1. Introduction

Ventilation is a critical safety component in subway and railway systems, particularly during fire emergencies. Effective management of smoke and heat during such events is crucial to ensure the success of evacuation efforts and the safety of passengers. Longitudinal ventilation, commonly achieved through the use of jet or impulse fans, is one of the most widely adopted methods for controlling the movement of smoke and heat in tunnel systems due to its relatively simple design and construction requirements. This ventilation method facilitates safe evacuation by maintaining a clear air path and preventing the accumulation of harmful smoke concentrations. However, the design and optimization of these systems require accurate predictive models that can simulate the airflow and thermal conditions during fire scenarios.

The SES model, developed by Parsons Brinckerhoff under the guidance of the Volpe National Transportation Systems Center of the U.S. Department of Transportation, is a widely used tool for predicting ventilation characteristics in subway and rail tunnels. SES is a one-dimensional, network-based model that simulates airflow, pressure, temperature, and the impacts of train and fire dynamics within tunnel systems. By accounting for variables such as train operations, ventilation system configuration, and fire behavior, SES provides insights into tunnel performance during fire events, particularly in terms of ensuring critical velocity for smoke control and determining prevailing dynamic temperature, airflow, and environmental conditions [

1].

The flow rate in a longitudinal ventilation system is primarily driven by pressure distribution within the tunnel. Since tunnels are not perfect cylinders and often feature obstacles, it is crucial to account for the various sources of pressure loss within the system. Fires in tunnels further complicate this process by impacting local temperatures and air densities, which mimic the effects of narrowing or blockage at the fire’s location, a phenomenon known as fire throttling or choking [

2,

3]. Fire throttling occurs when the rapid expansion of air passing through the fire location increases air velocity and, consequently, the viscous pressure losses in the tunnel. To counteract these pressure losses and maintain airflow above the critical velocity, jet fans are typically used in longitudinal ventilation systems. Thus, reliable system design depends on accurately determining mass, momentum, and energy balances within the tunnel.

Longitudinal ventilation systems have been extensively studied, particularly in relation to design fires, critical ventilation velocity, and tunnel pressure losses. Previous research has identified key parameters affecting pressure distribution, including exterior wind, obstacles, wall friction, buoyancy, inflow and outflow portals, and tunnel inclination [

2,

4,

5]. Studies have also examined the distribution of smoke temperature and velocity in tunnel fires, revealing that these parameters follow an exponential decay [

6,

7,

8]. The decrease in smoke temperature is attributed to heat loss to the tunnel boundaries and the entrainment of cooler air into the smoke flow [

9]. Near the fire, where smoke temperatures are elevated, heat exchange due to fresh air entrainment is often lower compared to heat loss to the tunnel walls. As the smoke flows further along the tunnel, its temperature approaches ambient levels, and the effect of fresh air entrainment becomes more significant [

9]. Recent research [

8] has supported confidence in the use of 1D equations to capture fire tunnel dynamics, as the heat losses predicted by these equations generally align well with experimental fire data under high-ventilation conditions.

Although SES is widely used in the design and evaluation of tunnel ventilation systems, there is a lack of published research validating its predictions with real-world experimental data. Notably, there has been no comprehensive comparison between SES predictions of jet fan effects in longitudinal ventilation during fire events and experimental results. Despite SES being required by major metro and train authorities such as AMTRAK in the US [

10] for modeling and testing tunnel ventilation system performance, its validation has been under-documented and not widely available in the public domain. Therefore, this study aims to fill this gap by providing a publicly available, detailed comparison of SES predictions with experimental data from the Memorial Tunnel fire ventilation experiments. These full-scale tests provide an invaluable opportunity to assess SES’s accuracy in simulating the effects of jet fans on airflow and temperature distributions under cold and fire conditions. Computational fluid dynamics (CFD) models have been successfully validated against the Memorial Tunnel fire ventilation experiments [

11,

12,

13,

14], demonstrating the value of these tests for model development, accuracy testing, and identifying both strengths and weaknesses. Therefore, the findings from this comparison provide a clearer understanding of SES’s strengths and limitations for both tunnel ventilation practitioners and researchers, contributing to its ongoing development as a reliable tool for fire safety planning and tunnel ventilation design.

2. SES Model Formulation

SES (Version 4.1) is a computer model that evaluates airflow characteristics within tunnel and station systems as a one-dimensional fluid network. As a one-dimensional network, incompressible, turbulent, slug-flow model, the tunnel domain is divided into sections, segments, and subsegments between nodes, with the program solving one-dimensional conservation equations for mass, momentum, and energy across these tunnel sections. This approach allows the model to predict the average airflow rate, temperature, and pressure distribution throughout the tunnel system. SES accounts for changes in airflow, temperature, and pressure resulting from ventilation system operations, steady-state heat sources, direct heat transfer from the fire to the tunnel air, radiative heat transfer to the tunnel walls from the flame, and both radiative and convective heat transfer from downwind air.

The governing equations solved by SES over nodes and segments , assuming no train present as in the simulations conducted in this study, are presented in Equation (1) through Equation (3). These equations are evaluated at each time step.

The equation for the conservation of mass at Node

in SES is expressed as:

where

is the airflow rate through segment

.

The equation for momentum conservation in segment

solved by SES is expressed as:

where

is the inertia coefficient,

is the Darcy–Weisbach pressure loss,

is minor pressure losses,

is the buoyancy pressure, and

is the jet fan pressure.

The equation for thermal energy balanced in subsegments

solved by SES is expressed as:

where

is the subsegment air temperature,

is the subsegment air density,

is the specific heat of air,

is the volume of the subsegment,

is the airflow into the subsegment,

is the air temperature of the air entering the subsegment,

is the air temperature in the subsegment,

is the sensible heat added by fire,

is the convective heat transfer coefficient,

is the wetted perimeter,

is the temperature of the tunnel wall surface in subsegment

, and

is the radiation to the wall.

The pressure added to the tunnel airflow by jet fans is determined by SES using Equation (4):

where

is the pressure efficiency of the jet fan,

is the air density at the upstream temperature (

),

is the cross-sectional area of the tunnel,

is the jet velocity, and

is the cold air velocity in the segment.

3. Memorial Tunnel Experiments and SES Simulations

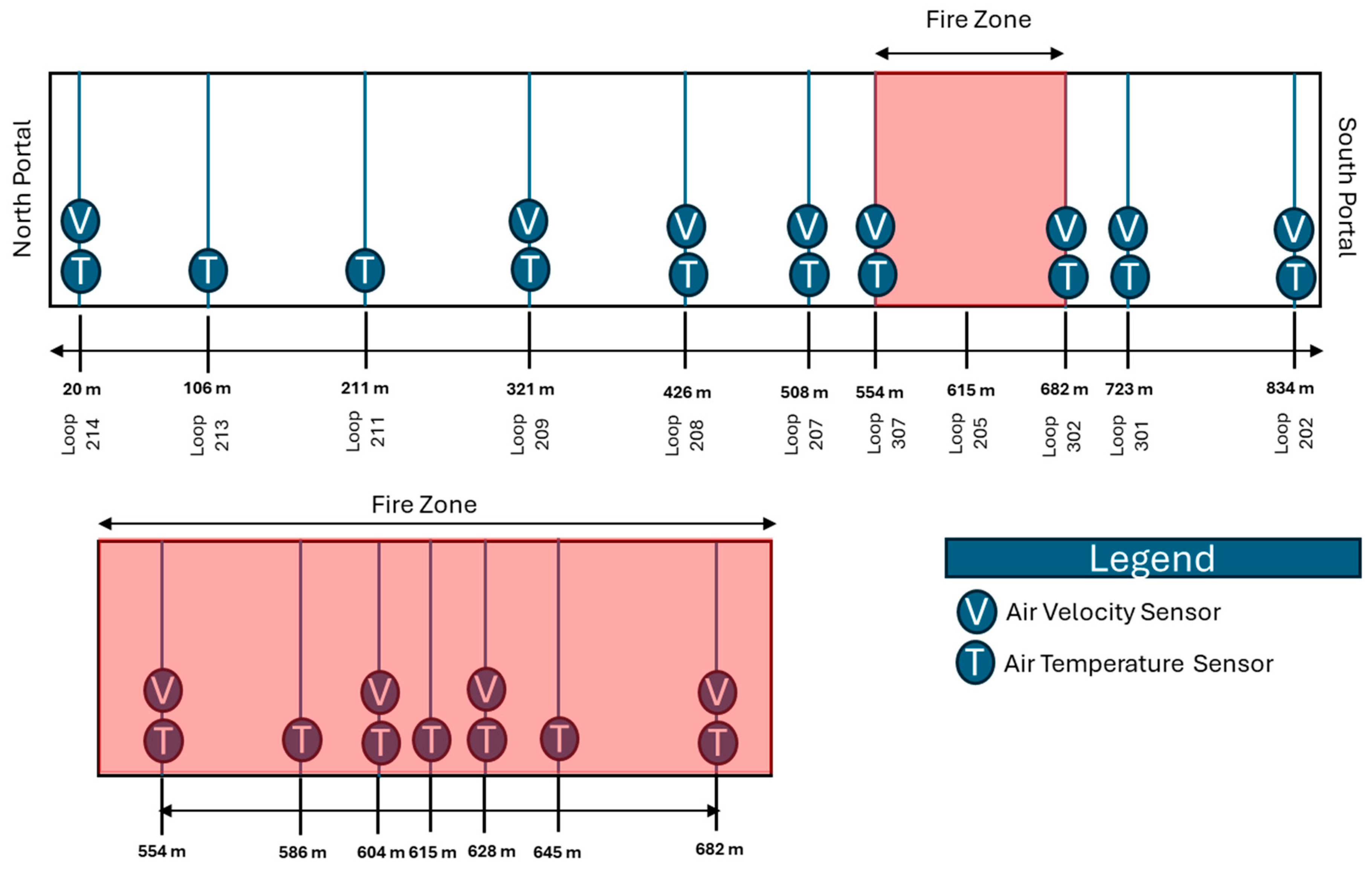

Between 1993 and 1995, 98 full-scale fire ventilation experiments were conducted in a decommissioned road tunnel in West Virginia to study the impact of different ventilation strategies on the movement of smoke in the tunnel. Additional experiments were conducted with varying quantities of jet fans operational without a fire to characterize the flow conditions in the absence of fire. The Memorial Tunnel, which is approximately 854 m long, features a constant 3.2% grade from the south to the north portal. The tunnel dimensions are 8.8 m wide and 7.9 m tall at the peak of its rounded ceiling. A walkway runs along the east wall, as depicted in the sketch in

Figure 1. Fifteen instrument loops in the tunnel were equipped to monitor the tunnel environment. The location of the 15 instrument loops in the tunnel and the data measured at each loop are shown in

Figure 2. Additional details on the instrumentation, configuration, and images of tunnel sections can be found in the original test report [

15].

The full-scale experiments, which involved longitudinal ventilation using jet fans, were selected for comparison with the SES model predictions. For the fire tests selected, the longitudinal ventilation system successfully controlled the back-layering, and quasi-steady-state tunnel flow conditions were achieved. Simulation results were compared with averaged test data from these quasi-steady-state periods. The test data were obtained from the Fire Research Division Experimental Database repository [

16], which has been used primarily for the Fire Dynamic Simulator (FDS) model validation. These test data were obtained from the Memorial Tunnel Fire Ventilation Test Program Reports [

11,

15].

Figure 3 shows the location of all jet fans in the tunnel along with the naming used in the selected tests. Jet fans were spaced approximately 95 m apart.

In the SES simulations, jet fans were modeled with a specified volume flow of 42.95 m

3/s and a discharge velocity of 34.2 m/s. The efficiency of the jet fans was modeled between 75% and 83%, based on the reported values [

11]. Additionally, a total tunnel K-loss coefficient of 10.6 and a fully turbulent friction factor for the tunnel sections of 0.0055 were set in the SES model for all simulations. These values resulted in a total K-loss value for the tunnel of 13.1 in the model. This value aligns with the total reported K-loss value for the tunnel, divided as follows: head loss due to wall friction (K = 2.5); tunnel inlet and exit, sudden tunnel area enlargements and contractions, and tunnel blockage caused by instrumentation and other obstructions used in the experiments (K = 10.6) [

11]. The SES model was divided into tunnel sections no longer than 25 m to ensure high spatial prediction resolution. Wind conditions were simulated using an impulse fan at the portals, as described in the following sections. For a detailed review of the experimental data, SES input and output results, and data processing scripts, see ref. [

17]. Additionally, the tables in

Appendix A provide a summary of the simulations conducted, along with selected input parameters. It is important to note that all input parameters used in the SES simulations were derived from available actual measured data [

16] or information from the Memorial Tunnel Experiment reports [

11,

15].

3.1. Cold Flow Tests

A series of cold flow tests were conducted in the Memorial Tunnel. No wind conditions were observed in the cold flow tests, and reported average fan efficiencies of 75% and 83% were used in the SES model [

11].

Figure 4 presents a comparison between the SES-predicted and measured flow rate values as a function of the number of operating jet fans.

3.2. Test 606A

In Test 606A, a nominal fire size of 10 MW was generated. In this test, five minutes after full pan engulfment, jet fans 3 and 6 were activated. This fan configuration remained in place for 20 min, after which an additional jet fan was turned on. The complete sequence of events for this test is summarized in

Table 1, where time zero represents the point of full pan engulfment. The measured heat release rate (HRR) and upwind airflow during the test are shown in

Figure 5, with the highlighted grey area indicating the period during which tunnel flows reached a quasi-steady-state and back-layering was controlled. During this period, minimum (MIN), average (AVE), and maximum (MAX) HRRs of 8657 kW, 10,445 kW, and 12,918 kW were measured, which were used in the SES fire simulations for this test. In all fire simulations conducted in this study, the minimum, average, and maximum HRRs were simulated as part of a sensitivity analysis due to the high variability of the measured HRR in the experiments.

In Test 606A, as shown in

Figure 5, an ambient tunnel flow of 41 m

3/s, traveling from south to north, was observed prior to the fire’s initiation. This flow was primarily driven by wind conditions at the portals. During the test, variations in temperature, flow, and other parameters along the tunnel were measured. After the fire was extinguished, flow measurements were recorded with two jet fans operating, yielding an average cold flow rate of 140 m

3/s (time > 1990 s). To evaluate and validate the SES model against the measured data from Test 606A, three simulation runs were performed.

The first run aimed to simulate the wind conditions before the operation of the jet fans and the initiation of the fire. An ambient south-to-north flow of 41 m3/s was observed, attributed to wind conditions. To replicate these conditions in the model, an impulse fan at the south portal was set to direct flow to the north portal, with a volume flow of 11.6 m3/s, a velocity of 10.0 m/s, and 100% efficiency. The simulation resulted in a bulk flow of 40.3 m3/s, which is 1.7% higher than the measured value. This level of accuracy was deemed sufficient for accounting for wind conditions.

The second run was performed using the reported jet fan efficiency, which ranged between 75% and 83%, and simulating wind conditions. During the cold flow conditions at the end of the test, when quasi-steady-state flow was achieved, the simulation using jet fan efficiency of 75% and 83% predicted cold flow rates of 135 m3/s and 142 m3/s, respectively, with jet fans 3 and 6 operating. The measured average cold flow rate was 140 m3/s with these fans, demonstrating the SES model’s accuracy in simulating the effects of ambient conditions during jet fan operation in the absence of fire.

In the third run, the minimum (MIN), average (AVE), and maximum (MAX) measured fire sizes of 8657 kW, 10,445 kW, and 12,918 Kw were incorporated into the model. The SES predictions of airflow and temperature along the tunnel were compared to the test data, as shown in

Figure 6.

Table 2 summarizes the SES predictions and experimental results for this test, with the corresponding legends provided at the bottom for clarification.

3.3. Test 607

In Test 607, a nominal fire size of 20 MW was generated. Initially, three jet fans (Fans 13, 14, and 15) were activated before the fuel oil ignition. This fan configuration was maintained for 443 s following full pan engulfment, after which jet fan 14 was deactivated and subsequently reactivated after 2 min. This fan setting remained unchanged for another 340 s. During the second half of the test, the fan settings were adjusted multiple times over a 15 min period. The complete sequence of events for the first half of this test is summarized in

Table 3, where time zero corresponds to full pan engulfment. The measured HRR and upwind flow during the test are shown in

Figure 7. The highlighted grey area indicates the period during which the tunnel flows reached a quasi-steady-state condition and backlayering was controlled. During this period, minimum (MIN), average (AVE), and maximum (MAX) HRRs of 12,460 kW, 14,138 kW, and 15,208 kW were measured, which were used in the SES fire simulations for this test.

To evaluate and validate the SES model against the measured data from Test 607, two simulation runs were performed. It is important to note that no ambient flow measurement was taken at the start of the test. Therefore, the wind conditions reported in Test 606A were applied to the model.

The first run aimed to confirm the assumption of similar wind conditions to Test 606A, along with the estimated jet fan efficiency between 75% and 83%. This run simulated the cold flow conditions at the beginning of the test, where quasi-steady-state flows were observed. The simulation predicted a cold flow rate of 167 m3/s and 176 m3/s, with all three jet fans in operation using jet fan efficiencies of 75% and 83%, respectively. The measured average cold flow rate of 174 m3/s shows that the wind assumption was valid and that the SES model effectively simulated the effects of ambient conditions during jet fan operation without fire.

In the second run, the minimum (MIN), average (AVE), and maximum (MAX) measured fire sizes of 8657 kW, 14,138 kW, and 12,918 Kw were incorporated into the model. The SES predictions for airflow and temperature along the tunnel were compared to the test data (

Figure 8).

Table 4 summarizes the SES predictions and experimental results for this test.

3.4. Test 611

In Test 611, a nominal fire size of 50 MW was generated. Five jet fans, three in one group and two in another, were activated two minutes after full pan engulfment. Steady tunnel conditions were achieved with this fan configuration, after which one fan was deactivated. The complete sequence of events for the first half of this test is outlined in

Table 5, where time zero corresponds to full pan engulfment. The measured HRR and upwind flow during the test are shown in

Figure 9. The highlighted grey area indicates the period when the flows in the tunnel reached a quasi-steady-state condition and backlayering was controlled. During this period, minimum (MIN), average (AVE), and maximum (MAX) HRRs of 35,677 kW, 49,202 kW, and 82,439 kW were measured, which were used in the SES fire simulations for this test.

To evaluate and validate the SES model against the measured data from Test 611, two simulation runs were performed.

The first run was conducted to determine the input required to model wind conditions prior to the operation of the jet fans and the initiation of the fire. An ambient south-to-north flow of 49 m3/s was observed, driven by wind conditions. To replicate these conditions, an impulse fan at the south portal was set to direct airflow toward the north portal, with a volume flow of 15.4 m3/s, a velocity of 11.0 m/s, and 100% efficiency. The simulation resulted in a bulk flow of 49 m3/s through the tunnel, which was considered sufficiently accurate for modeling the wind conditions.

In the second run, the minimum (MIN), average (AVE), and maximum (MAX) measured fire sizes of 35,677 kW, 49,202 kW, and 82,439 kW and jet fans in operation with an efficiency of 75% and 83% were incorporated into the model. SES’s predictions for airflow and temperature along the tunnel were compared to the test data, as shown in

Figure 10.

Table 6 summarizes the SES predictions and experimental results for this test.

3.5. Test 615B

In Test 615B, a nominal fire size of 100 MW was generated. Six jet fans (Fans 1, 3, 4, 6, 7, and 9), arranged in three groups of two, were activated 127 s after full pan engulfment. Steady tunnel conditions with controlled backlayering were achieved with this fan configuration, and one fan was deactivated after 840 s of full pan engulfment. The complete sequence of events for this test is shown in

Table 7, where time zero corresponds to full pan engulfment. The measured HRR and upwind flow are shown in

Figure 11. The highlighted grey area indicates the period when the tunnel flows reached a quasi-steady-state condition, with backlayering effectively controlled. During this period, minimum (MIN), average (AVE), and maximum (MAX) HRRs of 88,435 kW, 102,659 kW, and 113,492 kW were recorded.

In Test 615B, as shown in

Figure 11, an ambient tunnel flow of 40 m

3/s, directed south to north, was observed before the fire initiation (time < 0 s), primarily driven by wind conditions at the portals. Additionally, temperature, flow variations, and other parameters were measured during the fire and the operation of six jet fans (127 s < time < 843 s). To evaluate and validate the SES model against the measured data from Test 615B, two simulation runs were performed.

The first run aimed to model the wind conditions prior to the activation of the jet fans and the initiation of the fire. An ambient south-to-north flow of 40 m3/s was observed due to wind conditions. To simulate these conditions, an impulse fan at the south portal, directed towards the north portal, was set to a volume flow of 12.8 m3/s, a velocity of 9.2 m/s, and 100% efficiency. The simulation resulted in a bulk flow of 40.3 m3/s through the tunnel, which closely matches the measured value of 40 m3/s. This level of accuracy was deemed sufficient for modeling the wind conditions.

The second run incorporated the minimum (MIN), average (AVE), and maximum (MAX) measured fire sizes of 88,435 kW, 102,659 kW, and 113,492 kW and jet fans in operation with efficiencies of 75% and 83%. The SES predictions for airflow and temperature along the tunnel were compared with the test data, as shown in

Figure 12.

Table 8 summarizes the SES and experimental results for this test, both upstream and downstream.

4. Results Analysis and Discussion

Figure 13 and

Figure 14 present scatter plots illustrating the performance of the SES model, comparing the predicted values with experimental measurements for cold flow rate (m

3/s), average upstream flow rate (m

3/s), average downstream flow rate (m

3/s), average upstream temperature (°C), and average downstream temperature (°C). In each plot, the x-axis represents the experimental values from the Memorial Tunnel tests, while the y-axis represents the corresponding SES model predictions. A dashed black line indicates the 1:1 line, which represents perfect agreement between the predictions and measurements.

The average error percentage, error, and R

2 (coefficient of determination) are displayed in the bottom-right corner of each figure for simulations using the measured average fire size and jet fan efficiencies of 75% (AVE-75%) and 83% (AVE-83%). These error percentages and the corresponding errors for the evaluated parameters were calculated using Equations (5) and (6):

where

is the error percentage,

is the error,

is the SES prediction, and

is the experimental measurement.

Figure 13 shows the SES model’s predicted values versus the experimental measurements for the cold flow rate. The analysis reveals that the average SES error in predicting the cold flow rate is 0.16 m

3/s and 12.88 m

3/s, with a standard deviation of 2.44 m

3/s and 5.09 m

3/s, for fan efficiencies of 73% and 85%, respectively. In addition, the error percentages for this parameter were determined to be 4.7% and 0.8%. Results show that SES predictions had excellent agreement, with an efficiency of 75%. However, as the number of operating jet fans increases, SES tends to slightly overestimate the flow rates with an efficiency of 83%. This overprediction is likely due to the assumption of constant jet fan efficiency. While this efficiency is more accurate for cases with fewer fans and lower flow rates, it may not hold true for higher fan numbers, where increased turbulence, vibration, and noise can reduce jet fan efficiency closer to 75%.

Figure 14A shows the SES model’s predicted values versus the experimental measurements for the upstream flow rate. The analysis indicates that the mean SES error in predicting the upstream flow rate is 0.01 m

3/s and −12.95 m

3/s, with a standard deviation of 4.84 m

3/s and 6.79 m

3/s for the AVE-75% and AVE-83% simulations, respectively. The error percentages for this parameter were determined to be 3.0% for AVE-75% and 9.1% for AVE-83% simulations. It is worth noting that SES underpredicted the upstream flow rate for the smallest fire size (Test 606A) when modeling the average fire size and lower jet fan efficiency. However, SES showed more accurate upstream flows for larger fire sizes under this configuration. By contrast, for average fire size and a jet fan efficiency of 83%, SES overpredicts the upstream flow rate for larger fire sizes. A possible explanation for this discrepancy is primarily attributed to the actual jet fan efficiency being lower than 83%, as well as SES’s inaccuracies in the calculation of tunnel pressure losses, particularly due to SES’s difficulty in accurately modeling heat transfer both upstream and at the fire location. Additionally, SES predictions for Test 606A and Test 607 exhibited less variability, likely due to smaller differences between the minimum, average, and maximum simulated HRRs, as well as a lower number of jet fans in operation. In contrast, higher variations in fire size had a more significant impact on predicted tunnel pressure losses and consequently on predicted flow rates. Furthermore, variation in jet fan efficiency resulted in a more noticeable impact on the predicted flow rate when a larger number of jet fans were in operation, such as in Test 611 and Test 615B.

Figure 14B compares the SES model’s predicted values with experimental measurements for the average downstream flow rate. The analysis shows that the mean SES error for predicting the downstream flow rate is 15.12 m

3/s and 5.99 m

3/s, with a standard deviation of 9.52 and 22.09 m

3/s m

3/s for the AVE-75% and AVE-83% simulations, respectively. The average error percentages for this parameter were found to be 7.9% for the AVE-75% simulation and 1.5% for the AVE-83% simulation. SES slightly underpredicted the downstream flow for smaller fire sizes (Tests 606 and 607). However, for larger fire sizes, the model’s predictions for average fire size simulations showed closer agreement with the measured values. A possible explanation for the errors can be attributed to SES’s underestimation of heat transfer from the fire to the air in proximity to the fire, leading to lower predicted temperatures as illustrated in

Figure 6,

Figure 8,

Figure 10 and

Figure 12. This underprediction reduces the tunnel losses caused by the throttling effect. Furthermore, no significant difference in downstream flow rate was observed between average fire size simulations with jet fan efficiencies of 75% and 83%. This is due to the trade-off between upstream flow rate and tunnel heat dissipation: higher jet fan efficiency produces more thrust, leading to a higher upstream flow that dissipates more heat from the fire, thus reducing the volumetric expansion (throttling effect) downstream. Conversely, lower jet fan efficiency results in less thrust, lower upstream flow, and, consequently, less heat dissipation, which increases the volumetric expansion. This also explains the lower variability observed in SES predictions for Tests 606A and 607, in which there were smaller differences between the minimum, average, and maximum simulated HRRs. However, larger variations in fire size had a more significant impact on tunnel heat transfer dynamics and the throttling effect, causing higher variation in predicted upstream and downstream flow rates such as in Tests 611 and 615B.

Figure 14C shows the SES model’s predicted values versus experimental measurements for the average upstream temperature. The analysis reveals that the mean SES error for upstream temperature prediction is 9.16 °C, with a standard deviation of 3.56 °C. The error percentage for this parameter is 55.9%. As discussed later in this section, this error arises from SES’s inability to account for heat transfer from the fire to the upstream section of the tunnel. The SES model’s upstream temperature predictions are influenced by the initial ambient conditions and tunnel wall temperatures, as it assumes that backlayering is effectively controlled and no heat transfer to the upstream section is assumed. However, heat radiated to the upstream section occurred in the tests. In addition, in many of the experiments, backlayering was allowed to develop before it was controlled, and quasi-steady-state conditions were reached, which also likely caused an increase in the upstream temperature.

Figure 14D compares the SES model’s predicted values with experimental measurements for the average downstream temperature. The analysis indicates that the mean SES error for downstream temperature is 26.29 °C and 25.52 °C, with a standard deviation of 19.32 °C and 60.29 °C, for the AVE-75% and AVE-83% simulations, respectively. The error percentages for this parameter were 16.3% for AVE-75% and 25.52% for AVE-83% simulations. It is worth noting that SES underpredicted the downstream temperature for most of the tests when modeling the average fire size and both jet fan efficiencies. The error observed, particularly in Test 607, can be attributed to SES’s underprediction of temperatures near the fire source. This highlights a key limitation of the current SES model in accurately representing thermal behavior near the fire, as shown in most of the fire tests.

In summary, the observed errors and discrepancies in flow

s and temperature measurements during the fire tests can be attributed to the SES formulation, as follows: the model does not account for heat transfer from the fire to the upstream tunnel section. Additionally, SES underpredicts heat transfer at the fire location, as measured temperatures are significantly higher than those predicted by the model when average measured fire sizes were simulated. This results in an underestimation of tunnel losses caused by elevated temperatures upstream, downstream, and at the fire location. This issue is further supported by

Figure 14A, which demonstrates that for larger fire sizes, where higher heat transfer and losses are expected, SES tended to overpredict the upstream flow rates.

In addition to the SES formulation error sources, several experimental factors could also contribute to the observed discrepancies. First, the HRR measured during the tests sometimes varied significantly from the nominal fire size used in the SES simulations. The SES model assumed a constant HRR, whereas the experimental HRR fluctuated. Additionally, the test conditions prior to reaching quasi-steady-state may have influenced the measured values, particularly upstream of the fire, where backlayering was allowed, affecting the measurements used to validate the SES model. Another factor contributing to the errors is the limitation in SES’s maximum flame temperature, which is capped at 1093.3 °C, while the actual flame temperatures in the tests could have ranged between 1510 °C and 1566 °C. In addition, some of the bulk flow measurements from loops 214 and 207 were reported to have inconsistencies due to instrumentation issues, which could have influenced the experimental results. Finally, it is possible that the measured values do not fully represent the quasi-steady-state conditions assumed in the SES predictions. Specifically, in Test 607 and Test 611, the measured flow rate and temperature struggled to reach a quasi-steady-state due to significant variability in the fire’s HRR.

A literature review was conducted to provide context on SES’s performance relative to other modeling tools, particularly in simulating the effects of jet fans on longitudinal ventilation in tunnels. While other commercial network models, such as IDA Tunnel [

18], exist, no validation studies were identified that assess their accuracy in modeling jet fans under a longitudinal ventilation strategy for tunnel fire scenarios. In contrast, 3D CFD models such as Fire Dynamics Simulator (FDS) and FLUENT have undergone validation for this application using the Memorial Tunnel fire experiments. For example, McGrattan and Bilson [

12] compared FDS predictions of cold flow rates and back-layering locations against the same experimental tests analyzed in this study, which also involved longitudinal ventilation with jet fans. Their results demonstrated a level of agreement between FDS predictions and experimental cold flow data comparable to that observed in this study for SES. However, FDS was found to overpredict back-layering length, a parameter that SES does not compute, making direct comparison impossible. Similarly, Vega et al. [

13] evaluated FLUENT predictions of temperature profiles and smoke behavior for the same tunnel fire experiments under longitudinal ventilation. Their findings showed overall good agreement between numerical and experimental results, though discrepancies near the fire location, like those observed in this study, were noted.

Building on the findings of this study, future work should focus on conducting additional fire test comparisons to further validate the SES model’s predictions and extend the scope of the current analysis. By performing more SES validation with full-scale fire ventilation experiments, particularly under a variety of fire scenarios and with different ventilation configurations, a comprehensive comparison between SES predictions and experimental results can be established. This would allow for a better understanding of how the model performs across different fire sizes, ventilation strategies, and tunnel geometries, as well as in determining whether the trends observed in this study—such as the underprediction of temperatures near the fire source and inaccuracies in upstream and downstream flow rates—are consistent across multiple experiments.

Additionally, based on the results and the observed discrepancies, there is a clear opportunity for improving the SES model, particularly in areas where it underperforms. Specifically, further development could focus on enhancing the model’s ability to predict heat transfer from the fire to the upstream tunnel sections and improving its representation of thermal behavior in proximity to the fire. Given the demonstrated limitations in SES’s predictions for upstream and near-fire temperatures, it is recommended that future fire safety designs using SES predictions incorporate a safety margin based on the error values identified in this study. This would ensure a more conservative and safer approach when applying SES for tunnel ventilation system design.

By continuing to improve SES’s predictive capabilities and expanding the range of validated scenarios, future work can contribute to the refinement of tunnel ventilation design tools, ensuring that they are even more reliable for real-world fire safety planning and tunnel operations.

5. Conclusions

This study evaluated the performance of the Subway Environmental Simulation (SES) model by comparing its predictions against experimental data from the Memorial Tunnel fire ventilation tests. The primary objective was to assess SES’s accuracy in simulating the effects of jet fans in longitudinal ventilation during both cold flow and fire conditions. The findings from this study provide valuable insights into the strengths and limitations of the SES model, particularly in terms of predicting airflow rates and temperature distributions in tunnel fire scenarios. The results indicate that SES provides a reasonable approximation of the cold flow rate, with small discrepancies noted when a jet fan efficiency of 83% was used, particularly when a larger number of jet fans were in operation. These differences are attributed to the assumption of constant jet fan efficiency, which may not hold true under higher fan numbers, where increased turbulence and noise lead to reduced efficiency.

When simulating fire scenarios, SES generally predicted upstream and downstream flow rates with reasonable accuracy, though the model showed a tendency to underpredict temperatures near the fire source. This limitation in thermal behavior representation is linked to the SES model’s inability to fully account for heat transfer near the fire and from the fire to the upstream section of the tunnel and its limited maximum flame temperature. This limitation, particularly the capped maximum flame temperature, could be addressed by adjusting the SES source code restriction to improve SES’s accuracy in simulating thermal dynamics near the fire source. Additionally, some experimental uncertainties, such as variations in HRR and measurement inconsistencies, further contributed to the observed discrepancies.

Despite these limitations, SES’s predictions for both airflow and temperature are within an acceptable range of experimental data, demonstrating its potential as a reliable tool for tunnel ventilation system design. The findings highlight areas for improvement, particularly in modeling heat transfer dynamics and enhancing the prediction of fire-induced temperature effects. Although SES results are generally acceptable for regulatory use, caution should be exercised in the application of SES outputs. A more conservative approach, factoring in the identified error margins, is recommended to ensure the safety and reliability of fire safety designs.

This study could contribute to the ongoing development of the SES model, offering a clearer understanding of its capabilities and providing a foundation for future research aimed at improving its accuracy. Further fire testing and comparisons with additional experimental datasets are recommended to validate these findings and refine the model for better performance in real-world fire safety applications.