The Application of Nitrogen Curtain Technology to Longwall Goaf to Prevent the Spontaneous Combustion of Coal: A Case Study in Shajihai Coalmine, China

Abstract

:1. Introduction

2. Principle and Methods

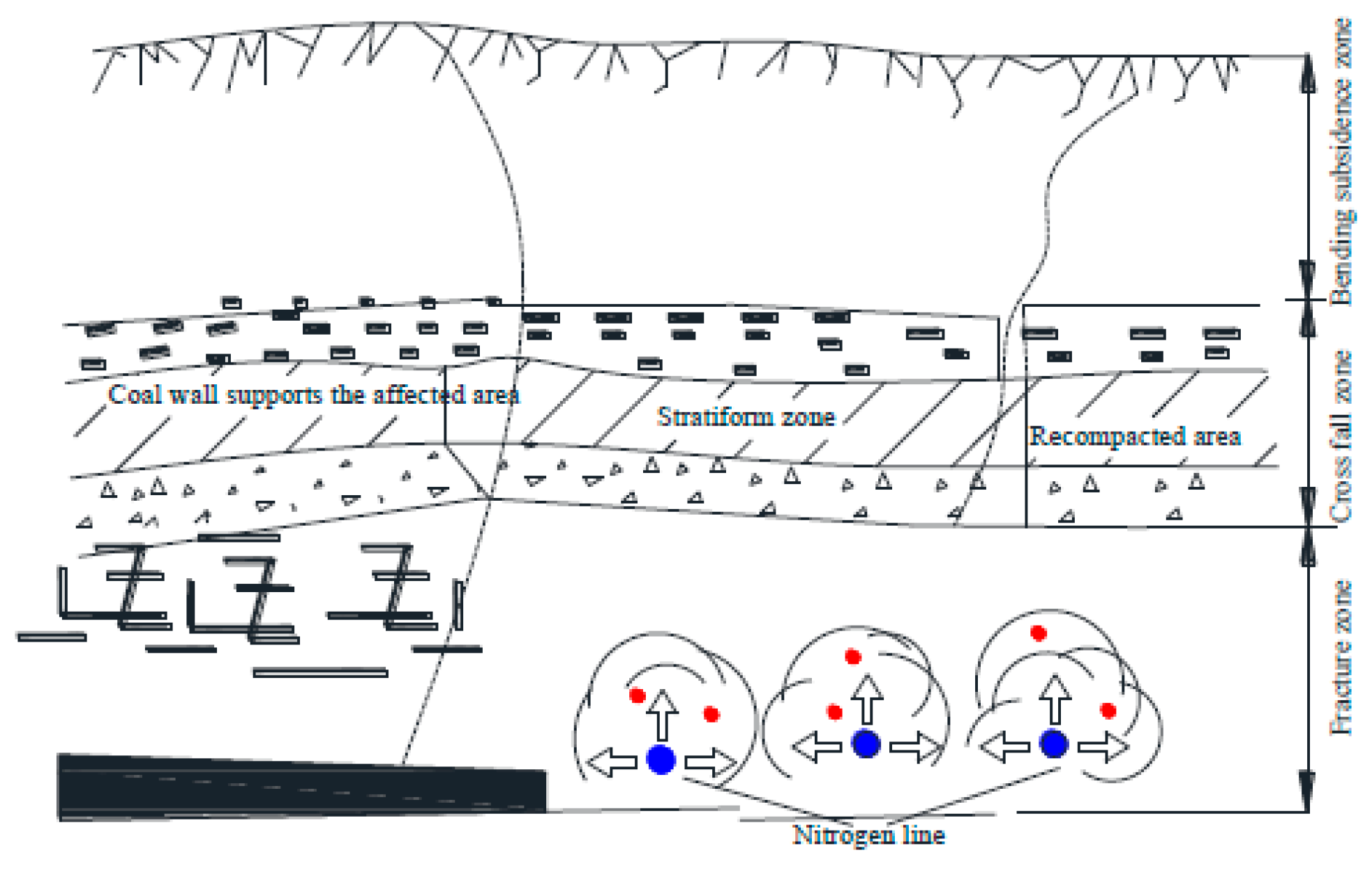

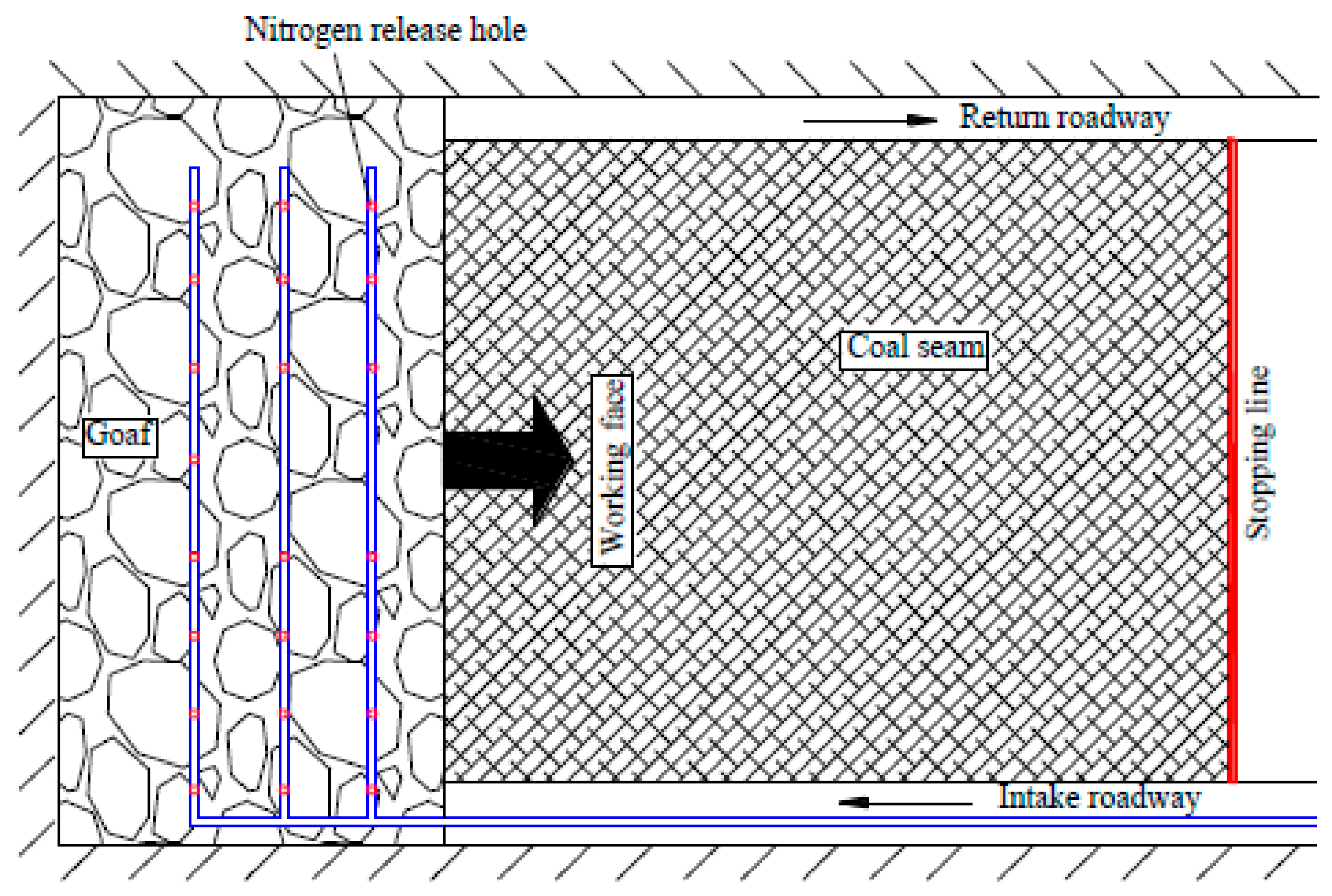

2.1. The Principle of Full Cross-Section Curtain Injection of Nitrogen

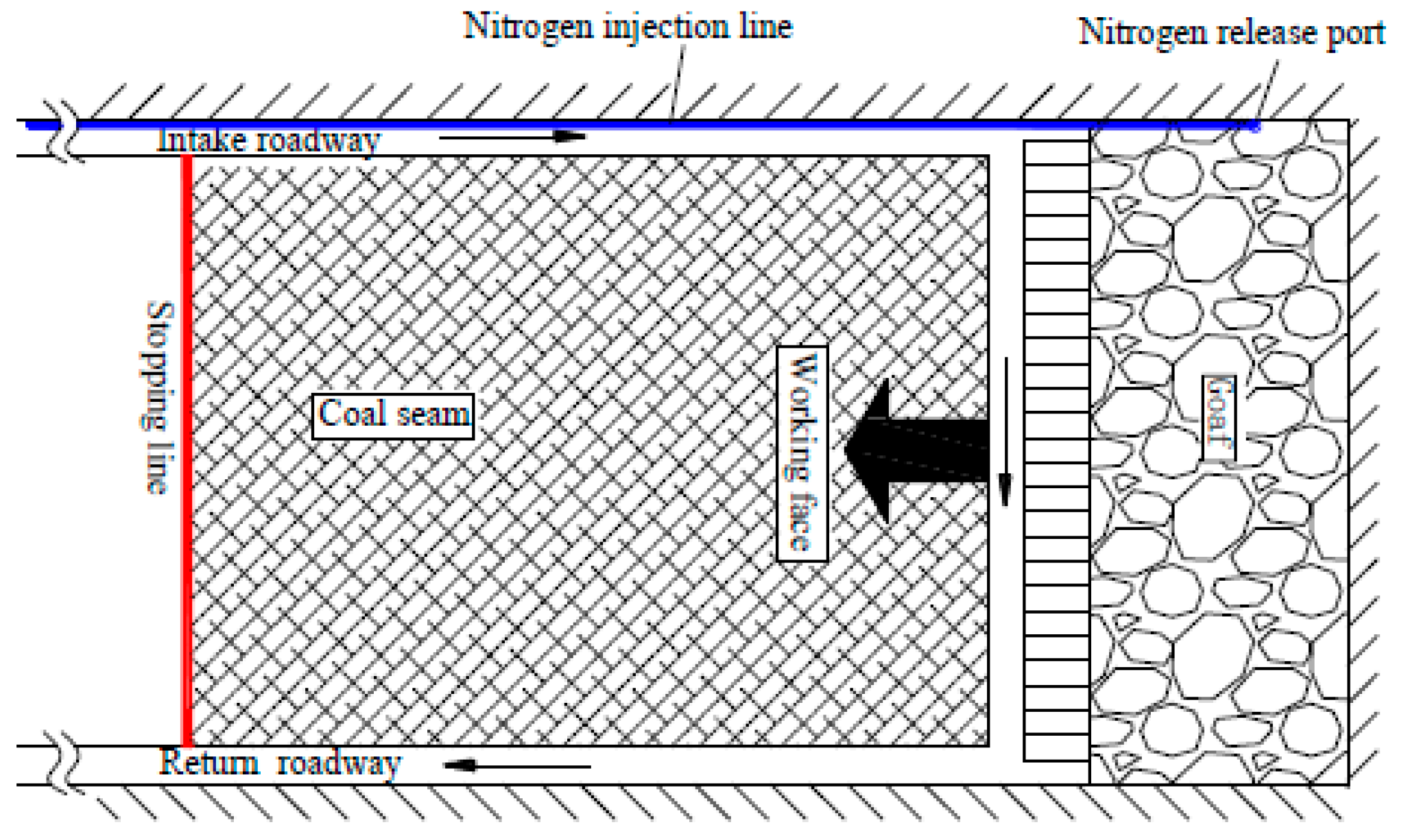

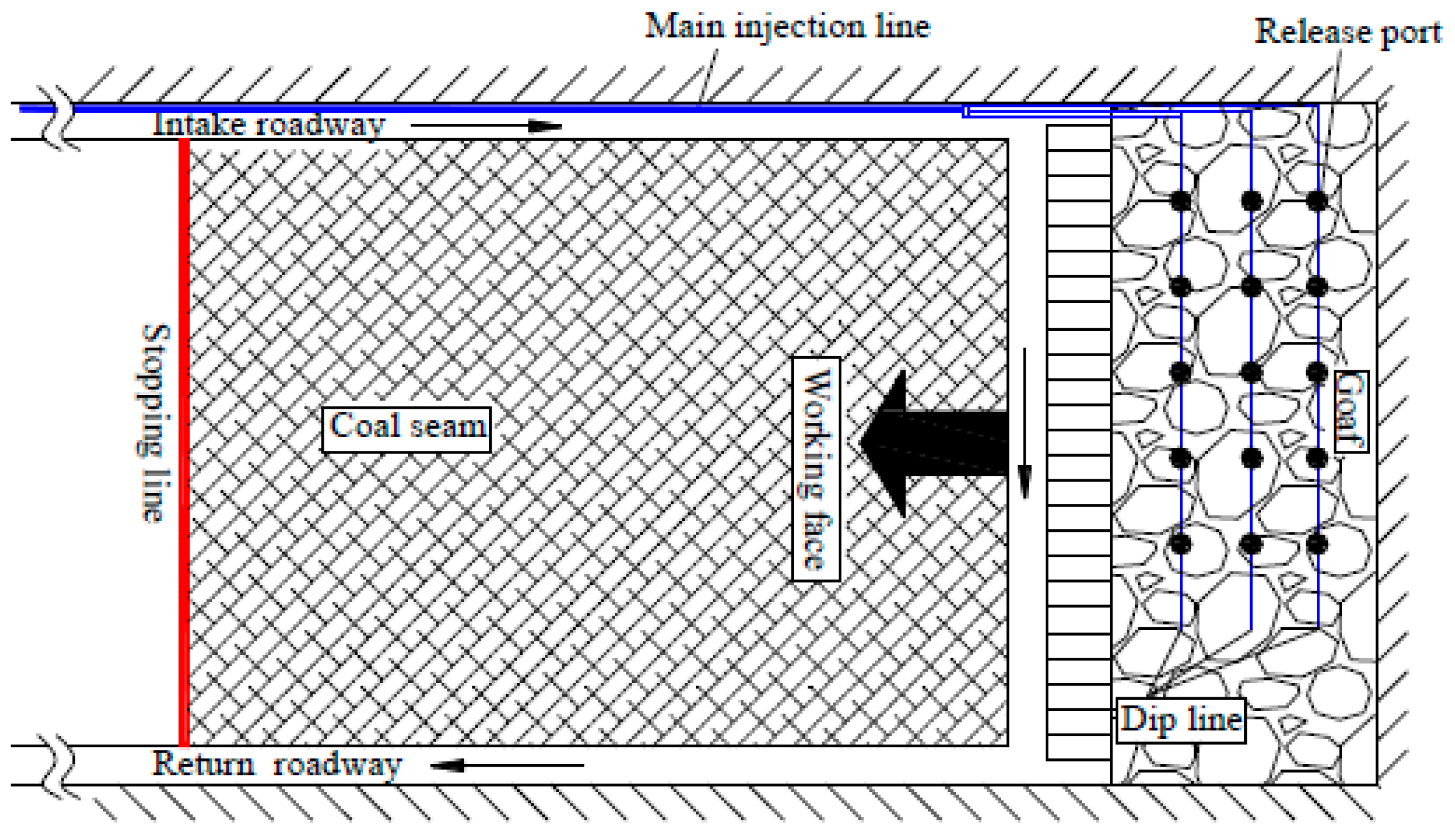

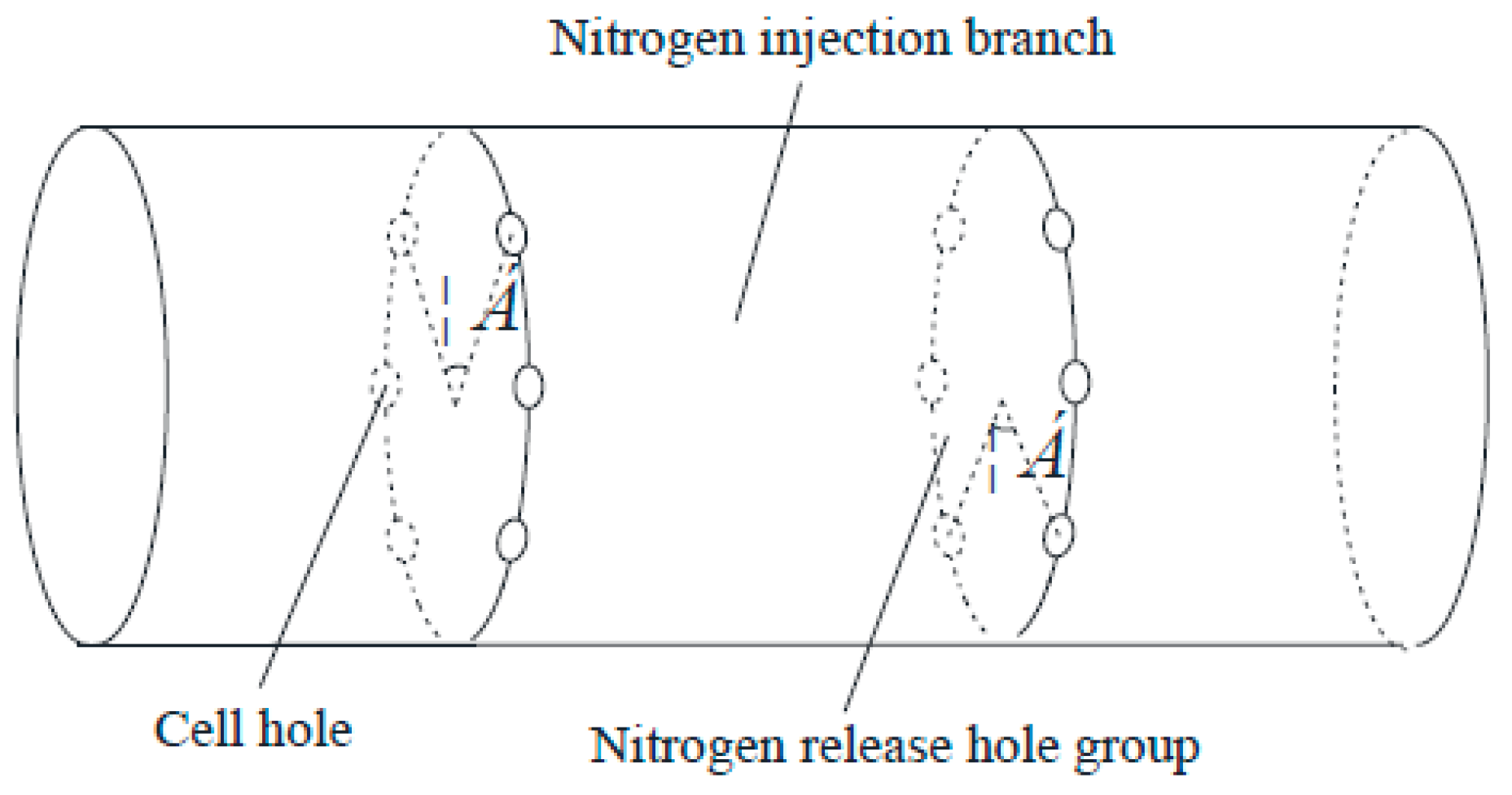

2.2. The Design of Full Cross-Section Curtain Injection of Nitrogen

3. Field Application

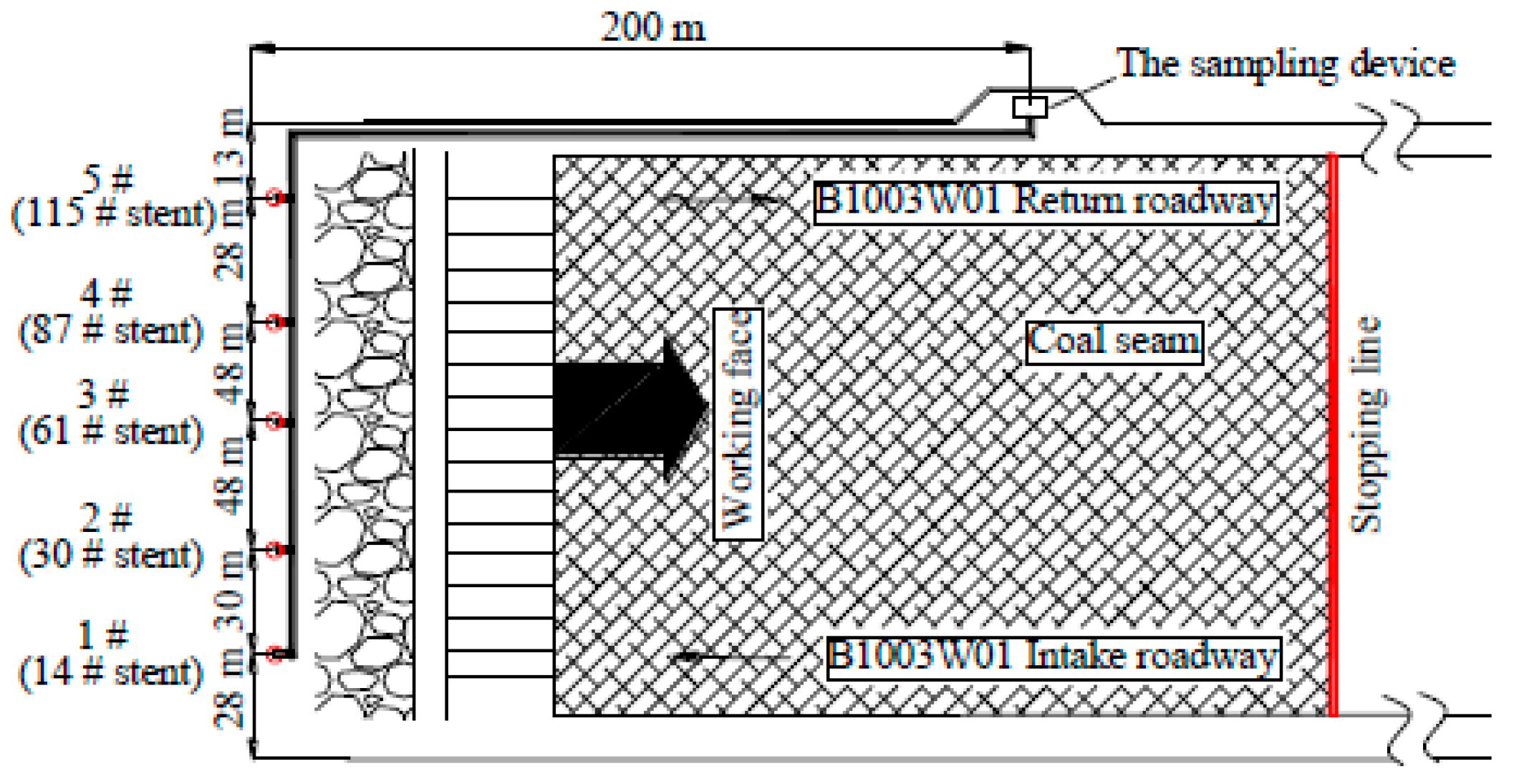

3.1. Layout and Operation

3.2. Effect Investigation

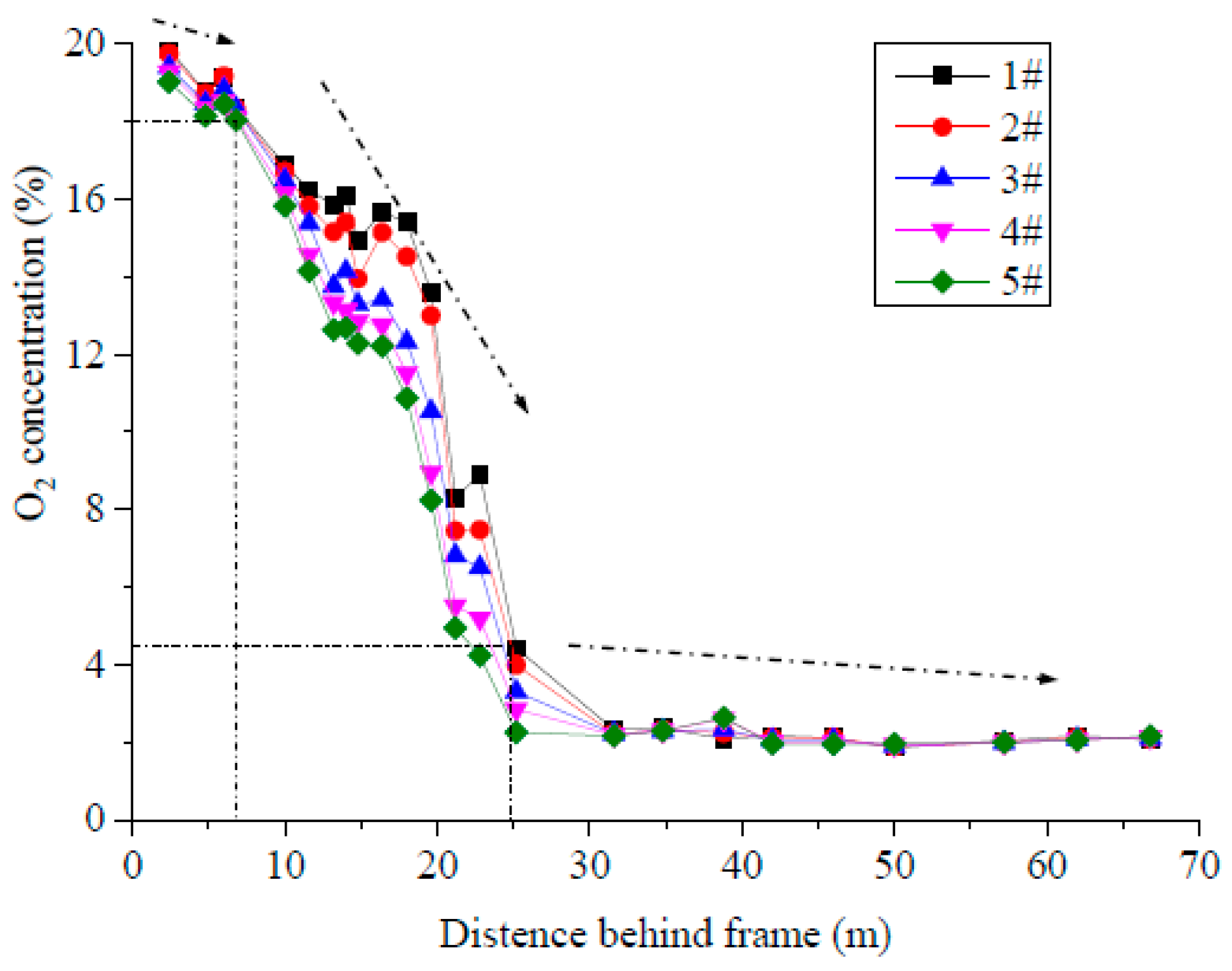

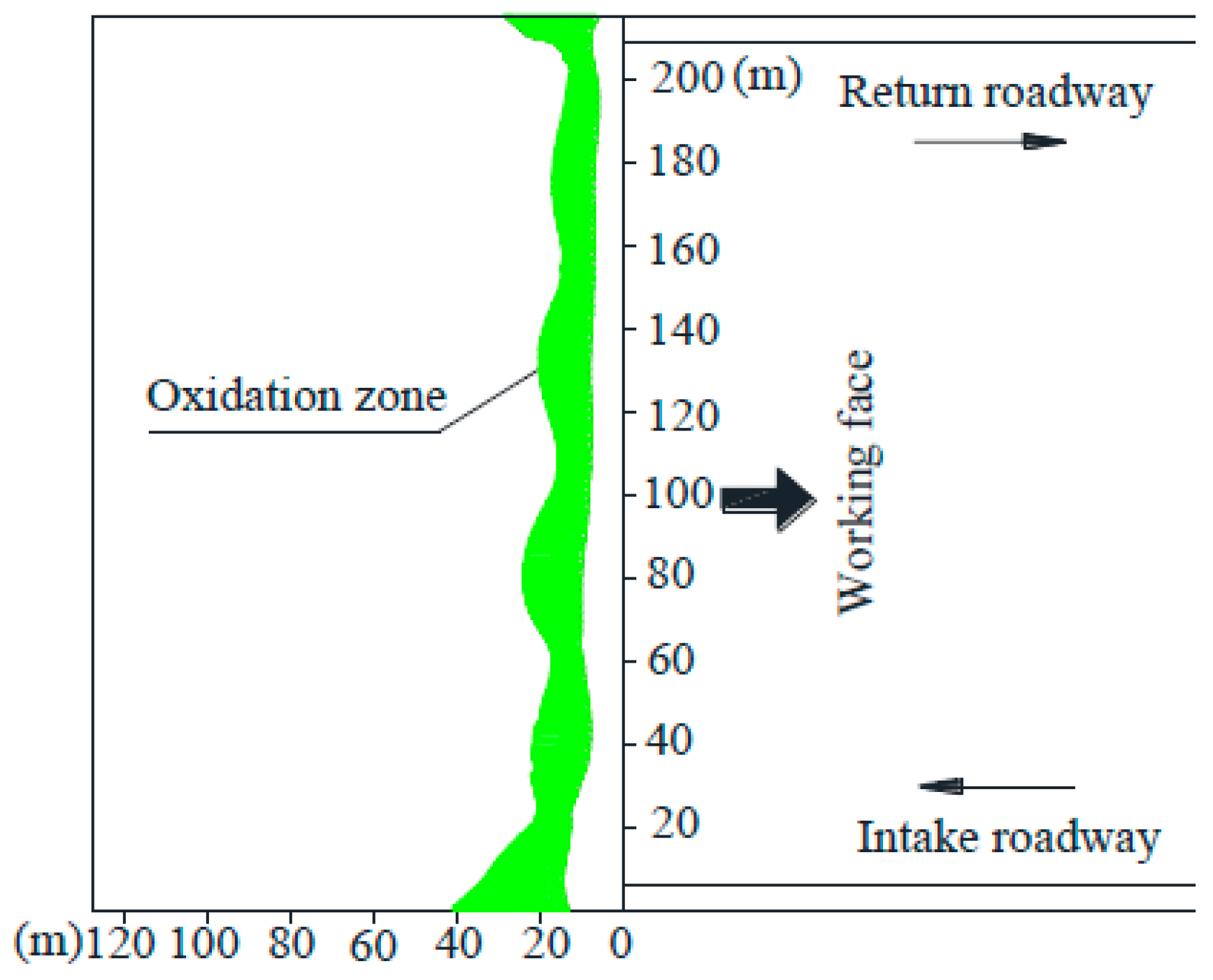

3.2.1. Change in Oxidation Zone Width

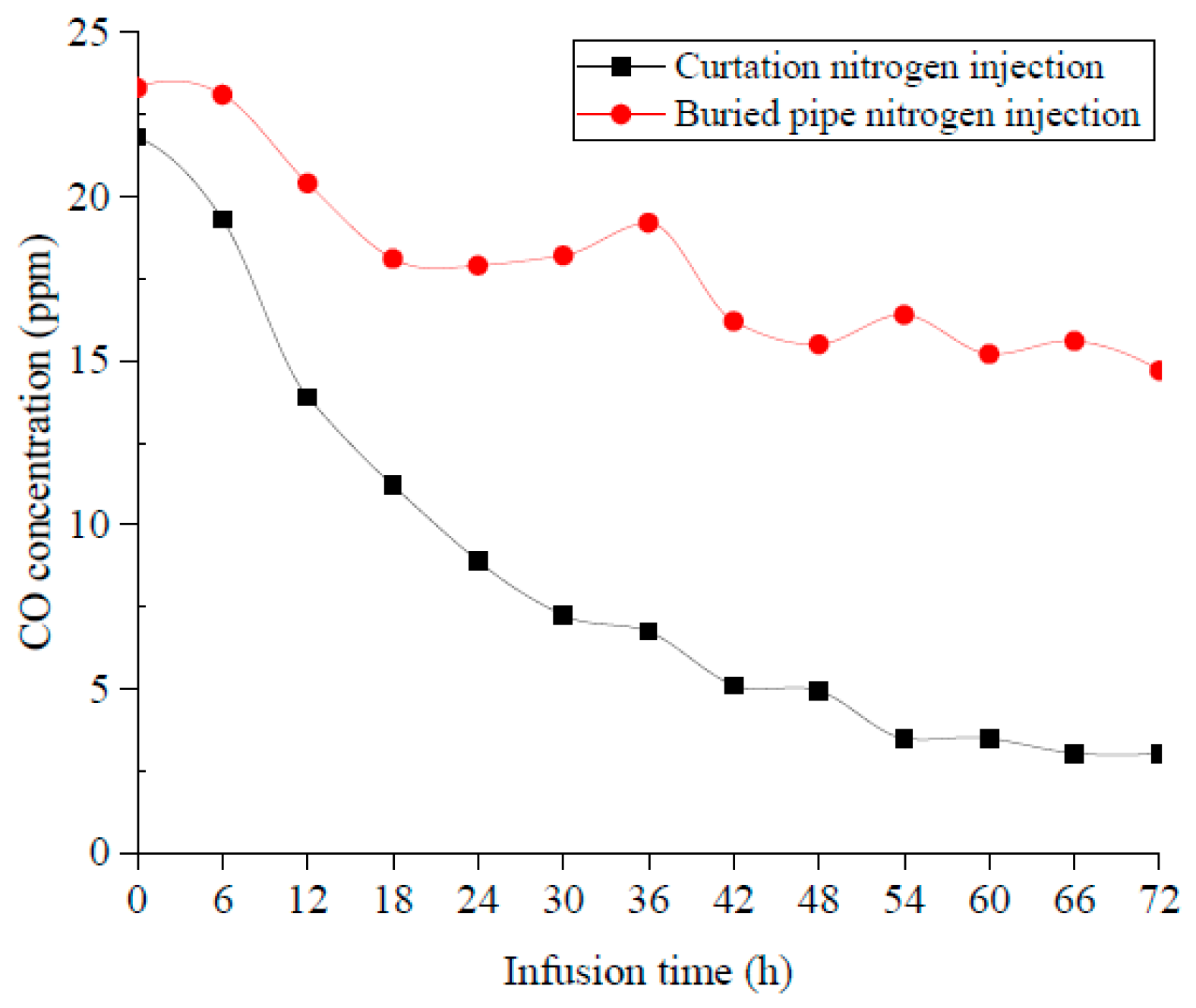

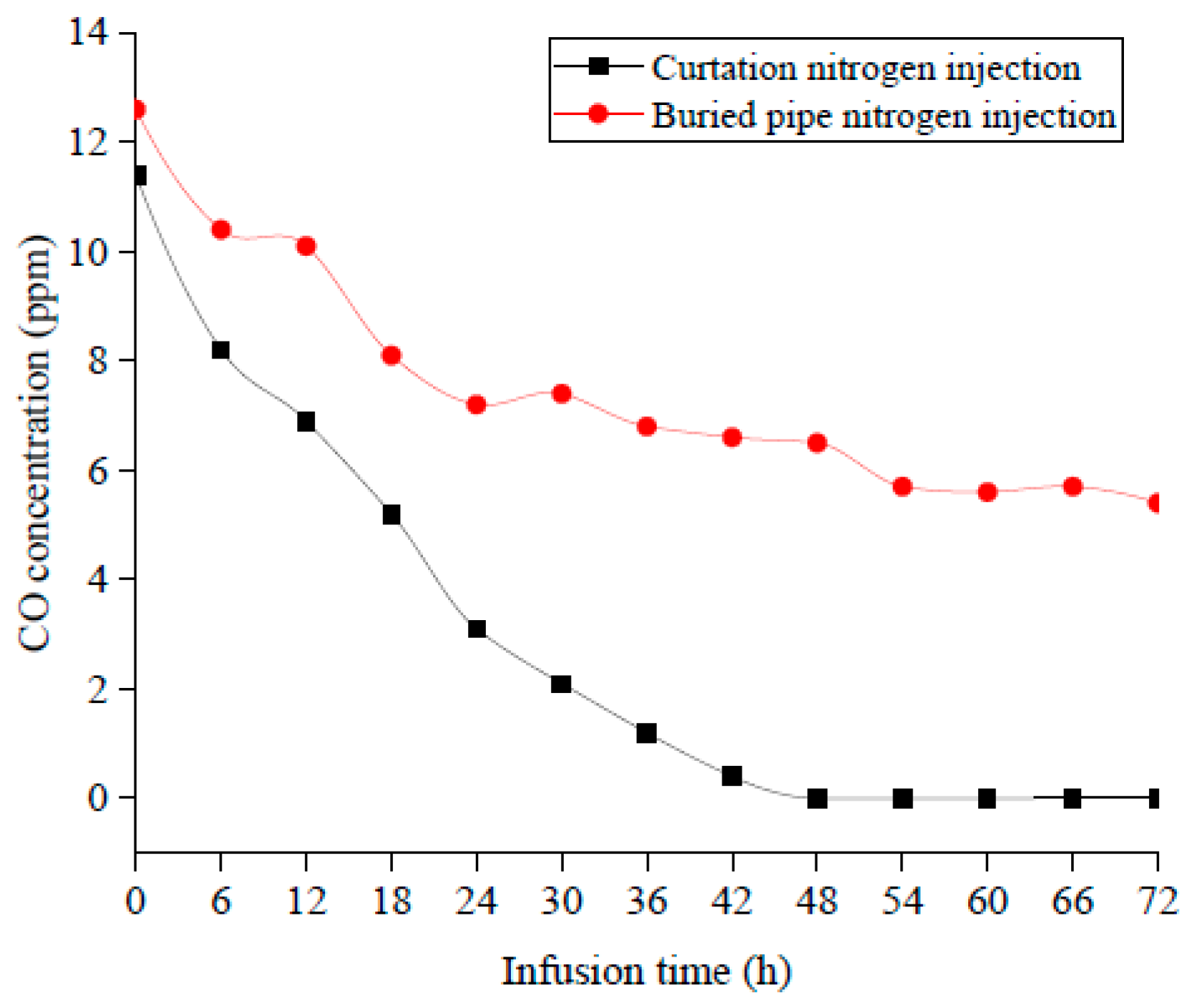

3.2.2. CO Concentration in the Working Face Corner

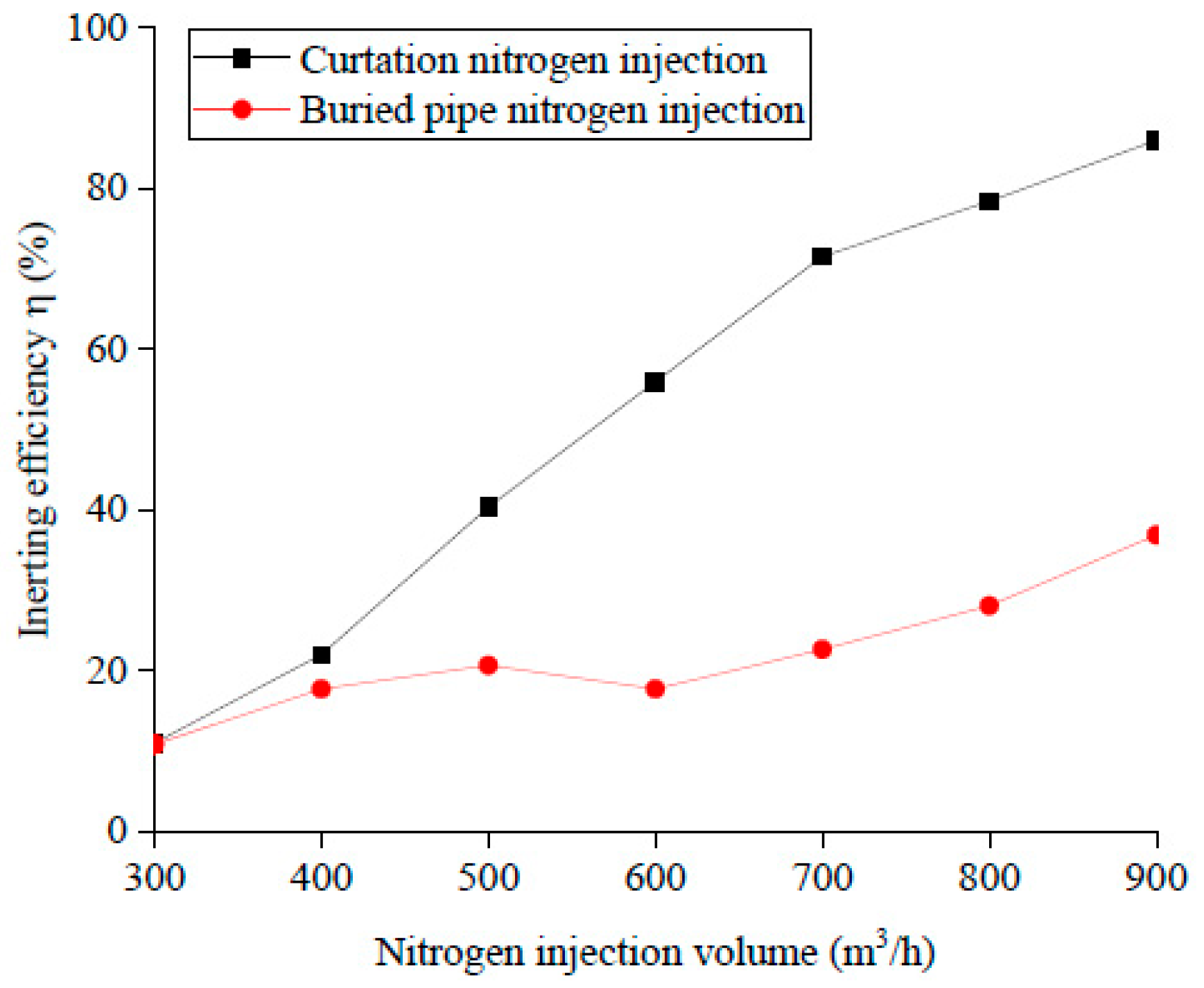

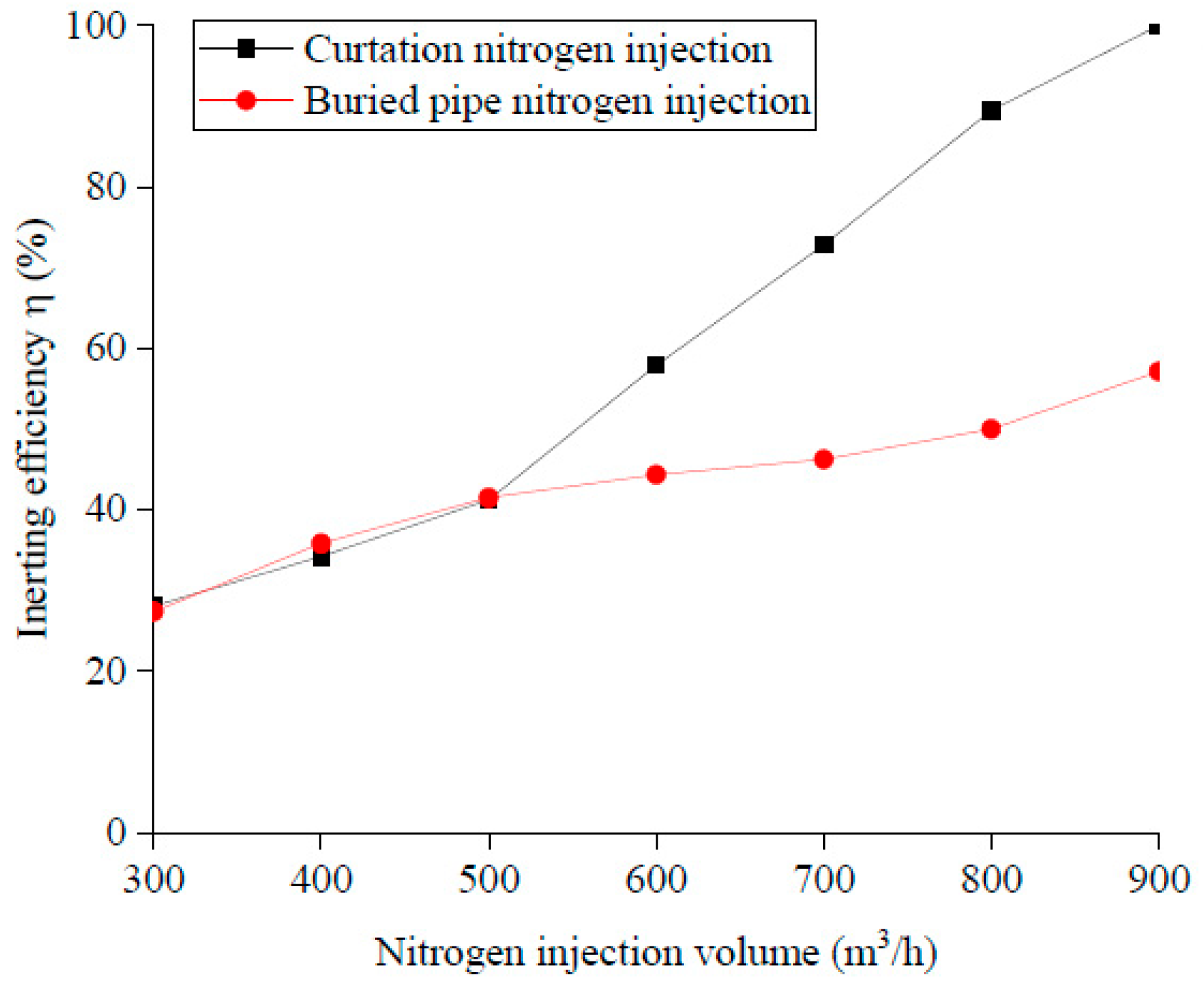

3.2.3. The Nitrogen Inerting Efficiency

4. Conclusions

- (1)

- The working principle of full cross-section curtain injection of nitrogen is elucidated and the design principles and key parameters of the nitrogen curtain are established, such as the nitrogen injection port layout, the nitrogen injection pipe array pitch, the number of hole groups and the cell hole radius. And from the above results, we know that the nitrogen injection hole groups should be evenly spaced, and that the closer the cell hole is to the inlet side, the smaller the radius is, which ensures the consistency of the amount of nitrogen released.

- (2)

- The field application was carried out in the B1003W01 working face to investigate the inerting effect of the nitrogen curtain technology. It is proved that the full cross-section curtain injection of nitrogen exhibits a superior extinguishment performance of goaf fires compared with the conventional buried pipe nitrogen injection method. After implementing curtain injection of nitrogen, the maximum width of the goaf oxidation zone is reduced from 70 m to 20 m and the upper corner CO concentration decreases from 21.8 ppm to 11.2 ppm after 18 h of nitrogen injection. Additionally, the upper corner CO concentration tends to stabilize at 3 ppm and the lower corner CO concentration drops to 0 ppm after 48 h.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, D.M. Mine Fire Science; China University of Mining and Technology Press: Xuzhou, China, 2008. [Google Scholar]

- Wang, L.K.; Ren, T.X.; Nie, B.S.; Chen, Y.; Lv, C.Q.; Tang, H.Y.; Zhang, J.F. Development of a spontaneous combustion TARPs system based on BP neural network. Int. J. Min. Sci. Technol. 2015, 25, 803–810. [Google Scholar] [CrossRef]

- Liang, Y.T.; Hou, X.J.; Luo, H.Z. The current situation and countermeasures of coal mine fire control in China. Coal Sci. Technol. 2016, 44, 1–6. [Google Scholar] [CrossRef]

- Mohalik, K.; Ray, M.; Varma, S. Application of CFD techniques to assess spontaneous heating/fire during extraction of thick coal seam using blasting gallery (BG) method. Combust. Sci. Technol. 2020, 192, 1772–1784. [Google Scholar] [CrossRef]

- Tian, L.; Liu, S.; Li, Y. Application of inorganic solidified foam to control the coexistence of unusual methane emission and spontaneous combustion of coal in the Luwa coal mine, China. Combust. Sci. Technol. 2020, 192, 638–656. [Google Scholar] [CrossRef]

- Zhou, F.B.; Ren, W.X.; Wang, D.M. Application of the three-phase foam to fight an extraordinarily serious coal mine fire. Int. J. Coal Geol. 2006, 67, 95–100. [Google Scholar] [CrossRef]

- Ray, S.K.; Singh, R.P. Recent developments and practices to control fire in underground coal mines. Fire Technol. 2007, 43, 285–300. [Google Scholar] [CrossRef]

- Lu, X.X.; Wang, D.M.; Qin, B.T.; Tian, F.C.; Shi, G.Y.; Dong, S.J. Novel approach for extinguishing large-scale coal fires using gas-liquid foams in open pit mines. Environ. Sci. Pollut. Res. 2015, 22, 18363–18371. [Google Scholar] [CrossRef]

- Guo, Q.; Ren, W.X.; Shi, J.T. Experimental investigations on foaming device used for coal spontaneous combustion prevention. Combust. Sci. Technol. 2020, 192, 1850–1862. [Google Scholar] [CrossRef]

- Adamus, A. Technical note: Review of nitrogen as an inert gas in underground mines. J. Mine Vent. Soc. S. Afr. 2001, 54, 60–61. [Google Scholar]

- Zhou, F.B.; Shi, B.B.; Cheng, J.W. A new approach to control a serious mine fire with using liquid nitrogen as extinguishing media. Fire Technol. 2015, 51, 325–334. [Google Scholar] [CrossRef]

- Yu, Q.X.; Wang, K.; Yang, S.Q. Study on Pattern and Control of Gas Emission at Coal Face in China. J. China Univ. Min. Technol. 2000, 1, 9–14. [Google Scholar] [CrossRef]

- Zhu, H.Q.; Liu, P.F.; Liu, X.K.; Yao, M.Q. Numerical simulation of temperature change and spontaneous combustion area in goaf during nitrogen injection process. J. Hunan Univ. Sci. Technol. (Nat. Sci. Ed.) 2012, 27, 1–6. [Google Scholar] [CrossRef]

- Liu, X.K.; Wang, G.Z.; Zhou, A.T. Nitrogen injection parameters design for goaf and Its 3D flow field analysis. J. Taiyuan Univ. Technol. 2015, 46, 312–317. [Google Scholar] [CrossRef]

- Li, Z.X.; Shan, L.B.; Zhang, W.J. Numerical simulation study of nitrogen injection process for fire prevention and extinguishment in goaf. J. Hunan Univ. Sci. Technol. 2004, 19, 5–9. [Google Scholar] [CrossRef]

- Yang, Z.G.; Mu, S.L. Practice of nitrogen injection and fire extinguishing technology in goaf of fully mechanized top coal caving face. Coal Mine Saf. 2008, 39, 30–34. [Google Scholar]

- Zhu, H.Q.; Li, F.; Zhang, Y.; Wang, W.H.; Liang, S.K. Design and analysis of the effect of non-interval nitrogen injection on fire extinguishing technology. Saf. Coal Mines 2013, 44, 175–178. [Google Scholar] [CrossRef]

- Liu, H.F. Optimization on calculation method of nitrogen injection and effect analysis of nitrogen injection. Coal Technol. 2016, 35, 202–203. [Google Scholar] [CrossRef]

- Wang, Y.H.; Wu, Y.; Zhang, J.L.; Guan, Y.J. Study on technological parameters of nitrogen injection for fire prevention and extinguishing in goaf. Min. Res. Dev. 2019, 39, 96–101. [Google Scholar] [CrossRef]

- Cui, C.F. Research on gas drainage drilling parameters and nitrogen injection for fire prevention in goaf. J. Mine Autom. 2020, 46, 12–20. [Google Scholar] [CrossRef]

- Yang, W.; Shi, J.L.; Chen, M.Q.; Zhang, L.K. Application of step type full section buried pipe nitrogen injection technology in preventing and extinguishing fire in goaf of fully mechanized top coal caving face. Coal Technol. 2023, 2, 154–157. [Google Scholar] [CrossRef]

- Hong, L.; Feng, C.C.; Zhou, X.H. Hongmiao mine fully mechanized caving face reasonable parameter of nitrogen injection fire prevention. J. Liaoning Tech. Univ. 2012, 31, 729–732. [Google Scholar] [CrossRef]

- He, Z.L. Optimization of nitrogen injection parameter for U-shaped ventilation goaf. Saf. Sci. Technol. China 2013, 9, 32–37. [Google Scholar] [CrossRef]

- Zhao, H.B.; Wang, Z.W.; Zhang, H.; Li, W. Effects of dynamic loads on development of internal microstructure and distribution of new surface fractures of coal. Chin. J. Rock Mech. Eng. 2016, 5, 971–979. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, S.; Xue, J.H.; Ren, T.X.; Zhang, C. Permeability of bituminous coal and its stress sensitivity under liquid nitrogen fracturing. J. Min. Saf. Eng. 2020, 37, 401–408. [Google Scholar] [CrossRef]

- Zhou, J.; Hou, B.Y. Tongxin mine goaf numerical simulation of nitrogen injection and preparation technology. Comput. Appl. Chem. 2016, 33, 343–347. [Google Scholar] [CrossRef]

- Cai, Z.J.; Yu, T.L. Fluid Mechanics Pumps and Fans, 4th ed.; China Building Industry Press: Beijing, China, 1999. [Google Scholar]

- Li, Y.L.; Yao, A.L.; Li, Y.J. Study on Diffusion Model of Gas Pipeline Leaking. Nat. Gas Ind. 2004, 24, 102–104. [Google Scholar]

- Yan, S.Y.; Pan, K. Development and application of the software on flammable, explosive & toxic cloud diffusion based on JAVA technique. China Saf. Sci. J. 2009, 19, 152–158. [Google Scholar]

- Wang, G.D.; Ren, T.X.; Qi, Q.X.; Zhang, J.; Zhang, L. Mathematical model of coal seam methane displacement by injecting CO2/nitrogen. Chin. J. Rock Mech. Eng. 2016, A02, 3930–3936. [Google Scholar] [CrossRef]

- Yu, C.Z. Turbulent Jet; Higher Education Press: Beijing, China, 1993. [Google Scholar]

- Lv, Z.J.; Ou, Y.H. Distribution of three zones in goaf of the first mining face with shallow buried depth. Saf. Coal Mines 2018, 49, 238–241. [Google Scholar] [CrossRef]

- Luo, X.R.; Jiang, S.G.; Li, Z.H. Experiment study on preventing goaf fire by nitrogen injection in fully-mechanized working faces. J. China Univ. Min. Technol. 1997, 26, 42–45. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, H.-J.; Zhao, Y.-M.; Liu, X.-L.; Tian, F.-C. The Application of Nitrogen Curtain Technology to Longwall Goaf to Prevent the Spontaneous Combustion of Coal: A Case Study in Shajihai Coalmine, China. Fire 2023, 6, 363. https://doi.org/10.3390/fire6090363

Geng H-J, Zhao Y-M, Liu X-L, Tian F-C. The Application of Nitrogen Curtain Technology to Longwall Goaf to Prevent the Spontaneous Combustion of Coal: A Case Study in Shajihai Coalmine, China. Fire. 2023; 6(9):363. https://doi.org/10.3390/fire6090363

Chicago/Turabian StyleGeng, Hai-Jiang, Ya-Ming Zhao, Xiang-Lan Liu, and Fu-Chao Tian. 2023. "The Application of Nitrogen Curtain Technology to Longwall Goaf to Prevent the Spontaneous Combustion of Coal: A Case Study in Shajihai Coalmine, China" Fire 6, no. 9: 363. https://doi.org/10.3390/fire6090363

APA StyleGeng, H.-J., Zhao, Y.-M., Liu, X.-L., & Tian, F.-C. (2023). The Application of Nitrogen Curtain Technology to Longwall Goaf to Prevent the Spontaneous Combustion of Coal: A Case Study in Shajihai Coalmine, China. Fire, 6(9), 363. https://doi.org/10.3390/fire6090363