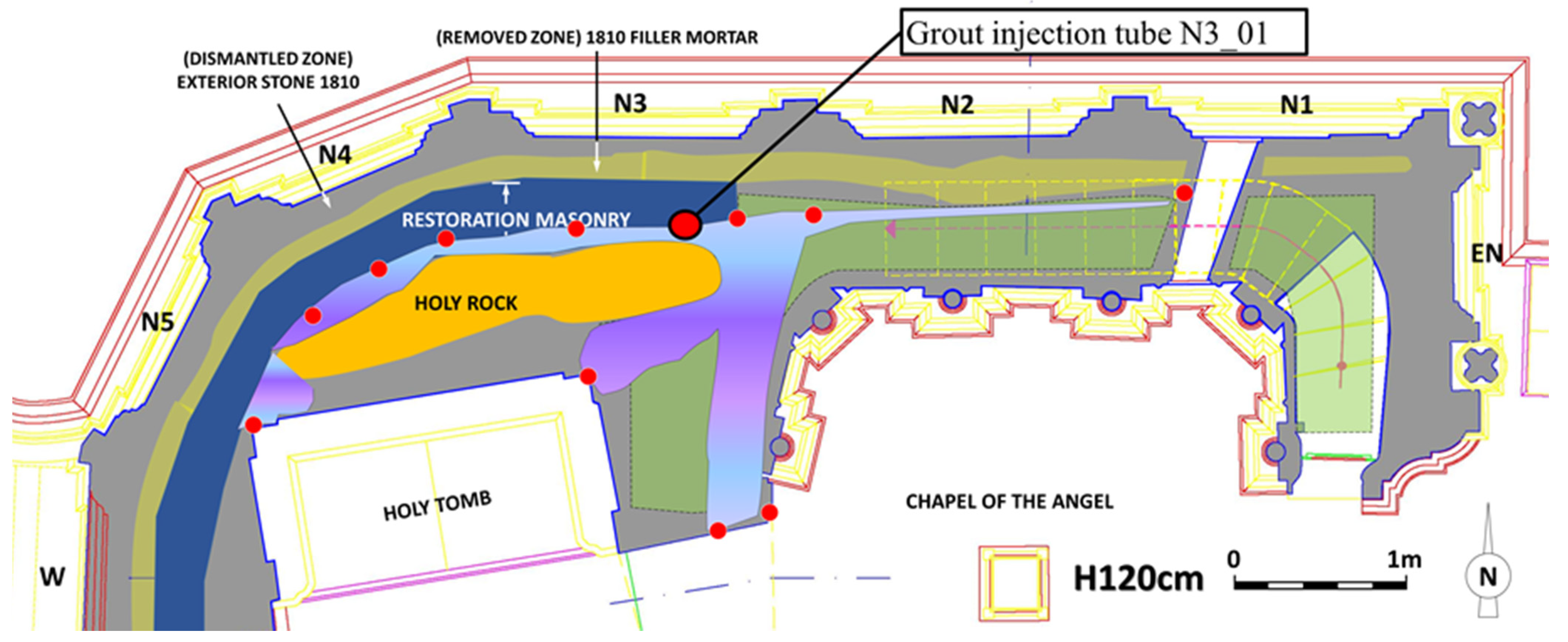

3.2.1. Three-Dimensional Documentation of Grouting Data—Pilot Application for Panel N3

3.2.2. Development and Application of Grouting Indices—Pilot Application for Panel N3

- One branch of the grout-filled cluster of interconnecting paths finds an exit point on the exterior surface (PXTj)—this exit point is sealed, the grouting process is halted, the entry tube is sealed off and the consumed grout volume VGROUTij is recorded;

- The interconnected cluster of paths is completely filled and no more grout can be injected under the pressure applied, but no exit point is observed on the surface. In this case, the grouting process is halted, the entry point is sealed off and the consumed grout volume VGROUTij is recorded.

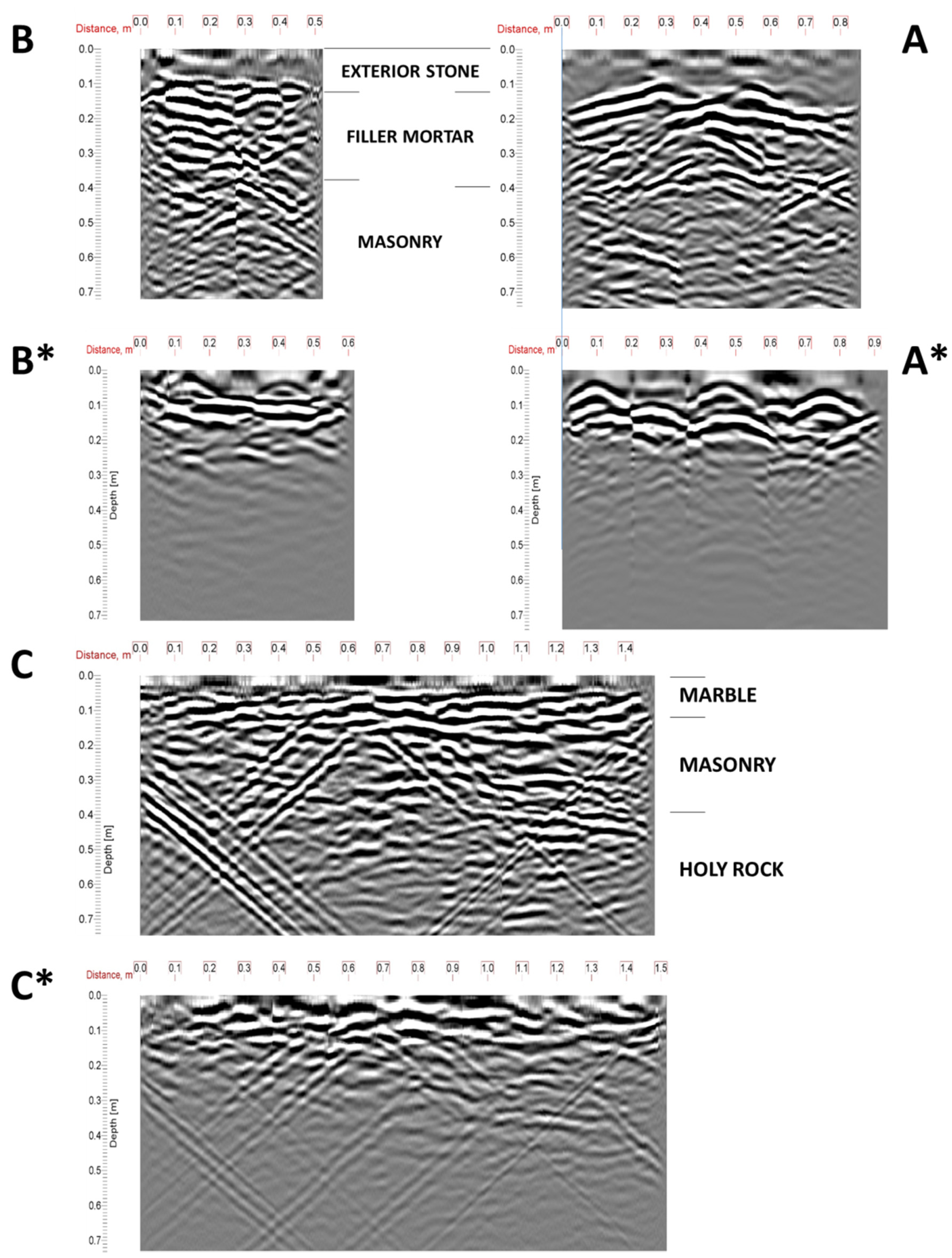

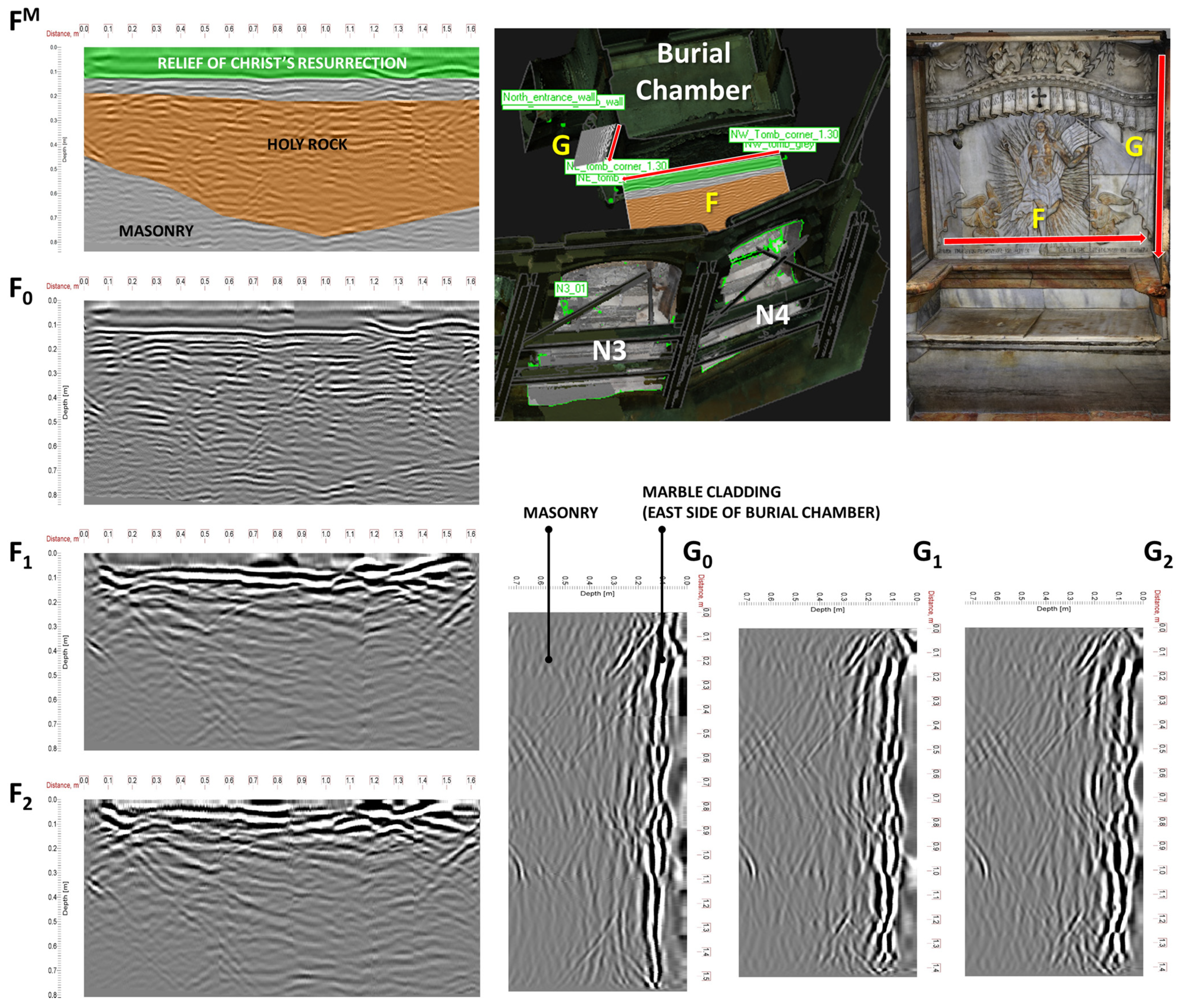

3.3. Merging Grouting Data, Geospatial Data and GPR Prospections to Reveal the Internal Structure and Assess the State of Preservation—Pilot Application for Panel N3

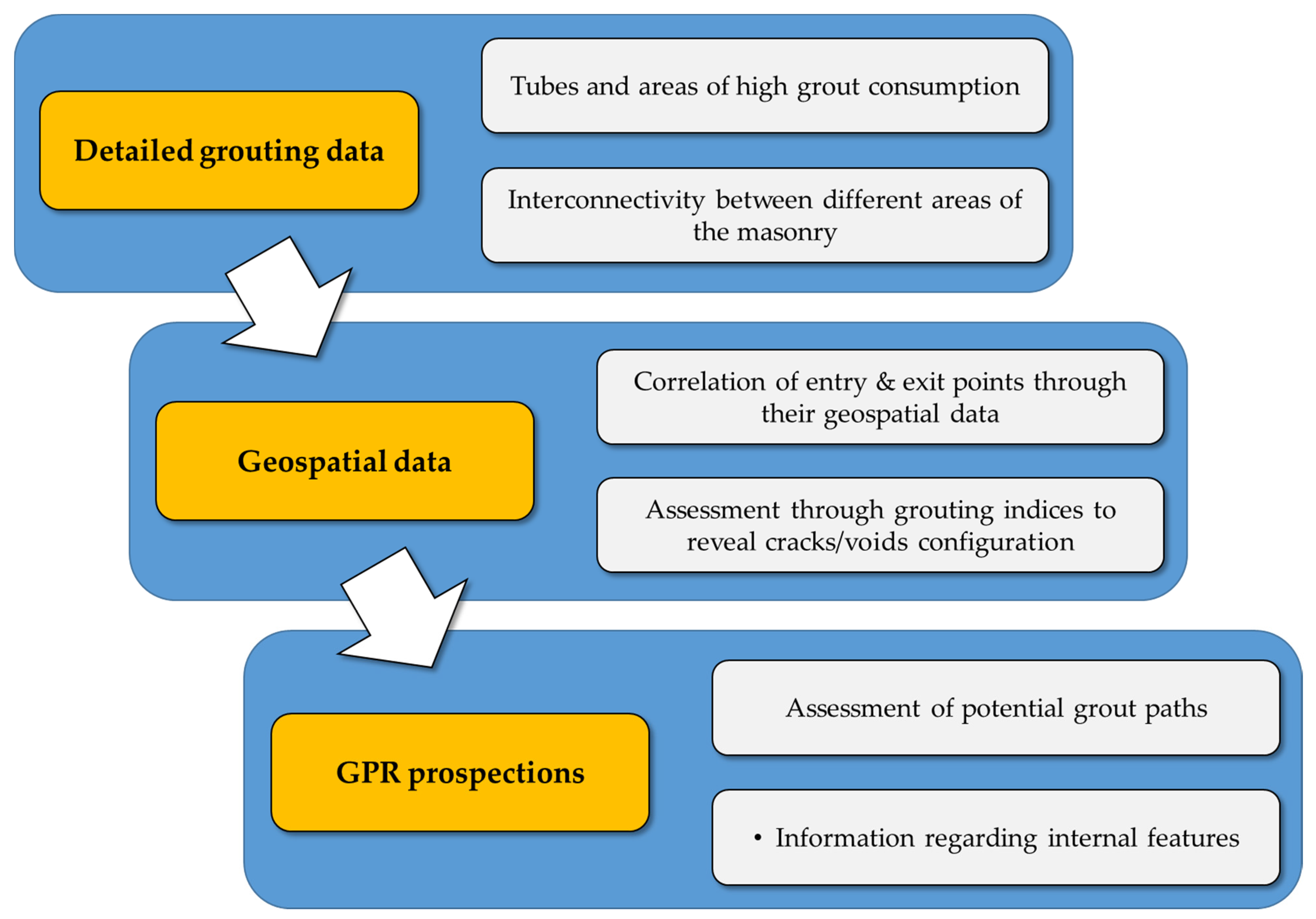

3.4. Methodological Approach

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Vogiatzis, S.; Floros, K. Conservation of the Church of the Holy Apostles in Kalamata. In Structural Conservation of Stone Masonry—Conservation Structurelle de la Maçonnerie en Pierre; ICCROM: Rome, Italy, 1990; pp. 485–494. [Google Scholar]

- Asthana, K.K.; Lakhani, R. Strategies for the Restoration of Heritage Building with Innovative Active Compatible Materials. In Studies in Art and Archaeological Conservation (Dr. BB Lal Commemoration Volume); Bisht, A.S., Singh, S.P., Eds.; Agam Kala Prakashan: Delhi, India, 2004; pp. 9–26. [Google Scholar]

- Keersmaekers, R.; Schueremans, L.; Van Rickstal, F.; Van Gemert, D. Development of an Appropriate Grout for the Consolidation of the Column Foundations in Our Lady’s Basilica at Tongeren (B). In CANMET/ACI International Conference on Recent Advances in Concrete Technology; Malhotra, V.M., Ed.; American Concrete Institute: Farmington Hills, MI, USA, 2006. [Google Scholar]

- Miltiadou-Fezans, A.; Kalagri, A.; Kakkinou, S.; Ziagou, A.; Delinikolas, N.M.; Zarogianni, E.; Chorafa, E. Methodology for In Situ Application of Hydraulic Grouts on Historic Masonry Structures. The Case of the Katholikon of Dafni Monastery. In Structural Analysis of Historic Construction: Preserving Safety and Significance; D′Ayala, D., Fodde, E., Eds.; Taylor & Francis Group: London, UK, 2008; pp. 1025–1033. [Google Scholar]

- Raptis, K.T.; Zombou-Asimi, A. The Consolidation and Restoration Project of Acheiropoietos Basilica in Thessaloniki. In Proceedings of the 8th International Symposium on the Conservation of Monuments in the Mediterranean Basin-MONUBASIN, Patras, Greece, 31 May–2 June 2010; pp. 411–428. [Google Scholar]

- Miltiadou-Fezans, A.; Vintzileou, E.; Mouzakis, C.; Dourakopoulos, J.; Giannopoulos, P.; Delinikolas, N. Structural Analyses of the Katholikon of Daphni Monastery with Alternative Interventions Improving its Overall behaviour. In Proceedings of the 16th European Conference on Earthquake Engineering—ECEE, Thessaloniki, Greece, 18–21 June 2018; pp. 18–21. [Google Scholar]

- Miltiadou-Fezans, A.; Delinikolas, N. The Restoration of the Katholikon of Daphni Monastery: A Challenging Project of Holistic Transdisciplinary Approach, Novel Methodologies and Techniques and Digital Modelling. In Transdisciplinary Multispectral Modeling and Cooperation for the Preservation of Cultural Heritage; Moropoulou, A., Korres, M., Georgopoulos, A., Spyrakos, C., Mouzakis, C., Eds.; Springer: Cham, Switzerland, 2019; Volume 962, pp. 59–77. [Google Scholar]

- Laidlaw, K. Preventing water penetration in traditional masonry using injection mortar and micro-grouting conservation techniques. J. Build. Surv. Apprais. Valuat. 2020, 9, 106–119. [Google Scholar]

- Papayianni, I.; Pachta, V. Experimental study on the performance of lime-based grouts used in consolidating historic masonries. Mater. Struct. 2014, 48, 2111–2121. [Google Scholar] [CrossRef]

- Luso, E.; Lourenço, P.B. Experimental characterization of commercial lime based grouts for stone masonry consolidation. Constr. Build. Mater. 2016, 102, 216–225. [Google Scholar] [CrossRef] [Green Version]

- Vintzileou, E.; Miltiadou-Fezans, A. Mechanical properties of three-leaf stone masonry grouted with ternary or hydraulic lime-based grouts. Eng. Struct. 2008, 30, 2265–2276. [Google Scholar] [CrossRef]

- Apostolopoulou, M.; Delegou, E.; Alexakis, E.; Kalofonou, M.; Lampropoulos, K.; Aggelakopoulou, E.; Bakolas, A.; Moropoulou, A. Study of the historical mortars of the Holy Aedicule as a basis for the design, application and assessment of repair mortars: A multispectral approach applied on the Holy Aedicule. Constr. Build. Mater. 2018, 181, 618–637. [Google Scholar] [CrossRef]

- Alexakis, E.; Delegou, E.T.; Lampropoulos, K.C.; Apostolopoulou, M.; Ntoutsi, I.; Moropoulou, A. NDT as a monitoring tool of the works progress and the assessment of materials and rehabilitation interventions at the Holy Aedicule of the Holy Sepulchre. Constr. Build. Mater. 2018, 189, 512–526. [Google Scholar] [CrossRef]

- National Technical University of Athens Interdisciplinary Team for the Protection of Monuments, & Contributing Authors. Faithful Rehabilitation. Civil Eng. Mag. Arch. 2017, 87, 54–78. [Google Scholar] [CrossRef]

- Moropoulou, A.; Korres, M.; Georgopoulos, A.; Spyrakos, C.; Mouzakis, C.; Lampropoulos, K.C.; Apostolopoulou, M. The Project of the Rehabilitation of Holy Sepulchre’s Holy Aedicule as a Pilot Multispectral, Multidimensional, Novel Approach Through Transdisciplinarity and Cooperation in the Protection of Monuments. In Transdisciplinary Multispectral Modeling and Cooperation for the Preservation of Cultural Heritage; Moropoulou, A., Korres, M., Georgopoulos, A., Spyrakos, C., Mouzakis, C., Eds.; Springer: Cham, Switzerland, 2019; Volume 961, pp. 3–25. [Google Scholar]

- Spyrakos, C.C.; Maniatakis, C.A.; Moropoulou, A. Preliminary Assessment of the Structural Response of the Holy Tomb of Christ Under Static and Seismic Loading. In Transdisciplinary Multispectral Modeling and Cooperation for the Preservation of Cultural Heritage; Moropoulou, A., Korres, M., Georgopoulos, A., Spyrakos, C., Mouzakis, C., Eds.; Springer: Cham, Switzerland, 2019; Volume 961, pp. 44–57. [Google Scholar]

- Moropoulou, A.; Korres, E.; Georgopoulos, A.; Spyrakos, C.; Mouzakis, C.; Lampropoulos, K.C.; Apostolopoulou, M.; Delegou, E.T.; Alexakis, E. The rehabilitation of the Holy Aedicule. In Scienza e Beni Culturali XXΧIII; Arcadia Ricerche: Venice, Italy, 2017; pp. 1–16. [Google Scholar]

- Moropoulou, A.; Zacharias, N.; Delegou, E.; Apostolopoulou, M.; Palamara, E.; Kolaiti, A. OSL mortar dating to elucidate the construction history of the Tomb Chamber of the Holy Aedicule of the Holy Sepulchre in Jerusalem. J. Archaeol. Sci. Rep. 2018, 19, 80–91. [Google Scholar] [CrossRef]

- Lampropoulos, K.C.; Korres, M.; Moropoulou, A. A Transdisciplinary Approach to Reveal the Structural Evolution of the Holy Aedicule in the Church of the Holy Sepulchre. In Nondestructive Evaluation and Monitoring Technologies, Documentation, Diagnosis and Preservation of Cultural Heritage; Osman, A., Moropoulou, A., Eds.; Springer: Cham, Switzerland, 2019; pp. 107–120. [Google Scholar]

- Biddle, M. The Tomb of Christ; Sutton Publishing: Sutton, UK, 1999; p. 88. [Google Scholar]

- Lampropoulos, K.C.; Moropoulou, A.; Korres, M. Ground penetrating radar prospection of the construction phases of the Holy Aedicula of the Holy Sepulchre in correlation with architectural analysis. Constr. Build. Mater. 2017, 155, 307–322. [Google Scholar] [CrossRef]

- Loureiro, A.M.S.; Paz, S.P.A.; Veiga, M.D.R.; Angélica, R.S. Assessment of compatibility between historic mortars and lime-METAKAOLIN restoration mortars made from amazon industrial waste. Appl. Clay Sci. 2020, 198, 105843. [Google Scholar] [CrossRef]

- Aggelakopoulou, E.; Bakolas, A.; Moropoulou, A. Properties of lime-metakolin mortars for the restoration of historic masonries. Appl. Clay Sci. 2011, 53, 15–19. [Google Scholar] [CrossRef]

- Gameiro, A.; Silva, A.S.; Faria, P.; Grilo, J.; Branco, T.; Veiga, R.; Velosa, A. Physical and chemical assessment of lime-metakaolin mortars: Influence of binder: Aggregate ratio. Cem. Concr. Compos. 2014, 45, 264–271. [Google Scholar] [CrossRef] [Green Version]

- Moropoulou, A.; Georgopoulos, A.; Korres, M.; Bakolas, A.; Labropoulos, K.; Agrafiotis, P.; Delegou, E.T.; Moundoulas, P.; Apostolopoulou, M.; Lambrou, E.; et al. Five-Dimensional (5D) Modelling of the Holy Aedicule of the Church of the Holy Sepulchre Through an Innovative and Interdisciplinary Approach. In Mixed Reality and Gamification for Cultural Heritage; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Georgopoulos, A.; Ioannidis, C.; Soile, S.; Tapeinaki, S.; Chliverou, R.; Tsilimantou, E.; Lampropoulos, K.; Moropoulou, A. The Role of Digital Geometric Documentation for the Rehabilitation of the Tomb of Christ. In Proceedings of the 2018 3rd Digital Heritage International Congress (DigitalHERITAGE) Held Jointly with 2018 24th International Conference on Virtual Systems & Multimedia (VSMM 2018), San Francisco, CA, USA, 26–30 October 2018; pp. 1–8. [Google Scholar]

- Balodimos, D.; Lavvas, G.; Georgopoulos, A. Wholly Documenting Holy Monuments. In Proceedings of the CIPA XIX International Symposium, Antalya, Turkey, 30 September–4 October 2003. [Google Scholar]

- Daniels, D.J. Ground Penetrating Radar, 2nd ed.; Institute of Electrical Engineers: London, UK, 2004. [Google Scholar]

- Jol, H.J. (Ed.) Ground Penetrating Radar: Theory and Applications, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Binda, L.; Saisi, A.; Tiraboschi, C.; Valle, S.; Colla, C.; Forde, M. Application of sonic and radar tests on the piers and walls of the Cathedral of Noto. Constr. Build. Mater. 2003, 17, 613–627. [Google Scholar] [CrossRef]

- Leucci, G.; Cataldo, R.; De Nunzio, G. Assessment of fractures in some columns inside the crypt of the Cattedrale di Otranto using integrated geophysical methods. J. Archaeol. Sci. 2007, 34, 222–232. [Google Scholar] [CrossRef]

- Labropoulos, K.; Moropoulou, A. Ground penetrating radar investigation of the bell tower of the church of the Holy Sepulchre. Constr. Build. Mater. 2013, 47, 689–700. [Google Scholar] [CrossRef]

| No. of Grout Entry Tubes | Lower Zone Grouting (<1.5 m) | No. of Injection Tubes from Which Grout Exited per Panel | |||||||||||||

| Exit Panel | |||||||||||||||

| EN | N1 | N2 | N3 | N4 | N5 | W | S5 | S4 | S3 | S2 | S1 | ES | |||

| 0 | Entry Panel | EN | |||||||||||||

| 5 | N1 | 3 | 1 | ||||||||||||

| 3 | N2 | 1 | 1 | ||||||||||||

| 4 | N3 | 1 | 5 | 8 | 3 | ||||||||||

| 0 | N4 | ||||||||||||||

| 0 | N5 | ||||||||||||||

| 1 | W | 3 | |||||||||||||

| 2 | S5 | 4 | 4 | ||||||||||||

| 3 | S4 | 3 | |||||||||||||

| 2 | S3 | 2 | |||||||||||||

| 2 | S2 | 2 | |||||||||||||

| 1 | S1 | 1 | |||||||||||||

| 1 | ES | 2 | |||||||||||||

| No. of Grout Entry Tubes | Upper Zone Grouting (1.5–3 m) | No. of Injection Tubes from Which Grout Exited per Panel | |||||||||||||

| Exit Panel | |||||||||||||||

| EN | N1 | N2 | N3 | N4 | N5 | W | S5 | S4 | S3 | S2 | S1 | ES | |||

| 0 | Entry panel | EN | |||||||||||||

| 8 | N1 | 1 | 4 | ||||||||||||

| 5 | N2 | 2 | |||||||||||||

| 4 | N3 | 10 | 7 | ||||||||||||

| 2 | N4 | 1 | |||||||||||||

| 3 | N5 | ||||||||||||||

| 0 | W | ||||||||||||||

| 6 | S5 | 4 | 3 | ||||||||||||

| 3 | S4 | ||||||||||||||

| 3 | S3 | ||||||||||||||

| 2 | S2 | ||||||||||||||

| 3 | S1 | ||||||||||||||

| 0 | ES | ||||||||||||||

| Tube ID | TVLi (m) | (L) | (L/m) | (L) | (m) | |

|---|---|---|---|---|---|---|

| N1_07 | 5 | 4.157 | 37.79 | 9.09 | 7.56 | 0.83 |

| N2_20 | 4 | 7.071 | 46.73 | 6.61 | 11.68 | 1.77 |

| N3_01 | 14 | 25.412 | 82.36 | 3.24 | 5.88 | 1.82 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lampropoulos, K.C.; Apostolopoulou, M.; Tsilimantou, E.; Moropoulou, A. The Grouting Process as an Innovative Tool for the Assessment of the State of Preservation and Internal Features of the Holy Aedicule of the Holy Sepulchre. Heritage 2022, 5, 61-87. https://doi.org/10.3390/heritage5010004

Lampropoulos KC, Apostolopoulou M, Tsilimantou E, Moropoulou A. The Grouting Process as an Innovative Tool for the Assessment of the State of Preservation and Internal Features of the Holy Aedicule of the Holy Sepulchre. Heritage. 2022; 5(1):61-87. https://doi.org/10.3390/heritage5010004

Chicago/Turabian StyleLampropoulos, Kyriakos C., Maria Apostolopoulou, Elisavet Tsilimantou, and Antonia Moropoulou. 2022. "The Grouting Process as an Innovative Tool for the Assessment of the State of Preservation and Internal Features of the Holy Aedicule of the Holy Sepulchre" Heritage 5, no. 1: 61-87. https://doi.org/10.3390/heritage5010004

APA StyleLampropoulos, K. C., Apostolopoulou, M., Tsilimantou, E., & Moropoulou, A. (2022). The Grouting Process as an Innovative Tool for the Assessment of the State of Preservation and Internal Features of the Holy Aedicule of the Holy Sepulchre. Heritage, 5(1), 61-87. https://doi.org/10.3390/heritage5010004