Abstract

Small bookstores constructed before the 1970s have a high fire risk in the context of the revitalization of historical buildings; while the setup of simple sprinklers is an effective and cheap method of extinguishing fires, the parameters of the sprinklers are uncertain. In this study, small bookstores in Beijing were selected, and physical combustion experiments with/without a sprinkler system were carried out following the provisions of the Code for the Design of Sprinkler Systems. After the experiments, an FDS model was set up using fire dynamics software. The results show that the total heat release rate (HRR) of books and desks is related to the square of time, with a coefficient of 2.528 × 10−6, and the maximum heat release rate is 40 KW. Unlike the standard test, the physical combustion experiment is significantly affected by the space. According to numerical simulations, when the sprinkler flow velocity is 60~100 L/min, the water consumption of the sprinkler is 195~218 L. This study lays the foundation for the analysis of the combustion characteristics of small bookstores and provides data support for the installation of simple sprinkler systems in small bookstores.

1. Introduction

Fires are one of the main reasons for the loss of life and property in cultural spaces, e.g., libraries and bookstores. The high fire load of cultural spaces makes them particularly susceptible to the spread of fires. Thus, many researchers have focused on the fire safety of libraries in terms of fire risk assessment, the fire load density, and the safety evacuation ability, mainly through on-site investigation and Fire Dynamics Simulator (FDS) experiments [1,2,3].

The fire safety of libraries can be guaranteed through a sufficient fire detection system and fire suppression system and the fulfillment of the basic requirements of egress and evacuation [1]. Compared to libraries, the fire safety of bookstores, especially small ones, is difficult to ensure. Taking the bookstores located within the Third Ring Road of Beijing as an example, some courtyards in hutongs constructed in the 1970s or earlier, i.e., constructed before the introduction of fire prevention regulations, were not equipped with firefighting facilities when they were transformed into bookstores during the revitalization of historical buildings. In particular, these bookstores were not equipped with water facilities such as storage tanks or sprinkler systems at the time of their original construction. Once a fire breaks out, firefighting and rescue efforts can be difficult. In addition, the bookshelves lack the necessary fire separation distance due to space limitations, and bookstores consist of combustible materials like paper books, wooden bookshelves, desks, and plush toys, resulting in a significantly higher fire risk [4]. Therefore, it is necessary to systematically conduct a fire risk assessment for small bookstores and propose technical suggestions for fire protection. However, there are few reports on the parameters of simple sprinkler systems.

Many researchers have analyzed fire risk assessment and fire prevention measures for bookstores through numerical simulations by using FDS [5]. Numerical simulations and fire experiments are two methods used to explore firefighting strategies [6,7,8,9], but fire experimentation in small bookstores is less reported, requiring further study.

In order to extinguish bookstore fires effectively, a simple sprinkler system could be built by utilizing a municipal water source [10,11]. Although water is destructive to books, and halons show better fire-extinguishing performance than water, they result in the generation of bromine and chlorine free radicals [12,13]. Thus, a water fire-extinguishing system is more suitable for bookstores, but the appropriate fire extinguishing time and optimal water spray parameters need to be determined [14,15,16,17]. Predictions obtained via real experiments and numerical simulations could be used to effectively and economically determine the fire-extinguishing time and water spray parameters of a sprinkler system [18,19,20]. According to the Code for the Design of Sprinkler Systems (GB 50084-2017) [21], the empirical constant for fire extinguishment and the minimum operating pressure for a wet sprinkler system in a commercial site are 80 and 0.05 MPa, respectively, while the flow intensity is in the range of 6–8 L/min·m2. However, the role of the flow velocity in the extinguishment performance needs to be explored. Therefore, in this study, both experiments and an FDS model were set up with an empirical constant of 80 and a pressure of 0.05 MPa (0.5 bar).

Furthermore, it is easier to extinguish fires using smaller water droplets; thus, a water mist with a droplet size of 150 µm or below has a better fire-extinguishing effect than those of 200 or 300 µm [22,23]. In the FDS model, the median droplet diameter is 150 µm and the flow velocity is varied from 60 to 100 L/min to explore the effects of the flow velocity on the extinguishment performance.

To systematically study the fire risk assessment of small bookstores and obtain the extinguishing time of the FDS model regarding bookstore fires, this study consists of the following: (i) an on-site investigation of three typical small bookstores in Beijing to obtain the spacing of bookshelves and desks and the placement form of books; (ii) the use of a cone calorimeter to conduct standard tests on desks and books to analyze the characteristics of the combustion mass loss; (iii) the design and performance of a physical combustion experiment on a small bookstore to obtain the necessary data; and (iv) the establishment of a numerical FDS model based on the results of physical tests, seeking to provide data on the extinguishing time and water spray parameters for simple sprinkler systems. The results could provide data support for the numerical simulation of fire spread and extinguishing in small bookstores and subsequent research on similar small commercial stores.

2. Investigation, Experimental Methods, and Materials

2.1. Method of On-Site Investigation

Three small bookstores located within the Third Ring Road of Beijing, built in the 1970s or earlier and renovated in the 2010s, were chosen as research subjects, with a primary focus on the size, layout, and spacing of bookshelves, as well as the placement of books, equipment, and fire extinguishing devices. The assessment and investigation methods refer to the requirements of the Guidelines for Fire Safety Assessment of Crowded Places (XF/T 1369-2016) [24].

2.2. Experimental Methods

2.2.1. Cone Calorimeter Test Arrangement

As shown in Figure 1, the cone calorimeter test is conducted according to the ISO 5660 standard to measure the heat release rate (HRR) of books and furniture. The cone calorimeter consists of a standard combustion chamber, a conical heater, and an exhaust duct, among other parts. The combustion chamber’s internal dimensions are 3.0 m × 3.0 m × 1.3 m. The test platform holds a 1.0 m × 0.6 m desk. Books are stacked horizontally on both sides and the back of the desk, while the central part of the front has books placed vertically. Finally, books are placed on top in an open manner to facilitate combustion.

Figure 1.

Furniture combustion test bench. (a) Test design drawing. (b) Test site drawing. (c) Test detail arrangement.

At the beginning of the experiment, an igniter is used to start the fire, with the ignition point located above the desk (Figure 1c). The heat release rate is calculated by following Formula (1):

where Q is the heat release rate of the fire source, in units of KW; is the fire growth coefficient; and t is the fire growth time. During the test, thermocouples, a camera, and weight sensors are used to record data in real time, and after the test, the residual flame is extinguished.

2.2.2. Physical Combustion Experiment Arrangement

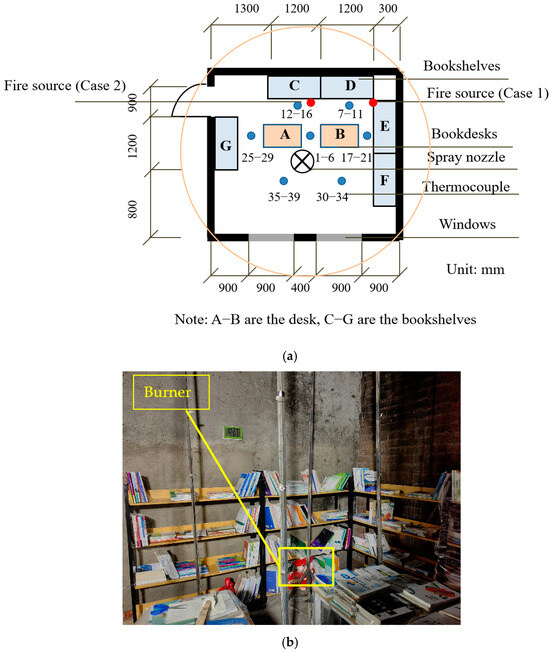

Considering the impact of spatial dimensions on the combustion experiment, the test site was selected as the China Southern Consumer National Fire Experimental Center, which measures 90 m × 20 m and is comparable to the experimental setup used by Gupta [25]. An internal experimental room with dimensions of 4 m × 3 m was utilized, designed to simulate an actual bookstore layout. The placement of desks, bookshelves, and thermocouples is illustrated in Figure 2a. The fire test room is a rectangular structure with a width of 3 m, length of 4 m, and height of 3 m. The north-facing 4 m long wall features two windows (0.9 m × 1.2 m each), while the east side has a door (0.9 m × 2.0 m).

Figure 2.

Layout diagram of bookstore combustion experiment. (a) Test layout. (b) Test site drawing.

Inside the bookstore, bookshelves and desks are arranged. The bookshelves, each measuring 1.2 m long, 0.3 m wide, and 1.54 m high, are placed along the east, south, and west sides, with one on the east and two each on the south and west sides. The dimension of each desk is 1 m long, 0.6 m wide, and 0.73 m high, and 60 Kg of books are placed on each desk, with the height of the books on the desk reaching about 20 cm. The weights of books, desks, and bookshelves are about 1320 Kg, 100 Kg and 500 Kg, resulting in about 1540 MJ/m2, 100 MJ/m2, and 500 MJ/m2 of fire load density. Due to the relatively large scale of the corner fire, the ignition point is located between the two bookshelves on the south side in order to simulate the corner fire in Case 1, and the other is near the first point on the left in Case 2. As shown in Figure 2b, books are arranged with horizontal stacking on desks, half lying flat and half upright on shelves, with predominantly horizontal stacking on shelves distant from the corner. Some books are scattered on the floor. Before the experiment, 50 mL of n-heptane is evenly sprayed onto shelves and books using a sprayer, with ignition initiated by a plush toy at the bottom corner (Figure 2b). The n-heptane fire load density (0.14 MJ/m2) is negligible compared to the books, serving only as an ignition aid for the first 10 s of the test.

Following the Code for Design of Sprinkler Systems, a wet spray nozzle of 80 L/min is set in the middle of the experiment site, while the empirical constant for fire extinguishment and minimum operating pressure are set as 80 and 0.05 MPa, respectively. Two experimental cases are set up; the spray nozzle in Case 1 is closed while in Case 2 it is open. A flowmeter is applied to monitor the flow velocity.

2.3. Simulation Methods

2.3.1. FDS Model

In this study, the PyroSim (2021) software was used to create the FDS model. The model is appropriately simplified, simulating the layout based on the physical combustion experimental configuration. The specific layout is shown in Figure 3. It is assumed that the desks are uniformly arranged as rectangular blocks measuring 1 m in length, 0.6 m in width, and 0.2 m in height. The dimensions and spacing of desks and bookshelves are almost the same as in the combustion experiment of Figure 2. A simplified model was created using CAD and then imported into FDS to establish the computational model. The external and internal structure of the experimental model is shown in Figure 3. The simulation time is set to 4000 s, and the environmental temperature is defined as 20 °C, with a relative air humidity of 40%. The mass fraction of oxygen is around 0.23 Kg/Kg, and the mass fraction of carbon dioxide is 5.95 × 10−4 Kg/Kg. Two-dimensional slices of temperatures are set at X = 1.65 m, Y = 1.65 m, Z = 0.73 m, Z = 1.7 m, and Z = 3.1 m. Followed the previous study [7], the materials for the desk, wall, fire, and steel were set, and Large Eddy Simulation was chosen as the simulation type.

Figure 3.

Simulation model. (a) Burner (Case 1); (b) open surfaces, front view; (c) 2D slice, front view.

2.3.2. Grid Size

The grid sensitivity analysis shows that the grid size should be between 1/4 and 1/16 of the characteristic flame diameter. In practical applications, it is typically between 1/12 and 1/8. The characteristic flame diameter is calculated using the following Formula (2):

where is the HRR of the fire source in units of KW; is the air density, taken as 1.2 Kg/m3; is the specific heat of air, taken as 1 KJ/(Kg·K); is the ambient air temperature, taken as 293 K; and is the gravitational acceleration, taken as 9.81 m/s2. In this study, the HRR of the simulated small bookstore is around 2.5 MW [26]; thus, we use the range between 2 and 4 MW, with the calculated characteristic flame diameter ranging from 1.27 m to 1.67 m. To ensure that the simulation results align more closely with the actual computational requirements, the grid size is set to 0.15 m × 0.15 m × 0.15 m for the simulation (as seen in Figure 3), and all regions use a uniform Cartesian coordinate grid.

2.3.3. Fire Source Setup

The fire source is configured in the triangular shape depicted in Figure 4. The burner is positioned in a location consistent with the design of the physical experiment, with detailed material parameters of the burner provided in Appendix A. The fire source is defined as a square with 0.3 m sides, and its heat release rate (HRR) is determined by the results of cone calorimeter tests. In accordance with the code [26], the fire growth rate is classified as a t2 fast fire.

Figure 4.

Spray nozzle scene diagram.

For the test and simulation of the actual size of the experiment, a sprinkler head is installed, as shown in Figure 4.

2.3.4. Sprinkler System

Referring to the provisions of the Code for Design of Sprinkler Systems [21], the flow intensity of the wet sprinkler system in bookstore was 6–8 L/min·m2. The empirical constant of fire extinguishment and minimum operating pressure were set as 80 and 0.05 MPa, respectively. Sprinkler flow velocities of 60 L/min, 80 L/min, and 100 L/min were selected. Four working conditions were designed to analyze the fire extinguishing situation for cases with and without a sprinkler response, as well as different flow velocities. The specific working conditions are shown in Table 1. The sprinkler pressure is set to 0.5 bar with a protection radius of 3 m. Following the previous study [7], the spray velocity and angle are set as 5 m/s and 60°, respectively, and the median diameter of water droplets is set at 150 µm with a constant size distribution. The nozzle activation temperature is set at 74.0 °C. The simulated working conditions are listed in Table 1, and the details of the sprinkler material model are provided in Appendix A. The sprinkler head activates when the activation temperature is reached, and the continuous spraying duration does not exceed 10 min. Under Conditions 2, 3, and 4, the fire extinguishing time under standard conditions can be observed.

Table 1.

Simulated working conditions.

2.3.5. Measurement Point Arrangement

To explore the fire spread pattern within the bookstore during a fire incident, multiple measurement slices were established in the FDS simulation. Taking into account the impact of the fire on the books’ preservation and intra-room temperature dynamics, eight typical temperature slices were configured at horizontal heights of 0.65 m, 0.75 m, 1.65 m, and 1.75 m. Additionally, vertical sections were set along the X-axis at 1.65 m, the Y-axis at 1.65 m.

3. Experiments and Simulations

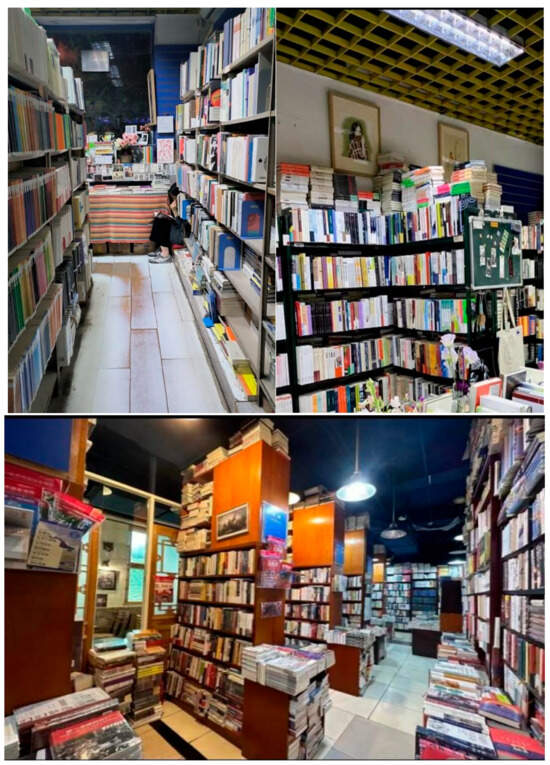

3.1. Investigation Results

As shown in Figure 5, the book placement in the bookstore is illustrated. As shown in the figure, nearly all bookshelves are fully stocked with books, with most volumes arranged vertically and some placed horizontally on top of the shelves. Research indicates that the spacing between bookshelves and desks ranges from 0.8 to 1.2 m. Each shelf row contains approximately 30 to 40 books, with a total weight of about 50 kg. To save space, an additional 20 to 30 books are stacked along shelf edges and on desks. Surveys reveal that books in these bookstores are often left disorganized after browsing, with random placement observed. Therefore, in this study, in the subsequent combustion experiments, the number of books was calibrated, and two placement methods—flat-laying and upright-standing—were selected with a 1:1 ratio.

Figure 5.

Bookstore’s book placement method.

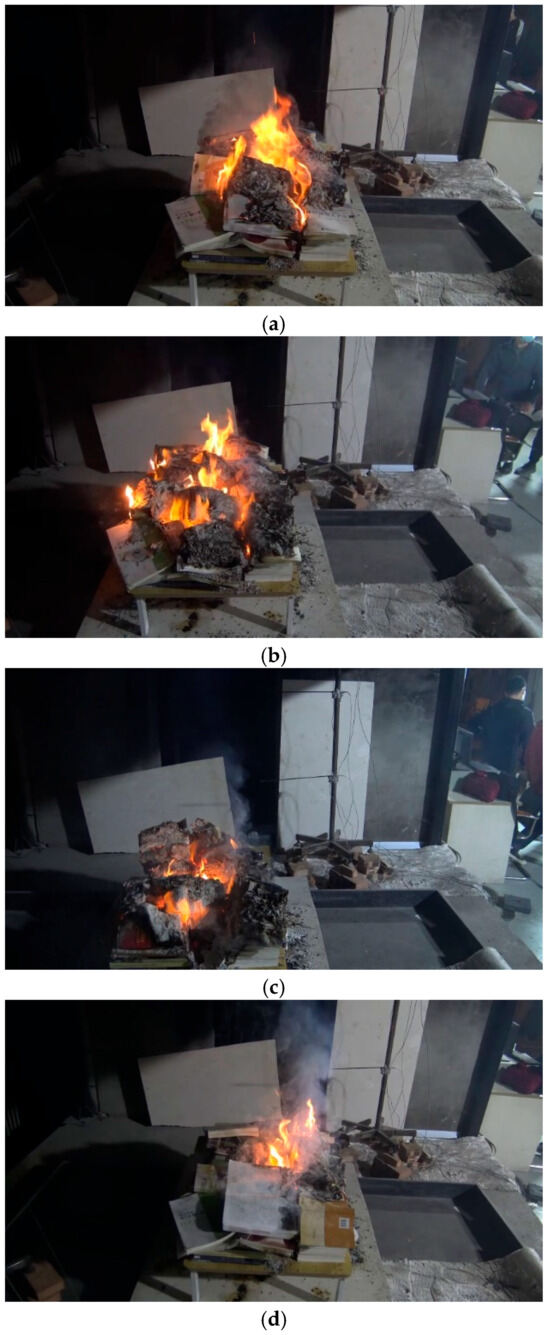

3.2. Book and Desk Combustion Test

Figure 6 shows the standard test phenomena of books and desks at different time points. During the initial ignition stage, the heating of the books caused the side closest to the fire source to darken, with smoke dispersing from the desk center—clearly distinguishable from the flame front. By 460 s, most ignited books had self-extinguished, while the fire had fully spread to both sides of the desk, intensifying combustion. At 800 s, only the books along the lower edges of the desk remained unburnt. The remaining books had formed charred residues that coated the combustible surfaces, inhibiting new fuel-oxygen contact and suppressing further burning. The originally conical flame structure became fragmented. By 1200 s, combustion remnants in front of the desk collapsed, and combustible material at the desk center was severely depleted, marking the fire’s transition to the decay stage. At 1600 s, upper-layer and central-desk books had decomposed into ash, while corner-bottom books remained relatively intact. The overall burned area exhibited an elliptical morphology, with white smoke emissions increasing alongside residual material accumulation.

Figure 6.

Schematic diagram of book burning phenomenon at different times. (a) t = 460 s. (b) t = 800 s. (c) t = 1200 s. (d) t = 1600 s.

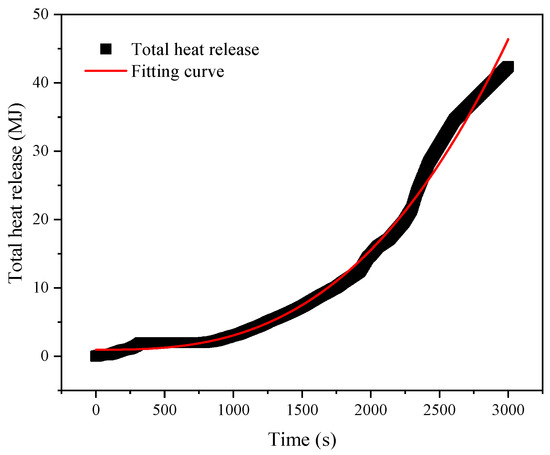

Figure 7 shows the heat release curve of the books and desks. It can be observed that the HRR is related to the square of time. Using Formula (1) with a coefficient of 2.528 × 10−6, the book burning rate is judged to be a slow fire [26]. This finding aligns with previous research, which indicates that fire growth in bookstore tests follows a slow-to-medium t-squared fire [5]. However, the deviation from the linear mass loss rate trend is primarily attributed to intensified combustion caused by the ignition of the wooden desk at approximately 1000 s. This event triggered an increase in the heat release rate (HRR), with a maximum value of 40 kW recorded during the test. In the physical combustion experiment, approximately 1200 Kg of books, together with desks and bookshelves, was consumed, leading to an estimated HRR of 2 MW for the fire source.

Figure 7.

Correlation between total heat release and square of time.

3.3. Physical Combustion Experiment

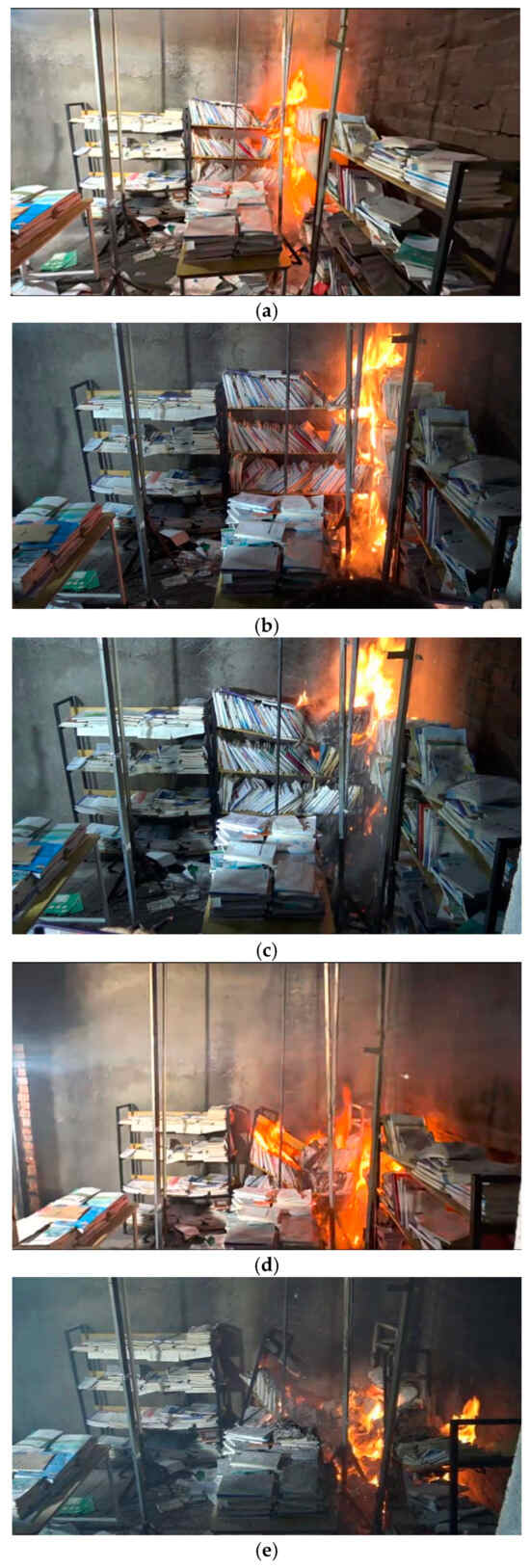

Figure 8 shows the combustion phenomenon in a small bookstore in Case 1. During the initial ignition stage, the corner-located fire source generated tall flames, readily igniting nearby combustibles on the bookshelves. By 100 s, flames had spread to nearly the entire corner-adjacent bookshelf. As combustion intensified, a burning scroll formed on the floor, accompanied by the increased tilting of the bookshelf. At 440 s, numerous books had fallen from the wooden shelves, with scattered flames present on the floor. The fire propagated to the third and fourth shelves farthest from the windows, emitting white smoke that filled the upper room. By 650 s, combustion intensified: some burnt books on the third shelf collapsed, exposing partially unburnt materials. Enhanced oxygen access to these exposed books further fueled combustion, causing flames to turn bright white. Meanwhile, fallen debris continued burning on the floor, generating new intense flames. Books on the first shelf were almost completely charred, and the fire had clearly spread to the bookshelf’s window-opposite end. Near-window books on the first shelf exhibited distinct bending, while the wooden planks’ central region became more warped. At 900 s, fire spread ceased, and flame intensity decreased significantly. The window-adjacent bookshelf had mostly collapsed, with only a few shelf books still smoldering and the rest intact; clear smoke emissions persisted. Nearby desk books showed no combustion signs, with only minor unburnt residues along the bookshelf edges. White ash settled onto desks and remaining books. By 2000 s, combustion residues gradually covered book surfaces, obstructing air contact and causing fire weakening as combustion entered the decay stage. At 2500 s, the smoke volume increased further: with most open flames extinguished, the fire transitioned to smoldering, and the entire room was enveloped in white smoke.

Figure 8.

Schematic diagram of phenomena at different moments of physical combustion experiments for Case 1. (a) t = 100 s. (b) t = 200 S. (c) t = 440 s. (d) t = 650 s (e) t = 2000 s. (f) t = 2500 s.

Although many books remained unburnt in the experiment, the fire intensity gradually diminished, with most visible flames extinguished. Smoke production increased, filling the room with white smoke that further suppressed combustion. Flames exhibited intermittent flickering due to insufficient oxygen, while some books and bookshelves continued smoldering. Compared to standard tests on books and desks, the physical experiment’s combustion rate showed a trend of an initial increase followed by a decline, with less complete combustion overall. These observations align with other small-scale room combustion experiments [27,28]. Unlike standard tests conducted in large, open-plan, well-ventilated spaces, this experiment’s small-scale environment—despite having a relatively high fire load density per unit volume—suffered from insufficient oxygen supply relative to combustible mass, thereby limiting the combustion process [29].

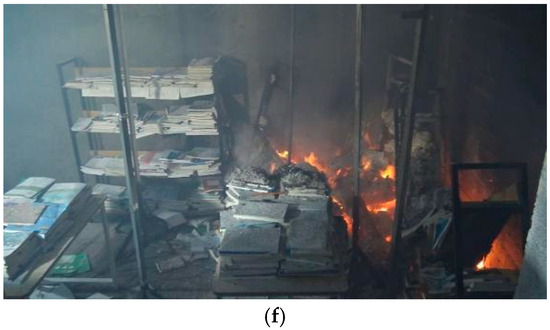

Figure 9 shows the temperature curves in Case 1. As shown in Figure 9a, during the combustion process, the temperature continuously rises and shows a wavy curve. This is attributed to the slow flame spread, where surrounding combustibles are ignited only as some flames subside. The flue gas temperature reaches its peak, the thickness of the flue gas layer increases continuously, and the heat transfer gradient remains gradual. The top temperature measurement point exhibits the highest temperature with volatility, as heat rises rapidly and accumulates at the ceiling, causing a sharp temperature increase. Compared to the 3 m and 2 m heights, temperatures at 0.5 m, 1 m, and 1.5 m heights are approximately 50 °C lower. Figure 9b shows a similar trend for 3 m and 2 m heights, with the temperature under the sprinkler being 40 °C higher than that near the fire source. Conversely, temperatures at 0.5 m, 1 m, and 1.5 m heights increase slowly, due to reduced heat absorption at lower elevations.

Figure 9.

Change in temperature in Case 1. (a) Near the fire source. (b) Under the sprinkler.

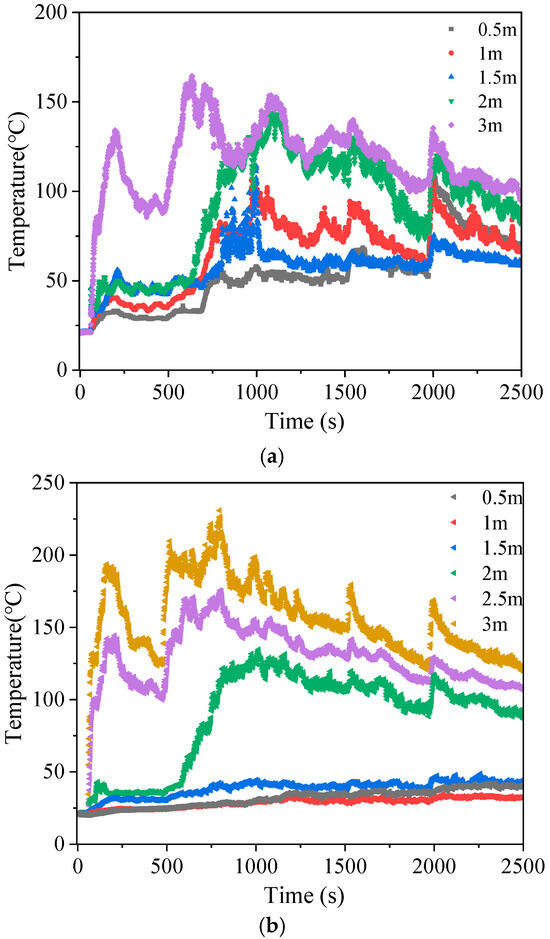

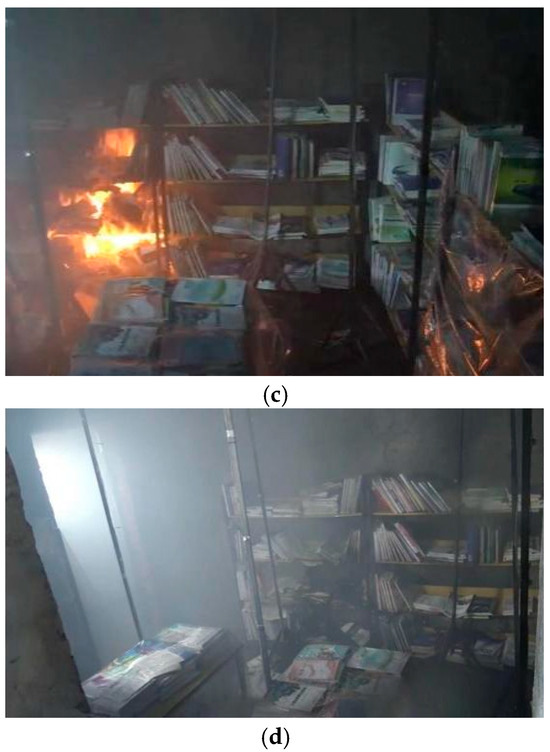

Figure 10 depicts the combustion phenomenon in the small bookstore in Case 2. Unlike Case 1 without water spray, when the temperature or heat release rate of the ignition source reaches the activation threshold of the sprinkler system at 220 s (as shown in Figure 10a), the sprinkler system is triggered, initiating fire control and minimizing fire impacts. At 230 s, significant smoke emissions are observed alongside noticeable flame attenuation. By 245 s, the flames are completely extinguished. The primary cause of smoke generation is the chemical interaction between water and the ignition source. A key mechanism involves water vaporizing into steam upon contact with the hot ignition source: as a liquid, water absorbs heat and rapidly expands into steam, carrying incomplete combustion particles and ignition-source heat upward, thus forming substantial smoke at the onset. Additionally, the high-volume water discharge at the sprinkler system’s activation rapidly absorbs heat from the fire source, causing the rapid cooling of combustible gases that would otherwise undergo complete combustion, thereby generating abundant smoke. With a sprinkler system volume of 200 L, the results indicate that an empirical constant of 80, combined with a system pressure of 0.05 MPa (0.5 bar), effectively controls fires. During the renovation of existing buildings, installing such sprinkler facilities is recommended as a fire protection strategy.

Figure 10.

Schematic diagram of phenomena at different moments of physical combustion experiments of Case 2. (a) t = 100 s. (b) t = 220 s. (c) t = 230 s. (d) t = 245 s.

Figure 11 shows the temperature curves in Case 2. At 125 s, the temperature increases and drops rapidly to 30 °C at 220 s, when the sprinkler is activated in 15 s. Additionally, Figure 11b shows that the temperature at a height of 3 m exceeds 100 °C, indicating that if the heat sensitivity of the fire detector or sprinkler head is set within 60–90 °C, early-stage fires could be controlled sooner. Combining the result of Case 1, the temperature continuously rises and shows a wavy curve, demonstrating that a simple sprinkler system using a municipal water source can quickly control a small bookstore fire in a short time.

Figure 11.

Change in temperature in Case 2. (a) Near the fire source. (b) Under the sprinkler.

3.4. Simulation Combustion Experiment

3.4.1. Analysis of Simulation Combustion Results

Without Sprinkler System

Figure 12 illustrates the simulated combustion phenomenon in the small bookstore in Case 1. At 200 s, flames emerge and engulf the top bookshelf, with visible tilting toward the sides and an incipient spreading tendency. From 440 s to 650 s, the fire intensity at the ignition source increases significantly, while horizontal spread remains limited. At 900 s, combustion within the shelves begins to diminish. By 2000 s, the top layer is nearly completely burned, with ash and other pollutants depositing downward.

Figure 12.

Schematic diagram of phenomena at different moments of simulation combustion experiments in Case 1. (a) t = 170 s. (b) t = 440 s. (c) t = 650 s. (d) t = 900 s. (e) t = 2000 s. (f) t = 2500 s.

Comparing the combustion results in Figure 8 (physical experiment) and Figure 12 (simulation), both methods show that combustion initiates at the ignition point and spreads vertically during 0–170 s, forming an orange-red corner flame. Between 170 and 440 s, the flame expands across the upper bookshelf layers while tilting laterally, indicating the onset of horizontal spread. From 440 s to 900 s, the fire intensifies at the source, with the full-scale combustion of the bookshelves marking the development stage. At 2000 s, the simulation shows the gradual depletion of combustibles in the shelves, whereas the physical experiment exhibits shelf tilting and collapse as combustion enters the stable stage. A key discrepancy arises at 2500 s: the simulated flame shows no obvious attenuation, contrasting with the physical experiment, where fire intensity gradually weakens and combustion transitions to the decay stage. This divergence is attributed to the physical experiment’s formation of combustion residues, which progressively cover the book surfaces and block air contact, thereby suppressing fire intensity. Such residue-mediated oxygen restriction is difficult to fully replicate in the simulation.

Through comparative analysis, the simulation and physical experiment demonstrate substantial similarity in the initial combustion stage, development stage, and stable stage, validating the feasibility of using a simulation to assess incipient fires.

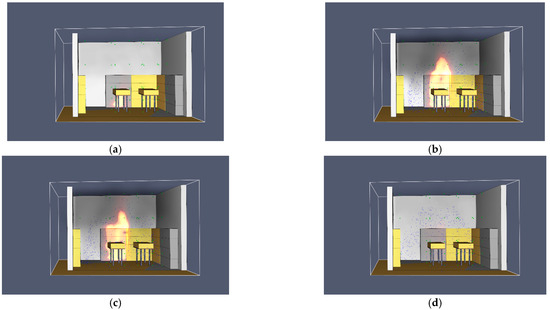

With Sprinkler System

Figure 13 illustrates the simulated combustion phenomena of the small bookstore in Case 2. When comparing the observations in Figure 10 and Figure 13, during the initial combustion stage (0–100 s), the fire sources in both the experiment and simulation exhibit slow burning, characterized by occasional fire tongues and faint smoke. At 100 s, combustion propagates upward from the ignition point, generating light smoke without significant accumulation. Between 100 s and 210 s, the fire intensifies, accompanied by an increase in heat release rate. Concurrently, the fire source emits substantial heat and smoke, which begins to accumulate at the room’s ceiling. The simulated sprinkler system activates at 212 s, which is 8 s faster than in the physical experiment. This discrepancy arises because the flame’s combustion state fluctuates prior to sprinkler activation, a phase that may persist for tens of seconds to minutes until the temperature or heat release rate of fire meets the sprinkler’s trigger threshold.

Figure 13.

Schematic diagram of phenomena at different moments of simulation combustion experiments in Case 2. (a) t = 100 s. (b) t = 212 s. (c) t = 230 s. (d) t = 245 s.

This consistency demonstrates that the simulated sprinkler activation timing aligns closely with the physical test results. Notably, the simulation produces less smoke than the experiment. This difference is attributed to incomplete combustion in the physical test, which generates solid particles (e.g., carbon black). Upon contact with sprinkler water, these particles are not fully dissolved but entrained into the thermal airflow, thereby enhancing the smoke concentration.

3.4.2. Analysis of Simulated Combustion Results

To better understand the extinguishing effects of different sprinkler flow velocities, this study monitored variations in parameters such as heat radiation and temperature across different flow velocity conditions.

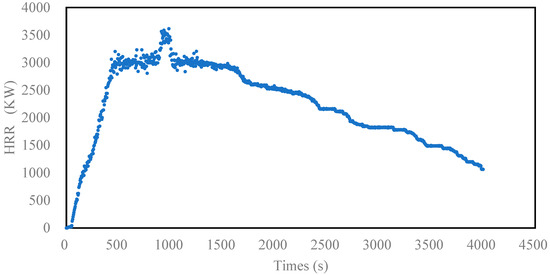

Water Consumption

Under the three working conditions, the fire extinguishing time and corresponding water consumption are summarized in Table 2. For Condition 1, the heat release rate (HRR) began to stabilize at approximately 350 s, while Condition 3 showed HRR stabilization at around 300 s. Notably, Condition 2 achieved HRR stabilization earlier than Condition 1, with a lower HRR value at 400 s. This analysis indicates that higher sprinkler flow velocities correlate with shorter fire control times. Specifically, flow velocities of 60 L/min, 80 L/min, and 100 L/min required water consumptions of 218 L, 213 L, and 195 L, respectively. These results align with previous research [7], which demonstrated that increased flow velocities reduce air quality velocity, enhancing heat absorption. Additionally, fine water mist effectively mitigates thermal convection, blocks fire-area thermal radiation, and lowers ambient temperatures [7]. Despite the 100 L/min flow rate being significantly higher than 60 L/min, its shorter extinguishing time results in lower total water consumption.

Table 2.

Comparison of water consumption under three working conditions.

Compared to the physical experiment’s water consumption of 200 L, the simulation tests exhibited a 6.5% higher consumption. This discrepancy may stem from the physical test (Figure 12) generating more smoke, which enhanced fire suppression efficiency by diluting oxygen and absorbing heat.

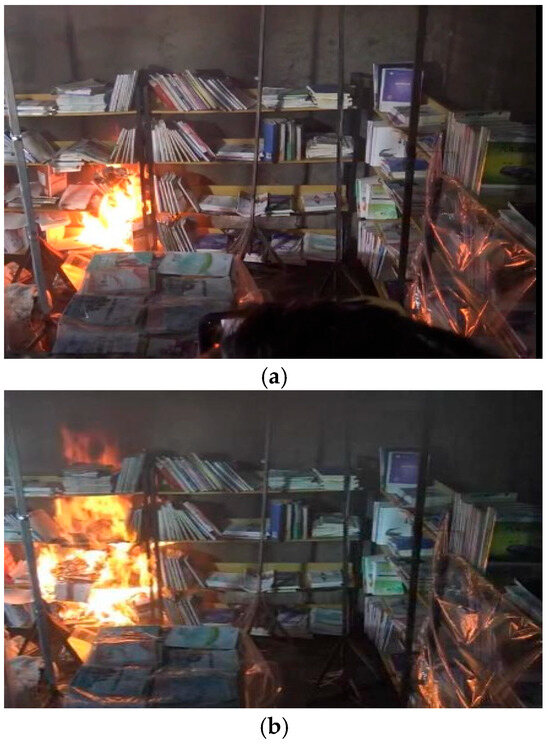

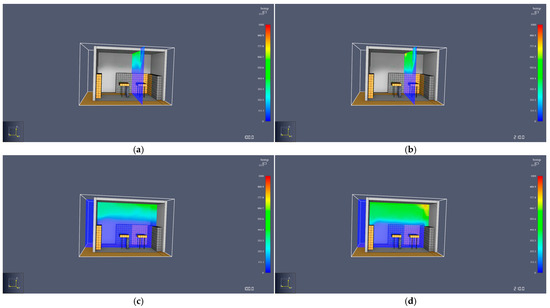

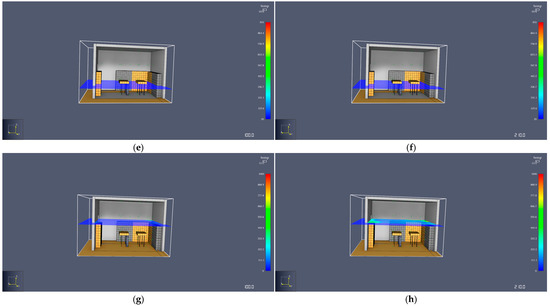

Temperature Slices

In addition to the temperature analysis based on measurement points, the simulation employs temperature cloud slices to visualize the temperature distribution throughout the fire development process upon sprinkler activation. To analyze temperature changes near the ceiling, horizontal slices at 0.75 m and 1.65 m heights, and vertical slices along the X-axis at 1.65 m, Y-axis at 1.65 m were selected. These slices offer insights into temperature variations to optimize sprinkler placement strategies.

Based on heat release rate and heat radiation analyses, the early-stage fire development processes were found to be analogous. Therefore, temperature variation characteristics during fire development were examined. As depicted in Figure 14, four sets of temperature cloud maps illustrate the distribution at 100 s and 210 s. At 100 s, X-axis and Y-axis cloud maps (Figure 14a,c) show high-temperature zones concentrated near the ceiling, with relatively low temperatures in the lower regions of the room. By 210 s, as the fire intensified, high-temperature areas expanded to fill the entire room (Figure 14b,d).

Figure 14.

Temperature variation curves. (a) X = 1.65 m, t = 100 s. (b) X = 1.65 m, t = 210 s. (c) Y = 1.65 m, t = 100 s. (d) Y = 1.65 m, t = 210 s. (e) Z = 0.65 m, t = 100 s. (f) Z = 0.65 m, t = 210 s. (g) Z = 1.65 m, t = 100 s. (h) Z = 1.65 m, t = 210 s.

Vertically, significant temperature gradient differences were observed along the Z-axis. At 0.65 m height, temperature changes remained negligible at both 100 s and 210 s (Figure 14e,f). This indicates that during early fire stages, temperatures near the ceiling rose rapidly with fire spread, while floor-level temperature changes proceeded more slowly.

4. Conclusions

(1) Through the standard test, it was found that the heat release of the books and desks was related to the square of time, with a coefficient of 2.528 × 10−6. The maximum heat release rate was 40 KW.

(2) Unlike the standard test, the physical combustion experiment was significantly affected by the space. Combustion intensified between 200 s and 650 s and showed a clear decline from 2200 s, with the books in a nearly extinguished state by 4950 s.

(3) Numerical simulations showed that when the sprinkler flow velocity was between 60 and 100 L/min, the temperature decreased rapidly between 117 and 210 s. The total water consumption for the sprinkler system was between 195 and 218 L.

(4) This study provides a basis for understanding the combustion characteristics of small bookstores, providing data support for the revitalization of historical buildings with simple sprinkler systems in small-sized bookstore.

Author Contributions

Investigation and Writing—original draft, P.D.; Formal analysis, J.L.; Methodology, C.Z. and J.Z. (Jiaming Zhao); Software, G.G. and R.L.; Visualization, Z.Z.; Project administration, F.Y.; Funding acquisition, S.L.; Methodology, J.Z. (Jun Zhang). All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by National Key R&D Program of China (No. 2022YFC3803500) and Youth Fund Project of China Academy of Building Research (No. 20230111331030038).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within the article.

Conflicts of Interest

Authors Rutian Li and Jun Zhang were employed by the company China First Highway Engineering Company Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Appendix A

Appendix A.1. Model of Simulation

The simulation test model is shown in Figure A1.

Figure A1.

Test model. (a) External structure. (b) Internal structure. (c) Open surfaces, left view.

Appendix A.2. Model of Simulation

The simulation test model is shown in Figure A2. The heat release rate curve can be seen in the following figure. An ignition point is set to ignite the combustible, which is burned in the model according to the value of the combustible ‘Yellow Pine’, considering the role of the spray. The heat release rate model for the overall model is shown in the figure below, and it can be found that over 0–1000 s, the value of HRR increased to a peak of 3500 kW, and then the value gradually decreased over 1000–4000 s.

Figure A2.

Heat release rate curve of simulation.

Based on the results of physical fire tests, the physical property parameters of the combustion medium for the simulated bookstore are adjusted to determine a set of flammable material physical property parameter ranges that best match the actual combustion effects. Obtaining the optimal physical property parameters of flammable materials serves as the best simulation basis for carrying out research on the water demand of simple sprinklers when existing buildings are transformed into small multi-functional mixed buildings in the future.

The details of material models regarding the burner and sprinkler are shown in Table A1 and Table A2, respectively.

Table A1.

Details of material models regarding burner.

Table A1.

Details of material models regarding burner.

| Material Model | Heat Release Rate Per Area KW/m2 | Ramp-Up Time s | Extinguishing Coefficient |

|---|---|---|---|

| Burner | 5000 | 100 | 0 |

Table A2.

Details of material models regarding sprinkler.

Table A2.

Details of material models regarding sprinkler.

| Material Model | Calculated L/min | Operating Pressure Bar | K Factor L/(min·atm)2 | Median Diameter μm | Distribution |

|---|---|---|---|---|---|

| Spray model | 59.71 | 0.5 | 80 | 150 | Constant |

References

- Mohammad, A.H.; Nagib, A.A. An approach to assess fire safety requirements in library facilities. Facilities 2005, 23, 239–252. [Google Scholar]

- Ma, C.X.; Sun, B.T.; Sun, S.M.; Liu, H. Analysis of performance-based fire safety evacuation in a college library. Procedia Eng. 2012, 43, 399–406. [Google Scholar]

- Supat, P. Modeling fire evacuation of a library building based on the numerical simulation. Am. J. Appl. Sci. 2011, 8, 452–458. [Google Scholar]

- Ehab, Z.; George, H. Characterizing of design fires for clothing stores. In Proceedings of the 5th International Seminar on Fire and Explosion Hazards, Edinburgh, UK, 23–27 April 2007; pp. 328–337. [Google Scholar]

- George, H.; Ehab, Z. Development of design fires for performance-based fire safety designs. Fire Saf. Sci.-Proc. Mon. Int. Symp. 2008, 9, 63–78. [Google Scholar]

- Lee, J.; Kim, B.; Lee, S.; Shin, W.G. Validation of the fire dynamics simulator (FDS) model for fire scenarios with twoliquid pool fires in multiple compartments. Fire Saf. J. 2023, 141, 103892. [Google Scholar] [CrossRef]

- Zhao, X.L.; Wei, S.Y.; Chu, Y.Y.; Wang, N. Numerical Simulation of Fire Suppression in Stilted Wooden Buildings with Fine Water Mist Based on FDS. Building 2023, 13, 207. [Google Scholar] [CrossRef]

- Yuan, S.S.; Sun, X.; Liu, S.T.; Li, Y.Q.; Du, P. Effectiveness of cluster-based inductive ventilation system in railway tunnels: Case study using full-scale experiment and fire dynamic simulation. Case Stud. Therm. Eng. 2022, 34, 102045. [Google Scholar] [CrossRef]

- Malgorzata, K.; Aleksander, K. An experimental and numerical study on fire spread in a furnished room. Buildings 2022, 12, 2189. [Google Scholar] [CrossRef]

- Chiu, C.W.; Li, Y.H. Full-scale experimental and numerical analysis of water mist system for sheltered fire sources in wind generator compartment. Process Saf. Environ. Prot. 2015, 98, 40–49. [Google Scholar] [CrossRef]

- Yu, P.W.; Yang, W.Q.; Wu, J.K.; Zhang, F. Discussion on the application of high pressure water mist fire extinguishing system in the fire protection design of ancient buildings. Water Wastewater Eng. 2021, 47, 89–92, 101. [Google Scholar]

- Wang, Z.H. Application of high-pressure water mist fire extinguishing system in Shanghai Tower. Water Wastewater 2015, 05, 80–81. [Google Scholar]

- Xiong, W.R. Discussion on the application of water mist fire extinguishing system in cultural relics and ancient buildings. Chin. New Commun. 2017, 19, 90–91. [Google Scholar]

- Wan, X.B.; Wang, Y.Z.; Xu, G.D.; Yang, W.Y.; Li, S.; Kang, N.; Lin, J. Experimental study on fire extinguishing performance of typical large space fires on ships. Ships Offshore Struct. 2023, 1–7. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, G.; Chai, G.; Zhou, Y.; Chen, C.; Zhang, W. Experimental study on the effect of release pressure on the extinguishing efficiency of dry water. Case Stud. Therm. Eng. 2021, 26, 101177. [Google Scholar] [CrossRef]

- Wu, Z.; Chai, G.; Zhu, G. Experimental study on the effectiveness of dry water material to suppress oil pool fire and analysis of fire extinguishing mechanism. J. Therm. Anal. Calorim. 2024, 149, 10193–10212. [Google Scholar] [CrossRef]

- Yuan, S.; Chang, C.; Yan, S.; Zhou, P.; Qian, X.; Yuan, M.; Liu, K. A review of fire-extinguishing agent on suppressing lithium-ion batteries fire. J. Energy Chem. 2021, 62, 262–280. [Google Scholar] [CrossRef]

- Mahmud, H.M.I.; Moinuddin, K.A.M.; Thorpe, G.R. Experimental and numerical study of high-pressure water-mist nozzle sprays. Fire Saf. J. 2016, 81, 109–117. [Google Scholar] [CrossRef]

- Sikanen, T.; Vaari, J.; Hostikka, S.; Paajanen, A. Modeling and simulation of high pressure water mist systems. Fire Technol. 2014, 50, 483–504. [Google Scholar] [CrossRef]

- Hua, J.; Kumar, K.; Khoo, B.C.; Xue, H. A numerical study of the interaction of water spray with a fire plume. Fire Saf. J. 2002, 37, 631–657. [Google Scholar] [CrossRef]

- GB 50084-2017; Code for Design of Sprinkler Systems. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2017.

- Liu, H.; Wang, C.; Cordeiro, I.M.D.C.; Yuen, A.C.Y.; Chen, Q.; Chan, Q.N.; Kook, S.; Yeoh, G.H. Critical assessment on operating water droplet sizes for fire sprinkler and water mist systems. J. Build. Eng. 2020, 28, 100999. [Google Scholar] [CrossRef]

- Ferng, Y.M.; Liu, C.H. Numerically investigating fire suppression mechanisms for the water mist with various droplet sizes through FDS code. Nucl. Eng. Des. 2011, 241, 3142–3148. [Google Scholar] [CrossRef]

- XF/T 1369-2016; Guidelines for Fire Safety Assessment of Crowded Places. The Standardization Administration of the People’s Republic of China: Beijing, China, 2016.

- Gupta, V.; Hidalgo, J.; Cowlard, A.; Abecassis-Empis, C.; Majdalani, H.A.; Maluk, C.; Torero, J.L. Ventilation effects on the thermal characteristics of fire spread modes in open-plan compartment fires. Fire Saf. J. 2021, 120, 103072. [Google Scholar] [CrossRef]

- GB 51251-2017; Technical Standard for Smoke Management Systems in Buildings. China Planning Press: Beijing, China, 2018.

- Cowlard, A.; Bittern, A.; Abecassis-Empis, C.; Torero, J.L. Some considerations for the fire Safe design of Tall Buildings. Int. J. High-Rise Build. 2013, 2, 63–77. [Google Scholar]

- Gann, R.G.; Hamins, A.; McGrattan, K.; Nelson, H.E.; Ohlemiller, T.J.; Prasad, K.R.; Pitts, W.M. Reconstruction of the fires and thermal environment in World trade center Buildings 1, 2, and 7. Fire Technol. 2013, 49, 679–707. [Google Scholar] [CrossRef]

- Ma, J.; Xiao, C.B. Large-scale fire spread model for traditional Chinese building communities. J. Build. Eng. 2023, 67, 105899. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).