Abstract

This article presents the results of the study of the morphological composition of municipal solid waste (MSW) from the landfill of Atyrau city, and the waste’s energy characteristics and presence of microorganisms, including bacteria, fungi and viruses. This study was carried out under a government order to determine the feasibility of recycling accumulated and incoming waste into electricity and its hazard to the environment and the workers involved in handling it. At the moment, there is no MSW recycling in Kazakhstan, which has led to the accumulation of more than 125 million tons of waste with an annual increase of 5 million tons. The research included four major cities (Almaty, Shymkent, Atyrau and Astana), which were selected not only on the basis of population, but also because the cities were located in different climatic zones. Samples were collected at the city landfills: 10 samples with an average distance of 100 m from each other were collected to provide a maximum coverage of both recently received waste and long-time stored waste. The research showed that neither climatic conditions nor the population size had a significant impact on MSW density, the values of which ranged from 120.1 kg/m3 to 145.4 kg/m3, as this indicator directly depends on the quality of life. The mass of the combustible fraction ranged from 39.41% to 54.62% and was mainly represented by plastic, textile and paper waste. The average value for the four cities was 50.30%. The higher calorific value fell in the range of 24.22–30.49 MJ/kg, with an average value of 26.71 MJ/kg. Microbiological studies showed little difference in average composition regardless of climatic conditions. Thus, no sharp differences in MSW composition, its energy characteristics and microbiological composition were found. The results of this study may be useful for optimising MSW recycling and disposal processes, as well as for developing measures to reduce their negative impact on the environment and human health.

1. Introduction

Modern society is facing a growing problem of municipal solid waste management caused by rapid population growth, increasing consumption and inefficient waste management systems. This leads to serious environmental and socio-economic consequences. In such a context, the study of energy and the biological characteristics of municipal solid waste assumes great relevance and importance [1,2].

Every year, the world generates more than 2 billion tons of municipal solid waste, and according to forecasts, the growth of volume by 2050 will be about 3.5 billion tons [3]. At the same time, one third of this waste is not utilised safely. The average amount of MSW per person per day is 0.74 kg, but this varies widely and depends primarily on the quality of life, with developed countries generating 34% of the waste. The quality of life also affects the composition of the waste, as the better the living conditions, the lower the amount of food waste and the higher the proportion of recyclable raw materials. Storage without recycling results in 1.6 billion tonnes of greenhouse gas emissions in terms of carbon dioxide, which is 5% of global emissions.

Municipal solid waste is a diverse mixture of organic and inorganic components including food waste, paper, plastic, glass, metals and other materials [4,5]. Together with the rapidly increasing volume of waste, there is a need to develop innovative approaches to its management in order to reduce its negative environmental impact while maximising the benefits of these resources. Research on the energy and biological characteristics of municipal solid waste is becoming a key factor in the effective treatment and utilisation of this waste. First of all, the energy aspect of the research helps to identify the potential of utilising municipal solid waste as an energy source [6]. This is especially important in the context of constantly growing energy demand and the need to diversify energy resources [7].

The biological characteristics of municipal solid waste also have great importance in the context of recycling. The use of biological processes such as composting can lead to the transformation of organic waste into useful products such as fertiliser or bio-gas [8,9]. Studies of the biological characteristics of waste allow the determination of the optimal conditions and methods for its treatment to improve processes and increase the efficiency of recycling.

In the trend of green technology development, the developed capitalist countries have traditionally led the way. But the countries in the Asian region, the Middle East and the African continent have recently joined this race [10,11,12]. This emphasises the need for waste recycling regardless of geography and distribution of the world’s wealth. The awareness of the limited availability of natural resources makes it necessary to provide a constant and predictable source of fuel and secondary raw materials. Municipal solid waste fulfils these requirements, which underlines the need to develop such technologies, including in terms of energy efficiency. The use of the combustible part of MSW for energy generation by direct incineration is widely found in many developed and developing countries [13,14]. In the USA, there are 75 enterprises generating electricity from MSW incineration. It is declared that 550 kW × h of energy is generated from one tonne of MSW, which, at an average cost of one kW × h of energy of 4 cents, makes it possible to obtain a profit from USD 20 to 30 [15]. It is obvious that the energy value will directly depend on the waste composition, and its value ranges from 300 to 700 kW × h per tonne [16,17]. In Kazakhstan, the processing of the entire volume of accumulated MSW at a price of 5 cents per kW × h with a minimum generation of 300 kW × h from one tonne can produce electricity worth USD 1.8 billion and generate USD 75 million annually.

Sweden is the leading European country in waste-to-energy conversion. It acts as an undisputed leader in its own waste recycling; United Kingdom, Ireland and Norway are exporting its MSW to Sweden. According to a report by the local waste management association Avfall Sverige, Sweden recycles 99% of its municipal waste [18]. It is important to note that 50.6% of waste is recycled, 48.6% is incinerated for energy, and only 0.8% is sent to landfills.

Pyrolysis is also a thermal method for processing the organic component of municipal solid waste [19,20,21]. Researchers emphasise, for example, the absence of combustion products, greenhouse gases and nitrogen oxides as strengths, and characterise the process as fully environmentally friendly. This characterisation is partly true, as pyrolysis itself meets these requirements, but the liquid fuel obtained by pyrolysis will be used for energy extraction in any case, with the occurrence of these negative consequences. If the final product of pyrolysis is predominantly synthesis gas, then the process requires significant temperatures of 750–900 °C and the use of a catalyst [22]. In general, it can be concluded that the choice of pyrolysis as a technology for MSW processing is reasonable if there is an appropriate production facility for the utilisation of its products nearby. Thus, incineration is simpler from the technological point of view and also does not require a source of energy for the implementation of the process.

In addition to thermal recycling and composting, recent years have introduced studies of the biological degradation of plastics into monomers using bacteria [23,24]. Both hydrolysable plastics such as polyethylene terephthalate and non-hydrolysable plastics such as polyethylene and polypropylene can be subjected to such recycling. Unfortunately, this method is not fast, and it is not practical to use it for large quantities of already accumulated waste. Moreover, different types of plastics are present in MSW at the same time.

Before the combustible part of MSW enters the furnace, the waste is sorted into separate non-combustible and food waste. Despite significant progress in the development of appropriate technologies, manual labour cannot be completely avoided. This raises concerns for the health of the people directly involved in sorting. Studies show that MSW can be a source of various pathogens such as Staphylococci, fungi and even Hepatitis B and C [25,26].

A new environmental policy has been initiated in Kazakhstan, and its intentions are to move towards world-class recycling standards. By 2030, it is planned to increase the recycling of rubbish to 40%. Simultaneously, there is insufficient available information about the morphological composition and potential biological risks associated with both historical waste and incoming waste. Additionally, it is important to have a clear understanding of the proportion of combustible components, their composition and energy properties when determining the method of waste management and recycling. In order to obtain an objective picture, the largest cities of Kazakhstan, having the status of republican importance and differing in climatic location and average quality of life of the population, were selected for research. Thus, Shymkent is the southernmost city with a population of about one million people and in terms of quality of life is in the 8th place [27]. Almaty is located 100 km to the north with a population of 1.8 million people and is in third place in terms of quality of life [28]. Atyrau is 700 km to the north, is in the second place in quality of life with a population of 235 thousand and has a strategic importance due to the presence of an oil refinery.

In Kazakhstan, there is a critical situation in the waste management system. There are several reasons for this. Kazakhstan is the ninth country by area and in terms of population density is at the very end of the list. The presence of huge territories and the lack of a waste processing system has led to the growth of landfills, where the waste is simply accumulated. As a rule, there are two to three official landfills near large cities and a large number of spontaneous ones, where waste is illegally dumped in order not to pay for burial. The environmental situation is seriously worsened by fires that occur in the summer period. The lack of a recycling system was a consequence of the necessity to solve more significant issues after gaining independence, such as medicine, education and improvement of the quality of life of the population. The main objective of this study was to determine the degree of suitability of historical and fresh MSW for recycling by using thermal methods, the quantity and quality of combustible components, their biological hazard and the composition of combustion products.

Taking into account the above mentioned factors, the project plans a comprehensive study of MSW from Kazakhstani landfills to obtain reliable information on their morphological composition and information necessary for further classification. Three main parameters are declared in the classification system: net calorific value (economic parameter), chlorine content (technical parameter) and mercury content (environmental parameter). In addition, a study of the presence of microorganisms is planned in order to establish the risks for people involved in the collection and sorting of MSW.

2. Materials and Methods

In this study, sampling was carried out in accordance with the requirements established by “Sanitary-epidemiological requirements for the collection, use, transportation, storage and burial of production and consumer wastes” approved by the Order of the Acting Minister of Healthcare of the Republic of Kazakhstan dated 23 April 2018 No. 187 [29]. For this purpose, polyethylene containers with a volume of 60 L, providing hermetic closure, were used. Figure 1 shows a map with the sampling marks labelled.

Figure 1.

Sampling locations.

Determination of the morphological composition of municipal waste was carried out in accordance with the “Methodology of determining the morphological composition of solid domestic waste”, established by the Order of the Agency of Construction and Housing and Communal Services of the Republic of Kazakhstan from 1 October 2012 №4 [30].

Preparation of samples for subsequent tests was carried out in accordance with the international standard ISO 21645:2021 [31]. There were two general methods used in the samples’ preparation: reducing the sample mass by separating it and grinding of samples [32,33].

In order to preserve the composition of the spot samples, the components were selected according to their percentage content. At this stage, it is important to manipulate the sample as quickly as possible to prevent the loss of moisture and volatile components because this will affect further determination of sample moisture content and volatile component yields. Once the combustible components had been extracted, manual grinding was carried out because any mechanised methods based on friction would inevitably lead to heating of the sample components and negative consequences. All sample components were ground separately to avoid the loss of moisture and were stored in tightly tied polythene bags. After grinding, the components were mixed to form the final sample.

The following standardised methods were used to investigate the physico-chemical parameters:

- -

- ISO 21660-3:2021 Solid recovered fuels—Determination of moisture content using the oven drying method [34]. The essence of the method is to bring to a constant mass the MSW sample in the drying chamber at a temperature of 105 °C and determine the desired parameter by the mass difference.

- -

- ISO 21656:2021 Solid recovered fuels—Determination of ash content [35]. According to this method, the sample in a muffle furnace is heated in steps: first by heating to 250 °C with a holding time of one hour, followed by heating to 550 °C and a holding time of two hours. Air shall be allowed to enter the furnace to ensure complete combustion.

- -

- ISO 22167:2021 Solid recovered fuels—Determination of the content of volatile matter [36]. In this method, the sample is heated for 7 min at 900 ± 10 °C in a tightly closed quartz crucible without access to air.

- -

- ISO 1928:2009 Solid mineral fuels—Determination of gross calorific value by the bomb calorimetric method and calculation of net calorific value [37]. Gross calorific value is determined by the combustion of a sample at constant volume and oxygen overpressure of 3 MPa. Modern calorimeters calculate the calorific value automatically by entering the mass of the sample into the memory of the instrument.

3. Results and Discussion

Volumetric and mass characteristics of MSW samples from the landfill of Atyrau city were investigated. Ten samples with a volume from 40 to 45 L and mass from 2.7 to 8 kg were taken in total. Waste density ranged from 89.8 to 259.1 kg/m3; the average value was 145.4 kg/m3. It is noteworthy that MSW density values can vary significantly between regions and countries due to different factors including consumption levels, population composition, level of industrial development and waste management systems. For example, researchers from China indicate densities ranging from 100 to 400 kg/m3 with an average of 325 kg/m3 across 31 provinces [38], while Bhutan has a MSW density of 160 kg/m3 [39]. A density of 311.73 kg/m3 is reported for the capital city of Oman [40]. The greatest contribution to the density should be made by food waste because its content in the total volume is significant and it contains a lot of moisture. It should also be noted that apart from the composition, the density will be affected by the time of year in which the sampling takes place, as precipitation will increase the density due to the absorption of water by hygroscopic materials such as paper and fabrics.

The species composition of MSW samples is presented in Table 1. In general, the composition corresponds to the world average values with the exception of a reduced content of food waste and an increased content of plastic components [41]. Food waste is the inedible parts of fruits and vegetables as well as leftovers of cooked food. Due to the availability and cheapness of plastic bags, people dispose of food waste in such tied bags. Preservation of humidity, positive temperature and limitation of UV light penetration favours microorganisms, and this type of waste determines the unpleasant odour of MSW in general.

Table 1.

Species analysis of MSW samples.

Paper waste is mainly packaging materials, boxes and containers of all kinds, printed materials such as advertising booklets, magazines and books, as well as used personal hygiene products such as napkins and toilet paper. In addition to the known ways of processing this type of waste, recycling is more rational, as paper waste can withstand several recycling cycles [42,43]. In Kazakhstan, there are no large-scale plants for the production of paper products, and minor recycling processes consist of the production of cardboard boxes and toilet paper from secondary raw materials.

Plastic waste has the widest range of types, most of which are polyethylene and polypropylene bags and other containers from food products and building materials, as well as various household appliance scraps. The chemical composition of plastic is the same as in the rest of the world; the proportions may differ due to the specifics of a particular region [44,45].

Textile waste is represented in the form of household worn-out clothes, yarns, threads and scraps of textile materials, which are generated at industrial facilities, from the transport, catering and health care sectors, medical institutions, domestic service enterprises, etc. Globally, 75% of textile waste is utilised and the rest is recycled [46]. At the same time, it can be used as fuel, although the calorific value is only 16.8 MJ/kg, which is significantly lower than for plastic waste [47].

Glass waste is mainly represented by broken beverage bottles and pharmacy containers. Whole containers are rare, since often whole bottles are handed over by the population at glass waste collection centres. Non-ferrous and ferrous metals are present in small quantities due to their value and availability at scrap metal collection centres, which are widely available.

The combustible fraction including wood, paper, polymer and textiles was selected and separated after sorting the samples. According to the data presented in Table 2, the total content of the combustible waste fraction is 53.18%, which is more than half and is mainly represented by plastic and paper waste. For the previous year, the volume of generated waste in Kazakhstan exceeded 5 million tonnes, and according to the forecast, by 2025 it will reach 8 million tonnes, which represents a promising opportunity for the organisation of an energy cluster independent of fossil fuels. More than three thousand landfills in Kazakhstan have already stored 125 million tonnes of waste.

Table 2.

The percentage composition of the combustible fraction of MSW.

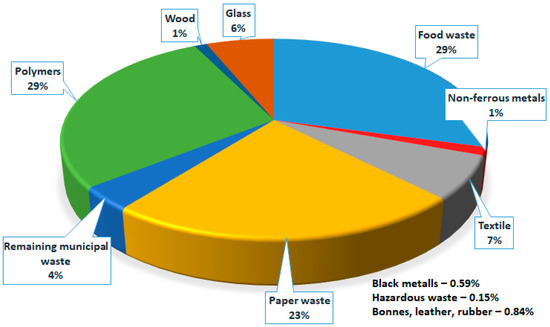

Figure 2 shows the general morphological composition.

Figure 2.

General morphological composition of MSW.

The moisture content of the samples ranged from 1.1 to 17.3%, with an average value of 3.72%. Determination of fuel moisture content plays an important role in various fields related to fuel utilisation and storage. Fuel moisture is one of the main parameters that affects fuel quality, combustion efficiency and safety of use [48]. High fuel moisture can lead to low combustion efficiency, increased emissions and energy loss. The optimum moisture content for pyrolysis has been determined as 20–25% [49], but in this process, water acts as a source of hydrogen in the formation of the syn-gas; in direct combustion any moisture content reduces the amount of generated heat. Also, in addition to the deterioration of fuel quality, it can lead to the occurrence of corrosion and package destruction. Moisture can also promote microbial growth and rotting, which can lead to the formation of harmful decomposition products. Both special sensors and neural networks can be used to determine the total humidity and its sources [50,51].

The determination of the ash content of fuels is crucial in various aspects related to their use in various industrial and energy processes. The ash content of a fuel determines the content of mineral residues that remain after combustion. This parameter has a significant impact on combustion efficiency and environmental effects as well as on waste treatment and equipment maintenance processes. The ash generated after MSW incineration is quite volatile and poses a certain threat to the environment and requires additional treatment for direct burial [52,53].

The nature of the difference between external ash content and internal ash content has a clear definition. External ash content arises from the contamination of extraneous impurities into the fuel; in the case of Municipal Solid Waste (MSW), these impurities include sand, dust, and soil particles, which are brought in as a result of storage at the landfill, where often no special base is prepared and the waste is stored directly on the ground. Combined packages made of cardboard and aluminium foil as well as various fillers for plastics will increase the internal ash content [54,55]. The ash content of the samples ranged from 3.94 to 22.27%, with an average ash content of 13.19%.

The determination of ash composition after the combustion of solid fuels plays an important role in understanding their properties, combustion efficiency and environmental impact. The composition of the ash reflects the mineral composition of the residue after complete or incomplete combustion of the fuel and may include various chemical compounds and elements. In addition, ash can also have commercial value; it can be used as an ingredient in concrete production [56] or for extracting useful elements [57,58]. Table 3 shows the elemental composition, which confirms that such ash can be used in concrete production [59]. Based on XRD analysis, CaO, MgO, SiO2, Fe2O3, TiO2, Ca12Al14O33, CaSO4, and NaCl phases were found in the sample.

Table 3.

Element composition of ash.

The yield of volatile substances is one of the important parameters that determine the quality of solid fuels. When solid fuel is heated without access to oxygen, decomposition takes place, releasing gaseous products called volatiles. After the volatiles have been removed, a solid residue (coke or semi-coke) remains, depending on the heating temperature in the mixture, with the mineral part remaining from mechanical impurities. The volatile yield also indicates the amount of gas that can be obtained by pyrolysis of the combustible part of the MSW. The decomposition of plastic waste present in MSW produces various alkanes and alkenes with chain lengths from C5 to C17; if the polymer consists of an aromatic monomer, toluene, ethylbenzene and m-xylene are found in the products of decomposition [60]. From paper and textile wastes, thermal decomposition produces H2, CO, CO2, and various hydrocarbons with chain lengths from C1 to C18 [61,62]. Table 4 summarises the volatile yield per dry state, with an average value of 82.8%. The high volatile yield and low ash content are caused by the high content of plastic and paper in the samples [63,64].

Table 4.

Yield of volatile substances from solid waste samples in a dry state.

The heat of combustion is the most important factor determining the quality of fuel and characterises its calorific value. Its determination is important for determining the amount of fuel required to achieve a certain level of energy performance or for assessing the efficiency of heating systems or energy plants. Gross calorific value was calculated according to ISO 1928:2009 standard “Solid mineral fuels—Determination of gross calorific value,” which was performed on an automatic calorimeter of the isoperibolic type GDY-1A+. Table 5 shows the values of the gross heat of combustion with and without taking into account the moisture content of the samples. The results indicate that the combustible fraction of Municipal Solid Waste (MSW) is well-suited for use as a fuel in the cement industry [65,66].

Table 5.

Gross calorific value of MSW samples.

The net calorific value of a fuel is the amount of heat released during the complete combustion of a unit mass of fuel minus the heat that is spent on the condensation of water vapour released from the combustion of hydrogen contained in the fuel. This value provides an estimate of the actual available energy that can be obtained from the fuel. The hydrogen content in MSW from different countries of the world, ranging from 5.5% to 11.5% with an average value of 7.1%, was taken for the calculation of the net calorific value [67,68]; the average value of the net calorific value was 25.38 mJ/kg.

The relevance of energy generation by the thermal processing of MSW, including gasification, pyrolysis and direct incineration, lies in solving two important problems of our time. Firstly, it contributes to the utilisation of waste, reducing its negative impact on the environment and preventing its accumulation in landfills. Secondly, it provides an opportunity to produce electricity and heat, which is relevant in the context of constantly growing energy demand and the depletion of traditional fuel sources. The choice of thermal method will be made depending on the existing demand for certain products. Pyrolysis can produce liquid and gaseous fuels, and then it is possible to redirect them to places of consumption. Gasification generates synthesis gas, which can be used to produce methanol or Fischer-Tropsch synthesis. Direct combustion makes it possible to produce thermal energy or electrical energy by converting steam energy in a turbine [69,70,71].

In addition to the economic, physicochemical and energy characteristics of MSW fuels, it is necessary to pay special attention to their biological hazards due to the presence of a large variety of pathogenic microorganisms [72,73]. Their danger is related to their ability to spread and cause diseases through contact with people [74] involved in MSW sorting and processing, through contact with groundwater, through soil contamination and atmospheric spread. In addition to the risk of contamination, the risk of explosion in the storage of MSW must be considered, as bacteria with the ability to ferment organic components are involved in the formation of flammable gases [75].

As shown in Table 6, the microbiological analysis of water extracts revealed the substantial presence of heterotrophic bacteria in all examined samples. The highest number of heterotrophic bacteria was found in sample 10, and the lowest was found in sample 3.

Table 6.

The number of studied groups of microorganisms in samples of water extracts.

Actinomycetes were found in samples 3 and 10. Their number in sample 3 was high and was counted as millions of cells in 1 mL. In sample 10, the number of actinomycetes was ten times lower.

Mycelial fungi were detected in all the studied samples of water extracts. Their number in samples 3 and 10 was approximately at the same level, and in sample 9, it was ten times lower. Yeast microflora was also detected. Their number in samples 3 and 9 was at the same level as the number of micro-mycetes, while in sample 10 it was three times lower.

Escherichia coli bacteria were also found in all the examined samples of water extracts. On Chromagar Orientation and Endo media in samples 3 and 10, their number is estimated in the millions, and in sample 9 their number is estimated in the tens of millions of cells in 1 mL. This indicates a strong fecal contamination of the samples.

4. Conclusions

The studied energy characteristics of the combustible part of MSW from the Atyrau landfill showed that it is possible to produce solid fuel of acceptable quality with a calorific value comparable to hard coal. At the same time, such fuel wins over coal in terms of ash content and volatile substances yield, as less waste will be generated. The composition of ash showed that it can also be used as a filler in the production of concrete, thereby reducing the cost of its production and minimising waste generation. When determining the parameters, the results for some samples are very different from the average value, which is caused by the heterogeneity of the composition and the introduced moisture and mechanical impurities. If the landfills are excluded from the recycling system and the waste is transported to prepared sites, the fuel quality will be slightly improved.

As calculations have shown, the conversion of this amount of waste into electricity can bring a profit of USD 1.8 billion, which is 0.91% of GDP. It should be noted that Kazakhstan today faces a shortage of electricity; during the years of independence, no new generating capacities have been built, and the existing ones are already insufficient. In this regard, the issue of building a nuclear power plant is put to a public vote. At the same time, MSW recycling per year is capable of producing 1500 GW×h of electricity.

Biological tests revealed the presence of microflora, including pathogenic microflora. Escherichia coli present a significant threat to workers engaged in the handling and incineration of Municipal Solid Waste (MSW). Particularly dangerous are virulent strains of this bacterium, which can cause various diseases such as gastroenteritis, peritonitis, septicaemia and others. Therefore, it is essential that personnel working in this area use personal protective equipment and keep good hygiene. These circumstances emphasise the importance of adopting appropriate safety and hygiene measures during the handling of MSW. Staff training and strict adherence to safety protocols will help to reduce the risk of disease and ensure the safety of workers in the field.

Author Contributions

Conceptualization, N.S.I. and A.Z.A.; methodology, N.S.I.; formal analysis, I.E.A.; investigation, N.S.I. and I.E.A.; resources, I.E.A.; writing—review and editing, N.S.I. and O.S.K.; visualization, I.E.A.; project administration, A.Z.A.; funding acquisition, A.Z.A. All authors have read and agreed to the published version of the manuscript.

Funding

The research was carried out in accordance with project AP09058076, “Research of energy potential and environmental safety of the municipal solid waste from Kazakhstani land-fills”, funded by the Committee of Science of the Ministry of Science and Higher Education of the Republic of Kazakhstan.

Data Availability Statement

Data available in a publicly accessible repository.

Conflicts of Interest

The authors have no relevant financial or non-financial interests to disclose. The authors have no competing interests to declare that are relevant to the content of this article. All authors certify that they have no affiliations with or involvement in any organisation or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript. The authors have no financial or proprietary interests in any material discussed in this article.

References

- Khan, A.H.; López-Maldonado, E.A.; Khan, N.A.; Villarreal-Gómez, L.J.; Munshi, F.M.; Alsabhan, A.H.; Perveen, K. Current solid waste management strategies and energy recovery in developing countries—State of art review. Chemosphere 2022, 291, 133088. [Google Scholar] [CrossRef] [PubMed]

- Ugwu, C.O.; Ozoegwu, C.G.; Ozor, P.A.; Agwu, N.; Mbohwa, C. Waste reduction and utilization strategies to improve municipal solid waste management on Nigerian campuses. Fuel Commun. 2021, 9, 100025. [Google Scholar] [CrossRef]

- The World Bank. Trends in Solid Waste Management. Available online: https://datatopics.worldbank.org/what-a-waste/trends_in_solid_waste_management.html (accessed on 23 October 2023).

- Dronia, W.; Połomka, J.; Jędrczak, A. Morphological composition of bio-waste collected selectively in towns and villages during autumn and winter. J. Air Waste Manag. Assoc. 2023, 73, 313–320. [Google Scholar] [CrossRef] [PubMed]

- Dehghanifard, E.; Dehghani, M.H. Evaluation and analysis of municipal solid wastes in Tehran, Iran. MethodsX 2018, 5, 312–321. [Google Scholar] [CrossRef] [PubMed]

- Bello, A.S.; Al-Ghouti, M.A.; Abu-Dieyeh, M.H. Sustainable and long-term management of municipal solid waste: A review. Bioresour. Technol. Rep. 2022, 18, 101067. [Google Scholar] [CrossRef]

- Alam, P.; Sharholy, M.; Khan, A.H.; Ahmad, K.; Alomayri, T.; Radwan, N.; Aziz, A. Energy generation and revenue potential from municipal solid waste using system dynamic approach. Chemosphere 2022, 299, 134351. [Google Scholar] [CrossRef]

- Saravanan, A.; Kumar, P.S.; Nhung, N.C.; Ramesh, B.; Srinivasan, S.; Rangasamy, G. A review on biological methodologies in municipal solid waste management and landfilling: Resource and energy recovery. Chemosphere 2022, 309, 136630. [Google Scholar] [CrossRef]

- Basinas, P.; Rusín, J.; Chamrádová, K. Dry anaerobic digestion of the fine particle fraction of mechanically-sorted organic fraction of municipal solid waste in laboratory and pilot reactor. Waste Manag. 2021, 136, 83–92. [Google Scholar] [CrossRef]

- Akhilesh, K.; Avlokita, A. Recent trends in solid waste management status, challenges, and potential for the future Indian cities—A review. Curr. Res. Environ. Sustain. 2020, 2, 100011. [Google Scholar] [CrossRef]

- Verma, R.L.; Borongan, G.; Memon, M. Municipal Solid Waste Management in Ho Chi Minh City, Viet Nam, Current Practices and Future Recommendation. Procedia Environ. Sci. 2016, 35, 127–139. [Google Scholar] [CrossRef]

- Ezeudu, O.B.; Ezeudu, T.S.; Ugochukwu, U.C.; Tenebe, I.T.; Ajogu, A.P.; Nwadi, U.V.; Ajaero, C.C. Healthcare Waste Management in Nigeria: A Review. Recycling 2022, 7, 87. [Google Scholar] [CrossRef]

- Rajasekhar, M.; Venkat Rao, N.; Chinna Rao, G.; Priyadarshini, G.; Jeevan Kumar, N. Energy Generation from Municipal Solid Waste by Innovative Technologies—Plasma Gasification. Procedia Mater. Sci. 2015, 10, 513–518. [Google Scholar] [CrossRef]

- Roy, H.; Alam, S.R.; Bin-Masud, R.; Prantika, T.R.; Pervez, M.N.; Islam, M.S.; Naddeo, V. A Review on Characteristics, Techniques, and Waste-to-Energy Aspects of Municipal Solid Waste Management: Bangladesh Perspective. Sustainability 2022, 14, 10265. [Google Scholar] [CrossRef]

- EPA. Frequent Questions on Energy Recovery from Combustion. Available online: https://www.epa.gov/smm/energy-recovery-combustion-municipal-solid-waste-msw (accessed on 13 October 2023).

- Dadario, N.; Gabriel Filho, L.R.A.; Cremasco, C.P.; Santos, F.A.d.; Rizk, M.C.; Mollo Neto, M. Waste-to-Energy Recovery from Municipal Solid Waste: Global Scenario and Prospects of Mass Burning Technology in Brazil. Sustainability 2023, 15, 5397. [Google Scholar] [CrossRef]

- Klinghoffer, N.; Castaldi, M. Waste to Energy Conversion Technology; Woodhead Publishing: Cambridge, UK, 2013; Chapter 8.4; ISBN 9780857096364. [Google Scholar]

- Milios, L.; Esmailzadeh Davani, A.; Yu, Y. Sustainability Impact Assessment of Increased Plastic Recycling and Future Pathways of Plastic Waste Management in Sweden. Recycling 2018, 3, 33. [Google Scholar] [CrossRef]

- Du, Y.; Ju, T.; Meng, Y.; Lan, T.; Han, S.; Jiang, J. A review on municipal solid waste pyrolysis of different composition for gas production. Fuel Process. Technol. 2021, 224, 107026. [Google Scholar] [CrossRef]

- Ławińska, O.; Korombel, A.; Zajemska, M. Pyrolysis-Based Municipal Solid Waste Management in Poland—SWOT Analysis. Energies 2022, 15, 510. [Google Scholar] [CrossRef]

- Hammoodi, S.I.; Almukhtar, R.S. Thermal Pyrolysis of Municipal Solid Waste (MSW). IOP Conf. Ser. Mater. Sci. Eng. 2019, 579, 012018. [Google Scholar] [CrossRef]

- He, M.; Xiao, B.; Liu, S.; Hu, Z.; Guo, X.; Luo, S.; Yang, F. Syngas production from pyrolysis of municipal solid waste (MSW) with dolomite as downstream catalysts. J. Anal. Appl. Pyrolysis 2010, 87, 181–187. [Google Scholar] [CrossRef]

- Cai, Z.; Li, M.; Zhu, Z.; Wang, X.; Huang, Y.; Li, T.; Gong, H.; Yan, M. Biological Degradation of Plastics and Microplastics: A Recent Perspective on Associated Mechanisms and Influencing Factors. Microorganisms 2023, 11, 1661. [Google Scholar] [CrossRef]

- Inderthal, H.; Tai, S.L.; Harrison, S.T.L. Non-Hydrolyzable Plastics—An Interdisciplinary Look at Plastic Bio-Oxidation. Trends Biotechnol. 2021, 39, 12–23. [Google Scholar] [CrossRef] [PubMed]

- Baghani, A.N.; Sorooshian, A.; Delikhoon, M.; Nabizadeh, R.; Nazmara, S.; Bakhtiari, R. Pollution characteristics and noncarcinogenic risk assessment of fungal bioaerosol in different processing units of waste paper and cardboard recycling factory. Toxin Rev. 2021, 40, 752–763. [Google Scholar] [CrossRef]

- Ayele, B.; Weldehanna, D.; Demsiss, W. Serological Evidence and Associated Factors of Hepatitis B Virus and Hepatitis C Virus Among Waste Handlers: A Cross-Sectional Study from Northeastern Ethiopia. Infect. Drug Resist. 2023, 16, 4881–4890. [Google Scholar] [CrossRef] [PubMed]

- Abilmagzhanov, A.Z.; Ivanov, N.S.; Kholkin, O.S.; Adelbaev, I.E. Assessment of the Energetical and Biological Characteristics of Municipal Solid Waste from One of the Largest Landfills in Kazakhstan. Recycling 2022, 7, 80. [Google Scholar] [CrossRef]

- Abilmagzhanov, A.Z.; Ivanov, N.S.; Kholkin, O.S.; Adelbaev, I.E. Study of energy characteristics of solid household waste from the Almaty landfill. Rep., Natl. Acad. Sci. Repub. Kaz. 2021, 5, 73–81. [Google Scholar] [CrossRef]

- Sanitary and Epidemiological Requirements for the Collection, Use, Application, Disposal, Transportation, Storage and Disposal of Production and Consumption Waste. Ministry of Healthcare of the Republic of Kazakhstan. Available online: https://adilet.zan.kz/rus/docs/V2000021934 (accessed on 13 October 2023).

- Method for Determining the Morphological Composition of Solid Domestic Waste. Approved. by order of the Chairman of the Agency of the Republic of Kazakhstan for Construction and Housing and Communal Services. Ministry of Industry and Construction of the Republic of Kazakhstan. Available online: https://online.zakon.kz/Document/?doc_id=31134077 (accessed on 13 October 2023).

- ISO 21645:2021; Solid Recovered Fuels—Methods for Sampling. International Organization for Standardization: Geneva, Switzerland, 2021; p. 56.

- Abdalqader, A.; Hamad, T.J. Municipal Solid Waste Composition Determination Supporting the Integrated Solid Waste Management in Gaza Strip. Int. J. Environ. Sci. Dev. 2012, 3, 172–176. [Google Scholar] [CrossRef]

- ASTM D5231-92; Standard Test Method for Determination of the Composition of Unprocessed Municipal Solid Waste. ASTM International: West Conshohocken, PA, USA, 2016.

- ISO 21660-3:2021; Solid Recovered Fuels—Determination of Moisture Content Using the Oven Dry Method—Part 3: Moisture in General Analysis Sample. International Organization for Standardization: Geneva, Switzerland, 2021; p. 10.

- ISO 21656:2021; Solid Recovered Fuels—Determination of Ash Content. International Organization for Standardization: Geneva, Switzerland, 2021; p. 13.

- ISO 22167:2021; Solid Recovered Fuels—Determination of Content of Volatile Matter. International Organization for Standardization: Geneva, Switzerland, 2021; p. 15.

- ISO 1928:2009; Solid Mineral Fuels—Determination of Gross Calorific Value by The Bomb Calorimetric Method and Calculation of Net Calorific Value. International Organization for Standardization: Geneva, Switzerland, 2009; p. 59.

- Zhu, Y.; Zhang, Y.; Luo, D.; Chong, Z.; Li, E.; Kong, X. A review of municipal solid waste in China: Characteristics, compositions, influential factors and treatment technologies. Environ. Dev. Sustain. 2020, 23, 6603–6622. [Google Scholar] [CrossRef]

- Phuntsho, S.; Dulal, I.; Yangden, D.; Tenzin, U.M.; Herat, S.; Shon, H.; Vigneswaran, S. Studying municipal solid waste generation and composition in the urban areas of Bhutan. Waste Manag. Res. 2010, 28, 545–551. [Google Scholar] [CrossRef]

- Palanivel, T.M.; Sulaiman, H. Generation and Composition of Municipal Solid Waste (MSW) in Muscat, Sultanate of Oman. APCBEE Procedia 2014, 10, 96–102. [Google Scholar] [CrossRef]

- Khan, S.; Anjum, R.; Raza, S.T.; Bazai, N.A.; Ihtisham, M. Technologies for municipal solid waste management: Current status, challenges, and future perspectives. Chemosphere 2022, 288 Pt 1, 132403. [Google Scholar] [CrossRef]

- Brown, R.M.; Hoover, A.N.; Klinger, J.L.; Wahlen, B.D.; Hartley, D.; Lee, H.; Thompson, V.S. Decontamination of Mixed Paper and Plastic Municipal Solid Waste Increases Low and High Temperature Conversion Yields. Front. Energy Res. 2022, 10, 834832. [Google Scholar] [CrossRef]

- Abushammala, H.; Masood, M.A.; Ghulam, S.T.; Mao, J. On the Conversion of Paper Waste and Rejects into High-Value Materials and Energy. Sustainability 2023, 15, 6915. [Google Scholar] [CrossRef]

- Areeprasert, C.; Asingsamanunt, J.; Srisawat, S.; Kaharn, J.; Inseemeesak, B.; Phasee, P.; Khaobang, C.; Siwakosit, W.; Chiemchaisri, C. Municipal Plastic Waste Composition Study at Transfer Station of Bangkok and Possibility of its Energy Recovery by Pyrolysis. Energy Procedia 2017, 107, 222–226. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Agamuthu, P. Plastics in municipal solid waste: What, where, how and when? Waste Manag. Res. 2019, 37, 1061–1062. [Google Scholar] [CrossRef] [PubMed]

- Juanga-Labayen, J.P.; Labayen, I.V.; Yuan, Q. A Review on Textile Recycling Practices and Challenges. Textiles 2022, 2, 174–188. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Godina, R.; Matias, J.C.O.; Catalão, J.P.S. Economic and environmental benefits of using textile waste for the production of thermal energy. J. Clean. Prod. 2018, 171, 1353–1360. [Google Scholar] [CrossRef]

- Kaur, A.; Bharti, R.; Sharma, R. Municipal solid waste as a source of energy. Mater. Today Proc. 2023, 81 Pt 2, 904–915. [Google Scholar] [CrossRef]

- Dong, J.; Chi, Y.; Tang, Y.; Ni, M.; Nzihou, A.; Weiss-Hortala, E.; Huang, Q. Effect of Operating Parameters and Moisture Content on Municipal Solid Waste Pyrolysis and Gasification. Energy Fuels 2016, 30, 3994–4001. [Google Scholar] [CrossRef]

- Gawande, N.A.; Reinhart, D.R.; Thomas, P.A.; McCreanor, P.T.; Townsend, T.G. Municipal solid waste in situ moisture content measurement using an electrical resistance sensor. Waste Manag. 2003, 23, 667–674. [Google Scholar] [CrossRef]

- He, T.; Niu, D.; Chen, G.; Wu, F.; Chen, Y. Exploring Key Components of Municipal Solid Waste in Prediction of Moisture Content in Different Functional Areas Using Artificial Neural Network. Sustainability 2022, 14, 15544. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Chen, L.; Ma, B.; Zhang, Y.; Ni, W.; Tsang, D.C.W. Treatment of municipal solid waste incineration fly ash: State-of-the-art technologies and future perspectives. J. Hazard. Mater. 2021, 411, 125132. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.Y.; Chuieh, T.Y. Life Cycle Assessment of Reusing Fly Ash from Municipal Solid Waste Incineration. Procedia Eng. 2015, 118, 984–991. [Google Scholar] [CrossRef]

- Post, W.; Kuijpers, L.J.; Zijlstra, M.; van der Zee, M.; Molenveld, K. Effect of Mineral Fillers on the Mechanical Properties of Commercially Available Biodegradable Polymers. Polymers 2021, 13, 394. [Google Scholar] [CrossRef] [PubMed]

- Móczó, J.; Pukánszky, B. Polypropylene Handbook; Springer: Cham, Germany, 2019; pp. 357–417. ISBN 978-3-030-12903-3. [Google Scholar] [CrossRef]

- Siddique, R. Use of municipal solid waste ash in concrete. Resour. Conserv. Recycl. 2010, 55, 83–91. [Google Scholar] [CrossRef]

- Fabricius, A.L.; Renner, M.; Voss, M.; Funk, M.; Perfoll, A.; Gehring, F.; Graf, R.; Fromm, S.; Duester, L. Municipal waste incineration fly ashes: From a multi-element approach to market potential evaluation. Environ. Sci Eur. 2020, 32, 88. [Google Scholar] [CrossRef]

- Liu, L.; Kong, S.; Zhang, Y.; Wang, Y.; Xu, L.; Yan, Q.; Lingaswamy, A.P.; Shi, Z.; Lv, S.; Niu, H.; et al. Morphology, composition, and mixing state of primary particles from combustion sources—Crop residue, wood, and solid waste. Sci. Rep. 2017, 7, 5047. [Google Scholar] [CrossRef] [PubMed]

- Vaičienė, M.; Simanavičius, E. The Effect of Municipal Solid Waste Incineration Ash on the Properties and Durability of Cement Concrete. Materials 2022, 15, 4486. [Google Scholar] [CrossRef]

- Pinto, F.; Costa, P.; Gulyurtlu, I.; Cabrita, I. Pyrolysis of plastic wastes. 1. Effect of plastic waste composition on product yield. J. Anal. Appl. Pyrolysis 1999, 51, 39–55. [Google Scholar] [CrossRef]

- Wu, C.H.; Chang, C.Y.; Tseng, C.H.; Lin, J.P. Pyrolysis product distribution of waste newspaper in MSW. J. Anal. Appl. Pyrolysis 2003, 67, 41–53. [Google Scholar] [CrossRef]

- Scheibe, A.S.; Pimenta de Araujo, I.; Janssen, L.; Amabile de Campos, T.; de Paulo Martins, V.; Vasques Mendonça, A.R.; Borges Valle, J.A.; Siqueira Curto Valle, R.C.; Guelli Ulson de Souza, S.M.A.; Ulson de Souza, A.A. Products from pyrolysis textile sludge as a potential antibacterial and alternative source of fuel oil. Clean. Eng. Technol. 2022, 6, 100408. [Google Scholar] [CrossRef]

- Akdağ, A.S.; Atımtay, A.; Sanin, F.D. Comparison of fuel value and combustion characteristics of two different RDF samples. Waste Manag. 2016, 47, 217–224. [Google Scholar] [CrossRef] [PubMed]

- Mehdi, M.; Siddiqi, M.H.; Liu, X.; Qureshi, T. Study of Hyrothermally RDF Samples for Energy Applications: Thermo-gravimetric Analysis. In IOP Conference Series: Earth and Environmental Science, Dali, China, 17–19 July 2020; IOP Publishing Ltd.: Bristol, UK, 2020; Volume 565, p. 012096. [Google Scholar] [CrossRef]

- Wojtacha-Rychter, K.; Smoliński, A. Multi-Case Study on Environmental and Economic Benefits through Co-Burning Refuse-Derived Fuels and Sewage Sludge in Cement Industry. Materials 2022, 15, 4176. [Google Scholar] [CrossRef] [PubMed]

- Kara, M. Environmental and economic advantages associated with the use of RDF in cement kilns. Resour. Conserv. Recycl. 2012, 68, 21–28. [Google Scholar] [CrossRef]

- Boumanchar, I.; Chhiti, Y.; M’hamdi Alaoui, F.E.; Sahibed-Dine, A.; Bentiss, F.; Jama, C.; Bensitel, M. Municipal solid waste higher heating value prediction from ultimate analysis using multiple regression and genetic programming techniques. Waste Manag. Res. 2019, 37, 578–589. [Google Scholar] [CrossRef] [PubMed]

- McPhail, A.S.; Griffin, R.; El-Halwagi, M.; Medlock, K.; Alvarez, P.J. Environmental, Economic, and Energy Assessment of the Ultimate Analysis and Moisture Content of Municipal Solid Waste in a Parallel Co-Combustion Process. Energy Fuels 2014, 28, 1453–1462. [Google Scholar] [CrossRef]

- Rezaei, M.; Ghobadian, B.; Samadi, S.H.; Karimi, S. Electric power generation from municipal solid waste: A techno-economical assessment under different scenarios in Iran. Energy 2018, 152, 46–56. [Google Scholar] [CrossRef]

- Gu, Q.; Wu, W.; Jin, B.; Zhou, Z. Analyses for Synthesis Gas from Municipal Solid Waste Gasification under Medium Temperatures. Processes 2020, 8, 84. [Google Scholar] [CrossRef]

- Lu, J.S.; Chang, Y.; Poon, C.S.; Lee, D.J. Slow pyrolysis of municipal solid waste (MSW): A review. Bioresour. Technol. 2020, 312, 123615. [Google Scholar] [CrossRef]

- Gerba, C.P.; Tamimi, A.H.; Pettigrew, C.; Weisbrod, A.V.; Rajagopalan, V. Sources of microbial pathogens in municipal solid waste landfills in the United States of America. Waste Manag. Res. 2011, 29, 781–790. [Google Scholar] [CrossRef]

- Ghanbarian, M.; Ghanbarian, M.; Ghanbarian, M.; Mahvi, A.H.; Hosseini, M. Determination of bacterial and fungal bioaerosols in municipal solid-waste processing facilities of Tehran. J. Environ. Health Sci. Eng. 2020, 18, 865–872. [Google Scholar] [CrossRef]

- Gutberlet, J.; Uddin, S.M.N. Household waste and health risks affecting waste pickers and the environment in low- and middle-income countries. Int. J. Occup. Environ. Health 2017, 23, 299–310. [Google Scholar] [CrossRef] [PubMed]

- Sakka, M.; Kimura, T.; Sakka, K.; Ohmiya, K. Hydrogen Gas Generation from Refuse-derived Fuel (RDF) under Wet Conditions. Biosci. Biotechnol. Biochem. 2004, 68, 466–467. [Google Scholar] [CrossRef] [PubMed][Green Version]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).