Effects of Fuel Removal on the Flammability of Surface Fuels in Betula platyphylla in the Wildland–Urban Interface

Abstract

:1. Introduction

2. Materials and Methods

2.1. Field Experiments

2.1.1. Set Sample Plot

2.1.2. Forest Characterization Survey

2.1.3. Fuel Treatment

2.1.4. Classification of Fuels

2.2. Laboratory Experiments

2.2.1. Calculation of Fuel Loading

2.2.2. Determination of Ash

2.2.3. Determination of Higher Heating Value and Ash-Free Calorific Value

2.2.4. Determination of the Ignition Point (IP)

2.2.5. Calculation of Heat per Unit Area of Fuel

2.2.6. Calculation of Comprehensive Combustion Score

2.3. Data Analysis

3. Results

3.1. The Dynamic Changes in Physical and Chemical Properties of Fuel

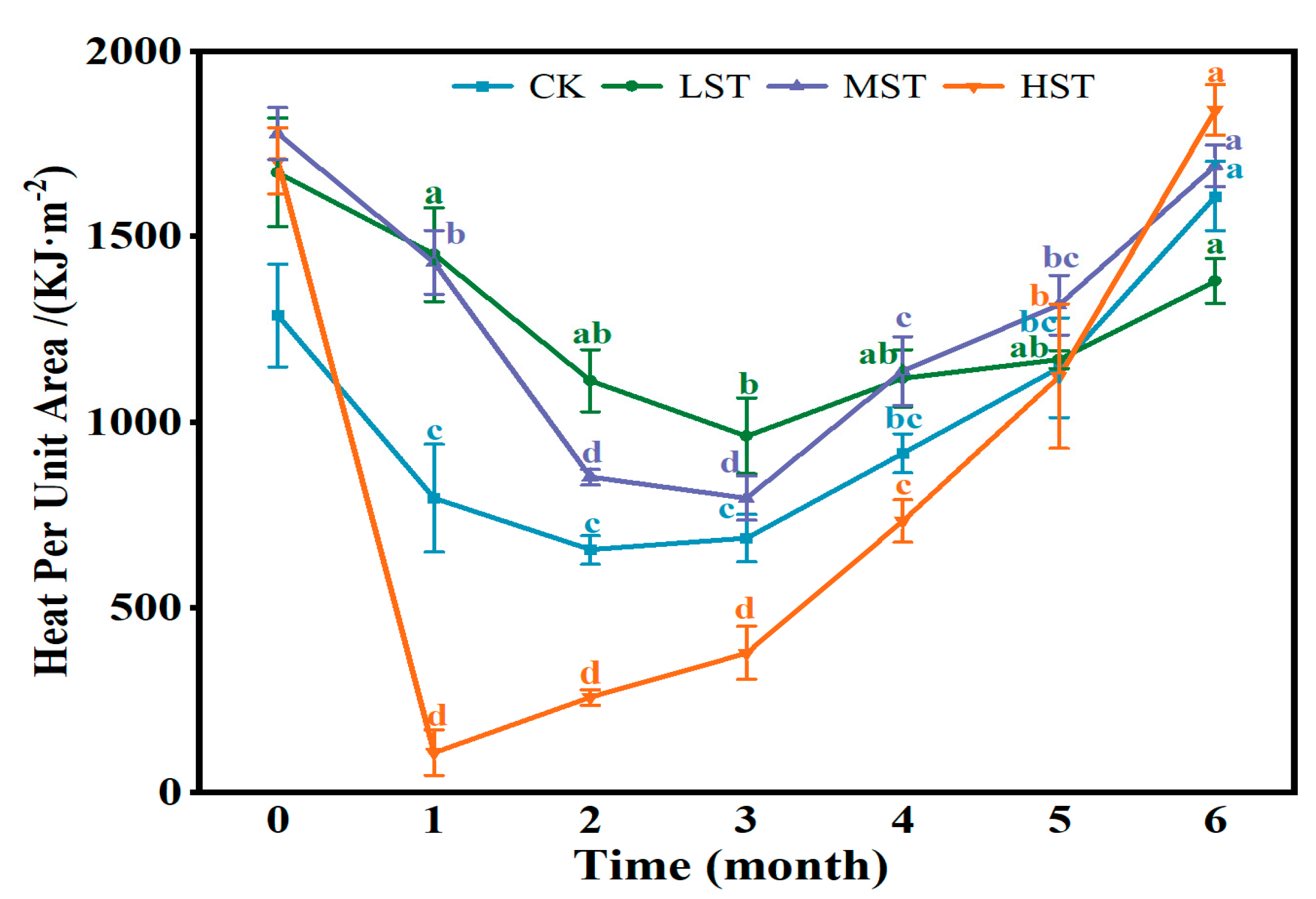

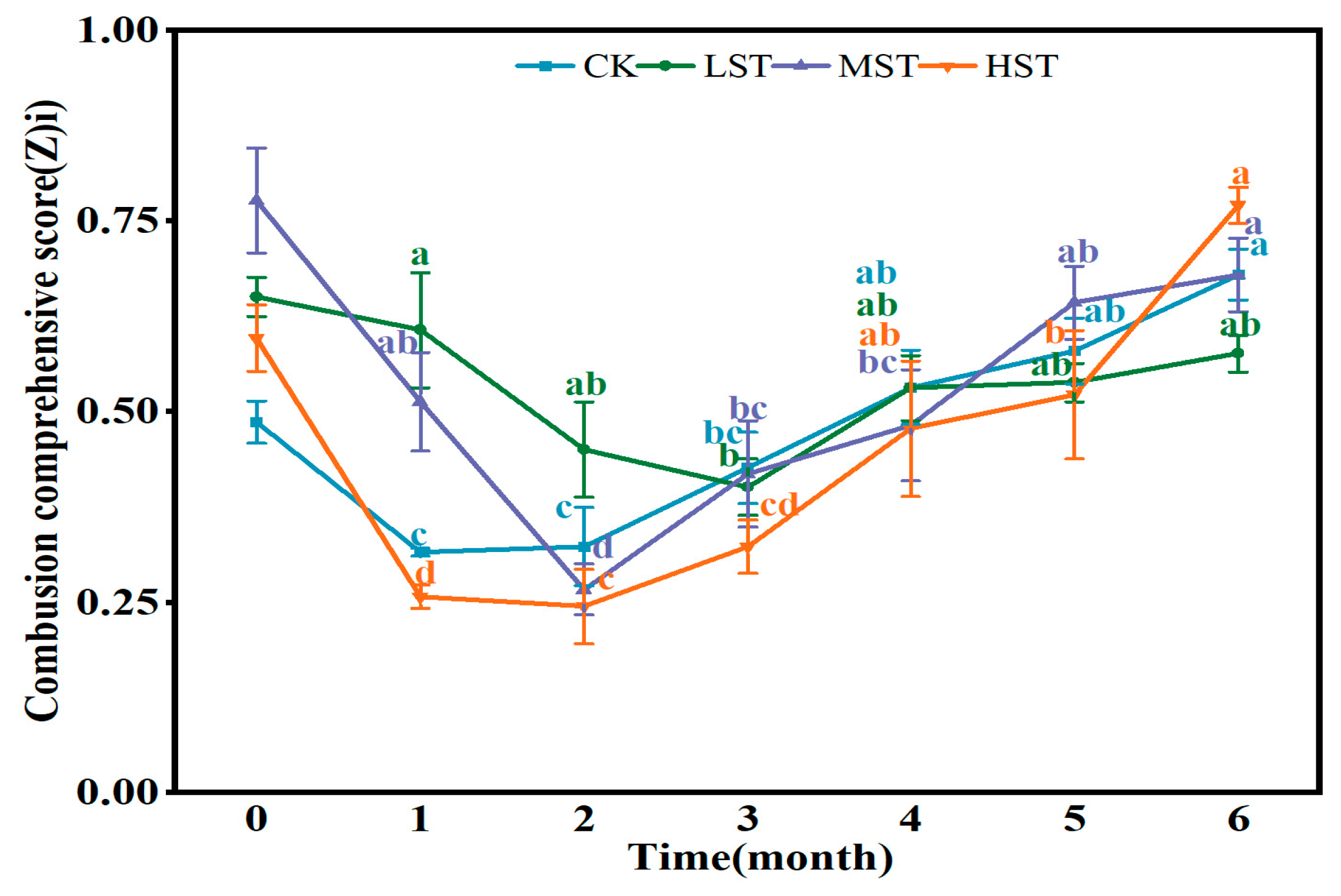

3.2. The Dynamic Changes of Flammability of Fuel

3.3. Correlation Analysis of the Indicators

4. Discussion

4.1. Effects of Fuel Treatment on the Physical and Chemical Properties of Fuel

4.2. Effects of Fuel Treatment on the Flammability of Fuel

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Le Goff, H.; Leduc, A.; Bergeron, Y.; Flannigan, M. The adaptive capacity of forest management to changing fire regimes in the boreal forest of Quebec. For. Chron. 2005, 81, 582–592. [Google Scholar] [CrossRef]

- Lamsaf, H.; Lamsaf, A.; Kerroum, M.A.; Almeida, M. Assessing trends in wildland-urban interface fire research through text mining: A comprehensive analysis of published literature. J. For. Res. 2024, 35, 71. [Google Scholar] [CrossRef]

- Synolakis, C.E.; Karagiannis, G.M. Wildfire risk management in the era of climate change. PNAS Nexus 2024, 3, 151. [Google Scholar] [CrossRef] [PubMed]

- Tang, W.; He, C.; Emmons, L.; Zhang, J. Global expansion of wildland-urban interface (WUI) and WUI fires: Insights from a multiyear worldwide unified database (WUWUI). Environ. Res. Lett. 2024, 19, 044028. [Google Scholar] [CrossRef]

- Li, L.; Niu, S.; Chen, F.; Tao, C.; Chen, L.; Zhang, P. Analysis on surface potential fire behavior and combustion of Miaofeng Mountain Forest Farm in Beijing. J. Beijing For. Univ. 2019, 41, 58–67. [Google Scholar] [CrossRef]

- Miranda, A.; Carrasco, J.; González, M.; Pais, C.; Lara, A.; Altamirano, A.; Weintraub, A.; Syphard, A.D. Evidence-based mapping of the wildland-urban interface to better identify human communities threatened by wildfires. Environ. Res. Lett. 2020, 15, 094069. [Google Scholar] [CrossRef]

- Chambers, J.C.; Strand, E.K.; Ellsworth, L.M.; Tortorelli, C.M.; Urza, A.K.; Crist, M.R.; Miller, R.F.; Reeves, M.C.; Short, K.C.; Williams, C.L. Review of fuel treatment effects on fuels, fire behavior and ecological resilience in sagebrush (Artemisia spp.) ecosystems in the Western U.S. Fire Ecol. 2024, 20, 32. [Google Scholar] [CrossRef]

- Hood, S.M.; Varner, J.M.; Jain, T.B.; Kane, J.M. A framework for quantifying forest wildfire hazard and fuel treatment effectiveness from stands to landscapes. Fire Ecol. 2022, 18, 33. [Google Scholar] [CrossRef]

- Stotlemyer, A.D.; Waldrop, T.A.; Wang, G.G. Prescribed burning and mastication effects on surface fuels in southern pine beetle-killed loblolly pine plantations. Ecol. Eng. 2015, 81, 514–524. [Google Scholar] [CrossRef]

- Stephens, S.L.; Moghaddas, J.J. Experimental fuel treatment impacts on forest structure, potential fire behavior, and predicted tree mortality in a California mixed conifer forest. For. Ecol. Manag. 2005, 215, 21–36. [Google Scholar] [CrossRef]

- Cram, D.S.; Baker, T.T.; Fernald, A.G.; Cibils, A.F.; VanLeeuwen, D.M. Fuel and vegetation trends after wildfire in treated versus untreated forests. For. Sci. 2015, 61, 753–762. [Google Scholar] [CrossRef]

- Vernon, M.J.; Johnston, J.D.; Stokely, T.D.; Miller, B.A.; Woodruff, D.R. Mechanical thinning restores ecological functions in a seasonally dry ponderosa pine forest in the inland Pacific Northwest, USA. For. Ecol. Manag. 2023, 546, 121371. [Google Scholar] [CrossRef]

- Schwilk, D.W.; Keeley, J.E.; Knapp, E.E.; McIver, J.; Bailey, J.D.; Fettig, C.J.; Fiedler, C.E.; Harrod, R.J.; Moghaddas, J.J.; Outcalt, K.W.; et al. The national Fire and Fire Surrogate study: Effects of fuel reduction methods on forest vegetation structure and fuels. Ecol. Appl. 2009, 19, 285–304. [Google Scholar] [CrossRef] [PubMed]

- Rivera, J.I.; Ebensperger, F.; Valenzuela, F.; Escandar, L.; Reszka, P.; Fuentes, A. Understanding the role of fire retardants on the discontinuous ignition of wildland fuels. Proc. Combust. Inst. 2023, 39, 3775–3783. [Google Scholar] [CrossRef]

- Fire Suppressant and Retardant Use in the 2003 Wildfires. Available online: https://parks.canada.ca/nature/science/conservation/feu-fire/feuveg-fireveg/incendies-wildfire/maitrise-control/extinct-suppress (accessed on 6 July 2024).

- Kane, J.M.; Varner, J.M.; Knapp, E.E. Novel fuelbed characteristics associated with mechanical mastication treatments in northern California and south-western Oregon, USA. Int. J. Wildland Fire 2009, 18, 686–697. [Google Scholar] [CrossRef]

- Li, B.; Shu, L.; Ding, Y.; Sun, W.; Wu, S.; Li, H.; Wang, M.; Zhao, F. Research Progress in Plantation Fuel Characteristics and Management in China. World For. Res. 2021, 34, 90–95. [Google Scholar] [CrossRef]

- Agee, J.K.; Skinner, C.N. Basic principles of forest fuel reduction treatments. For. Ecol. Manag. 2005, 211, 83–96. [Google Scholar] [CrossRef]

- Ohlson, D.W.; Berry, T.M.; Gray, R.W.; Blackwell, B.A.; Hawkes, B.C. Multi-attribute evaluation of landscape-level fuel management to reduce wildfire risk. For. Policy Econ. 2006, 8, 824–837. [Google Scholar] [CrossRef]

- Han, M.; Wen, P.; Xu, H.; Zhang, Y.; Li, W.; Liu, X. Simulation of surface fire behavior of Pinus tabuliformis forest in Ming Tombs Forest Farm in Beijing. J. Beijing For. Univ. 2018, 40, 95–101. [Google Scholar] [CrossRef]

- Zong, X. Impacts of Fuel Management on Forest Combustibility in Daxing’anling. Chin. Acad. For. 2021. [Google Scholar] [CrossRef]

- Gao, M.; Ren, Y.; Zhou, X.; Chen, S.; Gao, Y.; Wang, H.; Gu, Z.; Liu, X. Effects of thinning on canopy characteristics and potential crown fire behavior of Platycladus orientalis in Xishan Forest Farm of Beijing. J. Beijing For. Univ. 2022, 44, 56–65. [Google Scholar] [CrossRef]

- Espinosa, J.; Benito, D.M.; Rivera, O.R.D.; Hernando, C.; Guijarro, M.; Madrigal, J. Tree Growth Response to Low-Intensity Prescribed Burning in Pinusnigra Stands: Effects of Burn Season and Fire Severity. Appl. Sci. 2021, 11, 7462. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, X.; Guo, H. Surface fuel loading and relevant influencing factors of main forest types in southern Daxing’anling. J. Northwest Af. Univ. Nat. Sci. Ed 2014, 42, 131–137. [Google Scholar] [CrossRef]

- Li, Z.; Weng, Y.; Xu, J.; Geng, D.; Ning, J.; Yu, H.; Di, X.; Yang, G. Effect of the simulated surface fire behavior on water-soluble carbon and nitrogen in ash. Acta Ecol. Sin. 2022, 42, 1500–1511. [Google Scholar] [CrossRef]

- Zong, X.; Tian, X. Impacts of Fuel Treatment on Potential Fire Behavior of Main Forest Types in Daxing’anling. Sci. Silvae Sin. 2021, 57, 139–149. [Google Scholar] [CrossRef]

- Hu, H.; Niu, S.; Jin, S. Forest Fire Ecology and Management. China For. Publ. House 2005, 40–43. [Google Scholar]

- Ai, Y.; Cun, Y.; Fan, Y.; Cheng, R.; Liu, Y. Factors affecting surface fuel load of Pinus tabuliformis forest in Songshan, Beijing. Chin. J. Ecol. 2018, 37, 2559–2565. [Google Scholar] [CrossRef]

- Ma, C.; Wang, J.; Han, Z.; Wang, Q. Study on the potential fire behavior of surface fuels in coniferous forests in Haizhai Forestry, East Yunnan Province, China. Fire Sci. Technol. 2024, 43, 265–270. [Google Scholar]

- Wang, L.; Yang, G.; Gao, J.; Zheng, X.; Li, Z.; Weng, Y.; Di, X.; Yu, H. Changes in the Flammability of Post-Fire Aboveground Litter of Larix gmelinii. Sci. Silvae Sin. 2022, 58, 110–121. [Google Scholar] [CrossRef]

- Wang, J.; Shao, J.; Li, X.; Zhang, S.; Yan, D. Analysis of apoplastic load and potential burnability of old-growth Liquidambar formosana forests in Mount Qixia. For. Fire Prev. 2019, 15–18. [Google Scholar]

- Jiang, Q.; Zhong, S.; Zhu, W. Research on comprehensive risk assessment of forest fire in Beijing-Tianjin-Hebei region. China Saf. Sci. J. 2020, 30, 119–125. [Google Scholar] [CrossRef]

- Yurtgan, M.; Baysal, I.; Küçük, O. Fuel characterization and crown fuel load prediction in non-treated Calabrian pine (Pinus brutia Ten.) plantation areas. Iforest-Biogeosciences For. 2022, 15, 458–464. [Google Scholar] [CrossRef]

- Cruz, M.G.; Sullivan, A.L.; Gould, J.S.; Hurley, R.J.; Plucinski, M.P. Got to burn to learn: The effect of fuel load on grassland fire behaviour and its management implications. Int. J. Wildland Fire 2018, 27, 727–741. [Google Scholar] [CrossRef]

- Morici, K.E.; Bailey, J.D. Long-Term Effects of Fuel Reduction Treatments on Surface Fuel Loading in the Blue Mountains of Oregon. Forests 2021, 12, 1306. [Google Scholar] [CrossRef]

- Wang, Q.; Xiao, H.; Liu, W.; Yang, W.; Feng, A.; Li, S.; Ren, J. Study on Potential Combustibility of Ground Fuels in Kunming Xishan National Forest Park. J. Fujian For. Sci Tech. 2014, 41, 40–44. [Google Scholar] [CrossRef]

- Johnston, J.D.; Olszewski, J.H.; Miller, B.A.; Schmidt, M.R.; Vernon, M.J.; Ellsworth, L.M. Mechanical thinning without prescribed fire moderates wildfire behavior in an Eastern Oregon, USA ponderosa pine forest. For. Ecol. Manag. 2021, 501, 119674. [Google Scholar] [CrossRef]

- Jiménez, E.; Vega, N.D.; Rey, E.; Fernández, C.; Vega, J.A. Midterm fuel structure recovery and potential fire behaviour in a Pinus pinaster Ait. forest in northern central Spain after thinning and mastication. Eur. J. For. Res. 2016, 135, 675–686. [Google Scholar] [CrossRef]

- Monroe, M.C.; Jones, J.J.; Soldinger, A. Wildland-Urban Interface Forestry Success in Texas. South. J. Appl. For. 2012, 36, 107–109. [Google Scholar] [CrossRef]

- Xiao, W.; Diao, J.; Fei, F.; Guan, Q. Effects of Different Intensity Thinning on Litter Decomposition in Chinese Fir Plantations. Ecol. Environ. Sci. 2016, 25, 1291–1299. [Google Scholar] [CrossRef]

- Galicia, L.; Garcia, O.F. Litter quality of two remnant tree species affects soil microbial activity in tropical sea- sonal pastures in western Mexico. Arid Land Res. Manag. 2011, 25, 75–86. [Google Scholar] [CrossRef]

- Turner, M.G. Landscape ecology: The effect pattern on process. Annu. Rev. Ecol. Evol. Syst. 1989, 20, 171–197. [Google Scholar] [CrossRef]

- Hu, H.; Peng, X.; Liu, X.; Sun, L. Ash Contents of Several Principal Types of Fuels in Daxing’an Mountains. J. North-East For. Univ. 2009, 37, 55–57. [Google Scholar]

- Chen, M.; Shangguan, Z. Caloric Value and Nutrient Characteristics of Dominant Plant Species of Six Typical Vegetation Communities in Ziwuling Forest Area of the Loess Plateau. Sci. Silvae Sin. 2009, 45, 140–144. [Google Scholar]

- Yang, S.; Zhu, M.; Liu, X. Effect of thinning on fuel characteristics and carbon stock of Robinia pseudoacacia forest in Beijing Xishan Forest Farm. Ecol. Sci. 2018, 34, 94–100. [Google Scholar] [CrossRef]

- Song, J.; Zhu, M.; Liu, X.; Ren, Y.; Wang, Q.; Jin, Y. Effects of thinning on fuel characteristics and potential fire behaviors of Pinus tabuliformis forest in Beijing West Mountain. J. Beijing For. Univ. 2017, 39, 41–47. [Google Scholar] [CrossRef]

- Ritter, S.; Morici, K.; Stevens-Rumann, C. Efficacy of prescribed fire as a fuel reduction treatment in the Colorado Front Range. Can. J. For. Res. 2023, 53, 455–462. [Google Scholar] [CrossRef]

- Dai, L.; Zhang, X.; Liu, J. Review on Effects of Prescribed Fire on Vegetation and Soil. World For. Res. 2022, 35, 47–52. [Google Scholar] [CrossRef]

- Chang, Y.; He, H.; Bishop, I.; Hu, Y.; Bu, R.; Xu, C.; Li, X. Long-term forest landscape responses to fire exclusion in the Great Xing’an Mountains, China. Int. J. Wildland Fire 2007, 16, 34–44. [Google Scholar] [CrossRef]

| Sample Plot | Average DBH (cm) | Average Tree Height (m) | Crown Density |

|---|---|---|---|

| CK | 12.0 ± 3.23 | 12.5 ± 3.27 | 0.7 |

| LST | 12.7 ± 4.59 | 13.9 ± 3.16 | 0.6 |

| MST | 11.1 ± 3.31 | 12.6 ± 4.29 | 0.9 |

| HST | 14.4 ± 3.12 | 13.8 ± 4.08 | 0.8 |

| Sample Plot | Herbs | Shrubs | Trees | Dead Surface Fuel |

|---|---|---|---|---|

| LST | Mow stubble height of 15 cm | Shrubs smaller than 1.5 m, mowing retained to 15 cm | Tree pruning height of 1.5 m | Remove 85% of dead fuel above 100 h time lag |

| MST | Mow stubble height of 10 cm | Shrubs smaller than 2 m, mowing retained to 20 cm | Tree pruning height of 2 m | Remove 85% of dead fuel above 10 h time lag |

| HST | Remove all herbs from the sample plot | Remove shrubs smaller than 3 m | Tree pruning height of 3 m | Remove 85% of dead fuel above 1 h time lag |

| Time/ Month | 1 h Time-Lag Fuel | 10 h Time-Lag Fuel | ||||||

|---|---|---|---|---|---|---|---|---|

| Ash/% | Ignition Point/°C | Higher Heating Value/(KJ·g−1) | Ash-Free Calorific Value/(KJ·g−1) | Ash/% | Ignition Point/°C | Higher Heating Value/(KJ·g−1) | Ash-Free Calorific Value/(KJ·g−1) | |

| 0 | 14.36 ± 0.11 | 256.5 ± 1.5 | 15.89 ± 0.55 | 18.55 ± 0.41 | 4.37 ± 0.49 | 254.5 ± 0.5 | 15.36 ± 0.09 | 16.06 ± 0.07 |

| 1 | 15.01 ± 0.49 | 260.67 ± 1.86 | 15.66 ± 0.13 | 18.42 ± 0.12 | 3.71 ± 0.23 | 254.56 ± 2.8 | 17.29 ± 0.04 | 17.9 ± 0.01 |

| 2 | 15.12 ± 0.68 | 259.17 ± 1.97 | 15.5 ± 0.22 | 18.26 ± 0.30 | 2.88 ± 0.64 | 246.58 ± 1.72 | 17.02 ± 0.20 | 17.49 ± 0.23 |

| 3 | 14.28 ± 1.91 | 258.73 ± 2.77 | 15.82 ± 0.28 | 18.48 ± 0.67 | 3.76 ± 0.66 | 254.6 ± 1.16 | 17.12 ± 0.27 | 17.81 ± 0.47 |

| 4 | 10.85 ± 0.92 | 255.83 ± 2.19 | 16.56 ± 0.19 | 18.57 ± 0.33 | 6.58 ± 1.38 | 256.17 ± 2.2 | 17.5 ± 0.21 | 18.79 ± 1.15 |

| 5 | 8.49 ± 0.67 | 257.33 ± 3.37 | 16.97 ± 0.16 | 18.69 ± 0.11 | 3.67 ± 0.39 | 254.42 ± 4.64 | 17.46 ± 0.15 | 18.1 ± 0.20 |

| 6 | 8.11 ± 0.31 | 257.5 ± 2.65 | 17.57 ± 0.26 | 19.12 ± 0.57 | 3.31 ± 0.36 | 256.86 ± 2.74 | 17.58 ± 0.16 | 18.06 ± 0.30 |

| Time/ Month | 1 h Time-Lag Fuel | 10 h Time-Lag Fuel | ||||||

|---|---|---|---|---|---|---|---|---|

| Ash/% | Ignition Point/°C | Higher Heating Value/(KJ·g−1) | Ash-Free Calorific Value/(KJ·g−1) | Ash/% | Ignition Point/°C | Higher Heating Value/(KJ·g−1) | Ash-Free Calorific Value/(KJ·g−1) | |

| 0 | 8.56 ± 0.83 | 257 ± 3.2 | 17.57 ± 0.56 | 19.21 ± 0.44 | 3.08 ± 0.86 | 255 ± 2.6 | 17.78 ± 0.37 | 18.35 ± 0.46 |

| 1 | 10.73 ± 1.79 | 257.89 ± 1.26 | 17.09 ± 0.34 | 19.14 ± 0.23 | 3.41 ± 0.94 | 249.22 ± 4.03 | 17.83 ± 0.23 | 18.47 ± 0.56 |

| 2 | 9.47 ± 0.54 | 257.17 ± 2.2 | 17.16 ± 0.17 | 18.97 ± 0.44 | 2.58 ± 0.41 | 254.75 ± 1.91 | 17.41 ± 0.23 | 17.88 ± 0.54 |

| 3 | 8.57 ± 0.20 | 256.27 ± 1.66 | 17.10 ± 0.12 | 18.71 ± 0.28 | 2.94 ± 0.43 | 253.67 ± 3.54 | 17.15 ± 0.11 | 17.65 ± 0.38 |

| 4 | 8.86 ± 0.76 | 256.33 ± 1.05 | 17.24 ± 0.15 | 18.92 ± 0.33 | 3.04 ± 0.78 | 254.5 ± 1.4 | 17.7 ± 0.17 | 18.12 ± 0.29 |

| 5 | 10.35 ± 1.72 | 256.92 ± 4.41 | 17.57 ± 0.09 | 19.19 ± 0.43 | 4.09 ± 0.60 | 251.17 ± 3.34 | 17.63 ± 0.21 | 18.39 ± 0.56 |

| 6 | 6.42 ± 0.17 | 257.78 ± 2.49 | 18.12 ± 0.09 | 19.36 ± 0.31 | 3.48 ± 0.58 | 255.53 ± 1.79 | 17.78 ± 0.14 | 18.4 ± 0.49 |

| Time/ Month | 1 h Time-Lag Fuel | 10 h Time-Lag Fuel | ||||||

|---|---|---|---|---|---|---|---|---|

| Ash/% | Ignition Point/°C | Higher Heating Value/(KJ·g−1) | Ash-Free Calorific Value/(KJ·g−1) | Ash/% | Ignition Point/°C | Higher Heating Value/(KJ·g−1) | Ash-Free Calorific Value/(KJ·g−1) | |

| 0 | 10.02 ± 1.16 | 257 ± 1.2 | 17.01 ± 0.50 | 18.9 ± 0.27 | 4.96 ± 0.62 | 258 ± 1.5 | 17.51 ± 0.05 | 18.58 ± 0.17 |

| 1 | 11.03 ± 1.04 | 258.11 ± 1.26 | 17.08 ± 0.33 | 19.19 ± 0.26 | 3.96 ± 0.81 | 255.56 ± 2.55 | 17.06 ± 0.32 | 17.79 ± 0.49 |

| 2 | 13.06 ± 0.89 | 260 ± 0.47 | 16.08 ± 0.34 | 18.49 ± 0.45 | 3.5 ± 0.53 | 257.25 ± 1.87 | 17.54 ± 0.13 | 18.14 ± 0.33 |

| 3 | 12.82 ± 1.63 | 258.87 ± 3.09 | 15.91 ± 0.24 | 18.27 ± 0.83 | 3.4 ± 0.24 | 254.07 ± 4.25 | 17.34 ± 0.10 | 17.98 ± 0.31 |

| 4 | 9.94 ± 2.26 | 258.42 ± 2.01 | 16.58 ± 0.49 | 18.4 ± 0.50 | 3.53 ± 0.45 | 251.75 ± 0.92 | 17.32 ± 0.26 | 17.92 ± 0.44 |

| 5 | 12.11 ± 3.39 | 260.92 ± 0.57 | 16.95 ± 0.37 | 18.91 ± 0.36 | 4.1 ± 0.41 | 254.92 ± 2.73 | 17.7 ± 0.26 | 18.47 ± 0.48 |

| 6 | 8.77 ± 1.08 | 259.11 ± 1.94 | 17.48 ± 0.37 | 19.16 ± 0.74 | 3.67 ± 0.50 | 257.5 ± 3.82 | 17.71 ± 0.28 | 18.38 ± 0.64 |

| Time/ Month | 1 h Time-Lag Fuel | 10 h Time-Lag Fuel | ||||||

|---|---|---|---|---|---|---|---|---|

| Ash/% | Ignition Point/°C | Higher Heating Value/(KJ·g−1) | Ash-Free Calorific Value/(KJ·g−1) | Ash/% | Ignition Point/°C | Higher Heating Value/(KJ·g−1) | Ash-Free Calorific Value/(KJ·g−1) | |

| 0 | 15.23 ± 2.69 | 258 ± 1.6 | 16.13 ± 0.41 | 19.03 ± 0.16 | 5.27 ± 0.39 | 262 ± 2.1 | 16.44 ± 0.15 | 17.35 ± 0.49 |

| 1 | 8.01 ± 1.19 | 258.44 ± 4.07 | 17.08 ± 0.40 | 18.57 ± 0.40 | 3.98 ± 0.36 | 260.83 ± 3.82 | 16.43 ± 0.52 | 17.11 ± 0.83 |

| 2 | 11.31 ± 1.90 | 259.89 ± 1.99 | 16.47 ± 0.30 | 18.58 ± 0.18 | 3.46 ± 0.40 | 256 ± 1.58 | 17.5 ± 0.44 | 18.13 ± 0.81 |

| 3 | 16.3 ± 3.14 | 256.33 ± 1.41 | 16 ± 0.13 | 19.24 ± 1.78 | 4.45 ± 0.75 | 252 ± 3.05 | 17.49 ± 0.16 | 18.31 ± 0.39 |

| 4 | 17.1 ± 2.93 | 258.33 ± 1.56 | 16.28 ± 0.34 | 19.7 ± 1.04 | 5.8 ± 2.20 | 254.13 ± 1.55 | 17.72 ± 0.09 | 18.84 ± 0.93 |

| 5 | 12.98 ± 1.35 | 260.17 ± 2.4 | 16.83 ± 0.37 | 19.92 ± 0.53 | 3.9 ± 0.39 | 252.83 ± 2.2 | 16.95 ± 0.28 | 17.64 ± 0.64 |

| 6 | 9.77 ± 0.77 | 257 ± 2.28 | 17.64 ± 0.11 | 19.56 ± 0.41 | 4.96 ± 1.39 | 251.4 ± 4.58 | 17.36 ± 0.08 | 18.28 ± 0.67 |

| Time/ Month | CK 100 h Time-Lag Fuel | LST 100 h Time-Lag Fuel | ||||||

|---|---|---|---|---|---|---|---|---|

| Ash/% | Ignition Point/°C | Higher Heating Value/(KJ·g−1) | Ash-Free Calorific Value/(KJ·g−1) | Ash/% | Ignition Point/°C | Higher Heating Value/(KJ·g−1) | Ash-Free Calorific Value/(KJ·g−1) | |

| 0 | 3.71 ± 0.62 | 253 ± 3.24 | 17.24 ± 0.52 | 17.91 ± 0.74 | ||||

| 1 | 2.8 ± 0.52 | 253.33 ± 5.5 | 17.14 ± 0.15 | 17.66 ± 0.42 | ||||

| 2 | 2.59 ± 0.49 | 248.33 ± 4.73 | 17.3 ± 0.45 | 17.76 ± 0.94 | 1.23 ± 0.45 | 253.33 ± 3.79 | 17.5 ± 0.39 | 18.06 ± 1.35 |

| 3 | 3.63 ± 0.72 | 257.7 ± 4.1 | 17.66 ± 0.28 | 18.33 ± 0.49 | 1.76 ± 0.29 | 254 ± 8.76 | 17.38 ± 0.34 | 17.69 ± 0.63 |

| 4 | 5 ± 2.09 | 258.17 ± 6.35 | 17.39 ± 0.23 | 18.34 ± 0.98 | 1.23 ± 0.63 | 250.33 ± 1.53 | 18.06 ± 0.43 | 18.28 ± 0.64 |

| 5 | 1.79 ± 0.40 | 253.67 ± 4.04 | 16.93 ± 0.36 | 17.24 ± 0.70 | 0.97 ± 0.30 | 252.33 ± 7.23 | 17.74 ± 0.27 | 17.92 ± 0.56 |

| 6 | 3.59 ± 1.80 | 260.5 ± 4.95 | 17.75 ± 0.05 | 18.42 ± 0.48 | 0.57 ± 0.21 | 252 ± 4.28 | 18.48 ± 0.51 | 18.58 ± 0.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Wang, M.; Li, B.; Wang, L.; Ning, J.; Yang, G.; Yu, H. Effects of Fuel Removal on the Flammability of Surface Fuels in Betula platyphylla in the Wildland–Urban Interface. Fire 2024, 7, 261. https://doi.org/10.3390/fire7070261

Chen X, Wang M, Li B, Wang L, Ning J, Yang G, Yu H. Effects of Fuel Removal on the Flammability of Surface Fuels in Betula platyphylla in the Wildland–Urban Interface. Fire. 2024; 7(7):261. https://doi.org/10.3390/fire7070261

Chicago/Turabian StyleChen, Xintong, Mingyu Wang, Baozhong Li, Lixuan Wang, Jibin Ning, Guang Yang, and Hongzhou Yu. 2024. "Effects of Fuel Removal on the Flammability of Surface Fuels in Betula platyphylla in the Wildland–Urban Interface" Fire 7, no. 7: 261. https://doi.org/10.3390/fire7070261

APA StyleChen, X., Wang, M., Li, B., Wang, L., Ning, J., Yang, G., & Yu, H. (2024). Effects of Fuel Removal on the Flammability of Surface Fuels in Betula platyphylla in the Wildland–Urban Interface. Fire, 7(7), 261. https://doi.org/10.3390/fire7070261