Abstract

Various types of additives have been diachronically used in historic mortars, whereas their use in lime-based grouts, used for the restoration of historic structures, is rather limited. In this study, an effort was made to investigate the performance of glass additives in grouts, consisting of lime and natural pozzolan. The additives concerned glass fibers (3 and 6 mm in length), glass beads and bubbles, added in a proportion 0.3–3% w/w of binders. Five grout compositions were manufactured and their properties at fresh and hardened states were tested. From the evaluation of the results, it was asserted that glass additives influenced the grouts’ performance in a favorable way. Their fresh state and physical properties were maintained or slightly improved, while there was a significant enhancement of the long-term mechanical characteristics of the mixes. Additionally, the adhesion capability of grouts was notably increased, which is a crucial aspect indicating their efficacy.

1. Introduction

Various additives have been diachronically used in mortars in order to improve their properties at fresh and hardened state, concerning straw, wooden chips, charcoal, shells, etc. [1,2]. They were added in a low proportion (1–3% w/w of binders), enhancing the mixtures’ plasticity and volume stability, while contributing to the reduction of their density and shrinkage cracking [1,2,3,4].

During the past few decades, various types of additives have been applied in cement and lime-based mortars concerning fibers and glass powder, as well as waste materials [3,4,5,6,7,8,9,10,11]. Fibers are usually of natural (coconut, sisal, bamboo, jute), steel, glass or synthetic origin, concerning carbon, nylon, polyester, acrylic, basalt and polypropylene materials [2]. Their characteristics (origin, dimensions, mechanical properties) and proportion may positively influence the physico-mechanical properties of the final products [5,6,7,8,9,10].

The use of fibers in grouts has been studied since the 1990s, focusing, however, on cement-based grouts [12,13,14]. According to the literature, mainly steel, polypropylene and carbon fibers have been used, affecting both the fresh and hardened state properties of grouts [15,16,17,18,19]. The addition of fibers usually improves bleeding, flexural, and compressive strength, as well as cracking resistance [15,16,17,18,19]. The mixing procedure is a significant aspect, highlighted by researchers, as it is conducted to avoid fibers’ clumping and aggregation [12,13,14]. To this end, fibers are usually added in the grout mixtures during or after the last stage of mixing [13,14,15,16].

Glass beads, on the other hand, have been used in a variety of applications, such as blast cleaning processes, and as additives of concrete, mortars and grouts [20,21,22,23,24]. They present a smooth spherical surface, with increased filler ability, as well as enhanced flow properties [20]. Their elastic modulus and tensile strength depend on their diameter (the larger particles contribute to higher strength), and they may increase the strength of the modified composite systems [20]. The addition of glass powder and beads in cement matrixes [22,23] may contribute to a microstructure densification, improving strength and transport properties.

In the case of building heritage, grouting is an extensively applied technique for restoring and strengthening historic masonries, as well as for consolidating architectural surfaces [25,26,27,28,29,30,31,32,33,34,35,36,37]. During the past few decades, lime-based grouts have been widely developed, following the principle of compatibility, while multiple grouting systems have been applied, according to the needs of each restoration work [28,29,30,31,32,33,34,35]. In order to enhance their properties at fresh and hardened states, various additives have been also used [14,25,28,30,31,32,33,34].

The crucial aspect that must always be taken into account is the high water demand of this type of grouts, usually leading to volume instability, bleeding and low strength [14,25,32,33,34,35,36]. To address this, high speed mixing, superplasticizers and other additions are proposed [25,26,32,33,34,35].

The use of fibers in lime-based grouts has been scarcely investigated [14], likely because fibers are mostly accustomed to mortars and cement-based grouts, while glass microspheres have not been thoroughly assessed [30,31]. Their addition seems to enhance both the fresh and hardened state properties of the mixtures, but further documentation is needed to identify their contribution [14,30,31].

In this study, an effort was made to study the influence of a short proportion of glass fibers, beads, and bubbles in lime–pozzolan grouts, developed for the restoration of historic masonries. The fresh and hardened state properties of the mixtures were tested and the experimental results were comparatively assessed. From their evaluation, the positive impact deriving from the glass additives’ presence was asserted.

2. Methodology

2.1. Design of the Grout Compositions

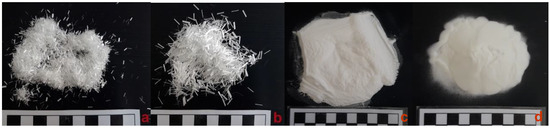

During the experimental part of the study, five grout compositions were manufactured and tested. Their binding system was based on hydrated lime and natural pozzolan, in a proportion of 1:1 (by mass), following former research work and literature [14,30,31,32,33,34,35,36,37]. The glass additives used concerned beads, bubbles, and fibers (Figure 1). Their proportion in the mixtures (w/w/ of binders) was low, ranging from 0.3% for fibers, 1% for bubbles and 3% for beads. In Table 1, the characteristics of the binding agents are presented, while Table 2 describes the properties of the glass additives.

Figure 1.

The glass additives used. (a) 3 mm fibers, (b) 6 mm fibers, (c) beads, (d) bubbles.

Table 1.

Characteristics of the binding agents used in the grout mixtures.

Table 2.

Characteristics of the glass additives used in grouts (according to the technical sheets of the products).

The composition of the grout mixtures is presented in Table 3, where the W/B ratio is also indicated. In an effort to reduce the water demand, a polycarboxilate superplastcizer (Master Glenium 11) was added in a proportion of 1% w/w of binders. According to the literature [14,32,35,37], the superplasticizer addition may enhance both the fresh and hardened state properties of grouts.

Table 3.

Constituents of the grout mixtures.

2.2. Mixing and Testing Procedure

The mixing procedure followed former research work [14,32,34,37], according to which the binders were firstly hand-mixed with the superplasticizer and a gradual proportion of water to prevent aggregation. When the mixture was homogenized, a high-speed mixer was applied (up to 6000 rps) for 5 minutes. The glass additives were added in different ways and according to several trials. Glass beads and bubbles were inserted with the binders, following the conventional method, whereas fibers were added and mixed by hand, at the end of the high-speed mixing. According to relevant studies [13,14,15,16], extreme foaming, fiber aggregation and clumping takes place when fibers are added at the beginning of the mixing procedure and especially when a high-speed mixer is used.

Immediately after mixing, the fresh properties of the grouts were tested, regarding fluidity (flow time), penetrability and volume stability (Figure 2). In each case, results concerned the mean values of three tests.

Figure 2.

Testing the fresh state properties of grouts. (a) Flow cone (ASTM C939-02); (b) flow cone (EN 445: 2007); (c) sand–column test (EN 1771:2004); (d) volume stability (ASTM C 940-98A).

Flow time was measured according to ASTM C939-02 [38] and EN 445: 2007 [39] standards (Figure 2a,b). Measurements were taken immediately and 1 h after mixing to further evaluate the efficiency of mixtures through time. The time limit applied was 10–11 s (measured at the ASTM cone), which, according to former research work [14,32,34,37], guarantees performable grouts both at fresh and hardened states. The water content was respectively adjusted.

Injectability (Figure 2c) was tested according to EN 1771:2004 (sand–column test) [40], using transparent plexiglas cylinders (390 × 22.2 mm). They were filled with natural sand of siliceous origin, of 2–4 mm gradation, corresponding to cracks of 0.3–0.6 mm range [14,32,41]. Under a pressure of 0.8 Atm, the grout was injected in the cylinder and the respective time (seconds) was recorded. The grout–sand material coming from the cylinders was further molded (5 × 5 × 5 cm) in order to assess its compressive strength. According to former research and literature [14,29,32,34], this method can indirectly indicate the grouts’ adhesive capability.

The volume stability measurement followed ASTM C 940-98A [42], determining both volume change and bleeding (Figure 2d) and using a reduced grout quantity (500 mL). The upper limit of 5% was taken into account to prevent segregation phenomena [14,32,34].

The mixtures were molded (sealed 4 × 4 × 16 cm molds) until hardening and were afterwards cured at a chamber with 90 ± 2% RH and temperature 20 ± 1 °C up to the testing ages (28, 90 and 210 days). Eighteen prismatic specimens of each composition were manufactured. The shrinkage deformations, through volume and mass change measurements, were recorded in two specimens cured at 60 ± 2% RH and 20 ± 1 °C, up to the age of 60 days.

At the age of 28, 90 and 210 days, the physical and mechanical properties of the grouts were recorded. Mechanical characteristics were conducted in three specimens/composition (mean values were taken), while for the physical properties, one specimen per test was assessed. Their physical properties concerned porosity, absorption and apparent specific gravity according to RILEM CPC 11.3 [43], as well as water absorption coefficient due to capillary action (EN 1015-18:2002) [44]. Mechanical properties concerned dynamic modulus of elasticity (BS 1881-209:1990) [45] and flexural and compressive strength (BS EN1015-11:1999) [46], while the compressive strength of the grout–sand specimens (derived from column test) was also determined at the age of 28 and 90 days (two specimens per test).

All results were comparatively evaluated to investigate the impact of the various glass additives on the overall performance of the grout compositions.

3. Results and Discussion

3.1. Water Content and Fresh State Properties

The water demand of the mixtures was slightly affected by the glass additives according to their individual characteristics (Table 2). The reference mixture (comp. 1) presented the lowest W/B ratio (0.97), which was increased by the glass fibers’ addition (around 10–20%). The fibers’ length influenced the water demand analogically (the longer the fibers, the higher the water content) and according to previous research [14] and literature [8]. Glass beads and bubbles slightly increased the W/B ratio (around 5%), in accordance with relevant research works [22].

Regarding the fresh state properties of the mixtures, as presented in Table 4, the following aspects could be asserted. As has been previously reported, fluidity according to the ASTM cone was maintained around 10–11 s, corresponding to 6–7 s at the EN cone [14]. The flow time increase, measured 1 h after manufacture, ranged from 1.4% to 4.2% for the ASTM cone to 0.15–3.8% in the EN cone, showing the performability of the mixtures throughout time. Generally, the addition of glass fibers, especially the larger ones (6 mm), showed the most intense time increase in the ASTM cone (2.6–4.2%), whereas glass beads had the higher increase in the EN cone (3.7%). The increase in the length of fibers increased the 1 h flow time, as well as the addition of glass beads and bubbles, whereas all mixes were still performable 1 h after manufacture.

Table 4.

Fresh state properties of the grouts.

Injectability ranged from 2.5 to 3.3 s, with the lower value shown in the reference mixture. Glass additives slightly increased injection time, with the higher value recorded in glass bubbles (comp. 5), while all mixes showed a good performance. Regarding volume stability, volume loss was recorded, ranging from 1.4% to 3.1%, as well as bleeding ranging from 0.9% to 3%. Values were significantly lower than the 5% limit [14,32,34], with the lower changes attributed to glass beads and bubbles. Again, the fibers’ length induced alterations, however at a performable level.

Generally, the fresh state properties of the mixtures were influenced by the glass additives, whereas their efficacy was maintained, according to relevant studies [14,15,24,28]. No aggregation phenomena were recorded (especially due to the fibers’ addition) during or after the fresh state properties testing.

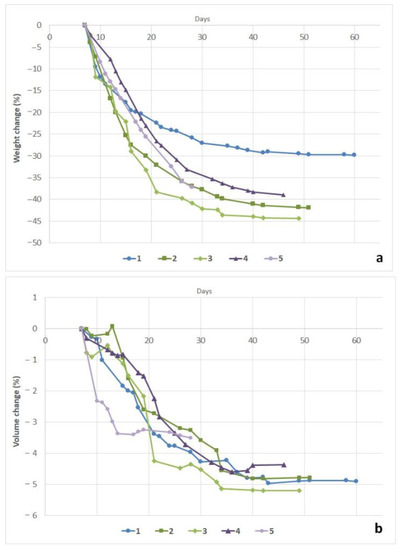

3.2. Physical Properties

The shrinkage deformations of the specimens, recorded through their weight and volume changes, are presented in Figure 3. The more extreme changes took place during the first 20 days; after this period, mass and volume were gradually stabilized [14,37]. The maximum weight loss ranged from 30% to 45% and was induced by glass additives (Figure 3a), whereas the reference grout showed fewer changes. Glass fibers exhibited the more extreme loss (especially the 6 mm ones). This could be attributed to the higher water content of the mixes, as well as the additives’ tendency (and especially fibers) to retain water further evaporated [8,14]. The maximum volume loss was around 4.5–5%, being improved by glass beads and bubbles. The 6 mm fibers, as well as the reference mixture, showed the more intense volume alterations.

Figure 3.

Shrinkage deformations of the grout specimens. (a) Weight changes; (b) volume changes.

It was generally asserted that shrinkage deformations were induced by increasing the fibers’ length, in accordance with studies on fiber reinforced lime-based mortars [8] and grouts [14]. Glass beads and bubbles slightly reduced volume alterations and increased mass loss, following respective studies [22,23,24]. Güllü et al. [22] reported that in cement grouts, glass powder (GP) increases the setting time of the mixtures (linearly to its proportion), attributed to the excess water attained. Kamali and Ghahremaninezhad [23], on the other hand, stated that hydration is enhanced by GP in cement pastes due to their high surface area which may provide increased nucleation sites, leading to shrinkage phenomena.

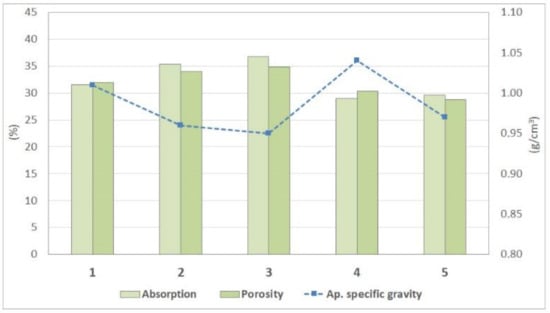

Porosity and absorption were also influenced by glass additives, as shown in Figure 4. They were increased by the fibers’ addition and especially by the 6 mm ones (comp. 3), around 10–15%, whereas they were decreased by beads (comp. 4) and bubbles (comp. 5), around 10%. Kamali and Ghahremaninezhad [23] also indicated a pore refinement of GP-modified cement pastes, derived from microstructure modifications and related with the pozzolanic behavior of GPs.

Figure 4.

Physical properties of grouts at 90 d age (porosity, absorption, apparent specific gravity).

Apparent specific gravity was decreased in compositions 2 and 3 and slightly increased in composition 4. In glass bubbles (comp. 5), it was slightly reduced, following its low density (Table 2) and in accordance with relevant literature [24]. These variations were in line with other research work [22], indicating that the density and grain size of GP may influence the density of the final products.

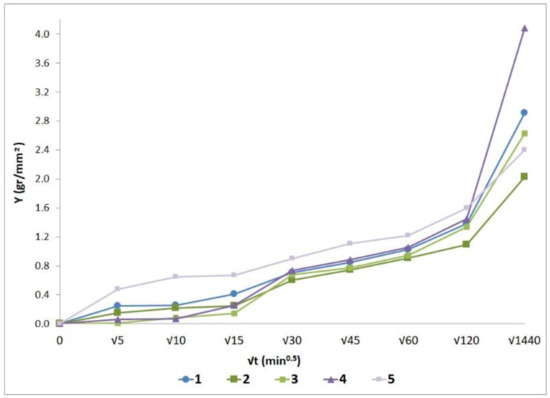

Water absorption due to capillary action (Figure 5) showed a higher tendency by glass beads (comp. 4) and bubbles (comp. 5), while it was lessened by fibers. The 6 mm glass fibers seemed to present lower values, according to former research work [14]. Generally, in all mixtures, capillary absorption was increased with time, presenting the higher values at 24 h (1440 min). This phenomenon was contrary to other building materials’ performance (i.e., lime-based mortars), which show an intense value increase during the first measurements and further stabilization due to the equilibrium achieved between the absorbed and evaporated water [3]. According to former research work [32,34,37], lime-based grouts present an increasing capillary absorption throughout time and depending on the nature and characteristics of their constituents.

Figure 5.

Water absorption due to capillary action (90 d).

3.3. Mechanical Properties

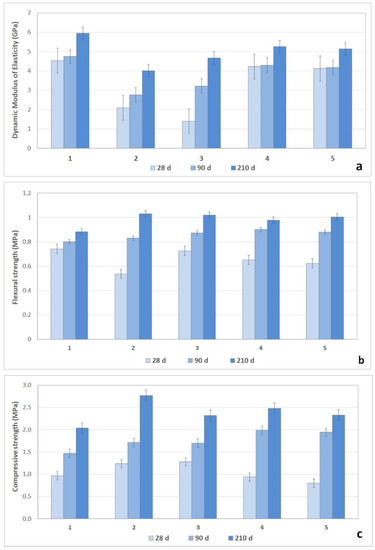

The mechanical properties of the grouts, measured at 28, 90 and 210 days, are presented in Figure 6. They were gradually enhanced up to 210 days, around 30–250%, with the more intense increase shown in compressive strength and depicting the low strength development rate of lime-based grouts [27,31,32,33,34].

Figure 6.

Mechanical properties of the grout compositions (28, 90, 210 days). (a) Dynamic modulus of elasticity; (b) flexural strength; (c) compressive strength.

Dynamic modulus of elasticity presented a 30–230% increase at 210 days, compared to the 28 d one (Figure 6a). The highest rise was recorded by the fibers’ presence, especially the 6 mm ones (comp. 3), which showed lower 28 d values (1.5–2 GPa). The 210 d modulus of elasticity was around 4–6 GPa, with the highest values recorded in the reference grout (comp. 1). It was generally decreased by all additives and especially by fibers (2, 3), according to relevant research and literature [4,14,22].

Flexural strength was also gradually enhanced, with the 90 d increase (compared to the 28 d) varying from 10% to 55% and the respective 210 d increase from 20% to 90% (Figure 6b). The lower increase rate was attributed to the reference composition (comp. 1), which showed the higher initial strength (0.75 MPa). The 28 d strength was around 0.5–0.75 MPa, 0.8–0.9 MPa at 90 days and 0.9–1 MPa at 210 days. Glass additives, although presented the lower 28 d flexural strength (compared to the reference grout), contributed to a further enhancement, showing the highest 90 and 210 d values. The 3 mm fibers (comp. 2) showed the lowest initial values, corresponding to a higher long-term increase. The flexural strength increase due to the fibers’ addition has also been recorded in the literature [3,13,14,15], however it should be stated that it mainly refers to the long-term strength level.

Compressive strength (Figure 6c) showed the more extreme changes throughout time. The values were 0.8–1.3 MPa at 28 days, 1.5–2 MPa at 90 days and 2–2.8 MPa at 210 days, resulting in a 30–150% strength increase at 90 days and 80–200% at 210 days. The highest increase for both ages was recorded with the addition of the glass beads and bubbles. The highest 28 d strength was given by fibers (comp. 2–3), whereas the highest 90 d strength was given by glass beads (comp. 4) and bubbles (comp. 5). The final (210 d) strength was enhanced by all additives (up to 40% compared to the reference grout), with the highest values recorded in the 3 mm glass fibers (comp. 2).

The positive impact of fibers on the compressive strength of lime and cement-based grouts has been documented by the literature [14,16]. Regarding glass beads, Güllü et al. [22] indicated that GP (up to a proportion of 3%) may increase the compressive strength of cement grouts, depending on its particle size and chemical composition.

Generally, it was asserted that the 28 d flexural strength of the mixtures corresponded to the 50–85% of the final (210 d) one, while the 28 d compressive strength to the 35–55%. These remarks show the very slow strength development rate of lime-based grouts, whose mechanical properties should be tested in due time and at least at the age of 90 days in order to better envisage their performance.

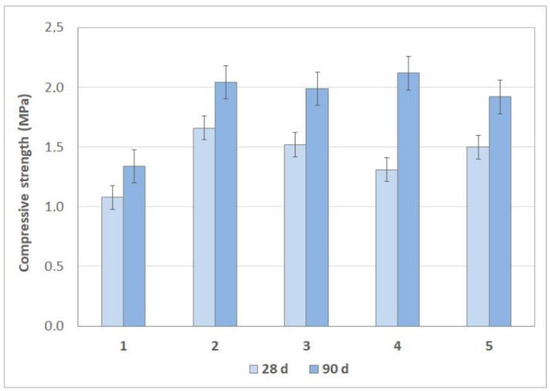

In Figure 7, the compressive strength of the grout–sand specimens is presented in order to indirectly evaluate the adhesive capability of grouts. The lower 28 and 90 d values were recorded in the reference grout (comp. 1), showing that the use of all glass additives enhanced the cohesion of the specimens. Fibers showed a strength increase of 40–55%, while beads and bubbles showed an increase of around 20–58% at both ages. The highest rise was shown at the 90 d age and was around 2 MPa (the reference grout had a respective strength of 1.3 MPa). It was therefore asserted that glass additives enhanced the adhesive capability of grouts, which is a crucial parameter that must be taken into account during grouting to guarantee the efficacy of the mixtures [14].

Figure 7.

Compressive strength of the grout–sand specimens (28 d, 90 d).

4. Conclusions

The use of a short proportion of glass additives in lime-based grouts (i.e., fibers, beads, bubbles) seems to be a promising alternative for producing efficient repair materials for the consolidation of historic structures. Their presence maintained the grout’s fresh and physical properties, and there was a significant enhancement of their mechanical characteristics, especially those concerning their long-term strength. Synoptically, their influence may be recorded as follows:

- The W/B ratio was increased by the glass additives by around 5–20%, with higher water demand given in the longer fibers (6 mm). The fresh state properties of the mixtures were maintained at a performable level. Flow time measured 1 h after manufacture was slightly increased by additives (especially the 6 mm fibers), as well as injection time. Volume changes and bleeding were slightly induced by the fibers’ addition (beyond the 5% limit), while glass beads significantly reduced alterations.

- Shrinkage deformations were primarily attained during the first 20 days and were slightly reduced by glass beads and bubbles, and induced by fibers. Porosity was increased by the fibers’ addition (especially the 6 mm ones) and was slightly decreased by beads and bubbles, with opposite results for apparent specific gravity. Water absorption coefficient was higher with the presence of beads and bubbles and was slightly lessened by fibers.

- The long-term mechanical properties of the grouts were significantly enhanced by glass additives. Dynamic modulus of elasticity was decreased due to their presence, while flexural strength was increased by around 10–20% (compared to the reference grout). Compressive strength was also enhanced (increased by 20–40%), with the 6 mm fibers found to be more effective.

- The adhesive capability of grouts, measured through the compressive strength of the grout–sand specimens, was significantly improved by the presence of the additives (around 20–55%), with the highest values given by the fibers’ addition.

In conclusion, it could be stated that glass beads and bubbles maintained or even improved the fresh and physical properties of grouts, while strength was increased. Fibers, on the other hand, altered the former characteristics (still at a performable level), contributing significantly to strength development. Naturally, the type and proportion of glass additives affected the overall performance of the matrix and should be further assessed, taking into account the limitations and requirements of each application.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The author declares no conflict of interest.

References

- Stefanidou, M.; Papayianni, I.; Pachta, V. Evaluation of inclusions in mortars of different historic periods from Greek monuments. Archaeometry 2011, 54, 737–751. [Google Scholar] [CrossRef]

- ACI Committee 544. Report on Fiber Reinforced Concrete; ACI 544.1R-96; American Concrete Institute: Farmington Hills, MI, USA, 1996; reapproved in 2002. [Google Scholar]

- Kesikidou, F.; Stefanidou, M. Natural fiber-reinforced mortars. J. Build. Eng. 2019, 25, 100786. [Google Scholar] [CrossRef]

- Lucolano, F.; Liguori, B.; Colella, C. Fibre-reinforced lime-based mortars: A possible resource for ancient masonry resto-ration. Constr. Build. Mater. 2013, 38, 785–789. [Google Scholar] [CrossRef]

- Monfore, G.E. A Review of Fiber Reinforced Portland Cement Paste, Mortar, and Concrete. J. Res. Dev. Labs. Portl. Cem. Assoc. 1968, 10, 36–42. [Google Scholar]

- Çomak, B.; Bideci, A.; Bideci, Ö.S. Effects of hemp fibers on characteristics of cement based mortar. Constr. Build. Mater. 2018, 169, 794–799. [Google Scholar] [CrossRef]

- Di Bella, G.; Fiore, V.; Galtieri, G.; Borsellino, C.; Valenza, A. Effects of natural fibres reinforcement in lime plasters (kenaf and sisal vs. Polypropylene). Constr. Build. Mater. 2014, 58, 159–165. [Google Scholar] [CrossRef]

- Izaguirre, A.; Lanas, J.; Alvarez, J. Effect of a polypropylene fibre on the behaviour of aerial lime-based mortars. Constr. Build. Mater. 2011, 25, 992–1000. [Google Scholar] [CrossRef]

- Trejbal, J. Mechanical properties of lime-based mortars reinforced with plasma treated glass fibers. Constr. Build. Mater. 2018, 190, 929–938. [Google Scholar] [CrossRef]

- Barbero-Barrera, M.M.; Medina, N.F. The effect of polypropylene fibers on graphite-natural hydraulic lime pastes. Constr. Build. Mater. 2018, 184, 591–601. [Google Scholar] [CrossRef]

- Shuai, J.; Zuo, X.; Wang, Z.; Sun, L.; Chen, R.; Wang, L.; Wang, A.; Ke, P. Erosion behavior and failure mechanism of Ti/TiAlN multilayer coatings eroded by silica sand and glass beads. J. Mater. Sci. Technol. 2021, 80, 179–190. [Google Scholar] [CrossRef]

- Allan, M.; Kukacka, L. Permeability and microstructure of plain and polypropylene fibre reinforced grouts. Cem. Concr. Res. 1994, 24, 671–681. [Google Scholar] [CrossRef]

- Allan, M.; Kukacka, L. Strength and durability of polypropylene fibre reinforced grouts. Cem. Concr. Res. 1995, 25, 511–521. [Google Scholar] [CrossRef]

- Pachta, V.; Goulas, D. Fresh and hardened state properties of fiber reinforced lime-based grouts. Constr. Build. Mater. 2020, 261, 119818. [Google Scholar] [CrossRef]

- Kim, D.J.; Park, G.-J.; Le, H.V.; Moon, D. Fresh and hardened properties of steel fiber-reinforced grouts containing ground granulated blast-furnace slag. Constr. Build. Mater. 2016, 122, 332–342. [Google Scholar] [CrossRef]

- Berndt, M.L. Strength and permeability of steel fibre reinforced grouts. Constr. Build. Mater. 2010, 24, 1768–1772. [Google Scholar] [CrossRef]

- Huang, W.-H. Improving the properties of cement–fly ash grout using fiber and superplasticizer. Cem. Concr. Res. 2001, 31, 1033–1041. [Google Scholar] [CrossRef]

- Yang, P.; Liu, Y.-H.; Gao, S.-W.; Li, Z.-C. Experiment on sealing efficiency of carbon fiber composite grout under flowing conditions. Constr. Build. Mater. 2018, 182, 43–51. [Google Scholar] [CrossRef]

- Ascione, F.; Lamberti, M.; Napoli, A.; Realfonzo, R. Experimental bond behavior of Steel Reinforced Grout systems for strengthening concrete elements. Constr. Build. Mater. 2020, 232, 117105. [Google Scholar] [CrossRef]

- Yang, W.; Shi, W.; Li, Z.-M.; Xie, B.-H.; Feng, J.-M.; Yang, M.-B. Mechanical Properties of Glass Bead-Filled Linear Low-Density Polyethylene. J. Elastomers Plast. 2004, 36, 251–265. [Google Scholar] [CrossRef]

- Bek, M.; Gonzalez-Gutierrez, J.; Kukla, C.; Pušnik Črešnar, K.; Maroh, B.; Slemenik Perše, L. Rheological Behaviour of Highly Filled Materials for Injection Moulding and Additive Manufacturing: Effect of Particle Material and Loading. Appl. Sci. 2020, 10, 7993. [Google Scholar] [CrossRef]

- Güllü, H.; Canakci, H.; Al Zangana, I.F. Use of cement based grout with glass powder for deep mixing. Constr. Build. Mater. 2017, 137, 12–20. [Google Scholar] [CrossRef]

- Kamali, M.; Ghahremaninezhad, A. An investigation into the hydration and microstructure of cement pastes modified with glass powders. Constr. Build. Mater. 2016, 112, 915–924. [Google Scholar] [CrossRef]

- Koleini, F.; Colomban, P.; Pikirayi, I.; Prinsloo, L.C. Glass Beads, Markers of Ancient Trade in Sub-Saharan Africa: Methodology, State of the Art and Perspectives. Heritage 2019, 2, 2343–2369. [Google Scholar] [CrossRef]

- Padovnik, A.; Bokan-Bosiljkov, V. Effect of Ultralight Filler on the Properties of Hydrated Lime Injection Grout for the Consolidation of Detached Historic Decorative Plasters. Materials 2020, 13, 3360. [Google Scholar] [CrossRef]

- Papayianni, I.; Stefanidou, M.; Pachta, V. Grouts for injection of historical masonries: Influence of the binding system and other additions on the properties of the matrix. RILEM Bookseries 2013, 7, 383–392. [Google Scholar]

- Alvarez, J.I.; Veiga, R.; Martínez-Ramírez, S.; Secco, M.; Faria, P.; Maravelaki, P.N.; Ramesh, M.; Papayianni, I.; Válek, J. RILEM TC 277-LHS report: A review on the mechanisms of setting and hardening of lime-based binding systems. Mater. Struct. 2021, 54, 1–30. [Google Scholar] [CrossRef]

- Dinç-Şengönül, B.; Oktay, D.; Yüzer, N. Effect of temperature, resting time and brick dust (Horasan) on the rheological properties of hydraulic lime-based grouts. Constr. Build. Mater. 2020, 265, 120644. [Google Scholar] [CrossRef]

- Miltiadou-Fezans, A.; Tassios, T.P. Penetrability of hydraulic grouts. Mater. Struct. 2013, 46, 1653–1671. [Google Scholar] [CrossRef]

- Pasian, C.; De Fonjaudran, C.M.; Rava, A. Innovative Water-Reduced Injection Grouts for the Stabilisation of Wall Paintings in the Hadi Rani Mahal, Nagaur, India: Design, Testing and Implementation. Stud. Conserv. 2020, 65, 244–250. [Google Scholar] [CrossRef]

- Pasian, C.; Secco, M.; Piqué, F.; Artioli, G.; Rickerby, S.; Cather, S. Lime-based injection grouts with reduced water content: An assessment of the effects of the water-reducing agents ovalbumin and ethanol on the mineralogical evolution and properties of grouts. J. Cult. Heritage 2018, 30, 70–80. [Google Scholar] [CrossRef]

- Pachta, V.; Papadopoulos, F.; Stefanidou, M. Development and testing of grouts based on perlite by-products and lime. Constr. Build. Mater. 2019, 207, 338–344. [Google Scholar] [CrossRef]

- Azeiteiro, L.C.; Velosa, A.; Paiva, H.; Mantas, P.Q.; Ferreira, V.M.; Veiga, R. Development of grouts for consolidation of old renders. Constr. Build. Mater. 2014, 50, 352–360. [Google Scholar] [CrossRef]

- Papayianni, I.; Pachta, V. Experimental study on the performance of lime-based grouts used in consolidating historic masonries. Mater. Struct. 2014, 48, 2111–2121. [Google Scholar] [CrossRef]

- Baltazar, L.; Henriques, F.M.; Jorne, F.; Cidade, M. Combined effect of superplasticizer, silica fume and temperature in the performance of natural hydraulic lime grouts. Constr. Build. Mater. 2014, 50, 584–597. [Google Scholar] [CrossRef]

- Vavričuk, A.; Bokan-Bosiljkov, V.; Kramar, S. The influence of metakaolin on the properties of natural hydraulic lime-based grouts for historic masonry repair. Constr. Build. Mater. 2018, 172, 706–716. [Google Scholar] [CrossRef]

- Pachta, V.; Papayianni, I.; Spyriliotis, T. Assessment of Laboratory and Field Testing Methods in Lime-based Grouts for the Consolidation of Architectural Surfaces. Int. J. Arch. Herit. 2020, 14, 1098–1105. [Google Scholar] [CrossRef]

- ASTM C939-02. Standard Test Method for Flow of Grout for Preplaced-Aggregate Concrete (Flow Cone Method); ASTM: West Conshohocken, PA, USA, 2002. [Google Scholar]

- EN 445. Grout for Prestressing Tendons-Test Methods; European Committee for Standardization: Brussels, Belgium, 2007. [Google Scholar]

- EN 1771. Products and Systems for the Protection and Repair of Concrete Structures. Test Methods-Determination of Injectability and Splitting Test; BSI: Milton Keynes, UK, 2004. [Google Scholar]

- Biçer-Şimşir, B.; Griffin, I.; Palazzo-Bertholon, B.; Rainer, L. Lime-based injection grouts for the conservation of architectural surfaces. Stud. Conserv. 2010, 55, 3–17. [Google Scholar] [CrossRef]

- ASTM C940-98a. Standard Test Method for Expansion and Bleeding of Freshly Mixed Grouts for Preplaced-Aggregate Concrete in the Laboratory; ASTM: West Conshohocken, PA, USA, 1998; reapproved in 2003. [Google Scholar]

- RILEM CPC 11.3. Absorption of water with immersion under vacuum. Mater. Constr. 1984, 17, 391–394. [Google Scholar]

- BS EN1015-18:2002. Methods of Test for Mortar for Masonry, Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar; BSI: Milton Keynes, UK, 2002. [Google Scholar]

- BS 1881-203. Testing Concrete. Part 203: Recommendations for Measurement of Velocity of Ultrasonic Pulses in Concrete; BSI: Milton Keynes, UK, 1986. [Google Scholar]

- BS EN1015-11:1999. Methods of Test for Mortar for Masonry, Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; BSI: Milton Keynes, UK, 1999. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).