Research on Temperature Distribution of Cable Fire in Utility Tunnel and Fire Extinguishing Efficiency of High-Pressure Water Mist Fire Extinguishing System

Abstract

1. Introduction

2. Experimental Setup

2.1. Utility Tunnel Platform

2.2. HWMFES

2.3. Fire Source

2.4. Ventilation System

2.5. Instrumentation

2.5.1. Temperature Measurement

- Directly above the fire source

- On the fire source side

- On the fire source opposite side

2.5.2. Ventilation Speed Measurement

2.6. Test Method

- Test Condition 1 served as a baseline. Twelve flame-retardant cables were laid on each tray layer on the fire source side, and the HWMFES was not activated. This condition aimed to investigate the natural temperature distribution characteristics of cable fires within the utility tunnel.

- Test Conditions 2 and 3 were designed with twelve flame-retardant cables per layer on the fire source side. The HWMFES was activated at spray intensities of 0.7 L/(min·m2) and 1.0 L/(min·m2), respectively, to compare the effect of this parameter on the extinguishing effectiveness of the HWMFES.

- Test Condition 4 differed from Test Condition 2 only in the number of cables on the fire source side, which was reduced to six per layer. This comparison evaluated the influence of cable fullness on the HWMFES ‘s performance.

- Test Condition 5 was conducted under the same cable configuration as Test Condition 4 (six cables per layer) but with the fan activated to create a 2 m/s ventilation speed. This condition examined the effect of longitudinal ventilation on the fire extinguishing performance of the HWMFES.

3. Results and Discussion

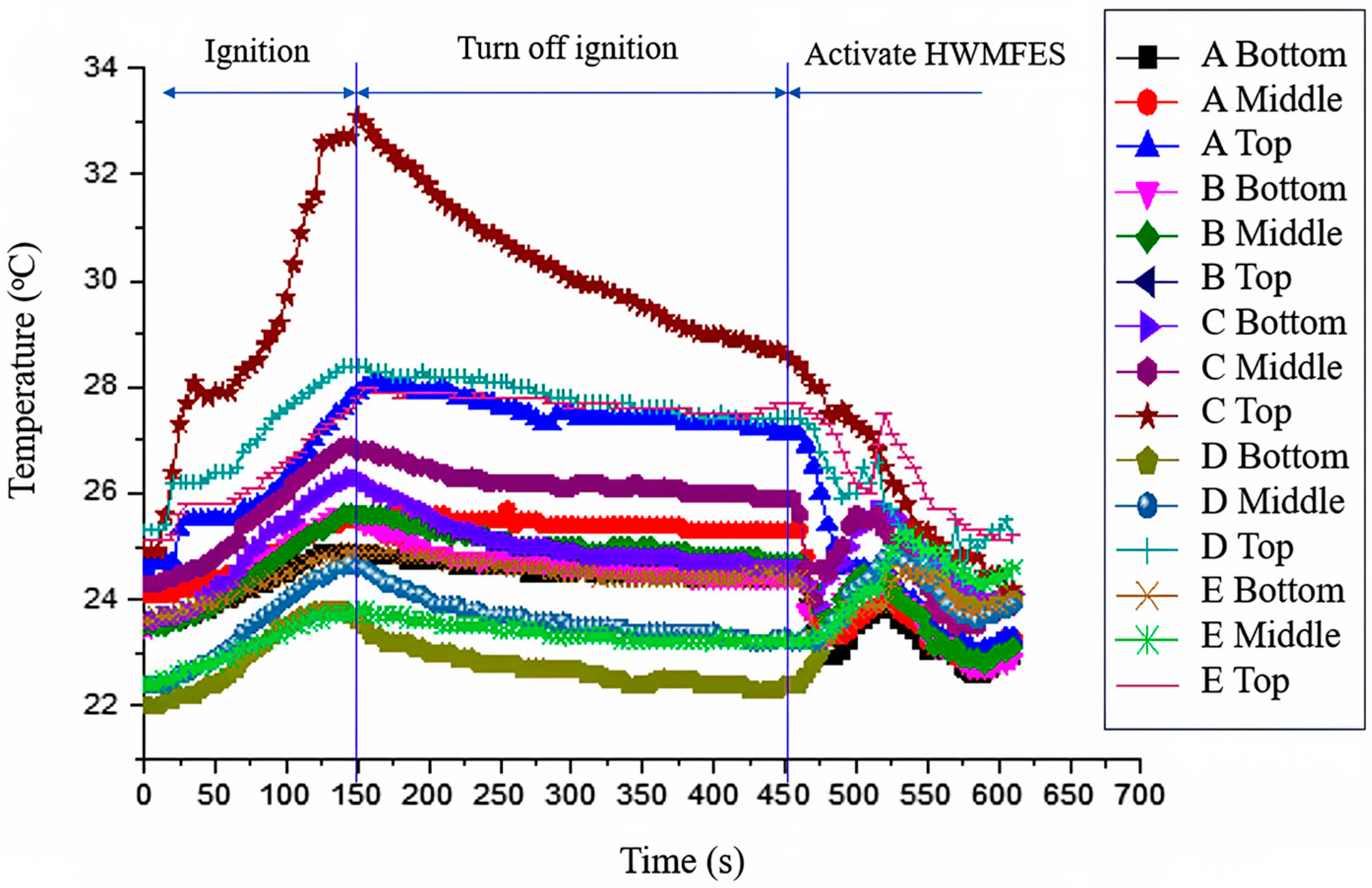

3.1. Temperature Distribution Characteristics of Cable Fire in the Utility Tunnel

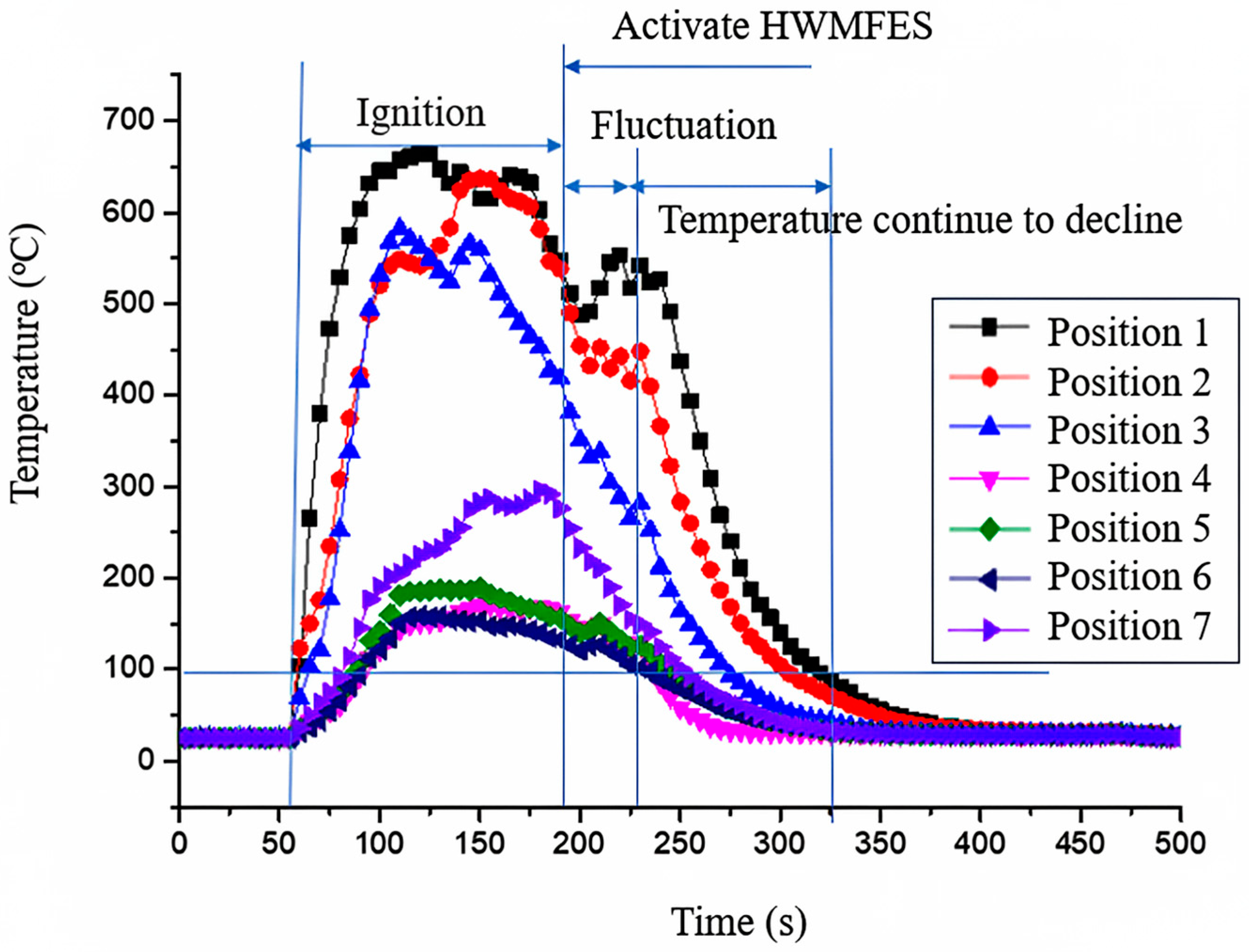

3.2. Influence of Spray Intensity on Fire Extinguishing Effect of HWMFES

3.3. The Influence of Cable Fullness on the Effectiveness of HWMFES

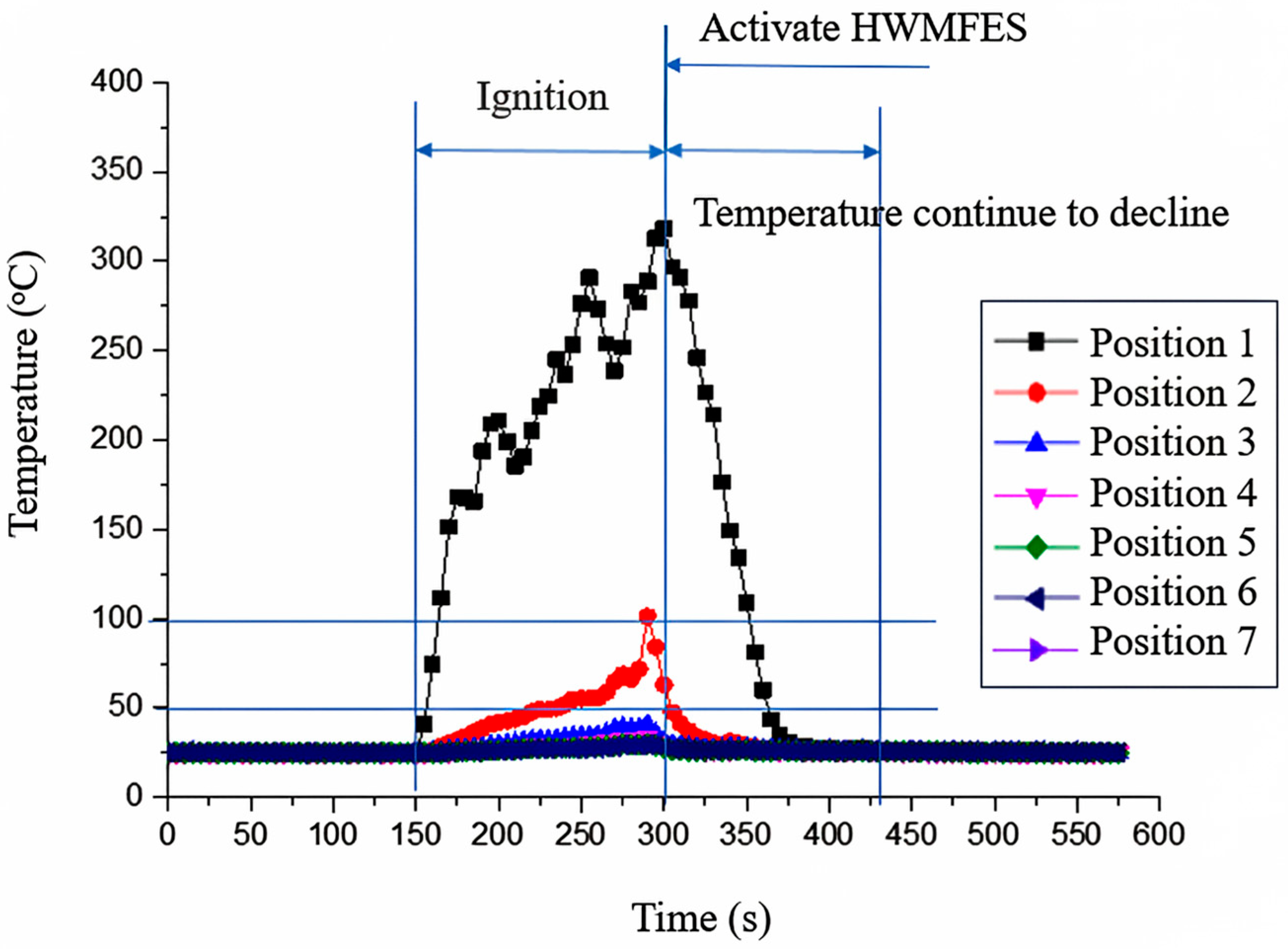

3.4. Impact of Longitudinal Ventilation on the Effectiveness of HWMFES

4. Conclusions

- (1)

- The maximum thermal hazard from cable fires is concentrated within the three tray layers directly above the fire source, where peak temperatures reach 825 °C, while adjacent and opposite areas experience negligible thermal impact. Fire protection design should prioritize these critical zones through a zoning approach. Thermal insulation and fire resistance requirements for structural elements should be specifically strengthened within this vertical region directly above potential ignition sources, while less stringent measures may be applied to other areas to optimize cost-effectiveness.

- (2)

- Increasing the spray intensity from 0.7 to 1.0 L/(min·m2) enhances cooling efficiency by 87.8%, reducing the time to achieve 100 °C by 38.2%. This finding establishes that for utility tunnel cable fire protection using HWMFES, the minimum spray intensity should be specified as 1.0 L/(min·m2).

- (3)

- Reducing cable fullness from 12 to 6 cables per tray decreases peak temperatures by 160 °C and reduces extinguishing time by 22.5%. These results suggest that the Standard for Urban Utility Tunnel Engineering (GB/T 50838-2015) should be revised to include maximum cable loading density provisions to ensure effective fire extinguishing system performance. This revision should be accompanied by additional design guidelines for cable arrangement and compartmentalization to maintain safe fire load levels while meeting operational requirements.

- (4)

- A longitudinal ventilation speed of 2 m/s increases HWMFES effectiveness by 67.5%, cutting extinguishing time from 194 s to 63 s compared to still air conditions. Consequently, relevant standards should mandate maintaining 2 m/s ventilation during fire events to optimize extinguishing performance. System designs should incorporate capabilities to sustain this optimal airflow.

- (5)

- The demonstrated synergistic effects between spray intensity, cable density management, and longitudinal ventilation control highlight the importance of an integrated approach to fire safety design in utility tunnels. Future design methodologies should incorporate performance-based approaches that consider these factors synergistically rather than treating individual systems in isolation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liang, K.; Hao, X.; An, W.; Tang, Y.; Cong, Y. Study on Cable Fire Spread and Smoke Temperature Distribution in T-Shaped Utility Tunnel. Case Stud. Therm. Eng. 2019, 14, 100433. [Google Scholar] [CrossRef]

- Wu, J.; Bai, Y.; Fang, W.; Zhou, R.; Reniers, G.; Khakzad, N. An Integrated Quantitative Risk Assessment Method for Urban Underground Utility Tunnels. Reliab. Eng. Syst. Saf. 2021, 213, 107792. [Google Scholar] [CrossRef]

- Lee, B.; Lee, M.; Jung, W. Acoustic Based Fire Event Detection System in Underground Utility Tunnels. Fire 2023, 6, 211. [Google Scholar] [CrossRef]

- Bian, H.; Zhu, Z.; Zang, X.; Luo, X.; Jiang, M. A CNN Based Anomaly Detection Network for Utility Tunnel Fire Protection. Fire 2022, 5, 212. [Google Scholar] [CrossRef]

- GB/T50838-2015; Standard for Urban Utility Tunnel Engineering. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2015.

- Seo, H.; Chung, Y.; Song, T. An Experimental Study for Deriving Fire Risk Evaluation Factors for Cables in Utility Tunnels. Fire 2023, 6, 342. [Google Scholar] [CrossRef]

- Pan, R.; Zhu, G.; Liang, Z.; Zhang, G.; Liu, H.; Zhou, X. Experimental study on the fire shape and maximum temperature beneath ceiling centerline in utility tunnel under the effect of curved sidewall. Tunn. Undergr. Space Technol. 2022, 99, 103304. [Google Scholar] [CrossRef]

- Ye, K.; Tang, X.; Zheng, Y.; Ju, X.; Peng, Y.; Liu, H.; Wang, D.; Cao, B.; Yang, L. Estimating the two-dimensional thermal environment generated by strong fire plumes in an urban utility tunnel. Saf. Environ. Prot. 2021, 148, 737–750. [Google Scholar] [CrossRef]

- Jia, B.; Xia, Y.; Ning, Z.; Li, B.; Zhang, G.; Zhang, Z. Research on the Fire Extinguishing Efficiency of Low-Pressure Water Mist in Urban Underground Utility Tunnel Cable Fires. Fire 2023, 6, 433. [Google Scholar] [CrossRef]

- Zheng, X.; Cai, G.; Guo, J.; Gao, W.; Huang, Y.; Tong, X. Combustion characteristics and thermal decomposition mechanism of the flame-retardant cable in urban utility tunnel. Case Stud. Therm. Eng. 2023, 44, 102887. [Google Scholar] [CrossRef]

- Khattri, S.; Log, T.; Kraaijeveld, A. Tunnel Fire Dynamics as a Function of Longitudinal Ventilation Air Oxygen Content. Sustainability 2019, 11, 203. [Google Scholar] [CrossRef]

- Carvel, R.; Beard, A.; Jowitt, P. The influence of longitudinal ventilation systems on fires in tunnels. Tunn. Undergr. Space Technol. 2001, 16, 3–21. [Google Scholar] [CrossRef]

- Barbato, L.; Cascetta, F.; Musto, M.; Rotondo, G. Fire safety investigation for road tunnel ventilation systems—An overview. Tunn. Undergr. Space Technol. 2014, 43, 253–265. [Google Scholar] [CrossRef]

- Zhu, H.; Du, W.; Li, W. Experimental Study on the Influence of High-Pressure Water Mist on the Ceiling Temperature of a Longitudinally Ventilated Tunnel. Fire 2024, 7, 262. [Google Scholar] [CrossRef]

- Kan, D.; Feng, S.; Yan, Z.; Zhou, L.; Zhu, H. Full-scale experimental study on the smoke and thermal insulation of a water mist fire extinguishing system in a short road tunnel with natural ventilation. Tunn. Undergr. Space Technol. 2025, 158, 106414. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Q.; Tang, Z.; Zheng, F. Effect of water mist system settings on fire and upstream smoke control in a longitudinally ventilated tunnel. Tunn. Undergr. Space Technol. 2025, 155 Pt 2, 106234. [Google Scholar] [CrossRef]

- GB 50898-2013; Technical Code for Water Mist Fire Extinguishing System. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2013.

- NFPA 750; National Fire Protection Association. Standard on Water Mist Fire Protection Systems. National Fire Protection Association: Quincy, MA, USA, 2018.

- Sun, J.; Zheng, F.; Tang, Z.; Tarek, B.; Bart, M. Experimental study of the effectiveness of a water system in blocking fire-induced smoke and heat in reduced-scale tunnel tests. Tunn. Undergr. Space Technol. 2016, 56, 34–44. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, W.; Cai, X.; Pan, L.; Liao, G. Experimental study of water mist fire suppression in tunnels under longitudinal ventilation. Build. Environ. 2009, 44, 446–455. [Google Scholar] [CrossRef]

- Alenezi, M.; Sadek, H. Fire-suppression performance of high-pressure water mist system inside scaled-down road tunnel section. J. Eng. Res. 2023, 11, 100024. [Google Scholar] [CrossRef]

- Li, Q.; Tang, Z.; Fang, Z.; Yuan, J.; Wang, J. Experimental study of the effectiveness of a water mist segment system in blocking fire-induced smoke and heat in mid-scale tunnel tests. Tunn. Undergr. Space Technol. 2019, 88, 237–249. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, P.; Lin, Z.; Sun, S. Combustion characteristics and heat transfer mechanisms analysis of cable fire over ladder-type tray. Int. J. Therm. Sci. 2025, 215, 109935. [Google Scholar] [CrossRef]

- An, W.; Wang, T.; Liang, K.; Tang, Y.; Wang, Z. Effects of interlayer distance and cable spacing on flame characteristics and fire hazard of multilayer cables in utility tunnel, Case Stud. Therm. Eng. 2020, 22, 100784. [Google Scholar] [CrossRef]

- Song, H.; Yao, H.; Wei, X. Experimental study on fire suppression of the outdoor oil-immersed transformer by high-pressure water mist system. Fire 2023, 6, 238. [Google Scholar] [CrossRef]

- Blanchard, E.; Boulet, P.; Fromy, P.; Desanghere, S.; Carlotti, P.; Vantelon, J.; Garo, J. Experimental and Numerical Study of the Interaction Between Water Mist and Fire in an Intermediate Test Tunnel. Fire Technol. 2014, 50, 565–587. [Google Scholar] [CrossRef]

- Yan, W.; Li, C.; Zhao, P.; Gao, Z. Validation of the Froude model applicability for flame and thermal properties of tunnel fires with different cross-section scale ratios. Int. Commun. Heat Mass Transfer. 2025, 164 Pt B, 108916. [Google Scholar] [CrossRef]

| Test Condition No. | Number of Cables | Ventilation Speed (m/s) | Spray Intensity (L/min·m2) |

|---|---|---|---|

| 1 | 12 | - | - |

| 2 | 12 | - | 0.7 |

| 3 | 12 | - | 1.0 |

| 4 | 6 | - | 0.7 |

| 5 | 6 | 2 | 0.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, K.; Du, P.; Liu, H.; Fu, Y.; Li, T. Research on Temperature Distribution of Cable Fire in Utility Tunnel and Fire Extinguishing Efficiency of High-Pressure Water Mist Fire Extinguishing System. Fire 2025, 8, 404. https://doi.org/10.3390/fire8100404

Xiang K, Du P, Liu H, Fu Y, Li T. Research on Temperature Distribution of Cable Fire in Utility Tunnel and Fire Extinguishing Efficiency of High-Pressure Water Mist Fire Extinguishing System. Fire. 2025; 8(10):404. https://doi.org/10.3390/fire8100404

Chicago/Turabian StyleXiang, Kun, Peng Du, Hongrun Liu, Yaojia Fu, and Taoran Li. 2025. "Research on Temperature Distribution of Cable Fire in Utility Tunnel and Fire Extinguishing Efficiency of High-Pressure Water Mist Fire Extinguishing System" Fire 8, no. 10: 404. https://doi.org/10.3390/fire8100404

APA StyleXiang, K., Du, P., Liu, H., Fu, Y., & Li, T. (2025). Research on Temperature Distribution of Cable Fire in Utility Tunnel and Fire Extinguishing Efficiency of High-Pressure Water Mist Fire Extinguishing System. Fire, 8(10), 404. https://doi.org/10.3390/fire8100404