Decarbonizing the Cement Industry: Technological, Economic, and Policy Barriers to CO2 Mitigation Adoption

Abstract

1. Introduction

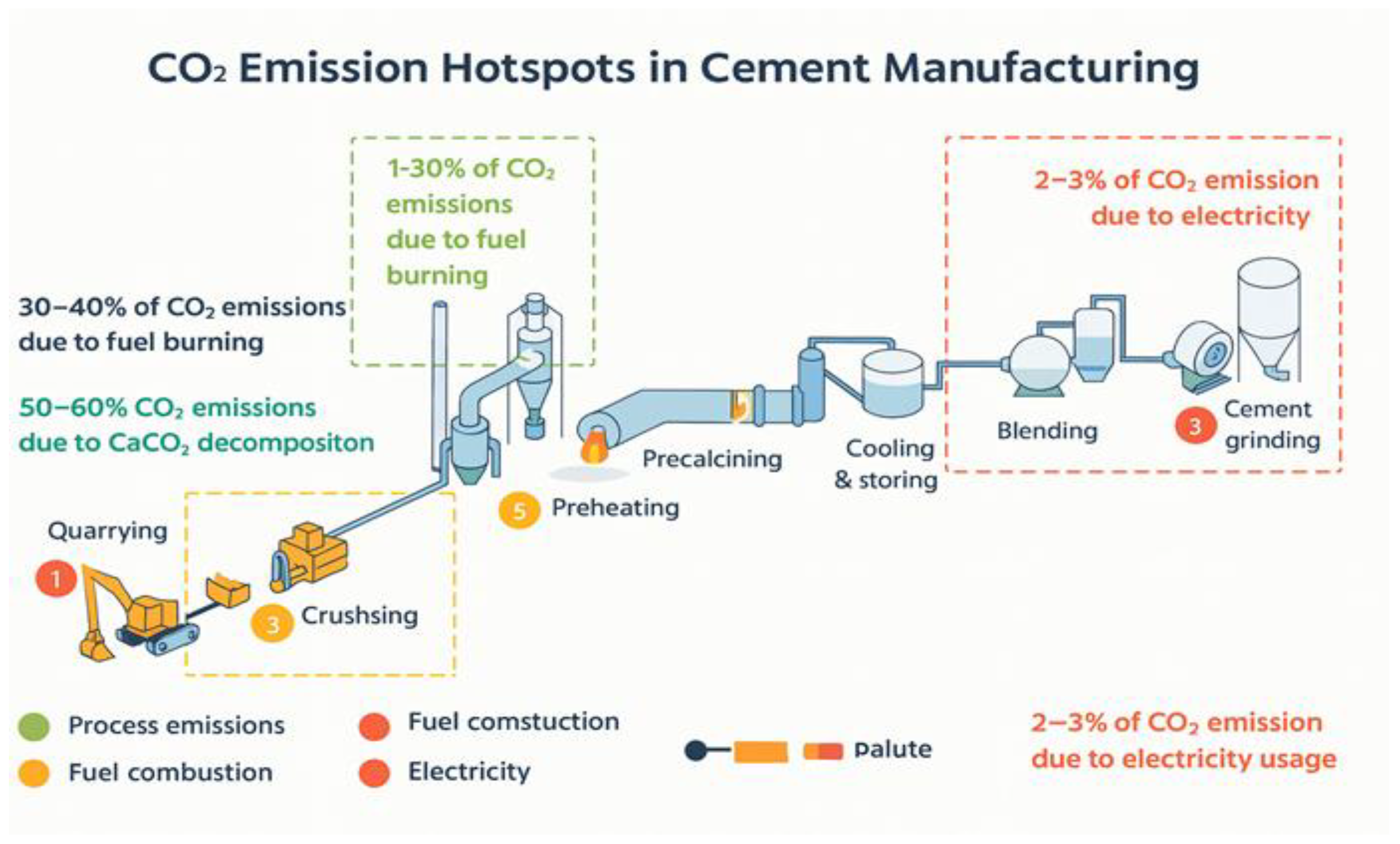

- Inefficient production processes: Wet and semi-wet kiln technologies consume significantly more thermal energy than dry processes. Transitioning from wet to dry processes can reduce energy consumption by 13% and fuel use by 28% [6].

- Outdated machinery: Reliance on obsolete equipment lacking modern energy-saving and emission-reduction technologies leads to higher energy consumption and CO2 emissions.

- High-carbon fossil fuels and inappropriate raw materials: Utilizing fuels with high carbon content, such as coal and unsuitable raw materials, increases combustion-related CO2 output.

- Excessive thermal losses: Significant heat losses occur through exhaust gases and kiln surfaces, resulting in wasted energy. Studies have shown that about 40% of the total input energy is lost through waste gas and heat dissipation on the surface of the rotary kiln [7].

- High clinker-to-cement ratios: Clinker production accounts for over 90% of the CO2 emissions in cement production. Reducing the clinker content in cement by substituting it with alternative materials can significantly lower emissions [8].

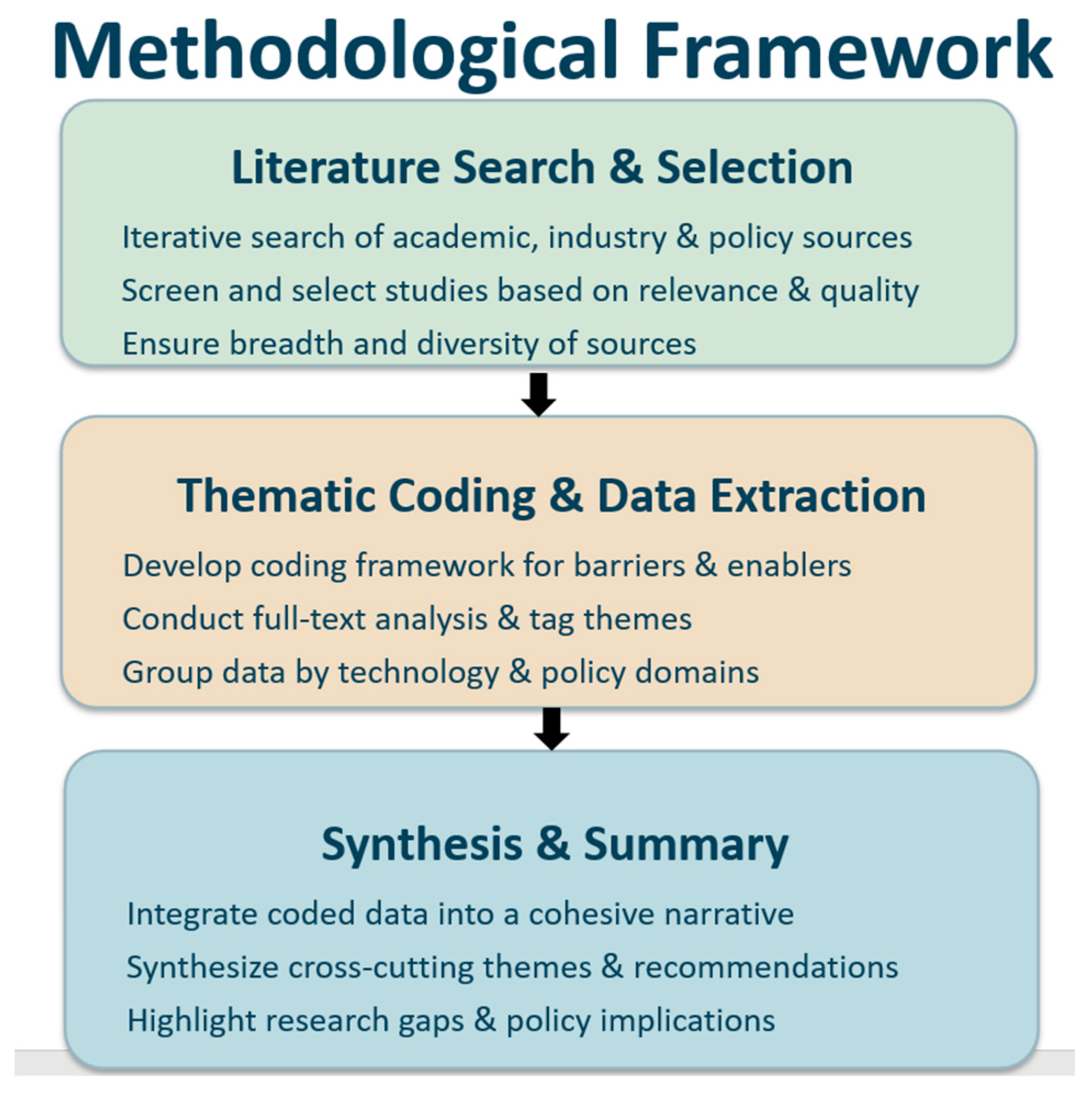

2. Methodology

Data Extraction

- Clinker and material substitution: barriers related to alternative cement chemistries and SCMs, e.g., quality/performance concerns, supply of raw materials.

- Energy efficiency improvements: obstacles to upgrading kilns and processes, e.g., capital costs, operational complexity, and expertise gaps.

- Carbon capture, utilization, and storage: issues in deploying capture technologies in cement plants and transport/storage infrastructure, e.g., technological readiness, high costs, and regulatory support.

- Alternative fuels: challenges in replacing fossil fuels with biomass or waste-derived fuels, e.g., fuel availability, handling and process compatibility, emissions regulations.

3. Overview of Key Studies on Barriers to CO2 Mitigation in the Cement Industry

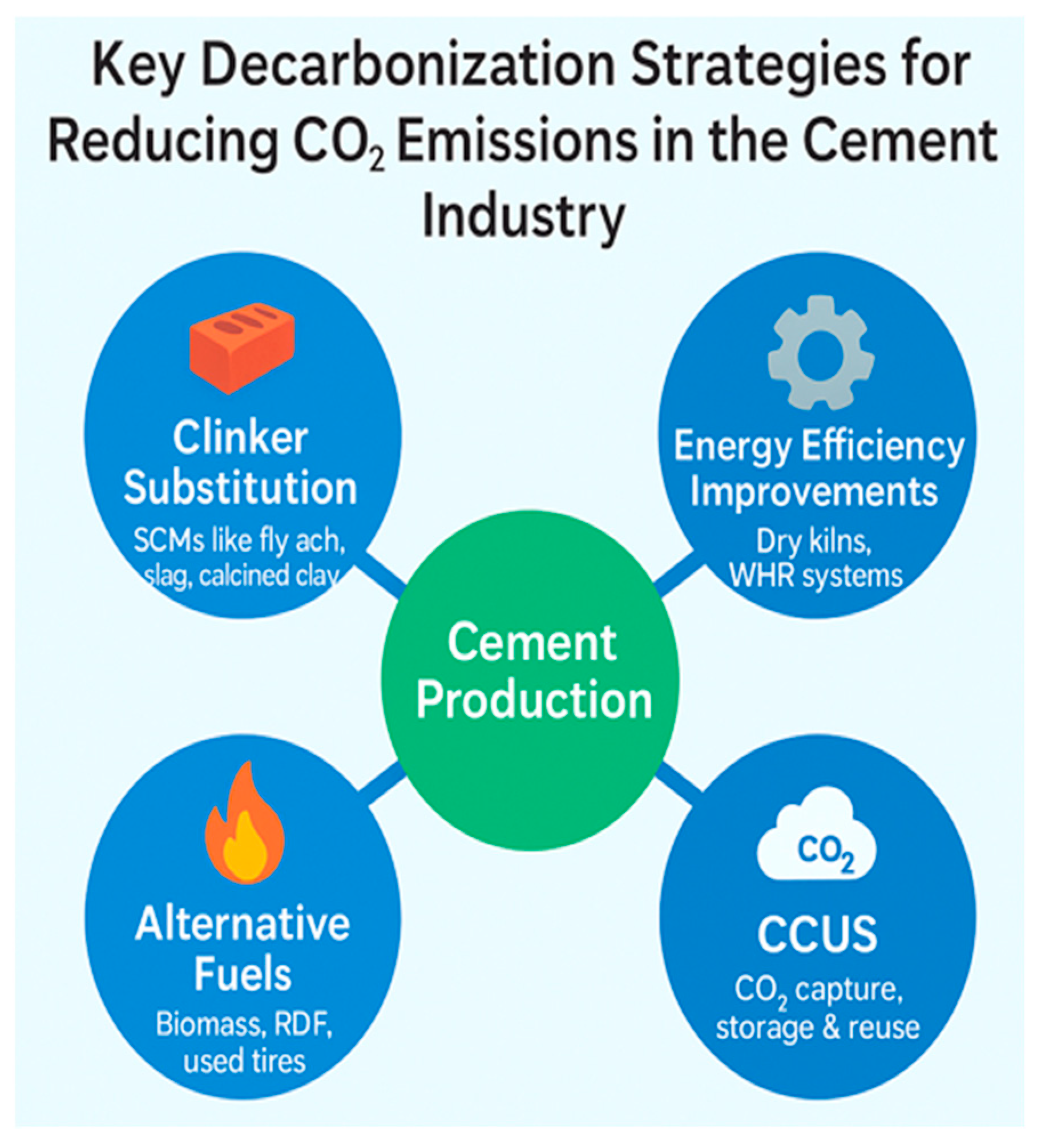

4. Overview of CO2 Mitigation Strategies in the Cement Industry

4.1. Clinker Substitution (Low-Carbon Cements)

4.1.1. Technical Barriers

4.1.2. Economic Barriers

4.1.3. Policy and Regulatory Barriers (Clinker Substitution)

4.2. Energy Efficiency in Cement Production

4.2.1. Technical Barriers

4.2.2. Economic Barriers

4.2.3. Policy Barriers

4.3. Carbon Capture, Utilization, and Storage

4.3.1. Technical Barriers

4.3.2. Economic Barriers

4.3.3. Policy and Societal Barriers

4.4. Alternative Fuels (Fuel Switching)

4.4.1. Technical Barriers

4.4.2. Economic Barriers

4.4.3. Policy and Regulatory Barriers (Alternative Fuels)

5. Discussions

5.1. Standardization and Comparability of Data

5.2. Full-Scale Demonstrations and Pilot Data

5.3. Policy and Market Mechanisms Analysis

5.4. Life Cycle and Cross-Sector Interactions

5.5. Cross-Cutting Barriers to CO2 Mitigation Strategies

6. Conclusions and Recommendations

- Enable Clinker Substitution and Process Optimization (Short-term): Move to modernize cement standards and construction codes to accommodate higher SCM usage; prioritize the adoption of best-available technologies for thermal efficiency, grinding technologies upgrades, and process advance controls to capture short-term gains.

- Support Alternative Fuel Adoption (Short-term): Reform regulations to enable safe co-processing of biomass and waste-derived fuels in cement kilns. Invest in fuel preprocessing, build reliable supply chains and stakeholder engagement to build trust and secure social licenses.

- Accelerate CCUS Development (Long-term): Support public–private investment frameworks for pilot, demonstration projects and coordinated investment in CO2 transport and storage infrastructure. Implement policy instruments, such as carbon pricing or tax credits, to reduce commercial risk and improve commercial feasibility.

- Strengthen Policy Support and Collaboration (Long-term): Implement green procurement mandates and comprehensive carbon pricing; harmonize standards and data practices; and promote international cooperation to publicize global best practices and support technology transfer.

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Wu, S.; Shao, Z.; Andrew, R.M.; Bing, L.; Wang, J.; Niu, L.; Liu, Z.; Xi, F. Global CO2 uptake by cement materials accounts 1930–2023. Sci. Data 2024, 11, 1409. [Google Scholar] [CrossRef]

- Griffiths, S.; Sovacool, B.K.; Furszyfer Del Rio, D.D.; Foley, A.M.; Bazilian, M.D.; Kim, J.; Uratani, J.M. Decarbonizing the cement and concrete industry: A systematic review of socio-technical systems, technological innovations, and policy options. Renew. Sustain. Energy Rev. 2023, 180, 113291. [Google Scholar] [CrossRef]

- Ripley, K.M.; Saadi, F.H.; Burke, Z.L.H. Cost-motivated pathways towards near-term decarbonization of the cement industry. RSC Sustain. 2025, 3, 255–263. [Google Scholar] [CrossRef]

- Cheng, D.; Reiner, D.M.; Yang, F.; Cui, C.; Meng, J.; Shan, Y.; Liu, Y.; Tao, S.; Guan, D. Projecting future carbon emissions from cement production in developing countries. Nat. Commun. 2023, 14, 8213. [Google Scholar] [CrossRef] [PubMed]

- Khaiyum, M.Z.; Sarker, S.; Kabir, G. Evaluation of Carbon Emission Factors in the Cement Industry: An Emerging Economy Context. Sustainability 2023, 15, 15407. [Google Scholar] [CrossRef]

- Madlool, N.A.; Saidur, R.; Hossain, M.S.; Rahim, N.A. A critical review on energy use and savings in the cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2042–2060. [Google Scholar] [CrossRef]

- Liu, E.; Jiang, Y.; Guo, Z.; Qian, Y.; Wang, Y.; Wang, S. Waste Heat Recovery and Utilization of Cement Rotary Kiln Based on Biomass Energy. BioResources 2023, 18, 3056–3072. [Google Scholar] [CrossRef]

- Shah, I.H.; Miller, S.A.; Jiang, D.; Myers, R.J. Cement substitution with secondary materials can reduce annual global CO2 emissions by up to 1.3 gigatons. Nat. Commun. 2022, 13, 5758. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Hashim, H. A novel design for green and economical cement manufacturing. J. Clean. Prod. 2012, 22, 60–66. [Google Scholar] [CrossRef]

- World Business Council for Sustainable Development (WBCSD), International Energy Agency (IEA). Technology Roadmap-Low-Carbon Transition in the Cement Industry; World Business Council for Sustainable Development (WBCSD), International Energy Agency (IEA): Paris, France, 2018; Available online: https://www.iea.org/reports/technology-roadmap-low-carbon-transition-in-the-cement-industry (accessed on 18 April 2025).

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Mikulčić, H.; Klemeš, J.J.; Vujanović, M.; Urbaniec, K.; Duić, N. Reducing greenhouse gasses emissions by fostering the deployment of alternative raw materials and energy sources in the cleaner cement manufacturing process. J. Clean. Prod. 2016, 136, 119–132. [Google Scholar] [CrossRef]

- Kajaste, R.; Hurme, M. Cement industry greenhouse gas emissions—Management options and abatement cost. J. Clean. Prod. 2016, 112, 4041–4052. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable cement production—Present and future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Leeson, D.; Mac Dowell, N.; Shah, N.; Petit, C.; Fennell, P.S. A Techno-economic analysis and systematic review of carbon capture and storage (CCS) applied to the iron and steel, cement, oil refining and pulp and paper industries, as well as other high purity sources. Int. J. Greenh. Gas Control 2017, 61, 71–84. [Google Scholar] [CrossRef]

- Zhang, C.-Y.; Yu, B.; Chen, J.-M.; Wei, Y.-M. Green transition pathways for cement industry in China. Resour. Conserv. Recycl. 2021, 166, 105355. [Google Scholar] [CrossRef]

- Wei, J.; Cen, K. Empirical assessing cement CO2 emissions based on China’s economic and social development during 2001–2030. Sci. Total Environ. 2019, 653, 200–211. [Google Scholar] [CrossRef]

- Ige, O.E.; Olanrewaju, O.A.; Duffy, K.J.; Collins, O.C. Environmental Impact Analysis of Portland Cement (CEM1) Using the Midpoint Method. Energies 2022, 15, 2708. [Google Scholar] [CrossRef]

- Ige, O.E.; Duffy, K.J.; Olanrewaju, O.A.; Collins, O.C. An Integrated System Dynamics Model and Life Cycle Assessment for Cement Production in South Africa. Atmosphere 2022, 13, 1788. [Google Scholar] [CrossRef]

- Plaza, M.G.; Martínez, S.; Rubiera, F. CO2 capture, use, and storage in the cement industry: State of the art and expectations. Energies 2020, 13, 5692. [Google Scholar] [CrossRef]

- Schorcht, F.; Kourti, I.; Scalet, B.M.; Roudier, S.; Sancho, L.D. Best Available Techniques (BAT) Reference Document for the Production of Cement, Lime and Magnesium Oxide. Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control); Publications Office of the European Union: Luxembourg, 2013; Available online: https://op.europa.eu/en/publication-detail/-/publication/12dbe9f3-28c6-44c9-8962-50a1359443d6 (accessed on 10 July 2025).

- Barbhuiya, S.; Bhusan Das, B.; Adak, D. Roadmap to a net-zero carbon cement sector: Strategies, innovations and policy imperatives. J. Environ. Manag. 2024, 359, 121052. [Google Scholar] [CrossRef] [PubMed]

- Chandler, D.L. New Approach Suggests Path to Emissions-Free Cement. Retrieved from Massachusetts Institute of Technology. 2019. Available online: https://news.mit.edu/2019/carbon-dioxide-emissions-free-cement-0916 (accessed on 20 August 2025).

- Wilhelmsson, B. Major Breakthrough for Plasma-Heated Cement Kiln in Sweden. In Heidelberg Materials Northern Europe—News & Articles; Heidelberg Materials: Sweden 17 February 2025. Available online: https://www.heidelbergmaterials-northerneurope.com/en/major-breakthrough-for-plasma-heated-cement-kiln-in-sweden (accessed on 20 August 2025).

- Volaity, S.S.; Aylas-Paredes, B.K.; Han, T.; Huang, J.; Sridhar, S.; Sant, G.; Kumar, A.; Neithalath, N. Towards decarbonization of cement industry: A critical review of electrification technologies for sustainable cement production. NPJ Mater. Sustain. 2025, 3, 23. [Google Scholar] [CrossRef]

- Hills, T.P.; Sceats, M.; Rennie, D.; Fennell, P. LEILAC: Low Cost CO2 Capture for the Cement and Lime Industries. Energy Procedia 2017, 114, 6166–6170. [Google Scholar] [CrossRef]

- Dunant, C.F.; Joseph, S.; Prajapati, R.; Allwood, J.M. Electric recycling of Portland cement at scale. Nature 2024, 629, 1055–1061. [Google Scholar] [CrossRef]

- Liu, M.; Dai, W.; Jin, W.; Li, M.; Yang, X.; Han, Y.; Huang, M. Mix proportion design and carbon emission assessment of high strength geopolymer concrete based on ternary solid waste. Sci. Rep. 2024, 14, 24989. [Google Scholar] [CrossRef]

- Benhelal, E.; Shamsaei, E.; Rashid, M.I. Challenges against CO2 abatement strategies in cement industry: A review. J. Environ. Sci. 2021, 104, 84–101. [Google Scholar] [CrossRef]

- Miller, S.A.; Habert, G.; Myers, R.J.; Harvey, J.T. Achieving net zero greenhouse gas emissions in the cement industry via value chain mitigation strategies. One Earth 2021, 4, 1398–1411. [Google Scholar] [CrossRef]

- Ige, O.E.; Von Kallon, D.V.; Desai, D. Carbon emissions mitigation methods for cement industry using a systems dynamics model. Clean Technol. Environ. Policy 2024, 26, 579–597. [Google Scholar] [CrossRef]

- Marinelli, M.; Janardhanan, M. Green cement production in India: Prioritization and alleviation of barriers using the best–worst method. Environ. Sci. Pollut. Res. 2022, 29, 63988–64003. [Google Scholar] [CrossRef]

- Cavalett, O.; Watanabe, M.D.B.; Voldsund, M.; Roussanaly, S.; Cherubini, F. Paving the way for sustainable decarbonization of the European cement industry. Nat. Sustain. 2024, 7, 568–580. [Google Scholar] [CrossRef]

- Habert, G.; Billard, C.; Rossi, P.; Chen, C.; Roussel, N. Cement production technology improvement compared to factor 4 objectives. Cem. Concr. Res. 2010, 40, 820–826. [Google Scholar] [CrossRef]

- Busch, P.; Kim, A.; Murphy, C.W.; Miller, S.A. Policy mechanisms to decarbonize cement production: Through the lens of California. Environ. Res. Infrastruct. Sustain. 2025, 5, 025003. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Uwasu, M.; Jiang, Y.; Saijo, T. On the Chinese Carbon Reduction Target. Sustainability 2010, 2, 1553–1557. [Google Scholar] [CrossRef]

- Benhelal, E.; Rashid, M.I.; Holt, C.; Rayson, M.S.; Brent, G.; Hook, J.M.; Stockenhuber, M.; Kennedy, E.M. The utilisation of feed and byproducts of mineral carbonation processes as pozzolanic cement replacements. J. Clean. Prod. 2018, 186, 499–513. [Google Scholar] [CrossRef]

- Dandautiya, R.; Singh, A.P. Utilization potential of fly ash and copper tailings in concrete as partial replacement of cement along with life cycle assessment. Waste Manag. 2019, 99, 90–101. [Google Scholar] [CrossRef]

- Paris, J.M.; Roessler, J.G.; Ferraro, C.C.; DeFord, H.D.; Townsend, T.G. A review of waste products utilized as supplements to Portland cement in concrete. J. Clean. Prod. 2016, 121, 1–18. [Google Scholar] [CrossRef]

- Bentz, D.P.; Hansen, A.S.; Guynn, J.M. Optimization of cement and fly ash particle sizes to produce sustainable concretes. Cem. Concr. Compos. 2011, 33, 824–831. [Google Scholar] [CrossRef]

- García-Gusano, D.; Herrera, I.; Garraín, D.; Lechón, Y.; Cabal, H. Life cycle assessment of the Spanish cement industry: Implementation of environmental-friendly solutions. Clean Technol. Environ. Policy 2015, 17, 59–73. [Google Scholar] [CrossRef]

- Knight, K.A.; Cunningham, P.R.; Miller, S.A. Optimizing supplementary cementitious material replacement to minimize the environmental impacts of concrete. Cem. Concr. Compos. 2023, 139, 105049. [Google Scholar] [CrossRef]

- Berndt, M.L. Properties of sustainable concrete containing fly ash, slag and recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 2606–2613. [Google Scholar] [CrossRef]

- Morrow, W.R.; Hasanbeigi, A.; Sathaye, J.; Xu, T. Assessment of energy efficiency improvement and CO2; emission reduction potentials in India’s cement and iron & steel industries. J. Clean. Prod. 2014, 65, 131–141. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Alcalá, J. Life cycle greenhouse gas emissions of blended cement concrete including carbonation and durability. Int. J. Life Cycle Assess. 2014, 19, 3–12. [Google Scholar] [CrossRef]

- Ammenberg, J.; Baas, L.; Eklund, M.; Feiz, R.; Helgstrand, A.; Marshall, R. Improving the CO2 performance of cement, part III: The relevance of industrial symbiosis and how to measure its impact. J. Clean. Prod. 2015, 98, 145–155. [Google Scholar] [CrossRef]

- Global, C.; Concrete, A. GNR 2.0—GCCA in Numbers. Available online: https://gccassociation.org/sustainability-innovation/gnr-gcca-in-numbers/ (accessed on 10 July 2025).

- Chennoufi, L.; Hoagland-Grey, H.; Breisinger, M.; Boulet, E. Cement Manufacturing Plant Guidelines: An Approach to Reconciling the Financing of Cement with Climate Change Objectives; IDB Publications: Washington, DC, USA, 2010. [Google Scholar]

- Zajac, M.; Skocek, J.; Skibsted, J.; Ben Haha, M. CO2 mineralization of demolished concrete wastes into a supplementary cementitious material—A new CCU approach for the cement industry. RILEM Tech. Lett. 2021, 6, 53–60. [Google Scholar] [CrossRef]

- Ekincioglu, O.; Gurgun, A.P.; Engin, Y.; Tarhan, M.; Kumbaracibasi, S. Approaches for sustainable cement production—A case study from Turkey. Energy Build. 2013, 66, 136–142. [Google Scholar] [CrossRef]

- Shanks, W.; Dunant, C.F.; Drewniok, M.P.; Lupton, R.C.; Serrenho, A.; Allwood, J.M. How much cement can we do without? Lessons from cement material flows in the UK. Resour. Conserv. Recycl. 2019, 141, 441–454. [Google Scholar] [CrossRef]

- Imbabi, M.S.; Carrigan, C.; McKenna, S. Trends and developments in green cement and concrete technology. Int. J. Sustain. Built Environ. 2012, 1, 194–216. [Google Scholar] [CrossRef]

- Di Filippo, J.; Karpman, J.; DeShazo, J. The impacts of policies to reduce CO2 emissions within the concrete supply chain. Cem. Concr. Compos. 2019, 101, 67–82. [Google Scholar] [CrossRef]

- IEA, W. Cement Technology Roadmap 2009–Carbon Emissions Reductions Up to 2050. World Business Council on Sustainable Development (WBCSD), International Energy Agency (IEA). 2009. Available online: https://iea.blob.core.windows.net/assets/897b7ad9-200a-4314-b870-394dc8e6861a/CementTechnologyRoadmap-CarbonEmissionsReductionsupto2050.pdf (accessed on 18 April 2025).

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Meida, L.O. Carbon dioxide emissions from the global cement industry. Annu. Rev. Energy Environ. 2001, 26, 303–329. [Google Scholar] [CrossRef]

- Lu, H.; Price, L.; Zhang, Q. Capturing the invisible resource: Analysis of waste heat potential in Chinese industry. Appl. Energy 2016, 161, 497–511. [Google Scholar] [CrossRef]

- Crijns-Graus, W.; Yue, H.; Zhang, S.; Kermeli, K.; Worrell, E. Energy efficiency improvement opportunities in the global industrial sector. Encycl. Renew. Sustain. Mater. 2020, 2016, 377. [Google Scholar] [CrossRef]

- Dhas, S. Decarbonisation Pathways for the Cement Industry. Master’s Thesis, The Delft University of Technology and the Leiden University, Delft/Leiden, The Netherlands, 2021. [Google Scholar]

- Ogbeide, S. Enhancing Energy Efficiency in the Cement Industry. J. Emerg. Trends Eng. Appl. Sci. 2024, 15, 93–102. [Google Scholar]

- KEMA. Industrial Case Study: The Cement Industry; Lawrence Berkeley National Laboratory: San Francisco, CA, USA, 2005. [Google Scholar]

- Best, R.; Zhang, Q.Y. What explains carbon-pricing variation between countries? Energy Policy 2020, 143, 111541. [Google Scholar] [CrossRef]

- Mandil, C. Tracking Industrial Energy Efficiency and CO2 Emissions; International Energy Agency: Paris, France, 2007; pp. 1–12. [Google Scholar]

- Gambhir, A.; Schulz, N.; Napp, T.; Tong, D.; Munuera, L.; Faist, M.; Riahi, K. A hybrid modelling approach to develop scenarios for China’s carbon dioxide emissions to 2050. Energy Policy 2013, 59, 614–632. [Google Scholar] [CrossRef]

- Citaristi, I. International energy agency—Iea. In The Europa Directory of International Organizations 2022; Routledge: Oxfordshire, UK, 2022; pp. 701–702. [Google Scholar]

- IEA. CCUS in clean energy transitions. In Energy Technology Perspectives; IEA: Paris, France, 2020; Available online: https://www.iea.org/reports/ccus-in-clean-energy-transitions/ccus-technology-innovation#abstract (accessed on 16 June 2023).

- Bjerge, L.-M.; Brevik, P. CO2 Capture in the Cement Industry, Norcem CO2 Capture Project (Norway). Energy Procedia 2014, 63, 6455–6463. [Google Scholar] [CrossRef]

- Abdelshafy, A.; Walther, G. Analyzing current carbon capture, utilization and storage (CCUS) research and pilot projects in the European cement sector. In EconStor; The Oxford Institute for Energy Studies: Oxford, UK, 2023. [Google Scholar]

- Vågerö, O. Alternatives to CCS in the Deep Decarbonisation of the Norwegian Cement Industry. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2020. Available online: https://www.diva-portal.org/smash/get/diva2%3A1453168/FULLTEXT01.pdf (accessed on 18 June 2025).

- Yu, S.; Horing, J.; Liu, Q.; Dahowski, R.; Davidson, C.; Edmonds, J.; Liu, B.; McJeon, H.; McLeod, J.; Patel, P.; et al. CCUS in China’s mitigation strategy: Insights from integrated assessment modeling. Int. J. Greenh. Gas Control 2019, 84, 204–218. [Google Scholar] [CrossRef]

- Monteiro, J.; Roussanaly, S. CCUS scenarios for the cement industry: Is CO2 utilization feasible? J. CO2 Util. 2022, 61, 102015. [Google Scholar] [CrossRef]

- Do, T.N. Reimagining carbon border adjustment mechanisms: A path to climate and development synergy. Glob. Transit. 2025, 7, 144–147. [Google Scholar] [CrossRef]

- Olabi, A.G.; Wilberforce, T.; Elsaid, K.; Sayed, E.T.; Maghrabie, H.M.; Abdelkareem, M.A. Large scale application of carbon capture to process industries—A review. J. Clean. Prod. 2022, 362, 132300. [Google Scholar] [CrossRef]

- Sievert, K.; Cameron, L.; Carter, A. Why the Cost of Carbon Capture and Storage Remains Persistently High. In Bottom Line: Unpacking Future Canada’s Oil; International Institute of Sustainable Development: Winnipeg, MB, Canada, 2023. [Google Scholar] [CrossRef]

- Li, Z.; Sun, L.; Zhang, R.; Hanaoka, T. Decarbonization pathways promote improvements in cement quality and reduce the environmental impact of China’s cement industry. Commun. Earth Environ. 2024, 5, 769. [Google Scholar] [CrossRef]

- Daniels, J. Global Status of CCS 2022; Global CCS Institute: Melbourne, Australia, 2024. [Google Scholar]

- Bellora, C.; Fontagné, L. EU in search of a Carbon Border Adjustment Mechanism. Energy Econ. 2023, 123, 106673. [Google Scholar] [CrossRef]

- Eicke, L.; Weko, S.; Apergi, M.; Marian, A. Pulling up the carbon ladder? Decarbonization, dependence, and third-country risks from the European carbon border adjustment mechanism. Energy Res. Soc. Sci. 2021, 80, 102240. [Google Scholar] [CrossRef]

- Nilsson, A.; Hans, F.; Lopez Legarreta, P.; Lui, S.; Röser, F. Decarbonisation Pathways for the EU Cement Sector. Technology Routes and Potential Ways Forward. Available online: https://newclimate.org/wp-content/uploads/2020/12/SGCCC-EU-Cement-paper-NewClimate_Nov2020.pdf (accessed on 25 April 2025).

- Wojtacha-Rychter, K.; Kucharski, P.; Smolinski, A. Conventional and Alternative Sources of Thermal Energy in the Production of Cement—An Impact on CO2 Emission. Energies 2021, 14, 1539. [Google Scholar] [CrossRef]

- Burman, T.; Engvall, J. Evaluation of Usage of Plasma Torches in Cement Production; Master in Programme Sustainable Energy Systems Chalmers University of Technology: Gothenburg, Sweden, 2019; Available online: https://hdl.handle.net/20.500.12380/257463 (accessed on 25 April 2025).

- Fooladgar, E.; Sepman, A.; Ögren, Y.; Johansson, A.; Gullberg, M.; Wiinikka, H. Low-NOx thermal plasma torches: A renewable heat source for the electrified process industry. Fuel 2024, 378, 132959. [Google Scholar] [CrossRef]

- Supriya; Chaudhury, R.; Sharma, U.; Thapliyal, P.C.; Singh, L.P. Low-CO2 emission strategies to achieve net zero target in cement sector. J. Clean. Prod. 2023, 417, 137466. [Google Scholar] [CrossRef]

- Camargo-Bertel, A.A.; Hincapie, D.; Pugliese, V.; Gonzalez-Quiroga, A.; Pupo-Roncallo, O. Decarbonizing the cement industry in Latin America and the Caribbean: A comprehensive review of strategies, barriers, and policies. Energy Convers. Manag. X 2025, 26, 100956. [Google Scholar] [CrossRef]

- Friedman, J. Cement and Concrete Companies Leading the Net-Zero Transition; Center for American Progress Action Fund: Washington, DC, USA, 2024; Available online: https://www.americanprogress.org/article/cement-and-concrete-companies-leading-the-net-zero-transition/ (accessed on 25 April 2025).

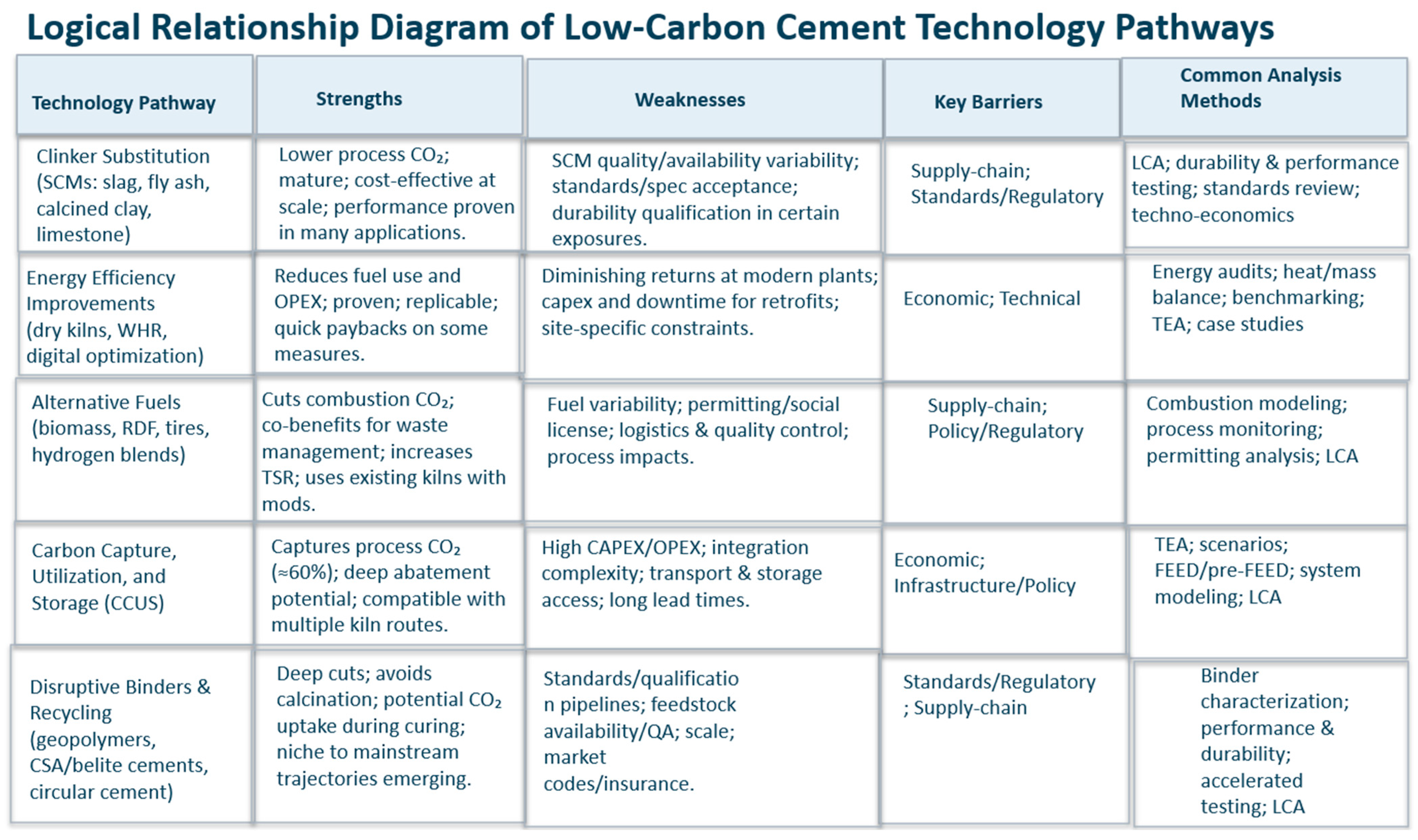

| Authors/References | Scope | Key Findings | Strengths | Limitations | Barrier Category |

|---|---|---|---|---|---|

| Benhelal, et al. [32] | Global review of CO2 reduction technologies in cement. | The review finds that economic, policy and logistical barriers, rather than technical barriers, are the primary causes. Shown technologies, such as clinker substitution, alternative fuels and carbon capture, are not widely adopted. | Comprehensive synthesis highlighting the gap between technical, policy and practical adoption. | No original data; broad focus with limited regional detail. | Economic/policy highlights financing and regulatory hurdles as the main bottlenecks. |

| Miller, et al. [33] | Complete value-chain and circular-economy analysis of cement emissions across production, use, and end-of-life. | The study identifies that cement accounts for about 7% of global GHG emissions; it emphasizes that deep decarbonization measures require lifecycle strategies beyond production, including circular design and green public procurement. | Holistic, cross-sectoral perspective covering the entire lifecycle. | High-level overview with limited discussion of costs and implementation challenges. | Policy/economic focuses on circular-economy policies, procurement incentives and market mechanisms. |

| Griffiths, et al. [2] | Systematic review on cement and concrete decarbonization using a socio-technical systems framework | The study concludes that technological innovation alone cannot decarbonize cement; supportive economic, social and policy environments are essential. | Holistic integration of technical and socio-economic factors | Comprehensive synthesis with limited depth on individual barriers. | Multiple emphasizes that technical, economic and policy factors are inseparable. |

| Ige, et al. [34] | Meta-review of system dynamics (SD) modeling studies for cement CO2 mitigation. | The study finds that existing SD models focus on technical solutions but often overlook real-world implementation barriers. | Highlights modelling gaps and the need for integrated approaches. | No case validation; minimal stakeholder input; relies on existing literature. | Technical, with a primary focus on the inadequacy of existing modeling tools. |

| Marinelli and Janardhanan [35] | Empirical multi-criteria decision analysis (Best–Worst Method) to green cement in India using expert rankings to rank decarbonization barriers. | The study identifies top barriers (low corporate commitment, skill shortages, financial gaps) and recommends R&D support, workforce training, green financing, and public procurement policies as alleviation strategies. | Provides Country-specific insights with expert-driven prioritization of barriers. Moderate to high fills the gap in emerging market data. | Small expert sample; findings may not generalize beyond the context. | Economical emphasizes financing and organizational capacity constraints. |

| Cavalett, et al. [36] | Lifecycle assessment and scenario modeling of 15 European cement mitigation strategies by 2050. | The study shows that combining alternative fuels, energy efficiency and clinker substitution can reduce emissions by about 50% by 2050; net zero requires carbon capture. | Data-rich with robust LCA and strong scenario analysis | Region-specific and assumes a stable policy context. Not capture global diversity. | Technical/economic highlights, technological limits of current options and cost implications. |

| Habert, et al. [37] | Techno-economic assessment of CO2 reduction potential under Factor 4 targets. | The study finds that the capital-intensive nature of cement production is a core barrier; it emphasizes that deep decarbonization needs significant financial/policy support. | Data-driven; identifies financial constraints ahead of trend. | Slightly outdated; social or policy dynamics underexplored. | Economic focuses on the cost barrier to technology adoption. |

| Busch, et al. [38] | Comprehensive case study of Net-Zero Cement mandate (SB 596) in California, analyzing six decarbonization strategies for cement/concrete using policy analysis and stakeholder input. | The study identifies outdated building codes and low market demand as key barriers and suggests policy performance standards and green procurement to drive adoption. | Real-world policy context with stakeholder engagement. | Limited to a proactive policy jurisdiction (California) and may not transfer directly to other regions. | Policy emphasizes regulatory reform and market-pull measures. |

| Barbhuiya, et al. [25] | Comprehensive roadmap analysis of the global cement sector to achieve net-zero carbon by combining technological innovations, strategy roadmaps, and policy frameworks. | The study identifies barriers like short policy horizons and inadequate R&D funding in both developed and emerging economies. | Integrates technology and policy to provide a comprehensive strategic vision. | Recommendations are general; lacks detailed quantitative scenario modeling. | Policy/economic—stresses regulatory vision and funding as critical gaps. |

| Habert, et al. [39] | A critical review of environmental impacts and decarbonization strategies for cement and concrete. | The study finds no single solution, advocates a portfolio approach, such as material substitution, alternative fuels, energy shifts, and CCS. The study highlights that some measures may increase other environmental impacts. | Balanced LCA perspective with global scope. | Conceptual review; lacks new modeling or empirical evidence. | Technical, analyzes technological and the need for complementary options. |

| Barrier Theme | Clinker Substitution | Energy Efficiency Improvements | Alternative Fuels | CCUS | Description and Evidence |

|---|---|---|---|---|---|

| High Capital Costs | Moderate; cost of SCM processing facilities, quality control, | High; kiln upgrades, digital systems, and WHR. | Moderate; fuel preprocessing, upgrades. | Very High; capture units, transport and storage infrastructure | Upgrading existing kilns, adding waste-heat recovery, or switching to more efficient grinding technologies requires significant investment. CCUS installations are currently priced comparable to building a new plant, and their revenue streams remain unclear. Even plant upgrades to enable clinker substitution or high-replacement SCMs can be capital-intensive when additional drying, calcination, or material-handling systems are required. |

| Supply Chain Constraints | High; availability and logistics of SCMs like slag, fly ash, and calcined clays | Moderate; supply of modern equipment, spare parts. | High; biomass/waste availability, logistics and co-processing plants. | High; CO2 transport pipelines, storage sites, and infrastructure gaps | The availability and consistent quality of SCMs such as fly ash, slag, calcined clay, and natural pozzolans limit clinker substitution. Alternative fuel supply chains require reliable sourcing, preprocessing and storage; biomass, waste-derived fuels, and hydrogen are often unavailable at scale. CCUS also depends on transport and storage infrastructure, which is scarce or non-existent in many regions. |

| Restrictive regulations and standards | Moderate; standards limiting clinker replacement levels | Low–Moderate; lack of mandatory efficiency targets. | High waste legislation, permitting issues, and co-firing regulations | Very High lack of CO2 pricing, liability for storage, and unclear policy support. | Construction codes and cement standards often limit the allowable proportion of alternative binders and discourage the use of low-carbon cements. Regulations governing the co-processing of waste-derived and biomass fuels can be prohibitive or inconsistent across jurisdictions. The absence of clear permitting processes for CO2 transport and injection slows CCUS projects. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ige, O.E.; Kabeya, M. Decarbonizing the Cement Industry: Technological, Economic, and Policy Barriers to CO2 Mitigation Adoption. Clean Technol. 2025, 7, 85. https://doi.org/10.3390/cleantechnol7040085

Ige OE, Kabeya M. Decarbonizing the Cement Industry: Technological, Economic, and Policy Barriers to CO2 Mitigation Adoption. Clean Technologies. 2025; 7(4):85. https://doi.org/10.3390/cleantechnol7040085

Chicago/Turabian StyleIge, Oluwafemi Ezekiel, and Musasa Kabeya. 2025. "Decarbonizing the Cement Industry: Technological, Economic, and Policy Barriers to CO2 Mitigation Adoption" Clean Technologies 7, no. 4: 85. https://doi.org/10.3390/cleantechnol7040085

APA StyleIge, O. E., & Kabeya, M. (2025). Decarbonizing the Cement Industry: Technological, Economic, and Policy Barriers to CO2 Mitigation Adoption. Clean Technologies, 7(4), 85. https://doi.org/10.3390/cleantechnol7040085