6.1. Analysis of the Influence Radius of a Single Vehicle Fire

Currently, most new energy vehicles use lithium batteries, and the capacity of these batteries is continuously increasing. Many researchers focus on the thermal runaway mechanism, gas generation, and flame behavior of large-capacity lithium iron phosphate batteries [

31,

45,

46,

47]. The battery capacities used in the above studies range from 27 Ah, 86 Ah, 105 Ah, to 243 Ah. Although the thermal runaway mechanism of batteries in the same material system is the same, due to the difference in capacity, the flame behavior after vehicle ignition shows significant differences. This study takes the fire scenario of lithium-ion battery energy storage facilities as the simulation object, systematically exploring the influence of different battery capacities on the spread range of electric vehicle fires. Referring to existing studies, the battery capacities selected for testing were 20 Ah, 60 Ah, 120 Ah, 180 Ah, and 240 Ah, covering the range from typical small to large commercial power batteries. In terms of heat release rate setting, Cui [

48] and Wang [

49] pointed out that the heat release rates of multiple groups of batteries are not a simple multiple relationship with that of a single group of batteries, showing significant non-linear characteristics, and approximately following a 1.2th power relationship. The lithium battery warehouse studied in reference [

48] was a confined ventilation environment with poor air circulation, reflecting the thermal coupling effect under the condition of limited oxygen supply. This study, however, focused on the vehicle compartments of the ro-ro passenger ships, which had side ventilation openings and natural ventilation conditions. Theoretically, improved ventilation conditions would promote combustion, and the intense radiation feedback caused by flames and hot smoke accumulation might accelerate the battery thermal runaway process. However, the confined space might also lead to incomplete combustion in the later stage of the fire. These complex factors make the actual heat release rate likely to deviate from any simple linear relationship. This paper adopts the 1.2 power relationship for estimation, which provides a unified reference for performance evaluation. However, the natural ventilation environment of ro-ro passenger ships may lead to more severe fires, which poses the risk of insufficient safety margin for the fire protection system designed based on data, but also indicates the necessity of optimizing the fire protection system for the natural ventilation environment.

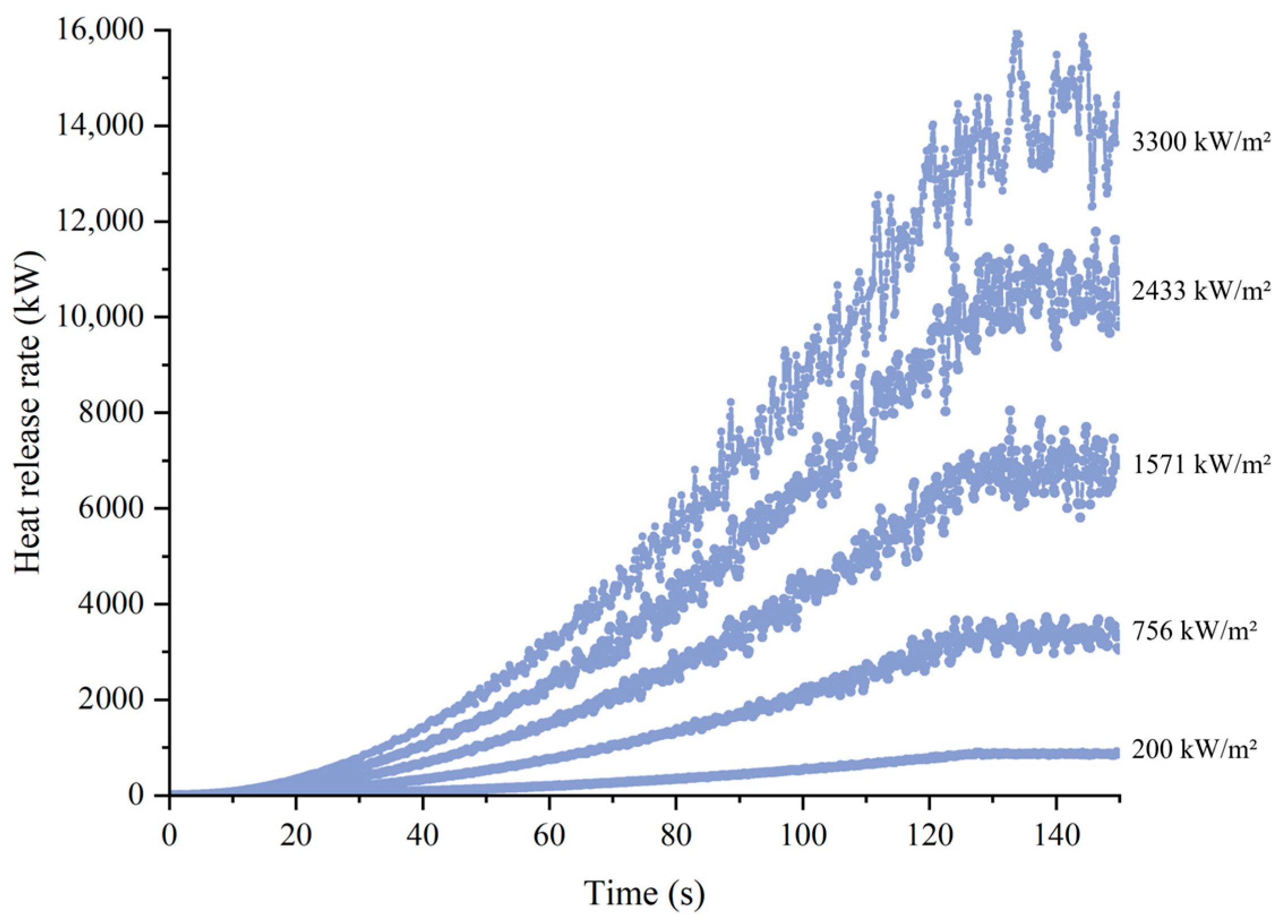

Although there is uncertainty regarding the precise power exponent, the core conclusion that “fire risk increases super-linearly with battery capacity” is robust and can provide a reasonable and conservative benchmark for the performance assessment of fire protection systems. Based on this, when conducting research on battery capacity, the reference value of the unit area heat release rate corresponding to a 240 Ah battery is set at 3300 kW/m

2, which is within the reasonable range of the peak heat release rate of large-capacity batteries. The unit area heat release rates corresponding to different battery capacities are obtained as follows: 200 kW/m

2 (20 Ah), 756 kW/m

2 (60 Ah), 1571 kW/m

2 (120 Ah), 2433 kW/m

2 (180 Ah), and 3300 kW/m

2 (240 Ah). This parameter setting ensures that the simulation conditions have systematicity and comparability among different capacities, thereby effectively evaluating the impact of battery capacity on the fire dynamics behavior. At the same time, to improve computational efficiency, in this section, only a single fire source is set, and the simulation time is uniformly set to 150 s. The initial conditions and fire source settings have been given in

Section 5.

Figure 12 shows the curves of the heat release rate changes over time when different battery capacities catch fire as obtained through FDS simulation. The HRR gradually increases in the initial stage, then rises sharply, remains fluctuating in the stable stage, and the higher the battery capacity, the more chemical energy is stored internally, and the total energy released during thermal runaway is also higher.

Lithium-ion batteries inevitably experience thermal runaway at 150 °C [

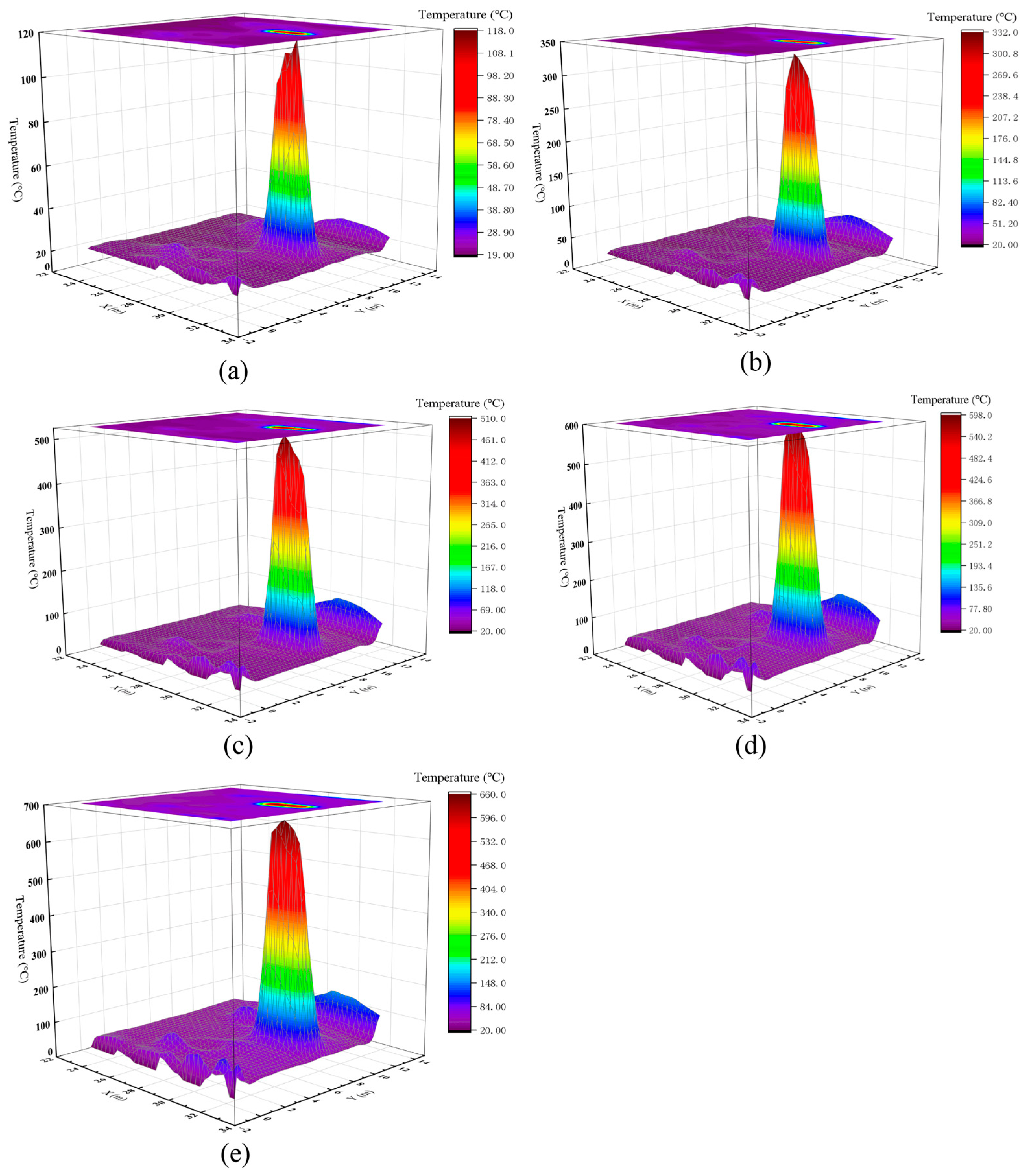

50], which is the critical threshold identified for individual battery modules under controlled laboratory conditions. When this threshold is extended to the vehicle interior scenario in a ship cabin, factors such as the vehicle’s thermal inertia, battery pack insulation, and the shielding effect of the metal body may increase the actual environmental temperature required to trigger thermal runaway in adjacent vehicles. However, using the 150 °C standard-which is derived from the battery itself-provides a key safety benchmark. This approach ensures that the fire suppression system is designed to intervene before the spread of battery thermal runaway, thereby providing a safety margin. Therefore, this simulation uses an isothermal surface of 150 °C as a clear and crucial indicator for assessing the risk of fire spread to adjacent vehicles. Based on the simulation results, when the fire source is at a height of 3 m in the z-direction relative to the battery (at monitoring point 7), contour maps and three-dimensional diagrams of the fire temperature radius for different battery capacities of 20 Ah (a), 60 Ah (b), 120 Ah (c), 180 Ah (d), and 240 Ah (e) are plotted, as shown in

Figure 13 and

Figure 14.

To objectively quantify the spread of the fire, the study adopts the equivalent radius of the fire source as the key evaluation parameter. The calculation method is as follows: taking the center of the initial fire source as the center of the circle, measure the distance to the farthest point of the 150 °C isotherm as the radius (R), and the diameter of the corresponding circular area is the equivalent circular diameter (D = 2R). When the battery capacity is 20 Ah, the corresponding equivalent radius of the 150 °C fire source is almost 0. However, when the capacity reaches 240 Ah, the equivalent radius of the fire source expands to about 3.3 m. Therefore, as the battery capacity increases from 20 Ah to 240 Ah, the equivalent radius of the fire source based on the 150 °C standard shows a gradually increasing trend. The temperature also significantly rises from the 118.0 °C cross-sectional temperature to 660.0 °C, and the high-temperature area continuously expands. The car will ignite more quickly and in a larger area. This super-linear growth is mainly due to the higher heat release rate of the large-capacity battery and the stronger jet combustion effect: on the one hand, the increase in the active substances inside the battery leads to an increase in the total energy of thermal runaway cubically; on the other hand, the jet flow rate of the electrolyte increases linearly and forms a secondary combustion outside. In the ideal situation without fire prevention measures, based on the 150 °C thermal runaway temperature, an equivalent temperature surface for battery ignition is established at a heat release rate of 3000 kW/m2 per unit area.

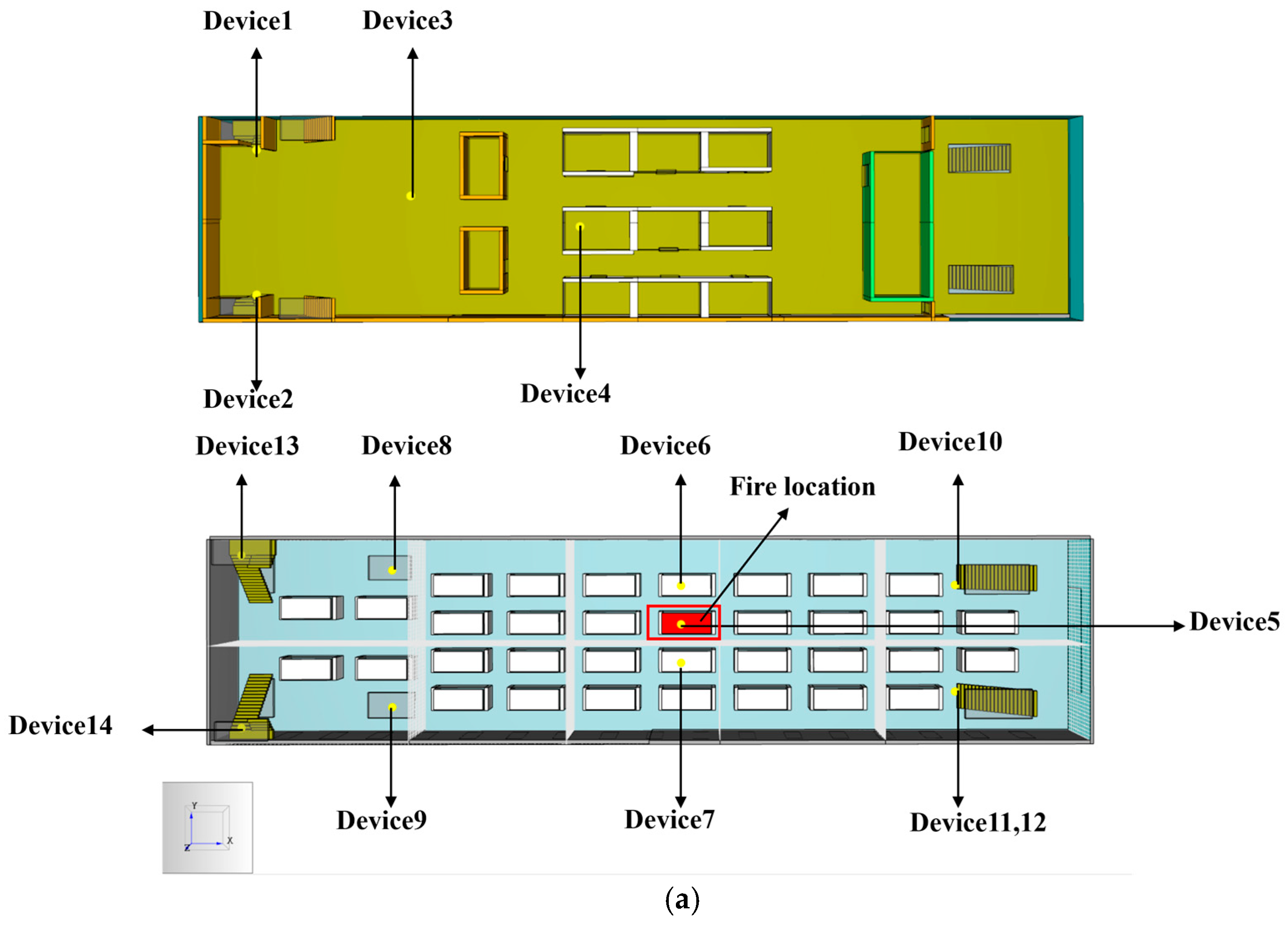

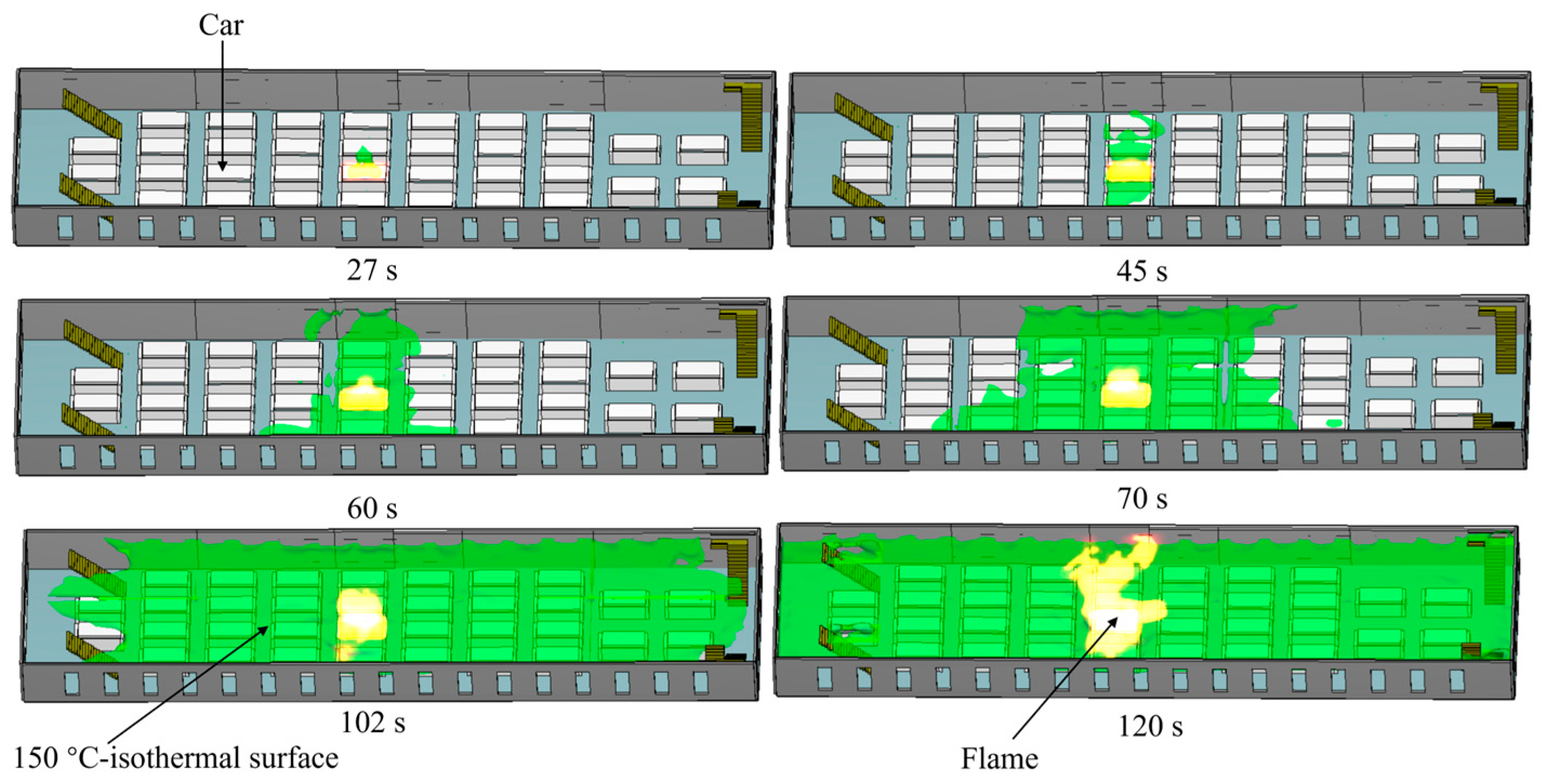

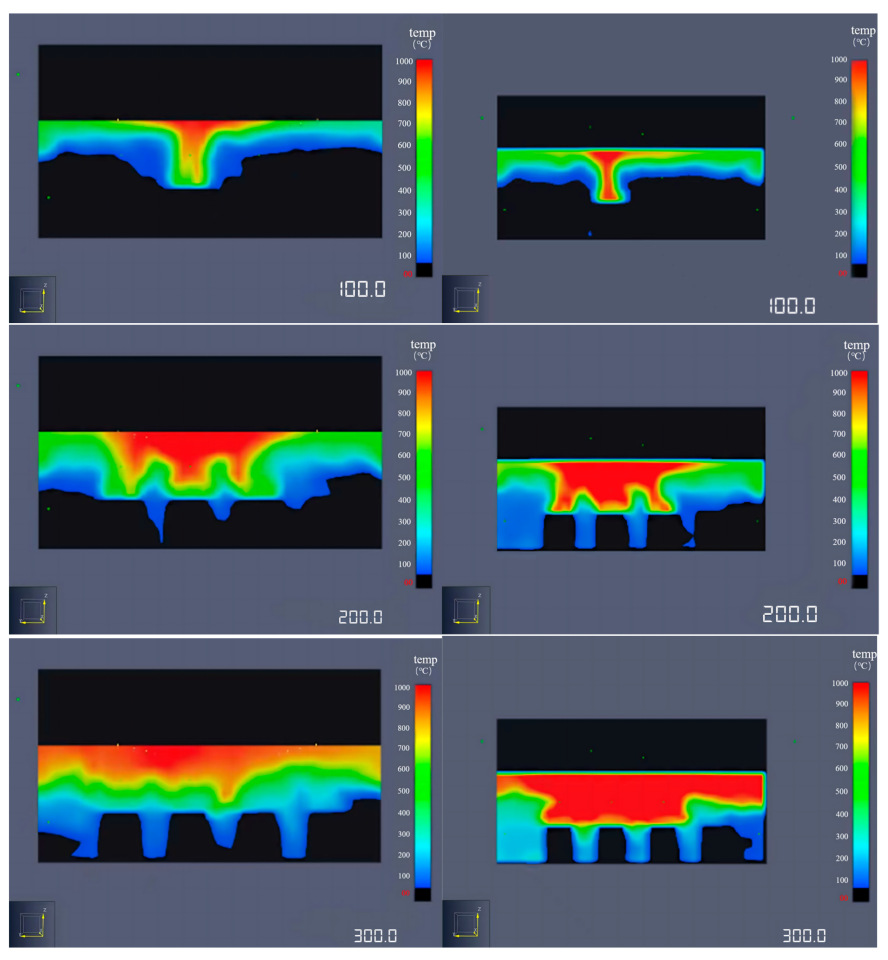

Under simulated conditions, the temperature isosurface analysis in

Figure 15 indicates that the thermal influence range generated by the fire source shows a relatively symmetrical distribution characteristic. The vehicle thermal runaway occurs at 27 s, and the temperature spreads to adjacent vehicles at the 45 s, with an extension distance of 1.2 m. At the 60 s, all adjacent vehicles reach the thermal runaway temperature, and the farthest extension distance of the isosurfaces reaches 4.5 m. At the 120 s, the temperature of the entire vehicle cabin reaches the critical value for the vehicle battery thermal runaway. However, the spatial form of the flame is affected by the turbulent characteristics of the jet flame and the environmental wind field, that is, natural ventilation. The volume of the isosurfaces increases exponentially within 100 s of thermal runaway, and the expansion speed is significantly faster than that of traditional hydrocarbon fires. This is due to the intense gas production process accompanying the battery thermal runaway.

According to the relevant provisions of the “International Convention on Maritime Safety for Human Life at Sea”, clear requirements have been made for the water spray system in the fire protection system regarding the number, flow rate, and protection area (i.e., the spacing of fire sprinklers) of the fire sprinklers. Combined with various factors such as feasibility and economic benefits, a comprehensive analysis is conducted. During the ship construction process, the number and spacing of fire sprinklers are generally fixed and difficult to further increase or decrease. Therefore, the parameters related to the number, spacing, and flow rate of the water spray fire suppression system are kept unchanged. The research focuses on the use of high-expansion foam [

51], the droplet size of the liquid sprayed by the sprinkler [

52], the spraying angle [

53], and whether fire curtains are installed [

54].

Given the different opinions raised by the member states of IMO, this article selects fine water mist and high-expansion foam as the comparison examples. In the article, the parameter of System 2 from reference [

51] is selected and combined with Chapter 6 of the “International Fire Protection System Rules” to set up a high-expansion foam fire extinguishing system. The design parameters of System 2 are as shown in the following

Table 3:

In the simulation, all the holes were removed to simulate the air-tight and closed space during the use of foam fire extinguishing. Since FDS does not have a built-in foam model, we created a dedicated foam equivalent particle by equivalenting its properties through system 2 parameters. The particle has a density of 2.0 kg/m

3 to reflect the extremely low-density characteristic of the foam. Its value is derived from the expansion of water solution with a density of 1000 kg/m

3 by 500 times, simulating the macroscopic movement behavior of foam lumps with a diameter of 1200 μm. The molecular weight is changed to the corresponding air molecular weight, 29 g/mol, to better simulate the physical coverage fire extinguishing mechanism. At the same time, the particles are defined as moving. However, the model mainly captures the physical isolation mechanism of the foam. For the additional suffocating effect of oxygen dilution and temperature reduction caused by the evaporation of water vapor in the foam, due to the limitations of FDS, it could not be fully depicted. But physical coverage isolation effect of the simulated foam was reproduced. Therefore, the conclusion of this simulation regarding the effectiveness of foam fire suppression remains reliable and valid.

Figure 16a and

Figure 16b are, respectively, the tracer diagrams of fine water mist and high-expansion foam particles.

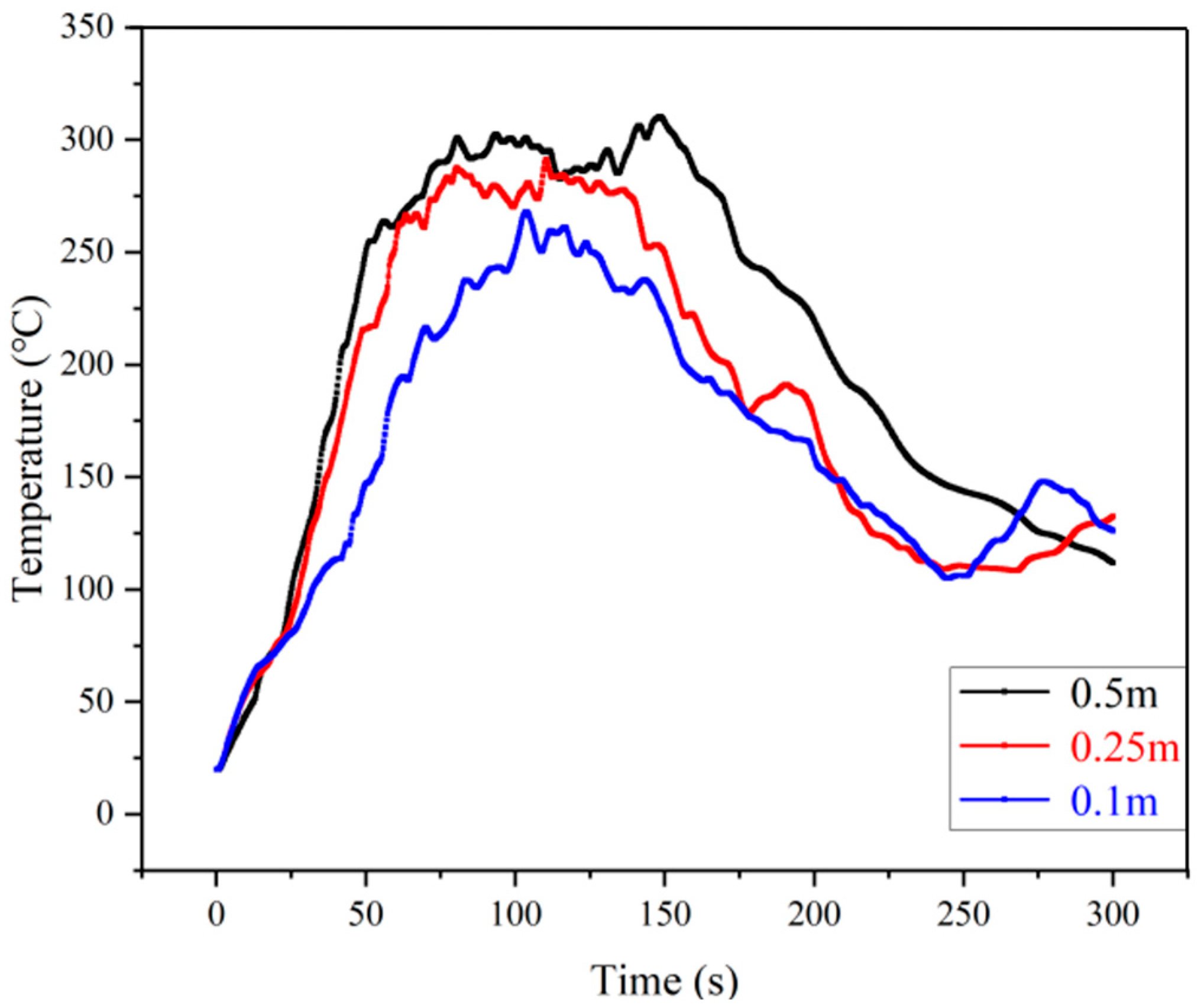

During the simulation, the sprinkler system used nozzle angles of 60° to 75° and droplet sizes of 500 μm. As shown in

Figure 17,

Figure 17a shows the temperature change above the fire source, and

Figure 17b shows the temperature change near the fire source.

From the figure, it can be observed that there are differences in the temperature control characteristics of the two systems during the fire cycle. In the early stage of the fire, the small-sized droplets of the fine water mist, due to their rapid evaporation property, achieved rapid cooling of the area above the fire source, effectively curbing the peak growth of the heat release rate; in the later stage of the fire, the continuous evaporation and heat absorption mechanism of the droplets enabled the efficient removal of heat from the fire scene, and the temperatures in the core area of the fire source and the adjacent areas could be maintained at relatively low levels. The high-expansion foam system, through equivalent particle simulation, reproduced its coverage mechanism. However, due to the longer time required for foam generation, diffusion, and coverage, the temperature in the fire source area decreased slowly; in the middle and later stages, although a certain coverage layer could be formed, its cooling ability for deep fire sources was insufficient, and the temperature distribution map showed obvious continuous high-temperature areas, indicating that its suppression effect on deep-position fires such as lithium-ion batteries was limited. Therefore, the fine water mist solution demonstrated a relative advantage in temperature control. This system achieved temperature management from the early stage to the middle stage of the fire through the strong heat absorption mechanism of droplet evaporation. In contrast, the high-expansion foam system was limited by its inherent response lag characteristics and insufficient penetration cooling ability for complex combustion bodies and was less applicable in the ro-ro passenger ship vehicle compartment fire control scenarios that emphasized rapid response and deep cooling. However, after the fire was initially controlled, the high-expansion foam system could still be used for long-term coverage to prevent re-ignition.

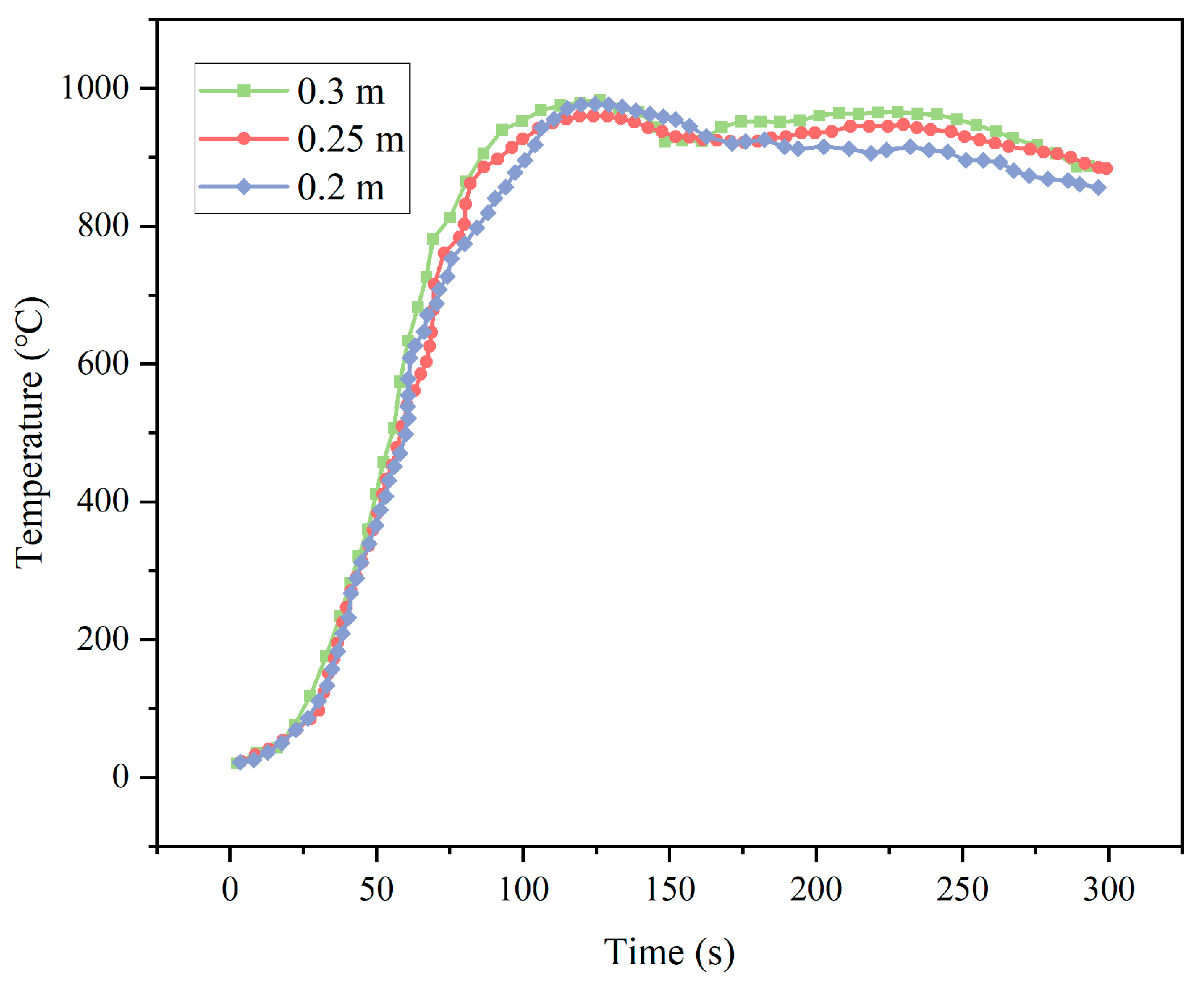

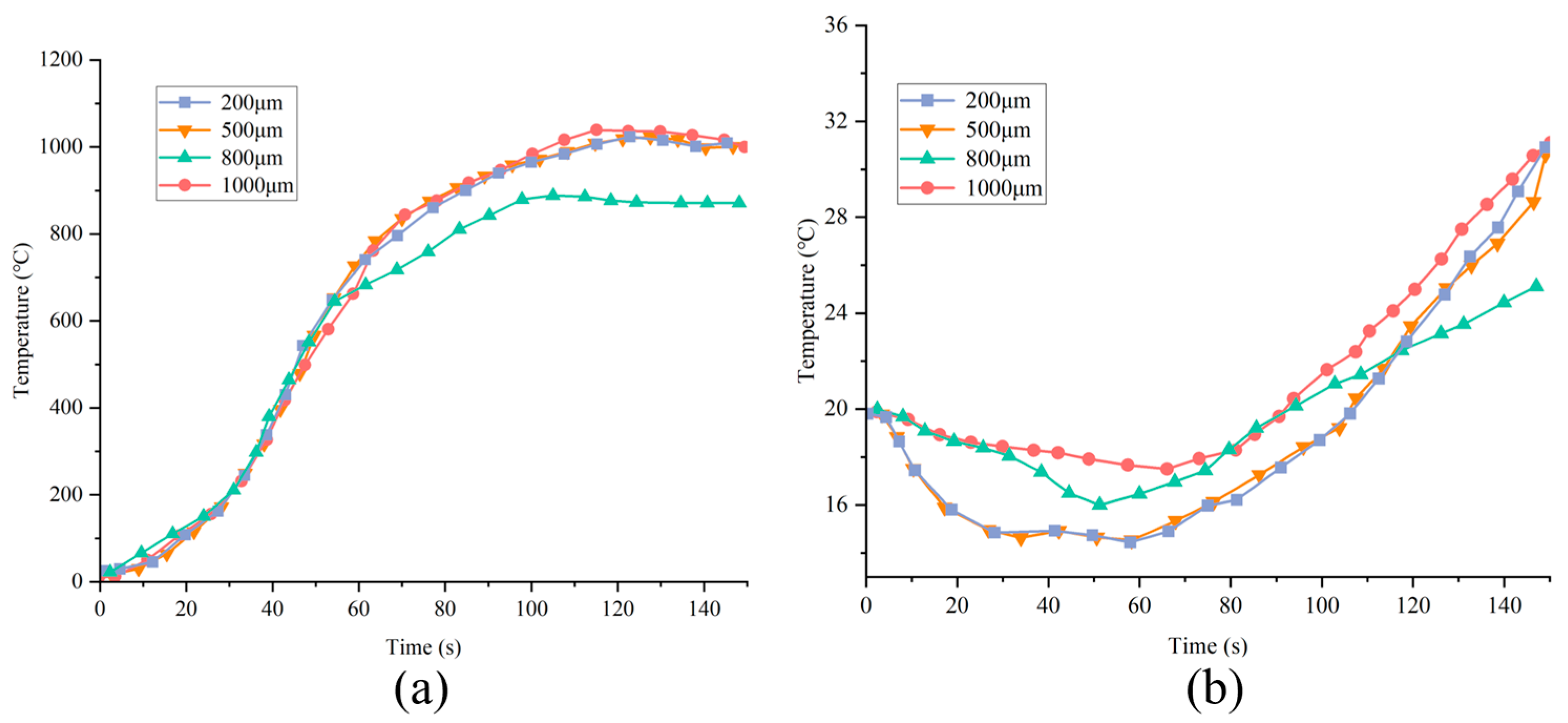

Under the same conditions, the droplet size was changed to 1000, 800, 500 and 200 µm to study the different fire suppression effects. As shown in

Figure 18, they are, respectively, the temperature distribution maps of monitoring point 5 above the fire source (a) and monitoring point 11 at the staircase entrance (b). As shown in

Figure 18a, the cooling effects of different diameter droplets on the battery fire were tested, and the performance ranking was 800 µm > 200 µm > 500 µm > 1000 µm. The results differ from the classical evaporative cooling theory and reveal the change in the dominant fire suppression mechanism under specific experimental conditions. The analysis suggests that in the battery fire scenario set in the study, the flames produced a very strong upward thermal airflow. The 800 µm droplets, with their penetrating power, could effectively overcome the upward airflow and directly wet the battery surface, achieving the cooling of the thermal runaway body. Although the 200 µm droplets evaporated prematurely in the airflow and achieved excellent gas cooling effect, they could not penetrate the core of the fire source. The 500 µm droplets, although having sufficient penetrating power, could not stabilize and take effect, and their evaporation rate was also slower than the smaller droplets. Therefore, the performance was actually worse than the previous one. The 1000 µm droplets had the lowest evaporation efficiency and the poorest cooling performance. As shown in

Figure 18b, when the measurement point was at the staircase entrance, the ranking of cooling effects was 200 µm > 500 µm > 800 µm > 1000 µm. This indicates that with the change in spatial position, the dominant cooling mechanism has changed. In the area away from the fire source, the diffusion ability of the droplets and the suspension evaporation time in the air become the decisive factors. Small diameter droplets, due to their good diffusion ability and large total surface area, can form a wide and uniform cooling fog curtain, effectively reducing the temperature of the surrounding environment; while large diameter droplets, due to their fixed trajectory and fast settling speed, have a significantly weakened cooling effect at this distance. This phenomenon highlights the important influence of the spatial distribution characteristics of fine water mist on the fire suppression effect.

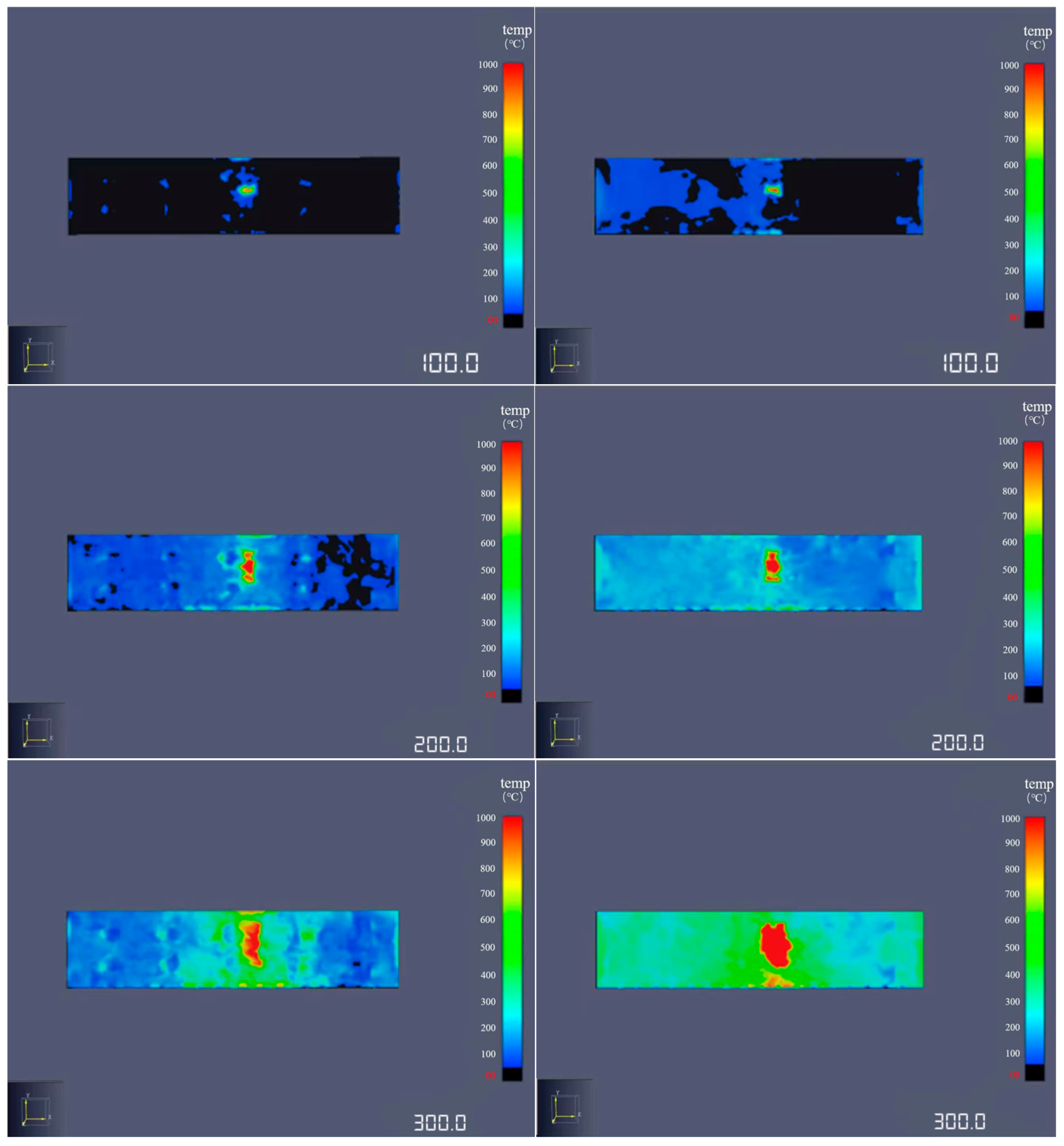

Figure 19 presents a contour map showing the relationship between the temperature above the fire source and the distance of the fire’s spread, corresponding to liquid droplet sizes of 200 (a), 500 (b), 800 (c), and 1000 μm (d). As the droplet size changes, the equivalent effective radius of the fire source also varies. Among them, the equivalent effective radius of the 800 μm droplet is the smallest, approximately 2.8 m, significantly smaller than the high-temperature range of the 1000 μm droplet. When the droplet size further decreases to 200 μm, the equivalent effective radius shrinks to approximately 3 m, and the spatial distribution of the high-temperature area is continuously compressed. This is due to the coupling effect of the droplet momentum, evaporation heat absorption characteristics, and the fire thermal environment. The 500 μm droplet has insufficient penetration force and evaporation efficiency compared to smaller droplets, so it is weaker than the 800 μm droplet in the compression effect of the equivalent effective radius; the 1000 μm droplet cannot effectively suppress the expansion of the high-temperature area due to its low evaporation efficiency, and its equivalent effective radius is the largest. This pattern reveals the key regulatory role of the momentum, evaporation heat absorption characteristics of the droplets, and the fire thermal environment in the spatial influence range of the fire source in battery fire scenarios. At the same time, small droplets have relatively limited ability to capture and settle suspended carbon black particles in the smoke due to their lighter mass and smaller momentum, which leads to a larger smoke diffusion range in their control area, accelerating the decline in visibility and expanding the potential secondary danger area.

The commonly used nozzle angle ranges in the spray fire extinguishing systems of passenger and cargo ships were selected as 30° to 80° (a), 60° to 75° (b), 60° to 90° (c), 80° to 90° (d), and 80° to 120° (e), respectively. At the same time, the droplet size was controlled at 500 μm. As shown in

Figure 20, the water coverage areas of each nozzle are presented.

As shown in

Figure 21,

Figure 21a depicts the temperature change at monitoring point 5 above the fire source, and

Figure 21b shows the temperature change at monitoring point 6 near the fire source. It can be seen that under the action of nozzles with angles ranging from 30° to 80°, the temperature rises at the fastest rate and reaches the highest peak; while for angles ranging from 60° to 75°, 60° to 90°, 80° to 90°, and 80° to 120°, the temperature rise is more gradual, and the peak value is significantly lower. The reason is that the smaller the angle, the stronger the concentration and impact of the water column, but the coverage area is limited, making it difficult to achieve uniform cooling over a large area, resulting in local heat accumulation; while for larger angles, the spray range is wider, although the cooling efficiency per unit area may decrease, it can more widely disperse or remove heat, and the overall temperature control effect is better. Specifically, the 30° to 80° nozzle angle is concentrated and has strong impact, which can reach the core of the fire source, but the coverage area is insufficient, lacking comprehensiveness in cooling a large-scale thermal runaway, and prone to causing rapid local temperature accumulation; the 60° to 75° nozzle angle is relatively concentrated, achieving a better balance between coverage area and water column pressure, being able to achieve uniform cooling to some extent, making the temperature rise more gradual; the 60° to 90° nozzle angle is further expanded, the coverage area increases, although the cooling efficiency per unit area may decrease, but the overall heat dispersion effect is better; the 80° to 90° nozzle angle is more concentrated, with sufficient water column impact, which can penetrate the flames to cool the local heat source, reducing local high-temperature accumulation; the 80° to 120° nozzle angle range is the largest and has the widest coverage, able to remove heat over a larger area, so the temperature rise is the slowest and the peak value is the lowest. In summary, the small-angle nozzles have strong impact but limited coverage, resulting in faster and higher peak temperature rise at the top and bottom of the fire source; the large-angle nozzles, due to their “wide coverage”, can more effectively disperse or remove heat, achieving better overall temperature performance. Their wide coverage characteristic is more conducive to suppressing the spread of the fire and reducing the overall temperature, but it needs to be optimized in combination with flow rate and pressure to balance coverage area and cooling efficiency.

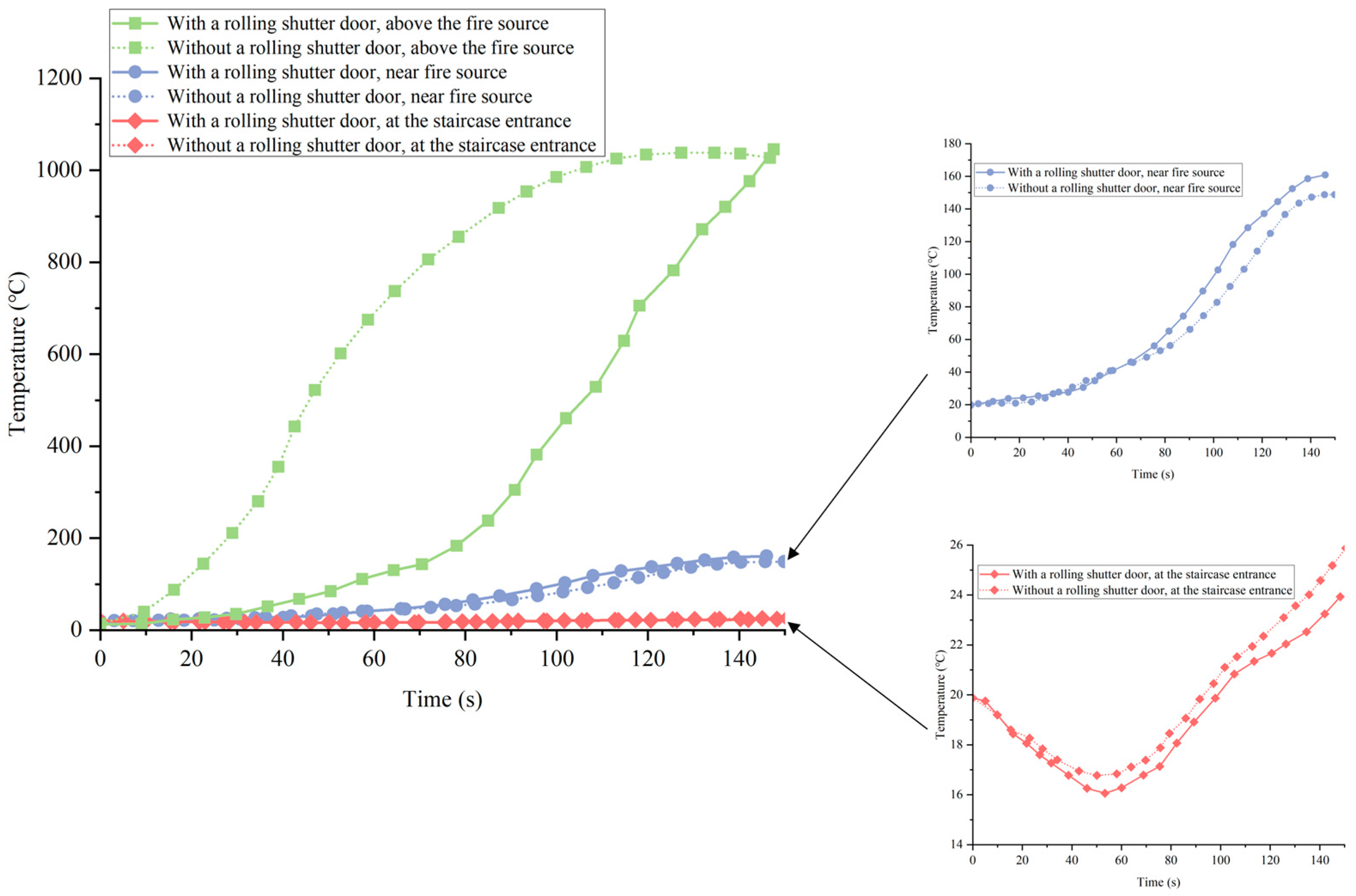

By constructing a thin wall 0.05 m thick around the fire source for containment and simulating the protective effect of the fireproof rolling shutter door after a fire occurs, the material was set as a heat insulation material. After multiple simulation tests, the height was finally adjusted to 3.5 m to ensure the best protective effect without affecting the function of the water spray fire extinguishing system. As shown in

Figure 22, after opening the fireproof rolling shutter door, compared with when it was not opened, the temperature rise speed above the fire source (monitoring point 5) was slower, and the temperature rise speed in the area close to the fire source (monitoring point 6) and the staircase entrance area (monitoring point 11) was also more gentle. However, due to the effect of the fireproof rolling shutter door, the smoke rose in a smaller space, resulting in higher peak temperatures above and around the fire source than in the case without the shutter door installed. In addition, as the air temperature above the fire source gradually increased over time, the density of the hot air decreased and flowed upward and outward. At the same time, the fireproof rolling shutter door can effectively prevent the air below from entering. Under the combined effect of these two factors, the external air and the fire source could not obtain sufficient fuel for combustion, ultimately leading to a decrease in the overall temperature.

As shown in

Figure 23, the temperature distribution propagation within the entire carriage before (a) and after (b) the addition of the fireproof door is presented. The top and bottom images, respectively, show the perspective view from above and the side view. The fireproof curtain exerts an inhibitory effect on the fire spread radius through physical isolation and thermodynamic regulation, and causes the high-temperature smoke to accumulate above the carriage. The 0.05 m thick insulation material structure can effectively delay the temperature rise above the fire source, reducing the thermal radiation influence radius by approximately 3 m. At the same time, by blocking the air supply below, the oxygen concentration in the combustion zone is controlled below the critical value, limiting the fire spread radius to within the 3.5 m height range of the curtain enclosure. According to the simulation, the activation of the curtain not only reduces the core high-temperature area of the fire source by 80–100 °C, but also compresses the diffusion radius of toxic smoke. This “temperature-oxygen-smoke” control mechanism enables the fireproof curtain to reduce the effective dangerous radius of the fire from 6 to 8 m in the open state to 3–5 m in the closed state, without affecting the fire-extinguishing efficiency of the sprinkler system, and forms a “three-dimensional blockade” fire prevention zone effect.

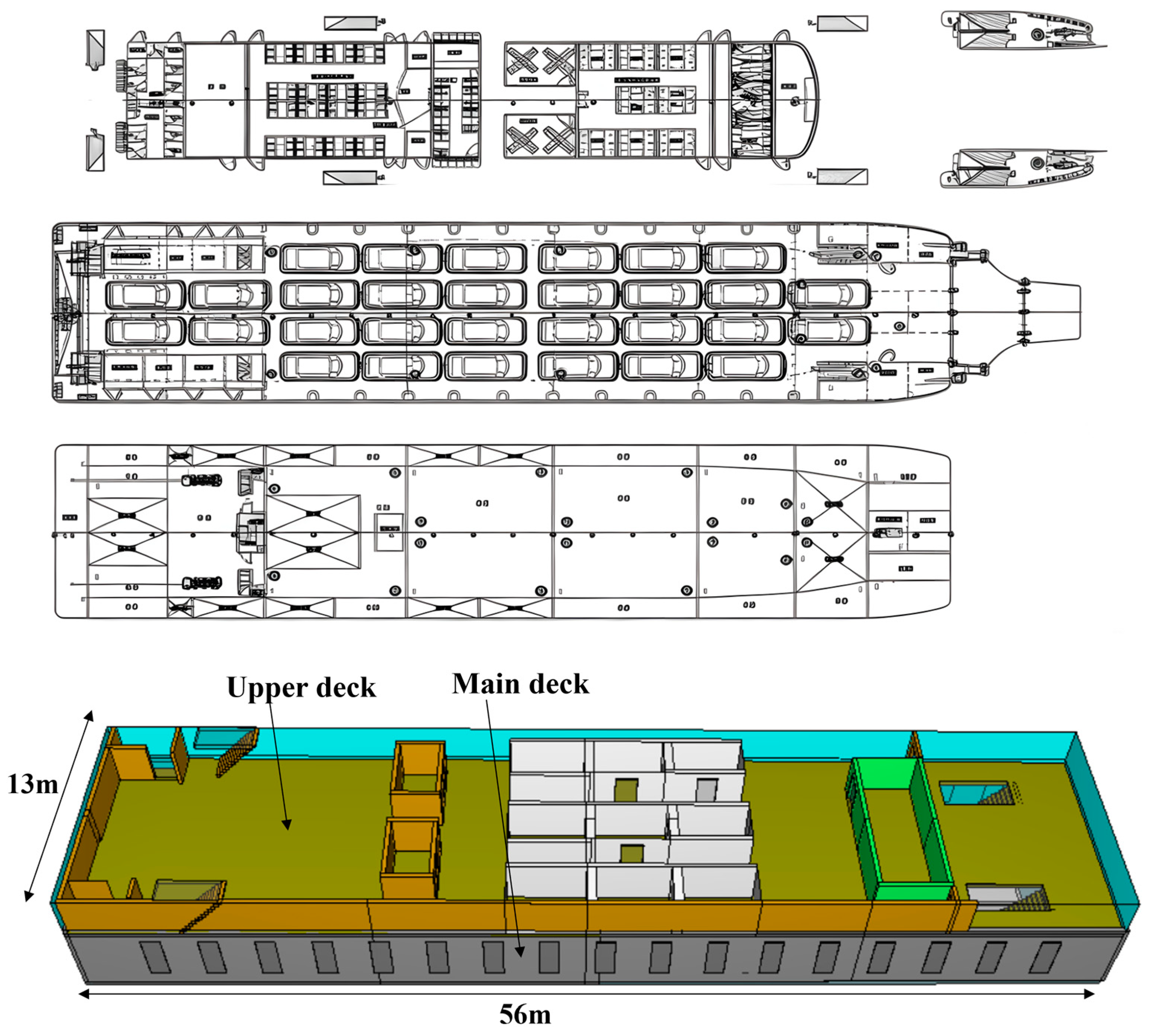

6.2. Analysis of the Smoke Spread Characteristics, Visibility and Temperature Field in a Ro-Pax Ship Fire

As shown in

Figure 24, the flame of the fire source gradually increases over time. The initial flame height of the fire source reaches the upper deck at 52 s, the delayed flame height reaches the upper deck at 180 s, and the flame reaches its most vigorous stage at 240 s, with the maximum radiation range in all directions.

The Fick diffusion equation describes how concentration changes over time. This is a differential that shows how diffusion occurs when continuous diffusion takes place [

55].

In the formula, binary diffusion coefficient between molecules [m2/s].

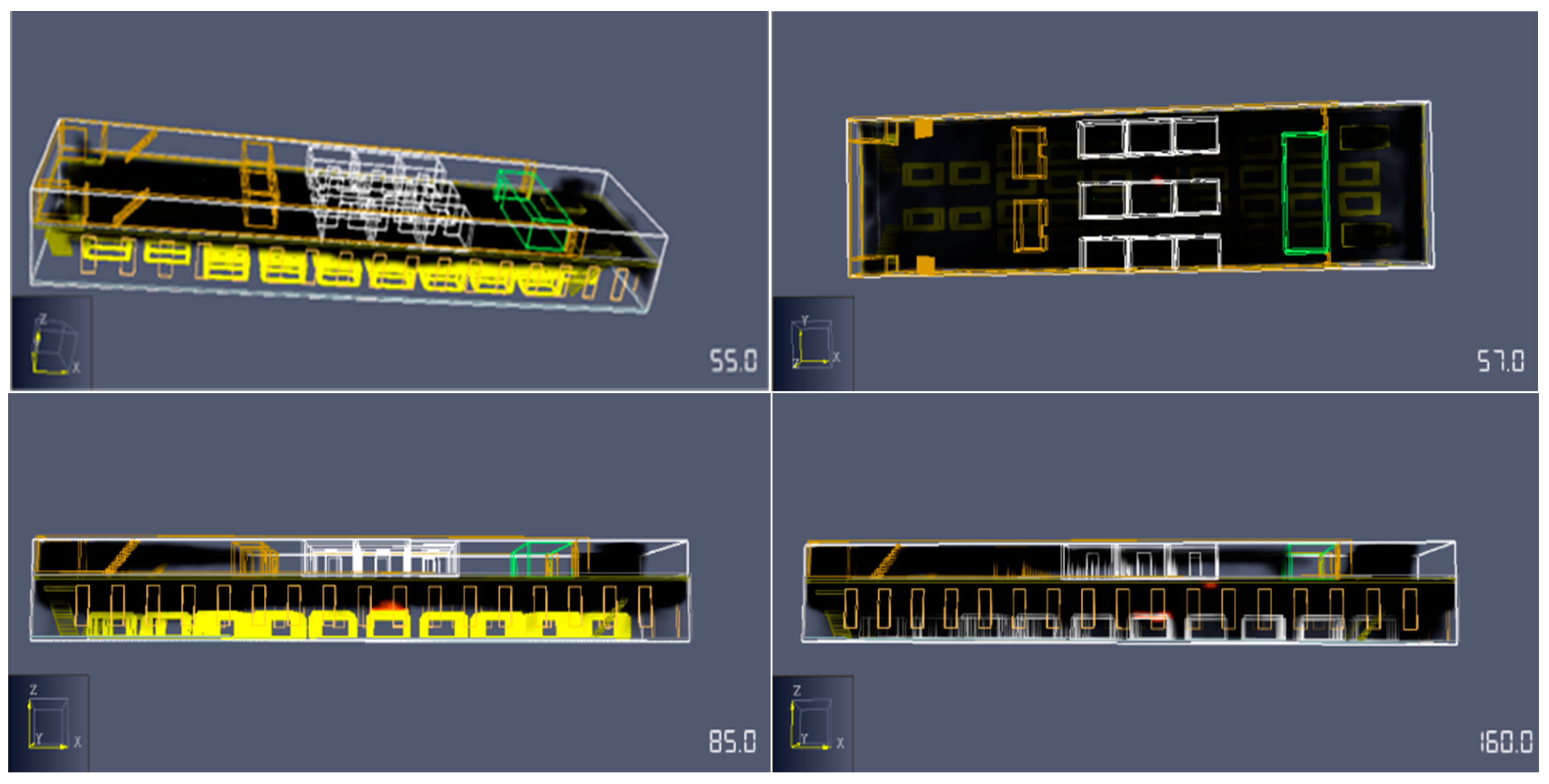

In FDS, the finite volume method is used for discretization. The open area is set to zero concentration gradient, and the adsorption boundary is adopted on the solid wall surface. The solution is obtained in FDS through the Fick diffusion equation to determine the smoke diffusion situation during the thermal runaway of the vehicle. After the car fire occurs, due to the relatively sealed environment inside the car, there is incomplete combustion in the car fire, which will produce a large amount of toxic and harmful smoke, as shown in

Figure 25. At 7 s, the smoke height reaches the main deck ceiling, and after 55 s, the smoke begins to enter the upper deck from the rear staircase. At 57 s, the smoke completely covers the car compartment on the main deck. At 85 s, the smoke enters the living area on the upper deck and completely covers the upper deck compartment at 160 s. Its spread trajectory follows the classic theory of thermal buoyancy driven smoke plume and roof jet, providing a basis for the optimization of the subsequent fire protection system.

The car fire is a fully developed type of fire. In this kind of fire, the heat release rate increases with time and tends to stabilize after reaching the maximum heat release rate.

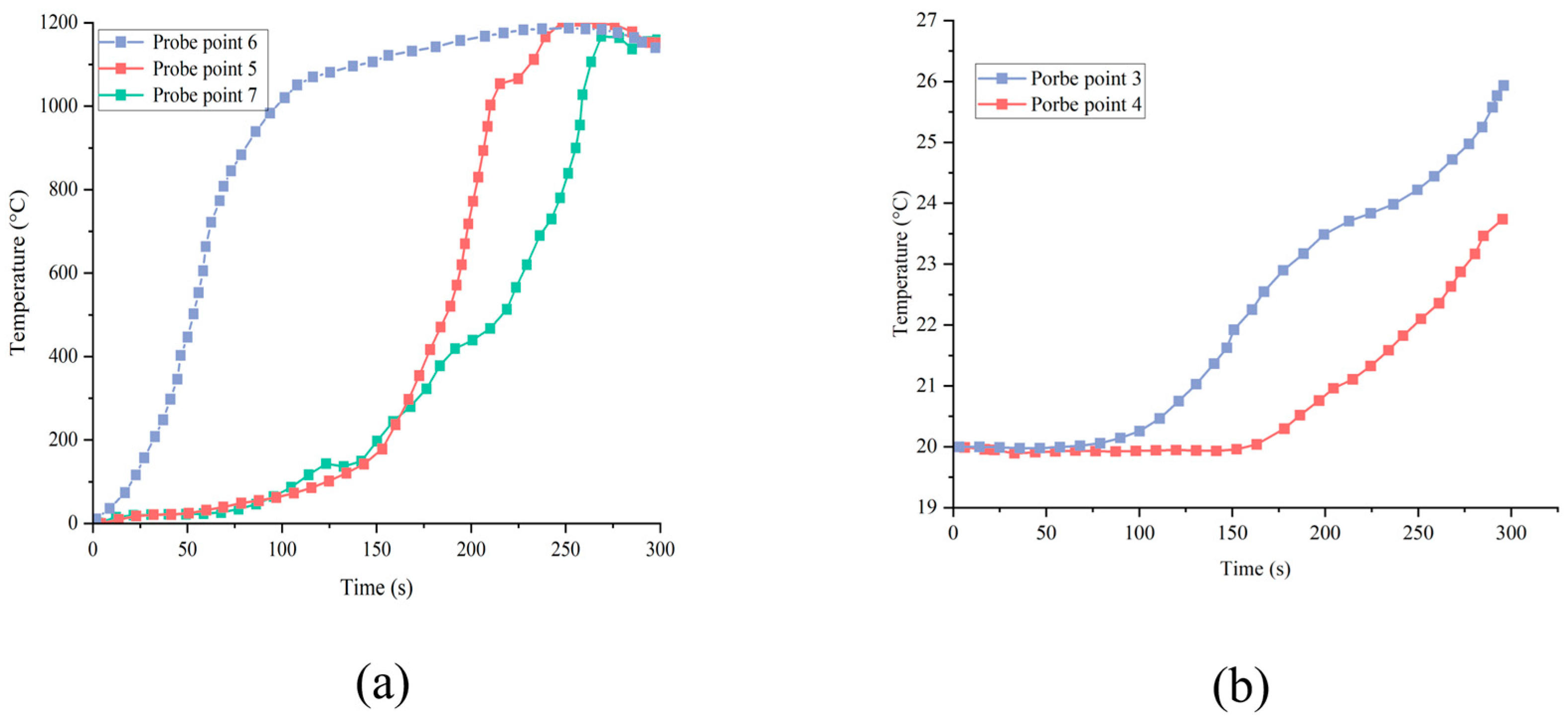

Figure 26a shows the temperature curves at the characteristic point height Z = 3.0 m above the three fire sources. It can be seen that the temperature rise curve during combustion is basically consistent with the HRR change law of the heat release rate. After t = 120 s, the initial fire source enters the stable combustion stage, and the highest temperature above the fire source reaches about 1200 °C. After t = 240 s, the inner delayed fire source enters the stable combustion stage, and the highest temperature above the fire source is also about 1200 °C. The outer delayed fire source, due to its proximity to the ventilation opening, has a slower temperature rise compared to the inner side, and the temperature fluctuation is larger. After t = 270 s, tending towards stability, with a maximum temperature of 1200 °C.

Figure 26b shows the temperature in the corridors and rooms of the living area on the upper deck.

The results show that, influenced by the smoke and wind generated by thermal convection, the temperature in the corridor starts to rise after 100 s and reaches 27 °C at t = 300 s, with significant fluctuations. The temperature in the room remains unchanged for the first 170 s and gradually increases after 170 s, reaching 24 °C at t = 300 s.

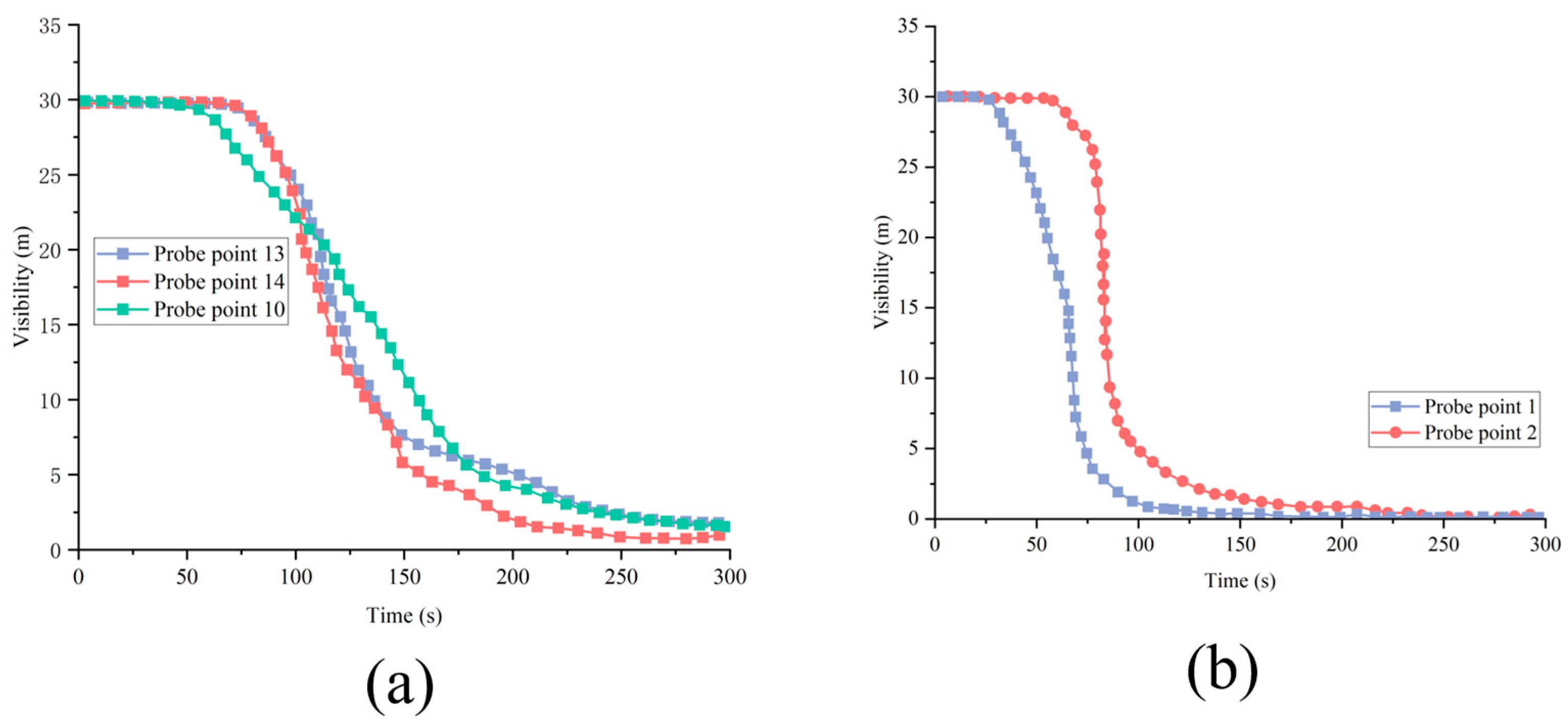

After a fire occurs, a large amount of heat is released at the source of the fire, and combustible materials burn and release a large amount of smoke. The smoke generated near the source of the fire belongs to a light fluid, and the hot smoke spreads upward to the roof of the ship’s deck building under buoyancy, forming a roof jet. After filling the roof, the smoke spreads outwards and affects visibility in other areas of the deck layer. In addition, smoke contains a large number of tiny black particles, which have strong shading properties and absorb light, reducing visibility around the smoke. The visibility changes during the fire simulation process are mainly obtained through the data obtained from the arrangement of detection points. The following analysis focuses on the time when the visibility reaches the safe visibility range of 5 m.

Figure 27 show the changes in visibility at a total of five stairwell detection points after a fire broke out on the main deck (a) and upper deck (b). It can be seen that due to the fact that smoke is a light fluid, it preferentially propagates upwards under buoyancy. Therefore, the visibility at the two stairwells on the upper deck decreased at the fastest rate to below 5 m at 70 s and 80 s, respectively, followed by the changes in visibility at the three detection points on the upper and lower stairwells on the main deck. As smoke first covered the ceiling of the main deck and then spread downwards, the decrease in visibility at this detection point was slower compared to the upper stairwell detection point, dropping to below 5 m between 150 s and 170 s.

After the cabin sprinkler system is activated, the temperature of the three fire sources, the main deck staircase, the

X-axis, the

Y-axis and the

Z-axis are monitored and analyzed. As shown in

Figure 28,

Figure 29 and

Figure 30, by comparing the temperatures at y = 7.5 m, x = 30 m, and z = 3 m after a fire occurs at 100 s, 200 s, and 300 s with and without the water sprinkler system, it can be seen from the comparison of the charts that the temperature rise in each section when the water sprinkler system is turned on at the same time after the fire occurs is much smaller than the temperature rise in each section when the water sprinkler system is not turned on at the same time. For the convenience of observation, the color of the area between the temperature range below 60 °C and above 0 °C was changed to black in this simulation. Comparing the

x-axis temperature slice with the y-axis temperature slice, it can be seen that when the sprinkler system is not turned on, the temperature in the car cabin rises rapidly. At 260 s, except for the black rectangular area representing the car model in the middle of the slice, there is no black area inside the entire space of the main deck car cabin, indicating that after 260 s, the temperature inside the entire cabin space is above 60 °C. On the other hand, after activating the water spray system, the temperature in the lower half of the interior of the main deck car compartment remained below 60 °C even after reaching the maximum value of 300 s. By comparing the

z-axis temperature slices, it can be seen that after starting the sprinkler system, the heat propagation rate and diffusion range of the fire source within the same time period are much smaller than those of the source without turning on the water sprinkler system, which can effectively suppress the spread of the fire.

Because the water mist sprayed by the sprinkler system will fill the main deck car cabin, causing further decrease in visibility, this article mainly focuses on setting up visibility monitoring points at the upper deck staircase to monitor the spread of smoke after a fire occurs. As shown in

Figure 31, the decrease rate of visibility data at the measurement points after turning on the water spray system is smaller than that without turning on the water spray system. It can be seen that fire water mist can slow down and block the spread of smoke, and at the same time, the water drips in the mist can also adsorb carbon particles and harmful components in the smoke.

6.3. Exploration of Optimization Strategies for Fire Protection Systems

The simulation results of the high-expansion foam fire suppression system indicate that it works by physically covering and isolating, effectively reducing the temperature of the vehicle compartment. However, this system has a significant response lag. The generation, diffusion, and formation of the foam to create an effective covering layer require a considerable amount of time, resulting in poor fire suppression efficacy in the early stages of a fire. Additionally, the foam has limited penetration and cooling capabilities for deep-seated fires such as lithium-ion battery fires. In the simulation, it can be observed that there is still continuous high temperature below the covered area, posing a risk of re-ignition. Therefore, in the scenario of ro-ro passenger ships with new energy vehicles where rapid suppression and deep cooling are emphasized, the high-expansion foam system is not the optimal choice. However, after the fire is initially controlled, it can be used to establish a long-lasting covering layer to play an auxiliary role in preventing re-ignition.

By comparing and analyzing the experimental results, it can be found that there is no optimal droplet size that is applicable to all scenarios. Fire suppression and cooling efficiency depend on the spatial position and the dominant fire suppression mechanism. In the core area of the fire source, due to the strong upward hot air current generated by the battery fire, larger particle size droplets, with better penetration ability, can effectively break through the hot air current and directly cool the surface of the battery, showing the best fire control effect. While in the areas far from the fire source, smaller particle size droplets, with better diffusion, longer suspension time and rapid heat absorption and evaporation characteristics, can form a wide cooling fog curtain, thereby most effectively reducing the temperature of the surrounding environment. Therefore, in extinguishing the fire in the carriage, the fine water mist system exhibits multi-mechanism protective characteristics: it can achieve cooling of the fire source through large particle size droplets and also achieve large-scale environmental cooling with small particle size droplets. However, due to the smaller diameter of the fine water droplets, their weight is relatively light, and their adsorption and blocking effect on smoke diffusion is also relatively limited.

The steam generated by heating water to its boiling point can both extinguish fires and has the advantages of low cost and high efficiency. However, due to the lack of cooling effect, when the gas supply is stopped and the steam condenses, the air and gas will reoccupy the space, posing a risk of re-ignition. In spray fire suppression operations, water mist particles are small in diameter, and the water vapor produced by the evaporation of water can dilute oxygen and exert a suffocating fire-extinguishing effect. However, FDS provides large-scale turbulence simulation capabilities to accurately capture the flow field and temperature field, but FDS regards the evaporation of water mist as a physical phase change process, calculates its heat absorption cooling effect, and does not consider the generated water vapor as an inert medium to participate in the combustion chemical reaction. In addition, this paper, apart from high-expansion foam, in the experiments, natural ventilation was adopted, and the suffocating effect of water vapor was not fully simulated. But this will be addressed in future work. Meanwhile to partially compensate for this limitation, this paper indirectly reflects the fire-extinguishing effectiveness of fine water mist by fully modeling its physical cooling mechanism. The simulation calculated the huge amount of heat absorbed by water droplets during evaporation, which directly led to a decrease in the temperature in the fire area, thereby inhibiting the rate of the combustion reaction.

The water mist system nozzles with different spray angles have their own advantages and disadvantages in terms of fire-fighting effectiveness after a fire occurs. Nozzles with a small spray angle have a more concentrated water flow, which can more efficiently penetrate and extinguish fires in batteries; while nozzles with a large spray angle have a more uniform water distribution, a wider coverage area, better effect in blocking smoke diffusion, and can effectively disperse or remove heat. For different types and sizes of ro-ro passenger ships, corresponding spray angles should be adopted to ensure the best smoke-blocking effect while achieving the required fire-extinguishing efficiency.

After a fire occurs, if the part of the space where the ignition source is located can be separated from other spaces, the concentration of combustion aids can be significantly reduced, thereby exerting a suffocating and extinguishing effect on the fire source. At the same time, it can effectively block the heat radiation and smoke diffusion of the fire source. Taking this article as an example, by constructing a barrier thin wall with insulation materials on all four sides to isolate the fire source, the risk of fire occurrence is greatly reduced, and the fire protection system also plays a more effective role. Therefore, in response to the possibility of secondary ignition caused by the presence of cars and a large number of combustibles in the surrounding area after a fire, it is recommended to install a fire shutter device above the ceiling of the car compartment on the main deck. At the same time, water spray and mist function can be added on the basis of the rolling shutter door to further enhance the fire prevention effect. The fire roller shutter door can fall simultaneously with the start of the water sprinkler system. Once a fire is detected, it quickly divides the interior of the main deck car compartment into multiple small spaces, separating the ignition area from other areas and greatly reducing the possibility of igniting surrounding combustibles. At the same time, research and design should be carried out on the type, hanging height, quantity, etc., of the fire roller shutter. Whether to choose a movable or fixed fire roller shutter should be based on the actual situation of different types and sizes of passenger roller boat car compartments, and the most suitable solution should be selected to ensure that the fire roller shutter plays a role while not hindering the water sprinkler system from exerting the same effect.