Fire Resistance and Mechanical Properties of Wooden Dou-Gong Brackets in Chinese Traditional Architecture Exposed to Different Fire Load Levels

Abstract

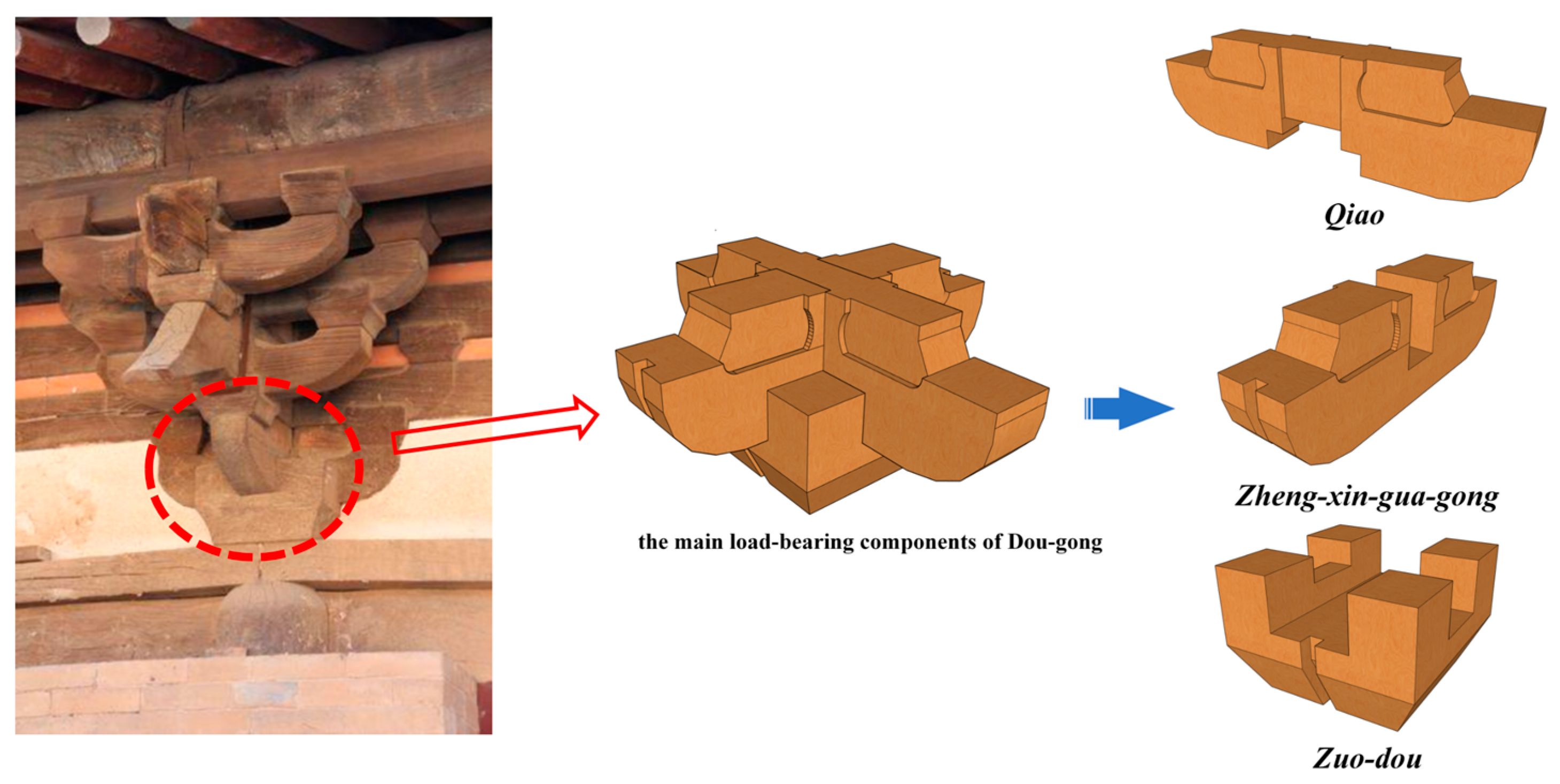

1. Introduction

2. Experimental

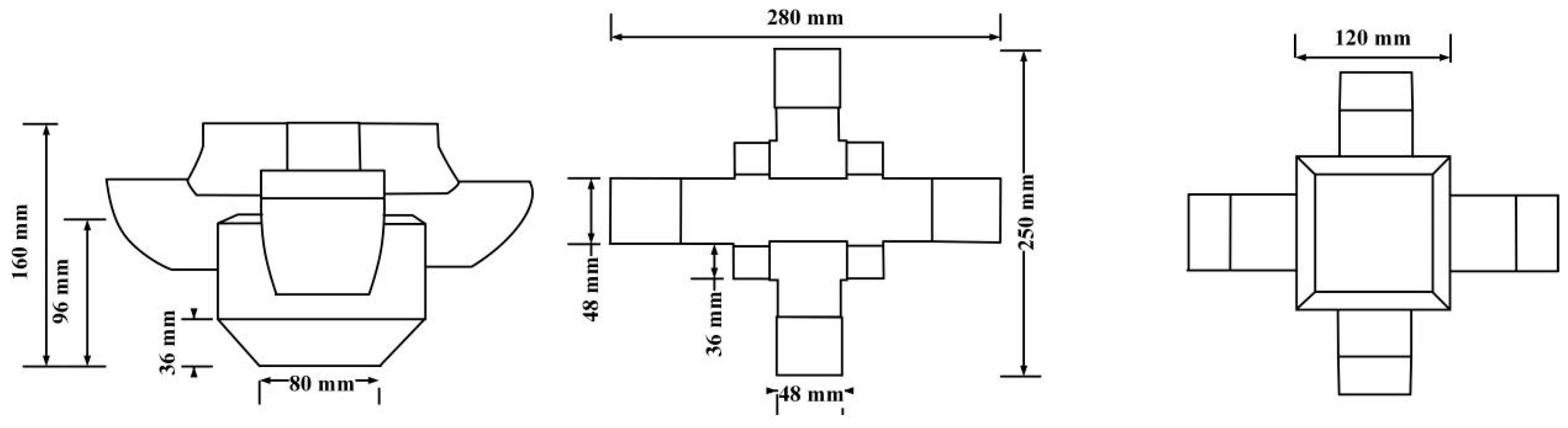

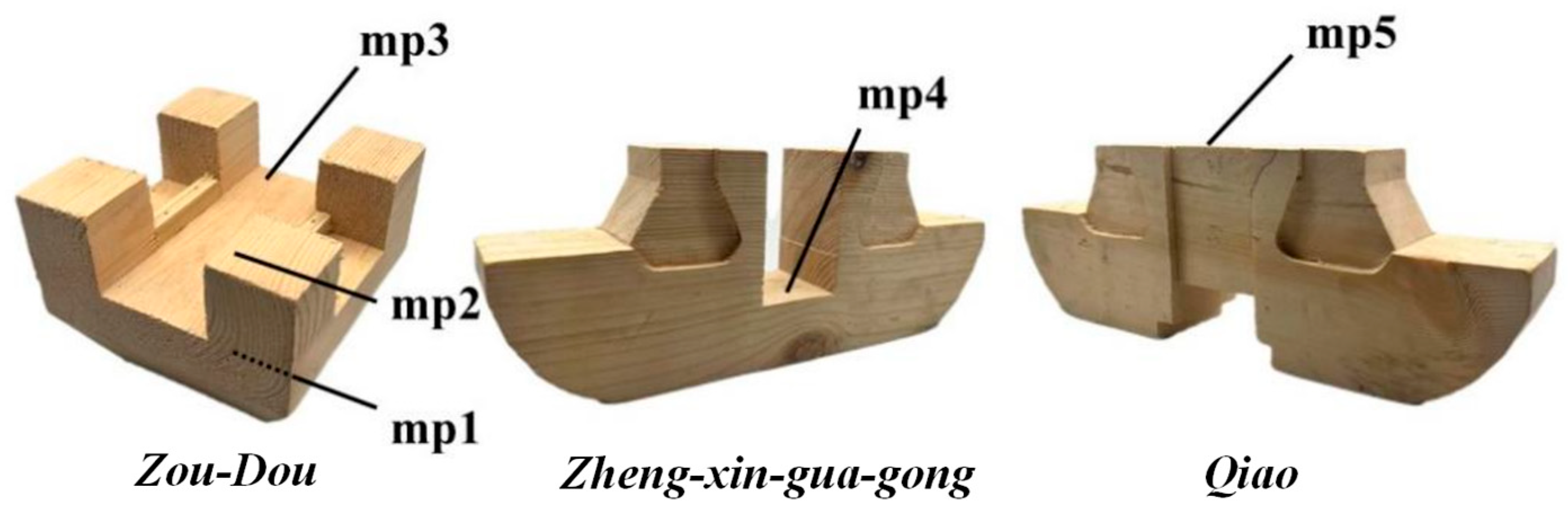

2.1. Materials

2.2. Fire Source Setting

2.3. Fire Source Location Determination

2.4. Fire Resistance Test

2.5. Residual Bearing Capacity Test

3. Results and Discussion

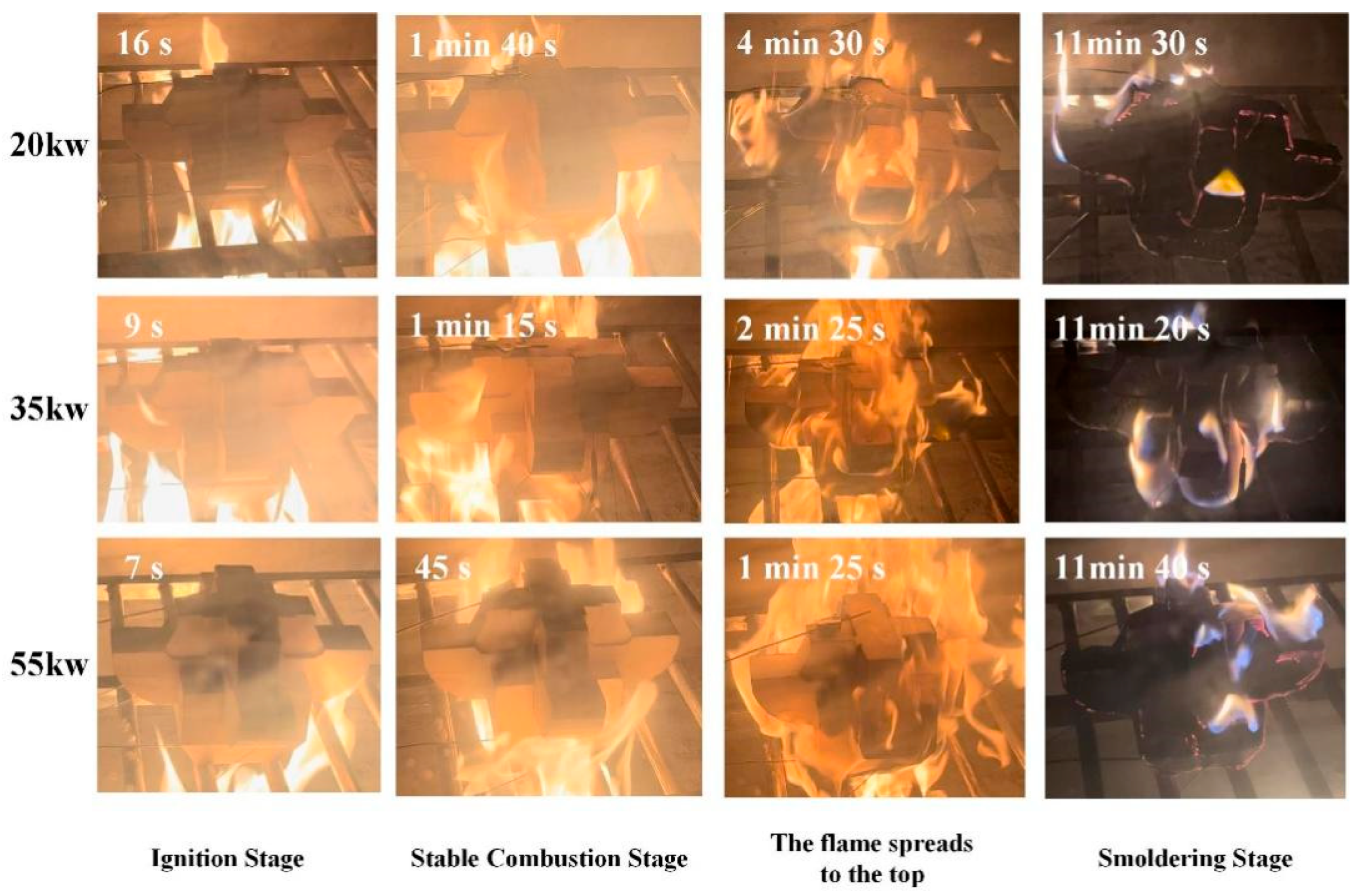

3.1. Combustion Process Analysis

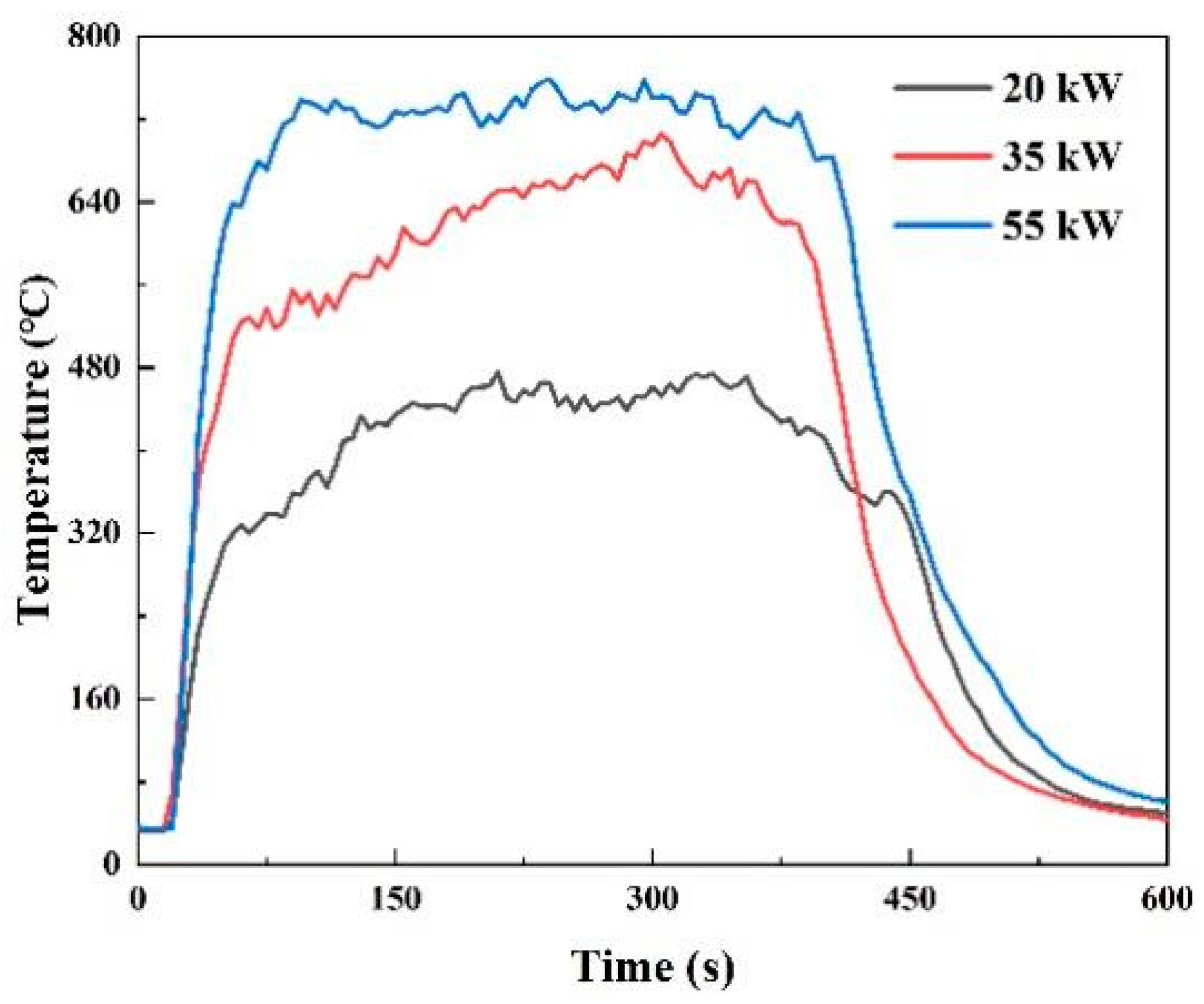

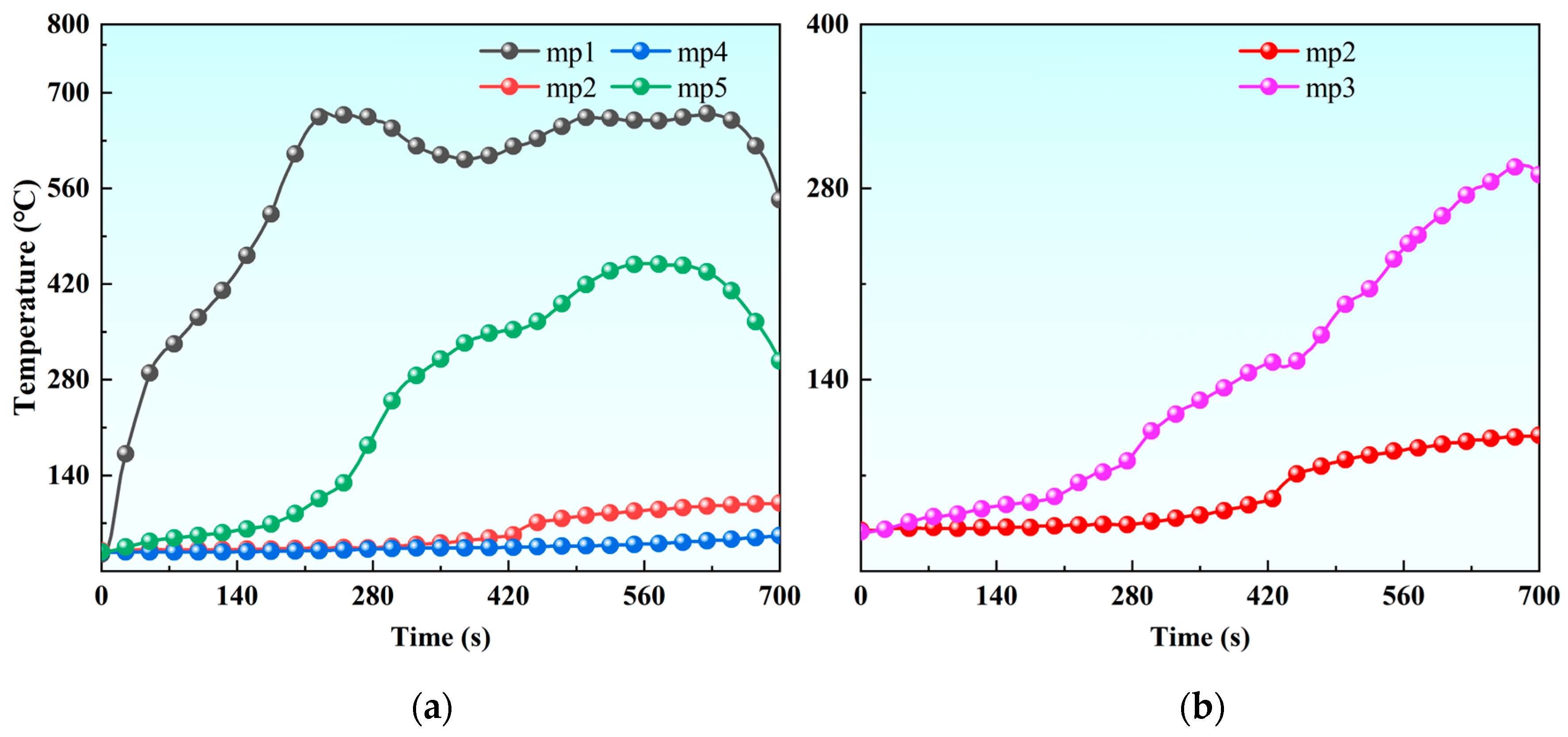

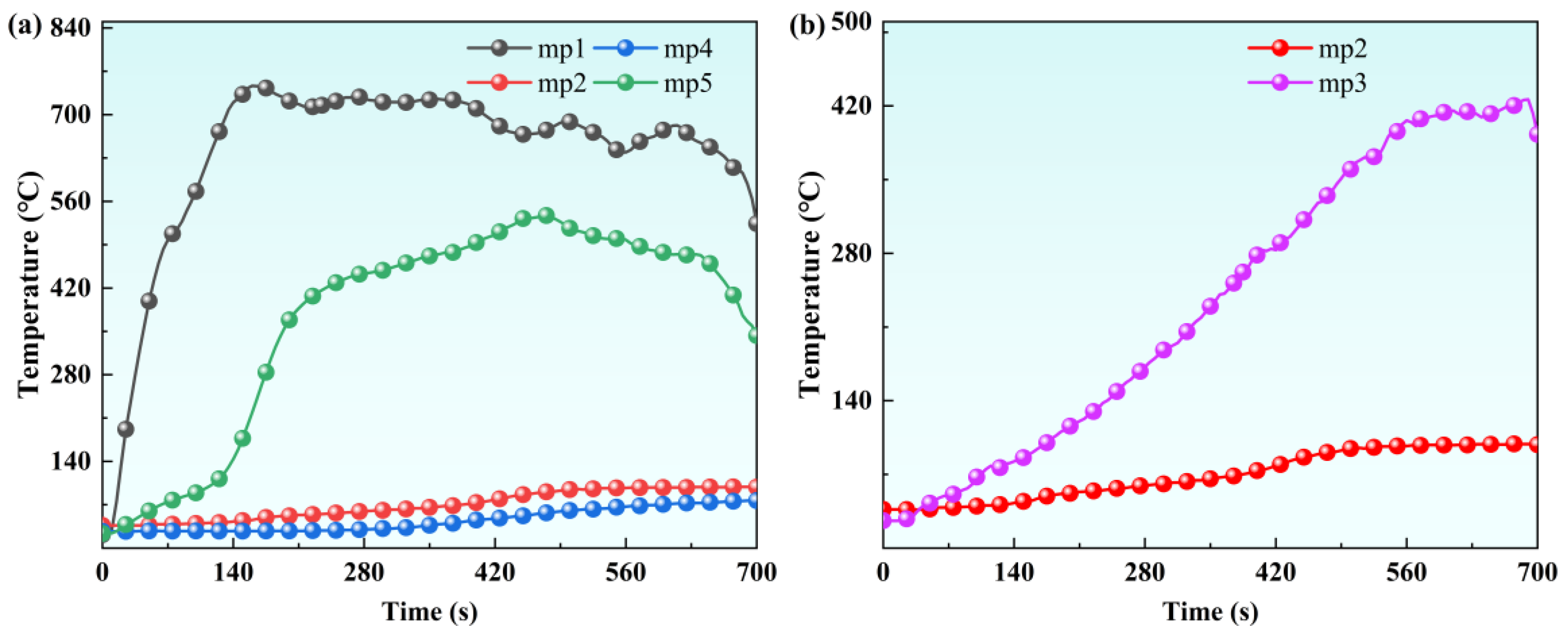

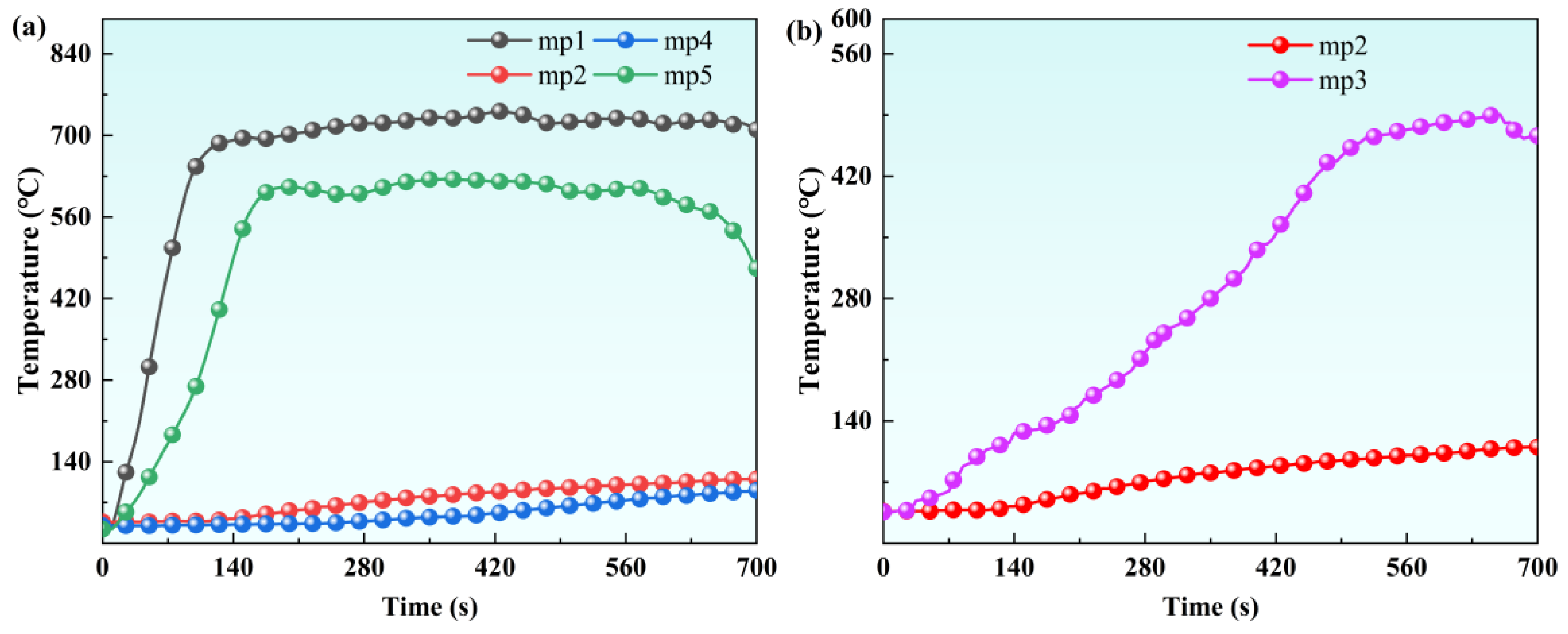

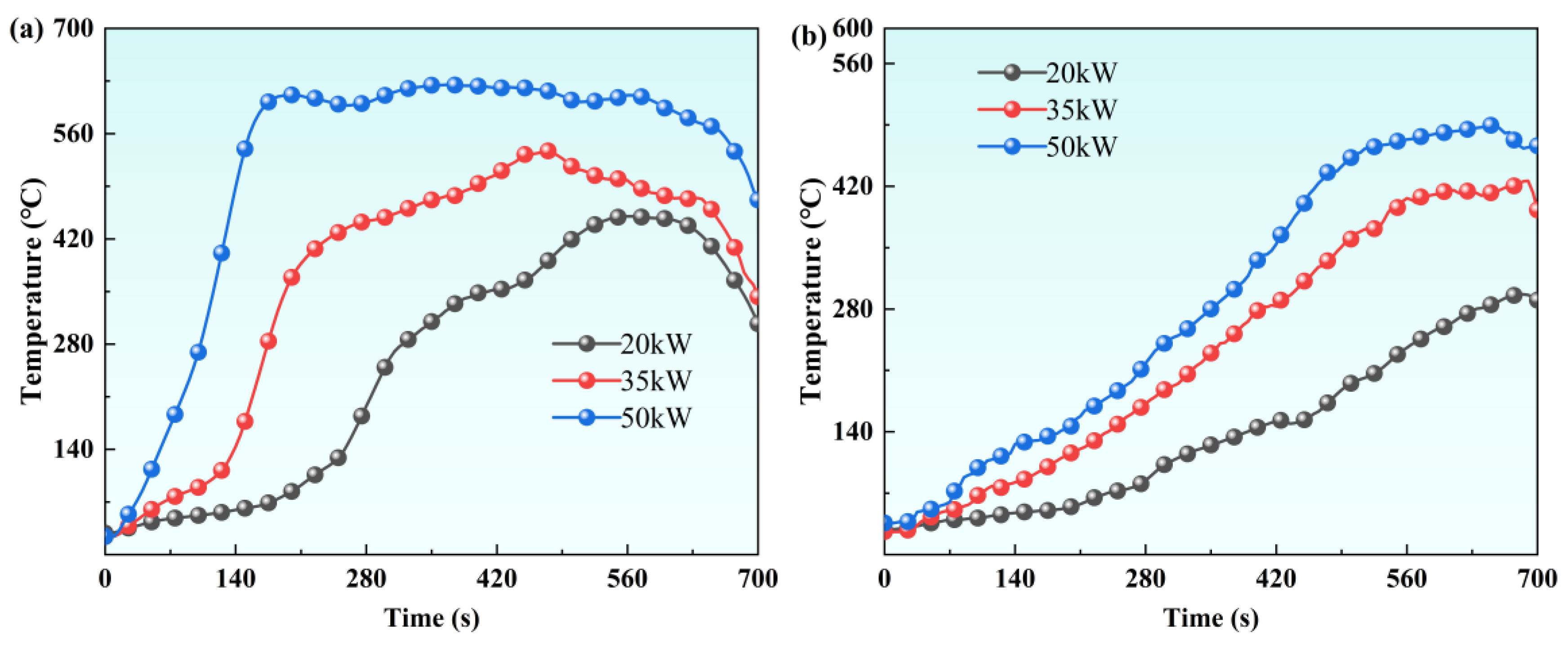

3.2. Combustion Temperature Analysis

3.3. Charring Behavior Analysis

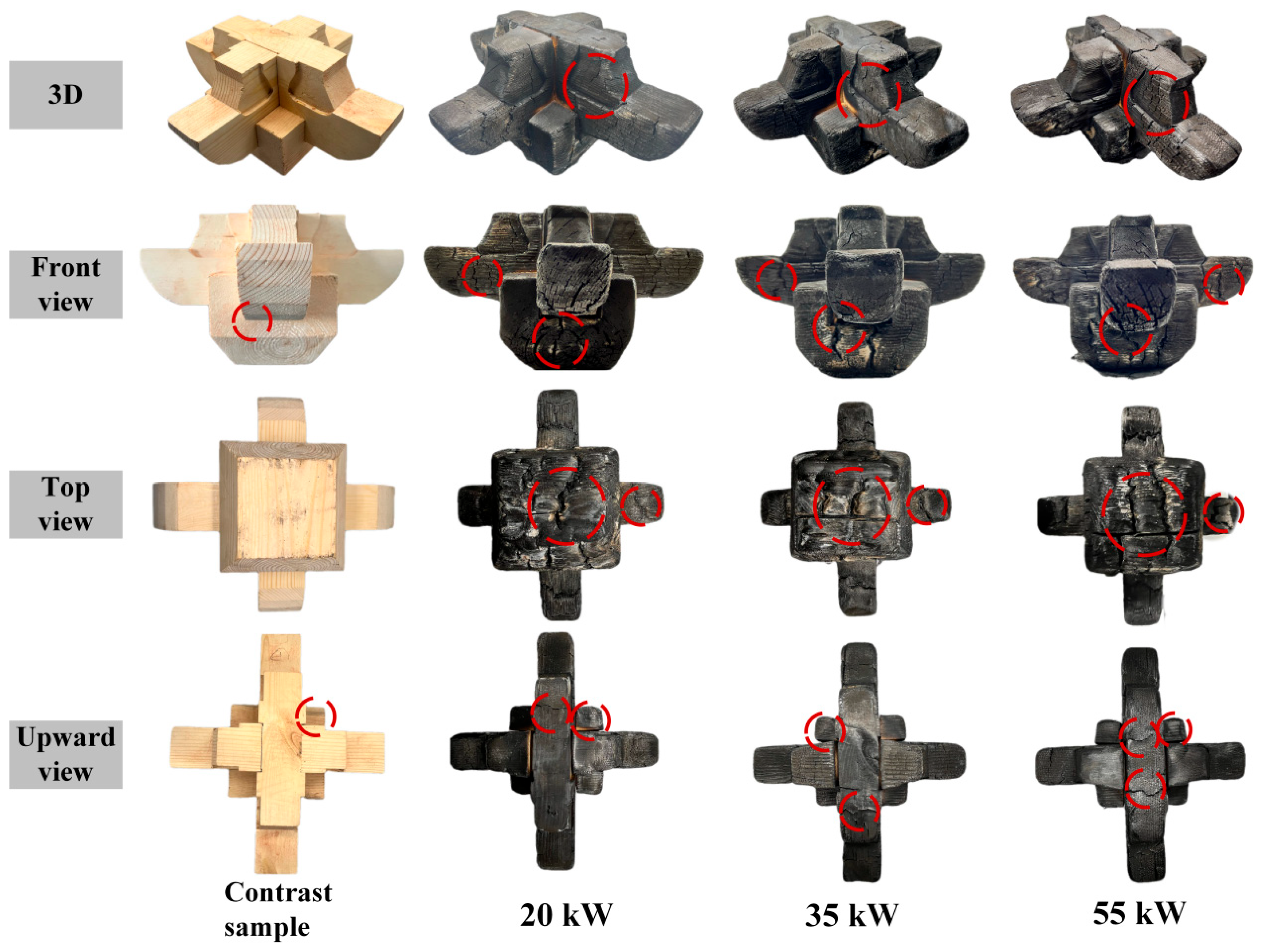

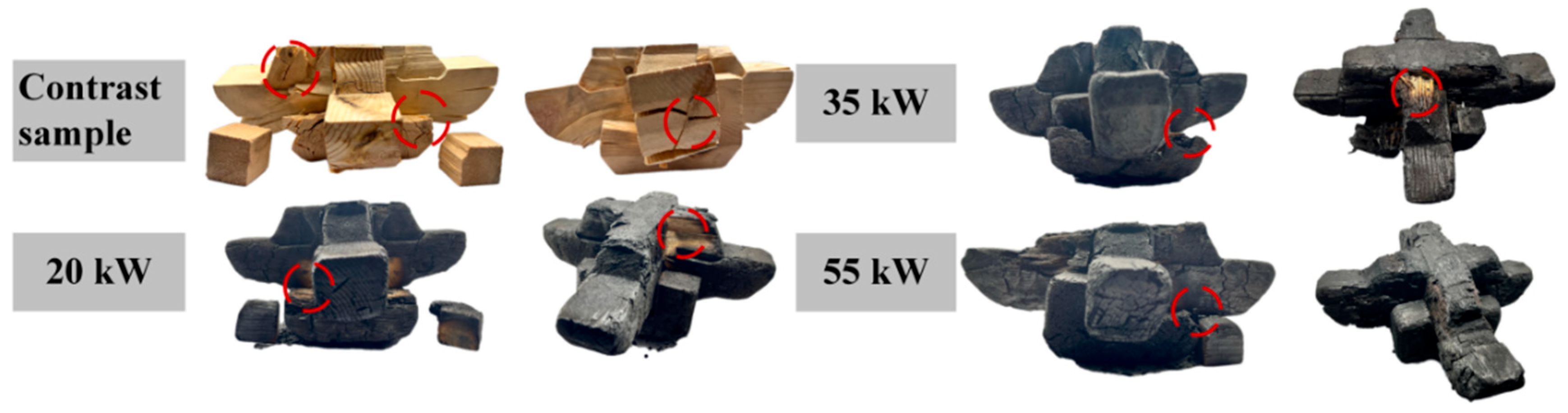

3.4. Residual Bearing Capacity Analysis

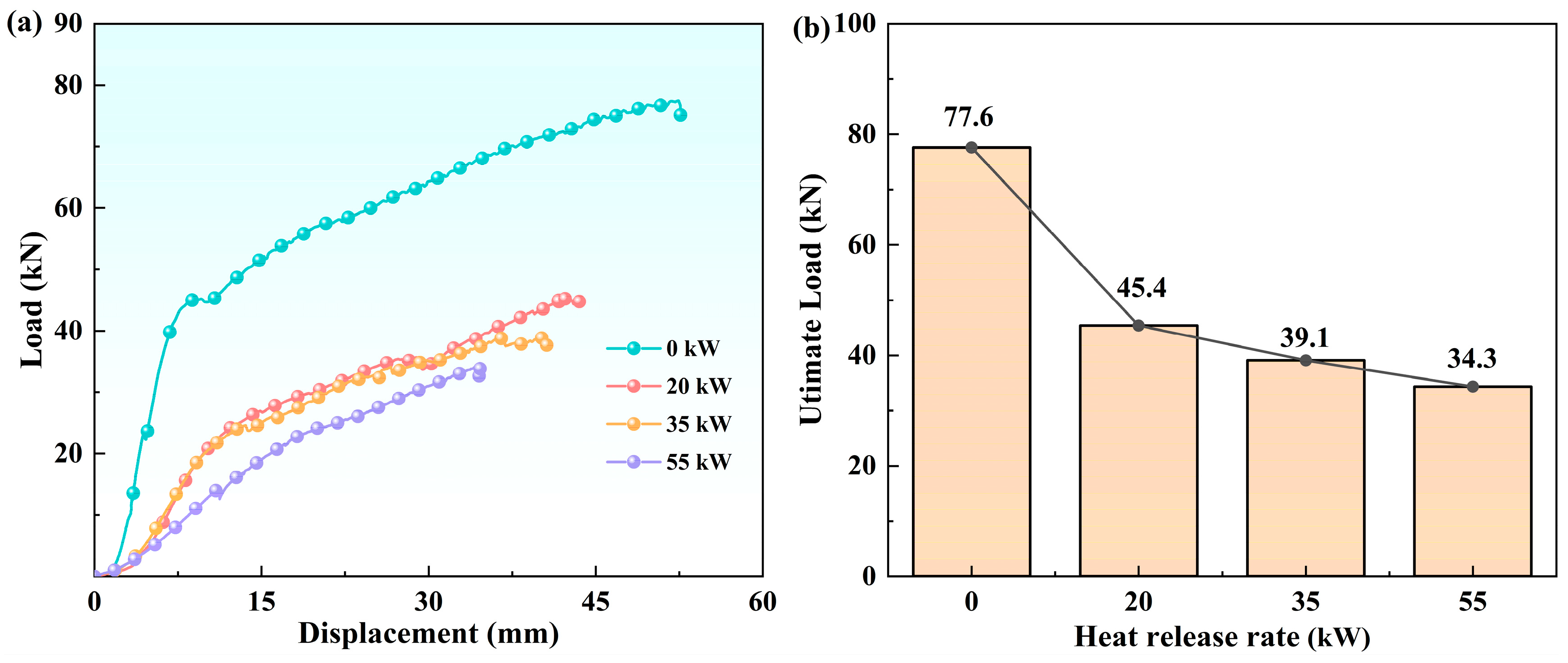

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schnabl, S.; Turk, G.; Planinc, I. Buckling of timber columns exposed to fire. Fire Saf. J. 2011, 46, 431–439. [Google Scholar] [CrossRef]

- Firmanti, A.; Subiyanto, B.; Kawai, S. Evaluation of the fire endurance of mechanically graded timber in bending. J. Wood Sci. 2006, 52, 25–32. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Z.; Xu, Y.; Ma, S.; Xu, Q. An experimental and numerical study on the charring rate of timber beams exposed to three-side fire. Sci. China Technol. Sci. 2012, 55, 3434–3444. [Google Scholar] [CrossRef]

- Babrauskas, V. Charring rate of wood as a tool for fire investigations. Fire Saf. J. 2005, 40, 528–554. [Google Scholar] [CrossRef]

- Gernay, T.; Franssen, J.-M. A performance indicator for structures under natural fire. Eng. Struct. 2015, 100, 94–103. [Google Scholar] [CrossRef]

- Yang, T.-H.; Wang, S.-Y.; Tsai, M.-J.; Lin, C.-Y. The Charring Depth and Charring Rate of Glued Laminated Timber after a Standard Fire Exposure Test. Build. Environ. 2009, 44, 231–236. [Google Scholar] [CrossRef]

- Wu, C.; Xue, J.; Song, D.; Liang, X. Analysis on the mechanical performance of Dougong bracket sets under eccentric vertical load. Constr. Build. Mater. 2022, 314, 125652. [Google Scholar] [CrossRef]

- Zhang, L.; Dong, W.; Zhou, T. Study on the mechanical characteristics of Xia-Ang in the Song-style Dou-Gong brackets set on columns. Structures 2022, 41, 475–487. [Google Scholar] [CrossRef]

- Friedrich, D. Comparative study on artificial and natural weathering of wood-polymer compounds: A comprehensive literature review. Case Stud. Constr. Mater. 2018, 9, e00196. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Zhou, H.; Qi, F. Burning Characteristics of Ancient Wood from Traditional Buildings in Shanxi Province. China. Forests 2022, 13, 190. [Google Scholar] [CrossRef]

- Yan, L.; Tang, X.; Xu, Z.; Xie, X. Fabrication of talc reinforced transparent fire-retardant coating towards excellent fire protection, antibacterial, mechanical and anti-ageing properties. Polym. Degrad. Stab. 2022, 203, 110074. [Google Scholar] [CrossRef]

- Frangi, A.; Erchinger, C.; Fontana, M. Charring model for timber frame floor assemblies with void cavities. Fire Saf. J. 2008, 43, 551–564. [Google Scholar] [CrossRef]

- Zhang, A.; Xia, L.; Li, X.; Qing, Y.; Wu, Y. In-situ synthesized phosphorus–boron–magnesium hybrid flame retardants with core-shell structures in wood microstructures: An effective strategy for realizing durable fire retardancy, smoke suppression, and anti-degradation. Compos. Part B Eng. 2024, 283, 111630. [Google Scholar] [CrossRef]

- Long, M.; Yi, L.; Yan, L.; Xu, Z.; Zheng, J. Comparative analysis of microstructure, combustion characteristics and mechanical properties of Pinus massoniana lamb. under natural aging conditions. Therm. Sci. Eng. Prog. 2024, 48, 102425. [Google Scholar] [CrossRef]

- Song, X.; Lu, Y.; Peng, Y.; Zhang, Y.; Zhou, H. Sequentially coupled thermal-stress analysis of traditional timber mortise-tenon joints with damage. J. Build. Eng. 2024, 86, 108781. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, J.; Shen, H. Residual compressive load-carrying capacity of cross-laminated timber walls after exposed to one-side fire. J. Build. Eng. 2021, 34, 101931. [Google Scholar] [CrossRef]

- Wiesner, F.; Hadden, R.; Deeny, S.; Bisby, L. Structural fire engineering considerations for cross-laminated timber walls. Constr. Build. Mater. 2022, 323, 126605. [Google Scholar] [CrossRef]

| Fire Load (kW) | Component Name | D (mm) | t (min) | v (mm/min) |

|---|---|---|---|---|

| 20 | Zuo-dou | 3.0 | 11.5 | 0.26 |

| Zheng-xin-gua-gong | 2.8 | 0.24 | ||

| Qiao | 2.5 | 0.22 | ||

| 35 | Zuo-dou | 5.0 | 11.3 | 0.44 |

| Zheng-xin-gua-gong | 4.5 | 0.40 | ||

| Qiao | 5.0 | 0.44 | ||

| 55 | Zuo-dou | 6.5 | 11.7 | 0.56 |

| Zheng-xin-gua-gong | 5.8 | 0.50 | ||

| Qiao | 6.0 | 0.51 |

| Fire Load (kW) | Component Name | m1 (g) | m2 (g) | w (%) | wall (%) |

|---|---|---|---|---|---|

| 20 | Zuo-dou | 413.7 | 287.1 | 30.6 | 28.5 |

| Zheng-xin-gua-gong | 301.1 | 219.9 | 27.0 | ||

| Qiao | 398.5 | 288.5 | 27.6 | ||

| 35 | Zuo-dou | 412.3 | 262.2 | 36.4 | 33.9 |

| Zheng-xin-gua-gong | 295.2 | 201.7 | 31.7 | ||

| Qiao | 387.1 | 259.4 | 33.0 | ||

| 55 | Zuo-dou | 411.9 | 255.0 | 38.1 | 36.9 |

| Zheng-xin-gua-gong | 321.6 | 211.3 | 34.3 | ||

| Qiao | 403.6 | 250.7 | 37.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, Z.; Li, X.; Long, M.; Yan, L.; Xu, Z. Fire Resistance and Mechanical Properties of Wooden Dou-Gong Brackets in Chinese Traditional Architecture Exposed to Different Fire Load Levels. Fire 2025, 8, 201. https://doi.org/10.3390/fire8050201

Lai Z, Li X, Long M, Yan L, Xu Z. Fire Resistance and Mechanical Properties of Wooden Dou-Gong Brackets in Chinese Traditional Architecture Exposed to Different Fire Load Levels. Fire. 2025; 8(5):201. https://doi.org/10.3390/fire8050201

Chicago/Turabian StyleLai, Zhenzhong, Xin Li, Miaotian Long, Long Yan, and Zhisheng Xu. 2025. "Fire Resistance and Mechanical Properties of Wooden Dou-Gong Brackets in Chinese Traditional Architecture Exposed to Different Fire Load Levels" Fire 8, no. 5: 201. https://doi.org/10.3390/fire8050201

APA StyleLai, Z., Li, X., Long, M., Yan, L., & Xu, Z. (2025). Fire Resistance and Mechanical Properties of Wooden Dou-Gong Brackets in Chinese Traditional Architecture Exposed to Different Fire Load Levels. Fire, 8(5), 201. https://doi.org/10.3390/fire8050201