Reactivity of Ground Coal Bottom Ash to Be Used in Portland Cement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Analytical Methodology

2.3. Pozzolanic Activity Assessment of the Coal Bottom Ash, Coal Fly Ash, Cement and Their Mixes

3. Results and Discussion

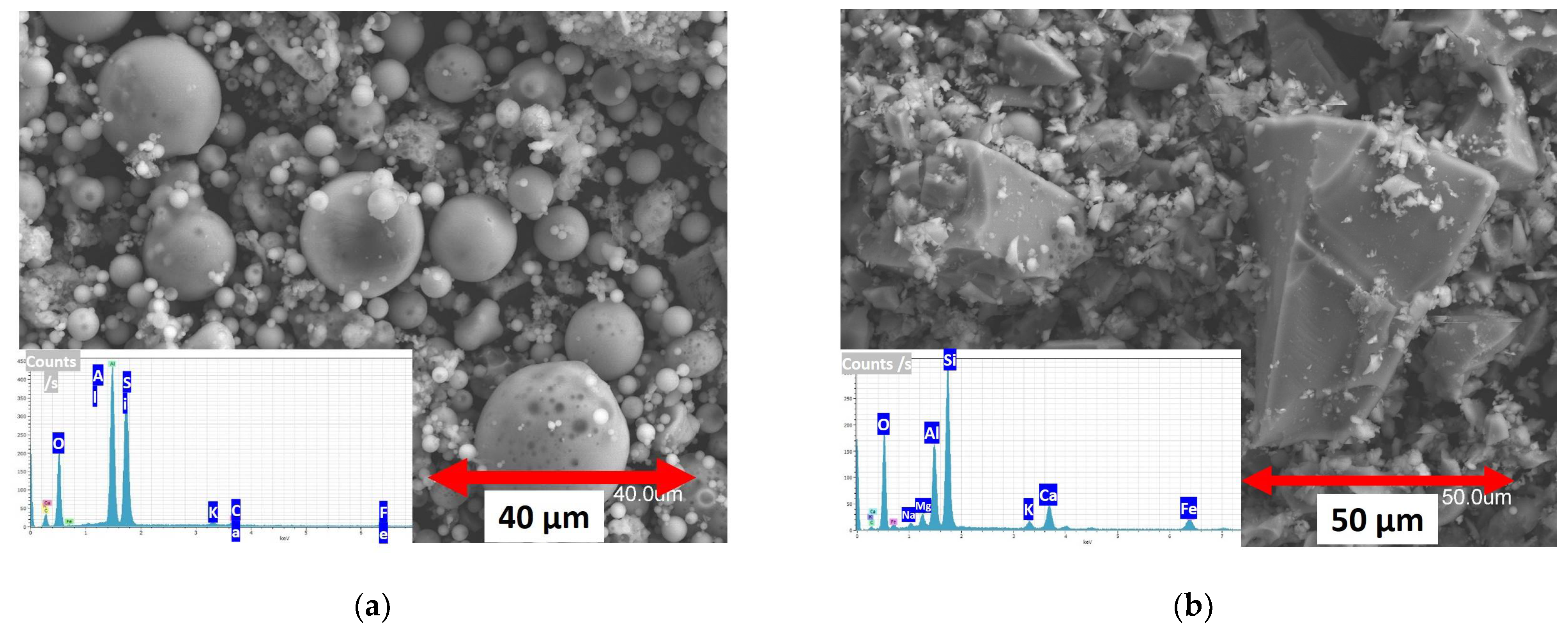

3.1. Characterization of the Coal Bottom Ash, Coal Fly Ash and Cement

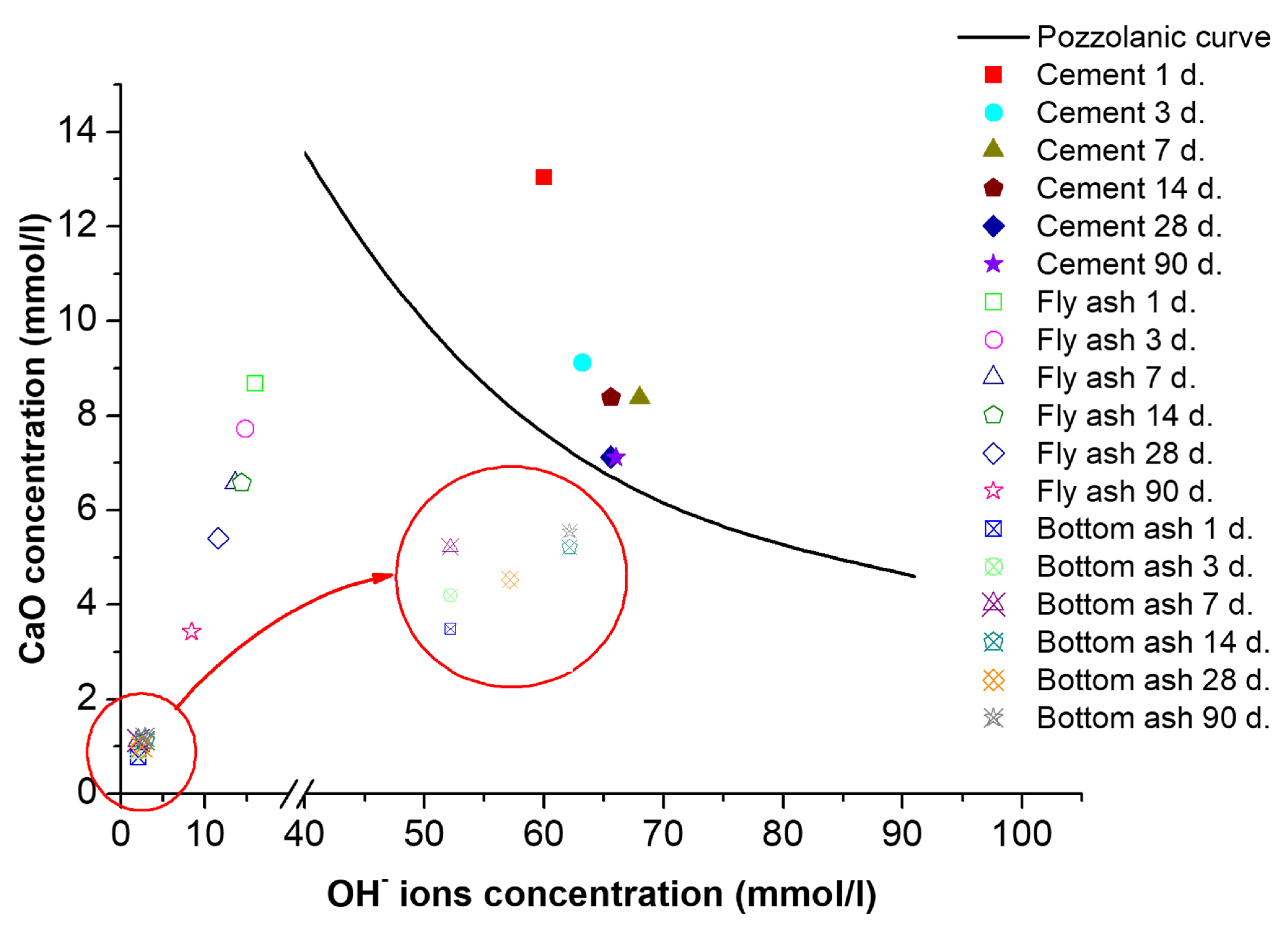

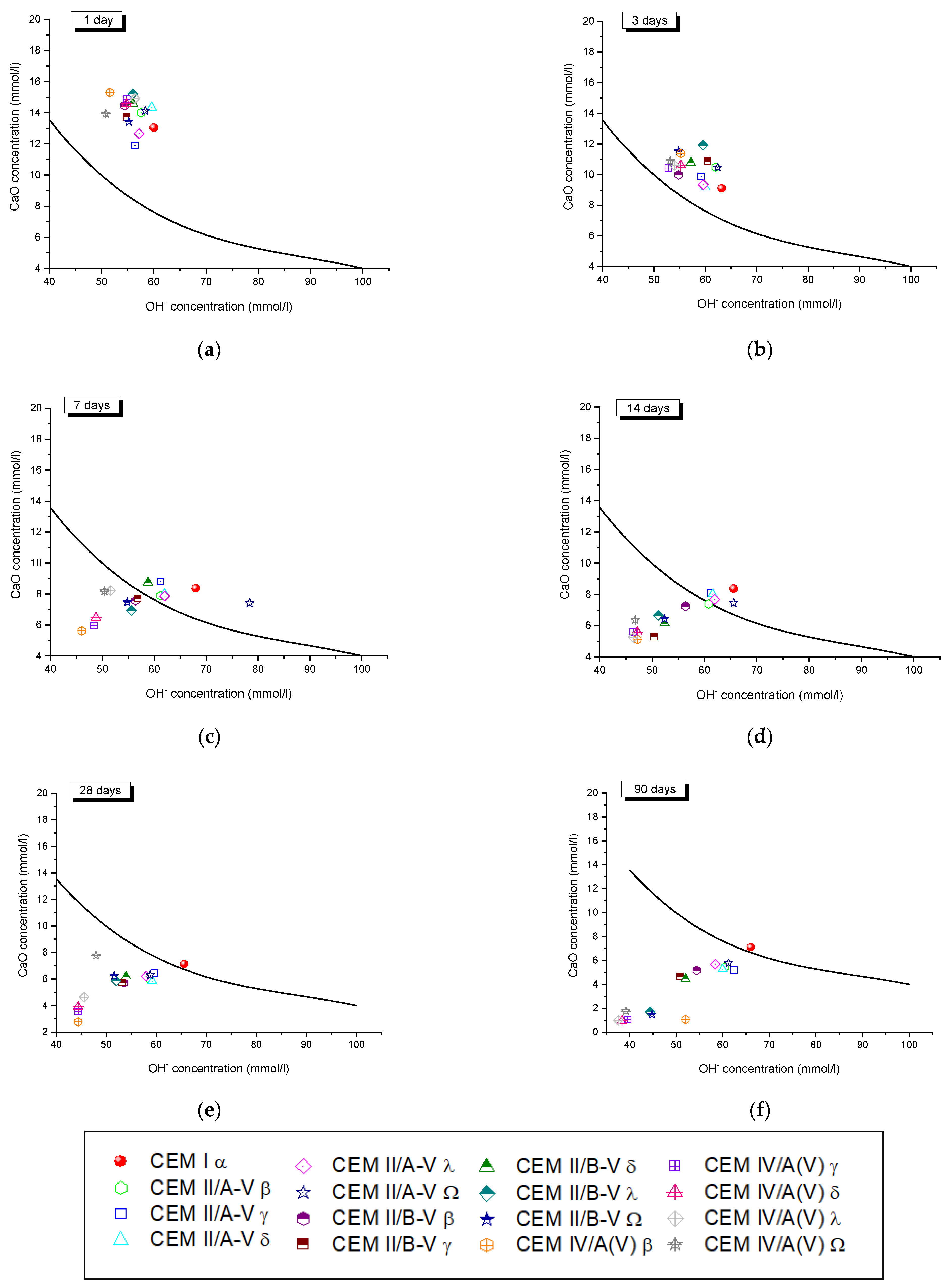

3.2. Pozzolanic Activity of Ground Coal Bottom Ash, Coal Fly Ash and Cement Mixes Determined by Chemical Testing

3.3. Pozzolanic Activity of Ground Coal Bottom Ash and Coal Fly Ash Mortars Determined by Means of the Strength Activity Index

4. Conclusions

- GCBA has a pozzolanic performance in a similar manner to coal fly ash (CFA). Then, partial or total replacement of coal fly ash by ground coal bottom ash in Portland fly ash and pozzolanic cements does not have a significant effect on pozzolanic properties;

- CFA reacts slowly with lime until 7 days. Reactivity increases at 14 days and, later on, at 28 days, the Ca(OH)2 consumption sharply increases;

- GCBA mixed with CFA is adequate to be standardized as new blended cement. Therefore, it is recommended to standardize the GCBA in the cement standards all around the world;

- This experimental method provides reliable information about the quality of the coal bottom ash.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- International Organization for Standardization. ISO 1928E Solid Mineral Fuels. Determination of Gross Calorific Value by the Bomb Calorimetric Method and Calculation of Net Calorific Value; The International Organization for Standardization (ISO): Geneva, Switzerland, 2009. [Google Scholar]

- International Organization for Standardization. ISO 1171 Solid Mineral Fuels. Determination of Ash. Specifies a Method for the Determination of the Ash of All Solid Mineral Fuels; The International Organization for Standardization (ISO): Geneva, Switzerland, 2010. [Google Scholar]

- Argiz, C.; Menéndez, E.; Sanjuán, M.A. Effect of mixes made of coal bottom ash and fly ash on the mechanical strength and porosity of Portland cement. Mater. Construcc. 2013, 309, 49–64. [Google Scholar] [CrossRef] [Green Version]

- Valentim, B.; Guedes, A.; Flores, D.; Ward, C.R.; Hower, J.C. Variations in fly ash composition with sampling location: Case study from a Portuguese power plant. CCGP J. 2009, 1, 14–24. [Google Scholar] [CrossRef]

- Van den Heede, P.; Ringoot, N.; Beirnaert, A.; Van Brecht, A.; Van den Brande, E.; De Schutter, G.; De Belie, N. Sustainable High Quality Recycling of Aggregates from Waste-to-Energy, Treated in a Wet Bottom Ash Processing Installation, for Use in Concrete Products. Materials 2016, 9, 9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Valentim, B.; Białecka, B.; Gonçalves, P.A.; Guedes, A.; Guimarães, R.; Cruceru, M.; Całus-Moszko, J.; Popescu, L.G.; Predeanu, G.; Santos, A.C. Undifferentiated Inorganics in Coal Fly Ash and Bottom Ash: Calcispheres, Magnesiacalcispheres, and Magnesiaspheres. Minerals 2018, 8, 140. [Google Scholar] [CrossRef] [Green Version]

- Churcill, V.E.; Amirkhanian, S.N. Coal ash utilization in asphalt concrete mixtures. J. Mater. Civil Eng. 1999, 11, 295–297. [Google Scholar] [CrossRef]

- Bai, Y.; Darcy, F.; Basheer, P.A.M. Strength and drying shrinkage properties of concrete containing furnace bottom ash as fine aggregate. Constr. Build. Mater. 2005, 19, 691–697. [Google Scholar] [CrossRef]

- Bentz, D.P.; Snyder, K.A. Protected paste volume in concrete, extension to internal curing using saturated lightweight fine aggregate. Cem. Concr. Res. 1999, 29, 1863–1867. [Google Scholar] [CrossRef]

- Predeanu, G.; Popescu, L.G.; Abagiu, T.A.; Panaitescu, C.; Valentim, B.; Guedes, A. Characterization of bottom ash of Pliocene lignite as ceramic composites raw material by petrographic, SEM/EDS and Raman microspectroscopical methods. Int. J. Coal Geol. 2016, 168, 131–145. [Google Scholar] [CrossRef]

- Valentim, B.; Abagiu, A.T.; Anghelescu, L.; Flores, D.; French, D.; Gonçalves, P.; Guedes, A.; Popescu, L.G.; Predeanu, G.; Ribeiro, J.; et al. Assessment of bottom ash landfilled at Ceplea Valley (Romania) as a source of rare earth elements. Int. J. Coal Geol. 2019, 201, 109–126. [Google Scholar] [CrossRef]

- CEN-CENELEC. European Standard EN 197-1 Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements; The European Committee for Standardization (CEN): Brussels, Belgium, 2011. [Google Scholar]

- CEN-CENELEC. European Standard EN 196-2 Methods of Testing Cement—Part 2: Chemical Analysis of the Cement; The European Committee for Standardization (CEN): Brussels, Belgium, 2013. [Google Scholar]

- CEN-CENELEC. European Standard EN 196-5 Methods of Testing Cement—Part 5: Pozzolanicity Test for Pozzolanic Cement; The European Committee for Standardization (CEN): Brussels, Belgium, 2011. [Google Scholar]

- CEN-CENELEC. European Standard EN 450-1 Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria; The European Committee for Standardization (CEN): Brussels, Belgium, 2012. [Google Scholar]

- CEN-CENELEC. European Standard EN 196-1 Methods of Testing Cement—Part 1: Determination of Strength; The European Committee for Standardization (CEN): Brussels, Belgium, 2005. [Google Scholar]

- ASTM International. ASTM C618–15 Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; American Society for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Menéndez, E.; Argiz, C.; Sanjuán, M.Á. Chloride Induced Reinforcement Corrosion in Mortars Containing Coal Bottom Ash and Coal Fly Ash. Materials 2019, 12, 1933. [Google Scholar] [CrossRef] [Green Version]

- Sanjuán, M.Á.; Argiz, C.; Menéndez, E. Assessment of a new Portland cement component: Ground coal bottom ash. DYNA 2018, 93, 192–196. [Google Scholar] [CrossRef] [Green Version]

- McCarthy, G.J.; Swanson, K.D.; Keller, L.P.; Blatter, W.C. Mineralogy of western fly ash. Cem. Concr. Res. 1984, 14, 471–478. [Google Scholar] [CrossRef]

- Dembas, A. Optimizing the physical and technological properties of cement additives in concrete mixtures. Cem. Concr. Res. 1996, 26, 1737–1744. [Google Scholar] [CrossRef]

- Hanehara, S.; Tomosawa, F.; Kobayakawa, M.; Hwang, K.R. Effects of water/powder ratio, mixing ratio of fly ash, and curing temperature on pozzolanic reaction of fly ash in cement paste. Cem. Concr. Res. 2001, 31, 31–39. [Google Scholar] [CrossRef]

- Damidot, D.; Lothenbach, B.; Herfort, D.; Glasser, F.P. Thermodynamics and cement science. Cem. Concr. Res. 2011, 41, 679–695. [Google Scholar] [CrossRef]

- Goñi, S.; Lorenzo, M.P.; Guerrero, A.; Hernández, M.S. Calcium hydroxide saturation factors in the pore solution of hydrated Portland cement fly ash pastes. J. Am. Ceram. Soc. 1996, 79, 1041–1046. [Google Scholar] [CrossRef]

- Douglas, E.; Pouskouleli, G. Prediction of compressive strength of mortars made with Portland cement–blast-furnace slag–fly ash blends. Cem. Concr. Res. 1991, 21, 523–534. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete, Microstructure, Properties and Materials; Prentice Hall, Inc.: Englewood Cliffs, NJ, USA, 2001. [Google Scholar]

- Tsimas, S.; Moutsatsou-Tsima, A. High-calcium fly ash as the fourth constituent in concrete: Problems, solutions and perspectives. Cem. Concr. Compos. 2005, 27, 231–237. [Google Scholar] [CrossRef]

- Felekoğlu, B. Utilisation of Turkish fly ashes in cost effective HVFA concrete production. Fuel 2006, 85, 1944–1949. [Google Scholar] [CrossRef]

- Bouzoubaa, N.; Zhang, M.H.; Bilodeau, A.; Malhotra, V.M. The effect of grinding on the physical properties of fly ashes and a Portland cement clinker. Cem. Concr. Res. 1997, 27, 1861–1874. [Google Scholar] [CrossRef]

- Bouzoubaa, N.; Zhang, M.H.; Malhotra, V.M. Mechanical properties and durability of concrete made with high-volume fly ash blended cements using a coarse fly ash. Cem. Concr. Res. 2001, 31, 1393–1402. [Google Scholar] [CrossRef]

- Kiattikomol, K.; Jaturapitakkul, C.; Songpiriyakij, S.; Chutubtim, S. A study of ground coarse fly ashes with different fineness from various sources as pozzolanic materials. Cem. Concr. Comp. 2001, 23, 335–343. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Homwuttiwong, S.; Sirivivatnanon, V. Influence of fly ash fineness on strength, drying shrinkage and sulfate resistance of blended cement mortar. Cem. Concr. Res. 2004, 34, 1087–1092. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chotithanorm, C.; Cao, H.T.; Sirivivatnanon, V. Influence of fly ash fineness on the chloride penetration of concrete. Constr. Build. Mater. 2007, 21, 356–361. [Google Scholar] [CrossRef]

- Erdogdu, K.; Türker, P. Effects of fly ash particle size on strength of Portland cement fly ash mortars. Cem. Concr. Res. 1998, 28, 1217–1222. [Google Scholar] [CrossRef]

- Slanicka, S. The influence of fly ash fineness on the strength of concrete. Cem. Concr. Res. 1991, 21, 285–296. [Google Scholar] [CrossRef]

- Felekoğlu, B.; Türkel, S.; Kalyoncu, H. Optimization of fineness to maximize the strength activity of high-calcium ground fly ash—Portland cement composites. Constr. Build. Mater. 2009, 23, 2053–2061. [Google Scholar] [CrossRef]

- Jaturapitakkul, C.; Kiattikomol, K.; Sata, V.; Leekeeratikul, T. Use of ground coarse fly ash as a replacement of condensed silica fume in producing high-strength concrete. Cem. Concr. Res. 2004, 34, 549–555. [Google Scholar] [CrossRef]

- Haque, M.N.; Kayali, O. Properties of high-strength concrete using a fine fly ash. Cem. Concr. Res. 1998, 28, 1445–1452. [Google Scholar] [CrossRef]

| CEMENT MIX | % Material | Coal Fly Ash + Coal Bottom Ash Mix Codification | ||||||

|---|---|---|---|---|---|---|---|---|

| α | β | γ 1 | δ 1 | λ 1 | Ω | |||

| CEM I | Fly ash | 0% | 0% | |||||

| Bottom ash | 0% | |||||||

| Cement | 100% | 100% | ||||||

| CEM II/A-V | Fly ash | 10% | 10% | 9% | 8% | 5% | 0% | |

| Bottom ash | 0% | 1% | 2% | 5% | 10% | |||

| Cement | 90% | 90% | 90% | 90% | 90% | 90% | ||

| CEM II/B-V | Fly ash | 25% | 25% | 22.5% | 20% | 12.5% | 0% | |

| Bottom ash | 0% | 2.5% | 5% | 12.5% | 25% | |||

| Cement | 75% | 75% | 75% | 75% | 75% | 75% | ||

| CEM IV/A (V) | Fly ash | 35% | 35% | 31.5% | 28% | 17.5% | 0% | |

| Bottom ash | 0% | 3.5% | 7% | 17.5% | 35% | |||

| Cement | 65% | 65% | 65% | 65% | 65% | 65% | ||

| Chemical Composition (%) | Cement | Fly Ash (CFA) | Bottom Ash (CBA) | Physical Properties of Cement | |

|---|---|---|---|---|---|

| SiO2 | 20.9 | 50.5 | 52.2 | Specific gravity (kg/m3) | 3.10 |

| Al2O3 | 4.3 | 28.9 | 27.5 | Initial setting time (min) | 205 |

| Fe2O3 | 3.5 | 4.7 | 6.0 | Final setting time (min) | 325 |

| CaO | 62.7 | 5.0 | 5.9 | Volume expansion (mm) | 0.70 |

| MgO | 1.9 | 1.8 | 1.7 | Blaine Specific surface (m2/kg) | 4050 |

| SO3 | 3.4 | 0.21 | 0.13 | Compressive strength | (MPa) |

| K2O | 0.9 | 0.80 | 0.57 | 1 days | 13.30 |

| Ti2O5 | 0.25 | 1.56 | 1.53 | 3 days | 19.45 |

| P2O5 | 0.10 | 0.76 | 0.74 | 7 days | 37.95 |

| LOI | 3.69 | 3.6 | 1.8 | 14 days | 45.25 |

| Insoluble residue 1 | 1.04 | 71.3 | 75.7 | 28 days | 50.98 |

| CI- | 0.023 | 0.001 | 0.001 | 90 days | 55.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menéndez, E.; Argiz, C.; Sanjuán, M.Á. Reactivity of Ground Coal Bottom Ash to Be Used in Portland Cement. J 2021, 4, 223-232. https://doi.org/10.3390/j4030018

Menéndez E, Argiz C, Sanjuán MÁ. Reactivity of Ground Coal Bottom Ash to Be Used in Portland Cement. J. 2021; 4(3):223-232. https://doi.org/10.3390/j4030018

Chicago/Turabian StyleMenéndez, Esperanza, Cristina Argiz, and Miguel Ángel Sanjuán. 2021. "Reactivity of Ground Coal Bottom Ash to Be Used in Portland Cement" J 4, no. 3: 223-232. https://doi.org/10.3390/j4030018

APA StyleMenéndez, E., Argiz, C., & Sanjuán, M. Á. (2021). Reactivity of Ground Coal Bottom Ash to Be Used in Portland Cement. J, 4(3), 223-232. https://doi.org/10.3390/j4030018