Optimization of Composting Locations for Livestock Manure in Bangladesh: Spatial Analysis-Based Potential Environmental Benefits Assessment

Abstract

1. Introduction

2. Methodology

2.1. Study Approach

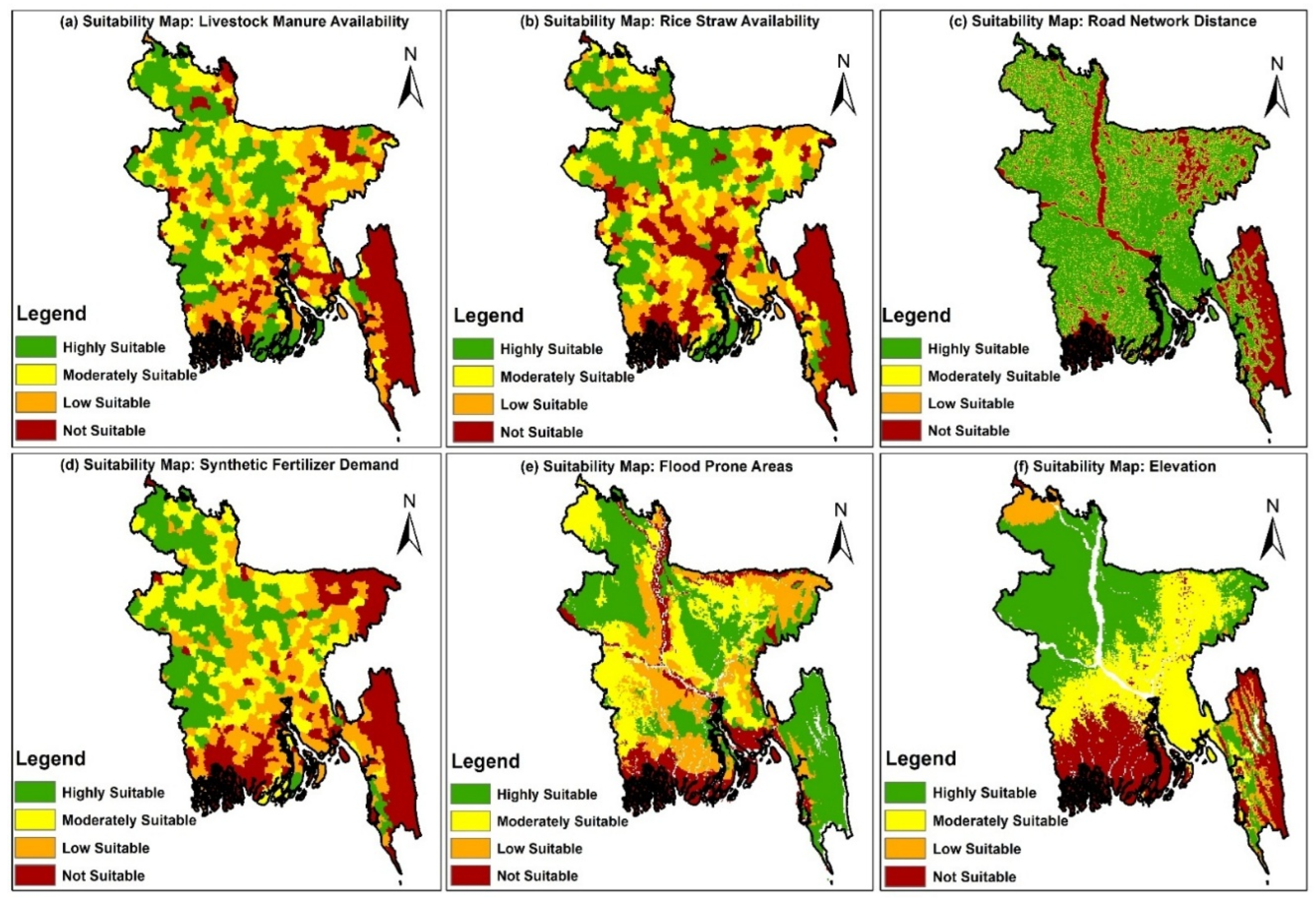

2.2. GIS Suitability Analysis

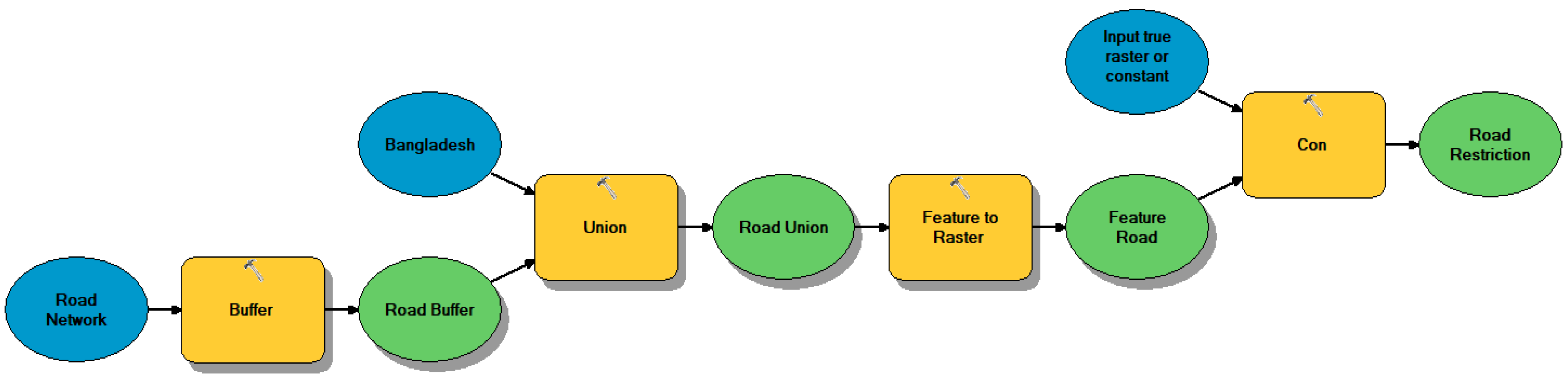

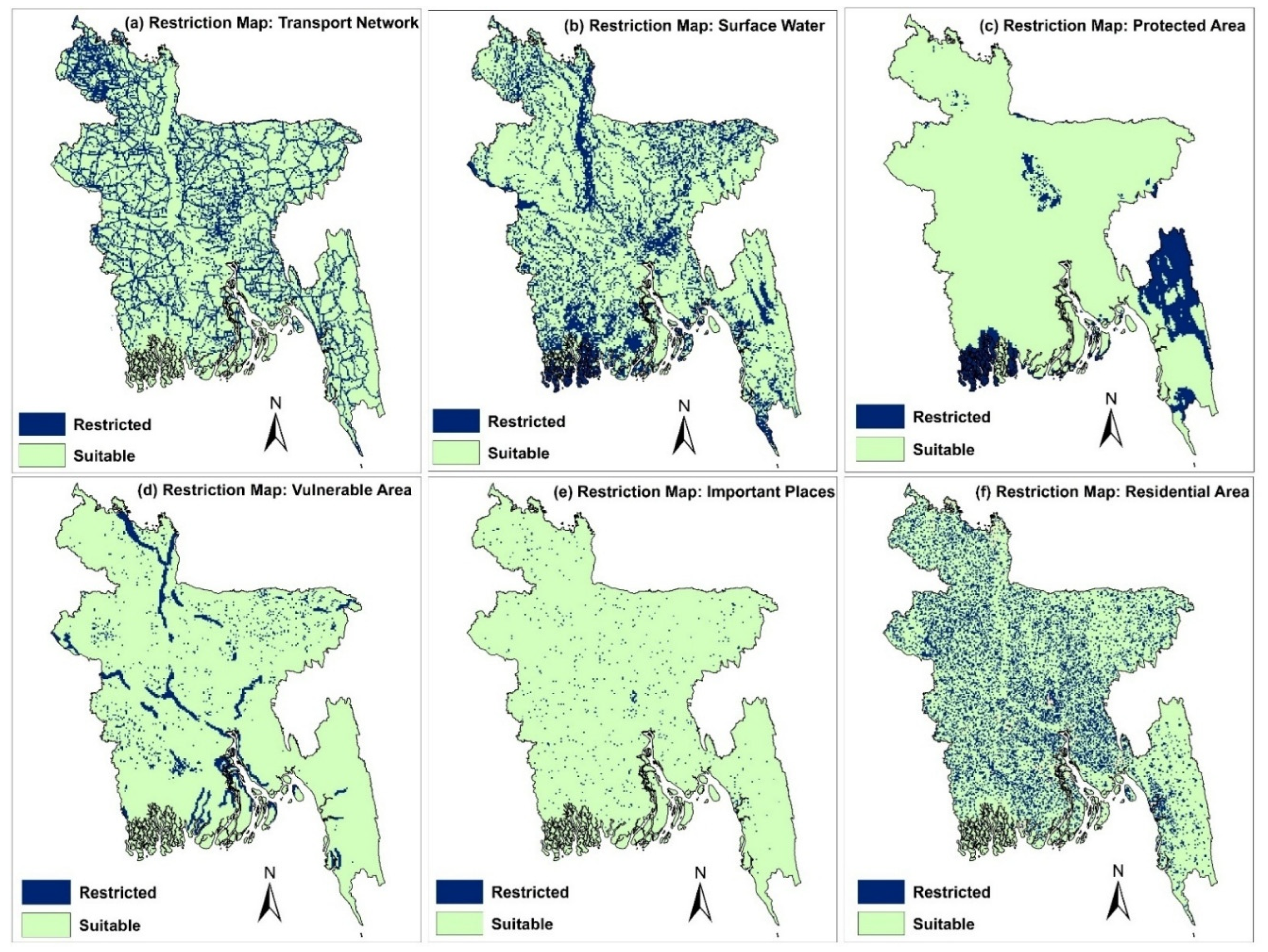

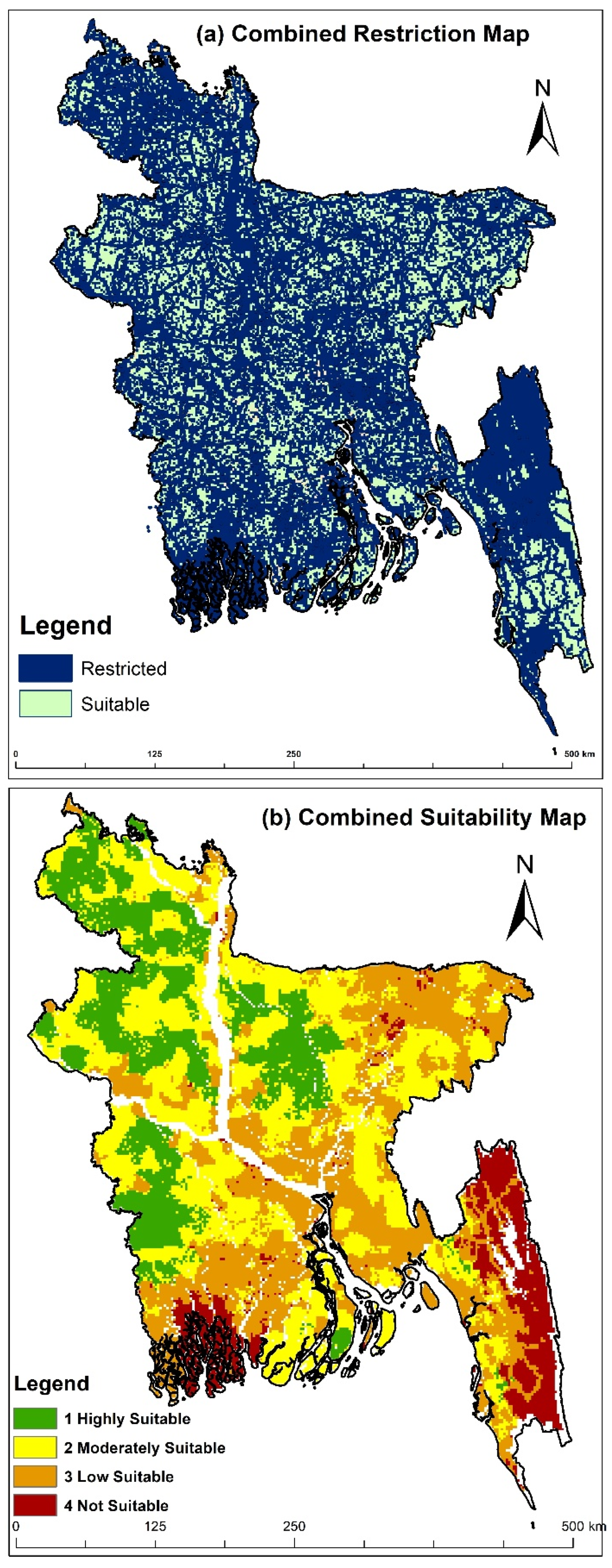

2.2.1. Restriction Mapping

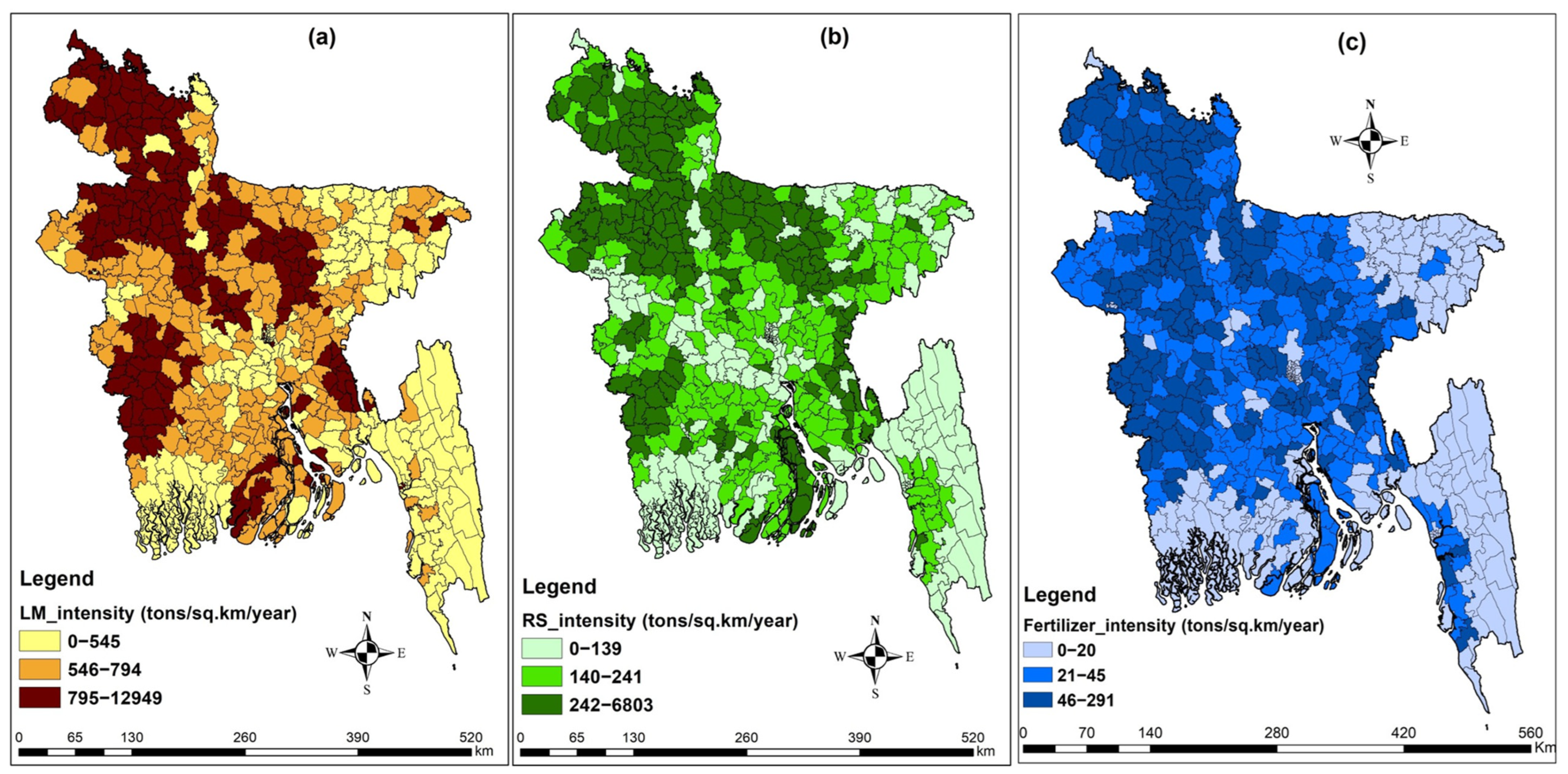

2.2.2. Suitability Mapping

2.3. Generation of Livestock Manure and Rice Straw

2.4. Compost Production Potential

2.5. Scenario Design and Analysis

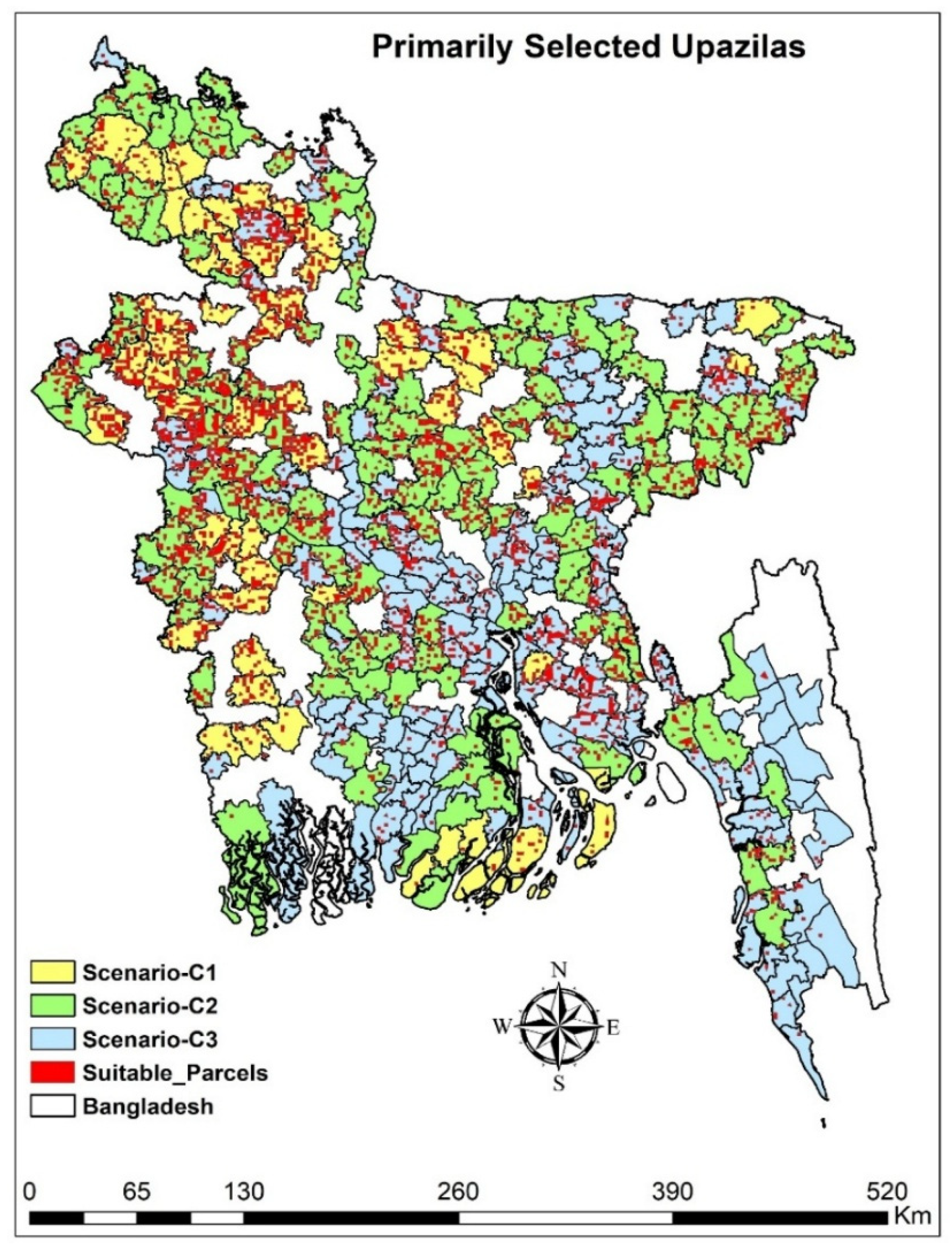

2.5.1. Primary Upazila Selection

2.5.2. Upazila Categorization for Different Scenarios

2.5.3. Required Land Areas and Number of Plants

2.5.4. Network Analysis

2.6. Environmental Benefits Assessment

2.6.1. Synthetic Fertilizer Replacement

2.6.2. GHG Emissions Reduction Potential

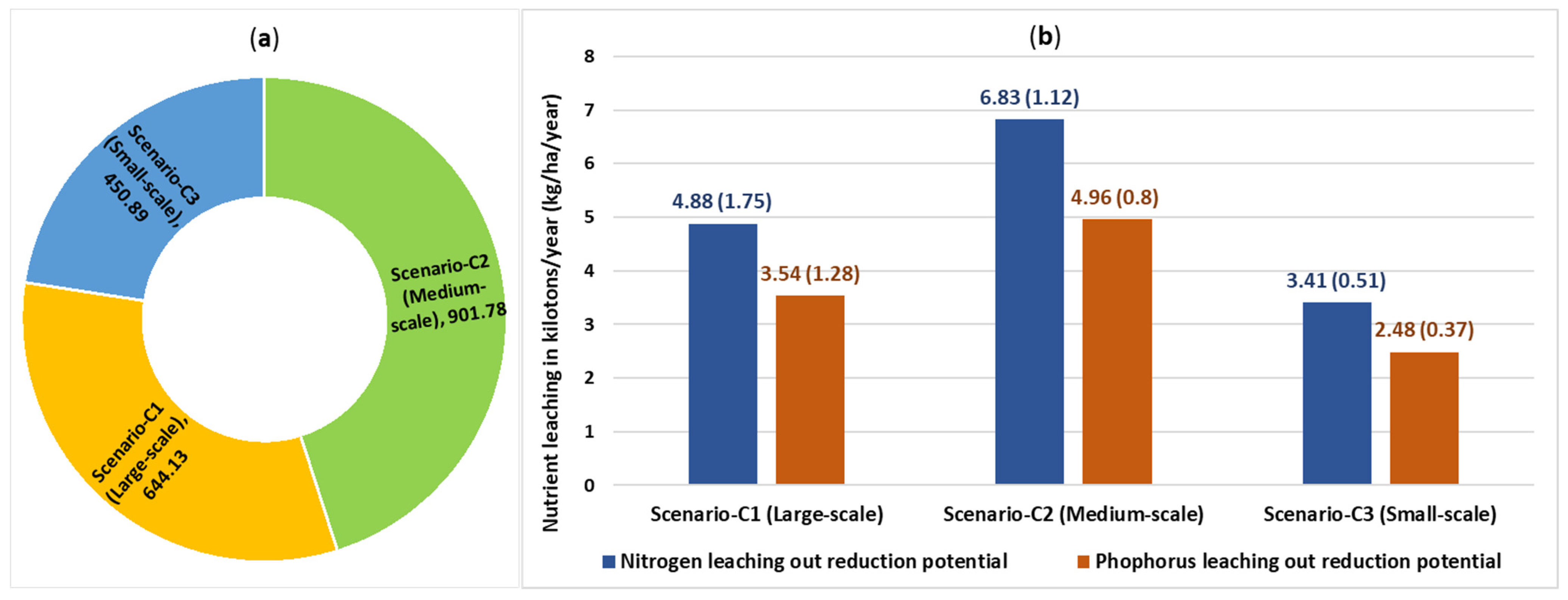

2.6.3. Nutrients Leaching Reduction Potential

3. Results

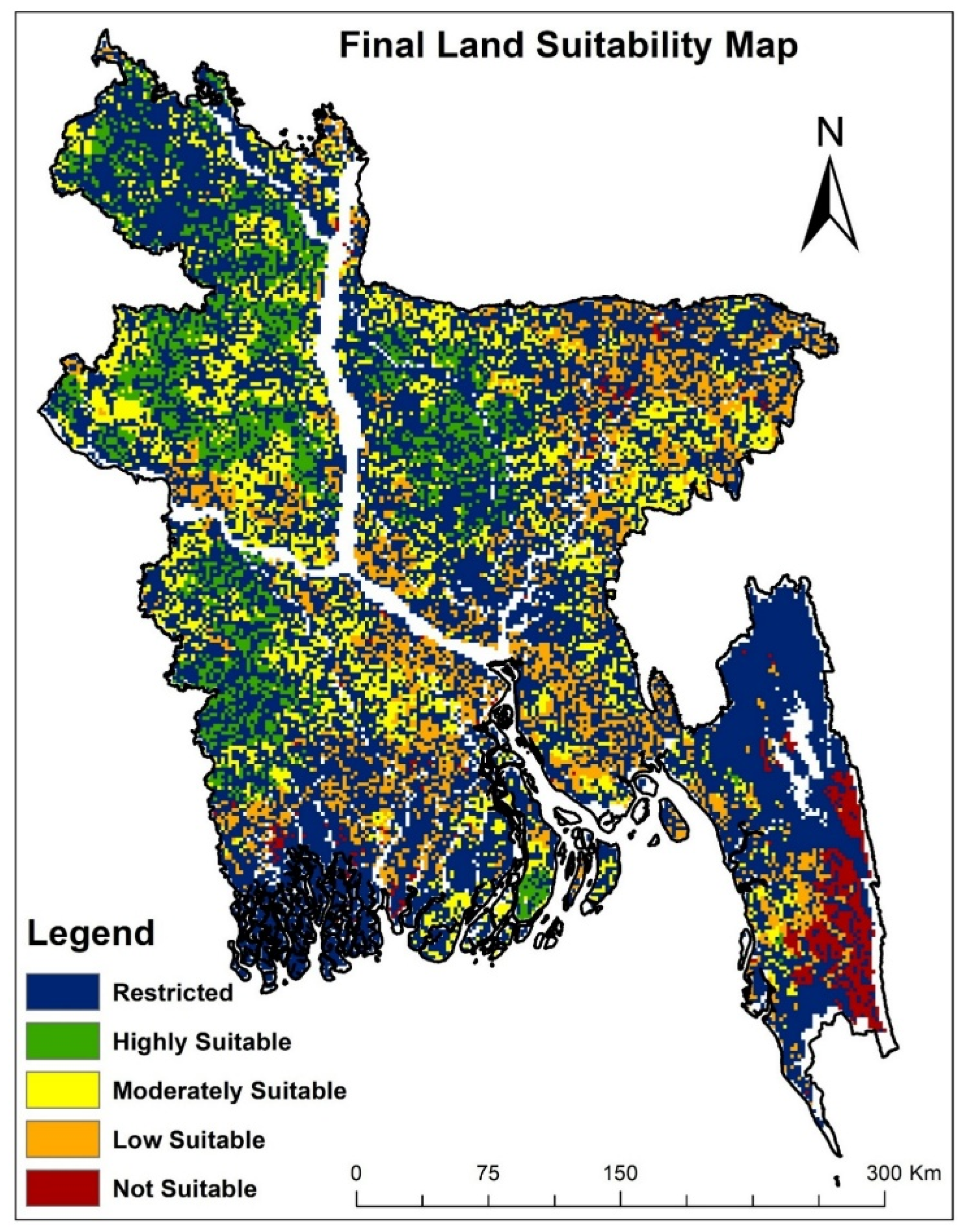

3.1. Identification of Suitable Areas

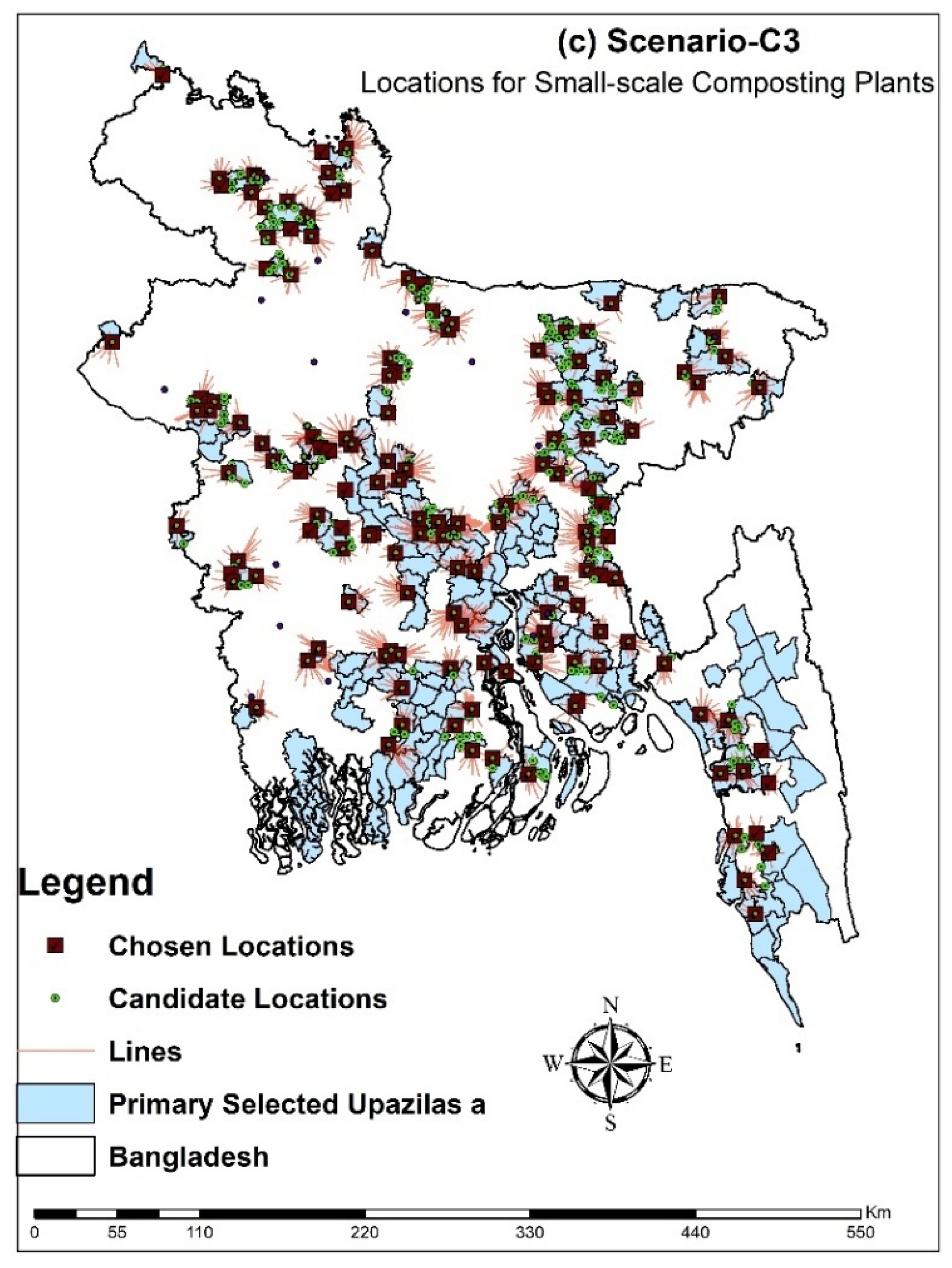

3.2. Optimizing the Locations for Composting Plants

3.3. Potential Environmental Benefits

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Suitability Features | Livestock Manure Availability | Rice Straw Availability | Distance to Road Network | Demand for Synthetic Fertilizer | Flood-Prone Area | Elevation |

|---|---|---|---|---|---|---|

| Livestock manure availability | 1 | 2 | 3 | 4 | 5 | 6 |

| Rice straw availability | 0.5 | 1 | 1.5 | 2 | 3 | 4 |

| Distance to the road network | 0.33 | 0.66 | 1 | 1.5 | 2 | 3 |

| Demand for synthetic fertilizer | 0.25 | 0.5 | 0.66 | 1 | 2 | 3 |

| Flood-prone area | 0.2 | 0.33 | 0.5 | 0.5 | 1 | 3 |

| Elevation | 0.166 | 0.25 | 0.33 | 0.33 | 0.33 | 1 |

| Sum | 2.446 | 4.74 | 6.99 | 9.33 | 13.33 | 20 |

| Suitability Features | Livestock Manure Availability | Rice Straw Availability | Distance to the Road Network | Demand for Synthetic Fertilizer | Flood-Prone Area | Elevation | Criteria Weights |

|---|---|---|---|---|---|---|---|

| Livestock manure availability | 0.408831 | 0.421941 | 0.429185 | 0.428725 | 0.375094 | 0.3 | 0.393962 |

| Rice straw availability | 0.204415 | 0.21097 | 0.214592 | 0.214362 | 0.225056 | 0.2 | 0.211566 |

| Distance to the road network | 0.134914 | 0.139241 | 0.143062 | 0.160772 | 0.150038 | 0.15 | 0.146338 |

| Demand for synthetic fertilizer | 0.102208 | 0.105485 | 0.094421 | 0.107181 | 0.150038 | 0.15 | 0.118222 |

| Flood-prone area | 0.081766 | 0.06962 | 0.071531 | 0.053591 | 0.075019 | 0.15 | 0.083588 |

| Elevation | 0.067866 | 0.052743 | 0.04721 | 0.03537 | 0.024756 | 0.05 | 0.046324 |

| Suitability Features | Livestock Manure Availability | Rice Straw Availability | Distance to the Road Network | Demand for Synthetic Fertilizer | Flood-Prone Area | Elevation | Weighted Sum Value | Criteria Weights | Ratio | Average (λmax) | CI = (λmax-n)/n − 1 | CR = CI/RI * |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Livestock manure availability | 0.393962 | 0.423132 | 0.439013 | 0.472888 | 0.417939 | 0.277945 | 2.4249 | 0.3681 | 6.5867 | 6.0748 | 0.0148 | 0.0119 |

| Rice straw availability | 0.196981 | 0.211566 | 0.219506 | 0.236444 | 0.250763 | 0.185297 | 1.3006 | 0.1987 | 6.5467 | |||

| Distance to the road network | 0.130008 | 0.139634 | 0.146338 | 0.177333 | 0.167175 | 0.138972 | 0.899 | 0.1899 | 4.7368 | |||

| Demand for synthetic fertilizer | 0.098491 | 0.105783 | 0.096583 | 0.118222 | 0.167175 | 0.138972 | 0.725226 | 0.1153 | 6.2884 | |||

| Flood-prone area | 0.078792 | 0.069817 | 0.073169 | 0.059111 | 0.083588 | 0.138972 | 0.503449 | 0.083 | 6.0576 | |||

| Elevation | 0.065398 | 0.052892 | 0.048291 | 0.039013 | 0.027584 | 0.046324 | 0.279502 | 0.0449 | 6.2282 |

| Components | N (%) | P (%) | K (%) | References |

|---|---|---|---|---|

| Large livestock manure | 2.7 | 0.624 | 0.6 | [87] |

| 1.79 | 1.68 | 6.17 | [88] | |

| 0.92 | 0.33 | 0.66 | [1] | |

| 0.55 | 0.90 | 0.50 | [89] | |

| Small livestock manure | 1.94 | 0.99 | 0.38 | [88] |

| 1.82 | 0.59 | 1.11 | [90] | |

| 1.04 | 0.28 | 1.01 | [1] | |

| Poultry manure | 4.52 | 1.68 | 2.12 | [88] |

| 2.7 | 1.32 | 1.45 | [1] | |

| 1.65 | 2.40 | 1.7 | [89] | |

| Compost | 3.3 | 0.92 | 2.1 | [91] |

| 2.1 | 0.94 | 3.67 | [92] | |

| 0.72 | 0.16 | 0.29 | [93] | |

| 6.1 | 2.7 | 5.5 | [94] | |

| 2.36 | 2.37 | - | [95] | |

| 0.22 | 0.012 | 0.03 | [96] |

| Nutrients | N | P | K | References |

|---|---|---|---|---|

| Loss of nutrients during composting (%) | 40 | 10 | 20 | [48] |

| Nutrient bioavailability by agricultural plants (%) | 40 | 80 | 90 | [48] |

References

- Brown, C. Available Nutrients and Value for Manure; The Ontario Ministry of Agriculture and Food and the Ministry of Rural Affairs: Toronto, ON, Canada, 2013. Available online: https://fieldcropnews.com/wp-content/uploads/2015/03/Nutrient-Value-of-Manure.pdf (accessed on 23 February 2025).

- Rayne, N.; Aula, L. Livestock Manure and the Impacts on Soil Health: A Review. Soil Syst. 2020, 4, 64. [Google Scholar] [CrossRef]

- Ellis, L.; Love, S.; Moore, A.; de Haro-Martí, M.E. Composting and Using Backyard Poultry Waste in the Home Garden. 2013. Available online: https://objects.lib.uidaho.edu/uiext/uiext31507.pdf (accessed on 6 March 2025).

- Mahal, Z.; Yabar, H.; Mizunoya, T. Spatial Assessment of Greenhouse Gas Emissions and Eutrophication Potential from Livestock Manure in Bangladesh. Sustainability 2024, 16, 5479. [Google Scholar] [CrossRef]

- Bayu, W.; Rethman, N.F.G.; Hammes, P.S. The Role of Animal Manure in Sustainable Soil Fertility Management in Sub-Saharan Africa: A Review. J. Sustain. Agric. 2005, 25, 113–136. [Google Scholar] [CrossRef]

- Sanford, G.R.; Cook, A.R.; Posner, J.L.; Hedtcke, J.L.; Hall, J.A.; Baldock, J.O. Linking Wisconsin Dairy and Grain Farms via Manure Transfer for Corn Production. Agron. J. 2009, 101, 167–174. [Google Scholar] [CrossRef]

- Lin, L.; Xu, F.; Ge, X.; Li, Y. Improving the sustainability of organic waste management practices in the food-energy-water nexus: A comparative review of anaerobic digestion and composting. Renew. Sustain. Energy Rev. 2018, 89, 151–167. [Google Scholar] [CrossRef]

- DLS. Livestock Economy at a Glance; Department of Livestock Services: Dhaka, Bangladesh, 2024. Available online: http://dls.portal.gov.bd/sites/default/files/files/dls.portal.gov.bd/page/ee5f4621_fa3a_40ac_8bd9_898fb8ee4700/2023-07-23-12-04-afbcccb96f8b27d4bab6501aa8c2c2ff.pdf (accessed on 21 March 2025).

- Adeoye, P.A.; Hasfalina, C.M.; Amin, M.S.M.; Thamer, A.M.; Akinbile, C.O. Environmental Implication of Poultry WasteGeneration and Management Techniques inMinna, Semi-arid Region of Nigeria. Annu. Res. Rev. Biol. 2014, 4, 1669–1681. [Google Scholar] [CrossRef]

- Cheng, H.; Ouyang, W.; Hao, F.; Ren, X.; Yang, S. The non-point source pollution in livestock-breeding areas of the Heihe River basin in Yellow River. Stoch. Environ. Res. Ris. Assess. 2007, 21, 213–221. [Google Scholar] [CrossRef]

- Yalcinkaya, S. A spatial modeling approach for siting, sizing and economic assessment of centralized biogas plants in organic waste management. J. Clean. Prod. 2020, 255, 120040. [Google Scholar] [CrossRef]

- Kumar, R. Site Suitability Analysis for Urban Development of a Hill Town Using GIS Based Multicriteria Evaluation Technique: A Case Study of Nahan Town, Himachal Pradesh, India. Int. J. Adv. Remote Sens. Gis 2014, 3, 516–524. [Google Scholar]

- ESRI. Types of Network Analysis Layers—ArcMap | Documentation. Available online: https://desktop.arcgis.com/en/arcmap/latest/extensions/network-analyst/types-of-network-analyses.htm (accessed on 12 September 2024).

- Ahn, H.K.; Mulbry, W.; White, J.W.; Kondrad, S.L. Pile mixing increases greenhouse gas emissions during composting of dairy manure. Bioresour. Technol. 2011, 102, 2904–2909. [Google Scholar] [CrossRef]

- Hao, X.; Chang, C.; Larney, F.J. Carbon, Nitrogen Balances and Greenhouse Gas Emission during Cattle Feedlot Manure Composting. J. Environ. Qual. 2004, 33, 37–44. [Google Scholar] [CrossRef]

- Nordahl, S.L.; Preble, C.V.; Kirchstetter, T.W.; Scown, C.D. Greenhouse Gas and Air Pollutant Emissions from Composting. Environ. Sci. Technol. 2023, 57, 2235–2247. [Google Scholar] [CrossRef]

- DAE. Department of Agricultural Extension-Government of the People’s Republic of Bangladesh. Available online: https://dae.gov.bd/ (accessed on 9 July 2024).

- DLS. Department of Livestock Services. Available online: https://dls.gov.bd/ (accessed on 24 April 2024).

- ArcGIS Online. Available online: https://www.google.com/search?client=firefox-b-d&q=arcgis+online (accessed on 13 November 2024).

- Berisa, G.; Birhanu, Y. Municipal Solid Waste Disposal Site Selection of Jigjiga Town Using GIS and Remote Sensing Techniques, Ethiopia. Int. J. Phy. Hum. Geogr. 2016, 4, 1–25. [Google Scholar]

- Chukwuma, E.; Chukwuma, G.; Orakwe, L. GIS Suitability Analysis for Anaerobic Treatment Facility for Slaughter Houses in Anambra State of Nigeria. ACRI 2016, 4, 1–10. [Google Scholar] [CrossRef]

- Ma, J.; Scott, N.R.; DeGloria, S.D.; Lembo, A.J. Siting analysis of farm-based centralized anaerobic digester systems for distributed generation using GIS. Biomass Bioenergy 2005, 28, 591–600. [Google Scholar] [CrossRef]

- Perpiña, C.; Martínez-Llario, J.C.; Pérez-Navarro, Á. Multicriteria assessment in GIS environments for siting biomass plants. Land. Use Policy 2013, 31, 326–335. [Google Scholar] [CrossRef]

- Silva, S.; Alçada-Almeida, L.; Dias, L.C. Multiobjective programming for sizing and locating biogas plants: A model and an application in a region of Portugal. Comput. Oper. Res. 2017, 83, 189–198. [Google Scholar] [CrossRef]

- Thompson, E.; Wang, Q.; Li, M. Anaerobic digester systems (ADS) for multiple dairy farms: A GIS analysis for optimal site selection. Energy Policy 2013, 61, 114–124. [Google Scholar] [CrossRef]

- Union of BC. Municipalities Landfill Guidelines. Available online: https://www.ubcm.ca/convention-resolutions/resolutions/resolutions-database/landfill-guidelines (accessed on 22 November 2024).

- Drobne, S.; Lisec, A. Multi-Attribute Decision Analysis in GIS: Weighted Linear Combination and Ordered Weighted Averaging. Available online: https://www.researchgate.net/publication/220166125_Multi-attribute_Decision_Analysis_in_GIS_Weighted_Linear_Combination_and_Ordered_Weighted_Averaging (accessed on 4 December 2024).

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83. [Google Scholar] [CrossRef]

- Mahal, Z.; Yabar, H. Spatial Optimization of Bioenergy Production by Introducing a Cooperative Manure Management System in Bangladesh. Resources 2025, 14, 111. [Google Scholar] [CrossRef]

- Rahman, M.M.; Paatero, J.V. A methodological approach for assessing potential of sustainable agricultural residues for electricity generation: South Asian perspective. Biomass Bioenergy 2012, 47, 153–163. [Google Scholar] [CrossRef]

- Mahal, Z.; Yabar, H. A Spatial Modeling Approach for Optimizing the Locations of Large-Scale Biogas Plants from Livestock Manure in Bangladesh. Land 2025, 14, 79. [Google Scholar] [CrossRef]

- Mahal, Z.; Yabar, H. Spatial Estimation of Biogas and Compost Potential for Sustainable Livestock Manure Management in Bangladesh. Appl. Sci. 2025, 15, 6753. [Google Scholar] [CrossRef]

- Abraham, A.; Mathew, A.K.; Sindhu, R.; Pandey, A.; Binod, P. Potential of rice straw for bio-refining: An overview. Bioresour. Technol. 2016, 215, 29–36. [Google Scholar] [CrossRef] [PubMed]

- Hiloidhari, M.; Baruah, D.C. Crop residue biomass for decentralized electrical power generation in rural areas (part 1): Investigation of spatial availability. Renew. Sustain. Energy Rev. 2011, 15, 1885–1892. [Google Scholar] [CrossRef]

- Singh, J. Identifying an economic power production system based on agricultural straw on regional basis in India. Renew. Sustain. Energy Rev. 2016, 60, 1140–1155. [Google Scholar] [CrossRef]

- Mary, A.K. Composting Animal Manures: A Guide to the Process and Management of Animal Manure Compost | NDSU Agriculture. Available online: https://www.ndsu.edu/agriculture/extension/publications/composting-animal-manures-guide-process-and-management-animal-manure-compost (accessed on 24 May 2024).

- Rynk, R.; van de Kamp, M.; Willson, G.B.; Singley, M.E.; Richard, T.L.; Kolega, J.J.; Gouin, F.R.; Laliberty, L.; Kay, D.; Murphy, D.; et al. On-Farm Composting Handbook (NRAES 54); Northeast Regional Agricultural Engineering Service (NRAES): Ithaca, NY, USA, 1992; Available online: https://hdl.handle.net/1813/67142 (accessed on 23 March 2025).

- Okopi, S.; Li, Y.; Xu, F. Biomass Digestion. In Encyclopedia of Sustainable Technologies; Elsevier: Amsterdam, The Netherlands, 2024; pp. 236–251. ISBN 978-0-443-22287-0. Available online: https://linkinghub.elsevier.com/retrieve/pii/B9780323903868000516 (accessed on 23 March 2025).

- Breitenbeck, G.A.; Schellinger, D. Calculating the Reduction in Material Mass And Volume during Composting. Compos. Sci. Util. 2004, 12, 365–371. [Google Scholar] [CrossRef]

- Palese, A.M.; Persiani, A.; D’Adamo, C.; Pergola, M.; Pastore, V.; Sileo, R.; Ippolito, G.; Lombardi, M.A.; Celano, G. Composting as Manure Disposal Strategy in Small/Medium-Size Livestock Farms: Some Demonstrations with Operative Indications. Sustainability 2020, 12, 3315. [Google Scholar] [CrossRef]

- Kalamdhad, A.S.; Singh, Y.K.; Ali, M.; Khwairakpam, M.; Kazmi, A.A. Rotary drum composting of vegetable waste and tree leaves. Bioresour. Technol. 2009, 100, 6442–6450. [Google Scholar] [CrossRef] [PubMed]

- Pandyaswargo, A.H.; Premakumara, D.G.J. Financial sustainability of modern composting: The economically optimal scale for municipal waste composting plant in developing Asia. Int. J. Recycl. Org. Waste Agric. 2014, 3, 4. [Google Scholar] [CrossRef]

- Miller, R.A. Calculating Capacity at Composting Sites. Available online: https://www.biocycle.net/calculating-capacity-at-composting-sites/ (accessed on 27 November 2024).

- The Organics Recycling Authority Calculating a Composting Facility Footprint. Available online: https://www.biocycle.net/calculating-a-composting-facility-footprint/ (accessed on 27 November 2024).

- Schnorf, V.; Trutnevyte, E.; Bowman, G.; Burg, V. Biomass transport for energy: Cost, energy and CO2 performance of forest wood and manure transport chains in Switzerland. J. Clean. Prod. 2021, 293, 125971. [Google Scholar] [CrossRef]

- Ashik-Ur-Rahman, M.; Waheduzzaman, M.; Waresul Hassan Nipun, M. Optimized municipal solid waste transportation with landfill requirement in a coastal city of Bangladesh. Environ. Qual. Manag. 2022, 31, 197–210. [Google Scholar] [CrossRef]

- Hasan, S. Problems of municipal waste management in Bangladesh: An inquiry into its nature. Habitat. Int. 1998, 22, 191–202. [Google Scholar] [CrossRef]

- Ikumo, H. Estimation of Potential Supply of Livestock Waste Compost to Replace Chemical Fertilizer Use in Japan Based on 2000 Census of Agriculture. Jpn. Agric. Res. Q. JARQ 2005, 39, 83–89. [Google Scholar] [CrossRef][Green Version]

- Andersen, J.K.; Boldrin, A.; Christensen, T.H.; Scheutz, C. Greenhouse gas emissions from home composting of organic household waste. Waste Manag. 2010, 30, 2475–2482. [Google Scholar] [CrossRef]

- Clemens, J.; Cuhls, C. Greenhouse gas emissions from mechanical and biological waste treatment of municipal waste. Environ. Technol. 2003, 24, 745–754. [Google Scholar] [CrossRef] [PubMed]

- Hellebrand, H.J. Emission of Nitrous Oxide and other Trace Gases during Composting of Grass and Green Waste. J. Agric. Eng. Res. 1998, 69, 365–375. [Google Scholar] [CrossRef]

- Friedrich, E.; Trois, C. GHG emission factors developed for the recycling and composting of municipal waste in South African municipalities. Waste Manag. 2013, 33, 2520–2531. [Google Scholar] [CrossRef]

- Phong, N.T. Greenhouse Gas Emissions from Composting and Anaerobic Digestion Plants. Ph.D. Thesis, Universität Bonn, Bonn, Germany, 2012. [Google Scholar]

- Luske, B. Reduced GHG Emissions due to Compost Production and Compost Use in Egypt Comparing Two Scenarios; Louis Bolk Instituu: Bunnik, The Netherlands, 2010; Available online: https://orgprints.org/id/eprint/17480/4/17480.pdf (accessed on 6 April 2025).

- White, P.; Dranke, M.; Hindle, P. Integrated Solid Waste Management: A Lifecycle Inventory; Springer Science & Business Media: Berlin, Germany, 2012; ISBN 978-1-4684-6705-5. [Google Scholar]

- Skowrońska, M.; Filipek, T. Life cycle assessment of fertilizers: A review. Int. Agrophysics 2014, 28, 101–110. [Google Scholar] [CrossRef]

- Albaugh, T.J.; Vance, E.D.; Gaudreault, C.; Fox, T.R.; Allen, H.L.; Stape, J.L.; Rubilar, R.A. Carbon Emissions and Sequestration from Fertilization of Pine in the Southeastern United States. For. Sci. 2012, 58, 419–429. [Google Scholar] [CrossRef]

- Brentrup, F.; Hoxha, A.; Christensen, B. Carbon Footprint Analysis of Mineral Fertilizer Production in Europe and Other World Regions; University College Dublin (UCD): Dublin, Ireland, 2016; Available online: https://www.researchgate.net/publication/312553933_Carbon_footprint_analysis_of_mineral_fertilizer_production_in_Europe_and_other_world_regions#fullTextFileContent (accessed on 21 April 2025).

- Davis, J.; Haglund, C. Life Cycle Inventory (LCI) of Fertiliser Production: Fertiliser Products Used in Sweden and Western Europe; SIK Institutet för livsmedel och bioteknik: Göteborg, Sweden, 1999; Available online: https://toc.library.ethz.ch/objects/pdf03/e16_91-7290-196-9_01.pdf (accessed on 25 April 2025).

- Williams, A.G.; Audsley, E.; Sandars, D.L. Environmental burdens of producing bread wheat, oilseed rape and potatoes in England and Wales using simulation and system modelling. Int. J. Life Cycle Assess. 2010, 15, 855–868. [Google Scholar] [CrossRef]

- Chen, W.; Geng, Y.; Hong, J.; Yang, D.; Ma, X. Life cycle assessment of potash fertilizer production in China. Resour. Conserv. Recycl. 2018, 138, 238–245. [Google Scholar] [CrossRef]

- Dunkerley, D. Effects of rainfall intensity fluctuations on infiltration and runoff: Rainfall simulation on dryland soils, Fowlers Gap, Australia. Hydrol. Process. 2012, 26, 2211–2224. [Google Scholar] [CrossRef]

- Jin, Z.; Guo, L.; Yu, Y.; Luo, D.; Fan, B.; Chu, G. Storm runoff generation in headwater catchments on the Chinese Loess Plateau after long-term vegetation rehabilitation. Sci. Total Environ. 2020, 748, 141375. [Google Scholar] [CrossRef]

- Zhong, S.; Tian, X.; Geng, Y.; Santagata, R.; Zhuang, M.; Chen, W.; Yang, S.; Ulgiati, S. Sustainability assessment in the anthropocentric watershed based on emergy and decomposition methods: A case study of Erhai Lake Basin, southwest China. Ecol. Indic. 2022, 139, 108932. [Google Scholar] [CrossRef]

- Du, Y.; Li, T.; He, B. Runoff-related nutrient loss affected by fertilization and cultivation in sloping croplands: An 11-year observation under natural rainfall. Agric. Ecosyst. Environ. 2021, 319, 107549. [Google Scholar] [CrossRef]

- Dybowski, D.; Dzierzbicka-Glowacka, L.A.; Pietrzak, S.; Juszkowska, D.; Puszkarczuk, T. Estimation of nitrogen leaching load from agricultural fields in the Puck Commune with an interactive calculator. PeerJ 2020, 8, e8899. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.R.; Kundu, D.K.; Dey, P.; Singh, P.; Mahapatra, B.S. Effect of balanced fertilizers on soil quality and lentil yield in Gangetic alluvial soils of India. J. Agric. Sci. 2018, 156, 225–240. [Google Scholar] [CrossRef]

- Yli-Halla, M.; Lötjönen, T.; Kekkonen, J.; Virtanen, S.; Marttila, H.; Liimatainen, M.; Saari, M.; Mikkola, J.; Suomela, R.; Joki-Tokola, E. Thickness of peat influences the leaching of substances and greenhouse gas emissions from a cultivated organic soil. Sci. Total Environ. 2022, 806, 150499. [Google Scholar] [CrossRef]

- Kløve, B.; Sveistrup, T.E.; Hauge, A. Leaching of nutrients and emission of greenhouse gases from peatland cultivation at Bodin, Northern Norway. Geoderma 2010, 154, 219–232. [Google Scholar] [CrossRef]

- Sun, C.; Zhou, H.; Chen, L.; Shen, Z. The pollution risk assessment of nitrogen and phosphorus loss in surface runoff from farmland fertilizer. J. Agro-Environ. Sci. 2017, 36, 1266–1273. [Google Scholar] [CrossRef]

- Pham, T.; Yli-Halla, M.; Marttila, H.; Lötjönen, T.; Liimatainen, M.; Kekkonen, J.; Läpikivi, M.; Klöve, B.; Joki-Tokola, E. Leaching of nitrogen, phosphorus and other solutes from a controlled drainage cultivated peatland in Ruukki, Finland. Sci. Total Environ. 2023, 904, 166769. [Google Scholar] [CrossRef] [PubMed]

- Sieczko, A.K.; Van De Vlasakker, P.C.H.; Tonderski, K.; Metson, G.S. Seasonal nitrogen and phosphorus leaching in urban agriculture: Dominance of non-growing season losses in a Southern Swedish case study. Urban. For. Urban. Green. 2023, 79, 127823. [Google Scholar] [CrossRef]

- Portela, S.I.; Reixachs, C.; Torti, M.J.; Beribe, M.J.; Giannini, A.P. Contrasting effects of soil type and use of cover crops on nitrogen and phosphorus leaching in agricultural systems of the Argentinean Pampas. Agric. Ecosyst. Environ. 2024, 364, 108897. [Google Scholar] [CrossRef]

- Norberg, L.; Linefur, H.; Andersson, S.; Blomberg, M.; Kyllmar, K. Nutrient losses over time via surface runoff and subsurface drainage from an agricultural field in northern Sweden. J. Environ. Qual. 2022, 51, 1235–1245. [Google Scholar] [CrossRef]

- Fu, J.; Wu, Y.; Wang, Q.; Hu, K.; Wang, S.; Zhou, M.; Hayashi, K.; Wang, H.; Zhan, X.; Jian, Y.; et al. Importance of subsurface fluxes of water, nitrogen and phosphorus from rice paddy fields relative to surface runoff. Agric. Water Manag. 2019, 213, 627–635. [Google Scholar] [CrossRef]

- Google Earth Pro Earth Versions. Google Earth. 2025. Available online: https://www.google.com/earth/about/versions/ (accessed on 16 January 2025).

- Venier, F.; Yabar, H. Renewable energy recovery potential towards sustainable cattle manure management in Buenos Aires Province: Site selection based on GIS spatial analysis and statistics. J. Clean. Prod. 2017, 162, 1317–1333. [Google Scholar] [CrossRef]

- Sharma, B.; Birrell, S.; Miguez, F.E. Spatial modeling framework for bioethanol plant siting and biofuel production potential in the U.S. Appl. Energy 2017, 191, 75–86. [Google Scholar] [CrossRef]

- Khan, M.T.; Aleinikovienė, J.; Butkevičienė, L.-M. Innovative Organic Fertilizers and Cover Crops: Perspectives for Sustainable Agriculture in the Era of Climate Change and Organic Agriculture. Agronomy 2024, 14, 2871. [Google Scholar] [CrossRef]

- Manea, E.E.; Bumbac, C.; Dinu, L.R.; Bumbac, M.; Nicolescu, C.M. Composting as a Sustainable Solution for Organic Solid Waste Management: Current Practices and Potential Improvements. Sustainability 2024, 16, 6329. [Google Scholar] [CrossRef]

- Zurbrügg, C.; Drescher, S.; Rytz, I.; Sinha, A.M.; Enayetullah, I. Decentralised composting in Bangladesh, a win-win situation for all stakeholders. Resour. Conserv. Recycl. 2005, 43, 281–292. [Google Scholar] [CrossRef]

- FAO. Faostat. Available online: https://www.fao.org/faostat/en/#data/EK (accessed on 23 April 2024).

- Economic Review. Finance Division, Ministry of Finance. Available online: https://mof.portal.gov.bd/site/page/28ba57f5-59ff-4426-970a-bf014242179e/Bangladesh-Economic-Review (accessed on 2 May 2024).

- Siedt, M.; Schäffer, A.; Smith, K.E.C.; Nabel, M.; Roß-Nickoll, M.; Van Dongen, J.T. Comparing straw, compost, and biochar regarding their suitability as agricultural soil amendments to affect soil structure, nutrient leaching, microbial communities, and the fate of pesticides. Sci. Total Environ. 2021, 751, 141607. [Google Scholar] [CrossRef]

- Goldan, E.; Nedeff, V.; Barsan, N.; Culea, M.; Panainte-Lehadus, M.; Mosnegutu, E.; Tomozei, C.; Chitimus, D.; Irimia, O. Assessment of Manure Compost Used as Soil Amendment—A Review. Processes 2023, 11, 1167. [Google Scholar] [CrossRef]

- Saaty, T.L. How to make a decision: The analytic hierarchy process. Eur. J. Oper. Res. 1990, 48, 9–26. [Google Scholar] [CrossRef]

- Cestonaro, T.; Costa, M.S.S.D.M.; Costa, L.A.D.M.; Pereira, D.C.; Rozatti, M.A.T.; Martins, M.F.L. Addition of cattle manure to sheep bedding allows vermicomposting process and improves vermicompost quality. Waste Manag. 2017, 61, 165–170. [Google Scholar] [CrossRef]

- Hossain, M.Z.; Bahar, M.M.; Sarkar, B.; Donne, S.W.; Wade, P.; Bolan, N. Assessment of the fertilizer potential of biochars produced from slow pyrolysis of biosolid and animal manures. J. Anal. Appl. Pyrolysis 2021, 155, 105043. [Google Scholar] [CrossRef]

- Dale, F.; Leikam, R.E. Lamond Estimating Manure Nutrient Availability; Kansas State University, Department of Agronomy: Manhattan, KS, USA, 2003; Report No.: MF-2562; Available online: https://bookstore.ksre.ksu.edu/download/estimating-manure-nutrient-availability_MF2562 (accessed on 25 April 2025).

- Raza, S.T.; Tang, J.L.; Ali, Z.; Yao, Z.; Bah, H.; Iqbal, H.; Ren, X. Ammonia Volatilization and Greenhouse Gases Emissions during Vermicomposting with Animal Manures and Biochar to Enhance Sustainability. Int. J. Environ. Res. Public Health 2020, 18, 178. [Google Scholar] [CrossRef]

- Costa, M.S.S.D.M.; Bernardi, F.H.; Costa, L.A.D.M.; Pereira, D.C.; Lorin, H.E.F.; Rozatti, M.A.T.; Carneiro, L.J. Composting as a cleaner strategy to broiler agro-industrial wastes: Selecting carbon source to optimize the process and improve the quality of the final compost. J. Clean. Prod. 2017, 142, 2084–2092. [Google Scholar] [CrossRef]

- Cao, Y.; Chang, Z.; Wang, J.; Ma, Y.; Yang, H.; Fu, G. Potential use of anaerobically digested manure slurry to suppress Phytophthora root rot of chilli pepper. Sci. Hortic. 2014, 168, 124–131. [Google Scholar] [CrossRef]

- Slepetiene, A.; Volungevicius, J.; Jurgutis, L.; Liaudanskiene, I.; Amaleviciute-Volunge, K.; Slepetys, J.; Ceseviciene, J. The potential of digestate as a biofertilizer in eroded soils of Lithuania. Waste Manag. 2020, 102, 441–451. [Google Scholar] [CrossRef] [PubMed]

- Mayerová, M.; Šimon, T.; Stehlík, M.; Madaras, M.; Koubová, M.; Smatanová, M. Long-term application of biogas digestate improves soil physical properties. Soil. Tillage Res. 2023, 231, 105715. [Google Scholar] [CrossRef]

- Alfa, M.I.; Adie, D.B.; Igboro, S.B.; Oranusi, U.S.; Dahunsi, S.O.; Akali, D.M. Assessment of biofertilizer quality and health implications of anaerobic digestion effluent of cow dung and chicken droppings. Renew. Energy 2014, 63, 681–686. [Google Scholar] [CrossRef]

- Ezemagu, I.G.; Ejimofor, M.I.; Menkiti, M.C.; Diyoke, C. Biofertilizer production via composting of digestate obtained from anaerobic digestion of post biocoagulation sludge blended with saw dust: Physiochemical characterization and kinetic study. Environ. Chall. 2021, 5, 100288. [Google Scholar] [CrossRef]

| Criteria | Features | Comments | * Buffer Area | * Referred Ranges [20,21,22,23,24,25,26] |

|---|---|---|---|---|

| Transport Network | Road network | It can expand the transport network in the future. | 200 m | 30–300 m |

| Railway network | 500 m | |||

| Surface Water | River | Restricted by existing laws and rules. | 500 m | 100–500 m |

| Water reservoir | 300 m | |||

| Protected Area | National park | Restricted by existing laws and rules. | 200 m | 100–500 m |

| Forest area | 500 m | |||

| Residential Area | Districts and sub-districts | Closeness to residential areas may create social disturbances and a nuisance. | 2 km | 200 m–1 km |

| Unions and Villages | 1 km | |||

| Important Places | Airports and helipads | Restricted by existing laws and rules. | 1 km | 300–500 m |

| Other developed places | 500 m | |||

| Vulnerable Area | River erosion area | It has a risk of developing in naturally vulnerable areas. | 500 m | 100–500 m |

| Wetlands | 300 m |

| Criteria | Features | Comments | Highly Suitable | Moderately Suitable | Low Suitability | Not Suitable | Weighted Preferences |

|---|---|---|---|---|---|---|---|

| Resource Availability | Livestock Manure Availability | The higher intensity has higher suitability (tons/sq.km) | >1000 | 700–1000 | 400–700 | 0–400 | 39.5% |

| Rice Straw Availability | The higher intensity has higher suitability (tons/sq.km) | >300 | 200–300 | 100–200 | 0–100 | 21.3% | |

| Economy | Distance to Road Network | The nearer road network has higher suitability. | 0-500 m | 1 km | 2 km | >2 km | 14.7% |

| Demand for Synthetic Fertilizer | More uses of fertilizer have higher suitability. (tons/sq.km/year) | >100 | 50–100 | 20–50 | 0–20 | 11.8% | |

| Geography | Flood Prone Area | The greater the chance of flood occurrence in the areas, the lower the suitability. | No flooding | Low flooding | Moderate flooding | Severe flooding | 8.2% |

| Elevation | The very high and very low elevations both have lower suitability. | 8–50 m | 4–7 m | 51–79 m | 0–3 m 80–940 m | 4.6% |

| Manure Types | C/N Ratio in Manure | C/N Ratio in Compost | Co-digestion Ratio of Manure: Straw | % of Manure | % of Rice Straw | Total Available Manure (Tons/Day) | Compost Production (Tons/Day) | Compost after 50% Mass Reduction (Tons/Day) |

|---|---|---|---|---|---|---|---|---|

| Large Livestock | 18:1 | - | ~4:1 | 80.64 | 19.35 | 248,975.75 | 308,730.55 | 154,365.27 |

| Small Livestock | 16:1 | 30:1 | ~4:1 | 78.12 | 21.87 | 297.15 | 380.33 | 190.16 |

| Poultry | 08:1 | - | ~2:1 | 69.44 | 30.56 | 15,213.62 | 23,142.48 | 11,571.45 |

| Waste Types for Compost Generation | Emission Factor (kgCO2eq/kg Compost) | References | |

|---|---|---|---|

| Municipal waste | 0.172–0.186 | [52] | |

| Biowaste | 0.18 | [53] | |

| Household waste | 0.239 | [49] | |

| Dairy manure | 0.145–0.173 | [14] | |

| Municipal waste | 0.413 | [50] | |

| Cattle manure | 0.423 | [15] | |

| Organic waste | 0.164 | [54] | |

| Grass and green waste | 0.381 | [51] | |

| Livestock manure | 0.229 | [16] | |

| Solid waste | 0.323 | [55] | |

| Types of fertilizer | Country/Region | Emission factor (kg CO2eq/kg of fertilizer) | References |

| Urea | Europe | 1.6 | [56] |

| USA | 3.1 | [57] | |

| Europe/Russia, USA | 1.9/2.7 | [58] | |

| Sweden and Europe | 4 | [59] | |

| United Kingdom | 3.5 | [60] | |

| Ammonium phosphate | Sweden and Europe | 1.3–1.8 | [59] |

| Europe/Russia, USA | 1.4/1.7 | [58] | |

| Single superphosphate | Sweden | 1 | [59] |

| United Kingdom | 0.6 | [60] | |

| Triple superphosphate | Europe, Russia, USA | 0.4–0.54 | [58] |

| Sweden | 1 | [59] | |

| United Kingdom | 1.2 | [60] | |

| Potassium chloride | China | 0.14–0.25 | [61] |

| TN (kg/ha) | TP (kg/ha) | Country | Soil Type | Crops | Others | Reference |

|---|---|---|---|---|---|---|

| 9.3 | 0.29 | Finland | Peat soil | Cereals, barley | Subsurface drainage | [68] |

| 21.7 | 0.30 | Norway | Mineral soil | Perennial grass | Subsurface drainage | [69] |

| 2.41 | 0.64 | China | - | Cereals | Runoff | [70] |

| 25 | 0.30 | Finland | Peat soil | Grass | Subsurface drainage | [71] |

| 39–191 | 0.9–2.4 | Sweden | Garden plants | Surface runoff | [72] | |

| 3.3–30.4 | 0.11–0.32 | Argentina | No-tillage | Cover crops | Rainfall | [73] |

| 4.3 | 0.04 | Sweden | Silty loam | Barley, grass | Subsurface | [74] |

| 28.5–40.0 | 0.7–4.3 | East Asia | - | Rice, Paddy | Subsurface | [75] |

| 4.5–12.9 | 0.5–2.6 | East Asia | - | Rice, Paddy | Surface runoff | [75] |

| Items | Scenario-C1 | Scenario-C2 | Scenario-C3 | Total |

|---|---|---|---|---|

| Manure types | Large scale | Medium scale | Small scale | - |

| Primarily selected upazilas | 53 | 138 | 222 | 413 |

| Number of composting plants | 15 | 42 | 147 | 204 |

| Total capacity of plants, kilotons/day | 1.5 | 2.1 | 1.17 | 4.78 |

| Total compost production, kilotons/year | 496.04 | 694.46 | 347.23 | 1537.73 |

| Total N supply as Urea, kilotons/year | 4.11 | 5.75 | 2.88 | 12.74 |

| Total P supply as P2O5, kilotons/year | 6.78 | 9.49 | 4.75 | 21.02 |

| Total K supply as K2O, kilotons/year | 9.88 | 13.83 | 6.91 | 30.61 |

| Total nutrient supply, kilotons/year (synthetic fertilizer replacement, %) | 20.77 (1.66) | 29.07 (1.32) | 14.54 (1.02) | 64.38 (3.996) |

| The required amount of manure, kilotons/year | 872.51 | 1221.52 | 610.76 | 2704.81 |

| Disposed amount of manure, kilotons/year | 1454.19 | 2035.87 | 1017.94 | 4507.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahal, Z.; Yabar, H.; Khan, M.F.A. Optimization of Composting Locations for Livestock Manure in Bangladesh: Spatial Analysis-Based Potential Environmental Benefits Assessment. Clean Technol. 2025, 7, 72. https://doi.org/10.3390/cleantechnol7030072

Mahal Z, Yabar H, Khan MFA. Optimization of Composting Locations for Livestock Manure in Bangladesh: Spatial Analysis-Based Potential Environmental Benefits Assessment. Clean Technologies. 2025; 7(3):72. https://doi.org/10.3390/cleantechnol7030072

Chicago/Turabian StyleMahal, Zinat, Helmut Yabar, and Md Faisal Abedin Khan. 2025. "Optimization of Composting Locations for Livestock Manure in Bangladesh: Spatial Analysis-Based Potential Environmental Benefits Assessment" Clean Technologies 7, no. 3: 72. https://doi.org/10.3390/cleantechnol7030072

APA StyleMahal, Z., Yabar, H., & Khan, M. F. A. (2025). Optimization of Composting Locations for Livestock Manure in Bangladesh: Spatial Analysis-Based Potential Environmental Benefits Assessment. Clean Technologies, 7(3), 72. https://doi.org/10.3390/cleantechnol7030072