Research on the Tensile-Bending Dynamic Response of the Half-Through Arch Bridge Short Suspender Considering Vehicle-Bridge Coupling Vibration

Abstract

1. Introduction

2. Vehicle-Bridge Coupled Vibration Model

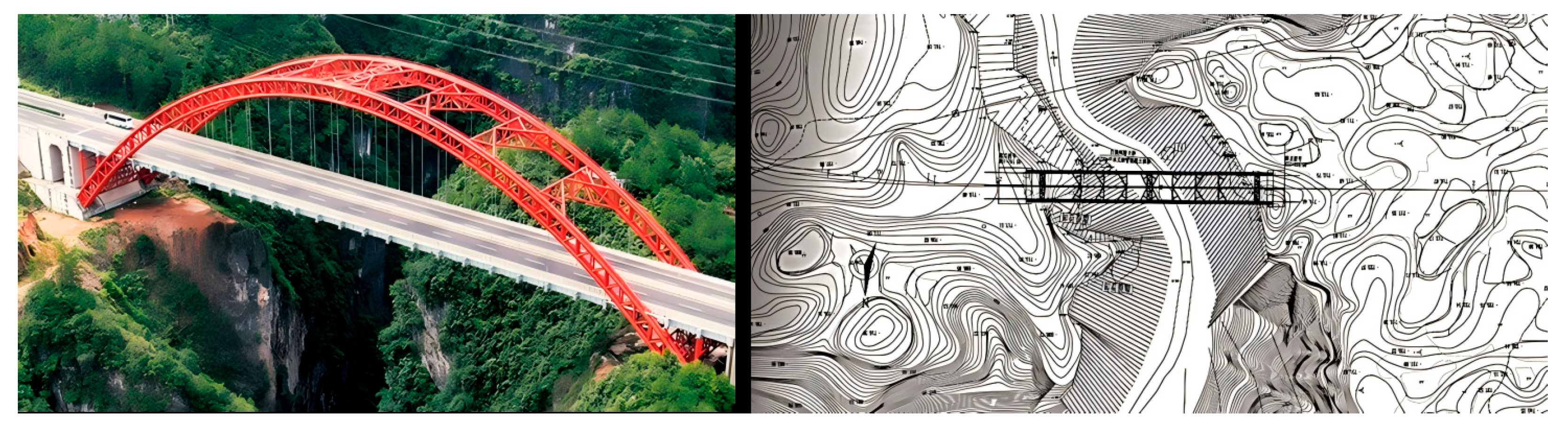

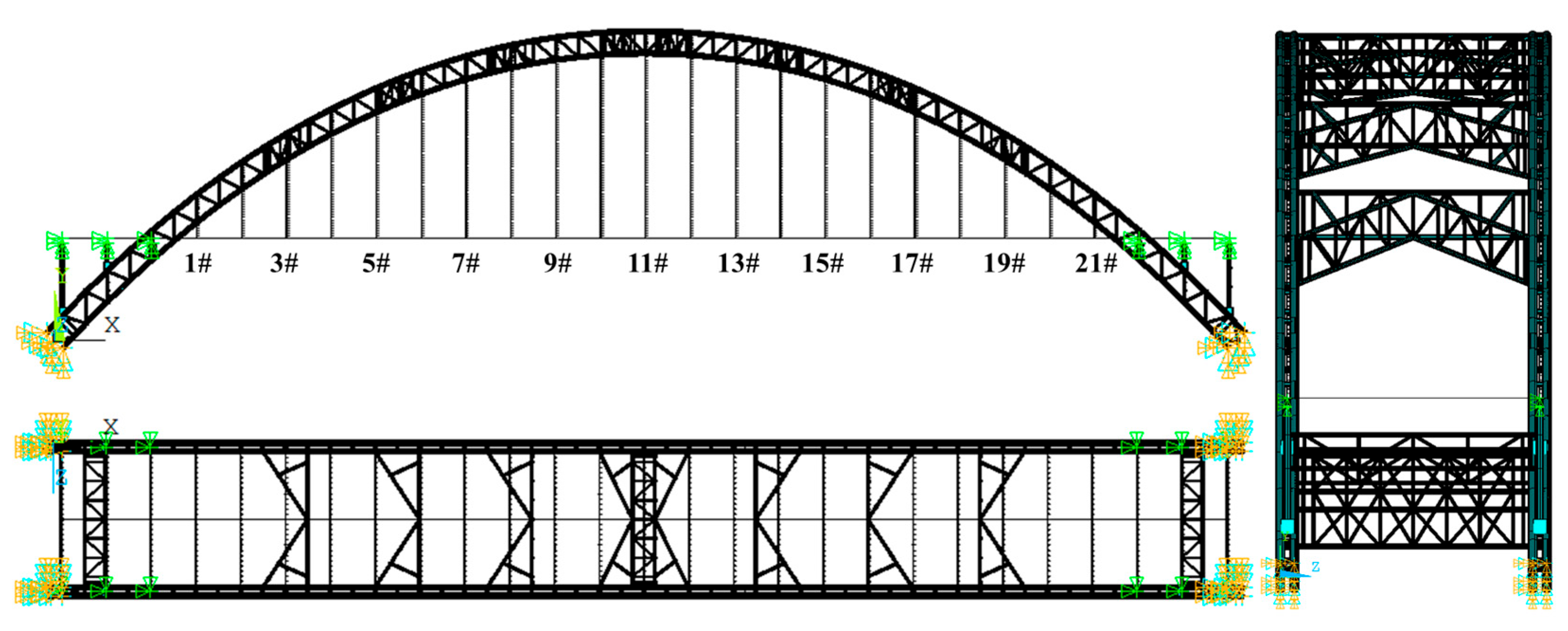

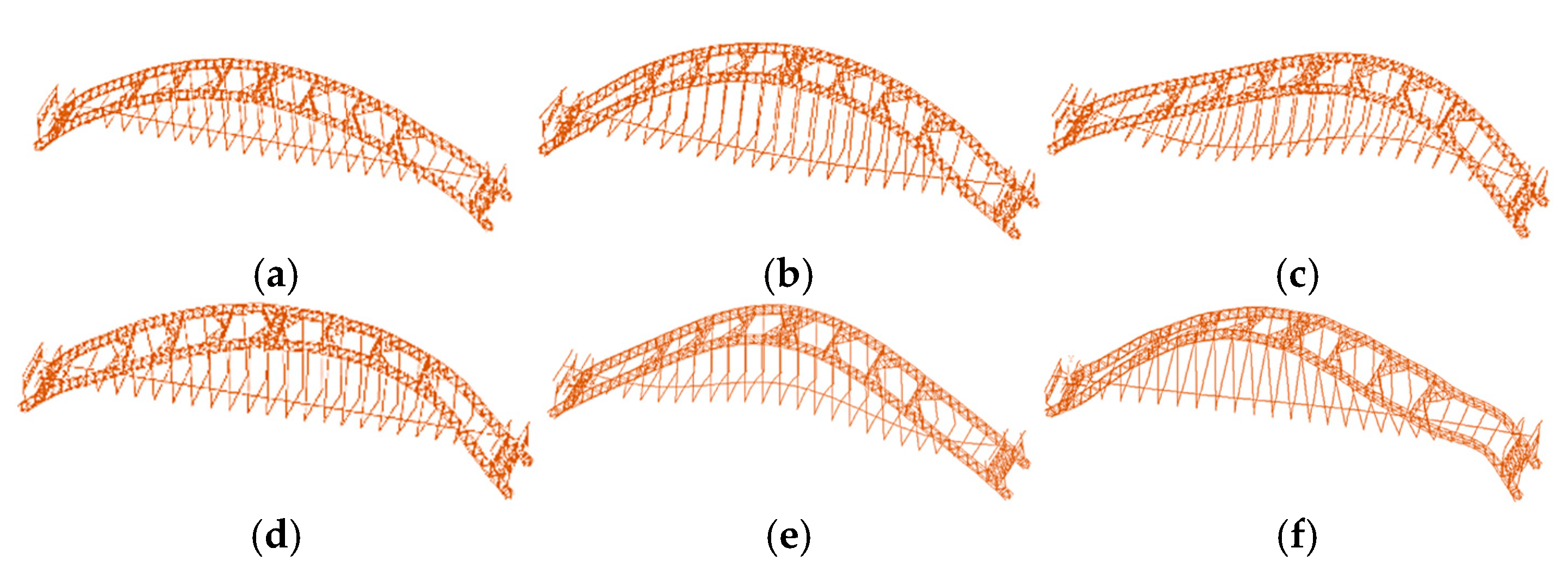

2.1. Half-Through Arch Bridge Model

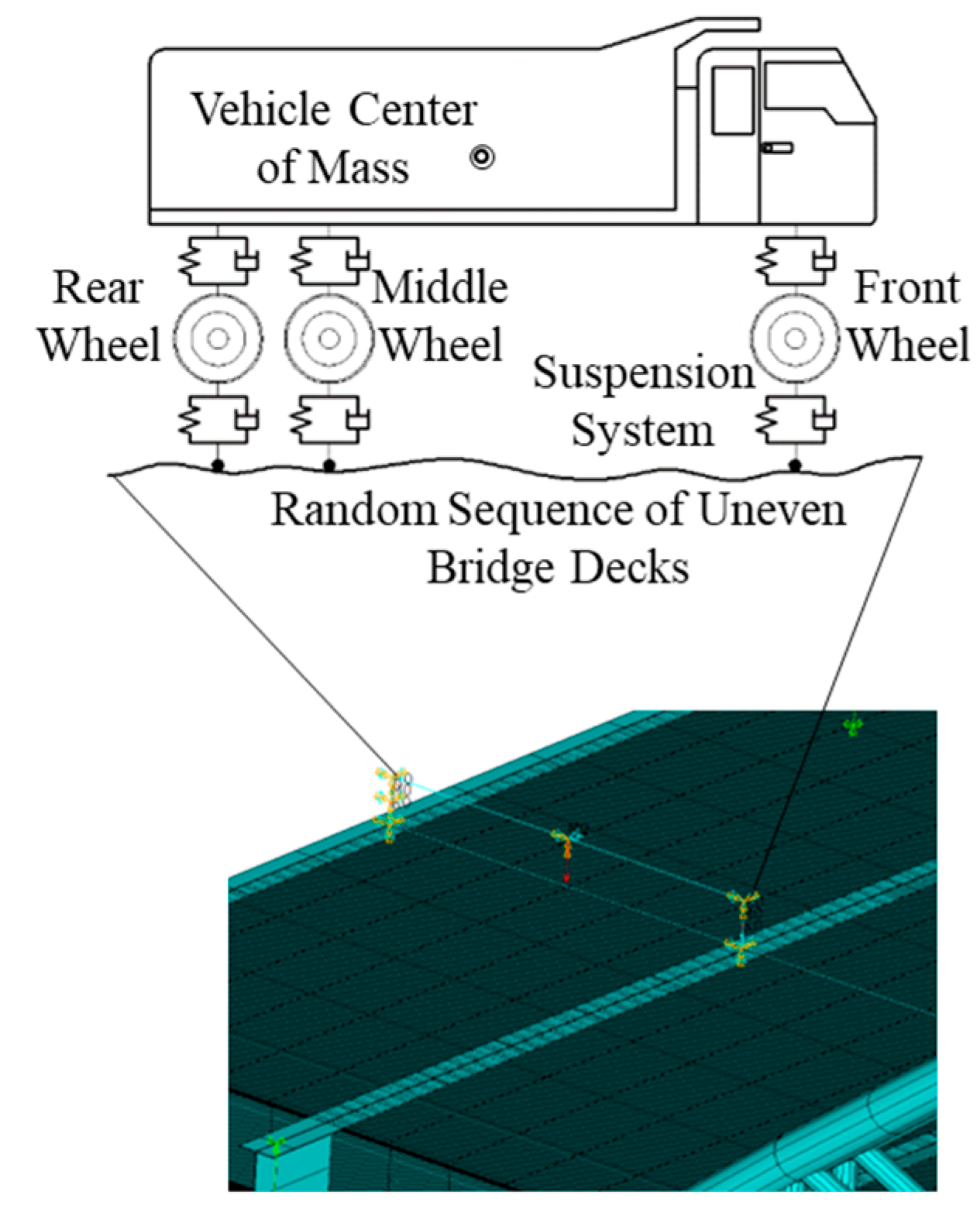

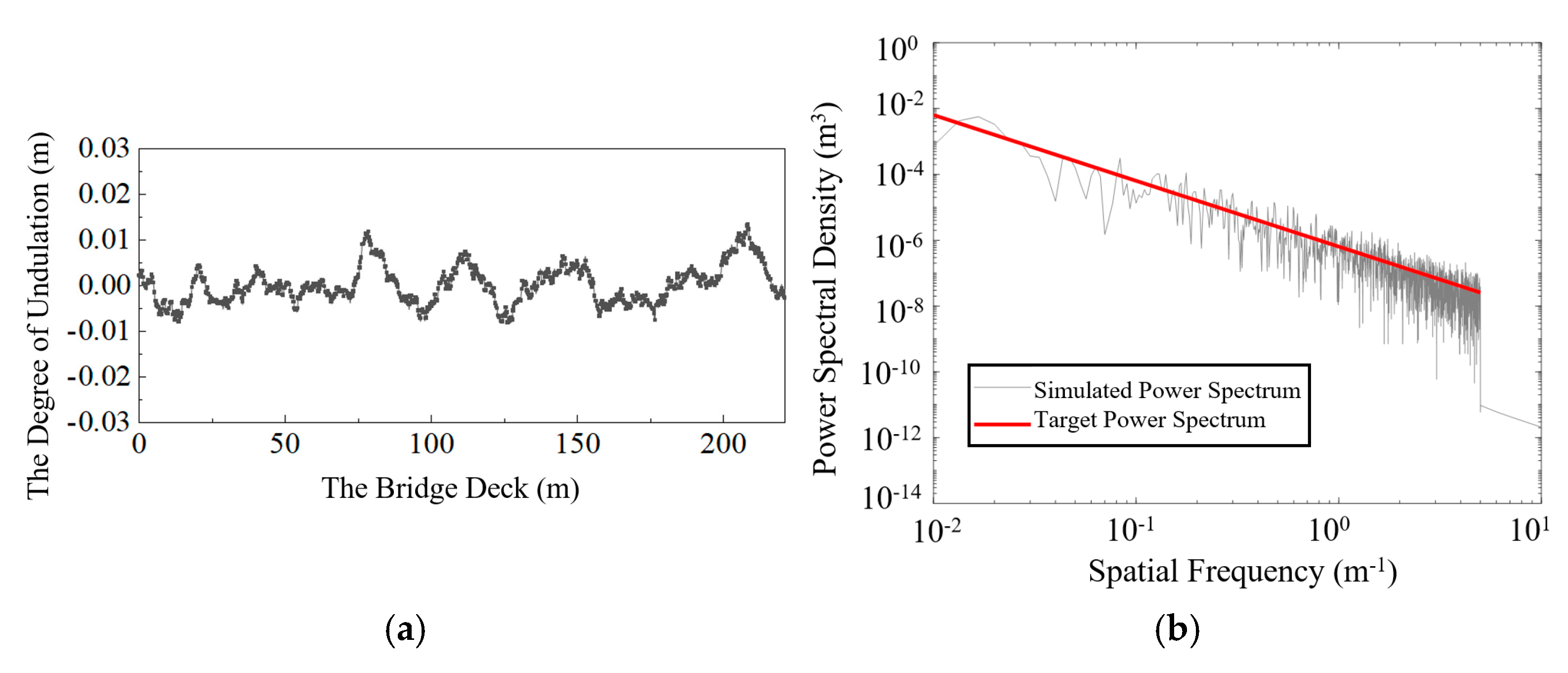

2.2. Vehicles and Deck Unevenness

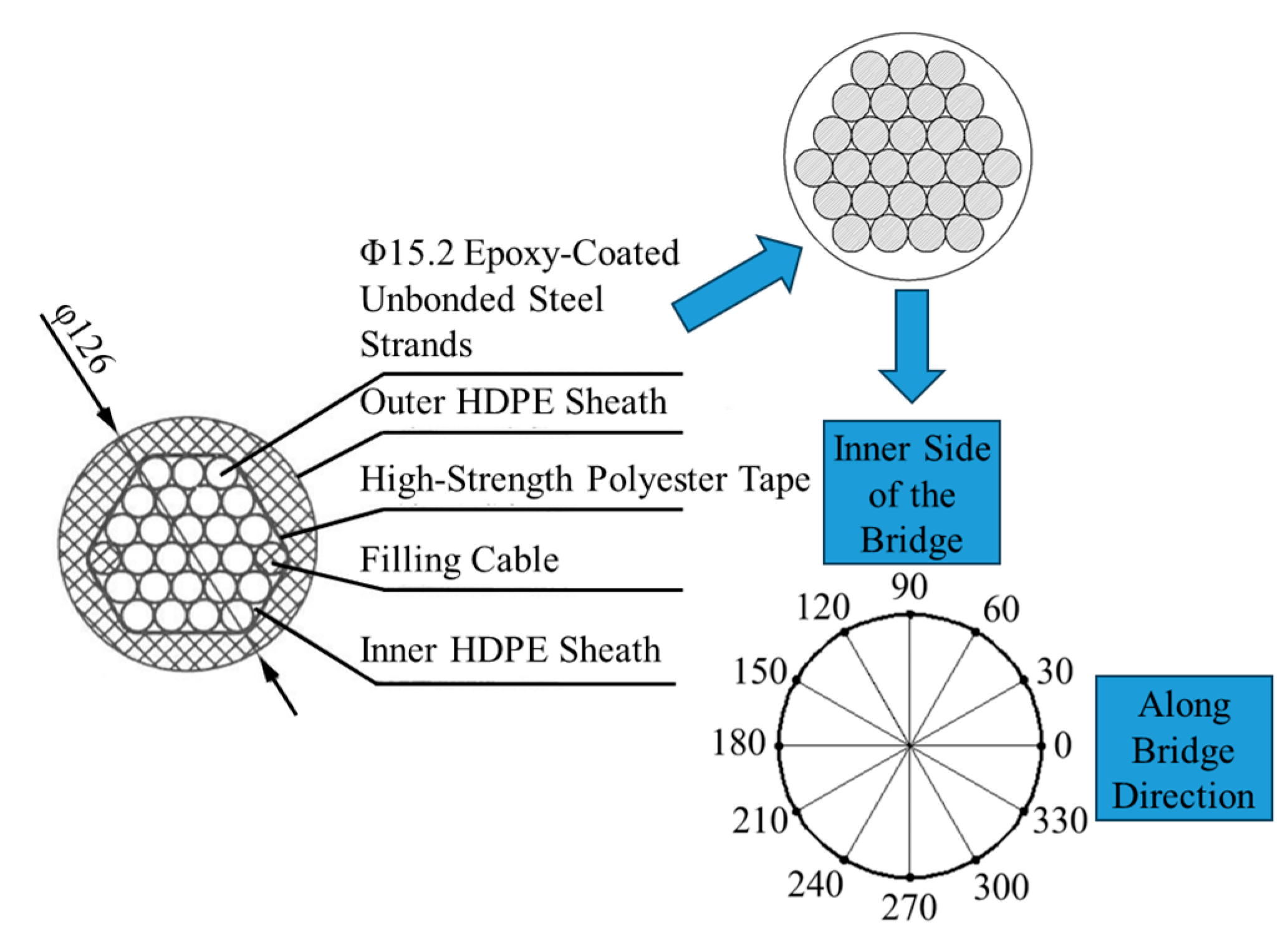

2.3. Equivalent Stress of the Suspenders

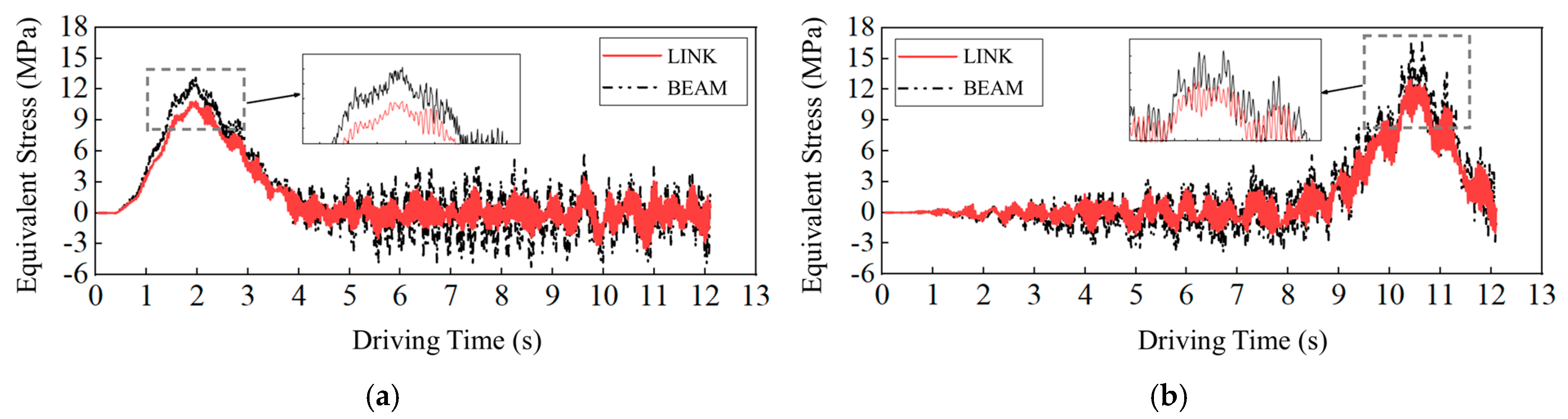

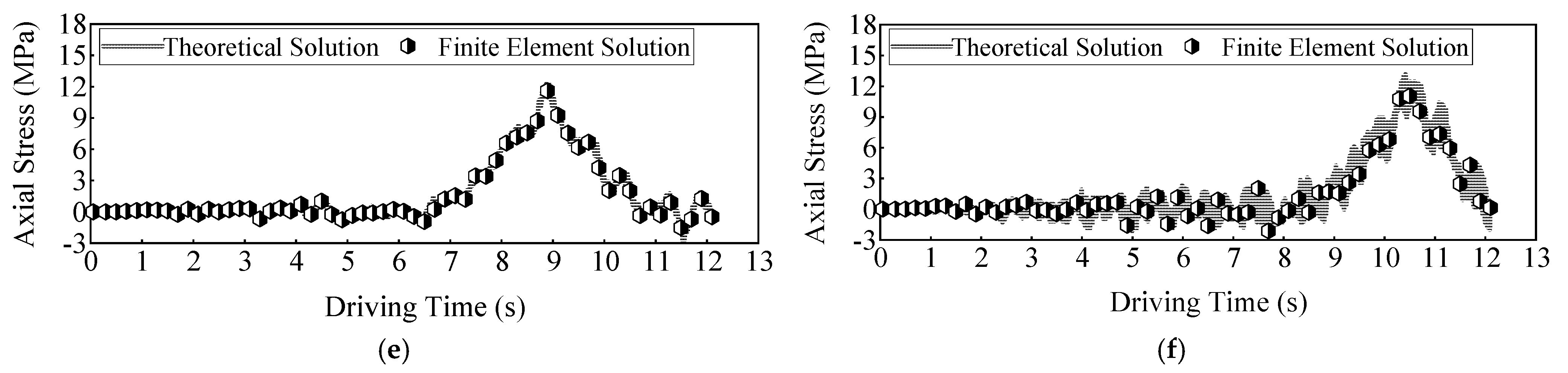

3. Dynamic Responses of Suspenders Under Different Simulation Methods

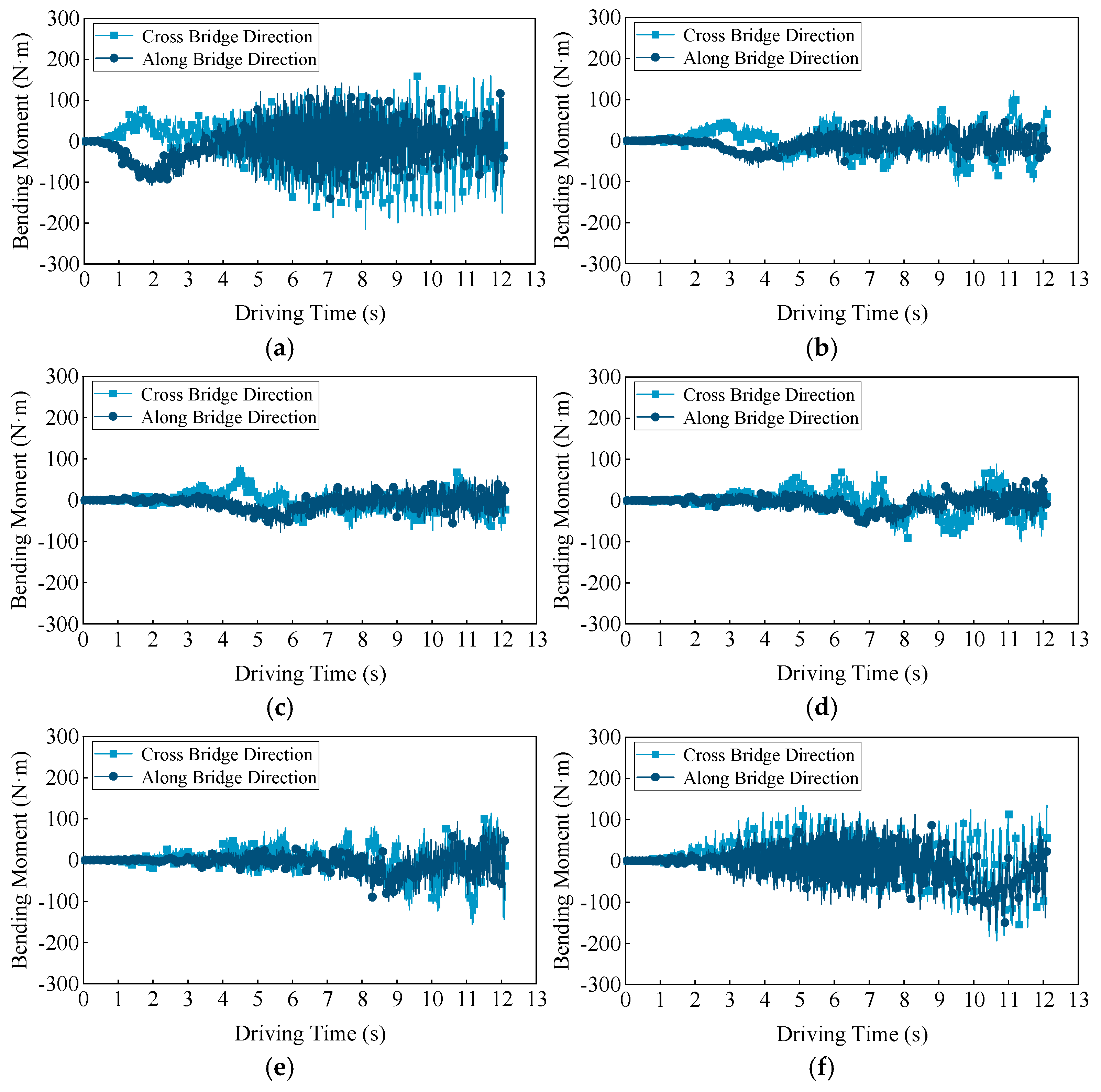

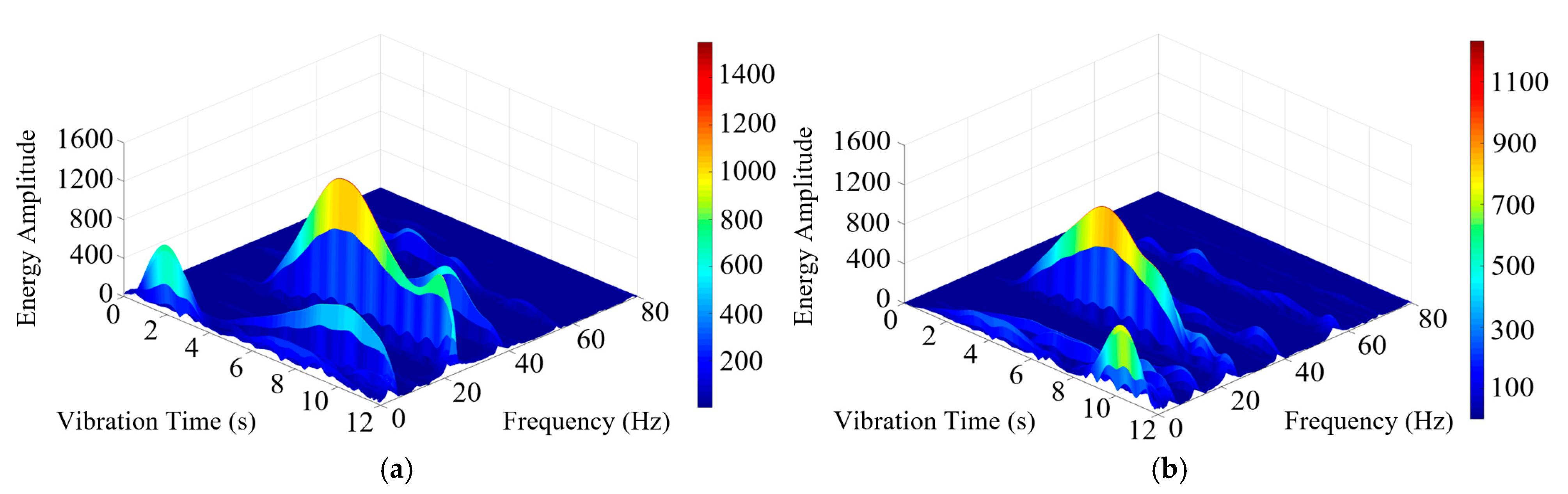

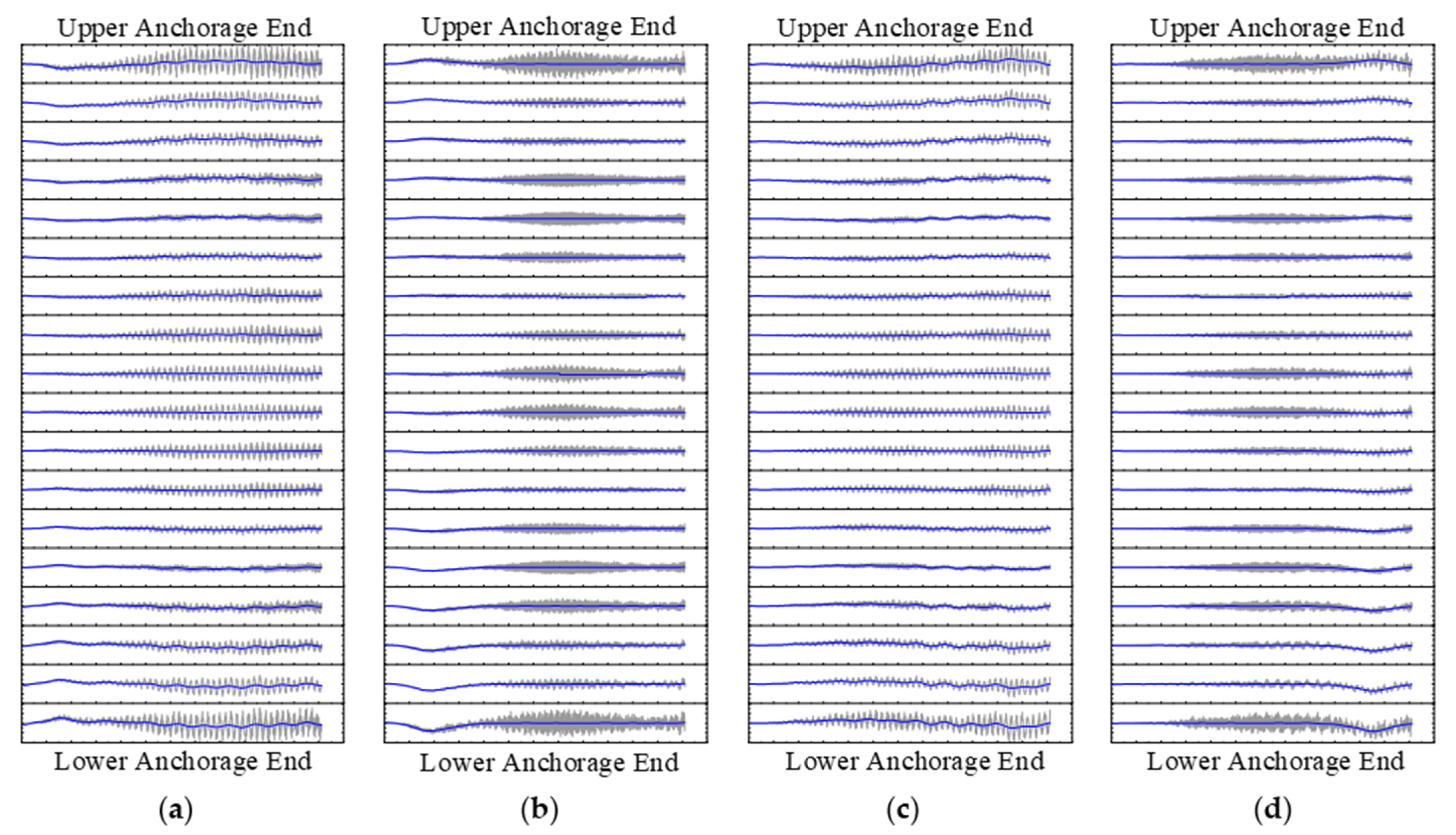

3.1. Vibration Time-History Characteristics of the Anchorage End

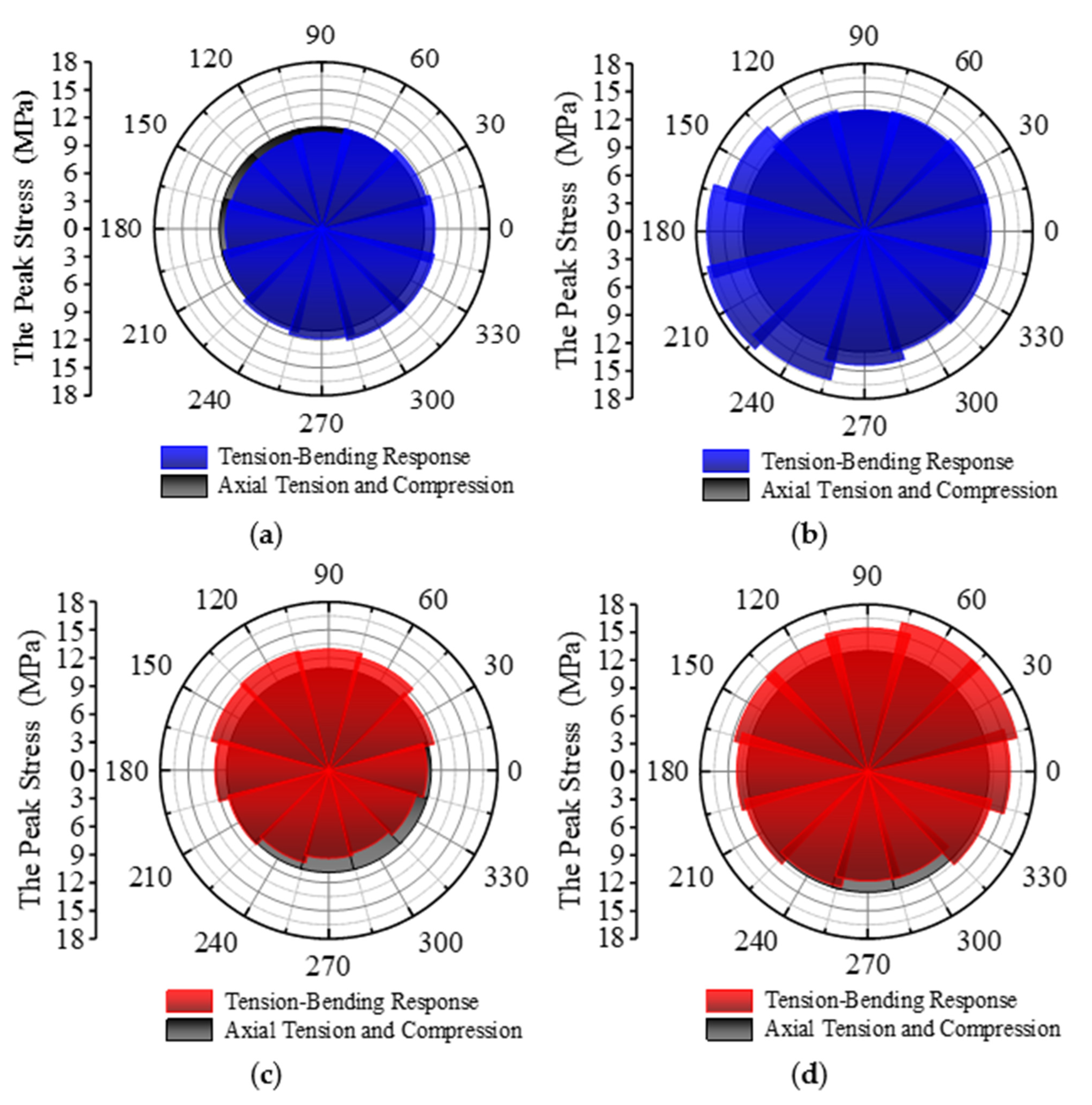

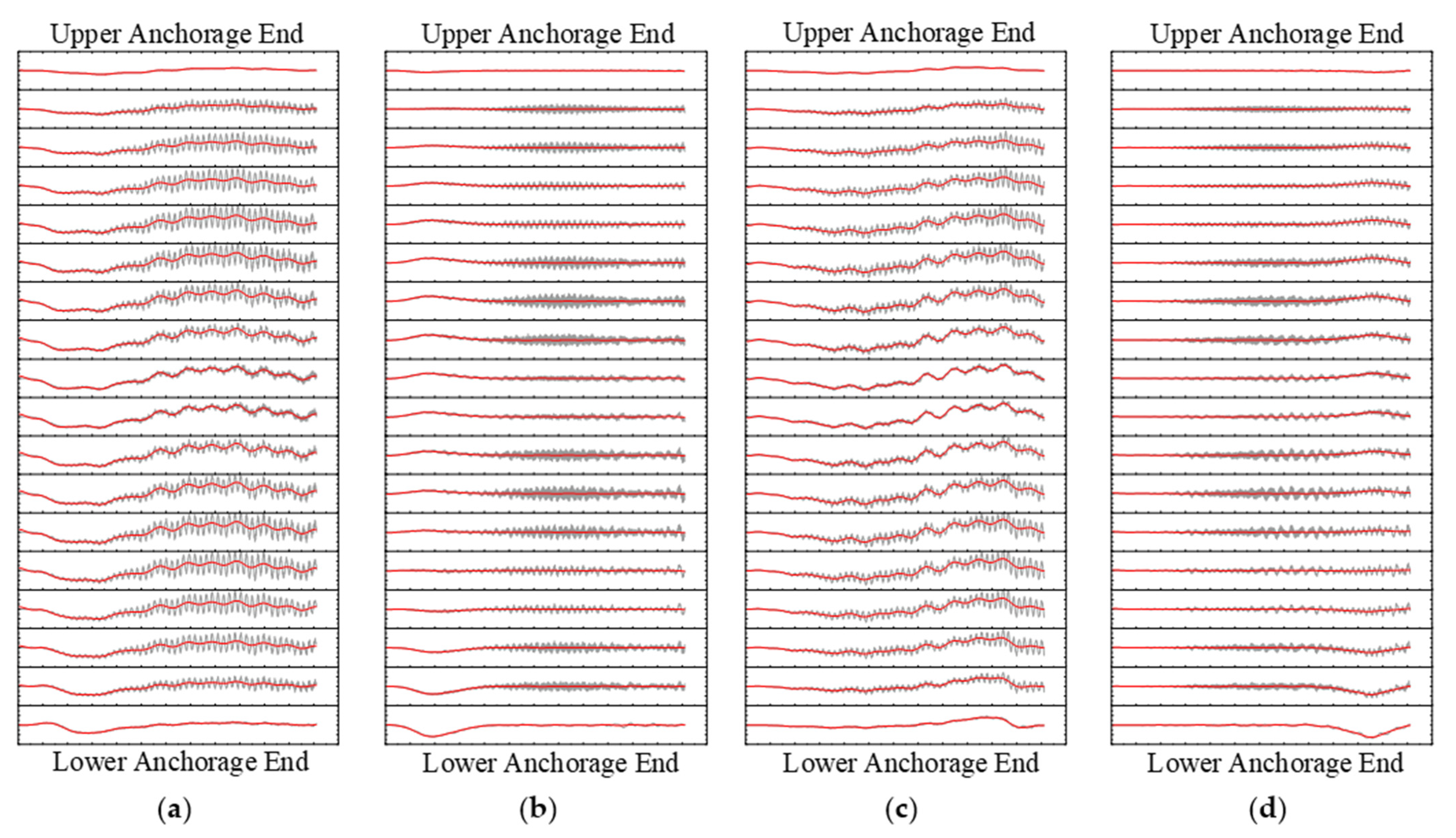

3.2. Cross-Sectional Stress Distribution of the Short Suspender

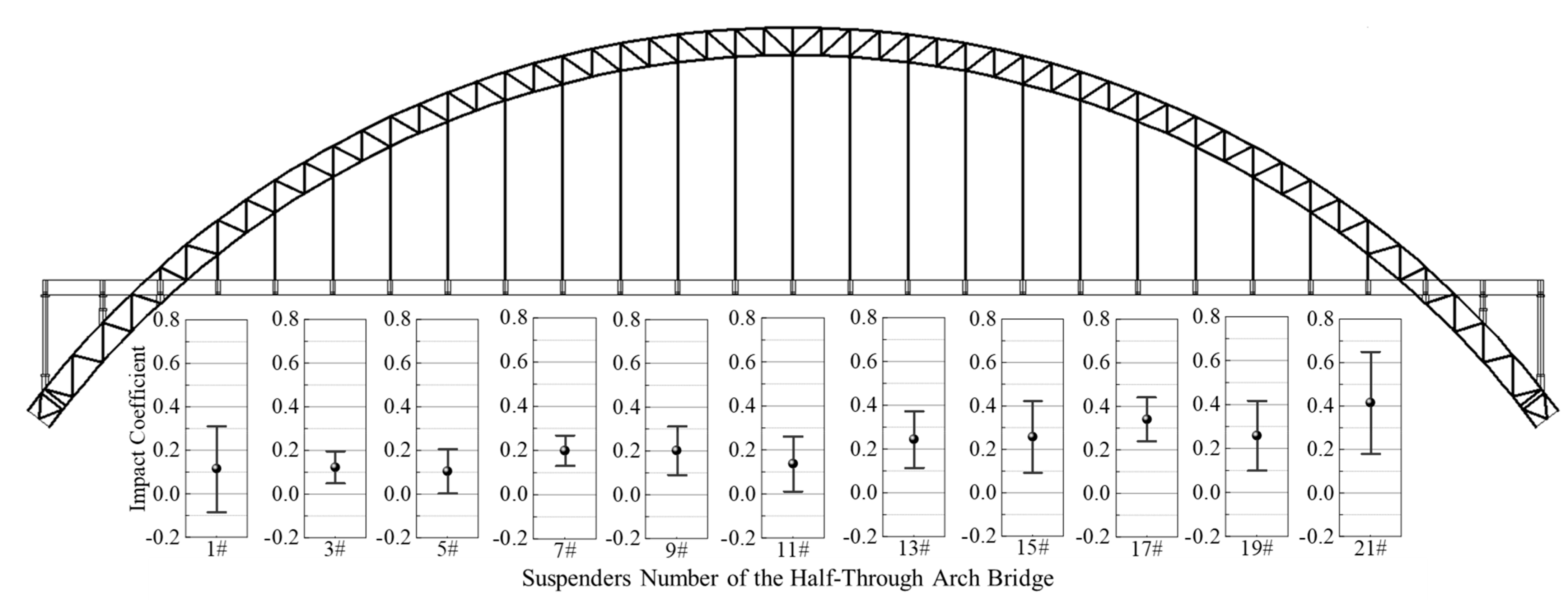

4. Vehicle-Induced Tension-Bending Impact Effects of the Short Suspender

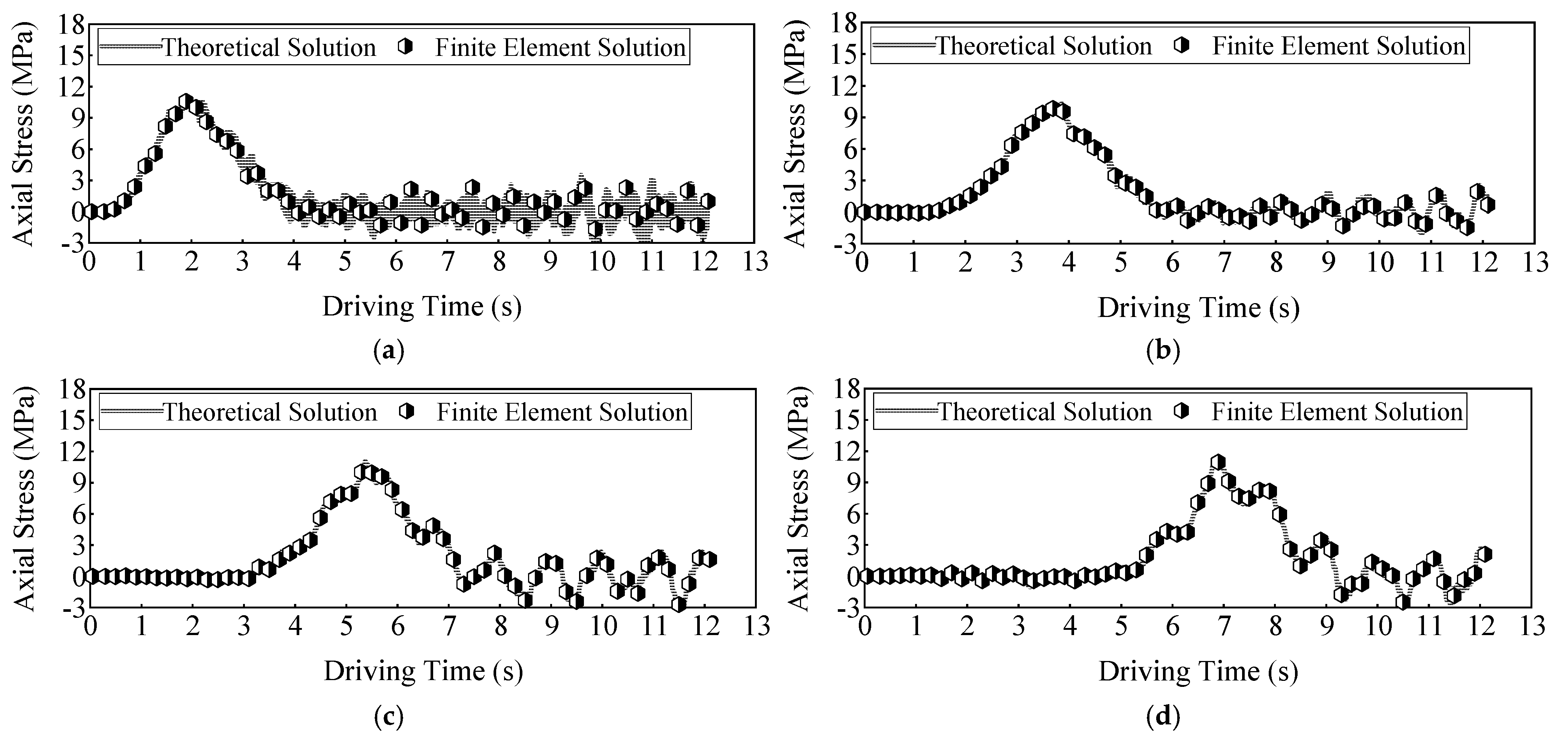

4.1. Axial Forces and Tensile Deformation at the Anchorage End

4.2. Bending Moment and Rotational Deformation of the Short Suspender

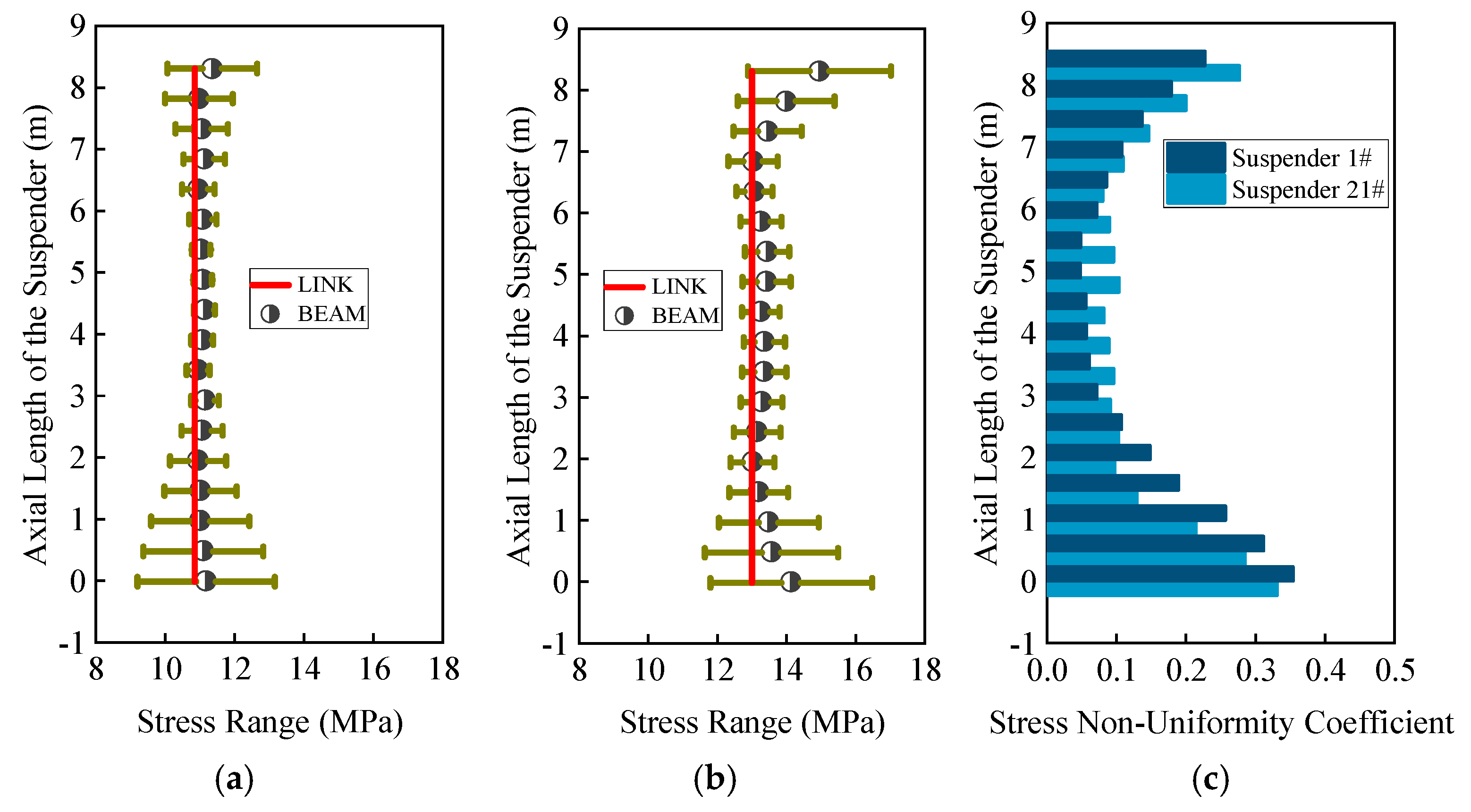

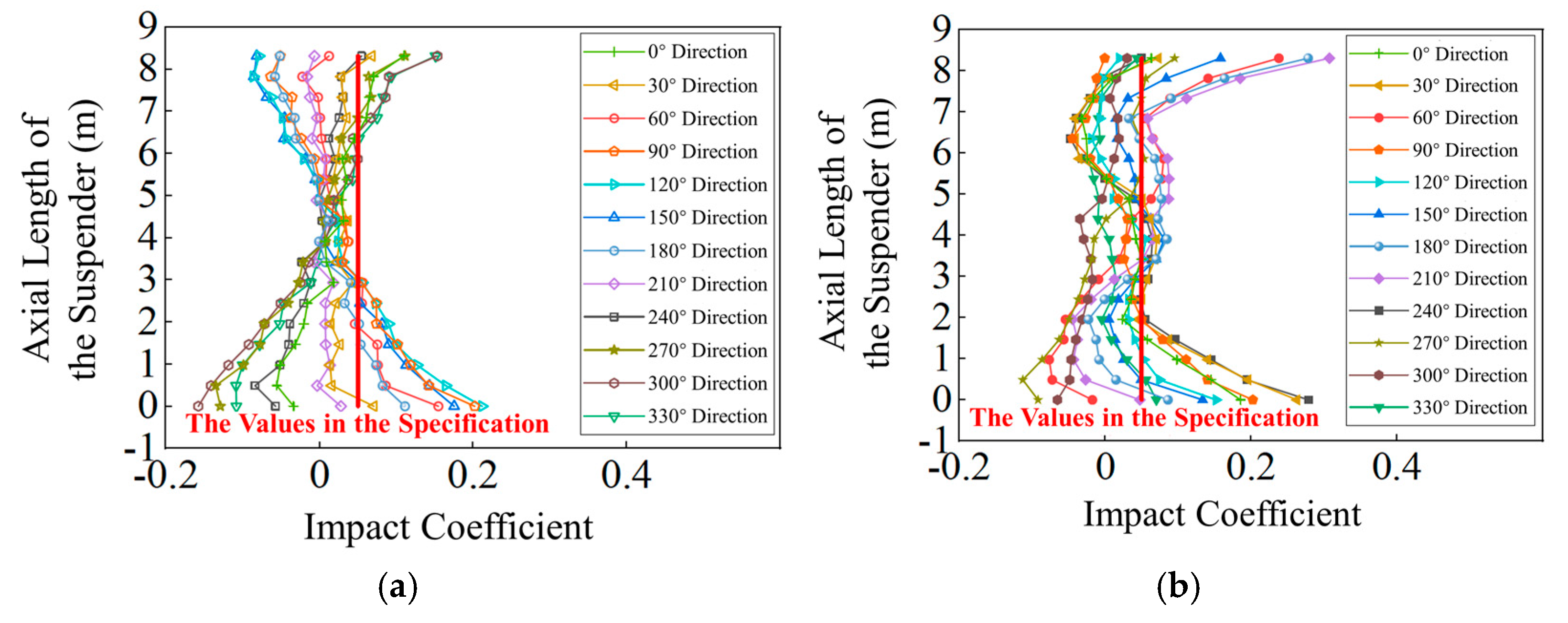

4.3. Analysis of the Uneven Impact Coefficient

5. Conclusions

- (1)

- Under vehicle loading, the bending moment in BEAM element suspenders increases as the suspender length decreases. With extended vehicle driving time, suspenders 1# and 21# exhibit higher frequency and amplitude of bending moments compared to long suspenders, indicating enhanced vibrational intensity.

- (2)

- LINK element short suspenders exhibit uniform stress distribution, while BEAM element short suspenders demonstrate non-uniform stress distribution and impact coefficients along the axial direction. Peak stresses and impact coefficients at lower anchorage end sections concentrate toward the side-span column. When vehicles move through the bridge mid-span region, these directional concentrations cause more severe damage in the corresponding direction of short suspender sections.

- (3)

- The deformation trend of short suspenders aligns with internal force variations: axial alternating loads originate from axial relative deformation between the arch rib and the transverse girder, while bending alternating loads are transmitted by rotational deformation at the lower anchorage end.

- (4)

- In engineering practice, it should be ensured that on the basis of the overall compliance with the impact coefficient specification requirements of the half-through arch bridge, the checking work of the vehicle-induced impact coefficient of the short suspender should be carried out through the combination of simulation and test, so as to ensure that the short suspender has sufficient impact resistance performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Editorial Department of China Journal of Highway and Transport. Review on China’s Bridge Engineering Research: 2024. China J. Highw. Transp. 2021, 34, 1–97. [Google Scholar]

- Li, Y.; Chen, Y.J.; Huang, X.Y. Impact effect study on long-span irregular concrete filled steel tube arch bridge under moving vehicles. J. Harbin Inst. Technol. 2010, 252, 109–114. [Google Scholar]

- Yan, Z.G.; Sheng, H.F.; Chen, Y.J. Effects of bridge deck roughness on vibration of long-span concrete filled steel tube arch bridges due to vehicles. China J. Highw. Transp. 2004, 17, 41–43. [Google Scholar]

- Malm, R.; Andersson, A. Field testing and simulation of dynamic properties of a tied arch railway bridge. Eng. Struct. 2006, 28, 143–152. [Google Scholar] [CrossRef]

- Zhu, Z.H.; Luo, S.H.; Zhang, L.; Wang, L.; Yu, Z.; Meng, X. Analysis of stress impact coefficient of hangers in arch bridge under vehicle-bridge coupled vibration. J. Vib. Meas. Diagn. 2019, 39, 1169–1176+1356–1357. [Google Scholar]

- Huang, D.Z.; Wang, T.L. Impact analysis of cable-stayed bridges. Comput. Struct. 1992, 43, 897–908. [Google Scholar] [CrossRef]

- Gu, A.B.; Xu, J.L. Structural behavior analysis of short suspender in half-through and through arch bridges. J. Chongqing Jiaotong Univ. 2002, 21, 1–3. [Google Scholar]

- Zhu, J.S.; Yi, Q. Non-uniformity of stress impact factor of suspenders on half- through or through arch bridges. J. Vib. Shock. 2012, 31, 5–10. [Google Scholar]

- Zhu, J.S.; Xu, Y.F. Research on the impact factor of the three-span continuous beam-arch combined bridge based on the vehicle-bridge coupled vibration. J. Railw. Sci. Eng. 2019, 16, 959–967. [Google Scholar]

- Zhang, K.Y.; Yang, J. Dynamic response analysis and redesign of short hangers in bridges. J. Wuhan Univ. Technol. (Transp. Sci. Eng.) 2017, 41, 934–937+942. [Google Scholar]

- Kong, Q.K. Structural Behavior Study on Short Suspender on Half Through Arch Bridges with Large Span. Ph.D. Dissertation, Southwest Jiaotong University, Chengdu, China, 2003. [Google Scholar]

- Yao, Z.Q.; Ruan, X.P.; Deng, Q. Prevention measures for bridge deck fracture caused by deformation difference of arch bridge hangers. Highway 2002, 7, 73–75. [Google Scholar]

- Gou, H.; Zhou, W.; Yang, C.; Bao, Y.; Pu, Q. Dynamic Response of a Long-Span Concrete-Filled Steel Tube Tied Arch Bridge and the Riding Comfort of Monorail Trains. Appl. Sci. 2018, 8, 650. [Google Scholar] [CrossRef]

- Huo, J.; Huang, Y.; Wang, J.; Zhuo, Q. Numerical Analysis on the Impact Effect of Cable Breaking for a New Type Arch Bridge. Buildings 2023, 13, 753. [Google Scholar] [CrossRef]

- Luan, J.; Hao, X.W. Evaluation of Reinforcement Effect of an RC Tied Arch Bridge Based on Vehicle Bridge Coupled Vibration. China J. Highw. Transp. 2018, 31, 227–234. [Google Scholar]

- Yang, J.X.; Chen, W.Z.; Gu, R. Analysis of Dynamic Characteristics of Short Hangers of Arch Bridge. Bridge Constr. 2014, 44, 13–18. [Google Scholar]

- Zhang, J.H. Research in the Carrying Capacity of the Simply Supported Composite Beam of Steel and Concrete. Ph.D. Dissertation, Hehai University, Nanjing, China, 2001. [Google Scholar]

- He, X.B. Research on Corrosion Fatigue Characteristics of Short Suspenders of Half-Through Arch Bridge Considering Vehicle Bridge Coupling Vibration. Ph.D. Dissertation, Chongqing Jiaotong University, Chongqing, China, 2022. [Google Scholar]

- JTG D60-2018; General Specifications for Design of Highway Bridges and Culverts. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015.

- Jiang, P.W. Coupled Vibration Between Vehicles and Highway Long-Span Continuous Series Bridge. Ph.D. Dissertation, Chang’an University, Xi’an, China, 2012. [Google Scholar]

- Chen, X.D. The Vehicle-Bridge Interaction Analysis of Corrugated Steel Web Box Girder Based on Contact-Constraint Method. Ph.D. Dissertation, Chongqing University, Chongqing, China, 2021. [Google Scholar]

- Shao, Y.; Sun, Z.G.; Chen, Y.F. A study on equal stiffness design of arch bridge suspenders and their dynamic response analysis. J. Vib. Shock 2018, 37, 219–225. [Google Scholar]

- He, X.B.; Guo, Z.W.; Xu, H. Vehicle Impact Effect of Suspender in Half-through Arch Bridge Considering Vehicle-bridge Coupled Vibration. Noise Vib. Control 2022, 42, 206–213. [Google Scholar]

- Du, H.; Xu, H.W.; Lou, W.J. Fast Bayesian modal parameter identification method based on short-time Fourier transform. J. Build. Struct. 2023, 44, 305–314+334. [Google Scholar]

- Zhou, Y.J.; Xue, Y.X.; Li, R.R.; Zhan, J.W.; Zhao, Y. State-of-the-art of Theory and Applications of Bridge Dynamic Load Allowance. China J. Highw. Transp. 2021, 34, 31–50. [Google Scholar]

| Vehicle Structure | Construction Parameter | Vehicle Structure | Construction Parameter | Vehicle Structure | Construction Parameter |

|---|---|---|---|---|---|

| Total Vehicle Mass | M = 46,000.0 kg | First-Class Rear Axle Suspension Stiffness | kd3 = 1.2675 × 106 N·m−1 | Second-Class Middle Axle Suspension Damping | cu2 = 4.9 × 104 N·m−1·s−1 |

| Vehicle Body Mass | m1 = 37,340.0 kg | First-Class Front Axle Suspension Damping | cd1 = 1.96 × 105 N·m−1·s−1 | Second-Class Rear Axle Suspension Damping | cu3 = 4.9 × 104 N·m−1·s−1 |

| Rotational Inertia | J = 2.446 × 106 kg·m2 | First-Class Middle Axle Suspension Damping | cd2 = 9.8 × 104 N·m−1·s−1 | Vehicle Wheelbase | L = 8.0 m |

| Front Wheel Mass | m2 = 4330.0 kg | First-Class Rear Axle Suspension Damping | cd3 = 9.8 × 104 N·m−1·s−1 | The Distance from Front Axis to Center of Mass | l2 = 4.0 m |

| Middle Wheel Mass | m3 = 2165.0 kg | Second-Class Front Axle Suspension Stiffness | ku1 = 4.28 × 106 N·m−1 | The Distance from Middle Axis to Center of Mass | l3 = 3.0 m |

| Rear Wheel Mass | m4 = 2165.0 kg | Second-Class Middle Axle Suspension Stiffness | ku2 = 2.14 × 106 N·m−1 | The Distance from Rear Axis to Center of Mass | l4 = 4.0 m |

| First-Class Front Axle Suspension Stiffness | kd1 = 2.535 × 106 N·m−1 | Second-Class Rear Axle Suspension Stiffness | ku3 = 2.14 × 106 N·m−1 | ||

| First-Class Middle Axle Suspension Stiffness | kd2 = 1.2675 × 106 N·m−1 | Second-Class Front Axle Suspension Damping | cu1 = 9.8 × 104 N·m−1·s−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Yao, G.; He, X. Research on the Tensile-Bending Dynamic Response of the Half-Through Arch Bridge Short Suspender Considering Vehicle-Bridge Coupling Vibration. Vibration 2025, 8, 51. https://doi.org/10.3390/vibration8030051

Wang L, Yao G, He X. Research on the Tensile-Bending Dynamic Response of the Half-Through Arch Bridge Short Suspender Considering Vehicle-Bridge Coupling Vibration. Vibration. 2025; 8(3):51. https://doi.org/10.3390/vibration8030051

Chicago/Turabian StyleWang, Lianhua, Guowen Yao, and Xuanbo He. 2025. "Research on the Tensile-Bending Dynamic Response of the Half-Through Arch Bridge Short Suspender Considering Vehicle-Bridge Coupling Vibration" Vibration 8, no. 3: 51. https://doi.org/10.3390/vibration8030051

APA StyleWang, L., Yao, G., & He, X. (2025). Research on the Tensile-Bending Dynamic Response of the Half-Through Arch Bridge Short Suspender Considering Vehicle-Bridge Coupling Vibration. Vibration, 8(3), 51. https://doi.org/10.3390/vibration8030051