The Engine House (Geradora) of Paços Reais was built in about 1900 [

27] and had different uses over the years. In the early 1900s, when the building was still called “Geradora de Electricidade dos Paços Reais”, it was intended to function as a power generator for the Ajuda region in Lisbon. At this time, the building belonged to the kingdom of Portugal. Later, already integrated with the Instituto Superior de Agronomia (ISA), it began to function as an agricultural museum with the exhibition of a variety of equipment, agricultural machines, and old photographs that show the evolution of technology in agriculture. Back then, the rooms were also used for university classes [

27,

28,

29,

30]. Currently, the building is poorly maintained, with rainwater falling from the roof, peeling walls, lack of paint, and general repair needed [

27]. Due to its current state, it is only being used to store equipment and other university furniture.

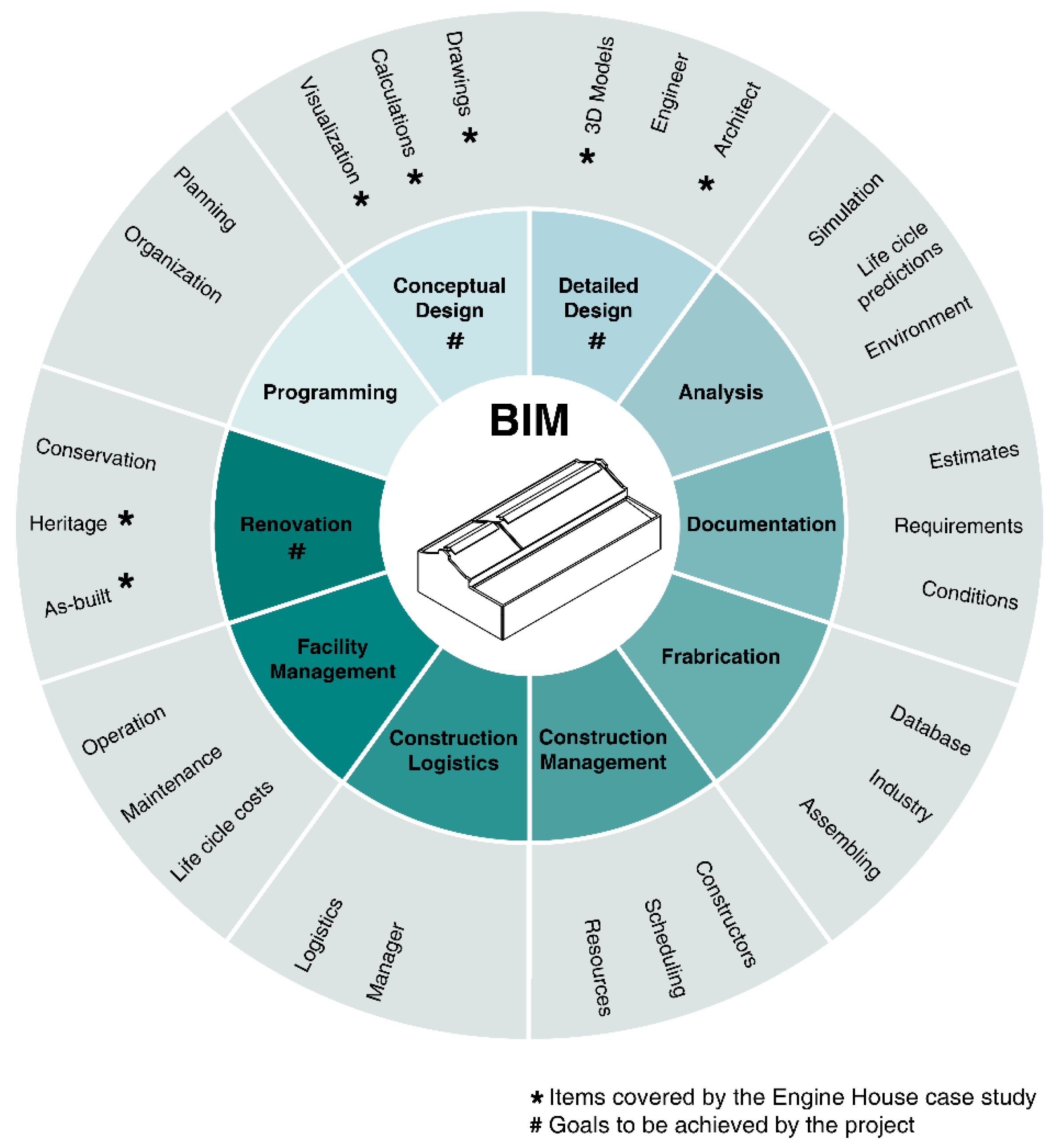

3.1. Data Collection, Processing and Manipulation

The types of equipment used to survey the Engine House were a Faro Focus 120 S 3D laser scanner, a DJI (Dà-Jiāng Innovations ™) phantom four drone equipped with a 4 k camera, a Trimble R8 GNSS GPS, a Reflex camera Nikon D7200, and a smartphone for additional photographic recording

A total of 144 scans were made, of which 143 covered the entire interior of the building, its exterior facades and the lower level. One scan was made of the lower roof. A total of 11 GPS control points for georeferencing were collected and later used to georeference the photogrammetric point clouds and the LIDAR survey. It is necessary to collect a good number of different points around the building to ensure that the georeferencing process is done correctly and that errors are minimized. These are simple techniques without significant challenges, but they are essential for a good workflow. Keeping the final model in its actual coordinates is vital so that all stakeholders involved in the project can easily add new information, files, or do verifications on the model. The strategy for the photogrammetric survey was divided into two phases. The first one was an aerial campaign using the drone equipped with a camera, capturing approximately 900 images in less than two hours. The second one was a terrestrial campaign, recording around 250 photos. The entire survey was conducted in four sessions, accounting for a total duration of 10 h.

For the scanner to capture the main elements of the building, some preparation steps were necessary. The entire outdoor area was cleaned, objects were removed from the walls, all corners of the windows, doors and walls were exposed, and the survey was conducted with the doors, both open and closed to ensure that details and connections between spaces were registered. Thus, it was possible to capture the geometry with better quality. Common consequences of skipping those steps are inconsistent and there are gaps of information in the point cloud that could compromise the understanding and modeling of the building.

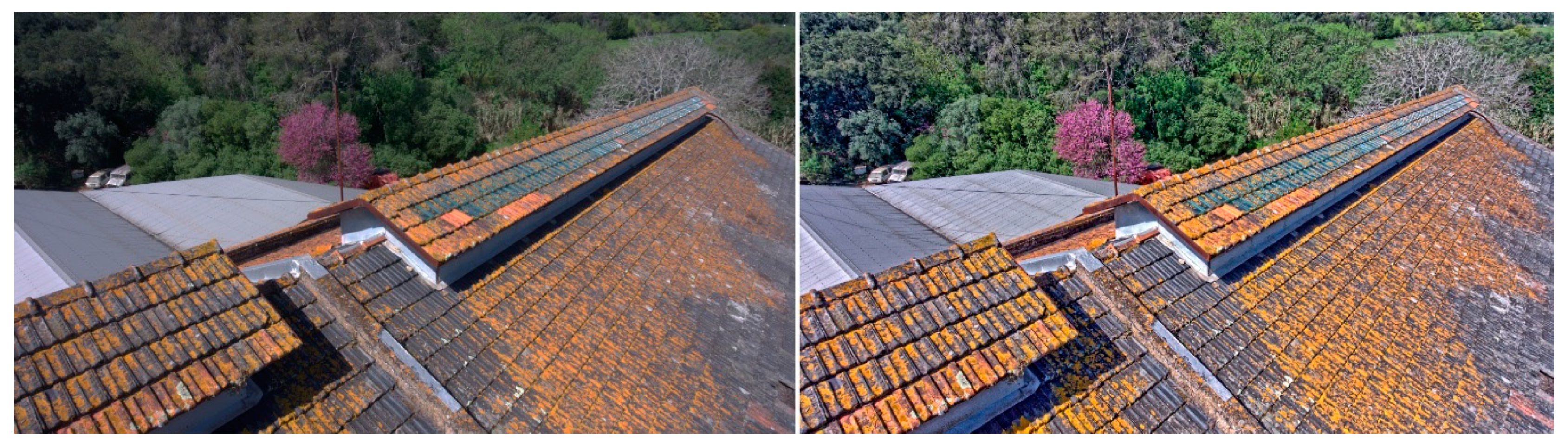

Drone imagery was used to capture the roof, which was not possible with the 3D laser scanner. Further, drone and ground-based imagery also enabled the capturing of the color and texture of the facades, which, later on, made possible the generation of orthoimages in elevations to perform studies of the state of conservation and damage mapping for each of them.

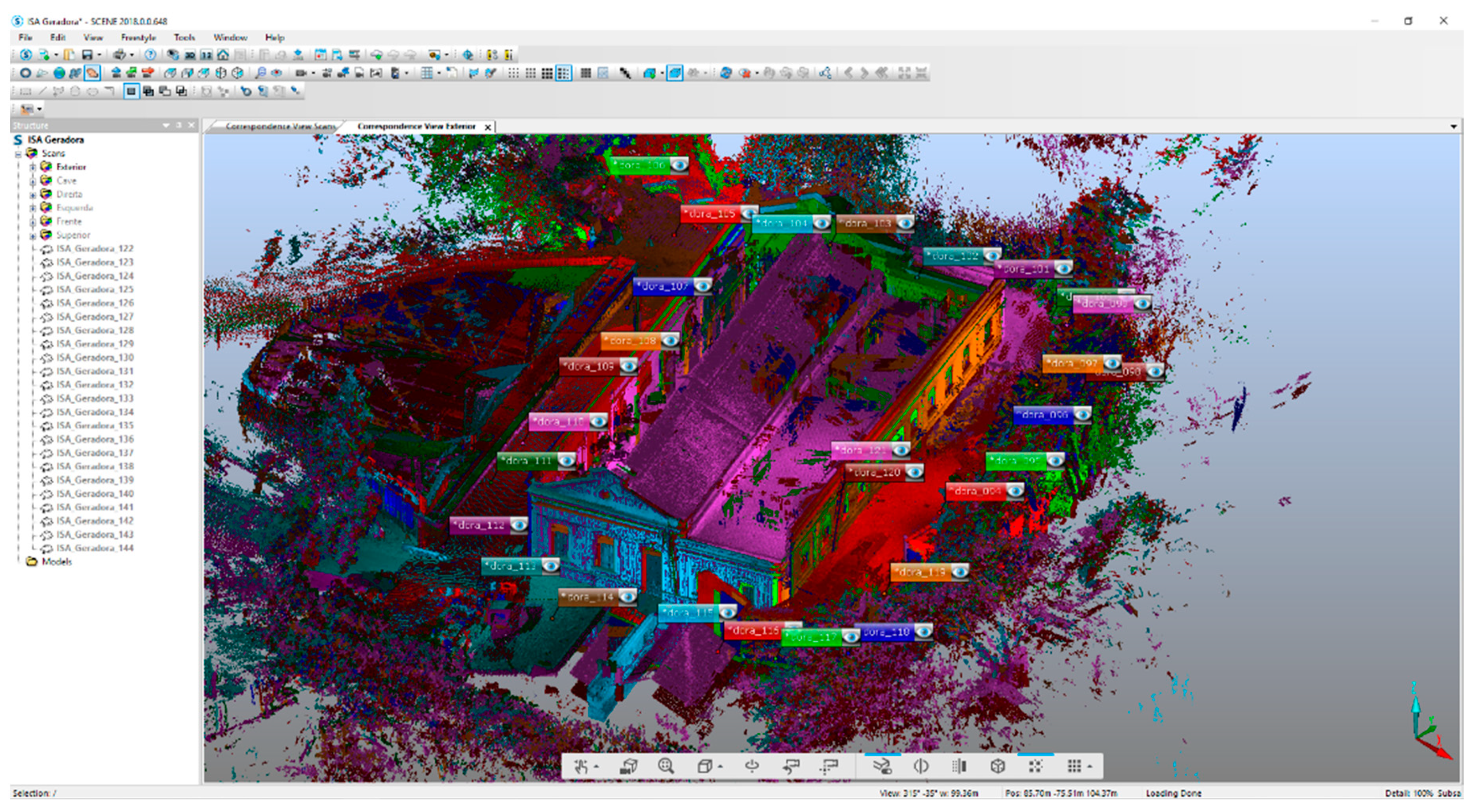

The processing and alignment of the scans generated in the survey were done with the Faro Scene software (

Figure 4). A semi-automatic cloud-to-cloud alignment was performed. For better results, the operator should manually do a pre-alignment by selecting the matching scans and positioning them with an approximate relative location and orientation. Due to the size of the building and the high number of scans, clusters were created. Each cluster corresponds to a logical building part (for example, the basement, a set of rooms or a flor). At first, the registration was performed within each cluster and then between the already registered clusters. On the inside areas, the average accuracy and correspondence between the scans were between 0.50 mm and 2.00 mm, while on outside areas, it was between 3.00 mm and 5.00 mm, which is justified by the presence of trees and vegetation and the higher distance ranges. While the numerical results are satisfactory, a visual inspection must be carried out throughout the building, at least in two orthogonal orientations. In this case, this was done by dynamically visualizing moving horizontal and vertical sectioning planes. The inspection was done every 50 cm in critical places like stairs and windows. After this procedure, if a mismatch in the alignment of point clouds is found, the registration process must be repeated. It is essential to notice that there are some artifacts due to mirrors, tangential scattering, or moving objects that must be removed. After the registration was validated, the project was georeferenced. For this step, five control points were used with an average error of around 3 cm. The remaining GPS points were used to validate the georeferencing process.

After georeferencing, the laser scanning point clouds were merged, subsampled, and then exported in a point cloud file with approximately 95 million points in an e57 format to be further manipulated.

The photogrammetric process started with the conversion of raw images (

Figure 5) under the criteria of adequate white balance, minimization of shadows and highlights, and masking of artifacts or undesirable objects (people, cars, and other elements). No correction in the lens distortion was applied since it represents a fundamental feature to conduct the internal calibration in further, proper, photogrammetric processing.

The Agisoft Photoscan software was used for internal and relative orientation. Both aerial and terrestrial converted images were processed together, while the internal orientation images were processed separately from them because they had different calibration parameters (1 in sensor + 8 mm lens in the DJI phantom vs. 1.11 in + 60 mm NIKKOR). The sparse cloud, obtained from the camera orientation, was filtered to remove outliers and weak reconstructed correspondences. The remaining point cloud was later densified using a half size of the photo (high Quality on the standard of Agisoft). Spatially reconstructed points were enhanced with the color information provided by the pixels of the corresponding photos (

Figure 6). To guarantee an accurate match of scale and orientation with the laser scanner data (external orientation), a collection of coordinates from relevant points, recognizable also from the photos feeding the photogrammetric model, was extracted from the LIDAR data.

Before beginning to model the building on BIM software, it is essential to perform some procedures on the point cloud, such as noise reduction, elimination of inaccurate points, and even scene elements that are not needed for the project [

23,

31]. These procedures result in an optimized point cloud, and consequently, in a reduction of impact that the file size has on computer processing. In the case of the Engine House, Autodesk Recap software was used for the cleanup. Reflection artifacts, unnecessary objects from outside, people, as well as all internal furniture, were selected and eliminated. After these procedures, the point cloud with approximately 83 million points (12.6% fewer points than point cloud before the cleaning process) was saved. It was also at this stage that the georeferenced photogrammetric point cloud was incorporated into the 3D laser scanning cloud. Since the photogrammetric cloud has less definition and accuracy, only the regions that were not possible to scan were selected, i.e., the higher roof and some regions of the facade (

Figure 7).

At this stage, the BIM modeling phase starts. In order to demonstrate our flow to a wider public, while ensuring the compatibility of data structure and formats to IFC (Industry Foundation Classes) standards, we selected the software Autodesk Revit. Autodesk has been a leading company in the promotion of IFC as the neutral-product model supporting the building lifecycle. In 1994, Autodesk organized a consortium, Industry Alliance for Interoperability (IAI), to advise on open language and classes to support software interoperability in the AEC/FM industries while promoting an information-centric solution and re-use of information [

32]. This initiative has evolved in the last 25 year to become the BuildingSmart Institution and international non-profit industry-led organization, which develops and updates the IFC as a neutral and open specification for BIM.

Autodesk Revit has been continuously certified with the official standard and its upgrades, currently in progress in the IFC4 scheme certification [

33]. Recent research has assessed the collaboration capacity in Revit [

34] and compared its performance as a full IFC-complier [

35], concluding that this software has the best performance in terms of standard compatibility, data loss, and misrepresentation along the data production processes. The selection of Revit for demonstration purposes in this paper is also supported by: (i) its effectiveness in importing and managing point clouds (through RCS and RCP Autodesk native formats); (ii) the provision of an intuitive three-dimensional virtual building modelling interface; and (iii) a powerful family editor tool, where standard Revit elements have corresponding IFC containers, requiring no user-actions [

36] and ‘modeling-in-place’ feature allows for straightforward Boolean operations. Our demonstrated flow can be repeated without the loss of object information or geometric misrepresentation in any non-proprietary software where the data structure and format match the open Official Standard of IFC model specifications: ISO 16739-1:2018.

3.2. HBIM Modeling and Results

Much like the scanning, some steps need to be done before the modeling itself. The first one is to get a coordinate of a point in the point cloud and to set the survey point in Revit with the same coordinates. In this case, a point at ground level was chosen. Revit works with two systems of coordinates: the project base point that defines the origin of the coordinate project system (0, 0, 0), and the survey point that identifies a real-world location near the model [

37]. With the survey point set-up, it was moved (without changing its coordinates) to the origin and the same position of the project base point. Thus, with this procedure, the model was guaranteed to be done close to the internal origin on Revit and to avoid some issues that could appear, as Revit does not perform well when the model is far from the internal origin coordinates. This also ensures that, when inserting the point cloud, the building’s ground level will be automatically be located at level 0 within Revit, thus avoiding the need to move or change its position.

The second step is inserting the point cloud into Revit. It must be done using the shared coordinates option, thus ensuring that the point cloud is positioned at the same coordinates that were defined when georeferenced. After that, it is essential to fix the point cloud within the project so that it is not accidentally moved or rotated. These operations are essential to ensure that the point cloud is always placed in the same position, even if it needs to be unloaded and later reinserted within the same project. In large projects, this positioning procedure allows us to segment the files and only load what is needed at that moment. The same reference guarantees that the multiple parts of a partitioned point cloud will always be loaded in the correct position.

With the point cloud inserted and fixed within Revit, it is possible to start the modeling procedures by reorienting the building within the workspace and doing a visual inspection to identify and create the existing levels. Defining a new orientation to reposition the building orthogonally in the work plane is essential. This procedure makes understanding geometry easier and avoids inconsistencies between the model and its conscious design intent, as in most cases, buildings are designed so that their walls are perpendicular to each other. This new orientation should be made by rotating the internal project North, whereas the true north of the survey should not be modified so that the model remains georeferenced. With the reoriented model, it is necessary to identify and create the primary levels of the building. These levels are necessary as they help in the creation of floors and walls and the correct insertion of the building elements. It is essential to take a pragmatic approach so that no excess levels are created, making the workflow confusing. In the Engine House case, the levels for all floors—main, lower, and upper levels—and roofs were created.

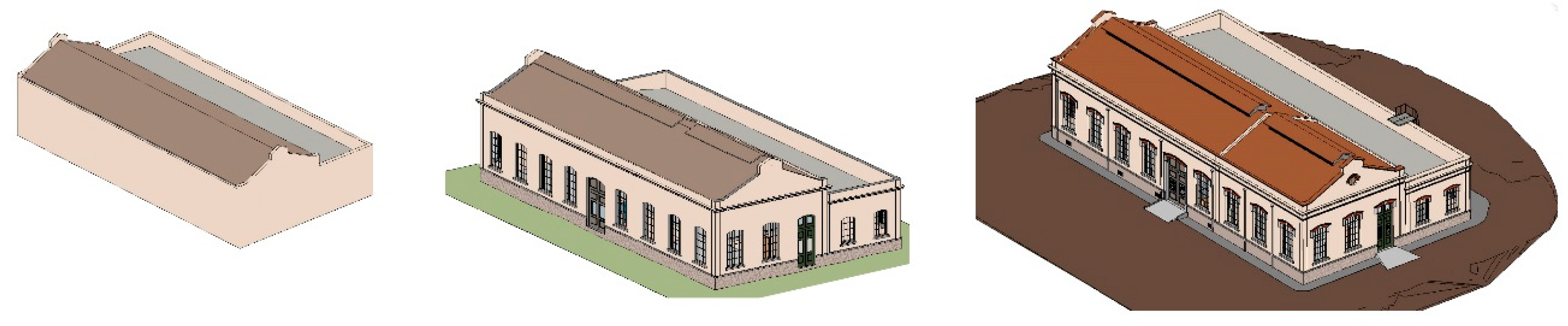

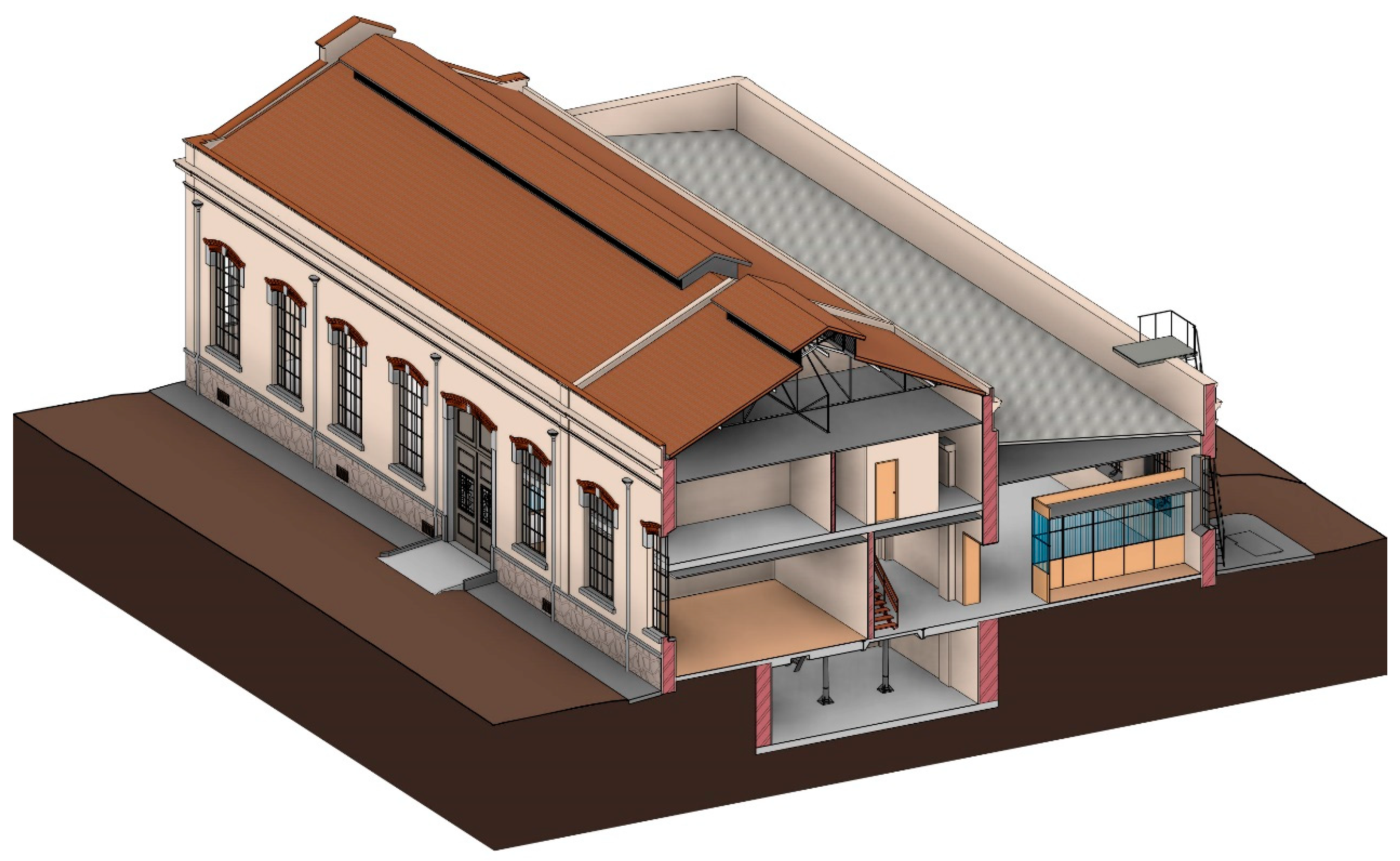

The approach adopted for modeling was to reconstruct the geometry of the building from macro to micro, that is, to prioritize the essential elements such as walls, floors, and roofs and then create complementary elements and other details (

Figure 8). This pragmatic and organized methodology assists in concentrating decision-making and problem-solving efforts, as attention will only be focused on one aspect of the building. For example, while setting wall-related parameters such as finish and thickness, it is not necessary to think at this time about how to resolve the insertion of doors, windows, or any other existing openings.

In historical buildings, it is common to have walls with inhomogeneous thicknesses, deviations, and the lack of perpendicularity. The non-orthogonal walls impair HBIM workflow, and it is necessary to pay attention to this aspect to decide the approach that will be taken. The Engine House did not show large deviations in internal walls, which allowed for the orthogonal modeling of these elements. However, its external perimeter was not perfectly rectangular. One of the walls presented a difference of more than 5 cm in its real position from an expected perpendicular angle. In this case, if a considerable deviation verified, a model of the wall in its real position, with the correct deviation to keep the geometric characteristics accurate to reality, was decided. The walls were created with the corresponding thicknesses, accurate up to 1 cm tolerance. It was also decided to separate the exterior and interior finishes, allowing, at the end of the process, for the generation of a schedule with the number of finishes related to external or internal applications.

The model was created in order to avoid conflicts and clashes between the construction elements. The modeling was carried out by a single team that had full control as to how it was to be performed in order to avoid those conflicts. The interaction of floors, beams, walls, and other elements was carefully performed to ensure a perfect intersection and to reflect the original building with high fidelity (

Figure 9). Still, we had conflict issues at some points, such as between the trusses with walls and roofs. This occurred due to the impossibility of accessing these points with proximity, making the survey of the highest areas of the building less accurate.

3.2.1. Family Creation

Within a BIM workflow, having an extensive family library makes modeling more natural and faster. Since, most of the time, these families are parametric elements, they can be adapted to project needs, thus enhancing productivity [

17]. However, there is a deficiency of libraries that meet the requirements of HBIM projects, resulting in the need for the complete modeling of these families.

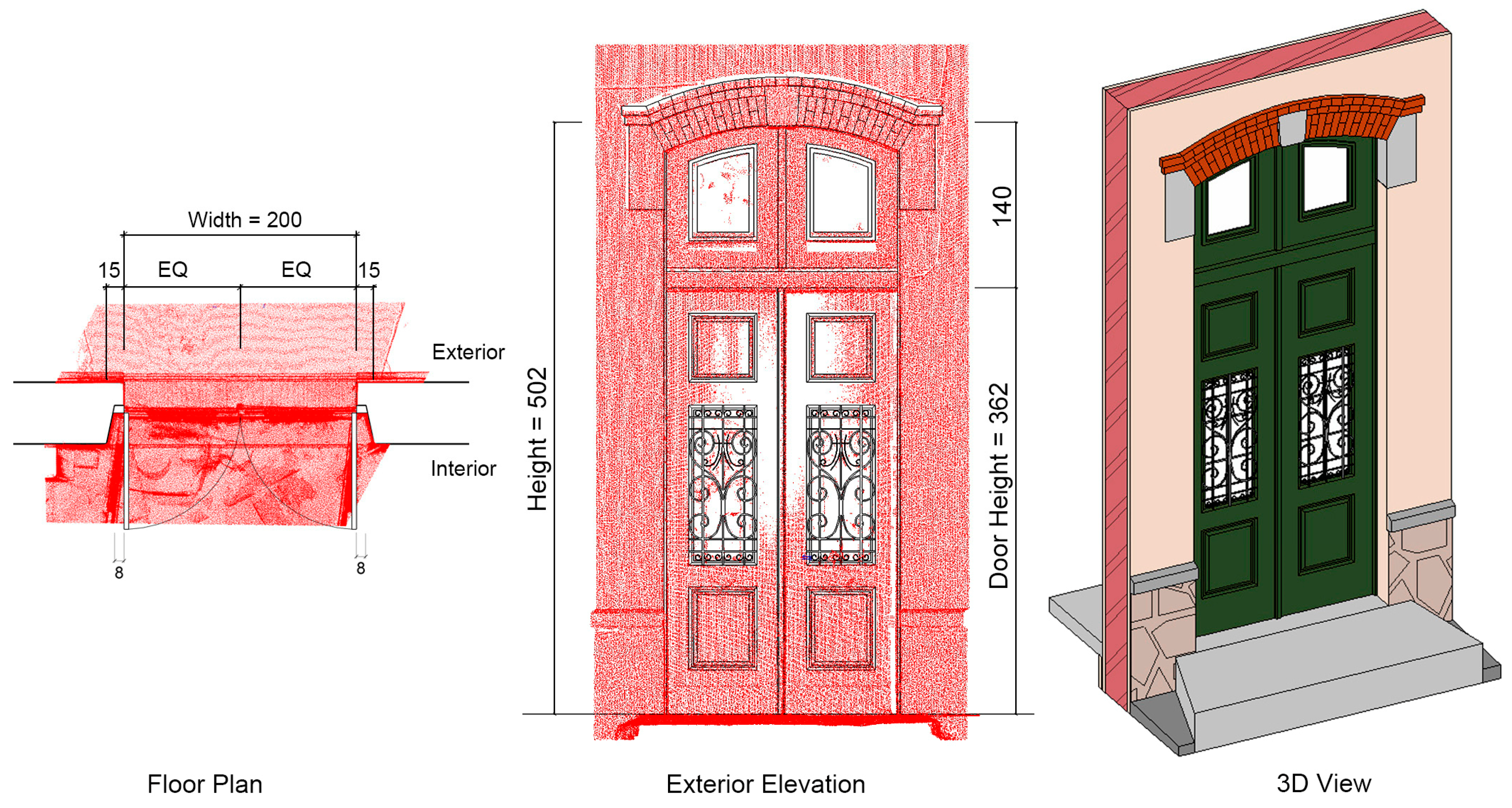

Autodesk Revit is a hugely versatile and powerful modeling tool, enabling us to create modeled families on the project itself or externally within the family editor. In either case, the element can be classified into the correct category so that it behaves appropriately within the project as a family made for this purpose. In the Engine House, all windows, external doors, and access hall doors were modeled. Other internal doors could be adapted from existing elements in the native software library.

Revit Family Editor does not support the insertion of point cloud files in traditional formats. Thus, it is necessary to separate the points referring to the objects to be modeled and export them in dxf format in order to insert it in the family editor (

Figure 10). In the case of study, this procedure was done using the software CloudCompare. Another challenge was that, by default, the doors and windows in Revit are modeled with a rectangular wall insertion cut; however, in historic buildings with thick walls, it is customary to the insert the cut to be chamfered both horizontally and vertically. This situation makes it impossible to use existing families, and it is necessary to create new ones that use another type of wall cuts by combining some Boolean operations such as void forms, sweep, extrude, revolution tools, and others.

Creating custom families can be time-consuming, complex, and highly parameterized elements can often make this modeling as laborious as that of a complete building. It is necessary to understand for what purpose the family will be destined to decide how modeling will be done and to avoid unnecessary work. At the Engine House, the adequate families were identified, and it was decided which dimensions within them would be necessary to be parameterized. This saves modeling time by taking advantage of the same window family, for example, in more than one situation.

In addition to doors and windows, other elements were created as specific families, such as profiles from roof and facade details, stairs, handrails, and columns. The building has two internal stairs, and each one was modeled with a specific approach. The staircase that connects the ground level to the mezzanine has a metal structure and wooden floors. It is quite particular because each of its runs has different floor heights. Thus, if we chose to model the stairs with the native Revit tool that standardizes each step with the same height, we would end up with a big difference in the height of some floors and the central landing. It was decided to segment the construction in two stages, with the first two runs having a floor height of 17.75 cm and the third run with 20 cm to avoid more significant deviations. The stair supports were modeled separately from the stairs so that we had control of their exact positions. The handrails were modeled with the specific Revit tool for this purpose, with custom handrails and balusters following the existing pattern. We had no issues with the stairs that connect the basement to the ground floor. It is a standard metal ladder and did not show significant differences in its floor heights. The most complicated element to model was the handrail because its balusters have a distinct shape. In this case, specific handrail families were created.

Both cases showed us that the solution is not the same for all situations. It is often necessary to decompose the geometry to be modeled and to use various techniques and tools to get an ideal model. The non-uniformity of geometry and imperfection, which are present in reality, are points to be considered so that the adopted decisions and approaches are made consciously. It is important to carry out the modeling carefully with attention paid to the detail of the building so that the model matches the building geometrically and visually and meets the client’s needs.

3.2.2. Automation in Topography Creation

Complex construction elements need to be modeled and analyzed accurately and on time. This goal is pushing researchers towards the search for automated solutions in BIM data generation. During the last five years, the publications in BIM automation have grown around 400% (229 paper from 2014–2019 and 57 paper from 2009–2013, retrieved on SCOPUS using the keywords BIM and Automation). However, there is a disconnection between industry practitioners and researchers, particularly on the criteria guiding the implementation of BIM in the construction industry [

38,

39]. These mainly affect the implementation/integration of automation on real non-modular contexts. Complex forms, multiple morphological, and typological variables remain primary barriers to standardize automated solutions in BIM modeling. However, there are substantial chances the increment in processing capabilities, and new knowledge in graphic and computer vision will bring reliable standard solutions in the short-term future. Within automation for BIM, Topography modeling has received extensive attention, and scientific developments have been efficiently implemented in commercial solutions. The topography around the case study building had a few slopes and deformations, yet manual modeling still meant excessive work and inaccuracy. To avoid errors and to save time, an external plugin installed on Revit called “Scan Terrain” was used. This plugin allows us to create a topographic surface from the point cloud automatically. Users can define the size of the crop within the cloud, the distance between the created points and the height limit of the points that will be on its surface.

In this way, the topographic surface can be created in seconds, but it is essential, nevertheless, to perform a visual inspection and correction of some points that may have been created incorrectly. The plugin algorithm can identify horizontal surfaces and avoid vertical elements such as walls and furniture, but some elements such as steps, floors, and plants can still be confused with topography. The lack of regularity in the point cloud, the presence of areas that were not well captured by the scan and half-height vegetation were also interfering in the proper plugin’s functioning. Therefore, for best results, a preliminary point cloud cleaning is required, and after the topography is created, manual adjustments are required. Still, this method proves to be very efficient in delivering a model with high quality and accuracy and saving modeling time.

3.2.3. Results and Discussion

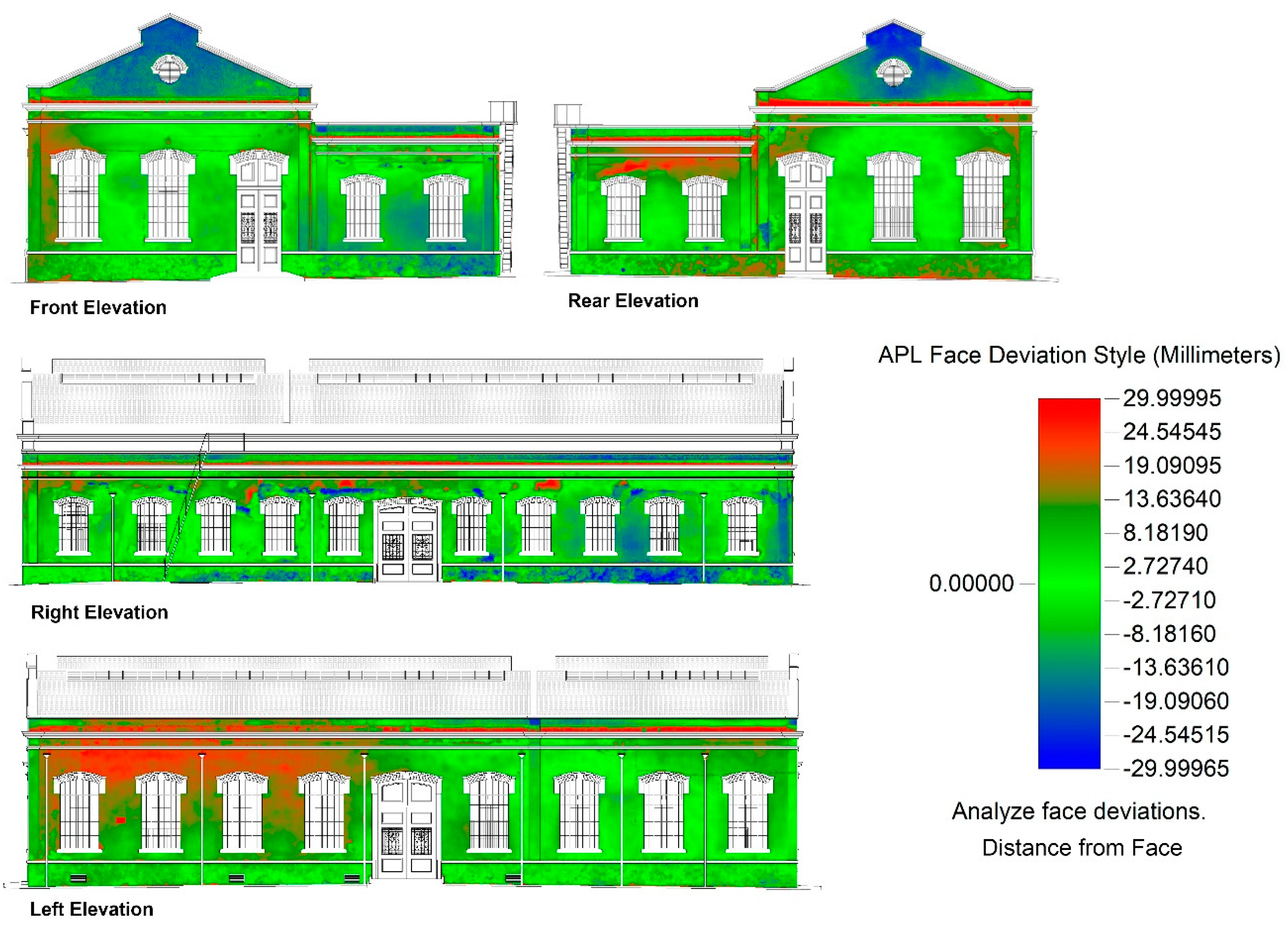

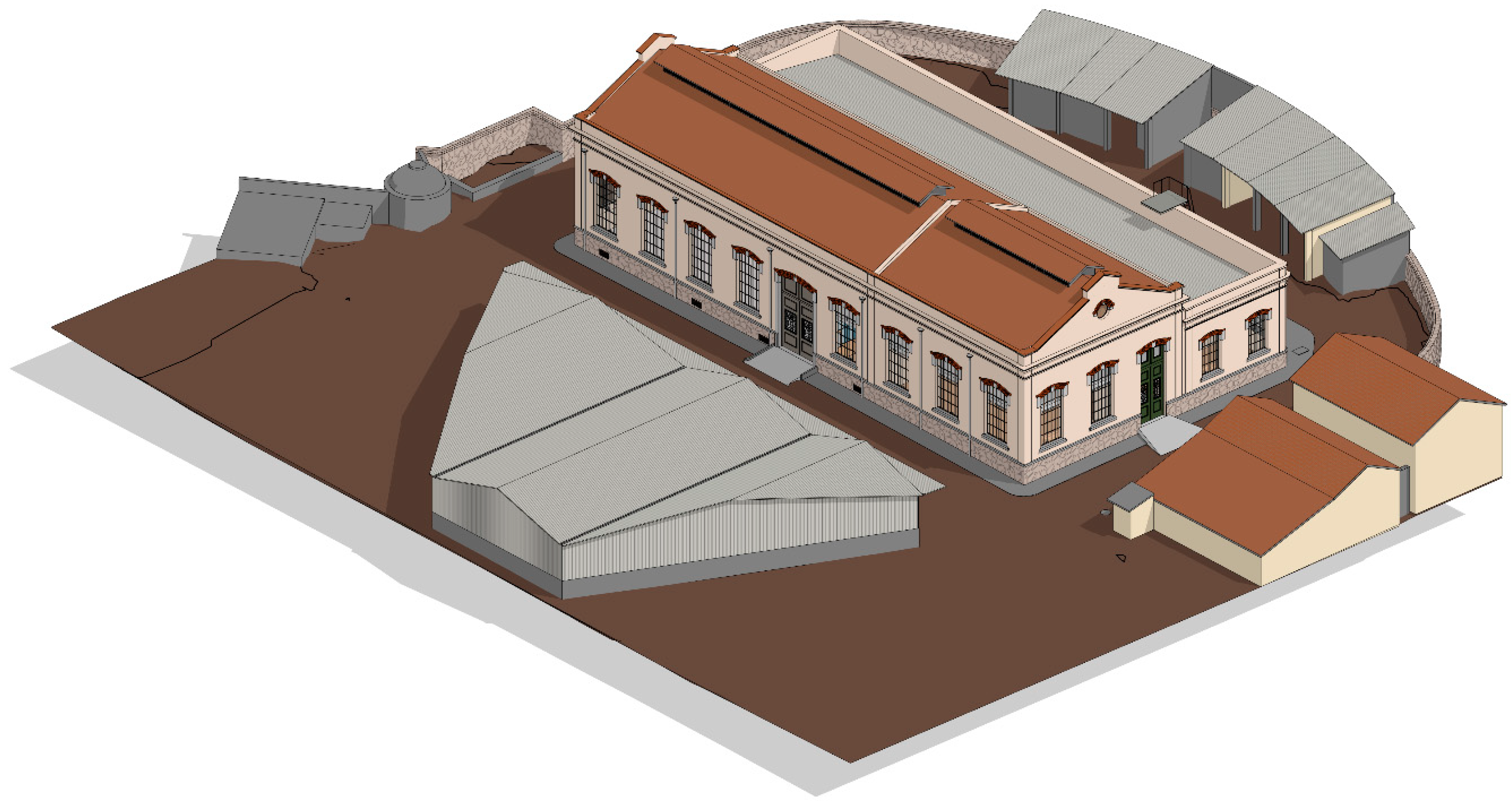

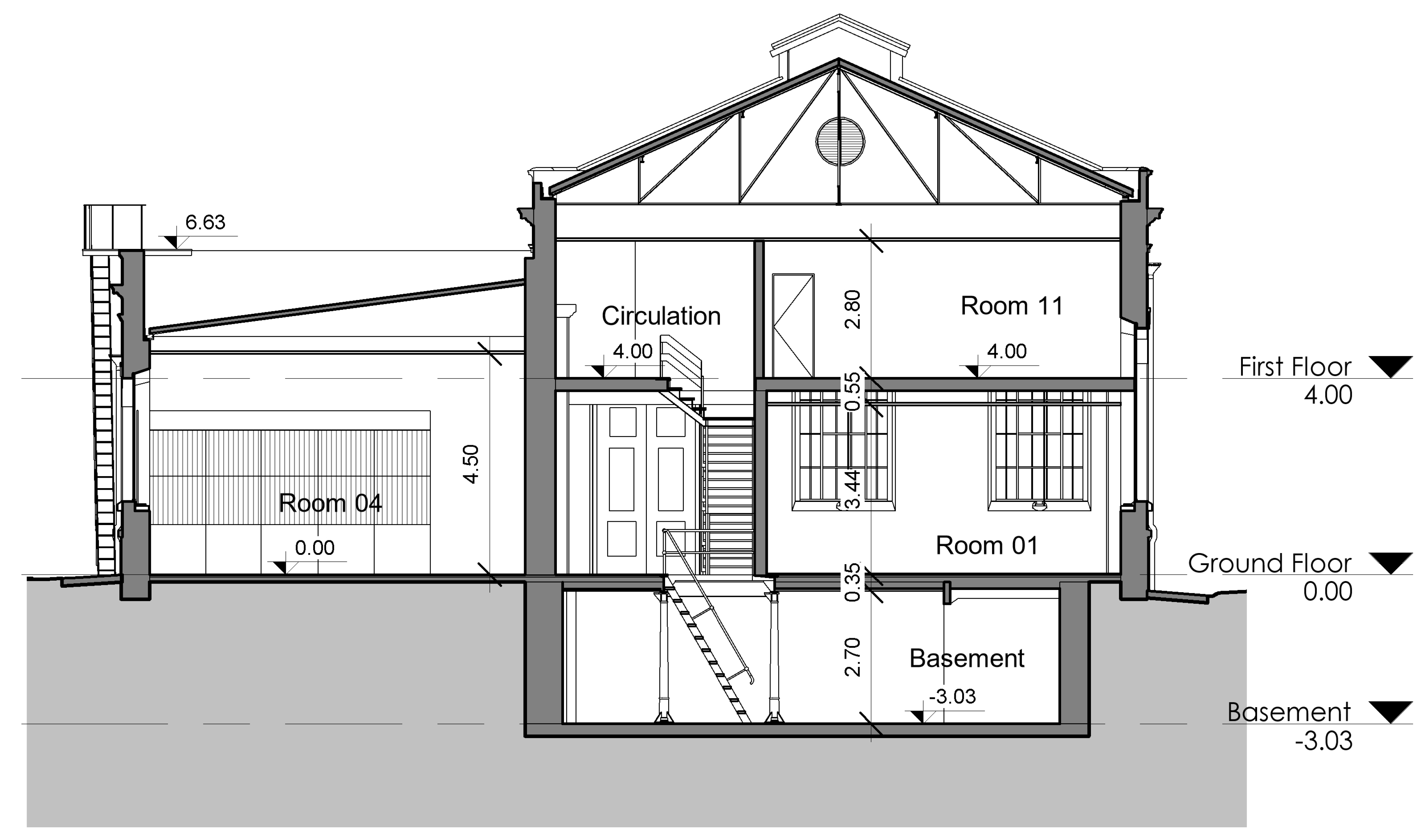

At the end of this modeling process, a BIM model with high accuracy and precision (

Figure 11,

Figure 12 and

Figure 13), with a level of detail between LOD 300/350, according to the document G202—2013—Project Building Information Modeling Protocol Form from AIA [

40], was obtained, thus integrating it with a restoration work methodology and enjoying the benefits that BIM brings to these projects. In addition to containing all the architectural elements, the final model also had the modeled structural building elements, roof, and stairs. Parametric families have been created for doors and windows, allowing them to be used in similar projects, simultaneously creating a verified library. In addition to the HBIM model, the complete set of plans with the floor plans (

Figure 14), sections (

Figure 15), and elevations were generated. The scan-to-BIM process proves to be extremely efficient when dealing with historic buildings as it not only saves a lot of field time in the survey, but also saves time in the office by using BIM software to do the three-dimensional reconstruction of the architecture as well as the technical drawings needed.

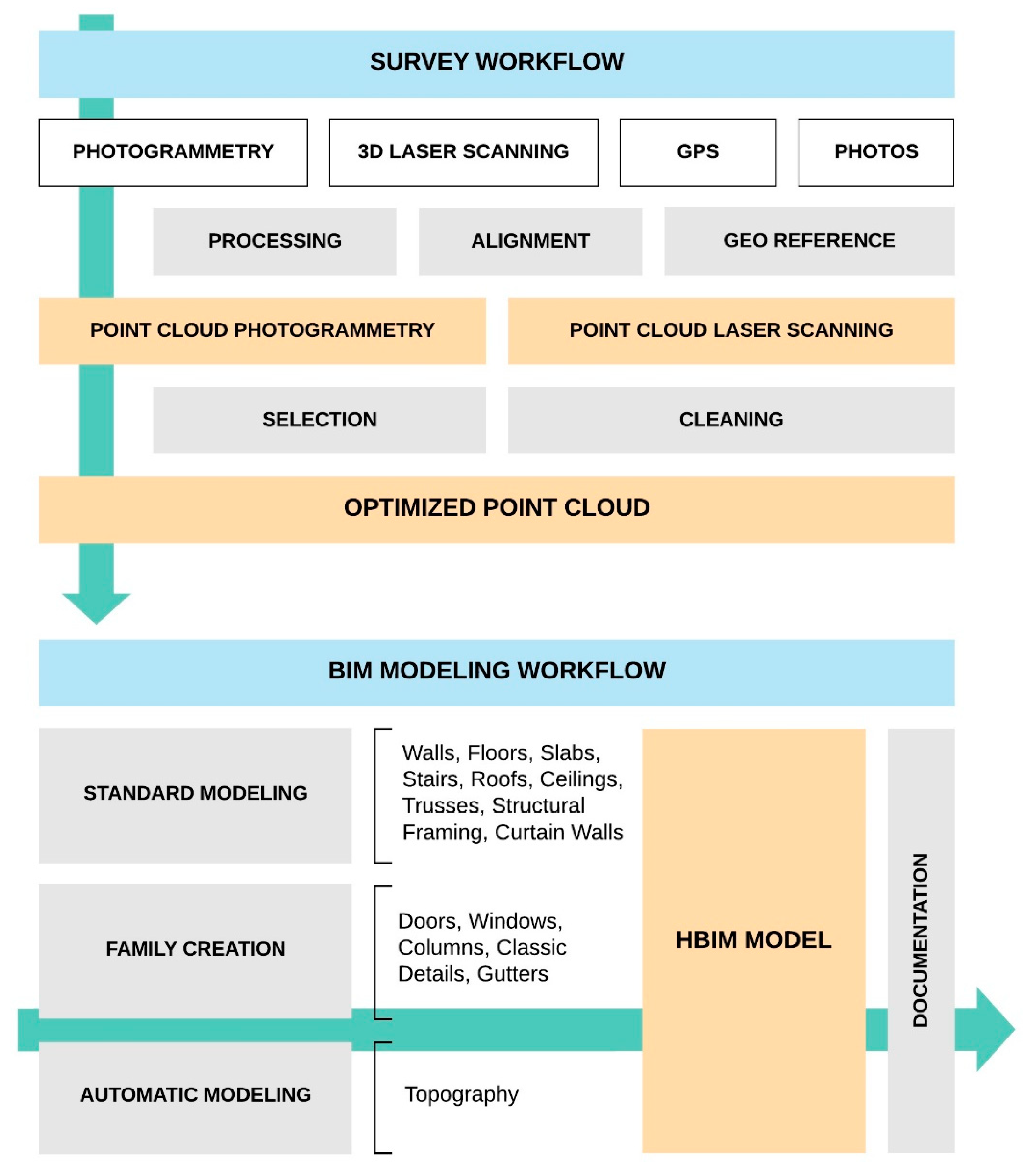

The proposed workflow (

Figure 16) (

Table 1) consisted of creating a BIM model that is prepared to have its level of detail increased if necessary in the future. Some of the elements were modeled in more detail, reaching the LOD 350 (trusses, doors and windows), while others stayed on the LOD 300 (walls and floors). This was due to the impossibility of checking the materials that constitute the core of some elements. Thus, their model was restricted to its dimensions, size, positions, orientation, and finishing materials, but without a distinction between the inner layers. The final model, besides the geometric reconstruction of the building, contains all the elements classified according to its use, with their finishing materials and structural and support elements when possible. The BIM model is not static; the LOD can be increased by updating geometric and non-geometric information (such as physical and material performance characteristics, costs, manufacturers, compositions, and others) at any time.

With this methodology established and applied, it is possible, in a second moment, to explore other specific points of the process, such as the modeling optimization of other building elements. Besides, there is a significant expansion potential when working with multidisciplinary teams to broadly approach the BIM methodology within heritage projects.

Scan-to-BIM mostly remains a manual process that consumes a lot of time and effort from users. This need for the manual approach is due to the enormous amount of data needed to be managed, the difficulties and challenges of rebuilding occluded parts of buildings, and the lack of semantic information in point clouds [

25]. Automation of modeling optimization has been a recurring research topic and has had little progress so far. One challenge is the variety of building typologies contrasted with the requirement of a universal approach that meets all of them. Another one is the ambiguity and errors in the data collected [

41,

42]. Walls are one of the possible points for conducting automation experiments, as they have few parameters and little variation in their shapes [

25,

43,

44]. It is also possible to think of approaches for the automatic generation of more complex geometries such as façade details, ornaments, and vaults [

2], because, in these cases, creating models with manual processes can be very laborious.