Experimental Study on Fire Resistance of Phase Change Energy Storage Concrete Partition Walls

Abstract

1. Introduction

2. Materials and Methods

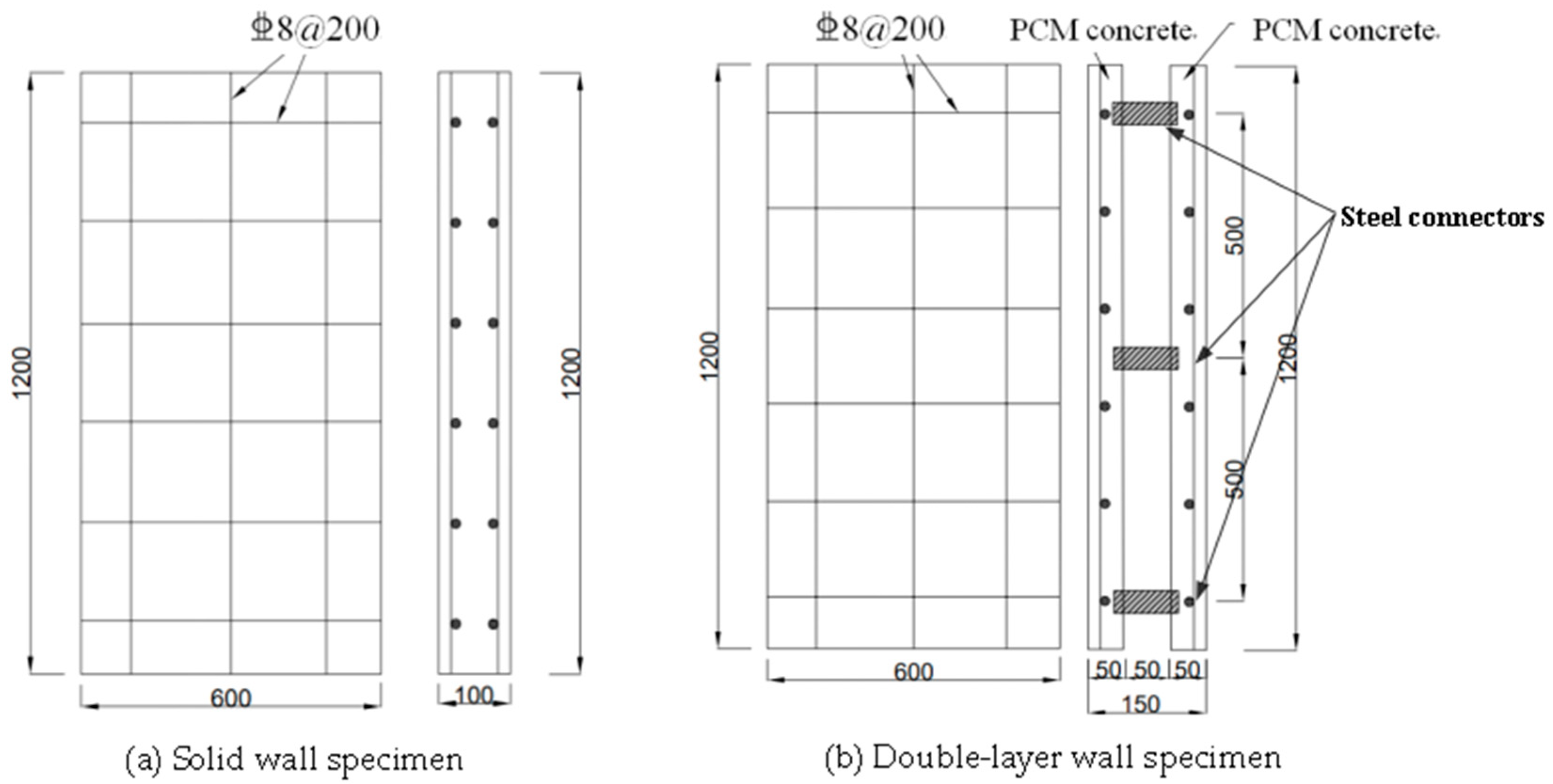

2.1. Specimen Design

2.2. Specimen Production

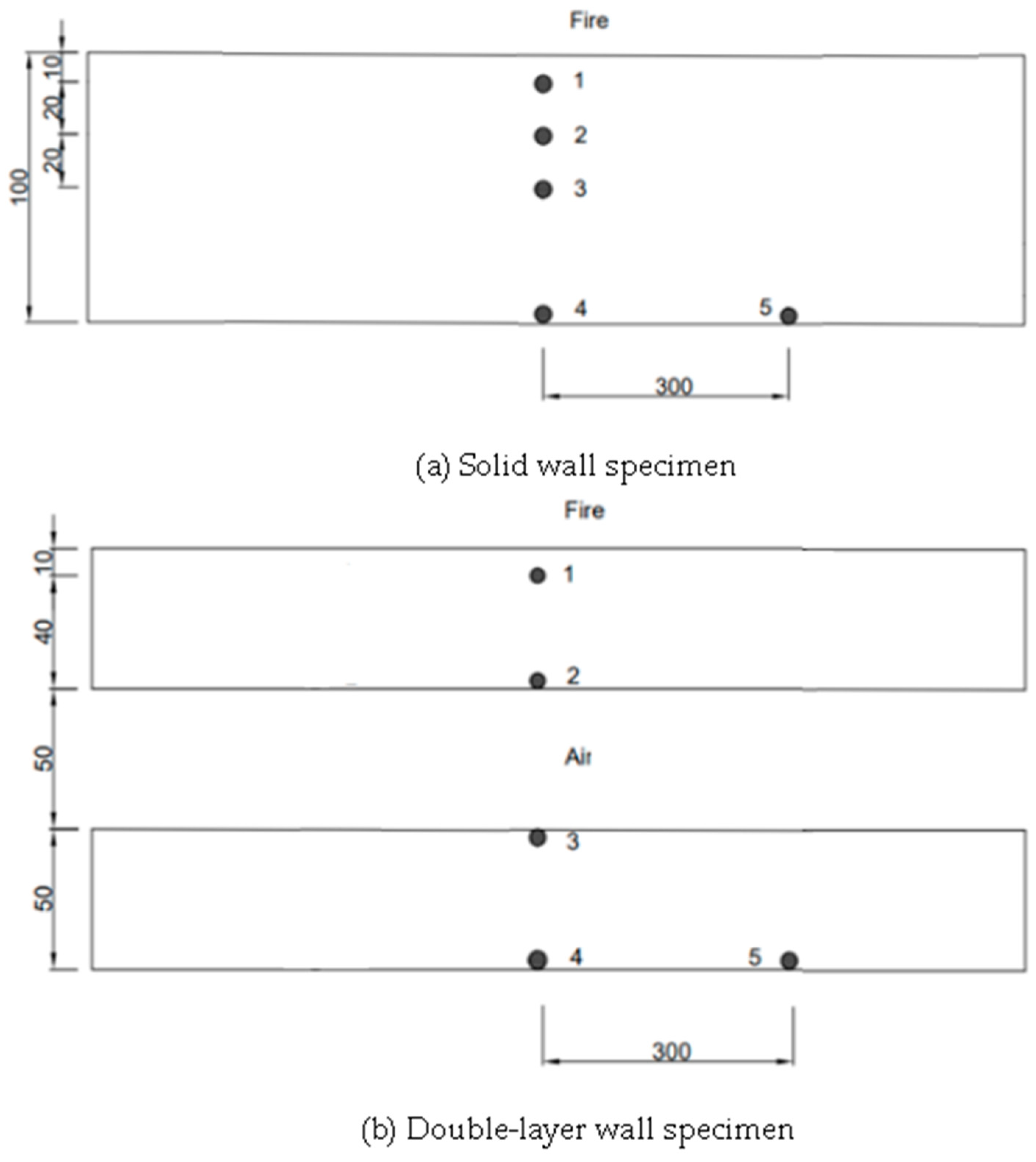

2.3. Thermocouple Layout

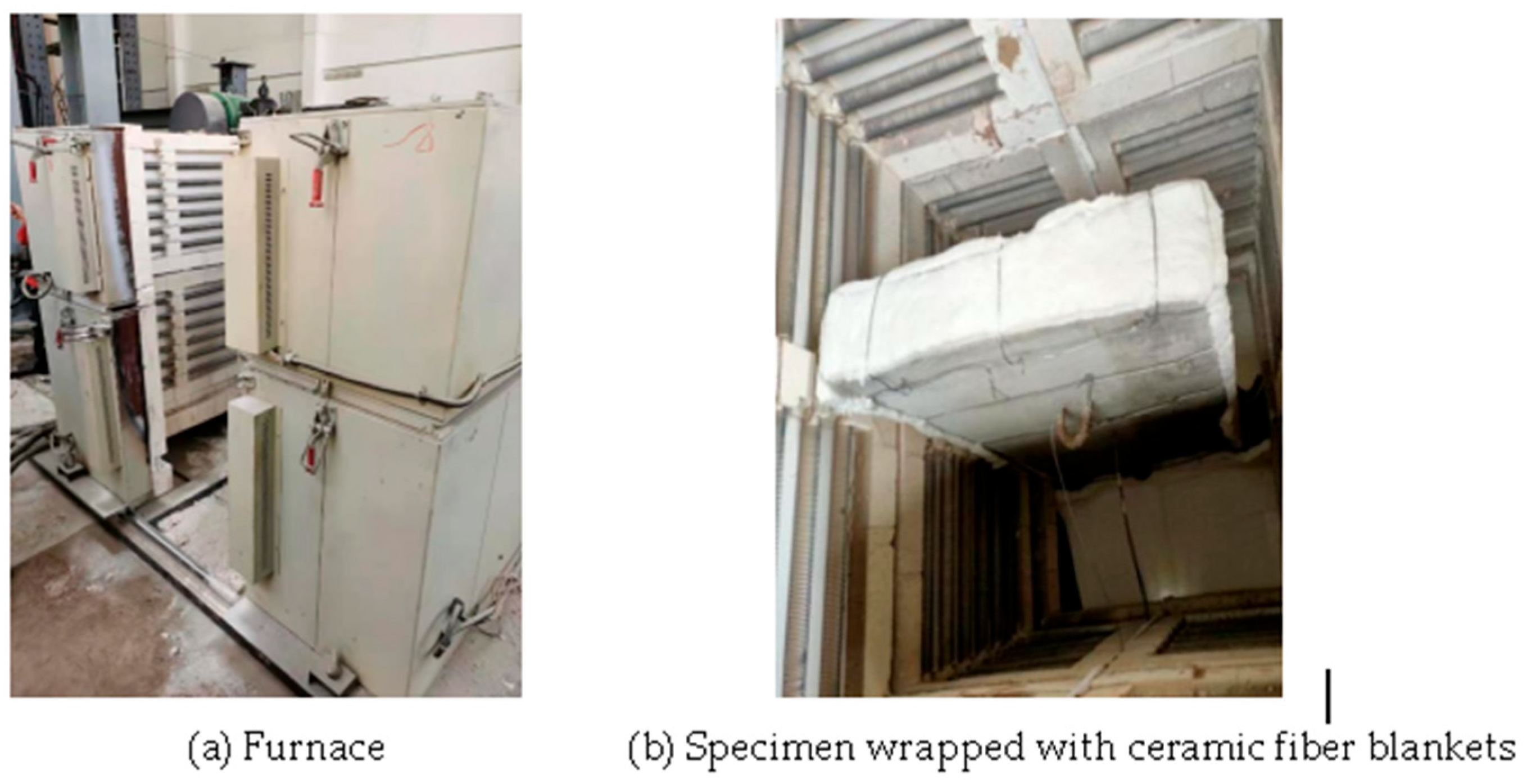

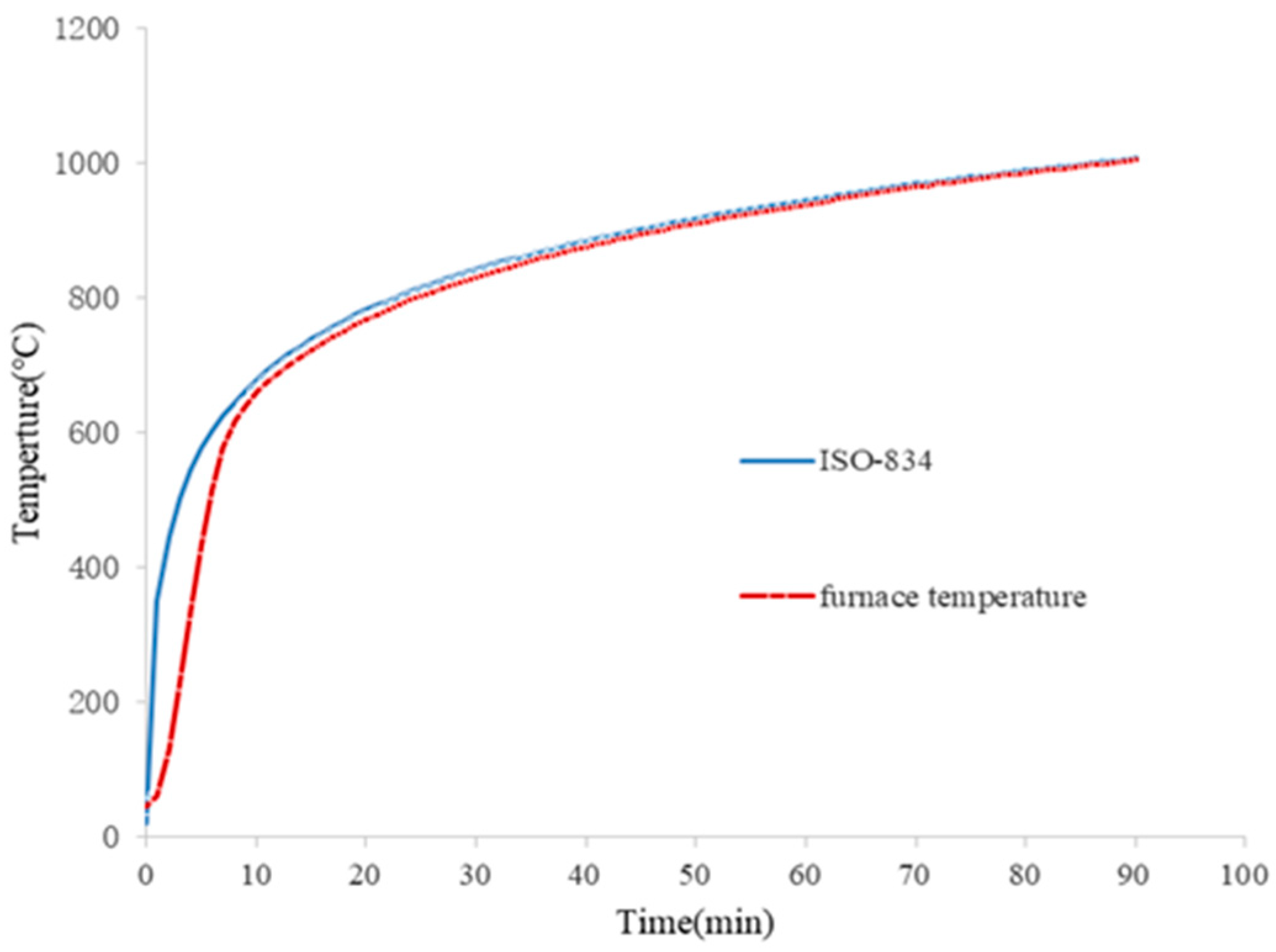

2.4. Test Device and Loading Scheme

3. Results

3.1. Test Results

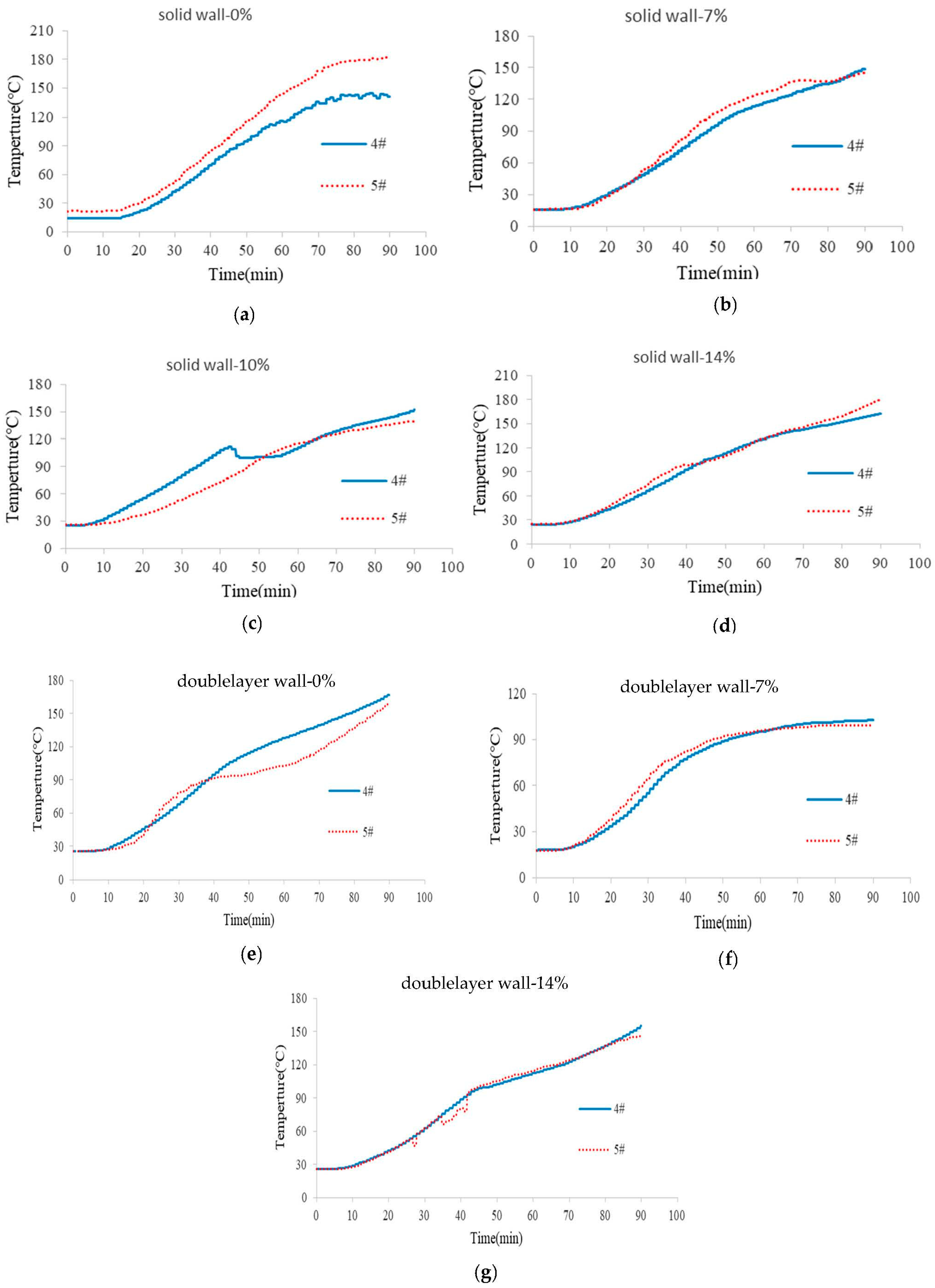

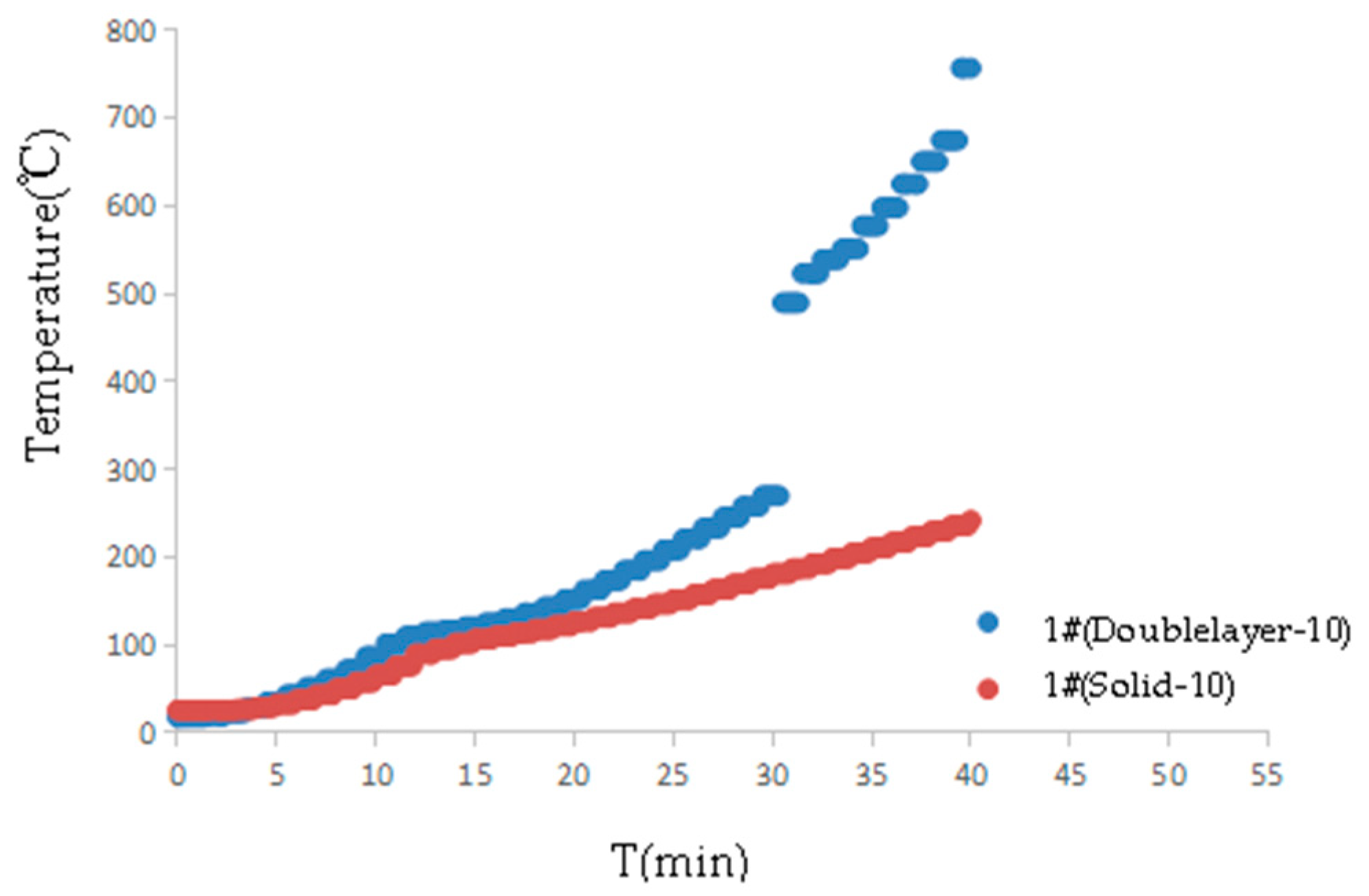

3.2. Time–Temperature Curves

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Caetano, N.S.; Salvini, C.; Giovannelli, A.; Felgueiras, C. ICEER 2021: Developing the World in 2021 with clean and safe energy. Energy Rep. 2022, 8, 636–847. [Google Scholar] [CrossRef]

- Aste, N.; Angelotti, A.; Buzzetti, M. The influence of the external walls thermal inertia on the energy performance of well insulated buildings. Energy Build. 2009, 41, 1181–1187. [Google Scholar] [CrossRef]

- Kensby, J.; Trüschel, A.; Dalenbäck, J. Potential of residential buildings as thermal energy storage in district heating systems—Results from a pilot test. Appl. Energy 2015, 137, 773–781. [Google Scholar] [CrossRef]

- Tonelli, C.; Grimaudo, M. Timber buildings and thermal inertia: Open scientific problems for summer behavior in Mediterranean climate. Energy Build. 2014, 83, 89–95. [Google Scholar] [CrossRef]

- Allcott, H.; Greenstone, M. Is there an energy efficiency gap? J. Econ. Perspect. 2012, 26, 3–28. [Google Scholar] [CrossRef]

- Eicker, U.; Nouvel, R.; Duminil, E.; Coors, V. Assessing passive and active solar energy resources in cities using 3D city models. Energy Procedia 2014, 57, 896–905. [Google Scholar] [CrossRef]

- Dora, S.; Kuznik, F.; Mini, K.M. A novel PCM-based foam concrete for heat transfer in buildings—Experimental developments and simulation modelling. J. Energy Storage 2025, 105, 114625. [Google Scholar] [CrossRef]

- Shree, V.; Dwivedi, A.; Saxena, A.; Pathak, S.K.; Agrawal, N.; Tripathi, B.M.; Goel, V. A comprehensive review of harnessing the potential of phase change materials (PCMs) in energy-efficient building envelopes. J. Build. Eng. 2025, 101, 111841. [Google Scholar] [CrossRef]

- Haurie, L.; Serrano, S.; Bosch, M.; Fernandez, A.I.; Cabeza, L.F. Single layer mortars with microencapsulated PCM: Study of physical and thermal properties, and fire behavior. Energy Build. 2016, 111, 393–400. [Google Scholar] [CrossRef]

- Hawes, D.W.; Feldman, D. Absorption of phase change materials in concrete. Sol. Energy Mater. Sol. Cells 1992, 27, 91–101. [Google Scholar] [CrossRef]

- Kuznik, F.; David, D.; Johannes, K.; Roux, J. A review on phase change materials integrated in building walls. Renew. Sustain. Energy Rev. 2011, 15, 379–391. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Zhu, X.; Tian, Y.; Cheng, J.; Zhang, J. Phase change energy storage material with photocuring, photothermal conversion and self-cleaning performance via a two-layer structure. ACS Appl. Mater. Interfaces 2022, 14, 57299–57310. [Google Scholar] [CrossRef] [PubMed]

- Hadjieva, M.; Stoykov, R.; Filipova, T. Composite salt-hydrate concrete system for building energy storage. Renew. Energy 2000, 19, 111–115. [Google Scholar] [CrossRef]

- Meshgin, P.; Xi, Y.P.; Abeyruwan, H. Effect of Phase-Change Materials on Properties of Concrete. ACI Mater. J. 2012, 109, 685–686. [Google Scholar]

- Figueiredo, A.; Lapa, J.; Vicente, R.; Cardoso, C. Mechanical and thermal characterization of concrete with incorporation of microencapsulated PCM for applications in thermally activated slabs. Constr. Build. Mater. 2016, 112, 639–647. [Google Scholar] [CrossRef]

- Min, H.W.; Kim, S.; Kim, H.S. Investigation on thermal; mechanical characteristics of concrete mixed with shape stabilized phase change material for mix design. Constr. Build. Mater. 2017, 149, 749–762. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castellón, C.; Nogués, M.; Medrano, M.; Leppers, R.; Zubillaga, O. Use of microencapsulated PCM in concrete walls for energy savings. Energy Build. 2007, 39, 113–119. [Google Scholar] [CrossRef]

- Eddhahak-Ouni, A.; Drissi, S.; Colin, J.; Neji, J.; Care, S. Experimental; multi-scale analysis of the thermal properties of Portland cement concretes embedded with microencapsulated Phase Change Materials (PCMs). Appl. Therm. Eng. 2014, 64, 32–39. [Google Scholar] [CrossRef]

- Essid, N.; Eddhahak, A.; Neji, J. Experimental; numerical analysis of the energy efficiency of PCM concrete wallboards under different thermal scenarios. J. Build. Eng. 2022, 45, 103547. [Google Scholar] [CrossRef]

- Cao, V.D.; Pilehvar, S.; Salas-Bringas, C.; Szczotok, A.M.; Rodriguez, J.F.; Carmona, M.; Al-Manasir, N.; Kjoniksen, A.L. Microencapsulated phase change materials for enhancing the thermal performance of Portland cement concrete and geopolymer concrete for passive building applications. Energy Convers. Manag. 2017, 133, 56–66. [Google Scholar] [CrossRef]

- ISO 834-1:1999; Fire-Resistance Tests—Elements of Building Construction—Part 1: General Requirements. International Organization for Standardization (ISO): Geneva, Switzerland, 1999.

- GB 50016-2014; Code for Fire Protection Design of Buildings. China Planning Press: Beijing, China, 2014. (In Chinese)

- GB 175-2023; Common Portland Cement. China Planning Press: Beijing, China, 2023. (In Chinese)

| PCM Replacement Proportion | Cement (kg/m3) | Sand (kg/m3) | Gravel (kg/m3) | Water (kg/m3) | PCM (kg/m3) |

|---|---|---|---|---|---|

| 0% | 575 | 455.96 | 1121.72 | 308.32 | 0.00 |

| 7% | 575 | 433.16 | 1121.72 | 308.32 | 9.96 |

| 10% | 575 | 410.36 | 1121.72 | 308.32 | 13.95 |

| 14% | 575 | 392.12 | 1121.72 | 308.32 | 19.49 |

| PCM Replacement Proportion | Measured Value 1 (N/mm2) | Measured Value 2 (N/mm2) | Measured Value 3 (N/mm2) | Average/Representative Value (N/mm2) |

|---|---|---|---|---|

| 0% | 36.0 | 40.2 | 40.7 | 39.0 |

| 7% | 36.6 | 33.0 | 29.6 | 33.1 |

| 10% | 31.7 | 29.8 | 17.0 | 29.8 |

| 14% | 41.0 | 35.5 | 33.8 | 35.5 |

| ID | Type | PCM Replacement Proportion | Integrity | Backfire Surface | Insulation | |

|---|---|---|---|---|---|---|

| Maximum Temp. Rise (°C) | Average Temp. Rise (°C) | |||||

| Solid-0 | Solid wall | 0 | Yes | 161 | 145 | No |

| Solid-7 | Solid wall | 7% | Yes | 133 | 131 | Yes |

| Solid-10 | Solid wall | 10% | Yes | 126 | 120 | Yes |

| Solid-14 | Solid wall | 14% | Yes | 156 | 147 | No |

| Doublelayer-0 | Double-layer wall with air gap | 0 | Yes | 141 | 137 | Yes |

| Doublelayer-7 | Double-layer wall with air gap | 7% | Yes | 82 | 79 | Yes |

| Doublelayer-10 | Double-layer wall with air gap | 10% | No | -- | -- | No |

| Doublelayer-14 | Double-layer wall with air gap | 14% | Yes | 130 | 125 | Yes |

| PCM Replacement Ratio | At Room Temperature | After Heating to 200 °C | After Heating to 300 °C |

|---|---|---|---|

| 0% | 2.81 | 14.89 | 20.76 |

| 7% | 2.59 | 15.74 | 21.13 |

| 10% | 1.97 | 14.00 | 15.16 |

| 14% | 1.53 | 12.03 | 13.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, M.; Li, J.; Wang, Y.; Meng, F. Experimental Study on Fire Resistance of Phase Change Energy Storage Concrete Partition Walls. Fire 2025, 8, 128. https://doi.org/10.3390/fire8040128

Zhu M, Li J, Wang Y, Meng F. Experimental Study on Fire Resistance of Phase Change Energy Storage Concrete Partition Walls. Fire. 2025; 8(4):128. https://doi.org/10.3390/fire8040128

Chicago/Turabian StyleZhu, Meichun, Jiangang Li, Ying Wang, and Fanqin Meng. 2025. "Experimental Study on Fire Resistance of Phase Change Energy Storage Concrete Partition Walls" Fire 8, no. 4: 128. https://doi.org/10.3390/fire8040128

APA StyleZhu, M., Li, J., Wang, Y., & Meng, F. (2025). Experimental Study on Fire Resistance of Phase Change Energy Storage Concrete Partition Walls. Fire, 8(4), 128. https://doi.org/10.3390/fire8040128