Abstract

Vast and important cultural resources are entrusted to magnetic tape around the world, but they are susceptible to degradation, which may lead to severe replay problems. Audio magnetic tapes are complex and multicomponent devices containing organic compounds and metal systems, which can be potential catalysts for many degradative reactions in the presence of water, light, or heating. The aim of this review is to collect the literature concerning the analytical determinations and instrumental approaches that can achieve the chemical identification of the components in the tape and the degradation state. Thus, a combination of destructive (such as acetone extraction) and non-destructive techniques (such as ATR FTIR spectroscopy) have been proposed, together with SEM, ESEM, XRD and TGA analyses to assess the chemical and physical characterization of the tape with the purpose to individualize restoration treatments and optimize conditions for preservation. The impact of the studies reviewed in this paper may go beyond audio, being potentially relevant to video, data, instrumentation, and logging tapes.

1. Introduction

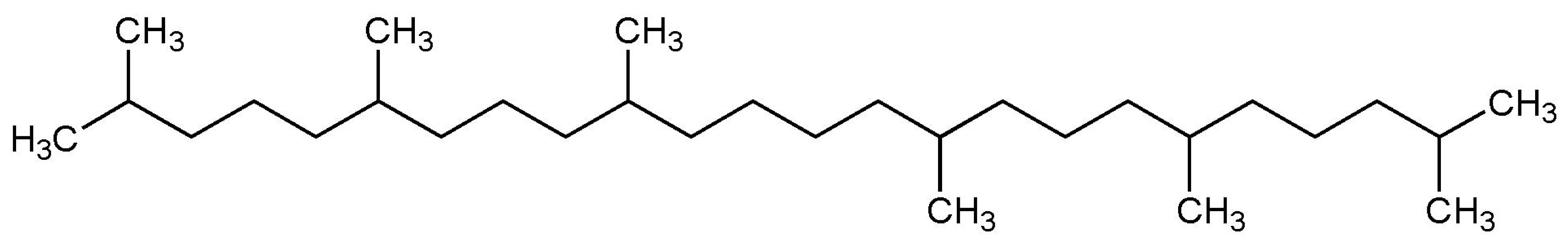

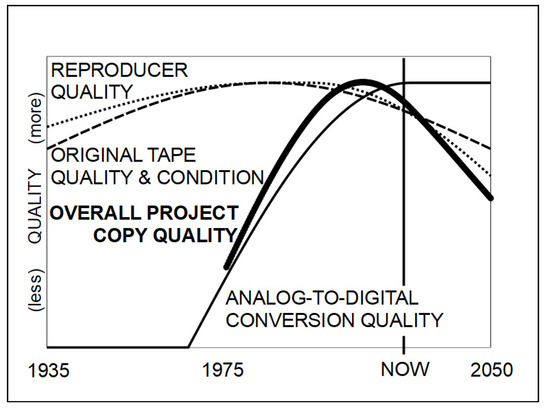

Analog magnetic audio tape recording was first proposed in 1878 and became a practical product in 1935. From 1947, it was the primary method of audio recording until challenged by digital recording (often still relying on magnetic tape) in the 1980s. It also influenced information storage in multiple environments as the technologies originally designed for audio were adapted to other uses1 [1]. Vast and important cultural resources are entrusted to magnetic tape around the world. In 2001, Dr. Dietrich Schüller defined the challenge, “The world’s stock of audio recordings is estimated to be more than 50 Mh (million hours) of materials…unique memorable and non-repeatable events, but also traditional and folkloristic music, as well as other bio-acoustic [material, and material of oral tradition, given its scientific, cultural, historical, juridical, social, and economic value. None of these recordings are on permanent carriers…” [2]. It is this challenge that informs the present study. In 2008, Hess attempted a review of the broad range of factors affecting tape life (Figure 1) [3]. A webpage collects reports from the field to keep the 2008 paper updated2.

Figure 1.

Conceptual time line of restoration quality.

There are many factors that complicate any chemical analysis of tape degradation. A primary consideration is that a tape is not a single homogeneous object (with the exception of some early German tapes during 1943–1954 that included the magnetic particles embedded in a Polyvinylchloride (PVC) substrate). The vast majority of tapes are made with at least a base-film layer and a coating that holds the magnetic particles on one face of the tape (mag coat). In the late 1960s, tapes with a third coating, on the face opposite the mag coat, came into prominence for high-end mastering uses. This back coat improved the winding of the tape and also was conductive, reducing static electricity charges.

Prior to the widespread use of tape as we know it today, both steel tapes and wires were used for magnetic recording. The first coated tape was introduced in 1935 in Germany with an acetate base. In 1943, an industrial accident destroyed the IG Farben tape manufacturing plant that made the acetate tape. The experimental homogeneous PVC tape was brought on line and was the mainstay into 19463. As the tape technology was brought to the United States by Mullin, Ranger, Orr, and others, Orr and Minnesota Mining and Manufacturing (3M) began making tape. Orr was ordered by General Eisenhower to provide American made tape for the Allies’ use after incomplete erasure of a German tape had Eisenhower’s and Hitler’s voices mixed in a broadcast. 3M’s first tape was on a paper base in 1947, but type 111 was introduced on an acetate base film in 1948 and was produced for about 25 years4.

Audio tape is generally made with either acetate (note that 3M refers to this as “plastic”) or Polyethylene terephthalate (PET) base films Mylar, Tenzar, Polyester, etc.), with small quantities of paper and PVC (both homogeneous and coated) also used early on. While not employed for analog audio tapes, some video and data tapes use a Polyethylene naphthalate (PEN) base film.

While the long-term stability of the base film is obviously very important, many of the degradations appear to occur in one or both of the coatings or the interaction between the two coatings. To a lesser extent, the adhesion of the coating to the base film may reduce tape life, and some acetate based tape has base film degradation issues. The major failure modes for PET based tape appear to be mag coat degradation. The influence of the back coat on that degradation (or the degradation of the back coat) is still not fully understood. Richardson persistently advances his theory that the back coat alone is the bad actor and that, after its removal, tape life is extended [4]. The process has been patented [5], but there appears to be no commercial operation regularly performing this restoration technique.

1.1. Challenges

The challenges to any successful study is that current tape archives date back to the late 1940s (only a small portion of tapes pre-date that) and many of the degradations do not become problematic until many years after the tape was manufactured. Several factors were discussed at the June 2018 AES International Conference on Audio Archiving, Preservation & Restoration held at the Library of Congress Packard Campus in Culpeper, Virginia. There seemed to be some consensus that the challenges affecting the research into the chemical breakdowns are many, including:

- Original formulations were and are considered trade secrets

- Audio tapes are rarely marked on the tape as to manufacturer and type

- Audio tapes often are placed in different boxes than they came in

- There were running changes during production

- There were process control variations

- There were different storage conditions

The first three points create confusion as to the manufacturer and type of any tape being studied. While one might assume that analysis such as FTIR can uniquely identify a particular tape, the last three points challenge this possibility. As Hess [3] pointed out:

Benoît Thiébaut, in his presentation to the 2005 AMIA conference, indicated that he had found a range of video cassettes with the same type designation comprised of four clearly different chemical formulations [6]. In discussing this result with Bob Perry5, he stated that one would never see this much variation in a particular type number during the time he was at Ampex (1969–1992). Scotch/3M was open about the variations in type 1116. Bradshaw indicated7 that aging could possibly create some of the differences found by Thiébaut and that additional analysis would be beneficial. He also indicated the potential for seasonal changes and the difficulties of moving a successful tape line from one climatic location to another. Outsourcing further complicates this analysis, as the box may have one brand on it and the tape may have been manufactured at another facility.

1.2. Goals

One of the oft-stated goals of research into tape degradation is to provide a toolkit to easily and inexpensively categorize the current condition of the tape and its likelihood to degrade in the near term, thus prioritizing making a digital preservation copy.

A second goal is, if degradation is observed, to suggest the correct method of treating the tape prior to making a digital preservation copy. This is important because treatments that can benefit one type of tape may damage another.

As outlined in the previous section, even if the tapes were slit from the same “jumbo” roll, there are factors which could result in tapes behaving differently after years of storage, thus any proposed tests need to be sensitive to the current condition. Figure 2 shows a typical analog audio tape machine.

Figure 2.

Studer A80-RC tape machine with an Arnold B-1022 Magnetic viewer at the ready and an EdiTall splicing block.

1.3. Related Fields

While this paper discusses studies focusing mostly on audio tapes, it is important to realize that collections may hold a mix of tapes which may appear similar but are separated by a variety of factors. Sometimes it is not easy to determine which category a tape falls into due to their visual similarities. While this is in no way an exhaustive list, it is a first pass at separating the different branches of tape recording as it evolved, which should be informative to those curating magnetic tape cultural heritage. Conversely, studies from other branches can also inform decisions for audio tape.

As stated previously, audio recording on magnetic tape began in 1935 and grew slowly due to many factors, not the least of which was World War II. However, by the end of the 1940s/early 1950s, it was exploding. Between about 1950 and about 1960, what started as analog audio magnetic tape split into five major branches (including audio). It is often convenient to address these four additional branches separately, as they morphed to do different jobs.

1.3.1. Data Tape

Stacks of Hollerith (later IBM) punched cards were the normal way of storing data in 1950. The Hollerith cards were patented in 1889 [7]. Hess recalls a summer job in 1968 where they were still being used. By 1952, IBM had delivered the first modern data tape drive. This was a fully implemented drive, complete with vacuum columns (the equivalent to tension arms on an audio machine, and implemented on a few high-end video machines) to allow rapid tape acceleration under program control. These machines recorded seven (later nine) tracks on 12.7 mm (half-inch) tape on 270 mm (10.5 in) reels [8], although their hubs were incompatible with the familiar NAB audio tape hub8 [9].

In the 1980s, data tape migrated to mostly single-reel cartridges that were able to be utilized in robotic library systems. This remains how vast amounts of data are stored in many operations. IBM originally had their data tapes manufactured by the audio tape manufacturers, but found they needed better quality control [8].

1.3.2. Instrumentation Tape

Instrumentation tape was developed as a spinoff of audio tape for recording signals for the United States Air Force in the early 1950s. These signals were telemetry from test flights. The Inter-Range Instrumentation Group (IRIG) has been developing standardized telemetry requirements since the mid-1950s. Instrumentation tapes became widely utilized outside of aerospace and can be found recording signals from seismometers, vibration and other sensors in structural and machine engineering, and bio-medical research [10]. For example, all the telemetry, including the low-scan-rate video, from the moon landing in 1969 was recorded on 14-track 25.4 mm instrumentation tape. Alas, those tapes of the moon landing were not preserved, and only lower quality scan converted broadcast signals were retained9.

IRIG instrumentation tapes look like audio tapes. The reels are the same; the tape width is generally 12.7 mm or 25.4 mm. The speeds look familiar to audio users, but contain a wider range, generally between 11.9 mm/s (15/32 in/s) and 6.1 m/s (240 in/s). The equalization is such that the speed can be slowed down or sped up at will without changing the relative response. The common track counts are 7, 14, and 28 tracks. Frequency modulation (FM) recording is part of the standard, extending the low frequency response to DC. Many of the failure modes found in audio tape exist in instrumentation tape. Instrumentation tape is an analog recording while data tape is a digital recording.

1.3.3. Video Tape

In 1956, Ampex introduced the first professional video tape recorder, the VR-1000. It used 50.8 mm (two-inch) tape and recorded tracks across the width of the tape via a spinning head. Because of the four heads on the rotating headwheel (14,400 rpm), it was called the quadruplex system. This format was still being used in 1990 at some smaller market TV stations. The second major format in North America (and elsewhere) was the SMPTE Type C helical format which used 25.4 mm (one-inch) open reel tape. These video tape reels had the standard NAB hub designs.

There have been over 100 different video tape formats, and the reference attempts to list them all along with their salient characteristics. Obviously, recovery of video tapes is a whole different art from audio with its own set of challenges and failure modes, but many of the same basic tape-oriented problems are similar10.

1.3.4. Logging Tape

Logging tapes are really audio tapes, except, they will not play on normal audio tape machines. These tapes are on 270 mm (10.5 in) NAB standard audio reels and are generally 12.7 or 25.4 mm in width. Tape length per reel is 1100 m (3600 ft.) and, with the tape running at 11.9 mm/s (15/32 in/s) provides over 25 h of recording allowing continuous recording with one tape per day with reasonable overlap with two recorders. The bigger challenge is that a typical logging tape may contain 40 or more channels/tracks on a 25.4 mm wide tape, plus a time code channel. One tape could hold 960 h of material (24 h × 40 tracks). This is a very obscure area of recording but is worth mentioning as logging tapes do show up in archives.

1.3.5. Beyond Reels

There is roughly a 30-year period from approximately 1980 to 2010 where a stupendous variety of dedicated formats were designed for audio, data, instrumentation, video, and logging purposes, and the reel-to-reel machines were replaced. Many of these players had special features that are not easy to replicate. While many of the tape degradation factors apply to these later tapes, finding working reproducers for recordings made roughly between 1980 and 2010 is a far bigger challenge than the tape degradation at this point. In audio, DAT is far more at risk than open reel analog.

The analysis and remediation of tape failure modes are an important part of the work in an archive, however, the tape is only part of a system, and the availability and viability of the entire system is required to recover the content entrusted to the tapes.

Many projects have been promoted and carried out around the world to preserve the magnetic archives [11].

Examples are the PrestoSpace project [6] and the FACET project [12]. PrestoSpace involved a significant amount of chemical research and attempted to map out how much European audiovisual material might be lost by 2015 (the prediction was 40%). The FACET project was a survey and assessment tool which looked at individual collections within larger archives at Indiana University and scored them based on their long-term risk of deterioration. After completing a portion of the survey, Indiana University was convinced to start an organized, all-inclusive media digitization process11.

Different perspectives are involved in a preservation project: (a) the digitization of the formats which would be realized within 15–20 years not to lose information due to deterioration of tapes, even if the amount of material is enormous [13,14]; (b) the disclosure of archives (taking into account also legal implications); and (c) the preservation of the tape as objects themselves [15,16].

Over time, great attention has been paid to the restoration of video tapes and data archives with the objective to digitize them, while much less interest and studies have been devoted to the restoration and preservation of audio material.

The aim of this paper is to review the scientific literature (academic and professional, including patents) concerning the analytical methods to identify tape formulations in terms of chemical components, the typology and origin of the degradation processes [3], and the known and applied remediation methods.

2. Composition of Magnetic Tapes for Audio Data Storage

Starting from the historical paper strips with iron particles, a search to improve the performance of magnetic recording tapes was carried out to increase the recording density, coercitivity, and mechanical properties according to the tape player technology [17,18,19]. For example, when video tape was introduced in 1956, the popular acetate tape would not sustain the high head rotation velocity. New tape formulations were required and PET-based tapes were used from 1956 forward for video recording.

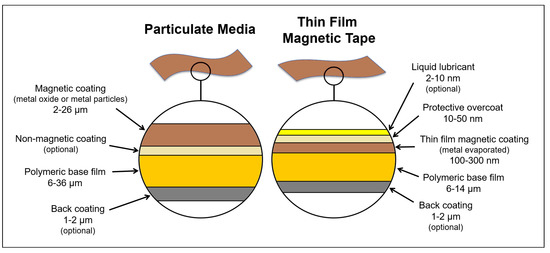

The structure of magnetic tapes is shown in Figure 3. The tapes considered to be inherently stable by JASA and which should be copied are: Standard play tapes (36–38 m base film with about 52 m total thickness), Long play tapes (24–25 m base film with about 35 m total thickness), Double play tapes (12–13 m base film with about 26 m total thickness) and triple play tapes (12–13 m base film with about 18 m total thickness). It is worth noting that thin film (evaporated) tapes have not been used in audio, and are most widely used in data storage.

Figure 3.

Scheme of the structure of audio magnetic tapes.

It was calculated that magnetic recording tapes consist of approximately 20% by weight of magnetic material (metal oxide or metal particles) and remaining 80% wt of polymeric material. The composition by volume is about 40% magnetic material, 40% polymers, and 20% minute pores (responsible for noise), which are necessary to prevent adhesion of the tape surface to the recording head of any playback equipment.

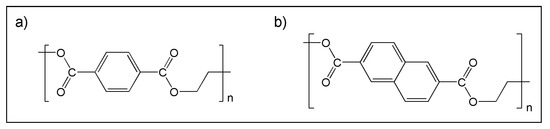

(A) The polymeric base film, which provides the mechanical properties and is responsible for the physical integrity of the tape, is a polymeric material that has been of different nature during the time [20], as shown in Figure 4, Figure 5, Figure 6 and Figure 7.

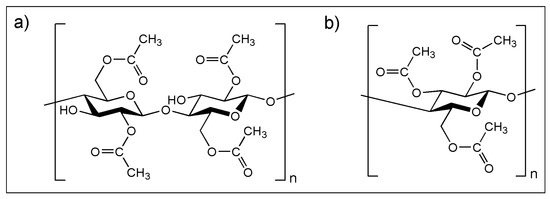

Figure 4.

(a) Cellulose acetate (used from 1935 to1972/73; examples: Ampex 611 and Scotch 111), hydrophilic and soluble in many common solvents; and (b) cellulose triacetate (CAS number 9012-09-3).

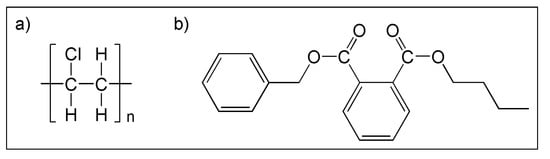

Figure 5.

(a) Polyvinyl chloride (PVC) (CAS number 9002-86-2; used from 1943–1969; manufactured particularly by BASF); and (b) benzyl butyl phthalate (BBP), one of the most used plasticizer for PVC.

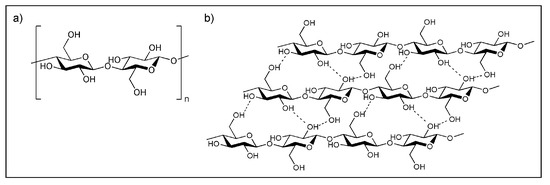

Figure 6.

Paper (used from 1947 to 1953; examples are Scotch 100 and 101): (a) Cellulose, the major constituent of paper; and (b) a strand of cellulose where hydrogen bonds bind cellulose molecules.

Figure 7.

(a) Polyethylene terephthalate (PET) (used from 1953, it is the only one in use; an example is Scotch 102); and (b) polyethylene naphthalate (PEN).

Cellulose diacetate polymer was used from the beginning of 20th century until about 1940, when it was substituted by the completely acetylated derivative, which is more thermally and chemically resistant than the diacetate. From 1943, in particular by BASF, PVC was used. Pure it is rigid, but can be made softer and more flexible by the addition of plasticizers, the most widely used being phtalates. Typical characteristics of PVC are high hardness and good mechanical properties; poor heat stability but good flame retardancy; and chemical resistance to acids, salts, bases, fats, and alcohols. Some solvents may only swell it but not dissolve it, but some, such tetrahydrofuran or acetone, may damage it. Very thin paper, which he coated with iron oxide powder using lacquer as glue, was used by Pfleumer (1881–1945) in 1928 to patent the first magnetic tape. Cellulose, the major constituent of paper, is a material chemically stable, but fragile and subject to tearing or breaking upon playback. From 1953, PET was used for its good chemical and mechanical properties sometimes substituted by polyethylene naphthalate with strength and modulus, chemical and hydrolytic resistance, gaseous barrier, thermal and thermo-oxidative resistance, and ultraviolet light barrier resistance higher than PET.

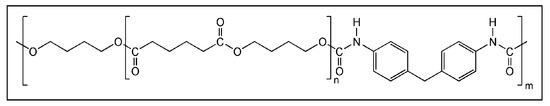

(B) The binders containing the magnetic particles (in particulate media) are typically polyester–polyurethane materials (PE-PU). The enormous number of formulations (different n and m values in Figure 8) give different polymers with specific chemical, physical, and mechanical properties [21,22,23] The amount of binder must be as low as possible, but sufficient to bind the high quantity of metal particles. It contains a hard part, given by the polyurethane chain (with high Tg, sometimes crystalline), and a soft one (with relatively low Tg), the polyester. The relative amount of soft and hard microphases, the degree to which they can separate and the resulting morphology have a strong effect on the copolymer’s ultimate properties and ageing [24].

Figure 8.

The structure of polyester–polyurethane materials.

In addition, polyurethane/polyisocianate as binders, and for certain products also cobinders (such as PVC or phenoxyresins), have been used. Isocyanate moieties are very sensitive to moisture: with water, the formation of an interpenetrating polyurea in the polyurethane matrix can occur [25]. The need of high density recording required using higher magnetization retentive Co-epitaxial, -Fe2O3 powder or -Fe powder in place of conventional -Fe2O3. Thus, the interfacial properties between the magnetic powder and the binder polymers had to be improved, being good dispersion, high packing and high orientation of acicular magnetic particles important factors. It was reported that a small amount of active functional groups in polymers improved the dispensability of -Fe2O3 and the magnetic properties of the magnetic tapes, anchoring the particles to the surface. The order of interaction force of the functional groups to -Fe2O3 was the following [26,27,28,29,30]12.)

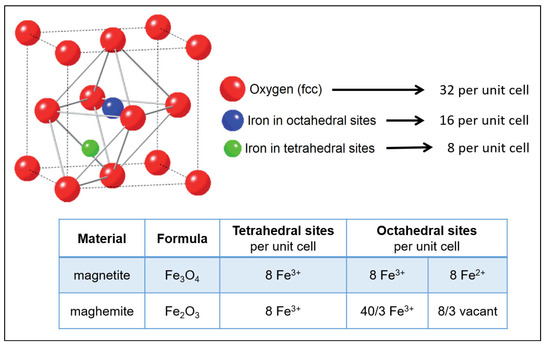

−PO3H2 > −SO3H2 > −COOH > −OH > epoxy moiety > −CN

(C) Magnetic particles: The most common particles are -Fe2O3 (Hc 250 Oe13), CrO2 and Co-doped -Fe2O3 (Hc 600 Oe) increasing both the regenerative output and recording density. CrO2 provides higher signal output than Fe2O3, but it is harmful to the polymer being an oxidant. To achieve high density recording applications, magnetic particles made from Barium ferrite particles, iron alloyed with Cobalt and Nickel have been used (in particular for data storage). Higher concentration of magnetic material in a given binder volume allows higher coactivity and magnetization [31]. The magnetic layer also contains lubricants (fatty acid esters) and small amounts of pigments as abrasives (Al2O3 or SiO2) which can cause damage to magnetic heads [32]. Metal magnetic powder was also widely employed instead of oxide magnetic powder to improve the performance further with Hc of about 1500 Oe [33]. Metal iron particles can give oxidation, forming oxides, hydroxides or oxide-hydroxides (collectively referred, usually, as iron oxides) which consist of close packed arrays of O2− anions in which the interstices are partly filled with or in octahedral (Fe(O, OH)6) or tetrahedral (FeO4) coordination. The various oxides differ in the way the basic structure units—Fe(O, OH)6 or FeO4—are arranged in the space.

The most common oxides, and present in nature, are goethite -FeOOH (the most thermodynamically stable at ambient temperature and, therefore, the first to form or the end member of many transformations, yellow brown, orthorombic structure, antiferromagnetic, d = 4.26 g cm), lepidocrocite -FeOOH (orange colored, orthorombic structure, antiferromagnetic, d = 4.09 g cm) and hematite -Fe2O3 (blood-red colored or black if finely divided, rombohedral hexagonal structure, weakly ferromagnetic or antiferromagnetic, d = 5.26 g cm).

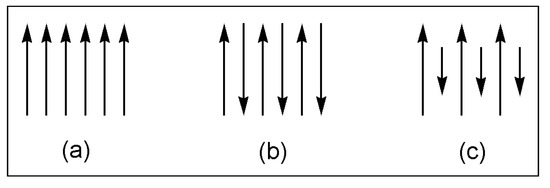

The most important iron magnetic oxides [34,35,36,37] are magnetite (Fe3O4) and maghemite (-Fe2O3), as shown in Figure 9. Magnetite is a black ferrimagnetic oxide containing both and ions forming two interpenetrating magnetic sublattices: occupies tetrahedral sites and octahedral sites are occupied by both and . Thus, the structure consists of octahedral and mixed tetrahedral/octahedral layers stacked along [111] direction. Below the Curie temperature (850 K), the spins of the tetrahedral and octahedral sites are antiparallel and have unequal magnitude: this causes ferrimagnetism (Figure 10). The spin arrangement is written as Fe3+[Fe3+Fe2+]O4. By controlling the particle size and morphology, magnetites with coercitivity ranging from 30 to 250 Oe can be produced. Particles smaller than 6 nm are super-paramagnetic at room temperature. If particle size of crystal is similar, coercitivity goes from spheres < cubes < octahedra according to the number of magnetic axes along these shapes. Maghemite occurs as a weathering product of magnetite and resembles magnetite in structure and magnetic properties. It is a red-brown ferrimagnetic oxide isostructural with magnetite but with cation deficient sites. The structure consists of two sublattices corresponding to located on tetrahedral and octahedral sites, cationic vacancies compensate for the oxidation of Fe2+ maintaining charge neutrality. Maghemite has a cubic unit cell, each containing 32 ions, 64/3 in both tetrahedral and octahedral sites (Figure 9) and 40/3 vacancies in octahedral sites. Measurement of Curie temperature is difficult because maghemite transforms to hematite (-Fe2O3) at temperatures above 700–800 K (TC has been estimated in the range 820–986 K) [38].

Figure 9.

Structural information on the spinel structure of magnetite (Fe3O4) and maghemite (g-Fe2O3).

Figure 10.

Arrangement of magnetic dipoles for different types of magnetism: (a) ferromagnetism; (b) antiferromagnetism; and (c) ferrimagnetism.

(D) Back coating, with a typical thickness of 1–3 m, provides good tape packing as the rough surface allows air to escape and since it is conductive it aids in dissipating the static charge accumulated during playing and rewinding. It contains carbon black (providing conductivity to drain electrostatic charges from the tape) in a PE-PU binder. It also imparts a certain amount of friction to the smooth carrier foil to facilitate improved winding characteristics.

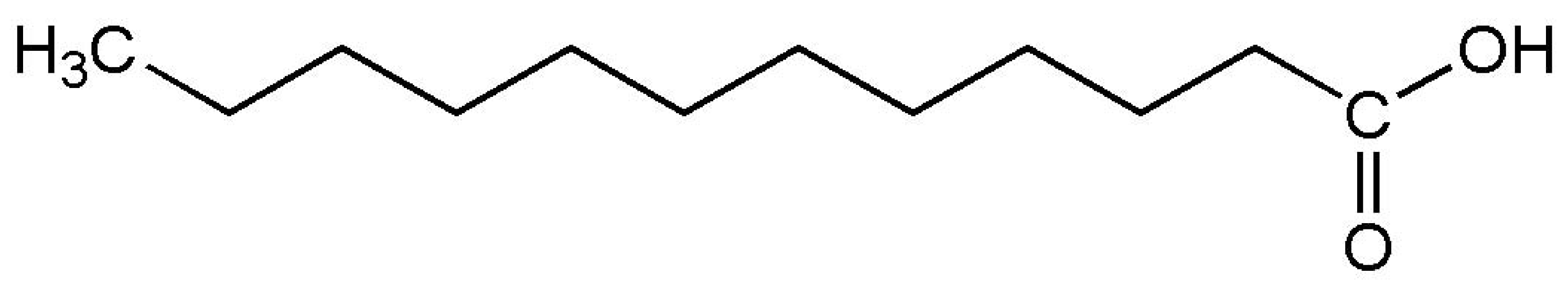

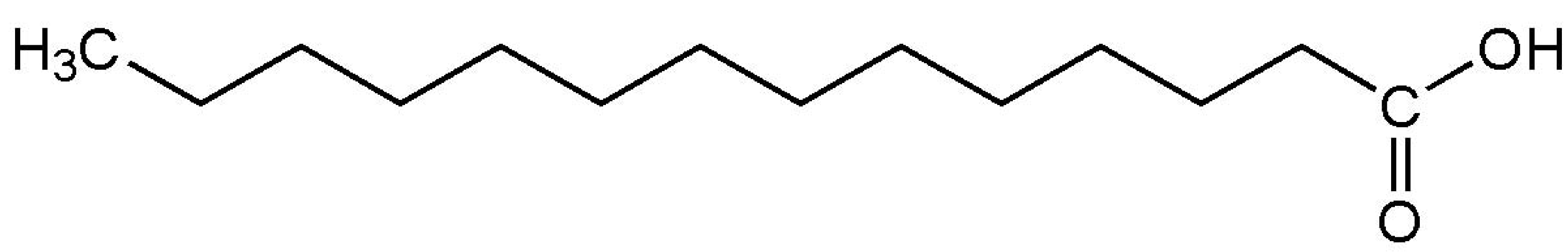

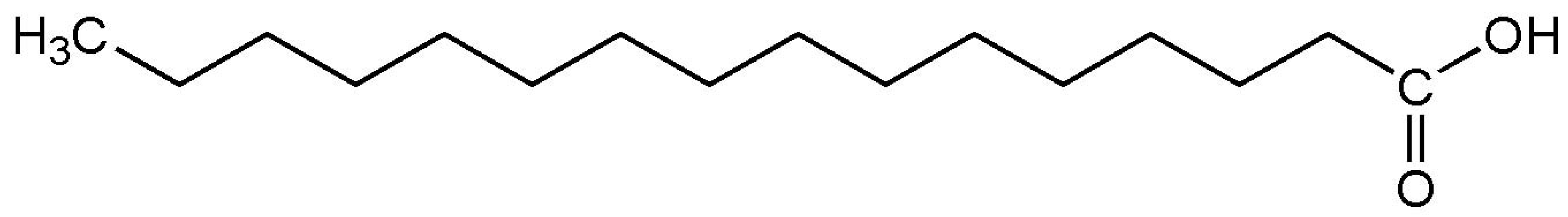

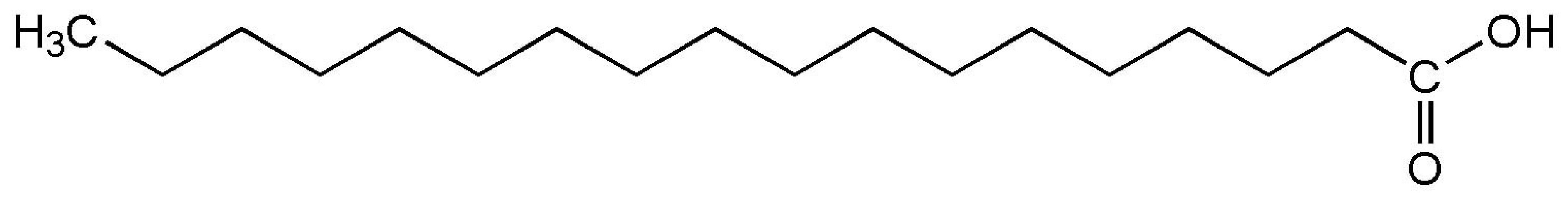

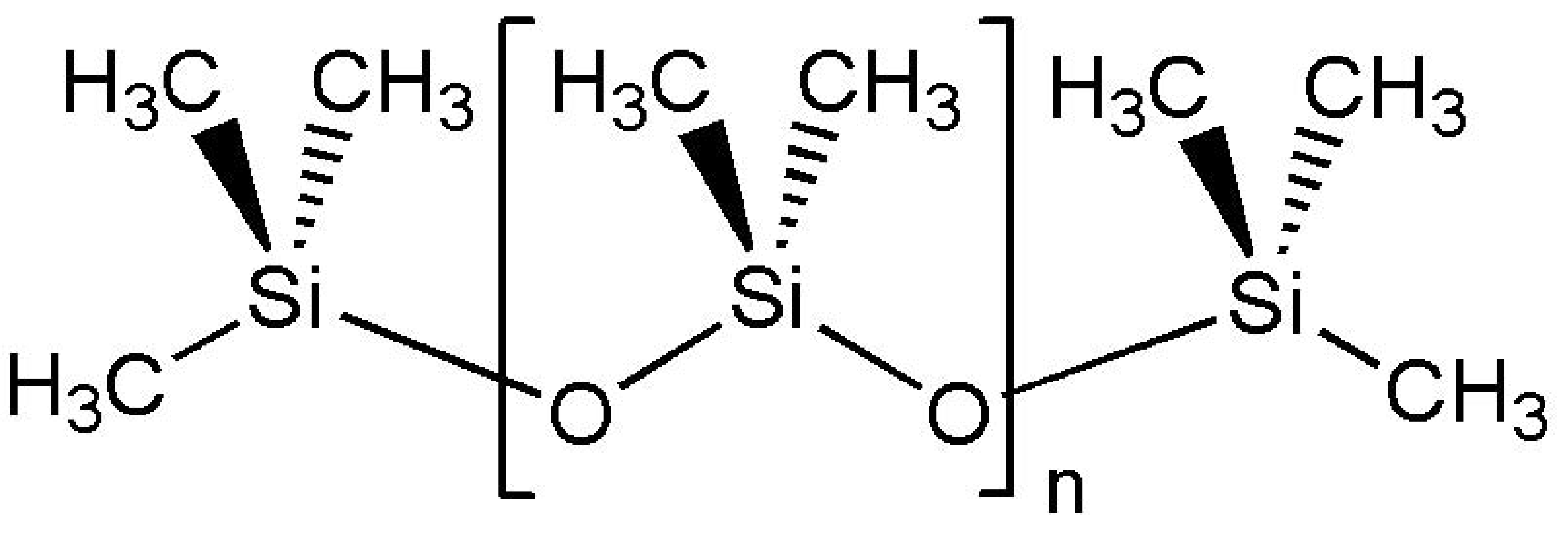

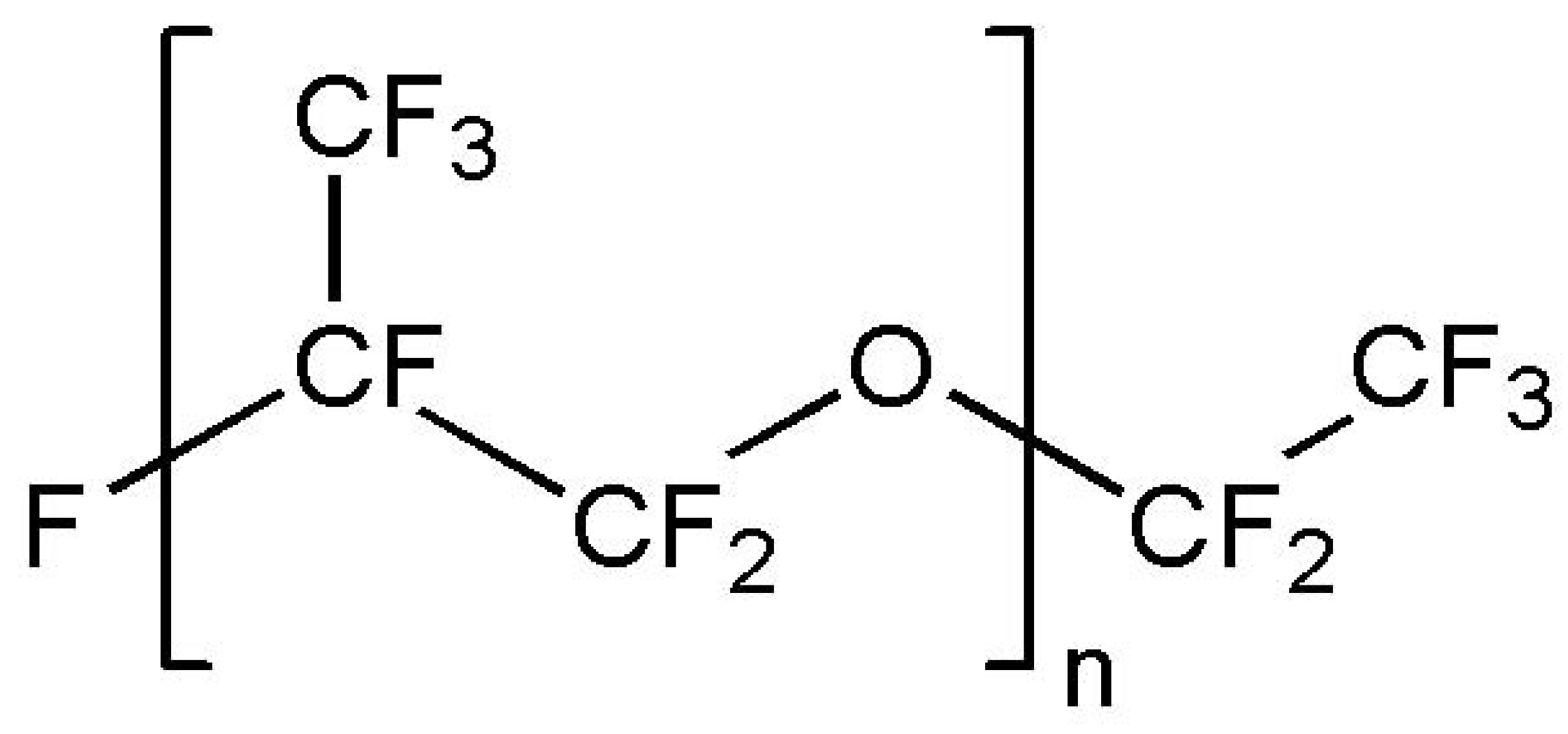

(E) Lubricants: They can be of different chemical nature, in particular fatty acids (more widely used myristic, lauric, palmitic, and stearic ones (Table 1); ester of fatty acids (including butyl, pentyl, isopropyl, and isobutyl derivatives); paraffinic oils (i.e., linear alkanes such as squalanes); and silicones and fluorinated lubricants have been used. Silicones, of general formula [R2SiO]n (where R is an alkyl or an aryl group), consist of an inorganic silicon-oxygen backbone chain (–Si–O–Si–O–Si–O–) with organic side groups attached to the tetravalent silicon atoms. Fluorinated lubricants are fluorocarbon–ether polymers of polyhexafluoropropylene oxide (PFPE). An example is Krytox working in the range from −90 to . It is chemically inert and does not burn. Synthesized perfluoropolyethers (PFPE) allow not only to have large coverage ratio of the outer most surface by lubricant but also a sufficient amount of sub-surface lubricant. It was also observed that the friction coefficients increased with increasing storage days because the polar lubricant is absorbed with magnetic particles and does not migrate easily to the surface [39,40,41,42,43,44,45].

Table 1.

Some different compounds which are generally used as lubricants in magnetic audio tapes: (a) silicones; and (b) fluorocarbon–ether polymers of polyhexafluoropropylene oxide (PFPE).

To reduce friction between guide and magnetic tape, a novel approach has been proposed by laser surface texturing giving the formation of an air bearing foil [46]. Advanced ultra-high density tapes (usually of PET or PEN) require minimal friction being in contact or near contact with the recording head at high relative velocities. New materials for thin film tapes (aramid systems) and for heads (Al2O3−TiC) have been proposed to minimize the negative effects of debris formation when playing aged tapes [41,47,48,49,50,51].

3. Tape Degradation Problems

It is important to consider when referring to the testing reported in this section that the testing was often done at higher-than-normal temperatures in an attempt to accelerate the degradation processes/reactions. While it is possible that accelerated testing will not identify all potential degradation processes, the lowering of the temperatures will not usually mean that the identified processes will be stopped, but only slowed. The authors realize that some of the testing was done above the recommended storage conditions for the tape, but that was only to more quickly analyze the material, not to stress test it. The reported processes below are all believed to continue at a slower pace at room temperature.

The interface temperature of the sliding surfaces (tape to head) may figure into some of the processes/reactions on a micro level. Bhushan provided a detailed analysis and calculation options. Carrying out this analysis might provide further understanding of these processes if the localized heating is high enough to locally increase the reaction rate [52].

Additives, such as dispersive products to ensure homogeneity of the magnetic particle dispersion, fillers (abrasive as “head cleaning agents”), carbon black for anti-static effect, lubricants, and stabilizers (antioxidant or anti hydrolytic agents) can be present. All these chemicals, in time, depending on their nature and environmental conditions, can modify the structure, the morphology, and chemical and physical properties. The first problem to face is the identification of the components of the tape. A few manufacturers marked their name and type designation on the back of the tape, but this does not guarantee the consistency of production over the long term [53]. Furthermore, in many collections, reels and boxes were separated and different tape types were also spliced together. On the bright side, sometimes information is available concerning where and under what conditions the tapes have been stored [54].

Many studies have been carried out to determine the environmental stability of tapes to evaluate lifetime expectancy [55,56] It was shown that long-term stability of magnetic tape is dependent upon many factors including integrity of polymer binder and oxidation of the metal particles. It is worth noting that the chemical age of a tape cannot be understood exclusively on the basis of the calendar time, but depends on the conditions of storage. Furthermore, it is usually not possible to know the actual manufacture date of an individual tape, but the date on which the tape was recorded is easier to obtain [57].

Immediately, after widespread application of magnetic audio tapes, problems concerning dimensional, chemical, and mechanical stability emerged [58].

The most evident problems, in particular in open reel tapes, which can affect the capacity for reading, can be winding defects, cinching, curling of flange pack, slotted hubs, spoking, deformations of tapes which lie wavy, and edge damage. These damages can originate from mechanical damage or heating during manufacture, storage, or playback. The entity of the problem, which can affect the ability to keep the recording safe, is strictly dependent upon the nature of the base film. Thinner tapes are more prone to breaking, stretching, twisting, or folding, exhibiting physical and mechanical rather than chemical problems more than thicker ones. Poor tape winding can cause irreversible deformations, which may lead to severe replay problems [12].

It is worth noting that also the integrity of the tape edge has been recognized as a key to maintain high performance of reproduction of the recorded signal. SEM should be used to quantify edge quality and AFM to achieve surface height information. Cracking or damage of the mag coat can induce differences in stress distribution for the two edges during tape slitting leaving one of the edges more prone to produce debris than the other [59].

The factors influencing tape degradation are:

- Chemical nature of materials in the tape

- Manufacturing defects

- Temperature and humidity conditions over the life of the tape

- Exposure to liquids, dust, debris, or corrosive gases

- Handling history including frequent access or playback without proper conditioning or on defective equipment

- Exposure to strong magnetic fields

For these reasons, there is no simple method for tape degradation classification, which must be batch specific [3,6].

Storage in light and/or at high relative humidity may lead to the growth of fungus or mold on the tapes. Mold colonies may be either active or dormant (most mold will become dormant below 70% RH [60]), while active fungi will continue to damage the tape. As with other factors, there are subtleties. Florian [61] provided a more nuanced view into mold prevention and The Image Permanence Institute’s Dew Point Calculator makes estimates of risk based on temperature and humidity.14 While light is often cited as a degradation factor for a variety of materials, we know of no studies addressing this with magnetic tape. Best practices recommend storing tapes within closed containers [62], which are generally opaque. Moldy tapes should be isolated from other archival materials to prevent contamination [63,64,65]. It is worth noting that the investigation concerning the degradation of tapes by mold and fungus are actually of relevant importance to study the biodegradation of plastics [66,67,68] also under gamma irradiation [69,70].

The magnetic layer is exposed to mechanical stress during playback more than other tape layers; it also contains different component other than the binder and magnetic particles, which can enable different degradation pathways.

In general, we could consider chemical degradation (due to ageing) involving: (i) the base film; (ii) the binder; and (iii) the magnetic material. The usual consequence of the degradation is decreasing of adhesion of the magnetic material to the base film and this is also accompanied by degrading mechanical properties of the tape-coating system.

3.1. (i) Base Film Degradation

- Acetate tapes, degrade overall by chemical decomposition with formation of acetic acid (vinegar syndrome) promoted by high temperature and humidity, but catalyzed by iron oxide. Acetic acid is able to break the bonds between the polymeric chain, thus the material becomes brittle and shrinkage is observed [3,71,72]. Consequently, the binder containing the magnetic particles separates. In addition, the components of the emulsion can separate and crystalline deposits or liquid-filled bubbles can appear. Heating is especially damaging to acetate tapes, too [3]. The thermal behavior of cellulose acetate was studied: the thermal degradation started with acetic acid formation followed by dehydration. The acid formed catalyzes the further degradation and the FTIR spectra showed that at the original absorptions at 1725 (>C=O stretching), 1375 (C–H deformation) and 1250 (–C–O– stretching) cm decreased and a new band at 1580 cm (−C=C−) appeared, indicating the complete removal of the ester groups at [73]. Acetate tapes should be considered unstable and at high priority for copying.

- PVC: The main way of degradation consists in the elimination of HCl with the formation of double bonds, which in turn can be oxidized to –C=O or –C–OH moieties, in the presence of oxygen and humidity. The polymer undergoes chain scission leading to a gradual deterioration of mechanical properties and chemical resistance. The entity of the HCl loss is depending on the presence of defects in the polymer structure (such as branching or allylic and tertiary labile chlorines).

- PET: Although the thermal stability is high, its sensitivity to humidity and the presence of trace metal ions play a significant role in the rate of degradation [74]. Thermal degradation can occur during processing into film or molded products (at 200–300 ): it can start with a random breaking of the in-chain ester linkage, with formation of vinyl ester and carboxylic end groups. The transesterification of vinyl esters produces vinyl alcohol and acetaldehyde. Extraction of hydrogen can also occur promoted by metal traces giving rise to macroradicals from which hydroperoxides can be formed by reaction with oxygen with further breakdown of the polymer. In fact, even if PET is essentially a hydrophobic polymer, the ester functionality is known to undergo significant hydrolysis in moist, wet or humid conditions; under basic conditions; under UV light; or at temperature above glass transition temperature, resulting in an increase of carboxyl end groups and reduction in the molecular weight [75]. It is assumed that water diffuses into the amorphous region of the polymer where hydrolysis occurs at a rate which depends upon the shape, morphology, degree of crystallinity, relative humidity, and temperature. Experiments concerning the heat and moisture diffusion in magnetic tape packs indicated that they can be described by the heat diffusion equation for a hollow cylinder and thermal and moisture diffusivity coefficients have been shown to be anisotropic and significantly higher in the axial direction compared with the radial one [76].The evolution of molecular orientation and microstructure during and following the deformation of amorphous PET above and below Tg was deeply investigated by URS-FTIR spectroscopy and PM-IRLD, furnishing interesting data concerning the modifications of thin films under stress [77].

3.2. (ii) Binder Degradation

Temperature and humidity have been considered responsible for PE-PU binder degradation.

Hygroscopic properties of tapes have been determined by measuring their weight changes when exposed to changing levels of RH [78,79,80,81]. Many experiments have been carried out to verify the hydrolysis of the PE-PU binders. The PE-PU elastomer is a copolymer containing a large number of ester linkages, which are susceptible to attack by moisture; the dominant mode of binder breakdown is below , in an autocatalytic process. The formation of low molecular weight carboxylic acids imparts a sticky, gummy property to the binder layer. The failures concerning the binder have been identified as sticky shed syndrome (SSS) and loss of lubricant (LoL), but can be unified in the broad term “soft binder syndrome” (SBS) [3]. By exposing tapes to different RH levels, Cuddihy [79,80,82] reported that the primary chemical aging mechanism is the binder hydrolysis which was shown to be accompanied by oxidation. Accelerated ageing has been carried out exposing samples of tapes (Agfa, Scotch, and Fuji) at 100% RH at increasing temperatures (from 50 to ) or exposing over saturated solutions of KF, NaBr and KCl, respectively. Under these conditions, the formation of hydroperoxides was detected using the standard iodometric method. It was observed that peroxides are formed, even in different amounts (minimal below 45% RH) under all the experimental condition tested and their levels decrease over ageing time in days depending on temperature and RH% in a different extent for different samples [83,84]. In all cases, FTIR spectra of the samples showed an increasing absorption in the C–O stretching region (around 1170 cm) due to the formation of esters, alcohols and carboxylic acid groups. It is worth noting that iron oxides are known to catalyze the decomposition of RCOOH moieties. FTIR analysis also indicates a marked growth in insaturation and eventual crosslinking, demonstrated by embrittlement of the material. Kinetic studies demonstrated also that the hydrolytic degradation of PE-PU elastomers is catalyzed by the carboxylic moieties formed [71,72]. Kinetics of the binder hydrolysis due to humid ageing was monitored by amount of the acetone extractable content, which was determined by weighting the tape pieces before and after acetone extraction, as a function of RH%, time and temperature. This study [78] aimed to individuate reasonable storage conditions (proposing and 40% RH).

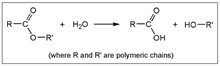

Deterioration by-products (shorter polymers) are abraded from the tape surface and form a gooey residue on the tape-guiding parts of heads, which increase in friction, so that the replay speed is reduced, which is frequently accompanied by high-pitch squealing noises and sound distorted. Increased tape traction can cause the elongation of the PET carrier film and can lead to a complete illegibility of tapes because magnetic material adhesion is reduced or lost [85,86]. Typical binders are the ESTANE class of polymers, containing soft segments of polyester oligomers of adipic acid with 1,4-butanediol and a hard segment consisting in a very short polyurethane made from 4,4-diphenylmethane diisocyanate molecules bonded together by urethane links to the butanediol’s that serve as chain extenders (Figure 8). These polymers are known to be degraded by thermolysis, photolysis, hydrolysis, ionizing radiation, and attack by air pollutant gases. These processes can cause the molecular weight to decrease, increase, or both increase and decrease, and destroy the elastomeric properties. It was reported that the hydrolysis of the ester link is the dominant mechanism for the decrease of molecular weight under ambient temperature and humidity with chain scission and increasing of the acid concentration, according to the following general scheme [71,87]:

Phase-separation measurements were used in comparison with FTIR data, to evaluate the effect of hydrolysis on the soft and hard domains in the PE-PU copolymer: the IR and shear storage modulus data indicate the formation of hard segment hydrogen bonded with time leading to a reduction of conformations and increasing of crystallinity [88].

It was observed that an initial crosslinking can be induced by NOx, O2, CH2O and ionizing radiations with subsequent degradation, too [89].

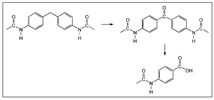

It was also demonstrated that the hydrolytic stability of polyester-polyurethanes could be significantly reduced by the presence of CrO2 (acting as on oxidant agent) much more than in the presence of maghemite [90]. The experiments have been carried out at and 30% RH on a commercially available polyester–polyurethane as a model. The polymer was significantly degraded within 60 days, as demonstrated by the low molecular weight extractable products. The oxidation of the hard urethane segment blocks by CrO2 involved oxidation of the benzylic carbons, conversion of primary aliphatic carbons to aldehydes and of secondary carbons to ketone products (see the following scheme). Related results have been obtained by analyzing through TGA mixtures of CrO2 particles slurried with the polyurethane hard-segment model: a strong exothermic signal associated with oxidation to benzophenone was observed from 35 to . The degradation products have been characterized by FT-IR, H and C NMR techniques.

A series of experiments on system models of binders (prepared by polymer casting and adsorption of polymers on -Fe2O3) have been performed to evaluate lifetime expectancy of binder on the basis of the tensile strength change in different environmental conditions. It was observed that, by increasing the cross linking, the durability is significantly improved [85].

A relevant aspect to consider is represented by the interaction between the tape back coat and the magnetic side in the reels compressed into a high pressure contact during the storage along the time. The binders containing the magnetic material and carbon black in the back coat are quite chemically similar, if not identical, so that they can interact each other blocking or exchanging inorganic content, thus degrading the pristine magnetic properties.

3.3. (iii) Stability of Magnetic Material

Even if demagnetization of a recording due to external magnetic field is a rare phenomenon, some magnetic security screening in airports can cause partial deletion of magnetic tapes. It is suggested to keep magnetic tapes at a safe distance from transformers and electric appliances15.

Magnetic particles also degrade and distort the signal16. The coercitivity characterizes the ability to retain a magnetic field and resist to demagnetization. Magnetic materials differ in their stability: iron oxides and Co-doped iron oxides are the most stable materials of those used in audio tapes. A study concerning the long-term behavior of iron particles has been reported in a relationship with temperature and humidity on the degradation of magnetic properties [91,92,93].

It was observed that, as the humidity increases, the rate of the magnetic moment degradation increases. For a given temperature, it was shown that there exists a critical RH above which the degradation rate of magnetic moment increases markedly.

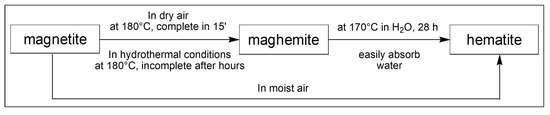

It is known that iron oxides and hydroxides (exhibiting different magnetic properties) can transform to the most stable forms goethite or hematite, depending on their origin, content of foreign ions, temperature, presence of water or humidity, morphology and crystal size. In the dry state, magnetite is readily oxidized to maghemite by air. Ultrafine crystals of magnetite change from black to the brown of maghemite even at room temperature. At temperatures >300 , the transformations proceed further to hematite. In the dry state, maghemite transforms to hematite in the temperature range 370–600 ; in hydrothermal conditions (150–180 ) magnetite transforms to hematite via a dissolution/reprecipitation mechanism. It is worth noting that, in general, during these transformations, due to the different crystal structure, the density of the starting material changes (in the case magnetite → maghemite, density falls) with an increasing of weight if oxidation processes occur due to oxygen taking up. It was reported [34,35,37] that, in magnetite particles larger than 300 nm, some hematite nuclei formed even at temperature lower than and maghemite formation was bypassed; at 200–250 , crystal smaller than 300 nm transformed to maghemite which in turn transformed to hematite (Figure 11). It was observed that small amount of OH favor maghemite formation. Under UHV, a magnetite film could be converted to hematite within 30 min at in the presence of oxygen. In the presence of acids, magnetite crystals transform to maghemite via an absorption reaction, which traps mobile electrons from the bulk material and reduced interfacial : ions formed can be selectively leached with further phases transformations. It is worth noting that often other metal ions, deriving from preparation, as contaminant are present, which can modify the kinetic of the transformations.

Figure 11.

Kinetic of transformations of iron oxides [34,35].

Research has been carried out over the better part of the last century, in particular for data storage magnetic tapes, to improve the performance of the methods and technologies increasing capacity and consequently data rate and reliability, proposing new materials and devices, such as thin films [94]. In the case of very thin particulate data storage media, the effect of the structure on noise was investigated as a function of magnetic layer thickness [95].

The effect of temperature on the long term magnetization stability for tapes prepared from ultrafine particles of Ba-ferrite was investigated observing that, when increasing the temperature (from 295 to 338 K), the oxidation of metal particles occurred significantly (with 0.04–0.07 dB/decade thermal decay rate) [96,97,98].

Metal particles (MP) and chromium dioxide (CrO2) pigments provide a higher tape signal output and permit higher recording frequencies than the iron oxides pigments, but are less stable. A decrease of two decibels may be observed over the lifetime of the tapes bearing MP/CrO2; however, the signal will still be better than a comparable iron oxide based tape. CrO2 and metal particulate are used in high grade audio tapes. Low temperature and low humidity can prevent the deterioration of pigments, which can be accelerated also by the products of the binder deterioration [63].

An intriguing study was carried out by Bowner et al. [99] concerning a comparison of the effect of accelerated aging on CrO2 or Fe2O3 based magnetic tapes under different environmental conditions (different temperature, relative humidity and pH values), by studying in particular, the magneto-TGA profiles. It was observed that magnetic changes in tapes occurred and arose from either a chemical change in the metal oxide to a non-magnetic state or a permanent loss in the ordering of the magnetic particles. At and 85% RH, degradation of the adhesive bond between the magnetic particles and the PET substrate also caused disruption of the particle array. The study demonstrated that CrO2-tapes were less stable than the Fe2O3-based tapes in all ageing experiments performed, indicating a synergism between the acid-catalyzed hydrolysis of the binder that holds the magnetic particles to the PET substrate and the thermally-induced physical degradation that disordered the particle array on the tape creating defect sites.

A patent proposed to improve CrO2 particles stability protecting against reactions with organic binders and water, by generating on the surface a more stable phase by treating with a reducing agent [100].

A plasma polymerized protective layer (in hexamethyldisiloxane or acrylonitrile) against corrosion was proposed to protect Co:Ni 80:20 alloy thin films suitable for magnetic data storage [101].

4. Analytical Methods to Characterize the Tapes Components and to Study the Degraded Tapes

As discussed above, a key point is the identification of the type of base film and nature of the chemicals in the tape. Problems can be associated with a group of tape types sharing coming characteristics, a single tape type, or just certain batches of one or more tape types. As mentioned elsewhere, it is often very difficult to determine the specific manufacturer and type of tape, but when it is known it eases the diagnosis of typical failure modes (an example is the base-binder adhesion failure in some batches of Scotch 201).

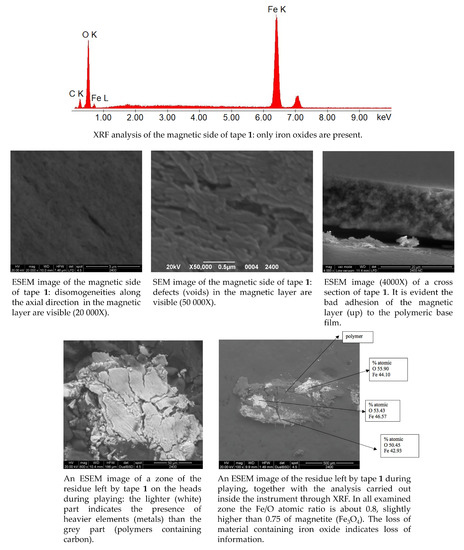

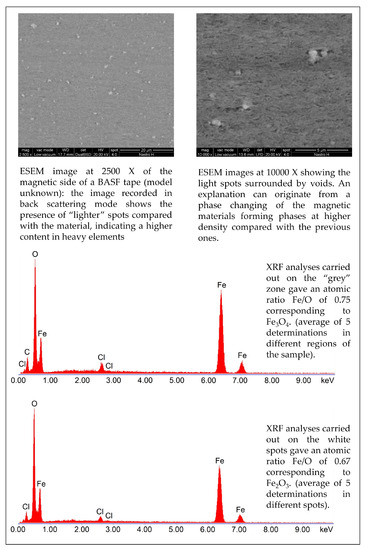

(a) Microscopy techniques. To undertake a preliminary characterization, ESEM or SEM together with XRF determinations could give rapid and extremely important information furnishing immediately data concerning the magnetic side of the tape, the nature of the magnetic material (iron and/or chromium oxides), the nature of base film in terms of presence of chlorine or not, indicating the presence of PVC or not, and the presence of other heteroatoms in the binder or lubricant (such as silicon or fluorine). Furthermore, the thickness is possible to measure and the presence of morphological damages can be observed [54]. Some authors reported a series of ESEM images together with XRF analytical date of 10 tapes (some of which unknown) to achieve preliminary data concerning the morphology, the elemental chemical composition and the presence of damages: in particular, the images of the cross-sections (simply achieved by gently braking of the tapes) showed that the samples were significantly different each other as for the relative thickness of the top coat and the substrate. Furthermore, in some cases, the base film appeared to be separated from the magnetic layer, suggesting that these tapes could present problems during playing with possible loss of magnetic material (Figure 12 and Figure 13). The morphological observations have been accompanied by XRF analyses.

Figure 12.

Electron microscopy images and data collected on an unknown magnetic audio tape 1 and on the residue left by the tape on the heads during playing. (Data collected by the authors and not previously published.)

Figure 13.

ESEM images of the magnetic side of an aged BASF audio tape (model unknown). (Data collected by the authors and not previously published.)

In Figure 13, ESEM images of the magnetic side of an aged BASF audio tape (model unknown) have been reported. The images have been recorded in back scattering mode, which indicates through different grey tones a different composition. In the photo, “lighter” spots compared with the average material are present: the XRF analysis shows that the atomic ratio Fe/O in the “grey” part is about 3/4 = 0.75 and in the “light” parts is about 2/3 = 0.67. Thus, the data suggest that a conversions from magnetic magnetite Fe3O4 to weakly magnetic hematite Fe2O3 occurred: the latter having higher density justifies the appearance of voids in the magnetic layer close to the light spots.

TEM micrographs have been used to evaluate the thickness of tape layers of IBM 3590 samples conditioned in accelerated temperature/humidity environments for different times as an indication of degradation amount in comparison with recording/playback performance. It was observed that the major mechanism for degradation and lifetime limits for tapes is oxidation of the metal particles from ferromagnetic iron to a non-ferromagnetic iron oxide [55].

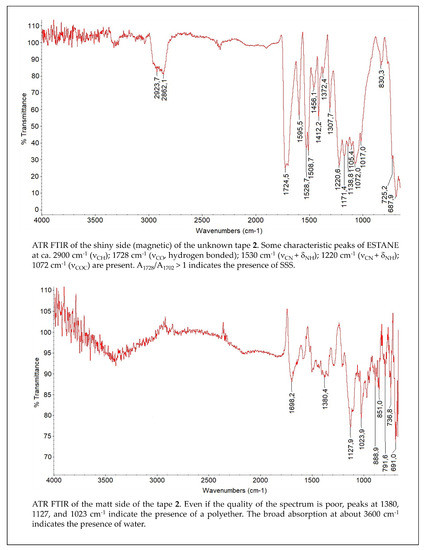

(b) Spectroscopic techniques. The FT-IR spectroscopic technique has been extensively used either to characterize tapes or to evaluate the degradation amount, on the basis of the wide literature concerning the application of spectroscopic techniques to study polymers’ chemistry and modifications for instance under heating [102] or stress [77]. Gómez-Sánchez [103] reported the data collected by recording the ATR spectra of a large number of tapes belonging to the archive at the Ethnological Museum of Berlin for which very little information on the damages or actual conservation state was available. A series of bands characteristic of base polymeric films and of the binders have been identified, including modifications due to degradation. Hobaica [104] identified spectral differences between SSS and non-SSS audio magnetic tapes: the shape of the carbonyl peak (in the range 1730 to 1693 cm), the presence of a peak at 1364 cm in SSS tapes (due to CH2 wagging indicating differences in molecular weight and orientation in polyester soft segment), the presence of a shoulder at 1252 cm and of a peak at 1138 cm (attributed to the formation of additional C-O bonds due to hydrolysis). In particular, SSS tapes spectra had a more pronounced free carbonyl peak at 1725 cm with respect to the signal attributed to the hydrogen bonded carbonyls at 1701 : for SSS tapes the main carbonyl peak absorption ratio A1725/A1701 was observed of 1.03 and of 0.88 for non-SSS tapes. In addition, the amide bands of the hard segment of PE-PU were studied comparing the absorption ratios for the amide peaks at 1527, 1308, and 1219 cm for SSS and non-SSS tapes. It was observed that they did not change significantly, thus indicating that chemical changes were not occurring in the polyurethane’s amide moieties, but are associated with the soft PE segment. The spectra after baking of tapes were also compared: again, significant spectral changes have been observed only for the soft PE segment with a decreasing of the signal of free carbonyl bonds (Table 2). Recently, an accurate investigation was carried out in order to demonstrate that, by applying a multivariate principal statistical analysis to a large number of ATR-FTIR data (in the spectral range 1750–950 cm), it is possible to distinguish playable from non-playable tapes with a non-destructive technique [105].

Table 2.

FT-IR characteristic absorptions of PE-PU binder. Data from [104].

In Figure 14, examples of the ATR FT-IR spectra of the shiny and the matte sides of the unknown magnetic audio tape 2 are reported.

Figure 14.

The ATR FT-IR spectra of the shiny and the matte side of an unknown magnetic audio tape 2. (Data collected by the authors and not previously published.)

Both FT-IR and Raman techniques are used also to distinguish magnetite from maghemite, resulting these methods more useful than X-ray powder spectra which are almost identical for these two phases [106]. Common IR and Raman absorptions are reported in Table 3.

Table 3.

FT-IR and Raman characteristic absorptions of some iron oxides (data from [37,106]).

X-ray diffraction spectra originate from diffraction of radiation occurring because the incident wave has a wavelength of the same order of magnitude as the spatial periodicity with which scattering centers in the sample are arranged. The diffraction condition is given by Bragg’s law: 2d sinθ = nλ (where n is an integer, is the wavelength of the radiation, is the angle between the incident beam and the diffracting planes and d is the spacing between those planes).

Powder diffraction is used in samples in which it is assumed that every possible orientation of the crystal lattice is present and a suitable single crystal of the sample is not available. The spectrum shows lines which correspond to the 2θ values satisfying Bragg’s law according to different planes distances, being characteristic of the crystalline structure. Maghemite and magnetite exhibit quite similar X-ray powder spectra. Furthermore, the spectra depend on how the sample was synthesized, so that good information to distinguish iron oxide can be achieved overall by using standards. In Table 4, some data regarding the crystalline structure of some iron oxides are reported.

Table 4.

General data regarding crystalline structure and properties of some iron oxides. ⋆Curie temperature. Data from [34].

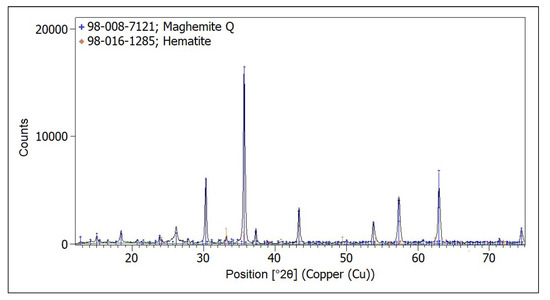

In Figure 15, an example of the XRD spectrum carried out on the magnetic side of the unknown audio tape 3 is reported. The intense signals of maghemite -Fe2O3 and the small ones of hematite -Fe2O3 are well visible (Table 4).

Figure 15.

XRD spectrum carried out on the magnetic side of the unknown audio tape 3. The spectrum has been collected by using a Cu source. (Data collected by the authors and not previously published).

(c) GC-MS techniques. The emission of VOCs in magnetic tapes after decades of natural ageing or after artificial ageing has been studied by using headspace SPME-GC-MS technique (sample collected from 30 cm of magnetic tape cut, put in a headspace glass vial and heated at for 5 min or directly mounting the fiber holder inside the player next to the surface of the running tape) with the aim to identify chemical degradation markers [107]. A wide variety of VOCs was detected including both oxygen-containing compounds (carboxylic acids, esters, ketones, lactones, aldehydes), and hydrocarbons such as linear alkanes. Some of the compounds extracted at were identified as additives dependent on the proprietary formulation of the manufactures. Typical fatty acid ester lubricants with an even number of carbons (from 12 to 22) and alcohols with 3 to 13 carbons, were detected together with butylated hydroxytoluene, a widely used phenolic antioxidant, p-benzoquinone (reasonably added for inhibition or retardation of free-radical polymerization during manufacturing process) and phtalates as plasticising agents. In addition, homogeneous series of carboxylic acids (such as acetic acid and hexanoic acid), ketones (in particular from 2-octanone to 2-dodecanone, acetophenone and cyclohexanone), furanones (such as 5-hexyldihydro-2(3)-furanone) and aldehydes (from hexanal to undecanal and benzaldehyde) have been detected for all tapes under investigation after ageing.

It is worth noting that, to evaluate the hydrolytic tape stability and to use the results as ageing test, pyrolysis (at ) coupled with GC-MS analyses have been carried out on naturally aged U-matic videotapes [108] with PET as base film and PE-PU as binder. It was confirmed that low molecular weight compounds were present by analyzing through size exclusion chromatography of the THF extracts.

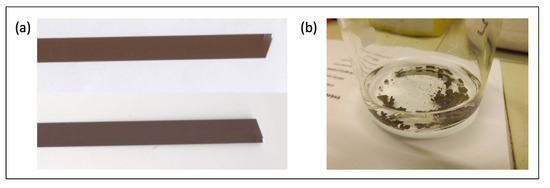

(d) Extraction tests. The most used methods to quantify the degree of degradation of the tapes are destructive and consist in extraction with solvent (in particular, acetone) of the soluble compounds formed by degradation [109] and the weight percentage of extractable was considered to be a measure of the degradation. In Figure 16, the effect of the treatment with acetone on an aged Scotch/3M (model unknown) is shown. The tape was recognized, by FT-IR data, bearing PET as polymers base film and resulted to be completely destroyed when treated with acetone [110]. The extracts, taken to dryness, can be characterized by GC-MS and spectrophotometric determination (such as FTIR, H and C NMR) [111].

Figure 16.

Photos of an aged Scotch/3M (model unknown) audio tape before and after treatment in acetone. (a) Images of the shiny side (light brown) and of the matte side (slightly darker brown). The ESEM determination indicates that the matt side carries the magnetic material. It shows (by the XRF determination) the presence of Fe and O in about 1:1 atomic ratio. (b) Image of the tape after treatment with acetone: the tape appears completely destroyed. The tape breaks giving small fragments. (Photos collected by the authors and not previously published.)

(e) Acidity Test. The formation of acids has been reported to occur due to degradation; thus, the test can be used as an indicator of tape conditions. The test consists in the extraction of acids in water (48 h at ) and their titration with NaOH (meta-cresol purple indicator) [109].

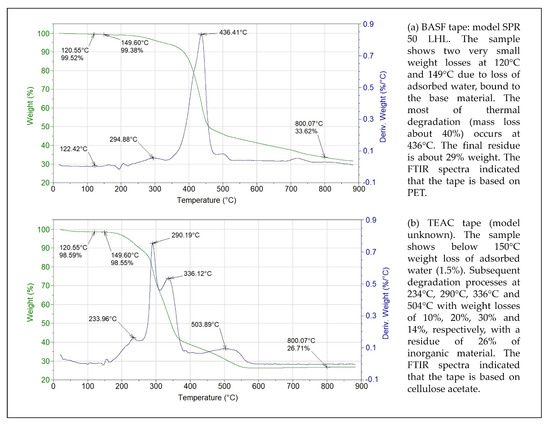

(f) Thermal behavior determinations. For the characterization of unknown tapes, the thermal behavior through TGA determination has been proposed [112]. Examples are reported in Figure 17. The observation that the degradation temperatures are quite different indicates that the two tapes contain different component: in particular, the most relevant degradation process at temperature higher than is in agreement with the hypothesis that the tape in Figure 17a has PET as the base film, while the tape in Figure 17b has cellulose acetate as the base film exhibiting degradation processes at lower temperatures17.

Figure 17.

TGA determinations of two aged magnetic audio tapes carried out under nitrogen, heating rate /min. (Data collected by the authors and not previously published.)

Recently, Davis [113] reported some results concerning the thermal changes (through DSC determinations) occurring in tape materials under ordinary storage, operating and baking temperatures. He observed that degraded tapes show a broad, irreversible, endothermic transition at about , generally absent in playable tapes. Furthermore, he observed by SEM that solid aggregates or defects contaminated the oxide layer surface of unplayable tapes, which disappeared upon heating, providing a smooth homogeneous oxide surface similar to the non-degraded tapes, which were most likely soft-segmented polymeric degradation products.

(g) Other determinations. As the binder deteriorates, it becomes sticky and may cause increasing friction, along the tape during playback. Thus, a nondestructive friction test has been proposed and standardized by ISO for motion-picture films [114].

It was reported that for two ESTANE polyester polyurethanes (ESTANE 5701, a linear one, and ESTANE 5706, a sterically hindered polymer) the presence of CrO2 pigment resulted in modulus reinforcement in the same manner as a conventional filler: higher pigment loading showed higher storage modulus in the glassy region. The addition of dispersant (which stay mostly on the surface of the pigment) and lubricants (which disperse in the polyurethane matrix as a plasticizer) showed some effects on mechanical properties [115].

In addition, physical-mechanical determinations have been carried out to characterize magnetic tapes made from PET and PEN: creep compliance, shrinkage, and dynamic mechanical analysis have been shown to be dependent upon temperature, which induces molecular movement providing dimensional instability, influenced also by processing methods [116].

Magneto-resistive microscopy has been shown to be useful for forensic analysis of audio tapes to recover data from specific areas of the tapes not accessible to standard players and for reading very old tapes that cannot be played18 [117].

To study the morphology, structure and degradation of tapes bearing very thin metal evaporated coatings as magnetic component, X-ray photoelectron spectroscopy (XPS) and Secondary Ion Mass Spectrometry (SIMS) determinations have also been carried out. A key point of the study was the optimization of the experimental details to achieve measurements able to furnish informative data on this particular kind of sample, which can degrade under the measurement conditions. The data demonstrated that in all the sample under study perfluoropolyethers have been used as lubricants, being this material able to realize and maintain a continuous coverage to protect the metal film, avoiding spacing losses even under severe wear. Superior measurement durability was observed for the tape exhibiting significantly greater thickness and higher semi-mobile component in the lubricant able to repair localized film damage due to tribological contact [118].

A rapid test to assess tape condition was proposed by Davis [113] using contact angle measurements. He observed that, in general, degraded tapes showed contact angles less than on both sides of the tape, while tapes in good conditions show contact angles higher than , in agreement with higher hydrophobicity properties.

5. Restoration

There are a few different restoration techniques that are in daily use around the world. Other techniques to render otherwise unplayable tapes playable are used as the need arises. The goals of these techniques is to render the tape playable at full quality in order to copy/digitize the content.

Thermal treatment (“baking”)

Perhaps the most widely used restoration method is the baking of tapes with “sticky shed syndrome” [119]. These are typically back-coated tapes on PET base film. Acetate based tapes should never be baked. Baking rarely renders a tape permanently playable [112]. Ongoing conversations indicate that baking times appear to be increasing, but one correspondent reports that 30 days backing for 16-inch reels of 1-inch instrumentation tape on windowless precision reels works very well [120].

Cold playback

One of the authors reported success with cold playback in 2012 [121]. In studying potential failure modes of recording tape, he became aware of the glass transition temperature (Tg) of the coating and the fact that degradation may lower the Tg of the coating, producing stick–slip as the tape moved past stationary items (such as heads and guides) in the tape path. Some tapes which showed evidence of stick–slip (audible squealing from the tape and in the audio) were analyzed. One sample showed a Tg of about and another showed that the normal lubricant load for the tape was still present. Although these tapes that showed stick–slip (without shedding) were often referred to as suffering from “loss of lubricant” that apparently was not the case, as chemical analysis showed there was still a full lubricant load in the tape. While over-lubricating the tape can render these tapes playable, the additional lubrication can interfere with the mechanics of the tape transport. We have received reports of cold playback at around to be successful in reducing or eliminating the stick–slip. We suspect that as these degradation modes continue to advance, that even lower temperatures might be necessary.

Adding more lubricant

It is possible to add more lubricant to the tape-head interface, which reduces or eliminates stick–slip. Marie O’Connell from New Zealand settled on isopropyl alcohol as that was certainly a technique that received some traction in the 1980s and 1990s19.

The interesting thing about this technique is, while the alcohol provides a lubricating film, it also provides a cooling effect. In recent conversations, O’Connell reported to Hess that more tapes were being baked and the alcohol drip was being reserved for tapes that did not respond to baking.

Scott Dorsey, who works at NASA as an instrumentation support technician, suggested using D5 or decamethylcyclopentasiloxane as a lubricant20. It evaporates relatively quickly so even if a tape mechanism is contaminated, it will return to normal working order in a few days. Recent research still considers this a safe product, which is reassuring as it is widely used in personal care products to provide the slippery feel [122]. One of the authors (Hess) has had good results for certain types of tapes with this lubricant.

One of the challenges is knowing when to lubricate, when to use cold playback, and when to bake. It is made more important to learn how to do this type of triage because using the wrong treatment may not be neutral to the degrading tape. We have found no gross ill effects on baking tapes that will respond to cold playback or adding lubrication, but subtle effects have been reported that the baking may exacerbate the degradation that has already occurred without ameliorating it.

6. Preservation, Handling, Storage

Guidelines for storage of reel of tape have been proposed, but many of the points have not gained wide acceptance and are controversial. In today’s operational environment, digitization of tapes with file storage in trusted digital repositories is the primary method of preserving the content of old tapes21 [11,63,121,123]

- Tapes must be wound end-to-end, onto a rigid hub, before being put into storage to avoid pack tension distortions.

- Any residue from degradation should be removed as long as there is no further damage to the tape.

- A current outline of storage recommendations for tape can be found in [124] (Section 3.3). There are some caveats to consider when analyzing these limits and this is an area of further research as film historians are freezing film to preserve it longer.

- ○

- It is likely that tapes coated on an acetate base film do not perform as well at the lower range of the recommended RH.

- ○

- The “do not freeze” warning about tape came from concerns over early tapes that used a variety of naturally occurring lubricants, often extracted from marine creatures. What is interesting is that some sample lubricants that Hess has in his possession appear to congeal below about , thus these would be congealed at the minimum recommended temperature of recommended in [124].

- The above two sub-points suggest further research.

The reason so much effort is put in the study of magnetic tapes is, of course, the audio content. When the tape is compromised, so is our ability to access the acoustic information it carries. However, if ageing has a destructive effect on tapes integrity, so can—in principle—treatments for cleaning, recovery, and optimization. Therefore, it is legitimate to ask whether certain procedures do not cause, besides the intended rejuvenation of the tape, an alteration of the sound signal. Whether the alteration is desirable (enhanced intelligibility, richer spectrum, etc.) or undesirable (further degradation) is to be determined. To do so, it is necessary to design studies that combine chemical and audio analyses. Bressan et al. [125] presented an example of a study that aims to determine the modifications that thermal treatment induces both on magnetic tape and on the audio signal on that tape. To do so, a set of chemical analyses were conducted on a tape sample before and after thermal treatment, and audio analyses were conducted on the corresponding digitized signals. A set of audio features was selected to characterize the audio spectrum. The results obtained testing a tape that did not show any marked sign of degradation (i.e., a tape that may be labeled “in good condition”) returned consistent results between the chemical and audio analyses, and did not reveal any significant differences between before and after the treatment. This is a positive result because it shows that thermal treatment, at these conditions, does not have a destructive effect on the tape or on the signal. Future work includes repeating the test on tape samples that show marked signed of degradation.

7. Conclusions

Audio magnetic tapes are complex and multi-component devices containing organic compounds and metal systems, which can potentially catalyze many reactions in the presence of water, light or heating.

Many common techniques for analytical chemistry have been used to identify unknown tapes and study the degradation state to prevent further degradation and individuate the best conditions for long storage. There is a rapid and continuous evolution in the instrumental equipment which allows studying materials; thus, all methods actually in use to study polymeric materials (such as neutron scattering or TEM) could be used for audio tapes, too, with the aim to better understand chemical, structural, morphological and functional aspects. The thermodynamic stability of iron oxides is sensitive to magnetization states, chemical surrounding, particles size and shapes, and defects in crystalline phases, thus forming a complicated parameter set, which represents a challenging research field with these specific devices.

An intriguing tool would be to combine destructive analyses on extracts (which can be carried out by GC-MS on very few milligrams of sample from the beginning of the tape, usually not recorded) with non-destructive approaches (such as ATR-FTIR, which could be performed continuously) and ESEM images, to build an as large as possible database, open to workers in archives interested in preserving our sounds heritage.

Author Contributions

Conceptualization, F.B., R.B. and R.L.H.; methodology, F.B., R.B. and R.L.H.; formal analysis, R.B.; investigation, F.B., R.B., P.S. and R.L.H.; resources, R.B. and P.S.; data curation, F.B. and R.H; writing—original draft preparation, R.B. and R.L.H.; writing—review and editing, F.B., R.B., P.S. and R.L.H.; visualization, P.S. and R.L.H.; supervision, F.B.; project administration, F.B.; and funding acquisition, F.B.

Funding

This study was partially supported by the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No. 703937.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| AES | Audio Engineering Society (New York, NY, USA) |

| ATR FTIR | Attenuated total reflectance Fourier transform infrared spectroscopy |

| ESEM | Environmental scanning electron microscopy |

| FT-IR | Fourier transform infrared spectroscopy |

| GC MS | Gas chromatography mass spectrometry |

| IASA | International Association of Sound and Audiovisual Archives (Amsterdam, The Netherlands) |

| LD | linear dichroism |

| NAB | National Association of Broadcasters (Washington, DC, USA) |

| NMR | Nuclear magnetic resonance |

| PEN | Polyethylene naphthalate (used as a base film) |

| PE-PU | Polyester polyurethane (used as a binder) |

| PET | Polyethylene terephthalate (common base film) |

| PM-IRLD | polarization modulation infrared linear dichroism |

| PVC | Polyvinyl chloride (historic base film) |

| RH | Relative humidity |

| SEM | Scanning electron microscopy |

| SIMS | Secondary ion mass spectrometry |

| SMPTE | Society of Motion Picture and Television Engineers (White Plains, NY, USA) |

| SPME | Solid phase micro extraction |

| Tg | Glass transition temperature |

| TGA | Thermogravimetric analysis |

| UHV | Ultra high vacuum |

| URS-FTIR | Ultra-rapid scanning spectroscopy |

| VOC | Volatile organic compounds |

| XRD | X-ray powder diffraction |

References

- Engel, F. Magnetic Tape from the Early Days to the Present. J. Audio Eng. Soc. 1988, 36, 606–616. [Google Scholar]

- Schüller, D. Preserving the Facts for the Future: Principles and Practices for the Transfer of Analog Audio Documents into the Digital Domain. J. Audio Eng. Soc. 2001, 49, 618–621. [Google Scholar]

- Hess, R. Tape Degradation Factors and Challenges in Predicting Tape Life. ARSC J. 2008, 39, 240–274. [Google Scholar]

- Richardson, C.A. Solving the Sticky Shed Problem in Magnetic Recording Tapes: New Laboratory Research and Analysis Provides a Safe and Effective Remedy; Audio Engineering Society: New York, NY, USA, 2006. [Google Scholar]

- Richardson, C. Process for Restoring Magnetic Recording tape Damaged by Sticky Shed Syndrome. U.S. Patent US6797072, 28 September 2004. [Google Scholar]

- Thiébaut, B. Particulate magnetic tape materials characterisation and degradation study. In Proceedings of the Association of Moving Image Archivists (AMIA) Conference, Austin, TX, USA, 30 November–1 December 2005. [Google Scholar]

- Hollerith, H. Art of Compiling Statistics. U.S. Patent US395782A, 8 January 1884. [Google Scholar]

- Bradshaw, R.; Schroeder, C. Fifty years of IBM innovation with information storage on magnetic tape. IBM J. Res. Dev. 2003, 47, 373–383. [Google Scholar] [CrossRef][Green Version]

- Braun, W.L. The NAB Recording and Reproducing Standards. J. Audio Eng. Soc. 1968, 16, 168–173. [Google Scholar]

- Telemetry Group; Range Commander Council. Telemetry Standards. IRIG STANDARD 106-04; US Army: Arlington County, VA, USA, 2004. [Google Scholar]

- Hauttekeete, L.; Evens, T.; Moor, K.D.; Schuurman, D.; Mannens, E.; de Walle, R.V. Archives in motion: Concrete steps towards the digital disclosure of audiovisual content. J. Cult. Herit. 2011, 12, 459–465. [Google Scholar] [CrossRef]

- Casey, M. FACET (Field Audio Collection Evaluation Tool)–Procedures Manual Version 1.0; Technical Report; Indiana University: Bloomington, IN, USA, 2008. [Google Scholar]

- Cassidy, B.M.; Breitung, E.M. Magnetic Tapes, Playable or Not? Against Grain 2015, 27, 1. [Google Scholar] [CrossRef]

- Casey, M. Why media preservation can’t wait: The gathering storm. IASA J. 2015, 44, 14–22. [Google Scholar]

- Allen-Robertson, J. The materiality of digital media: The hard disk drive, phonograph, magnetic tape and optical media in technical close-up. New Media Soc. 2017, 19, 455–470. [Google Scholar] [CrossRef]

- Heller, M.C. Orpheus unglued: sticky shed syndrome and tape’s archival anxieties. Sound Stud. 2017, 3, 64–70. [Google Scholar] [CrossRef]

- Green, C.V. Chemical Analysis of Magnetic Recording Tape. J. Audio Eng. Soc. 1960, 8, 156–158. [Google Scholar]

- Scheiman, J.; Schwartz, R. An Old-School Tape Evaluator. U.S. Patent US3359783, 1967. [Google Scholar]

- Cinadr, B. Details on Coating Systems. U.S. Patent US3650828, 1972. [Google Scholar]

- Kaempf, G.; Loewer, H.; Witman, M. Polymers as substrates and media for data storage. Polym. Eng. Sci. 1987, 27, 1421–1425. [Google Scholar] [CrossRef]