1. Introduction

During a bushfire, early evacuation may not always be possible and successful due to many reasons such as the rapid spread of the fire caused by extreme weather, late warnings given by the emergency service agencies, the occurrence of accidents and traffic jams as a result of mass evacuation, people’s refusal to leave their properties, people attempting to enter fire-affected areas to save their children, pets and properties, etc. Consequently, evacuation often takes place at the last moment, with flames, embers, intense heat and smoke resulting in more fatalities [

1]. Hence, taking shelter inside a structure such as a bunker or a community refuge is one of the options available for last-minute evacuees. However, when seeking shelter outside of their houses, people face a range of challenges such as a lack of visibility preventing them from finding and reaching the intended shelter at the right time, exposure to the heat and smoke resulting in exhaustion, dehydration and injuries, lack of suitable footwear and clothing, unexpected emergencies such as road blockages, difficulties associated with moving vulnerable household members, etc. [

2]. Therefore, having a well-designed and -constructed house that can be defended from bushfires is a possible solution, as it enables people to seek shelter inside their own house. Not only does it offer the possibility to shelter, but it also reduces the damage to the house and gives residents the chance to implement protective measures to protect their properties.

The application of bushfire-resistant building materials/products in each house component, such as walls, roofs, windows and doors, enhances the ability of the house to withstand bushfires. Bushfire-resistant building materials/products transfer a smaller amount of heat over a set period of time without any ignitions or structural failures. When developing these materials, they should be easily affordable to vulnerable communities so they can make their houses resilient. Also, it would be more cost-effective if these building materials have the capacity to provide resistance against several bushfire exposures. Since lightweight building materials are widely used, cost-effective and have other added advantages such as reducing the dead load of a structure, accelerating the construction rate, increasing the strength/weight ratio, enhancing energy absorption, improving thermal and sound insulation, etc., there has been interest in investigating their performance against bushfires and their properties after exposure to bushfire conditions to see if they can be used as materials for the walls of buildings in bushfire-prone areas.

Lightweight building materials such as concrete, masonry blocks, mortar, etc., can be produced using three types of methods: (a) introducing large air voids into the mix by adding chemical admixtures, (b) replacing normal aggregates partially or totally with lightweight aggregates and (c) eliminating fine aggregates completely from the mix [

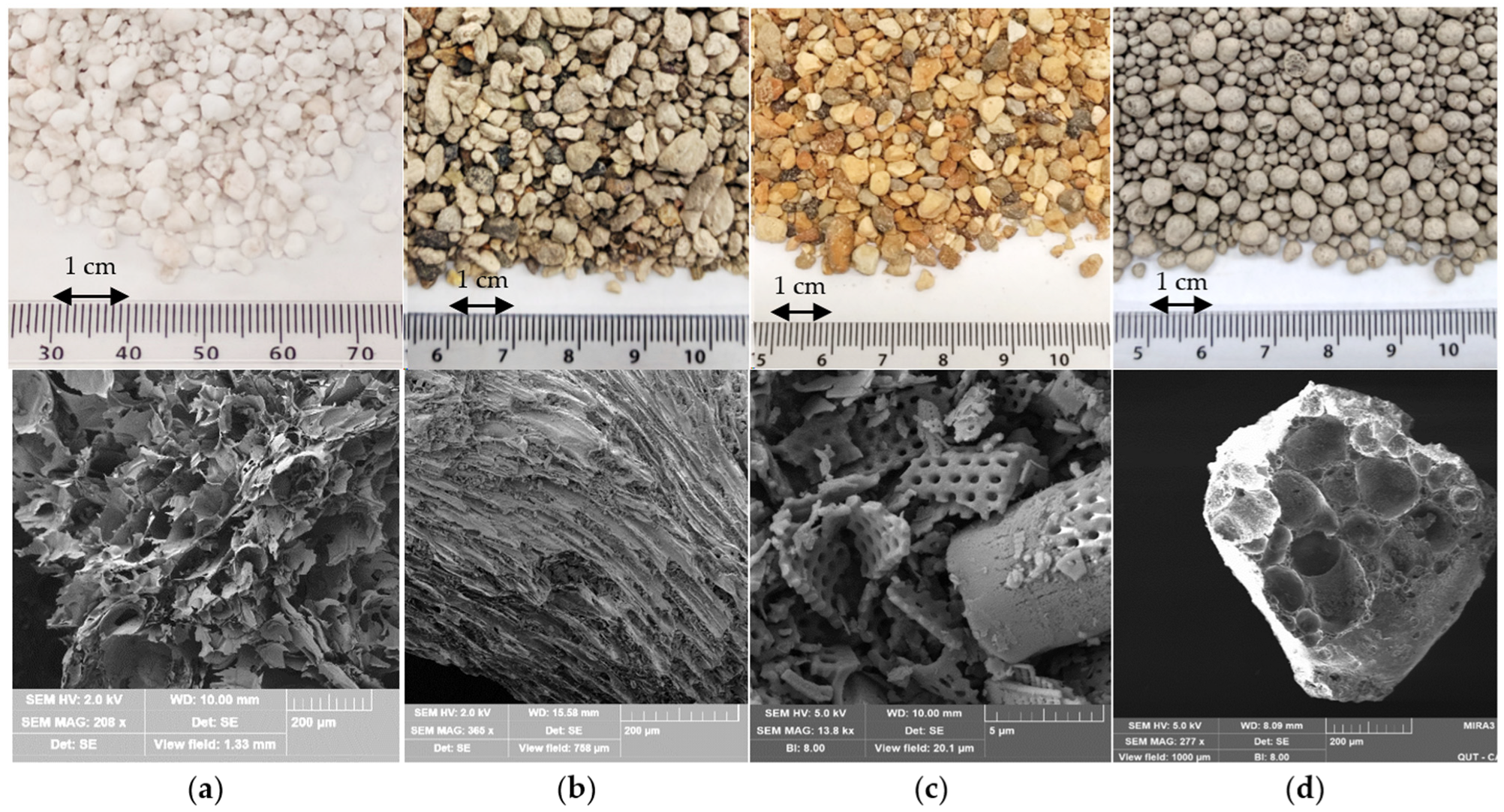

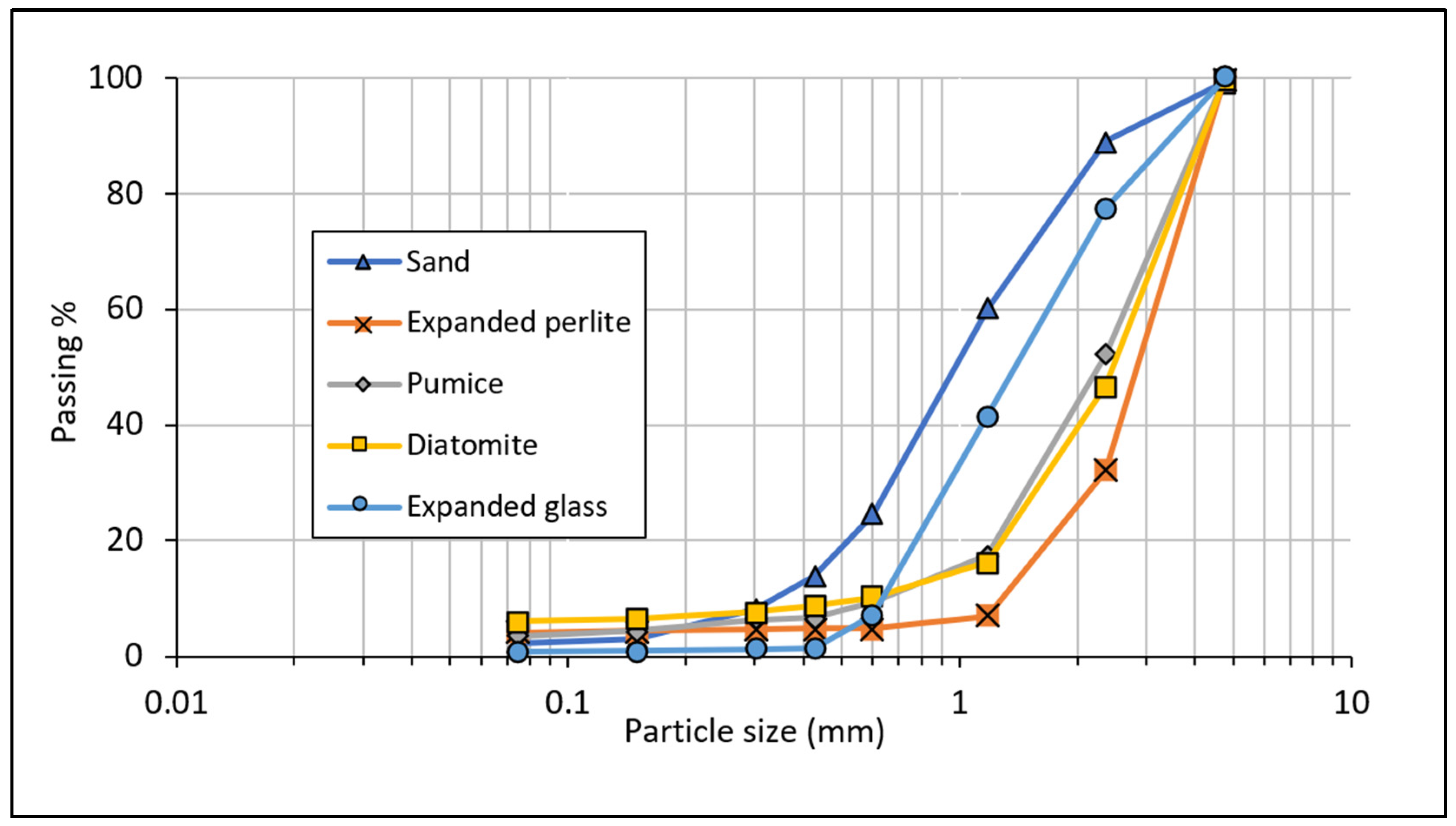

3]. In terms of lightweight aggregates, there are basically two types of aggregates: (i) natural aggregates and (ii) processed aggregates. For example, pumice and diatomite aggregates are natural, and expanded perlite and expanded glass aggregates are processed.

Pumice is a porous volcanic material and diatomite is a sedimentary rock made by fossilizing an aquatic plant called “Diatoms”. In contrast, expanded perlite and expanded glass are manufactured by heating the source material (i.e., perlite and recycled waste glass) to an elevated temperature. Generally, these aggregates have a porous structure, resulting in a low density and high thermal and sound insulation properties. Due to these unique properties, they are mostly used in the construction, agriculture and chemical industries [

4,

5].

Several past studies have been conducted investigating the properties of lightweight building materials such as concrete, masonry blocks, mortar and cement pastes after exposing to elevated temperatures [

6,

7,

8,

9]. In those studies, building materials were heated up to specific elevated temperature such as 400, 600, 800 and 1000 °C at a constant rate and then were exposed to that temperature for a set period. Following exposure to these elevated temperatures, the most tested property was the residual compressive strength [

6]. In general, the compressive strength decreases with an increase in temperature [

10]. However, the strength reduction is smaller than that of conventional building materials with the inclusion of lightweight aggregates [

10,

11]. For example, Cai et al. [

12] obtained the residual mechanical properties of polypropylene fiber-reinforced scoria aggregate concrete after exposing the material to elevated temperatures up to 800 °C. The residual compressive strength of the scoria aggregate concrete after being exposed to a temperature of 800 °C was 11.1 MPa, while it was 8.09 MPa for the normal concrete. Similarly, Karahan et al. [

10] observed improved fire resistance in ground granulated pumice-based mortar in terms of residual compressive strength compared to the control Portland cement mortar. Further, Celikten et al. [

13] observed improved residual strengths in alkali-activated mortars at elevated temperatures with an increase in perlite content. In addition to investigating the residual compressive strength, a few studies have also examined the effect of elevated temperature on density, porosity, flexural strength, elastic modulus, thermal strain, etc. [

10,

14,

15].

In summary, the effects of elevated temperatures on the properties of lightweight building materials have been investigated. Residual compressive strength was most commonly investigated, while a few studies examined the effect on properties such as density, porosity, flexural strength, thermal strain, etc. Also, in those studies, the materials were exposed to a specific elevated temperature for a set duration. Few studies have been conducted that assess the building fire and bushfire resistance of external wall systems [

16,

17]. Pancheti and Mahendran [

16] investigated the fire resistance of external light gauge steel-framed walls with brick veneer cladding, while Hendawitharana et al. [

17] evaluated the bushfire resistance of a safe room through full-scale experimental testing. However, no experimental studies have been conducted to investigate the effect of real fire conditions such as bushfires on the properties of lightweight masonry materials and also the effect of repeated fire exposure on their properties as well.

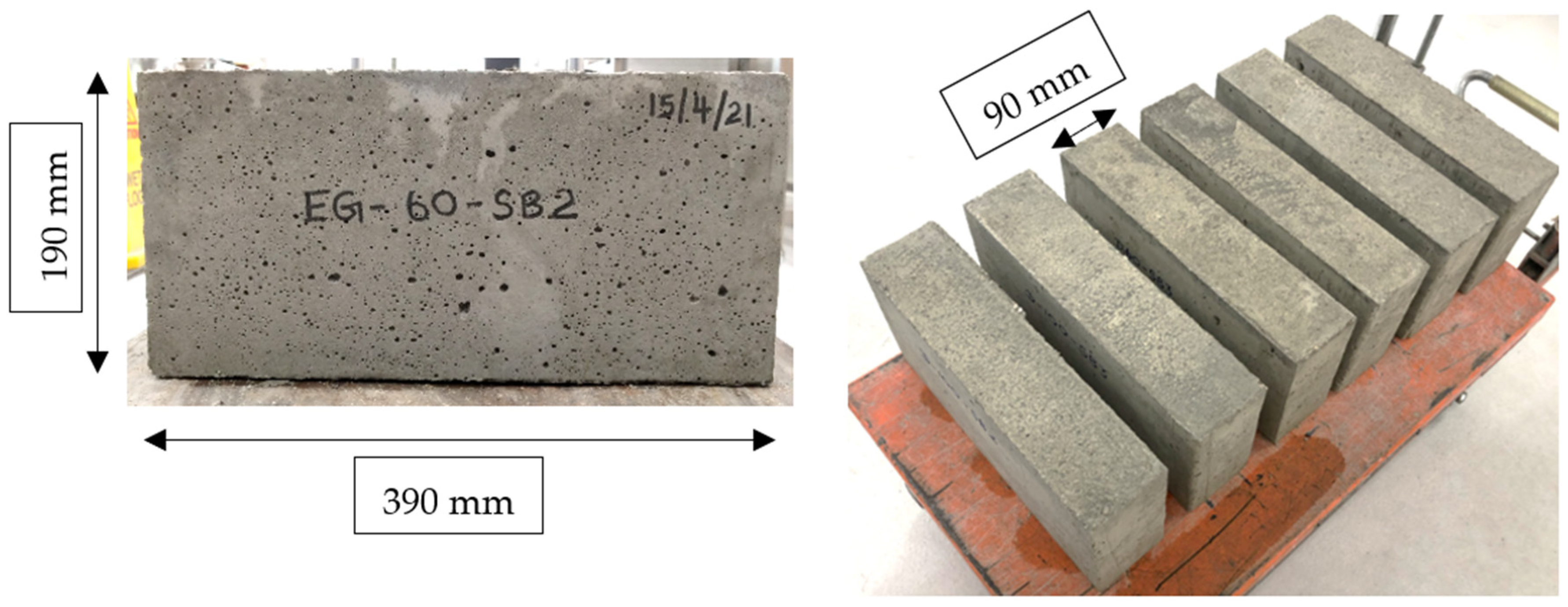

Thus, this study aimed to develop solid masonry (i.e., cement) blocks by adding four different lightweight aggregates (i.e., expanded perlite, pumice, diatomite and expanded glass) into a cement–sand mix and investigate their properties (i.e., residual compressive strength and bushfire resistance) after exposure to bushfire conditions. First, the properties of cement, sand and lightweight aggregates are presented. Second, details of the mix design, casting and test procedures are described. Then, the test results of the newly developed blocks investigating properties such as density, ambient compressive strength, residual compressive strength (i.e., strength after initial and repeated bushfire exposure) and bushfire resistance (i.e., resistance to initial and repeated bushfire exposures) are presented. Finally, the results of the newly developed blocks are discussed and compared with those of the blocks made of only the cement–sand mix and two types of commercially available masonry blocks.

3. Results and Discussion

In this section, bushfire resistance and residual strength results of all the lightweight aggregate masonry blocks, the control block and the commercially available blocks are presented, discussed and compared in detail.

3.1. First-Time Fire Exposure

During the first-time bushfire exposure, the average ambient-side surface temperature of most of the blocks was varied along three distinct phases.

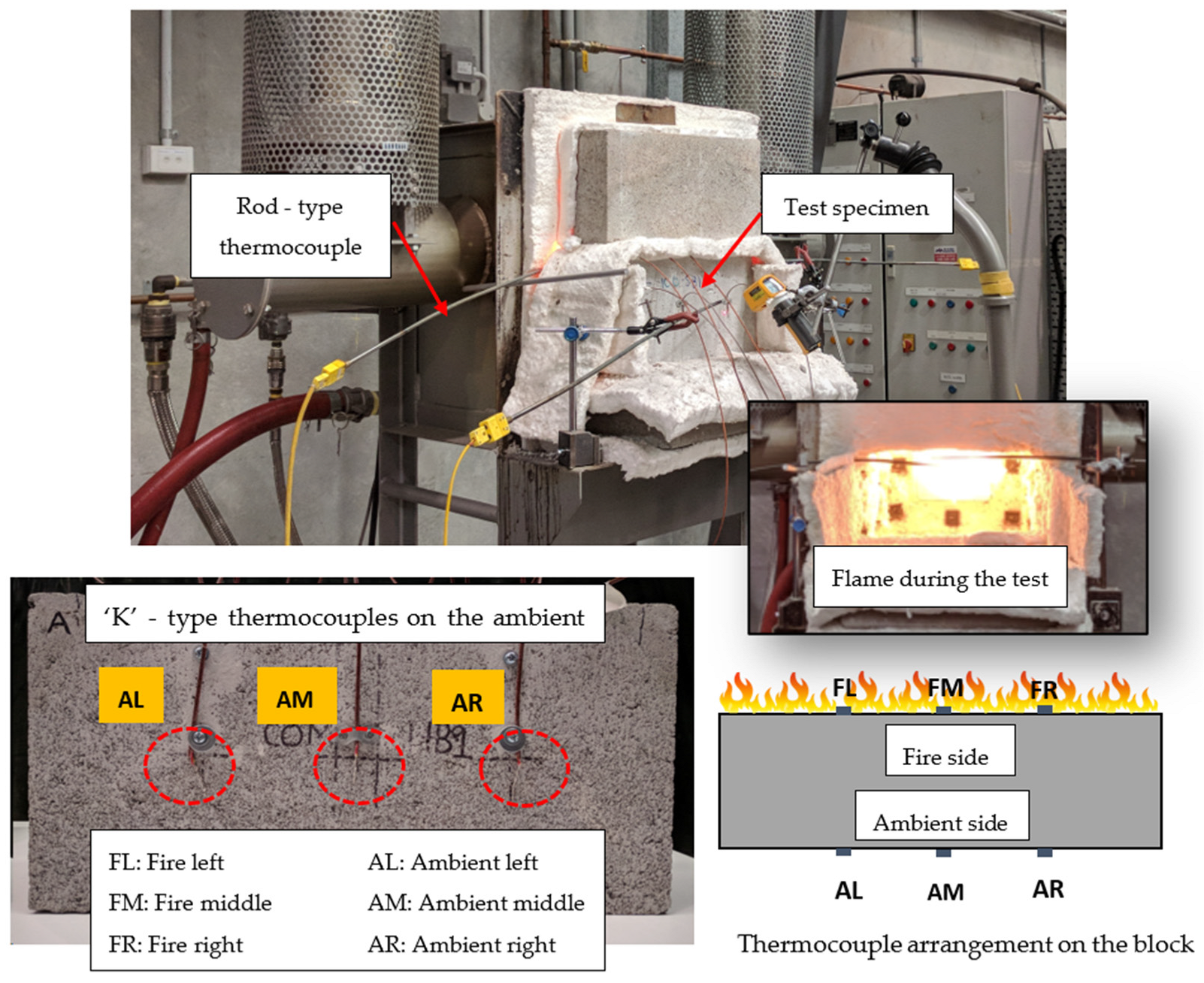

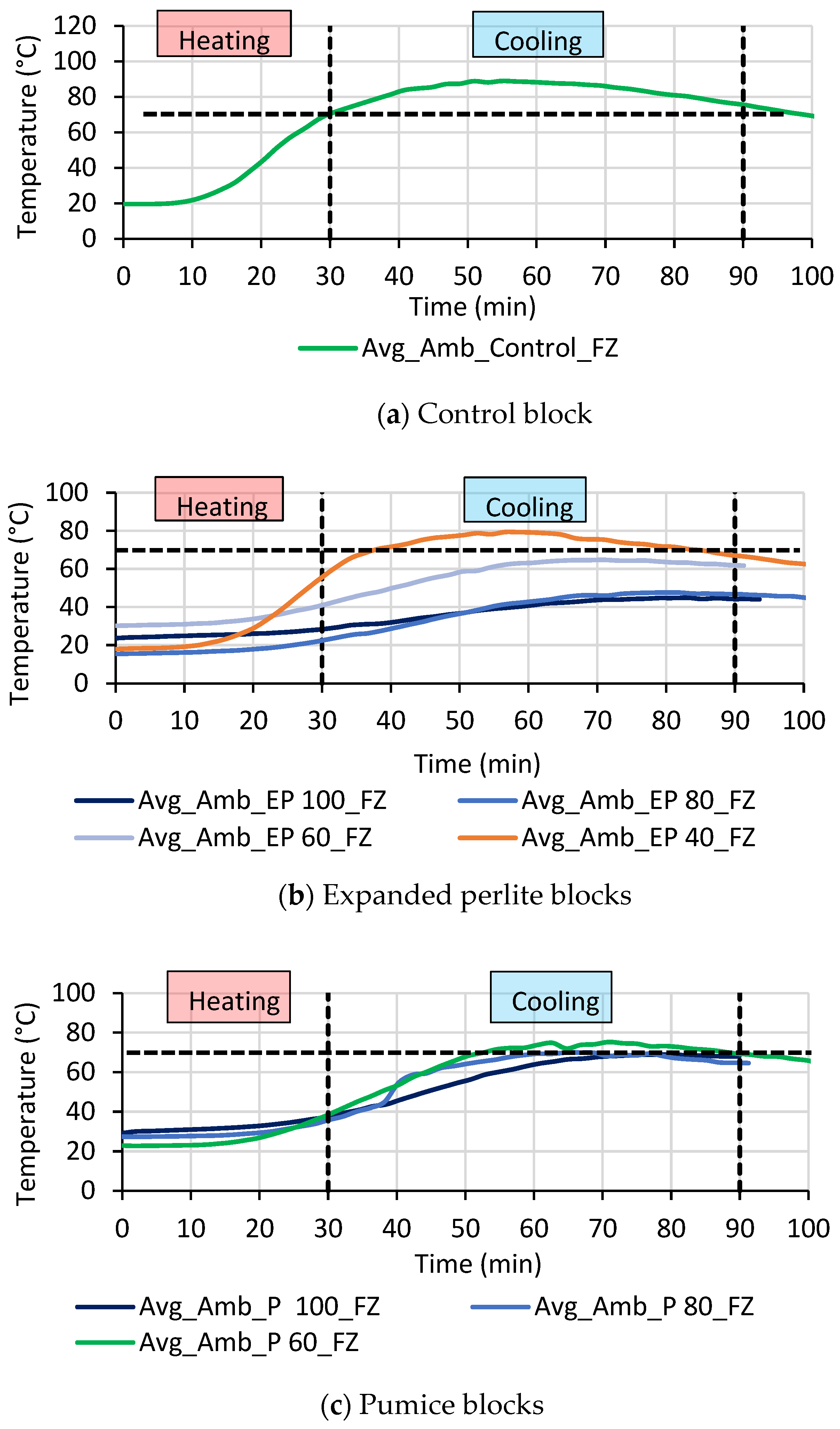

Figure 6 shows the time–temperature curves on the ambient-side surface of the control block, EP, P, D and EG blocks and commercial blocks. Ariyaratne [

23] provides the time–temperature curves of individual thermocouples attached on the fire-exposed and ambient-side surfaces.

The initial ambient side temperature of all the blocks appeared to be uniform for the first 10–20 min during the heating period. After that, temperatures started to increase during the heating period. This increment continued during the cooling period until the ambient surface reached the maximum temperature and then the temperature started to drop (

Figure 6).

The average ambient-side surface rise recorded by the control block was 69 °C, and it was in the range between 21 and 61, 40 and 52, 17 and 32 and 23 and 47 °C for the EP, P, D and EG blocks, respectively (

Table 4). Hence, the highest and lowest temperature increment was obtained by the control and diatomite aggregate blocks, respectively. Therefore, the inclusion of lightweight aggregates has been shown to lower the temperature rise during bushfire exposure. The temperature rise in the Com 1 and Com 2 blocks was 49 and 29, respectively.

Further, the maximum average ambient surface temperatures were achieved by different blocks at different times (

Table 4). The quickest block to reach its maximum was the control block (i.e., at 55 min), while the D 100 block was the slowest (i.e., 90 min). Therefore, the heating rate on the ambient surface can be calculated based on the temperature rise and the time taken to reach the maximum average temperature. For example, the heating rate of the control block is 1.26 °C/min (i.e.,

). All the other calculated heating rates are shown in

Table 4. Similarly to the pattern observed for the temperature rise, the highest and lowest heating rates were recorded by the control and diatomite aggregate blocks (i.e., 0.19–0.41 °C/min), respectively. The heating rate of lightweight aggregate blocks during first-time exposure is at least 15% lower than in the control block. Therefore, the inclusion of lightweight aggregates lowers the heating rate of masonry block ambient surfaces. In addition, the heating rate of the commercial blocks is also higher than that of the diatomite blocks. The diatomite blocks exhibited the lowest temperature rise and heating rate due to their high silica content (84.72% SiO

2) and highly porous, low-density structure (373 kg/m

3), which collectively enhances thermal resistance under bushfire conditions [

23].

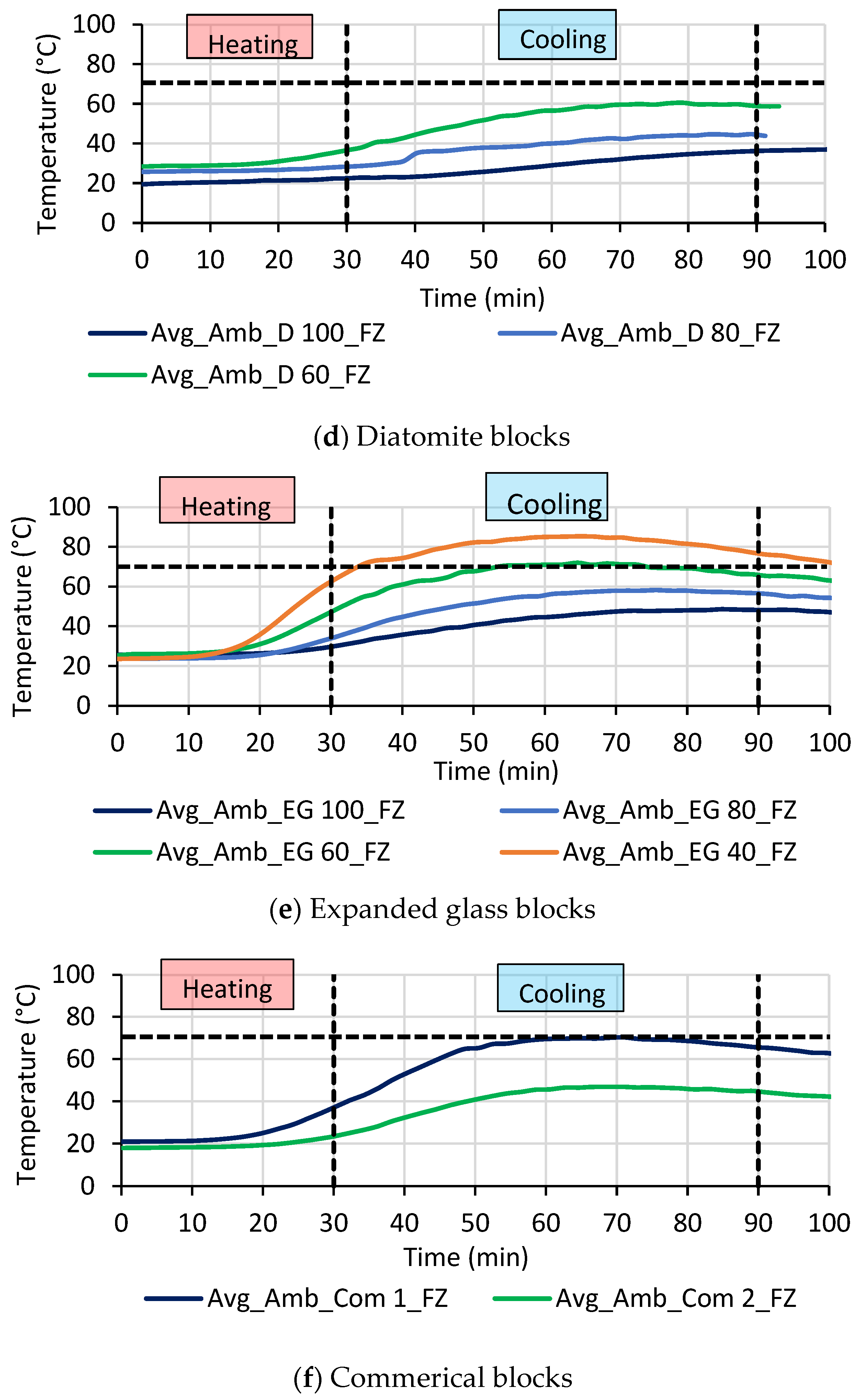

Further, the heating rate of the same lightweight aggregate-type blocks increases with decreases in the lightweight aggregate content or increases in the density of the block (see

Figure 7). Therefore, for the same lightweight aggregate-type blocks, there is a positive relationship between the heating rate and density of the block. Even in the commercial blocks, the highest heating rate was observed in the Com 1 block which has the highest density, but there was not much difference between the time to reach the maximum temperature.

A similar trend was observed in the control block, which has the highest density and recorded the highest heating rate and lowest time to reach maximum temperature. This is because the higher the density, the more closely packed together the particles in the mix are, and hence, it is easier to conduct heat. However, the density of the EP 60 block is lower than that of the D 60 block, and the lowest heating rate was recorded by the D 60 block. Therefore, not only the density of the block but also the aggregates’ unique properties such as surface texture, pore structure, thermal expansion, etc., and the bond between the cement paste and aggregates might have also contributed to the heating rate of the block.

When comparing the ambient surface temperature rise and heating rate of lightweight aggregate blocks with the same aggregate content, diatomite aggregates are more resistant against elevated temperatures, followed by the expanded perlite, expanded glass and pumice aggregates in order.

Finally, after reaching the maximum temperature, the ambient-side surface temperature of all the blocks except the D 100 block started to decline. The D 100 block demonstrated the lowest heating rate and no cooling rate during the test period. This might be due to the low thermal conductivity and thermal inertia of the material [

28]. The temperature drop on the ambient surface of the control, Com 1 and Com 2 blocks at the end of the cooling period was 13, 4 and 3 °C, respectively, while it was in the range of 1–12, 1–6, 1–2 and 1–7 for the EP, P, D and EG blocks, respectively. Also, the cooling rate on the ambient surface of the blocks can be approximately calculated based on the temperature drop and time period from the maximum average temperature to the end of the cooling period. All the calculated cooling rates are shown in

Table 4. The cooling rate of the control block is higher than those of most of the lightweight aggregate blocks. Similarly to the heating rates, the cooling rate of the same lightweight aggregate-type blocks mostly increases with a decrease in the lightweight aggregate content or an increase in the density of the block (i.e., a positive relationship with the density). Since the air-dry density of the Com 1 block is higher compared to that of the Com 2 block, the cooling rate is also higher in the Com 1 block. However, when the cooling rate of lightweight aggregate blocks with the same aggregate percentage is compared, there is no direct relationship between the cooling rate and the density of the block. Hence, the cooling rate might also depend on the aggregate’s surface and internal structure as well. This triphasic thermal response of the block can be modeled in thermophysical simulations, particularly in heat transfer models where conduction remains the dominant mechanism throughout all phases. Additionally, considering the heating and cooling rates of blocks, it can be observed that the cooling rates were lower than the heating rates except for in the D 100 and 80 blocks. This is primarily due to the use of forced heating and natural (unforced) cooling. However, the relationship between cooling rates and delayed spalling requires further investigation and is recommended for future study.

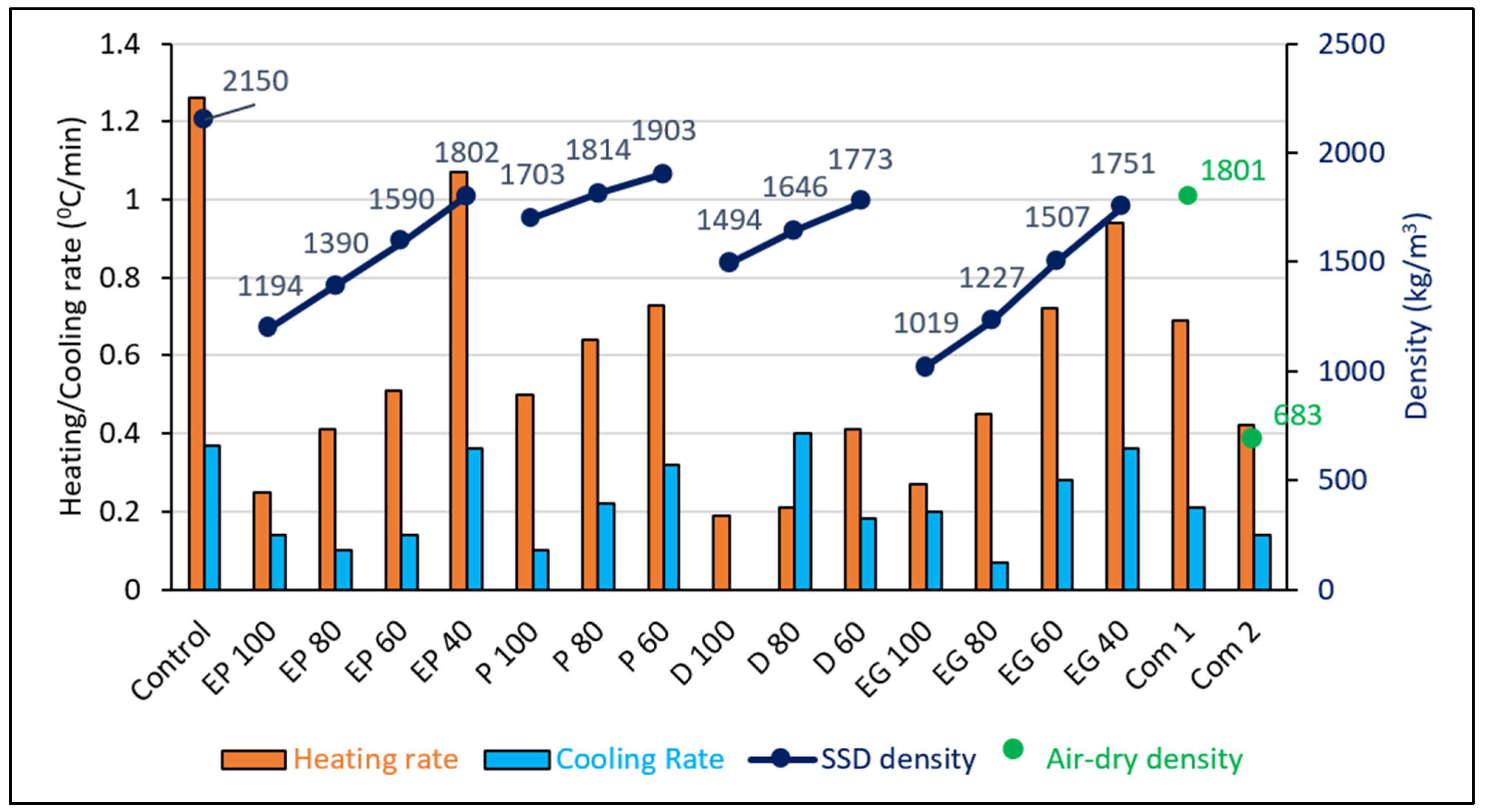

During the 90 min test period, none of the blocks were combustible and none of them failed in terms of insulation or integrity. All the blocks recorded surface cracks on the fire-exposed side except for the Com 1 block, and only the EP 80, P 100 and 80 and D 100, 80 and 60 blocks showed ambient-side surface cracks after the test (

Figure 8).

Moreover, the Australian Building Codes Board (ABCB) performance standard suggests that the temperature limit for the unguarded interior surfaces of a bushfire shelter should be 70 °C [

29]. In this study, the control, EP 40, P 80, P 60, EG 60, EG 40 and Com 1 blocks exceeded this limit. The control block was the first to exceed the limit among all the blocks (i.e., after around 30 min). All the diatomite blocks recorded temperatures of less than 70 °C (

Figure 6). Therefore, taking into consideration this compliance of the bushfire shelters’ interior surface temperature limit and other test properties determined in previous studies such as density, compressive strength and water absorption, the EP 60 [

30], P 80 [

31] and D 60 [

32] blocks were recommended to be more suitable for application in bushfire shelters, and hence, repeated bushfire exposure was only tested in these lightweight aggregate blocks.

3.2. Repeated Fire Exposure

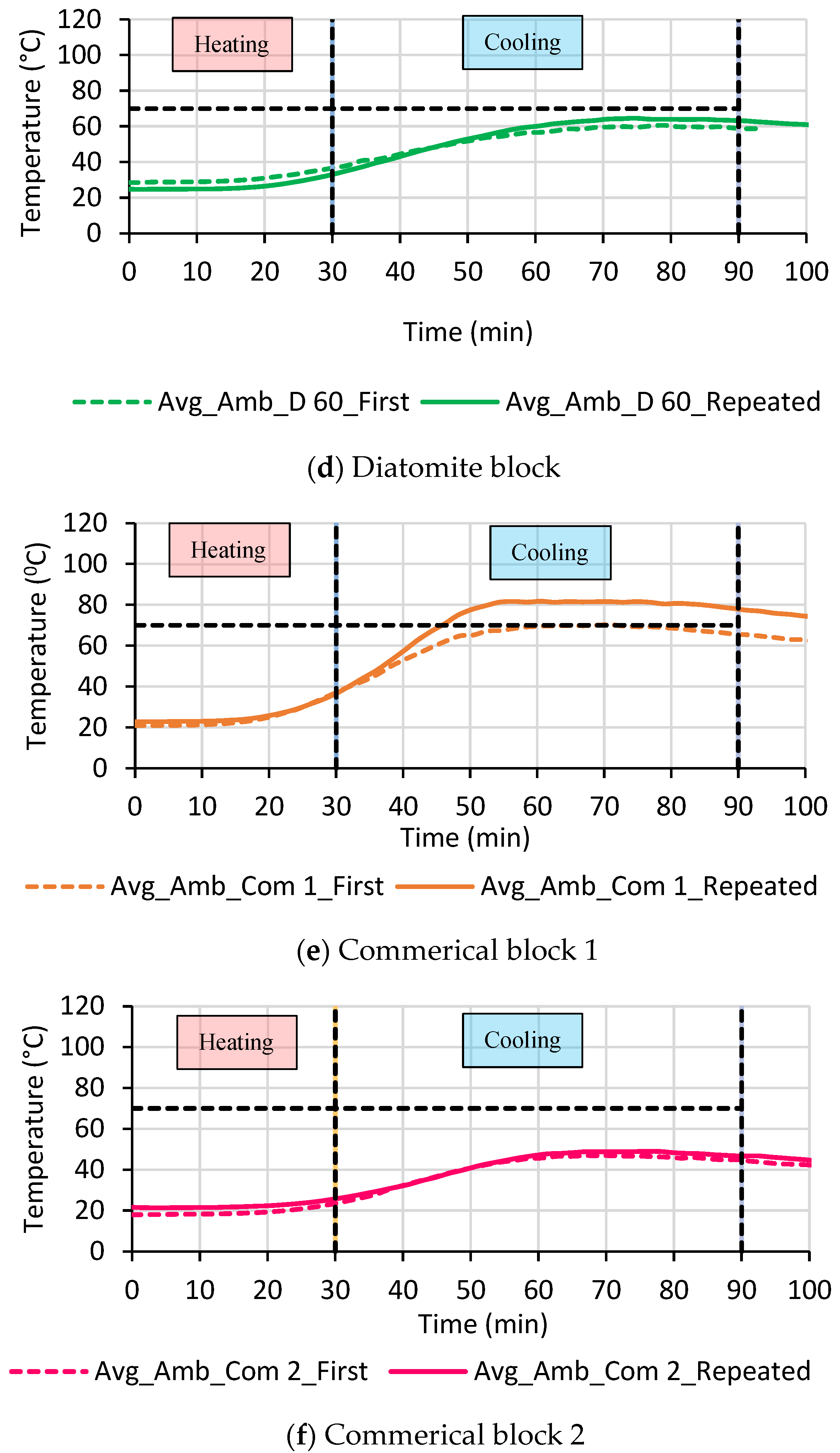

The average ambient-side surface time–temperature curves of the control, EP 60, P 80, D 60, Com 1 and Com 2 blocks recorded during first exposure and repeated bushfire exposure are presented in

Figure 9. During the first bushfire exposure, the time–temperature curves on the ambient side showed three different phases: uniform, rise and drop. A similar trend was also observed in the repeated bushfire-exposed blocks. Here, also, the average temperature on the ambient-side surface at the beginning of the flame almost remained the same for the first 10–20 min. From this point onwards, temperatures increased at different rates up to the maximum average temperature. The average ambient surface temperature rise recorded by the control, EP 60, P 80, D 60, Com 1 and Com 2 blocks was 84, 52, 53, 40, 59 and 27 °C, respectively (

Table 4). Therefore, the control block recorded the highest rise, and thus, the ambient surface temperature rise during the repeated exposure can be reduced with the inclusion of lightweight aggregates. The Com 2 block recorded the lowest rise, and among the lightweight aggregate blocks, the lowest rise was recorded by the D 60 block.

The time taken to record the maximum average ambient surface temperature by the control, EP 60, P 80, D 60, Com 1 and Com 2 blocks was 57, 71, 79, 75, 61 and 78 min, respectively (

Table 4). Therefore, the heating rate during repeated fire exposure can be calculated based on the temperature rise and time spent for the increment. The heating rate of the control, EP 60, P 80, D 60, Com 1 and Com 2 blocks is 1.47, 0.73, 0.67, 0.53, 0.97 and 0.35, respectively. The highest heating rate was recorded by the control block and the Com 2 block recorded the lowest. The heating rate of lightweight aggregate blocks during repeated exposure is at least 50% lower than that of the control block. Among the lightweight aggregate blocks, the lowest heating rate was obtained by the D 60 block, and it was 64% lower than that of the control block and 50 and 54% lower than that of the EP 60 and P 80 blocks, respectively.

The density of the control, Com 1 and Com 2 blocks declines in that order and the same order is followed for the heating rates (

Table 4). Therefore, it seems like the higher the density, the higher the heating rate. However, the density of the EP 60 block is lower than that of the D 60 block, while the EP 60 block recorded a higher heating rate (

Table 4). Therefore, not only the density of the block but also, as mentioned before, the aggregates’ unique properties such as surface texture, pore structure, etc., might have also contributed to the heating rate of the block during repeated exposure.

Furthermore, as shown in

Table 4, the heating rate of the first-time-exposed control, EP 60, P 80, D 60, Com 1 and Com 2 blocks is 1.26, 0.51, 0.64, 0.41, 0.69 and 0.42, respectively. Therefore, after exposing the samples to bushfire once, the heating rate of the repeatedly exposed blocks increases, except for in the case of the Com 2 block (see

Figure 10). This might be due to the morphological changes experienced by the Com 2 block after initial exposure to elevated temperatures that may have subsequently obstructed the heat transfer of the repeatedly exposed block. Similarly to the above trend, the average ambient-side surface temperature rises recorded by all the repeatedly exposed blocks, except the Com 2 block, were higher than the rise recorded during the first-time exposure (see

Figure 10). This might be because all of the non-recoverable thermal reactions and microcracks in the mix have already occurred during the first exposure, and hence, the heat energy absorbed during the repeated exposure is transferred to the ambient-side surface. Therefore, the higher the number of fire exposures, the higher the temperature rise on the ambient surface of the block. Among the lightweight aggregate blocks, the lowest rise in comparison to the first-time exposure was recorded by the D 60 block.

Beyond the maximum value, the average ambient-side surface temperature of all the blocks decreased with time. In the control block, the temperature dropped from 104 to 88 °C between 57 and 90 min. Hence, the cooling rate of the repeatedly exposed control block is approximately 0.49 °C/min. Similarly, the cooling rate of the EP 60, P 80, D 60, Com 1 and Com 2 blocks is 0.26, 0.27, 0.13, 0.17 and 0.17 °C/min, respectively. Therefore, the control and D 60 blocks recorded the highest and lowest cooling rate, respectively. Among the newly developed blocks, the density of the EP 60, D 60 and P 80 blocks increases in this order, but the increment order of their cooling rates is D 60, EP 60 and P 80. Additionally, even though the density of the Com 1 block is higher than that of the Com 2 block, both recorded the same cooling rate. Hence, the cooling rate of the repeatedly exposed block units is also not directly related to the density of the block. Similarly to the heating rate, the cooling rate of repeatedly exposed blocks might also have been affected by the aggregate’s surface and internal structural characteristics. As shown in

Figure 10, the cooling rate of repeatedly exposed blocks is always lower than the heating rates. In comparison to the cooling rate of first-time-exposed blocks, the cooling rate of repeatedly exposed blocks is higher, except in D 60 and Com 1 blocks.

Throughout the 90 min test period, no sustained flame was observed on either side of all the tested blocks and no gaps greater than 3 mm appeared as a result of fire exposure to the ambient side. Also, none of the blocks failed as a result of insulation. However, surface cracks were observed on the fire-exposed side of all the blocks, except for the Com 1 block, and no ambient-side surface cracks were observed in the control, EP 60, Com 1 and Com 2 blocks (

Figure 8). In comparison to the first-time-tested blocks, no difference in surface crack intensity was noticed on the control, P 80 and Com 2 blocks. However, surface crack intensity was comparatively higher in repeatedly exposed EP 60 and D 60 blocks.

Considering the temperature limits of a bushfire shelter stated in the Australian Building Codes Board (ABCB) performance standard, the allowable temperature for the unguarded interior surfaces should be up to 70 °C [

29]. Among the repeatedly exposed blocks, only the D 60 and Com 2 blocks did not exceed this limit during the testing period. However, the control, EP 60, P 80 and Com 1 blocks surpassed this value at 32, 57, 65 and 46 min, respectively. In comparison to the first-time-exposed blocks, the repeatedly exposed EP 60, P 80 and Com 1 blocks reached the temperature limit much faster or at the same duration. Therefore, the ability of most of the blocks to withstand the bushfire effects diminishes with increased number of exposures. This might be due to microstructural cracking and bonding loss from initial thermal loading. Therefore, considering the satisfaction of the bushfire shelters’ interior surface temperature limit, D 60 and Com 2 blocks are able to remain safe against bushfire flame zone conditions even after the initial bushfire exposure.

3.3. Residual Compressive Strength

The density and compressive strength properties of all the blocks are shown in

Table 5. Ariyaratne [

23] provides the average ambient compressive strength of all the blocks.

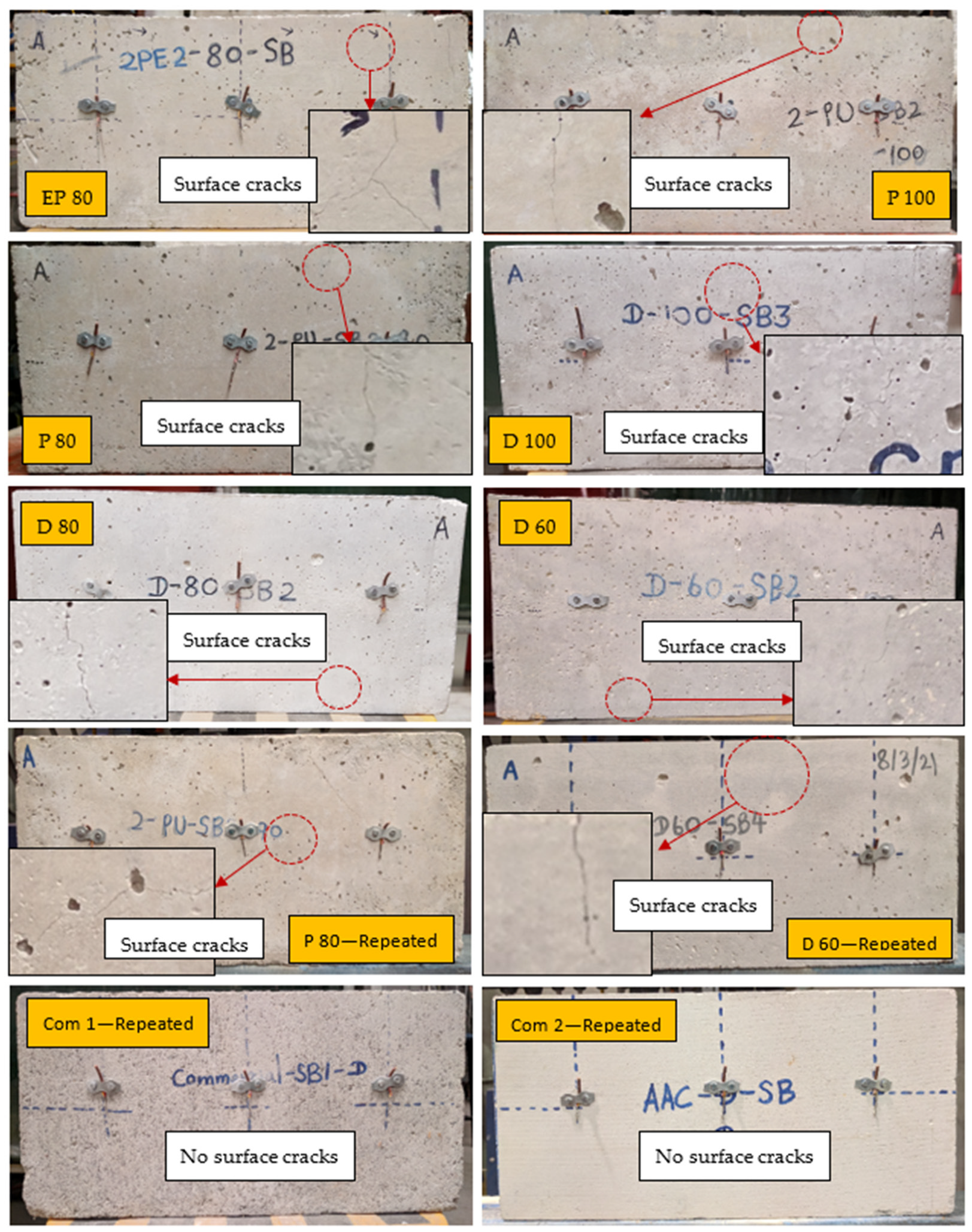

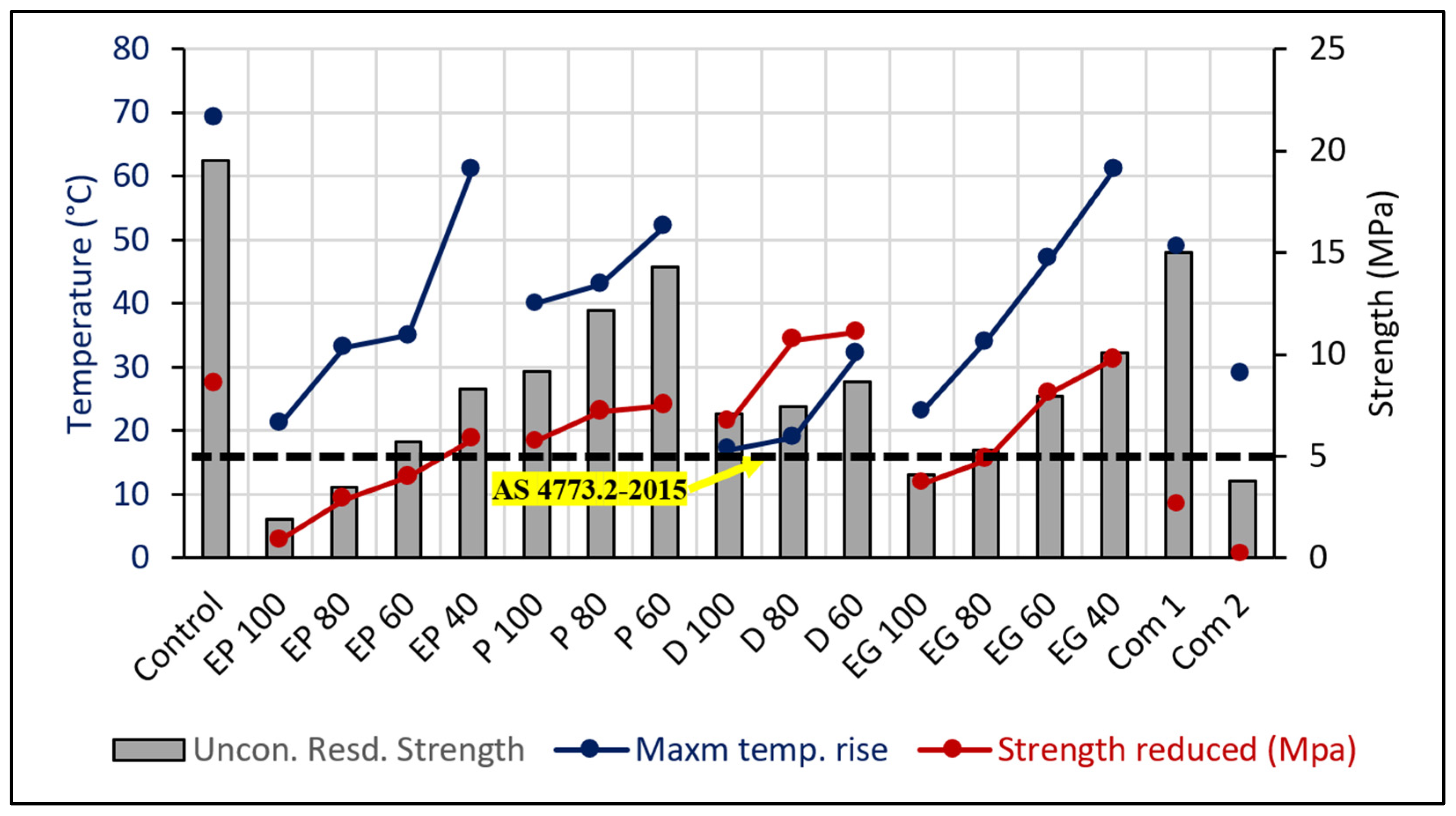

3.4. After First Exposure

The residual compressive strength of the control block after first exposing it to bushfire flame zone conditions was 25.0 MPa. Its ambient compressive strength was 33.6 MPa, and thus, the strength reduction due to fire exposure was 8.6 MPa. Similarly, the strength reduction in the EP, P, D and EG blocks was in the range between 0.9 and 5.8, 5.8 and 7.5, 6.7 and 11.1 and 3.6 and 9.7 MPa, respectively (

Table 5). The strength reduction was 2.6 and 0.2 MPa, respectively, for Com 1 and Com 2 blocks. The D 60 block recorded the highest and Com 2 block recorded the lowest strength reduction.

Figure 11 shows the unconfined residual compressive strength, strength reduction and average ambient surface temperature rise achieved by each block. Generally, when concrete is exposed to elevated temperatures, its compressive strength is reduced due to an increase in porosity with the decomposition of dehydration products and the formation of microcracks because of thermal incompatibility between the cement paste and aggregates [

14,

33]. Comparing the newly developed lightweight aggregate blocks and the control block, the strength was greatly reduced in the control block, more than in most of the other blocks, which implies the improved fire resistance in terms of strength with the inclusion of lightweight aggregates in the block. Also, it was noticed that for each lightweight aggregate-type block, the lower the lightweight aggregate percentage, the higher the strength reduction due to bushfire exposure. In other words, with the increase in density of the block, the strength reduction increases. As shown in

Figure 11, one of the reasons is that the ambient temperature rise recorded by the block increases with an increase in density or a reduction in lightweight aggregate percentage. Thus, the possibility of adversely affecting the physical and chemical properties of blocks is higher, resulting in a low strength. For example, the Com 1 block density is higher than that of the Com 2 block, and hence, the maximum ambient temperature recorded by the Com 1 block is also higher, resulting in increased strength reduction compared to the Com 2 block. However, for lightweight aggregate blocks, this pattern is only valid for the same lightweight aggregate blocks. Even though the D 60 block density and ambient temperature rise are lower than those of the P 60 block, its strength reduction was the highest. This might be because of some unique properties associated with the aggregate such as surface texture, particle strength, bond characteristics between cement paste and aggregates, etc. Therefore, it seems that not only the density and temperature of the block but also the aggregate type affects the residual strength of the fire-exposed blocks.

When comparing the strength reduction in lightweight aggregate blocks with the same aggregate content, expanded perlite aggregate is the most effective at sustaining strength when exposed to elevated temperatures, followed by the expanded glass aggregate. Between pumice and diatomite aggregates, pumice aggregates are more capable of maintaining strength against fire.

Considering the failure patterns observed during the residual compressive strength test of the blocks, in most cases, crack propagation and intensity are higher closer to the fire-exposed side of the block (see

Figure 12). This is because the fire-exposed side and its nearby regions are exposed to more elevated temperatures compared to the ambient side, and hence, the degradation of strength is relatively greater on the fire-exposed side.

The AS 4773.2-2015 standard specifies that the unconfined strength requirement for solid loadbearing masonry units is 5 MPa (

Table 5). Before exposure to fire, all of the blocks were loadbearing except for the EP 100 and Com 2 blocks. After initial exposure to bushfire flame zone conditions, the ambient compressive strength of all the blocks was reduced and the residual strength of the EP 80 and EG 100 blocks also did not satisfy the loadbearing strength requirement. All the other blocks complied with the loadbearing strength requirement after initial exposure to bushfire flame zone conditions.

3.5. After Repeated Exposure

Repeated bushfire exposure was only tested for the control, EP 60, P 80, D 60, Com 1 and Com 2 blocks.

Figure 13 shows the unconfined residual compressive strength of the repeatedly exposed blocks and the strength reduction in each block after the second bushfire exposure. The highest unconfined residual strength after the repeated exposure was recorded by the control block (i.e., 16 MPa). The unconfined residual strength of EP 60, P 80, D 60, Com 1 and Com 2 blocks after the repeated exposure was 5.6, 12.2, 8.3, 14.4 and 3.0 MPa, respectively. Hence, the strength reduction in repeatedly exposed blocks from the first-time-exposed block is 3.5, 0.1, 0.0, 0.4, 0.6 and 0.8 MPa, respectively, for the control, EP 60, P 80, D 60, Com 1 and Com 2 blocks. In terms of percentage, the strength reduction from the first-time fire-exposed control, EP 60, P 80, D 60, Com 1 and Com 2 blocks due to repeated exposure is 17.7, 2.1, 0.0, 3.9, 4.0 and 22.8%, respectively. Therefore, strength was highly reduced in the Com 2 block as a result of repeated exposure, whereas the opposite behavior was observed during the first exposure. Among the control and newly developed lightweight aggregate blocks, strength was highly reduced in the control block, which was the same observation made during the first-time exposure (i.e., improved fire resistance against strength with the inclusion of lightweight aggregates in the block).

As shown in

Figure 13, even though the difference between the average ambient surface temperature rises in first-time-exposed and repeatedly exposed EP blocks was the highest, the strength reduction was almost zero (i.e., 0.1 MPa). Similarly, pumice and diatomite blocks recorded a difference between temperature rise in first-time-exposed and repeatedly exposed blocks, but the strength reduction was almost zero (i.e., 0.0 and 0.4 MPa). Even though the ambient surface temperature rise difference between the first and repeated exposures was the same for the pumice and Com 1 blocks, the strength was only reduced in the Com 1 block. In contrast to the above behavior, ambient surface temperature rise in the Com 2 block was almost the same during first and repeated exposures, but its strength was reduced by 22.8%. Therefore, all the lightweight aggregate-based blocks are more effective at sustaining strength during repeated exposure.

In addition, when we consider the unconfined strength reduction in the blocks after the first exposure, it was 6.7, 3.1, 5.4, 8.6, 2.6 and 0.2 MPa for the control, EP 60, P 80, D 60, Com 1 and Com 2 blocks, respectively. Hence, in comparison to the strength reductions in first-time fire-exposed blocks due to repeated exposure, the control, EP 60, P 80, D 60, Com 1 blocks reduced their strengths by a lower value compared to the first-time-exposed blocks. For example, unconfined strength reduction in the control block due to first-time fire exposure was 6.7 MPa, and from that point onwards, strength was reduced by 3.5 MPa due to repeated exposure. This might be because the pore structure of the mix had already been changed during the first exposure, and hence, no more severe changes occurred during the repeated exposure, which affected the compressive strength. In contrast, strength reduction in the Com 2 block due to first-time fire exposure was 0.2 MPa, but strength was reduced by 0.8 MPa due to repeated exposure. Therefore, even the Com 2 block shows better resistance in terms of ambient surface temperature, while compressive strength is adversely affected by an increase in the number of exposures. Hence, newly developed lightweight blocks show better strength resistance against repeated fire exposure than the commercial blocks.

After the first-time fire exposure, cracks occurred in the blocks due to the compression test and these were mostly observed on/closer to the fire-exposed side. However, considering the compression failure patterns observed for the repeatedly fire-exposed blocks, as shown in

Figure 12, cracks were observed on both the fire and ambient sides of all the blocks, except for the D 60 block. In the D 60 block, compression cracks were propagated only closer to the fire-exposed side.

After exposing samples to the bushfire repeatedly, the residual strength of the control, EP 60, P 80, D 60 and Com 1 blocks was more than 5 MPa. Therefore, all these blocks maintained loadbearing strength even after the repeated bushfire exposure [

35]. However, the unconfined residual strength of the Com 2 block was 3.0 MPa, and thus, it satisfies the non-loadbearing strength requirement after repeated exposure.

Overall, considering the control block, the best block from each aggregate type, such as EP 60, P 80 and D 60 blocks, and two commercial blocks, only the EP 60, D 60 and Com 2 blocks satisfied the standard temperature limit for the unguarded surfaces of a bushfire shelter after one-time exposure to the bushfire flame zone conditions. This temperature limit was again satisfied only by the D 60 and Com 2 blocks, when all the above fire-tested blocks were exposed again to the bushfire flame zone conditions. Also, among the newly developed blocks, the lowest average ambient-side surface temperature rises during the first-time and repeated bushfire exposures was recorded by the D 60 block. In terms of the residual strength of first-time fire-exposed blocks, the ambient strength of the D 60 block was greatly reduced compared to the Com 2 block. However, the D 60 block’s residual strength complied with the standard requirement for loadbearing solid masonry units. In contrast, the strength of the Com 2 block comparatively reduced after the repeated exposure and satisfied the strength requirement for non-loadbearing masonry units. Strength reduction in the D 60 block was almost zero due to the repeated exposure and thus continued to be loadbearing, and no ambient side cracks were propagated during the compression test as well. Finally, based on the compliance of the temperature limit stated for the bushfire shelters and loadbearing strength requirement after first-time and repeated bushfire exposures, the D 60 block is more suitable to be used in the external walls of bushfire shelters and other buildings in bushfire-prone areas.