Abstract

Electric vehicle (EV) penetration has been increasing globally and is expected to continue its exponential growth over the coming decades. Several countries have already announced plans to achieve total or partial electrification of their vehicle fleets. Such rapid transportation electrification will have a significant impact on society and businesses that support the transportation industry. Additionally, new business opportunities will be available to support this technological evolution. In this paper, the business opportunities emerging from EVs and their supporting infrastructure are reviewed. It has been observed that several businesses, such as sustainable mining and manufacturing, will need to be developed before EV growth as they provide the initial platform required for EV adoption. Other businesses such as fleet optimization, battery management, and recycling can be developed at a later stage. All of these businesses will also have social and technological impacts, which will drive policy decisions. Regional governments play a critical role in ensuring the smooth execution of a transition to transportation electrification through social programs, such as training and education for equitable growth, and legislative decisions, such as technology standardization.

1. Introduction

Electric vehicles (EVs) were invented over a century ago but have only gained widespread popularity in the last decade [1]. Most car manufacturers have either launched or announced their lines of EVs, including cars, SUVs, and trucks [2,3,4]. Some companies have announced that they will only manufacture electric cars in the future (Tesla is currently the only large manufacturer of electric-only vehicles), while most have committed to dedicating a significant portion of their fleet to electric or hybrid vehicles.

Several factors, such as climate change, emissions reduction, growth of renewable energy resources, volatile oil prices, reducing battery costs, and governmental policies [5,6,7], have contributed to this shift among vehicle manufacturers. Most of these factors are interdependent, and, collectively, they help reduce the impact of climate change. Several researchers have been studying the details of electric vehicle technology so that their overall efficiency and performance can be improved. Hannan et al. reviewed the various aspects of hybrid electric vehicles [8], Du and Ouyang studied policy impact on the growth of the Chinese EV market [9], while De Santis et al. simulated the effect of using a back-to-back dual-motor mounting on powertrain efficiency [10]. In a more recent paper by Li et al., the powertrain efficiency of different configurations and resource types was compared [11]. Several other researchers have focused on the environmental impact of EV adoption as well as improvements in technology [12,13,14,15].

The growth of EVs will, however, not only positively impact environmental sustainability but will also have a significant impact on transportation businesses [9]. Many researchers have focused on the business and incentive models that will increase the rate of EV adoption in the community. Benzidia et al. focused on the buyer’s perspectives that impact the adoption of hybrid and battery electric vehicles [16]. Jones et al. studied the impact of EVs on the transport strategies of rural businesses that look for vehicle electrification [17]. Other researchers have also evaluated consumer behavior and preferences associated with ownership and lease structures, demographic diversity, and other factors that impact EV penetration [7,18,19]. However, not many researchers have focused on the business opportunities that entrepreneurs and established companies can create and develop through the accelerated growth of EVs. Many businesses will directly impact the growth of EVs, while many others will be impacted by the growth of EVs. Businesses, such as car manufacturers and charging infrastructure providers, will need to make technological and business model innovations ahead of EV growth, while some businesses such as battery recycling will experience growth following the widespread adoption of EVs. These businesses can be termed as “leading” and “lagging” businesses, respectively, based on the differences in their development cycle from that of EVs.

In this paper, a holistic view of the business opportunities enabled by electric vehicles and their socioeconomic effects on local and global communities is given. The lifecycle of an EV is reviewed, and the business models are classified based on which step of the lifecycle of EVs they contribute to. Finally, the social, technological, and policy impacts of these business models are discussed. The conclusions made in this paper can be useful for identifying new research opportunities that will have a business impact due to the EV revolution.

2. Current and Future EV Market Penetration

Electric vehicle (EV) penetration has been growing slowly but steadily across the globe, and EVs are expected to claim a substantial percentage of all consumer vehicles by 2030 [20]. Currently, EVs constitute ~1% of all light-duty consumer vehicles, while constituting >2.5% of all sales in 2019 [21,22]. Norway is the only country to have reached >50% EV penetration, followed by Iceland at ~22%, and the Netherlands at ~15%. China and the US, on the other hand, have achieved ~5% and ~2% penetration, respectively [22]. Most other countries in the developing economies have either had much lower EV penetration so far or lack the availability of reliable data. For example, most three-wheelers in many Indian cities have started using lead-acid batteries instead of oil for operation, but as they are not typical four-wheel vehicles, their data is not available publicly.

Even though the adoption rates observed so far seem low, the last few years have seen exponential growth in EV adoption. Such exponential trends are expected to continue in the future. Various countries have set up aggressive targets for EV adoption, and suppliers are racing to meet market demands. Table 1. shows some of the countries and their announced targets as of 2019.

Table 1.

Electric vehicle targets set by various countries [23].

These are ambitious targets for some countries; many of them will need to show expansive growth over the coming years to meet them. Since most of the countries do not have interim annual targets, it is difficult to assess whether or not they are on track to meet these targets. For example, India’s ambition of 30% EV cars by 2030 is equivalent to 102 million vehicles. However, as of March 2020, only half a million electric vehicles were registered [37]. Canada, on the other hand, has interim targets, but the progress made through the third quarter of 2020 shows that they will most likely miss those targets without any additional measures. These examples show that there is a mismatch between the vision and the current status of EV market share in several countries; these countries will need to deploy aggressive incentives or other promotional campaigns to achieve their goals. Despite these challenges, countries have been working on the path of increasing transportation electrification, and as they make progress towards their targets, businesses that rely on the current state of the transportation sector will need to adapt to the changing technology. Additionally, some new businesses will emerge as necessary, while some of the current businesses may experience shrinkage in revenue. The next sections describe various stages of the lifecycle of an EV and the associated business development opportunities.

3. Lifecycle of an EV

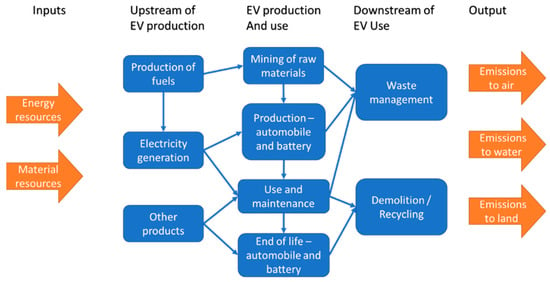

A typical lifecycle for a product consists of three phases—production, use, and end of life. Several upstream and downstream processes enable this product lifecycle. A cradle-to-grave assessment of electric vehicles would also include these stages, in addition to any upstream or downstream impacts. Figure 1 describes the overall value chain of an electric vehicle. The process takes energy and material inputs and results in emissions to air, water, and land.

Figure 1.

Stages in the lifecycle of an electric vehicle.

The process starts with mining or reclaiming recyclable raw materials. A typical car requires almost 50 different types of metals for production, including several rare earth metals, which are typically nonrecyclable [38]. Electric vehicles require an increased need for such rare earth metals, several of which, such as cobalt, gallium, indium, and magnesium, are considered critical due to their potential supply risk problems [39]. Currently, most of these metals are not recycled because mining them is cheaper than recycling them from old vehicles [38].

In the production phase, one of the key differences between the lifecycle of electric vehicles and internal combustion engine vehicles is battery manufacturing [40]. The lifecycle impact of battery manufacturing depends on aspects such as battery size and life [41], which are determined by customer requirements and design decisions such as battery chemistry and the type of solvent used in the battery [42,43]. Another aspect that should be included in the production phase is the manufacturing and installation of ancillary products that are needed for operating electric vehicles. Battery charging systems are one of the most important products that will be needed with increased electric vehicle penetration. These products will result in additional emissions but will also offset emissions due to mining and transporting fuel for internal combustion engine vehicles.

In the use and maintenance phase of electric vehicles, the efficiency and energy mix of the electricity generation system is the most important factor for determining the environmental impact [44]. This stage of the electric vehicle lifecycle has significant societal impacts and has the potential to disrupt the local economy. The first thing that gets impacted in this stage is the need for fuel. While electric vehicles will need electricity to operate, the electricity can be generated at a power plant or on someone’s off-grid rooftop, thus eliminating the need for going to gas stations. Second, electric vehicles need less maintenance and may impact the local automobile repair industry. These vehicles require technicians to develop a different skillset, and their spare parts requirements are significantly different from those needed for internal combustion vehicles [45]. This, in turn, would require local companies to adapt their manufacturing lines and educational institutes to update their curriculum. Third, as the battery is one of the most expensive pieces of an electric vehicle, understanding its behavior, increasing its life, managing its degradation, and maximizing the vehicle range will become important [46,47,48].

In the end-of-life stage, while most of the components of the electric vehicle can follow the same path as defined for ICE vehicles, current end-of-life management practices for batteries compromise the benefit of EV adoption [46]. Additionally, a greater emphasis will be needed on recycling and reusing the materials involved in electric vehicle manufacturing so that the need for raw material mining is minimized.

Existing literature on the lifecycle analysis of electric vehicles shows [41,49,50,51,52] that the tailpipe emission elimination by electric vehicles is replaced by increased emissions during the vehicle production phase and by electricity generation during production, use, and end-of-life phases.

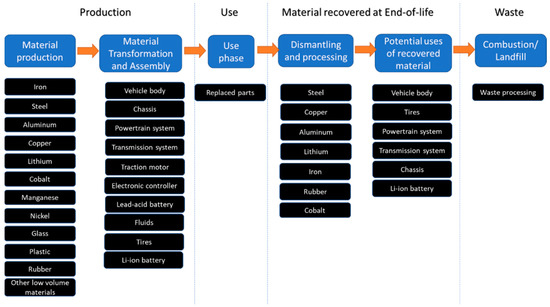

Various stages in electric vehicle production, use, and end-of-life phases are shown in Figure 2. Although the process is energy-intensive, end-of-life recycling of electric vehicles can result in the recovery of some materials that can be reused [53,54,55] in electric vehicles. With the volume of batteries being recycled expected to increase in the future [46,56], reducing energy consumption during battery recycling will help in making electric vehicles more sustainable. Adopting a battery recycling process that increases the yield of rare earth minerals (e.g., cobalt) will also help in increasing the long-term availability of these minerals [57]. Another approach to reducing battery lifecycle impact is to optimize battery degradation so that the distance traveled during its lifetime can be maximized [58].

Figure 2.

Electric vehicle production to end-of-life.

Emissions due to electricity generation can be reduced by using renewable energy generation sources such as solar and wind instead of more carbon-intensive electricity generation sources such as coal and natural gas.

Looking at the overall lifecycle, it can be concluded that depending on the electricity generation mix during the manufacturing and use phases, electric vehicles do result in a reduction of GHG emissions [59,60] but may cause an increase in the potential for human toxicity, freshwater ecotoxicity, freshwater eutrophication, and metal depletion [44]. Transitioning from internal combustion engine vehicles to electric vehicles will shift the points of GHG emissions, resulting in improved air quality in populated regions where vehicles are used and poorer air quality in regions where vehicle manufacturing and electricity generation (or electricity generation equipment manufacturing) take place. Policies such as switching to cleaner sources of electricity generation and following sustainable practices during the manufacturing process should also help in managing this shift.

With a better understanding of the lifecycle of an electric vehicle, it is possible to understand the business impact of the various stages of EVs. There will be some businesses that will need to be developed first as they will impact the pace of EV growth, while there will be other businesses whose development will follow the growth of EVs. The next two sections describe some of the most significant businesses related to EVs.

4. Businesses That Lead

Many businesses and infrastructures need to be developed first in order to ensure that EVs can grow at a fast pace as well. These are called “leading” businesses because their growth will come before the growth of EVs.

4.1. Sustainable Mining

Almost all of the electric vehicles commercially available in the market today use lithium-ion batteries [48]. Although Earth has huge reserves of lithium ore in the oceans and seas, its concentration is so small that isolating lithium from other seawater mineral salts is uneconomical [61]. Electric vehicles also require cobalt and several other rare earth metals [38]. While the world has significant and known resources for lithium, cobalt scarcity presents a greater concern for sustainability and long-term availability [62,63]. This presents significant technological challenges and emphasizes the need to focus on the cost-effective recycling of cobalt. Additionally, an effort must be made to identify alternatives for using cobalt in batteries to ensure sustainable EV growth.

The geographical location (Table 2) of these mineral deposits also present unique challenges to local society and lifestyles as it disrupts the region’s traditional way of life and increases the stress on local resources. For example, increased mining has not only caused increased deforestation in the Congo but has also resulted in more violence on the local population from the local warlords over the production and control of resources [64]. In Bolivia, where the Uyani salt flats have the largest lithium reserves on Earth, the discovery has resulted in conflict between the federal government, local government, and local residents, as the federal government has converted the region into a fiscal reserve and assigned a government-controlled company to operate and mine the reserve, while ~59% of local residents lived in extreme poverty [65]. In the Atacama region of Chile, social activism against lithium mining has increased in the last several years. Increased mining in this region has adversely impacted water availability, the employment of local residents, and tourism [66].

Table 2.

Active metals in lithium-ion battery cells [20].

Mining companies, battery manufacturers, and local governments will need to work together to create a framework and an implementation plan to ensure that mining activity does not adversely impact the lifestyle and standards of living of residents in these regions.

4.2. Battery Manufacturing

Most of the electric vehicles today use conventional Li-ion battery chemistry for energy storage. With the increase in EV adoption, the required Li-ion battery production is slated to grow 10-fold, from ~170 gigawatt-hours (GWh) per year in 2020 to ~1.7 terawatt-hours (TWh) per year in 2030. Currently, EVs use batteries sized between 5 and 95 kWh, and their single-charge driving range is capped at ~300 miles. The Li-ion batteries used in EVs are made of hundreds of single Li-ion cells that are connected inside a module. A Li-ion battery cell can be manufactured in prismatic, cylindrical, or pouch shapes [68]. Conventional Li-ion cells retain their basic architecture, wherein they use a host material to reversibly insert ions (Li+) within their matrix during charging and discharging. Conventional Li-ion technology typically employs a (nickel manganese cobalt oxide) NMC/(nickel cobalt aluminum oxide) NCA cathode, graphitic anode, and liquid electrolyte. The manufacturing of a Li-ion battery pack is typically divided into two stages: (1) cell manufacturing and (2) pack assembly. A Li-ion battery cell comprises an anode, a cathode, a separator, and current collectors. Electrodes are processed by the solution-processing method by roll-to-roll coating onto the current collectors. The coated electrodes are then dried extensively to remove the solvent and pressed to achieve the required density of the electrode. These electrodes are sandwiched with a polymer separator, cut to an appropriate size, and stacked to achieve the desired capacity. Current tabs are then welded to the current collectors; then, a liquid electrolyte is filled into the cell and sealed in a casing to make a single Li-ion cell. All operations are typically carried out in dry rooms with a controlled atmosphere with an absence of humidity. Subsequently, these cells are configured into the required pack configurations. All the cells are expected to have the same state-of-charge (SOC) at all times to achieve a uniform degradation rate and capacity over their lifetime [69]. This uniformity is achieved by a cell voltage equalizer, which actively measures and equalizes the voltage of each cell. Each battery pack is accompanied by a battery management system (BMS), an electronic system that operates and protects the battery by monitoring and operating it under safe conditions.

4.3. Charger Design and Installation

An extensive EV charging infrastructure is one of the key customer requirements for increasing EV penetration. Limited infrastructure leads to range anxiety, which can deter the decision to purchase an EV. Additionally, with EV manufacturers moving towards bigger batteries, the charging rate becomes critical for long-distance driving.

EV charging infrastructure is primarily classified based on the power at which it charges an EV. Level 1 and Level 2 chargers utilize alternating-current-based charging, where power is drawn from a regular power outlet used for other household electrical appliances. Level 1 charging operates at 110 V and provides ~1.4 kW of power. Level 2 charging operates at 220–240 V and provides power in the range of 6.6–19.2 kW [70]. Level 3 chargers are based on direct current charging. Since the power input to the EV can circumvent the onboard inverter, much higher power can be pushed into the battery during Level 3 charging. The power range of Level 3 charging starts at 50 kW, and ongoing work on the technology aims to increase its power output to ~350–400 kW [70].

EV charging connectors also vary across regions and EV manufacturers. The J1772 type charger is common in North America and Japan, whereas the Mennekes type charger is common in European Union. For DC charging, CCS1 and CHAdeMO type charger designs are used in North America and Japan, respectively. CCS2 is used in the European Union for DC charging [71]. Several institutes are interested in increasing their EV fleet, but the lack of a universal connector design is one of the reasons preventing them from entering the market. The transition to a universal connector design has its pros and cons. With a singular design, the end-user probability of finding a charging station increases, and this will help reduce their range anxiety while traveling. While manufacturing standards for charging infrastructure can be implemented and can help increase the life of the components involved in the charging system, regulating charging connector designs with a singular design may prevent innovation and discourage improvements. Hence, the industry will have to adopt a suitable strategy that promotes innovation while simplifying the charging experience for end consumers. Beyond conventional designs, developments in contactless charging (inductive charging) also has the potential to eliminate the hassle of connecting the charging cable to the car every time the car needs to be charged. This will also enable car charging while on the road. [72]

4.4. Electricity Generation to Support EV Charging

As the penetration of EVs grows throughout the world, it will be critical to ensure that the charging energy comes from renewable energy sources to reduce the emissions caused by EVs [73]. Additionally, the appropriate transmission and distribution networks will need to be in place to support the additional load on the electric grid. Increased EV adoption has significant implications for utilities. Transportation demand has strong peaks in the mornings and evenings on weekdays, with limited variation across modes. Power demand also shows morning and evening peaks in most regions, while demand is lower during the night and in the afternoon. Additionally, in warmer areas, the demand is high during summer; in cold areas, the demand is high during winter. As both electricity and grids operate below peak during the night, it makes sense to charge electric vehicles during the night. If electric vehicles start getting charged during grid demand peaks (mornings and evenings), the peak in the power draw will further increase, thus increasing the need for additional generation capacity. Therefore, controlling the charge/discharge cycle of electric vehicles is critical to avoid the economic and environmental effects of increased peak loads. From a utility’s perspective, electric vehicles should be charged during the night and not charging or discharging during morning and afternoon grid peaks.

4.5. Disposal and Recycling

Safe and environmentally sound disposal at the end of life of EVs will be critical for their long-term growth. As sustainability goals achieved during operation have been a major reason behind government promotions of EVs, the EV industry will also need to ensure sustainable disposal and recycling of its equipment. Some of the technologies that already exist for ICE vehicles can also be used for EVs, such as tire disposal and vehicle-body recycling (Figure 2), while others will need to be developed.

EV recycling can be separated into three sections [53]:

- Battery recycling: This is a business that follows the growth of EVs. It is discussed in the next section.

- Vehicle recycling: EVs differ from ICE vehicles in terms of their structural design as well, even though materials such as steel, aluminum, and plastic are common to both types of vehicles [53]. For recycling these materials more efficiently and cost-effectively, the entire transportation industry, including the EV industry, needs to make appropriate investments.

- Tire recycling: Similar to existing vehicles, EVs will need to ensure an appropriate tire recycling path long before the vehicle reaches its end of life. Tires are currently recycled as fuel, with concrete or asphalt, rubber compounds, or plastic composites [74]. Using the tires as toughening agents for thermoplastics and rubber products provide a profitable and environmentally friendly option to recycle and reuse them. The EV industry can take advantage of this existing value chain.

5. Businesses That Lag

The last section provided an overview of the businesses that will lead the development of accelerated EV penetration. There will be several other businesses whose growth will lag the growth of EVs and their development will follow the location and pace of EV growth. These can be considered “lagging” businesses.

5.1. Vehicle to Grid Integration

Batteries in electric vehicles can outweigh stationary energy storage by many times [75]. With over 1200 GWh of available battery capacity in the cars, the load on the electric grid can be severe if these EV batteries are considered load-only. However, the energy stored in EVs can also support the electric grid as a flexible generation source. Vehicle to Grid (V2G) or Vehicle to Home (V2H) integration can allow the bidirectional flow of energy between the EV and the electric grid to perform grid functions such as demand response and peak shifting and customer-sited functions such as demand charge management and backup power supply.

Stand-alone batteries have been proven to be extremely valuable for grid stability and reliability, renewable firming, and peak shifting. These benefits can also be obtained by using the batteries in electric vehicles. Additionally, the mobility provided by electric vehicles makes them even more suitable for applications that involve changing locations of electric loads. Some of the applications and associated advantages are listed below:

- Social events: Events such as major games, political rallies, or concerts, which attract a large number of attendees, usually require a lot of energy as well [76]. Many attendees at these events bring their vehicles, which can also support the electricity needs of the event. As EV penetration grows, the battery capacity available to support these events at the event venue itself will also increase, and effective utilization of that battery capacity to support the increased energy requirement will become critical.

- Disaster recovery: 2020 was one of the busiest hurricane seasons in history [77], which left thousands of people without electricity for days. Most of these electrical outages are caused by failed power lines that result in electricity not being delivered to the users [78,79]. By using EVs in those situations, it will be possible to charge the battery at a location that has access to electricity and then move the vehicle and the battery to a location that needs power for an extended period of time. Disaster recovery planning in Japan in the aftermath of the Fukushima disaster was a driving force behind the faster commercialization of V2H in the country [80].

- Back-up power: V2H and V2G can also function as a backup power supply to homes and commercial buildings in case of an electrical outage or grid emergency. As mentioned previously, this technology has already been commercialized in Japan, and other regions are following the trend through large-scale pilot projects [81].

5.2. Fleet Optimization

As the number of EVs grows, the transition of several fleets of vehicles to being electric will soon begin. Some examples of these fleets are school buses, local transportation, golf carts, utility vehicle fleets, and delivery and postal service vehicles. As the number of vehicles available at one location will be large, the impact on the electrical grid and associated charging cost for the fleet manager will also be significant. Several researchers have already published algorithms that can optimize the charging strategy of the fleet to include charging cost and the distribution grid impact [82,83,84]. These strategic algorithms also include the power balancing impact on the EV battery as well as state-of-charge management.

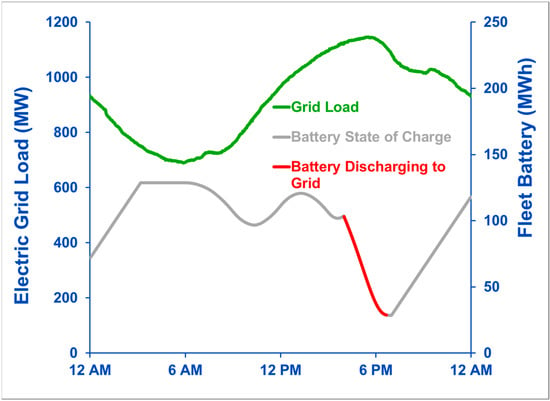

Additionally, large fleets can also be used to provide Vehicle-to-Grid functionality and operate similarly to a large-scale battery energy storage system. Pilot projects using EV fleets for the V2G function suggest that a hierarchical control system can be successfully used to participate in electricity markets and perform functions such as energy arbitrage and frequency regulation [85,86]. As shown in Figure 3, optimizing the charge/discharge dispatch profile for EV fleets can not only be beneficial for the user by providing lower-cost electricity but it can also support the electric grid by reducing the peak load. The example shown in the figure assumes an electric grid that has a peak load of ~1200 MW and a vehicle fleet with a combined battery capacity of 120 MWh. Various electrical parameters used for calculating the impact on the grid on a peak day are listed in Table 3. It is assumed that the vehicles use 25% of their energy capacity for the daily driving needs of the user and that a minimum of 25% energy must be maintained for any emergency needs. This leaves 50% of battery capacity available for use by the grid operator to support peak loads. As the MWh available in single or multiple fleets grow even further, commercial deployment of optimization algorithms by the grid operator or a third-party energy manager will be observed at all locations.

Figure 3.

Charge/discharge profile of EV fleets to support grid load.

Table 3.

Parameters used for calculating the impact on the grid.

5.3. Battery Recycling

Batteries used in a typical EV have a useful life till 80% of their initial capacity, after which they cannot provide enough power for the vehicle’s acceleration and range [58]. Battery packs unfit for EV use can be either refurbished, reused, or recycled. Since many stationary applications demand a lower current density, battery packs can be sorted and reassembled for stationary usage [87]. If the battery pack cannot be refurbished or reused, recycling the battery is important to reclaim battery materials and avoid accidents related to battery disposal [88]. Since the current recycling processes rely on first-generation recovery technologies, in which the different streams of raw materials are obtained by a physical treatment and the metals are then extracted by a hydrometallurgical process (leaching and extraction), battery recycling is one of the biggest opportunities that the EV industry needs to resolve for sustained EV adoption [89]. Battery capacity available for recycling is expected to increase by nearly 100 times in the next decade [90]. With such an increase in recyclable lithium-ion batteries, it will be critical to have a robust recycling industry that can reduce the need for raw material mining and refining and the associated emissions. Even with the current technologies, such as pyrometallurgy and hydrometallurgy, it is possible to achieve a net reduction in greenhouse gases by using recycled materials [53,90].

An important step for achieving high recycling rates is to, first, establish collection systems that can collect used batteries at the end of their life. The current collection rates for Li-ion batteries are less than 50% even in European countries with strong legislative policies [91]. This is much lower compared to lead-acid batteries, where the recovery rate is 99%. While lead-acid batteries have a simpler design, they also have an older and more established collection infrastructure. Lithium-ion batteries can achieve similar rates as they become more mature. Researchers have estimated that improved battery recycling processes and infrastructure could supply between 30% to 90% of the total demand for cobalt by 2050 [92] and 90% of lithium demand [93].

EVs should also focus on vehicle recycling by taking advantage of their unique design to reuse certain portions of the vehicles before considering recycling. For example, EV designs generally use different types of base and battery chassis that can be reused even if the rest of the vehicle parts are recycled. Their powertrain system, motors, and electronics can also be refurbished and reused. Business models around such refurbishments, reuse, and recycling will emerge with the growing EV industry.

6. Social and Technological Impacts of the New Businesses

An increase in electric vehicle adoption will result in several changes, and governments will need to proactively prepare policies and infrastructure for a smooth transition towards mobility electrification. This will require several societal changes, which involve a change in mindset around EVs and technological changes that involve upgrading existing infrastructure to support EV adoption.

- Social implications

- Prepare local communities for a transition to an EV-based economy: It has been found that consumer characteristics such as education, income, level of environmentalism, and love of technology impact the adoption of electric vehicles [94]. For this reason, it is important for governments to educate citizens on the benefits of owning an electric vehicle. Research suggests that more educated citizens, who are used to getting electricity from a renewable-energy-inclined grid, are more likely to adopt electric vehicles [95]. Fossil fuel favoritism makes people incorrectly believe that fossil fuel vehicles provide more power and are more rugged compared to electric vehicles [96]. To minimize misinformation about electric vehicles, governments should carry out publicity campaigns that highlight the benefit of electric vehicles and show how they can contribute to the betterment of society. Encouraging social discussion around electric vehicles and promoting science-based propaganda will also help promote EV adoption [97].

- Upskilling the workforce in the community by training them on the new technology: Electric vehicle manufacturing and maintenance require skillsets that are different from those of a traditional automobile mechanic. In Ghana, owners of hybrid electric vehicles have highlighted spare parts unavailability and the lack of skilled technicians to work on their cars as two of the key challenges for hybrid electric car ownership [45]. Local garage shops face great difficulty in hiring technicians skilled in maintaining electric vehicles, which is a barrier to increasing electric vehicle adoption [96]. Given this scenario, governments should focus on incorporating the skills needed for electric vehicles in the curriculum of local universities and ensuring that sufficiently skilled technicians are available in the market.

- Charging-infrastructure-related policy: Research has found that charging-fee-related policies have a significant impact on EV adoption [97,98], as charging fees can significantly influence the total cost of ownership and change the consumer perception of electric vehicles. Therefore, governments interested in increasing EV adoption should not only focus on charging infrastructure but also create policies that simplify the use of charging infrastructure.

- Technology implications

- Engine manufacturing: As society transitions from internal combustion engine vehicles to battery-based electric vehicles, demand for engine manufacturing will reduce and the demand for battery-related activities, such as battery recycling and battery management services, will increase [99]. This will result in job losses in the traditional manufacturing sector but will create new jobs in other sectors. Given this scenario, governments should proactively work towards upskilling the local workforce to adapt to this changing situation and enable them to pick up new jobs when they become available in the market. Mismanagement of this transition can result in the loss of local jobs and has the potential to disrupt economies in the regions where the economy is driven by combustion engine manufacturing companies. In the short term, this will result in an increase in manufacturing cost, which is one of the key barriers to the adoption of sustainable technologies [100]. Reducing such political and economic frictions, post-World War II, has been identified as one of the key drivers for the drastic increase in technology adoption in Japan [101].

- Infrastructure development: Charging concerns and supply chain segmentation are barriers to electric vehicle adoption that require the development of stronger infrastructure for electric vehicles [96]. Charging concerns can be tackled by either providing a larger battery with the car or by developing more closely placed fast-charging-enabled charging stations along key routes. Several automobile manufacturers are currently focusing on increasing battery range. Typically, gas stations are placed at such locations; therefore, replacing gas stations with charging stations or installing charging station infrastructure at current gas station locations is one of the options that the local governments or the charging companies can pursue. Governments can also help by funding battery-related research. Supply chain segmentation is another issue that the government can help tackle by promoting the manufacturing of the spare parts that are required in electric vehicles. If the demand for electric vehicle parts remains low, one of the options that can be explored is setting up 3D manufacturing facilities [102] that can manufacture a part on-demand. Processes and policies, including safety procedures, will need to be developed for in-home and community charging infrastructures. The density of charging infrastructure affects the utilization of electric vehicles [103], where a higher density of charging infrastructure makes it more likely for consumers to adopt EVs.

- Develop standards for electric vehicles: One of the key challenges with electric vehicles is the types of standards currently being used by each manufacturer [104]. To scale up EV adoption, governments will have to lead the discussion with key stakeholders and work towards minimizing duplicative infrastructure. For example, if charging plugs are not standardized, multiple types of charging stations will have to be commissioned to serve the population and many places will install multiple types of charging stations to cater to demand. This would result in a significant wastage of resources. The government should also drive the discussion on establishing standards for vehicle-to-grid integration and develop policies that enable consumers and businesses to sell the electricity stored in the vehicles back to the grid when needed [103]. This setup can also help during natural disasters and can be a substitute for diesel generators [105] that are used in countries, such as India, where power outages are more prevalent.

- Software development: Software development will also be extremely important for electric vehicles, as it is vital in the optimal performance of EVs. The battery management system (BMS) is one of the most important pieces of software–hardware systems to monitor performance and carry out the battery’s real-time diagnostics. Additionally, several types of software will need to be developed to provide services such as monitoring the EV range, route planning, and energy consumption planning.

7. Conclusions

In this paper, business opportunities related to electric vehicles and their impacts have been studied. The lifecycle review of an electric vehicle, performed in this paper, suggests that there are many businesses that will need to be accelerated in order to influence the growth of EV penetration, while there are others whose growth will trail the growth of EV penetration. Based on the review of the literature as well as the industry, the following conclusions can be made:

- The lifecycle of an EV can be separated into three parts: (1) upstream of production, which includes fuel production and electricity generation, (2) production and use phases, which include raw material mining, manufacturing, and maintenance throughout the usable life of an EV, and (3) the final downstream process, which focuses on recycling and waste management. Increasing EV adoption will result in more business opportunities across all three stages.

- Some of the businesses that need to lead the growth of EVs include sustainable mining, efficient manufacturing, charger design and installation, and clean energy generation for EV charging.

- Businesses that will follow EV growth include vehicle-to-grid and vehicle-to-home integration, fleet optimization, and battery recycling.

- Raw material mining for battery manufacturing and the manufacturing process itself are the two most resource- and energy-intensive processes that are unique to electric vehicles when compared to ICE vehicles. More research needs to be done to make the mining and manufacturing processes more sustainable and more efficient. Another way to procure raw materials in a clean and efficient way is through recycling. Hence, improving the recycling process to increase yield and reduce energy consumption is important for increasing EV adoption.

- Mining, in particular, has a high social footprint that can lead to human rights violations and local disruptions. Research and development in a sustainable supply chain will ensure the continued and sustainable growth of EVs.

- Widespread improvements in charging infrastructure, which comprises standardized charger designs as well as a generation source providing the energy used for charging the batteries, will result in increased charger utilization, reduced range anxiety, a reduced environmental footprint, and the improvement of the perception of EVs among consumers.

- Optimized use for batteries through grid integration and fleet management will increase product life, reduce the lifetime environmental impact of EV batteries, and support the electrical grid in peak management as well as disaster recovery.

- As most of these businesses do not exist for ICE vehicles and will be unique for EV deployments only, they will cause some major sociotechnological impacts.

- Governments and policy-makers should proactively assess the potential challenges associated with this transition and implement appropriate countermeasures. Investment in social awareness, training programs, and educational curriculums to focus on the changing transportation electrification can be beneficial for governments as well as society.

Author Contributions

Conceptualization, R.V. and P.S.; lifecycle analysis, P.S.; business model research and review, R.V., P.S. and A.P.; visualization, P.S. and A.P.; supervision, R.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| EV | Electric Vehicle |

| ICE | Internal Combustion Engine |

| SUV | Sport Utility Vehicle |

| GHG | Green House Gas |

| DRC | Democratic Republic of Congo |

| kWh | Kilowatt-hour |

| MWh | Megawatt-hour |

| GWh | Gigawatt-hour |

| TWh | Terawatt-hour |

| NMC | Nickel Manganese Cobalt Oxide |

| NCA | Nickel Cobalt Aluminium Oxide |

| V2G | Vehicle to Grid |

| V2H | Vehicle to Home |

| BMS | Battery Management System |

| SOC | State of Charge |

References

- Wilson, K.A. Worth the Watt: A Brief History of the Electric Car, 1830 to Present. Car Driv. 2014. Available online: https://www.caranddriver.com/features/g15378765/worth-the-watt-a-brief-history-of-the-electric-car-1830-to-present (accessed on 22 December 2020).

- Electric Vehicle Trends|Deloitte Insights. Available online: https://www2.deloitte.com/us/en/insights/focus/future-of-mobility/electric-vehicle-trends-2030.html (accessed on 22 December 2020).

- Woodward, M. New Market. New Entrants. New Challenges. Battery Electric Vehicles. 2018. Available online: https://www2.deloitte.com/content/dam/Deloitte/uk/Documents/manufacturing/deloitte-uk-battery-electric-vehicles.pdf (accessed on 15 December 2020).

- World’s 10 Biggest Automakers & Their EV Plans. Available online: https://cleantechnica.com/2018/10/29/worlds-10-biggest-automakers-their-ev-plans/ (accessed on 22 December 2020).

- Biresselioglu, M.E.; Demirbag Kaplan, M.; Yilmaz, B.K. Electric mobility in Europe: A comprehensive review of motivators and barriers in decision making processes. Transp. Res. Part A Policy Pract. 2018, 109, 1–13. [Google Scholar] [CrossRef]

- Sierzchula, W.; Bakker, S.; Maat, K.; van Wee, B. The influence of financial incentives and other socio-economic factors on electric vehicle adoption. Energy Policy 2014, 68, 183–194. [Google Scholar] [CrossRef]

- Liao, F.; Molin, E.; Timmermans, H.; van Wee, B. Consumer preferences for business models in electric vehicle adoption. Transp. Policy 2019, 73, 12–24. [Google Scholar] [CrossRef]

- Hannan, M.A.; Azidin, F.A.; Mohamed, A. Hybrid electric vehicles and their challenges: A review. Renew. Sustain. Energy Rev. 2014, 29, 135–150. [Google Scholar] [CrossRef]

- Du, J.; Ouyang, D. Progress of Chinese electric vehicles industrialization in 2015: A review. Appl. Energy 2017, 188, 529–546. [Google Scholar] [CrossRef]

- De Santis, M.; Agnelli, S.; Patanè, F.; Giannini, O.; Bella, G. Experimental Study for the Assessment of the Measurement Uncertainty Associated with Electric Powertrain Efficiency Using the Back-to-Back Direct Method. Energies 2018, 11, 3536. [Google Scholar] [CrossRef]

- Li, Z.; Khajepour, A.; Song, J. A comprehensive review of the key technologies for pure electric vehicles. Energy 2019, 182, 824–839. [Google Scholar] [CrossRef]

- Javid, R.J.; Salari, M.; Jahanbakhsh Javid, R. Environmental and economic impacts of expanding electric vehicle public charging infrastructure in California′s counties. Transp. Res. Part D Transp. Environ. 2019, 77, 320–334. [Google Scholar] [CrossRef]

- Rupp, M.; Handschuh, N.; Rieke, C.; Kuperjans, I. Contribution of country-specific electricity mix and charging time to environmental impact of battery electric vehicles: A case study of electric buses in Germany. Appl. Energy 2019, 237, 618–634. [Google Scholar] [CrossRef]

- Ahmadi, P. Environmental impacts and behavioral drivers of deep decarbonization for transportation through electric vehicles. J. Clean. Prod. 2019, 225, 1209–1219. [Google Scholar] [CrossRef]

- Yang, L.; Yu, B.; Yang, B.; Chen, H.; Malima, G.; Wei, Y.-M. Life cycle environmental assessment of electric and internal combustion engine vehicles in China. J. Clean. Prod. 2020, 124899. [Google Scholar] [CrossRef]

- Benzidia, S.; Luca, R.M.; Boiko, S. Disruptive innovation, business models, and encroachment strategies: Buyer’s perspective on electric and hybrid vehicle technology. Technol. Forecast. Soc. Chang. 2021, 165, 120520. [Google Scholar] [CrossRef]

- Jones, A.; Begley, J.; Berkeley, N.; Jarvis, D.; Bos, E. Electric vehicles and rural business: Findings from the Warwickshire rural electric vehicle trial. J. Rural Stud. 2020, 79, 395–408. [Google Scholar] [CrossRef]

- Liao, F.; Molin, E.; Timmermans, H.; van Wee, B. The impact of business models on electric vehicle adoption: A latent transition analysis approach. Transp. Res. Part A Policy Pract. 2018, 116, 531–546. [Google Scholar] [CrossRef]

- Asadi, S.; Nilashi, M.; Samad, S.; Abdullah, R.; Mahmoud, M.; Alkinani, M.H.; Yadegaridehkordi, E. Factors impacting consumers’ intention toward adoption of electric vehicles in Malaysia. J. Clean. Prod. 2021, 282, 124474. [Google Scholar] [CrossRef]

- Kah, M. Electric Vehicle Penetration and Its Impact on Global Oil Demand: A Survey of 2019 Forecast Trends; Columbia SIPA: New York, NY, USA, 2019; p. 29. [Google Scholar]

- McKinsey Electric Vehicle Index: Europe Cushions a Global Plunge in EV Sales|McKinsey. Available online: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/mckinsey-electric-vehicle-index-europe-cushions-a-global-plunge-in-ev-sales (accessed on 16 November 2020).

- Gorner, M.; Teter, J. Electric Vehicles—Analysis and Key Findings. A Report by the International Energy Agency; International Energy Agency: Paris, France, 2020; Available online: https://www.iea.org/reports/electric-vehicles (accessed on 29 November 2020).

- Cui, H. Update on the Global Transition to Electric Vehicles through 2019; International Council on Clean Transportation: Beijing, China, 2020; p. 15. [Google Scholar]

- Investing in the Middle Class. Budget 2019; Department of Finance Canada: Ottawa, ON, Canada, 2019; Available online: https://www.budget.gc.ca/2019/docs/plan/budget-2019-en.pdf (accessed on 3 December 2020).

- New Energy Vehicle Industry Development Plan (2021–2035), Proposal for Public Comments; Chinese Ministry of Industry and Information Technology: Beijing, China, 2019. Available online: http://www.miit.gov.cn/n1146285/n1146352/n3054355/n3057585/n3057589/c7552776/content.html (accessed on 27 November 2020).

- Law Number 2019-1428 of 24 December 2019 on Mobility Orientation 2019; Government of France: Paris, France, 2019. Available online: https://www.legifrance.gouv.fr/affichTexte.do?categorieLien=id&cidTexte=JORFTEXT000039666574&dateTexte= (accessed on 27 November 2020).

- International ZEV Alliance. International ZEV Alliance Announcement 2015. Available online: http://www.zevalliance.org/international-zev-alliance-announcement/ (accessed on 3 December 2020).

- India’s Electric Mobility Transformation 2019; NITI Aayog-Rocky Mountain Institute: New Delhi, India, 2019; Available online: https://rmi.org/insight/indias-electric-mobility-transformation/ (accessed on 27 November 2020).

- Japan Promotes Electrified Vehicle (xEV) Strategy ahead of 2050; Ministry of Economy, Trade and Industry: Tokyo, Japan, 2018; Available online: https://www.meti.go.jp/english/mobile/2018/20180911001en.html (accessed on 27 November 2020).

- Dutch Government, Klimaatakkoord [Climate Agreement]; Dutch Government: The Hague, The Netherlands, 2019. Available online: https://www.klimaatakkoord.nl/documenten/publicaties/2019/06/28/klimaatakkoord (accessed on 3 December 2020).

- Mendes, F.A. Governo Aumenta Apoios à Compra de Carros Eléctricos [Government Increases Support for the Purchase of Electric Cars]. Available online: https://www.publico.pt/2018/11/17/sociedade/noticia/governo-quer-veiculos-electricos-circular-portugal-1851418 (accessed on 10 January 2021).

- Aravindan, A.; Geddie, J. Singapore aims to phase out petrol and diesel vehicles by 2040. Reuters. 2020. Available online: https://www.reuters.com/article/us-singapore-economy-budget-autos/singapore-aims-to-phase-out-petrol-and-diesel-vehicles-by-2040-idUSKBN20C15D (accessed on 26 December 2020).

- Chung-un, C. Korea Aims to Become World’s No.1 Green Car Provider, First to Commercialize Autonomous Driving. Available online: http://www.koreaherald.com/view.php?ud=20191015000824 (accessed on 10 January 2021).

- Proposición de Ley Sobre Cambio Climático y Transición Energética [Proposed Law on Climate Change and Energy Transition]; Congress of Deputies of Spain: Madrid, Spain, 2019; Available online: http://www.congreso.es/public_oficiales/L13/CONG/BOCG/B/BOCG-13-B-48-1.PDF (accessed on 3 December 2020).

- Klimatpolitiska Handlingsplanen—Fakta-PM [Climate Policy Action Plan-Facts PM]; Government Offices of Sweden: Stockholm, Sweden, 2019. Available online: https://www.regeringen.se/4af76e/contentassets/fe520eab3a954eb39084aced9490b14c/klimatpolitiska-handlingsplanen-fakta-pm.pdf (accessed on 3 December 2020).

- Consulting on Ending the Sale of New Petrol, Diesel and Hybrid Cars and Vans. Available online: https://www.gov.uk/government/consultations/consulting-on-ending-the-sale-of-new-petrol-diesel-and-hybrid-cars-and-vans (accessed on 10 January 2021).

- Singh, V.P.; Chawla, K.; Jain, S. Financing India’s Transition to Electric Vehicles; Cent. Energy Financ: New Delhi, India, 2020; p. 69. [Google Scholar]

- Ortego, A.; Calvo, G.; Valero, A.; Iglesias-Émbil, M.; Valero, A.; Villacampa, M. Assessment of strategic raw materials in the automobile sector. Resour. Conserv. Recycl. 2020, 161, 104968. [Google Scholar] [CrossRef]

- Graedel, T.E.; Harper, E.M.; Nassar, N.T.; Nuss, P.; Reck, B.K. Criticality of metals and metalloids. Proc. Natl. Acad. Sci. USA 2015, 112, 4257–4262. [Google Scholar] [CrossRef]

- Shi, S.; Zhang, H.; Yang, W.; Zhang, Q.; Wang, X. A life-cycle assessment of battery electric and internal combustion engine vehicles: A case in Hebei Province, China. J. Clean. Prod. 2019, 228, 606–618. [Google Scholar] [CrossRef]

- Ellingsen, L.A.-W.; Singh, B.; Strømman, A.H. The size and range effect: Lifecycle greenhouse gas emissions of electric vehicles. Environ. Res. Lett. 2016, 11, 054010. [Google Scholar] [CrossRef]

- Notter, D.A.; Gauch, M.; Widmer, R.; Wäger, P.; Stamp, A.; Zah, R.; Althaus, H.-J. Contribution of Li-Ion Batteries to the Environmental Impact of Electric Vehicles. Environ. Sci. Technol. 2010, 44, 6550–6556. [Google Scholar] [CrossRef]

- Zackrissona, M.; Avellána, L.; Orlenius, J. Life cycle assessment of lithium-ion batteries for plug-in hybrid electric vehicles—Critical issues. J. Clean. Prod. 2010, 18, 1519–1529. [Google Scholar] [CrossRef]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2013, 17, 53–64. [Google Scholar] [CrossRef]

- Ayetor, G.K.; Quansah, D.A.; Adjei, E.A. Towards zero vehicle emissions in Africa: A case study of Ghana. Energy Policy 2020, 143, 111606. [Google Scholar] [CrossRef]

- Ai, N.; Zheng, J.; Chen, W.-Q. U.S. end-of-life electric vehicle batteries: Dynamic inventory modeling and spatial analysis for regional solutions. Resour. Conserv. Recycl. 2019, 145, 208–219. [Google Scholar] [CrossRef]

- Chung, C.-H.; Jangra, S.; Lai, Q.; Lin, X. Optimization of Electric Vehicle Charging for Battery Maintenance and Degradation Management. IEEE Trans. Transp. Electrif. 2020, 6, 958–969. [Google Scholar] [CrossRef]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Marmiroli, B.; Venditti, M.; Dotelli, G.; Spessa, E. The transport of goods in the urban environment: A comparative life cycle assessment of electric, compressed natural gas and diesel light-duty vehicles. Appl. Energy 2020, 260, 114236. [Google Scholar] [CrossRef]

- Qiao, Q.; Zhao, F.; Liu, Z.; He, X.; Hao, H. Life cycle greenhouse gas emissions of Electric Vehicles in China: Combining the vehicle cycle and fuel cycle. Energy 2019, 177, 222–233. [Google Scholar] [CrossRef]

- Marmiroli, B.; Messagie, M.; Dotelli, G.; Van Mierlo, J. Electricity Generation in LCA of Electric Vehicles: A Review. Appl. Sci. 2018, 8, 1384. [Google Scholar] [CrossRef]

- Kawamoto, R.; Mochizuki, H.; Moriguchi, Y.; Nakano, T.; Motohashi, M.; Sakai, Y.; Inaba, A. Estimation of CO2 Emissions of Internal Combustion Engine Vehicle and Battery Electric Vehicle Using LCA. Sustainability 2019, 11, 2690. [Google Scholar] [CrossRef]

- Hao, H.; Qiao, Q.; Liu, Z.; Zhao, F. Impact of recycling on energy consumption and greenhouse gas emissions from electric vehicle production: The China 2025 case. Resour. Conserv. Recycl. 2017, 122, 114–125. [Google Scholar] [CrossRef]

- Qiao, Q.; Zhao, F.; Liu, Z.; Jiang, S.; Hao, H. Cradle-to-gate greenhouse gas emissions of battery electric and internal combustion engine vehicles in China. Appl. Energy 2017, 204, 1399–1411. [Google Scholar] [CrossRef]

- Qiao, D.; Wang, G.; Gao, T.; Wen, B.; Dai, T. Potential impact of the end-of-life batteries recycling of electric vehicles on lithium demand in China: 2010–2050. Sci. Total Environ. 2020, 142835. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.; Rhee, S.-W. Current status and perspectives on recycling of end-of-life battery of electric vehicle in Korea (Republic of). Waste Manag. 2020, 106, 261–270. [Google Scholar] [CrossRef]

- Chen, M.; Ma, X.; Chen, B.; Arsenault, R.; Karlson, P.; Simon, N.; Wang, Y. Recycling End-of-Life Electric Vehicle Lithium-Ion Batteries. Joule 2019, 3, 2622–2646. [Google Scholar] [CrossRef]

- Saxena, S.; Le Floch, C.; MacDonald, J.; Moura, S. Quantifying EV battery end-of-life through analysis of travel needs with vehicle powertrain models. J. Power Sources 2015, 282, 265–276. [Google Scholar] [CrossRef]

- Bauer, C.; Hofer, J.; Althaus, H.-J.; Del Duce, A.; Simons, A. The environmental performance of current and future passenger vehicles: Life cycle assessment based on a novel scenario analysis framework. Appl. Energy 2015, 157, 871–883. [Google Scholar] [CrossRef]

- Ke, W.; Zhang, S.; He, X.; Wu, Y.; Hao, J. Well-to-wheels energy consumption and emissions of electric vehicles: Mid-term implications from real-world features and air pollution control progress. Appl. Energy 2017, 188, 367–377. [Google Scholar] [CrossRef]

- Grosjean, C.; Miranda, P.H.; Perrin, M.; Poggi, P. Assessment of world lithium resources and consequences of their geographic distribution on the expected development of the electric vehicle industry. Renew. Sustain. Energy Rev. 2012, 16, 1735–1744. [Google Scholar] [CrossRef]

- Babbitt, C.W. Sustainability perspectives on lithium-ion batteries. Clean Technol. Environ. Policy 2020, 22, 1213–1214. [Google Scholar] [CrossRef]

- Simon, B.; Ziemann, S.; Weil, M. Potential metal requirement of active materials in lithium-ion battery cells of electric vehicles and its impact on reserves: Focus on Europe. Resour. Conserv. Recycl. 2015, 104, 300–310. [Google Scholar] [CrossRef]

- Jacka, J.K. The Anthropology of Mining: The Social and Environmental Impacts of Resource Extraction in the Mineral Age. Annu. Rev. Anthropol. 2018, 47, 61–77. [Google Scholar] [CrossRef]

- Sanchez-Lopez, M.D. From a White Desert to the Largest World Deposit of Lithium: Symbolic Meanings and Materialities of the Uyuni Salt Flat in Bolivia. Antipode 2019, 51, 1318–1339. [Google Scholar] [CrossRef]

- Liu, W.; Agusdinata, D.B. Interdependencies of lithium mining and communities sustainability in Salar de Atacama, Chile. J. Clean. Prod. 2020, 260, 120838. [Google Scholar] [CrossRef]

- Månberger, A.; Stenqvist, B. Global metal flows in the renewable energy transition: Exploring the effects of substitutes, technological mix and development. Energy Policy 2018, 119, 226–241. [Google Scholar] [CrossRef]

- Yuan, C.; Deng, Y.; Li, T.; Yang, F. Manufacturing energy analysis of lithium ion battery pack for electric vehicles. CIRP Ann. Manuf. Technol. 2017, 66, 53–56. [Google Scholar] [CrossRef]

- Williamson, S.S.; Rathore, A.K.; Musavi, F. Industrial Electronics for Electric Transportation: Current State-of-the-Art and Future Challenges. IEEE Trans. Ind. Electron. 2015, 62, 3021–3032. [Google Scholar] [CrossRef]

- Lee, H.; Clark, A. Charging the Future: Challenges and Opportunities for Electric Vehicle Adoption. SSRN Electron. J. 2018. [Google Scholar] [CrossRef]

- Un-Noor, F.; Padmanaban, S.; Mihet-Popa, L.; Mollah, M.N.; Hossain, E. A Comprehensive Study of Key Electric Vehicle (EV) Components, Technologies, Challenges, Impacts, and Future Direction of Development. Energies 2017, 10, 1217. [Google Scholar] [CrossRef]

- Mouli, G.R.C.; Venugopal, P.; Bauer, P. Future of electric vehicle charging. In Proceedings of the 2017 International Symposium on Power Electronics (Ee), Novi Sad, Serbia, 19–21 October 2017; pp. 1–7. [Google Scholar]

- Vidhi, R.; Shrivastava, P. A Review of Electric Vehicle Lifecycle Emissions and Policy Recommendations to Increase EV Penetration in India. Energies 2018, 11, 483. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Recycling Waste Tires into Ground Tire Rubber (GTR)/Rubber Compounds: A Review. J. Compos. Sci. 2020, 4, 103. [Google Scholar] [CrossRef]

- Stubbe, R. Global Demand for Batteries Multiplies. Available online: Bloomberg.com (accessed on 21 December 2018).

- Superdome Power Outage Delays Super Bowl XLVII. Available online: https://www.nfl.com/news/superdome-power-outage-delays-super-bowl-xlvii-0ap1000000134895 (accessed on 22 December 2020).

- Record-Breaking Atlantic Hurricane Season Draws to an end|National Oceanic and Atmospheric Administration. Available online: https://www.noaa.gov/media-release/record-breaking-atlantic-hurricane-season-draws-to-end (accessed on 20 December 2020).

- Campbell, R. Hurricanes and Electricity Infrastructure Hardening. CRS Insight 2017, 2. Available online: https://fas.org/sgp/crs/misc/IN10781.pdf (accessed on 26 December 2020).

- Peters, G.; DiGioia, A.M., Jr.; Hendrickson, C.; Apt, J. Transmission Line Reliability: Climate Change and Extreme Weather. In Proceedings of the Electrical Transmission Line and Substation Structures, Birmingham, AL, UAS, 15–19 October 2006; pp. 12–26. [Google Scholar]

- Jensterle, M.; Venjakob, M. Smart power grids and integration of renewables in Japan. Berl. Adelphi 2019, 47, 35. [Google Scholar]

- Grundy, A. Europe’s Early Vehicle-to-Grid Projects Show ‘Huge Potential’ Goes Beyond Financial Benefits. Available online: https://www.energy-storage.news/news/europes-early-vehicle-to-grid-projects-demonstrate-huge-potential-beyond-fi (accessed on 21 December 2020).

- Sundström, O.; Binding, C. Optimization Methods to Plan the Charging of Electric Vehicle Fleets. Available online: https://www.zurich.ibm.com/pdf/csc/EDISON_ccpe_main.pdf (accessed on 21 December 2020).

- Usman, M.; Knapen, L.; Yasar, A.-U.-H.; Vanrompay, Y.; Bellemans, T.; Janssens, D.; Wets, G. A coordinated Framework for Optimized Charging of EV Fleet in Smart Grid. Procedia Comput. Sci. 2016, 94, 332–339. [Google Scholar] [CrossRef]

- Bland, R. Charging Electric-Vehicle Fleets Is a Huge Business Opportunity|McKinsey. Available online: https://www.mckinsey.com/business-functions/sustainability/our-insights/charging-electric-vehicle-fleets-how-to-seize-the-emerging-opportunity (accessed on 22 September 2020).

- DeForest, N.; MacDonald, J.S.; Black, D.R. Day ahead optimization of an electric vehicle fleet providing ancillary services in the Los Angeles Air Force Base vehicle-to-grid demonstration. Appl. Energy 2018, 210, 987–1001. [Google Scholar] [CrossRef]

- Škugor, B.; Deur, J. Dynamic programming-based optimisation of charging an electric vehicle fleet system represented by an aggregate battery model. Energy 2015, 92, 456–465. [Google Scholar] [CrossRef]

- Refurbished and Repower: Second Life of Batteries from Electric Vehicles for Stationary Application. Available online: https://www.sae.org/publications/technical-papers/content/2019-26-0156/ (accessed on 10 January 2021).

- Liu, K.; Liu, Y.; Lin, D.; Pei, A.; Cui, Y. Materials for lithium-ion battery safety. Sci. Adv. 2018, 4, eaas9820. [Google Scholar] [CrossRef]

- Lv, W.; Wang, Z.; Cao, H.; Sun, Y.; Zhang, Y.; Sun, Z. A Critical Review and Analysis on the Recycling of Spent Lithium-Ion Batteries. ACS Sustain. Chem. Eng. 2018, 6, 1504–1521. [Google Scholar] [CrossRef]

- Global EV Outlook 2020—Analysis; International Energy Agency: Paris, France, 2020; Available online: https://www.iea.org/reports/global-ev-outlook-2020 (accessed on 29 November 2020).

- Sommerville, R.; Zhu, P.; Rajaeifar, M.A.; Heidrich, O.; Goodship, V.; Kendrick, E. A qualitative assessment of lithium ion battery recycling processes. Resour. Conserv. Recycl. 2021, 165, 105219. [Google Scholar] [CrossRef]

- Baars, J.; Domenech, T.; Bleischwitz, R.; Melin, H.E.; Heidrich, O. Circular economy strategies for electric vehicle batteries reduce reliance on raw materials. Nat. Sustain. 2021, 4, 71–79. [Google Scholar] [CrossRef]

- Choubey, P.K.; Chung, K.-S.; Kim, M.; Lee, J.; Srivastava, R.R. Advance review on the exploitation of the prominent energy-storage element Lithium. Part II: From sea water and spent lithium ion batteries (LIBs). Miner. Eng. 2017, 110, 104–121. [Google Scholar] [CrossRef]

- Coffman, M.; Bernstein, P.; Wee, S. Electric vehicles revisited: A review of factors that affect adoption. Transp. Rev. 2017, 37, 79–93. [Google Scholar] [CrossRef]

- Li, X.; Chen, P.; Wang, X. Impacts of renewables and socioeconomic factors on electric vehicle demands—Panel data studies across 14 countries. Energy Policy 2017, 109, 473–478. [Google Scholar] [CrossRef]

- de Rubens, G.Z.; Noel, L.; Kester, J.; Sovacool, B.K. The market case for electric mobility: Investigating electric vehicle business models for mass adoption. Energy 2020, 194, 116841. [Google Scholar] [CrossRef]

- Li, J.; Jiao, J.; Tang, Y. Analysis of the impact of policies intervention on electric vehicles adoption considering information transmission—based on consumer network model. Energy Policy 2020, 144, 111560. [Google Scholar] [CrossRef]

- Qiu, Y.Q.; Zhou, P.; Sun, H.C. Assessing the effectiveness of city-level electric vehicle policies in China. Energy Policy 2019, 130, 22–31. [Google Scholar] [CrossRef]

- Taiebat, M.; Xu, M. Synergies of four emerging technologies for accelerated adoption of electric vehicles: Shared mobility, wireless charging, vehicle-to-grid, and vehicle automation. J. Clean. Prod. 2019, 230, 794–797. [Google Scholar] [CrossRef]

- Wang, L.; Morabito, M.; Payne, C.T.; Robinson, G. Identifying institutional barriers and policy implications for sustainable energy technology adoption among large organizations in California. Energy Policy 2020, 146, 111768. [Google Scholar] [CrossRef]

- Ikeda, D.; Morita, Y. The effects of barriers to technology adoption on japanese prewar and postwar economic growth. J. Jpn. Int. Econ. 2020, 55, 101061. [Google Scholar] [CrossRef]

- MacDonald, E.; Wicker, R. Multiprocess 3D printing for increasing component functionality. Science 2016, 353. [Google Scholar] [CrossRef]

- Thiel, C.; Julea, A.; Acosta Iborra, B.; De Miguel Echevarria, N.; Peduzzi, E.; Pisoni, E.; Gómez Vilchez, J.J.; Krause, J. Assessing the Impacts of Electric Vehicle Recharging Infrastructure Deployment Efforts in the European Union. Energies 2019, 12, 2409. [Google Scholar] [CrossRef]

- Bakker, S.; Leguijt, P.; van Lente, H. Niche accumulation and standardization—The case of electric vehicle recharging plugs. J. Clean. Prod. 2015, 94, 155–164. [Google Scholar] [CrossRef]

- Amiryar, M.E.; Pullen, K.R. Assessment of the Carbon and Cost Savings of a Combined Diesel Generator, Solar Photovoltaic, and Flywheel Energy Storage Islanded Grid System. Energies 2019, 12, 3356. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).