Biodigital Micro-Cellular Mashrabiya: Lattice Architectural Microbial Membranes for Sustainable Built Environments

Abstract

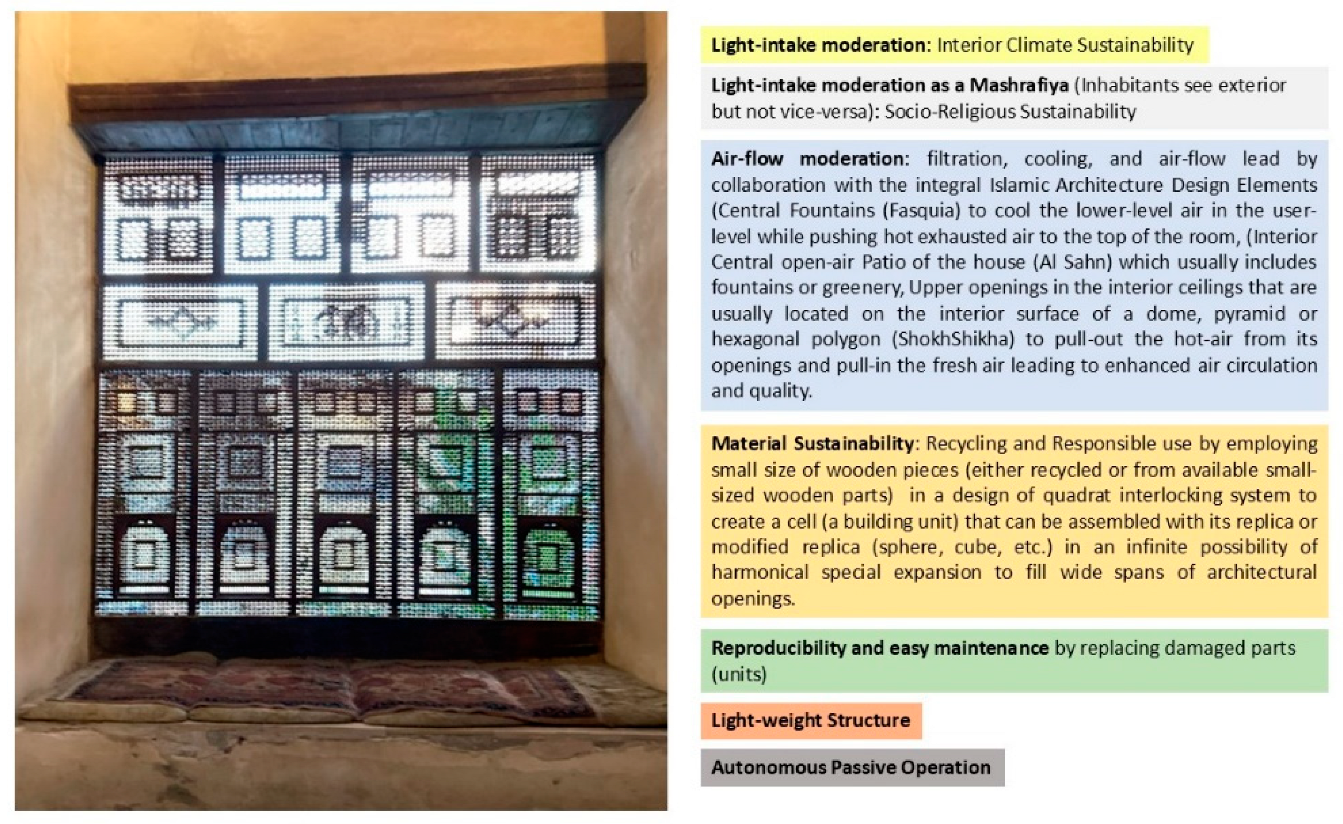

:1. Introduction and Background: Revaluation of Mashrabiya as a Soft Membrane and Interactive Environmental Interface

2. Methodology

2.1. The 3D-Printed Biodigital Microbial-Cellular Mashrabiya: The Interactive Living Membrane Feasibility

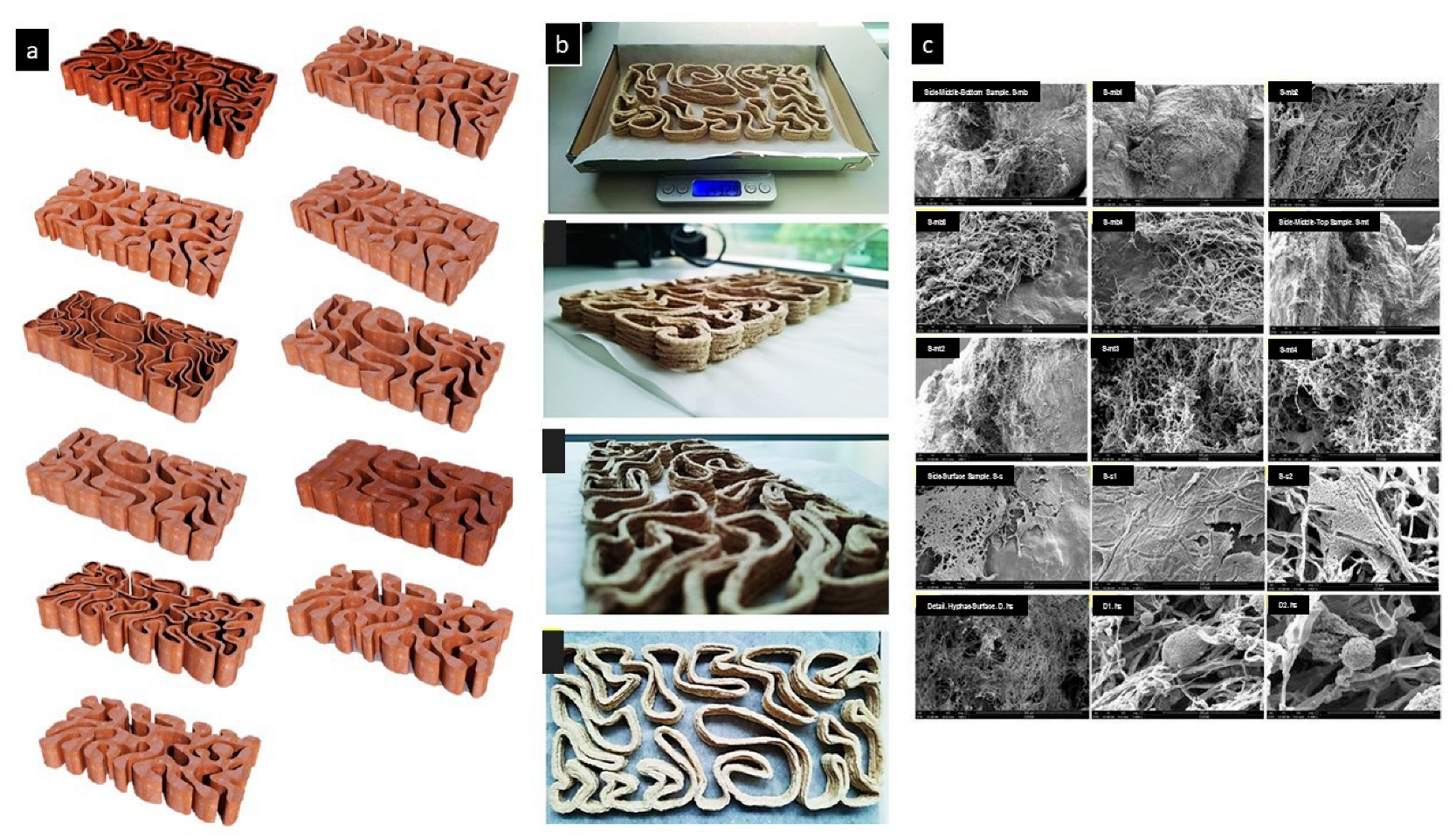

2.2. The 3D-Printed, Bio-Welded, Myco-Biocomposite Mashrabiya

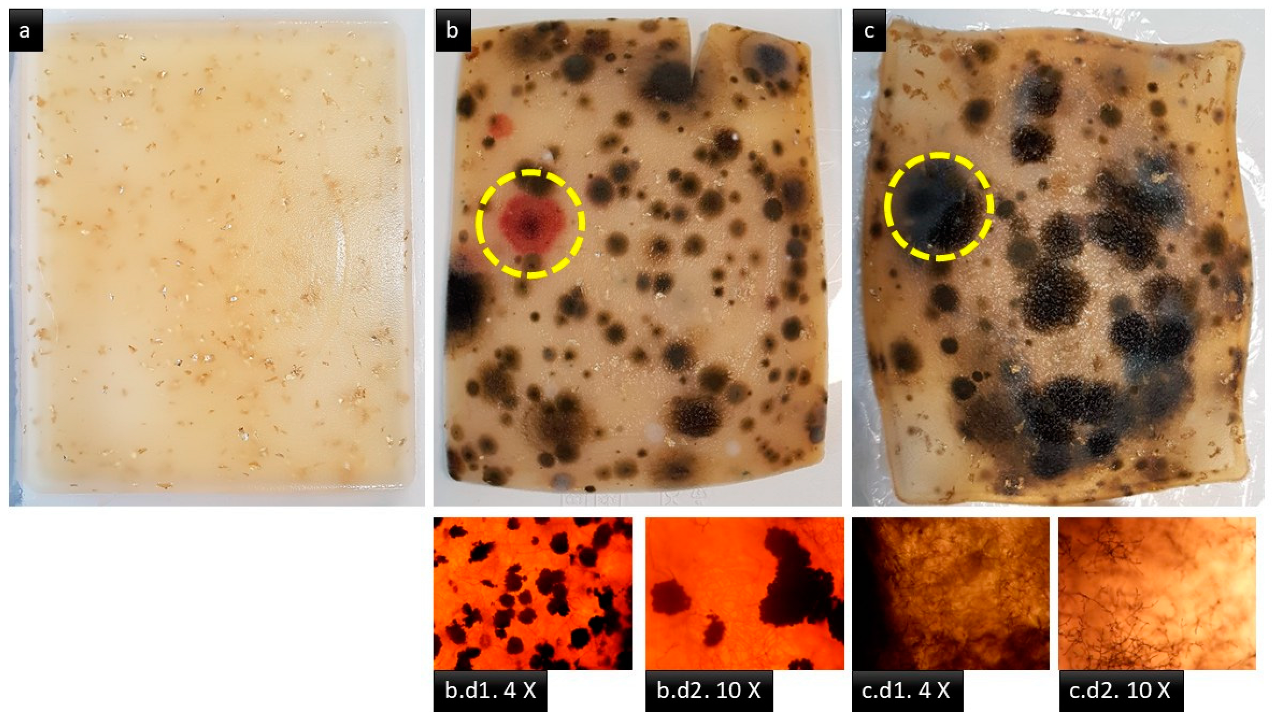

2.3. The 3D-Bioprinted Bone-Inspired Mashrabiya System

3. Discussion

3.1. Limitations and Future Research Trajectories

3.2. Between 3D Bioprinting and Casting: Future Application of Bioactive Lattice Membranes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Williams, C. Islamic Monuments in Cairo; American Univ in Cairo Press: Cairo, Egypt, 2008. [Google Scholar]

- Ayman, F.A. Islamic Architectural Heritage: Mashrabiya. In Islamic Heritage Architecture and Art II; Passerini, G., Ed.; WIT Press: Southampton, UK, 2018; pp. 245–254. ISBN 9781784662516. [Google Scholar]

- Fathy, H.; Shearer, W.; Sultan, A.A. Natural Energy and Vernacular Architecture: Principles and Examples with Reference to Hot Arid Climates; Published for the United Nations University by the University of Chicago Press: Chicago, IL, USA, 1986. [Google Scholar]

- Sahih al-Bukhari 2446. Book 46, Hadith 7. USC-MSA web (English) reference: Vol. 3, Book 43, Hadith 626. Available online: https://sunnah.com/bukhari:2446 (accessed on 20 March 2025).

- Ürge-Vorsatz, D.; Khosla, R.; Bernhardt, R.; Chan, Y.C.; Vérez, D.; Hu, S.; Cabeza, L.F. Advances Toward a Net-Zero Global Building Sector. Annu. Rev. Environ. Resour. 2020, 45, 227–269. [Google Scholar] [CrossRef]

- Ragheb, A.; El-Shimy, H.; Ragheb, G. Green Architecture: A Concept of Sustainability. Procedia Soc. Behav. Sci. 2016, 216, 778–787. [Google Scholar] [CrossRef]

- Arup.com. Engineering the Al Bahr Towers. 2024. Available online: https://www.arup.com/projects/al-bahr-towers/ (accessed on 14 August 2024).

- Ateliers Jean Nouvel. (n.d.). Institut du Monde Arabe (IMA). [online]. Available online: https://www.jeannouvel.com/projets/institut-du-monde-arabe-ima/ (accessed on 6 October 2024).

- Designboom, cat Garcia Menocal I. Jean Nouvel: Burj Doha Shapes Gulf City’s Skyline. [online] Designboom|Architecture & Design Magazine. 2013. Available online: https://www.designboom.com/architecture/jean-nouvel-burj-doha-shapes-gulf-citys-skyline/ (accessed on 20 March 2025).

- Dikou, C.; Kourniatis, N. Sustainability through passive energy biomimetics systems in Architecture. Comparative analysis of case studies. IOP Conf. Ser. Earth Environ. Sci. 2022, 1123, 012027. [Google Scholar] [CrossRef]

- Happersett, S. Neri Oxman—Fibonaccisusan. [online] Fibonaccisusan. 2024. Available online: https://fibonaccisusan.com/tag/neri-oxman/ (accessed on 6 October 2024).

- Abdallah, Y.K.; Estévez, A.T. 3D-Printed Biodigital Clay Bricks. Biomimetics 2021, 6, 59. [Google Scholar] [CrossRef]

- Abdallah, Y.K.; Estévez, A.T. Biowelding 3D-Printed Biodigital Brick of Seashell-Based Biocomposite by Pleurotus ostreatus Mycelium. Biomimetics 2023, 8, 504. [Google Scholar] [CrossRef]

- Candido, A.; Amiri, A.; Junnila, S.; Pittau, F. Mycelium-wood composites as a circular material for building insulation. Front. Sustain. Cities 2024, 6, 1412247. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, Z.; Zhang, R.; Peng, Y.; Wang, M.; Cao, J. Lightweight, thermal insulation, hydrophobic mycelium composites with hierarchical porous structure: Design, manufacture and applications. Compos. Part B Eng. 2023, 266, 111003. [Google Scholar] [CrossRef]

- Bonga, K.B.; Bertolacci, L.; Contardi, M.; Paul, U.C.; Zafar, M.S.; Mancini, G.; Marini, L.; Ceseracciu, L.; Fragouli, D.; Athanassiou, A. Mycelium Agrowaste-Bound Biocomposites as Thermal and Acoustic Insulation Materials in Building Construction. Macromol. Mater. Eng. 2024, 309, 2300449. [Google Scholar] [CrossRef]

- Sağlam, S.S.; Özgünler, S.A. An experimental study on production opportunities of biocomposite by using fungal mycelium. J. Des. Resil. Arch. Plan. 2022, 3, 237–260. [Google Scholar] [CrossRef]

- Huang, Z.; Wei, Y.; Hadigheh, S.A. Variations in the Properties of Engineered Mycelium-Bound Composites (MBCs) under Different Manufacturing Conditions. Buildings 2024, 14, 155. [Google Scholar] [CrossRef]

- Chan, X.Y.; Saeidi, N.; Javadian, A.; Hebel, D.E.; Gupta, M. Mechanical properties of dense mycelium-bound composites under accelerated tropical weathering conditions. Sci. Rep. 2021, 11, 22112. [Google Scholar] [CrossRef]

- Estévez, A.T.; Abdallah, Y.K. The New Standard Is Biodigital: Durable and Elastic 3D-Printed Biodigital Clay Bricks. Biomimetics 2022, 7, 159. [Google Scholar] [CrossRef]

- Estevez, A.T.; Abdallah, Y.K. Biomimetic Approach for Enhanced Mechanical Properties and Stability of Self-Mineralized Calcium Phosphate Dibasic–Sodium Alginate–Gelatine Hydrogel as Bone Replacement and Structural Building Material. Processes 2024, 12, 944. [Google Scholar] [CrossRef]

- Turdialieva, S.; Nomozov, S.; Namazov, S.; Ishmanova, Z.; Kholmurodov, J.; Oxundadayev, A.; Kamalov, A. Production of food-grade calcium phosphate utilizing thermal phosphoric acid and lime. E3S Web Conf. 2025, 613, 01010. [Google Scholar] [CrossRef]

- Trautvetter, U.; Ditscheid, B.; Jahreis, G.; Glei, M. Habitual Intakes, Food Sources and Excretions of Phosphorus and Calcium in Three German Study Collectives. Nutrients 2018, 10, 171. [Google Scholar] [CrossRef]

- Hossain, F.; Follett, P.; Vu, K.D.; Salmieri, S.; Senoussi, C.; Lacroix, M. Radiosensitization of Aspergillus niger and Penicillium chrysogenum using basil essential oil and ionizing radiation for food decontamination. Food Control 2014, 45, 156–162. [Google Scholar] [CrossRef]

- Bonenberg, A.; Sydor, M.; Cofta, G.; Doczekalska, B.; Grygorowicz-Kosakowska, K. Mycelium-Based Composite Materials: Study of Acceptance. Materials 2023, 16, 2164. [Google Scholar] [CrossRef] [PubMed]

- Alaneme, K.K.; Anaele, J.U.; Oke, T.M.; Kareem, S.A.; Adediran, M.; Ajibuwa, O.A.; Anabaranze, Y.O. Mycelium based composites: A review of their bio-fabrication procedures, material properties and potential for green building and construction applications. Alex. Eng. J. 2023, 83, 234–250. [Google Scholar] [CrossRef]

- Javadian, A.; Le Ferrand, H.; Hebel, D.E.; Saeidi, N. Application of Mycelium-Bound Composite Materials in Construction Industry: A Short Review. SOJ Mater. Sci. Eng. 2020, 7, 1–9. [Google Scholar] [CrossRef]

- Jang, J.-H.; Shin, S.; Kim, H.-J.; Jeong, J.; Jin, H.-E.; Desai, M.S.; Lee, S.-W.; Kim, S.-Y. Improvement of physical properties of calcium phosphate cement by elastin-like polypeptide supplementation. Sci. Rep. 2018, 8, 5216. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, W.; Schnitzler, V.; Tancret, F.; Bouler, J.-M. Calcium phosphate cements for bone substitution: Chemistry, handling and mechanical properties. Acta Biomater. 2014, 10, 1035–1049. [Google Scholar] [CrossRef] [PubMed]

- Abdallah, Y.K.; Estevez, A.T.; Tantawy, D.E.D.M.; Ibraheem, A.M.; Khalil, N.M. Employing Laccase-Producing Aspergillus sydowii NYKA 510 as a Cathodic Biocatalyst in Self-Sufficient Lighting Microbial Fuel Cell. J. Microbiol. Biotechnol. 2019, 29, 1861–1872. [Google Scholar] [CrossRef] [PubMed]

- Reyes, C.; Fivaz, E.; Sajó, Z.; Schneider, A.; Siqueira, G.; Ribera, J.; Poulin, A.; Schwarze, F.W.M.R.; Nyström, G. 3D Printed Cellulose-Based Fungal Battery. ACS Sustain. Chem. Eng. 2024, 12, 16001–16011. [Google Scholar] [CrossRef]

- Abdallah, Y.K.; Estévez, A.T. 3D-Printed Bioreceptive Tiles of Reaction–Diffusion (Gierer–Meinhardt Model) for Multi-Scale Algal Strains’ Passive Immobilization. Buildings 2023, 13, 1972. [Google Scholar] [CrossRef]

- Abdallah, Y.K.; Estévez, A.T.; Afsar, S. Sistemas bioaprendidos y bioreceptivos de materiales biocompuestos en Arquitectura. Cuad. Cent. Estud. Disen. Y Comun. Ens. 2023, 178, 53–69. [Google Scholar] [CrossRef]

- Huang, G.; Zhao, Y.; Chen, D.; Wei, L.; Hu, Z.; Li, J.; Zhou, X.; Yang, B.; Chen, Z. Applications, advancements, and challenges of 3D bioprinting in organ transplantation. Biomater. Sci. 2024, 12, 1425–1448. [Google Scholar] [CrossRef]

- Ramadan, Q.; Zourob, M. 3D Bioprinting at the Frontier of Regenerative Medicine, Pharmaceutical, and Food Industries. Front. Med. Technol. 2021, 2, 607648. [Google Scholar] [CrossRef]

- Fabijański, M. Effect of calcium carbonate addition on mechanical properties of polylactide Wpływ zawartości węglanu wapnia na właściwości mechaniczne polilaktydu. Przemysl Chem. 2017, 1, 196–198. [Google Scholar] [CrossRef]

| Typical Mashrabiya Key-Criteria | 3D-Printed Myco-Biocomposite Mashrabiya | 3D-Bioprinted Bone-Inspired Mashrabiya |

|---|---|---|

| Light-intake moderation | Moderately achieved due to the large openings of the lattice curvilinear biodigital bricks design in comparison to the typical Mashrabiya. | Fully achieved varied scale moderation of light intake since this project proposes micro-, meso-, and macro-scale organization of the trabecular-inspired lattice pores, with the added value of the self-organization fractality of the system based on mineralization on the material scale. |

| Socio-cultural compliance of the Mashrafiya | Moderately achieved in comparison to the interior camouflage effect of the typical Mashrafiya due to the wider voids in the biodigital brick design. | Fully achieved varied scale diffusion and camouflage of the interior based on the fractal varied scale pores of the material system. |

| Air filtration and flow moderation | Achieved with the added value of air filtration due to the designed material mineralization reaction that captures carbon dioxide to produce and precipitate calcium carbonate as a side product of the interaction between the mycelium and the seashell-based biocomposite [13]. | Achieved with the added value of air filtration thanks to the designed material mineralization that captures carbon dioxide in the mineralization pathway of the hydrogel interface reaction with the surrounding air to produce calcium carbonate and hydroxyapatite [20]. |

| Air cooling and air-flow moderation requires further experimentation in collaboration with the other architectural elements that facilitate the air flow and circulation inside the building. | ||

| Material sustainability | Fully achieved since the myco-biocomposite biodigital bricks are developed from recycled seashells from food waste and edible fungi mycelium (Pleurotus ostreatus) which is identified as a current material in sustainability to exploit waste and cheap microbial cultures in architecture and construction. | Partially achieved. Gelatine and alginate are abundant biopolymers that are affordable and available; however, the 3D bioprinter is less economic democratically. Nevertheless, domestically developed and manufactured bioprinters are a possible solution to overcome the cost of commercially available bioprinters. |

| Reproducibility and easy maintenance | The biodigital myco-biocomposite bricks are considered reproducible and self-healing. However, patch-to-patch variations caused by uneven bioagent growth on the replicated bricks can be considered a challenge in the reproducibility of this system. Another challenge is the inoculation-to-growth duration that can last two weeks minimum and requires further study on the system life-cycle in reaching the full mineralization of the system by the proposed reaction. | The biomimetic bone-like material system is reproducible and easily maintained thanks to its easy preparation procedures and autonomous mineralization. Thus, this system is more suitable for application as a biodigital Mashrabiya. |

| Lightweight structure | This system achieves an enhanced lightweight structure in comparison to clay and wood. However, further research is required to evaluate the structural and mechanical property variations of the myco-biocomposite material upon mineralization and dense welding by the bioagent (mycelium). | This system achieves a lightweight structure that is based on the material biomimetic morphology of cortical–trabecular hierarchical structural motifs. This qualifies this material system as a fractal load-bearing lightweight system. Further research is needed to study the morphological variation and fractality of the mineralized material, as well as estimating the mechanical property variation chronologically to the mineralization rate and sites. |

| Autonomous passive operation | This system is autonomously and passively operating by the effect of the bioagent (mycelium) welding and reinforcing the material while absorbing carbon dioxide in the mineralization reaction, generating a coherent welded system of a mineralized biodigital Mashrabiya. | This system autonomously and passively operates by the effect of the acellular chemical mineralization reaction consuming carbon dioxide in the mineralization of the outer interfaces of the material while providing enhanced mechanical performance and the possibility of encapsulating living cells of useful organisms [20] (for instance, bioluminescent bacteria or algae strains) to add to the sustainability of this biodigital Mashrabiya system by fostering biodiversity. |

| Sustainability added values | This system offers wide potential in sustainability functions in the production of food by employing edible mushrooms’ mycelium as applied in this case using the King Oyster Mushroom [13], as well as producing industrially valuable enzymes (e.g., Laccase) according to the fungal strain used to weld the seashell biocomposite [29]. Another possible added value is the generation of bioelectricity based on the oxidation–reduction reaction of the fungal strain used in the bio-welding of the biocomposite which consumes the auxiliary media in the system [29,30]. This can lead to a fully self-sufficient biodigital Mashrabiya that is an integral sustainable solution for an architectural bioactive and functional membrane. | Because of the excellent encapsulation properties of this biomimetic hydrogel, this system can host and maintain the viability of various useful microbial strains such as bioluminescent algae that can produce oxygen, proteins, enzymes, and naturally emitted light [31]. This is currently under experimentation and will be published in a future study. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdallah, Y.K.; Estevez, A.T. Biodigital Micro-Cellular Mashrabiya: Lattice Architectural Microbial Membranes for Sustainable Built Environments. J 2025, 8, 13. https://doi.org/10.3390/j8020013

Abdallah YK, Estevez AT. Biodigital Micro-Cellular Mashrabiya: Lattice Architectural Microbial Membranes for Sustainable Built Environments. J. 2025; 8(2):13. https://doi.org/10.3390/j8020013

Chicago/Turabian StyleAbdallah, Yomna K., and Alberto T. Estevez. 2025. "Biodigital Micro-Cellular Mashrabiya: Lattice Architectural Microbial Membranes for Sustainable Built Environments" J 8, no. 2: 13. https://doi.org/10.3390/j8020013

APA StyleAbdallah, Y. K., & Estevez, A. T. (2025). Biodigital Micro-Cellular Mashrabiya: Lattice Architectural Microbial Membranes for Sustainable Built Environments. J, 8(2), 13. https://doi.org/10.3390/j8020013