Experimental Investigation of Concrete Cylinders Confined with PBO FRCM Exposed to Elevated Temperatures

Abstract

:1. Introduction

2. Experimental Program

2.1. Test Matrix

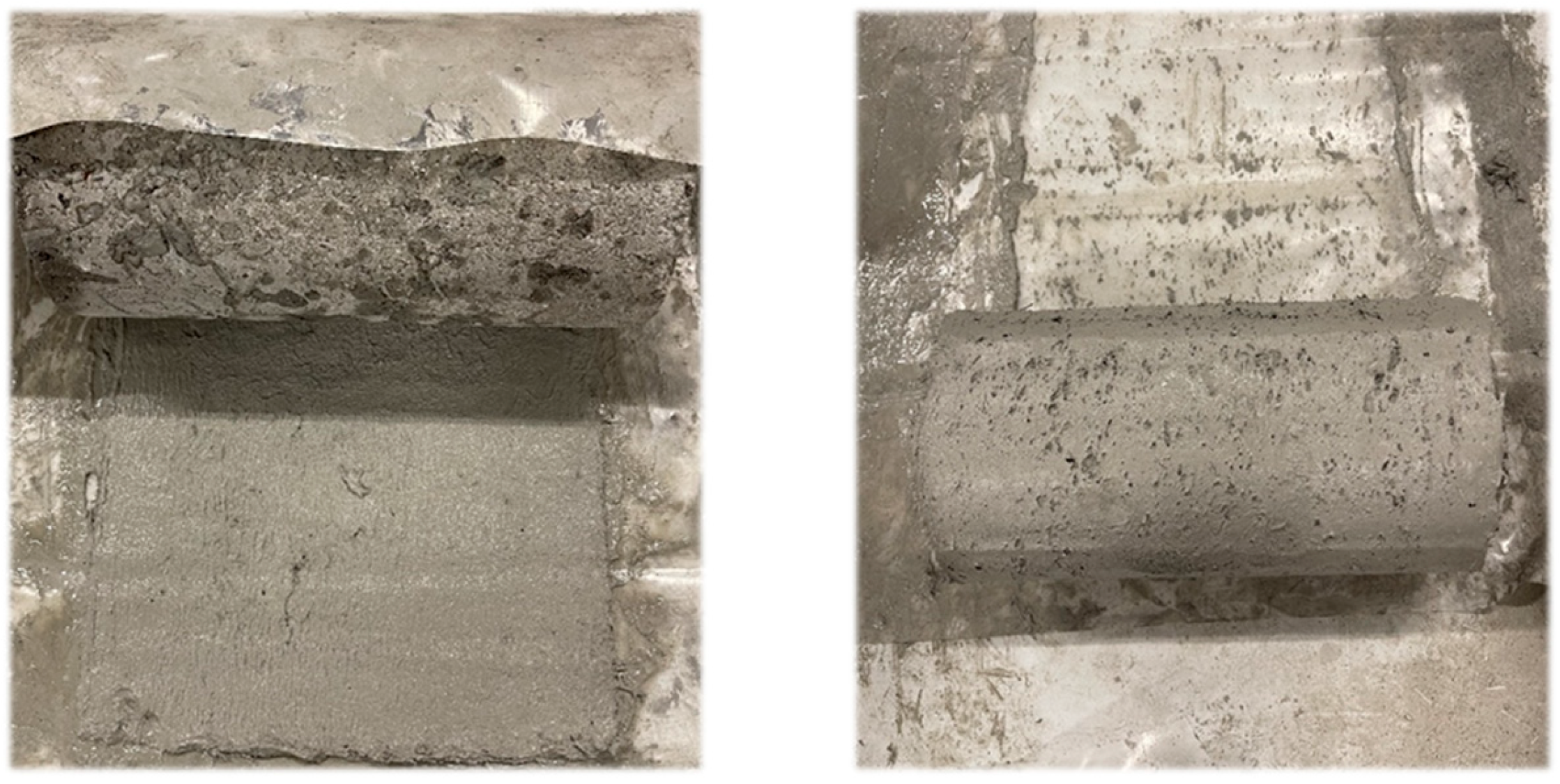

2.2. Specimen Preparation

2.3. Thermal Exposure

3. Results and Discussion

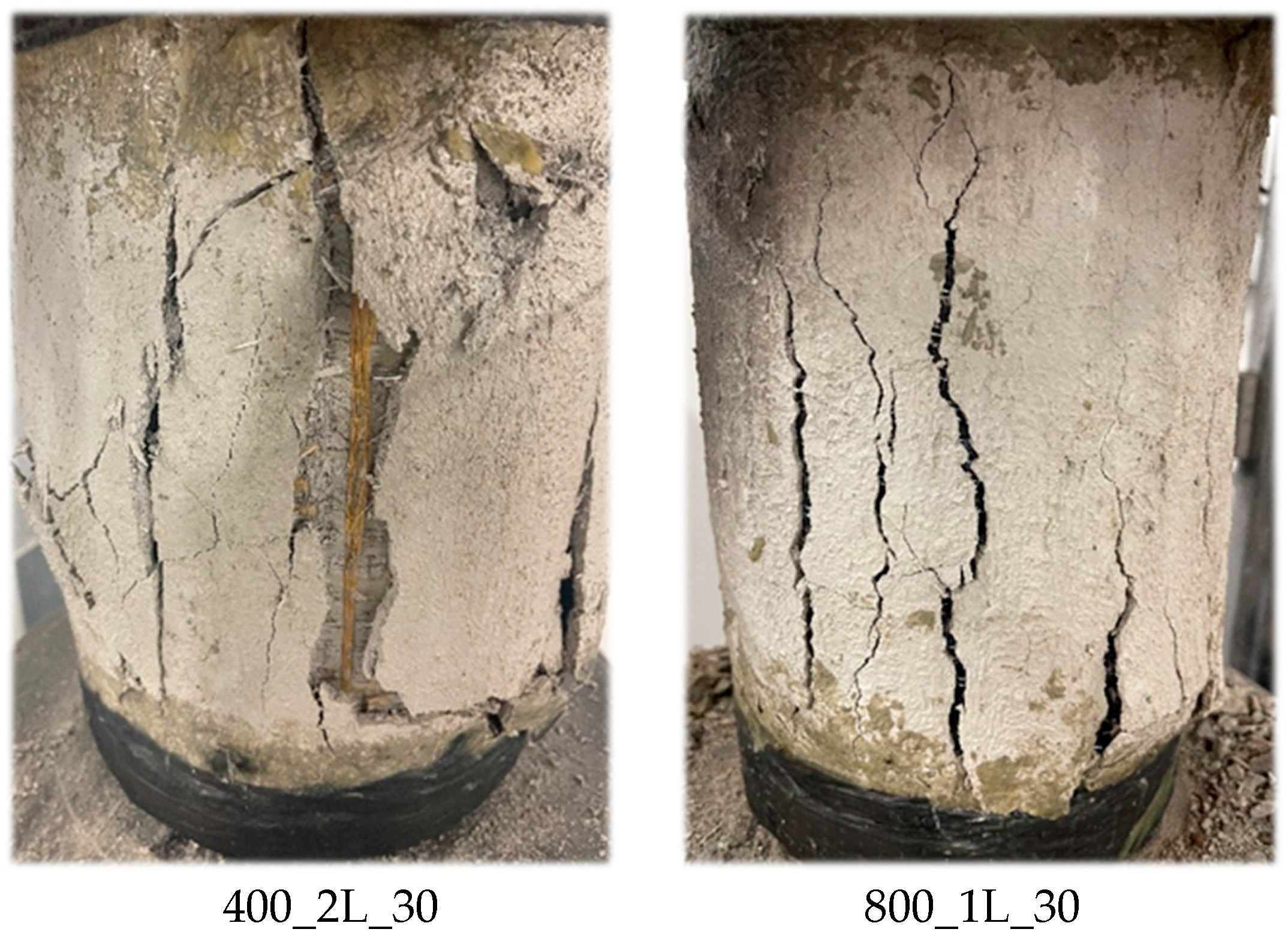

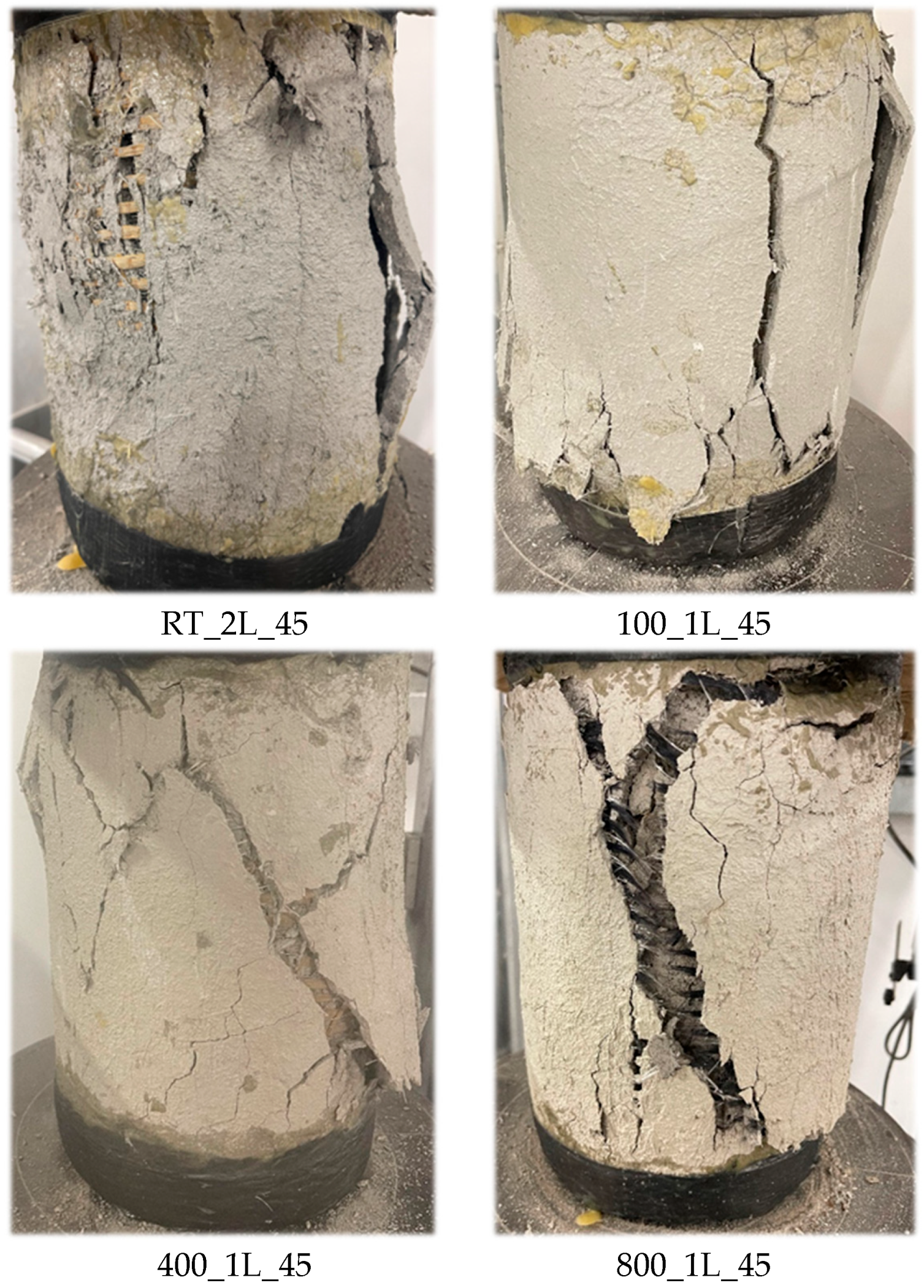

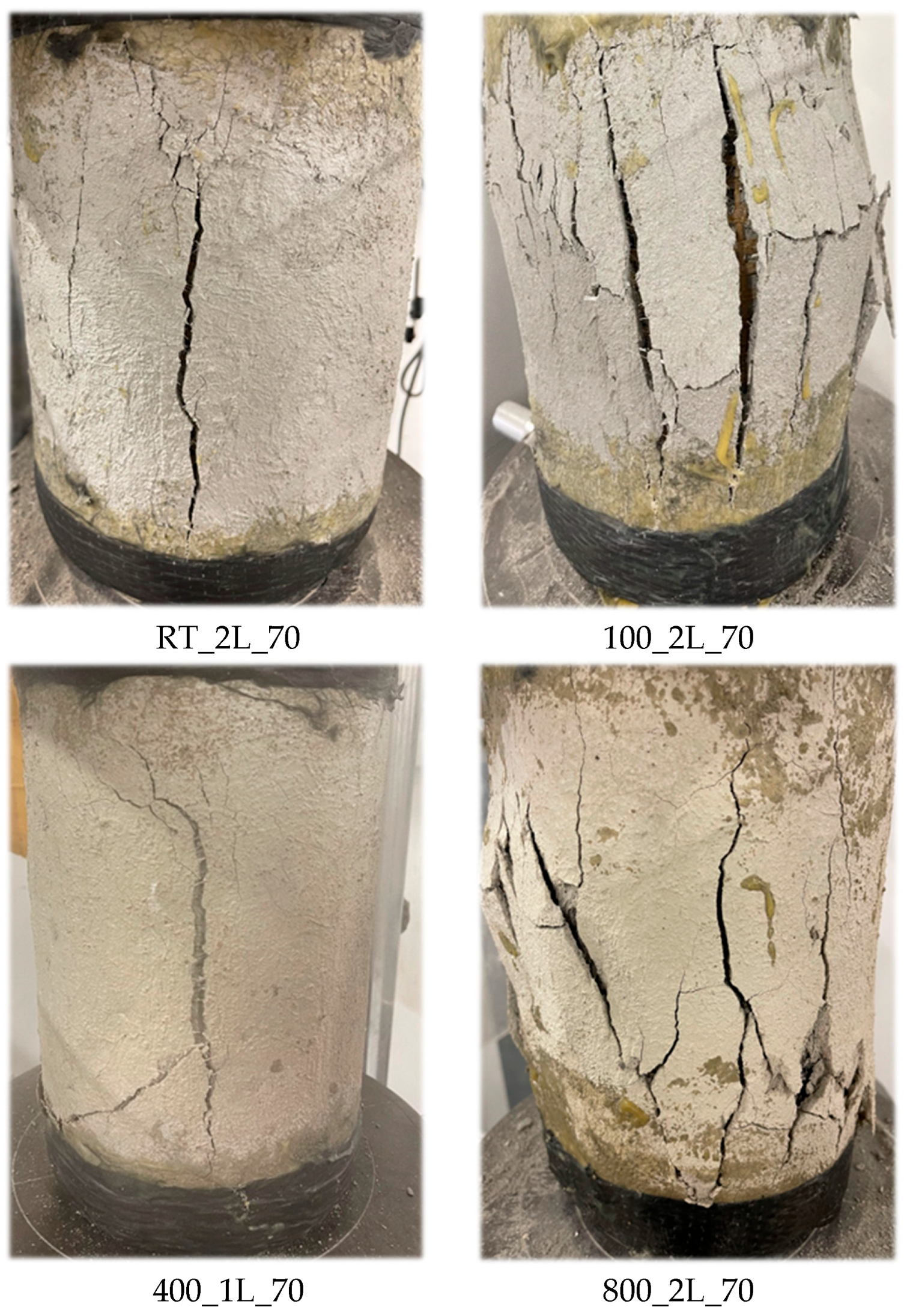

3.1. Failure Modes

3.2. Effect of the Concrete Strength and the Number of FRCM Layers

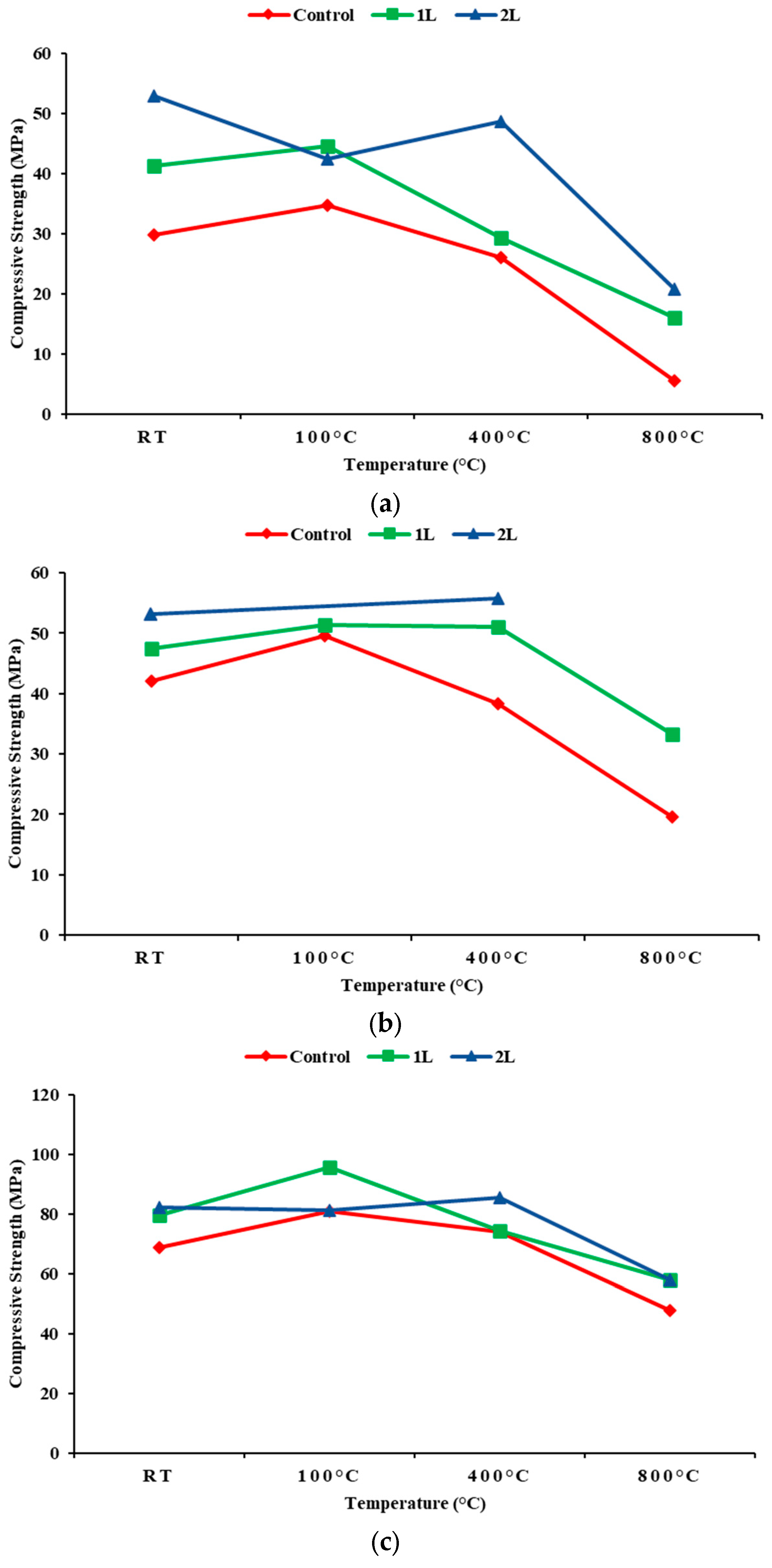

3.3. Effect of Elevated Temperatures

4. Conclusions

- Delamination between the fibers and the cement matrix was the most common failure mode for the FRCM-confined cylinders. However, specimens 100_2L_30 and 100_1L_45 experienced rupture or debonding of the FRP strips, leading to premature failure.

- The effect of the PBO-FRCM-confinement was more pronounced in cylinders with a low concrete strength (30 MPa) regardless of the exposure temperature.

- Heating the cylinders to 100 °C resulted in a slight increase in strength, possibly due to prolonged curing of the concrete at this temperature. Increasing the temperature to 400 °C resulted in marginal differences in strength; however, no consistent trend was observed. Some specimens experienced an increase in strength while others experienced a drop in their axial capacity.

- Heating the confined cylinders to 800 °C resulted in a significant reduction in their capacity that reached 82%. This finding emphasized the necessity of insulating the externally bonded composite materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Firmo, J.P.; Correia, J.R.; Bisby, L.A. Fire behaviour of FRP-strengthened reinforced concrete structural elements: A state-of-the-art review. Compos. B Eng. 2015, 80, 198–216. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A.; Almusallam, T.H.; Elsanadedy, H.M.; Iqbal, R.A. Effect of elevated temperature environments on the residual axial capacity of RC columns strengthened with different techniques. Constr. Build. Mater. 2016, 115, 345–361. [Google Scholar] [CrossRef]

- Ombres, L. Analysis of the bond between Fabric Reinforced Cementitious Mortar (FRCM) strengthening systems and concrete. Compos. B Eng. 2015, 69, 418–426. [Google Scholar] [CrossRef]

- Al-Lami, K.; D’Antino, T.; Colombi, P. Durability of fabric-reinforced cementitious matrix (FRCM) composites: A review. Appl. Sci. 2020, 10, 1714. [Google Scholar] [CrossRef]

- Lau, D.; Qiu, Q.; Zhou, A.; Chow, C.L. Long term performance and fire safety aspect of FRP composites used in building structures. Constr. Build. Mater. 2016, 126, 573–585. [Google Scholar] [CrossRef]

- Donnini, J.; de Caso y Basalo, F.; Corinaldesi, V.; Lancioni, G.; Nanni, A. Fabric-reinforced cementitious matrix behavior at high-temperature: Experimental and numerical results. Compos. B Eng. 2017, 108, 108–121. [Google Scholar] [CrossRef]

- Tello, N.; Alhoubi, Y.; Abed, F.; el Refai, A.; El-Maaddawy, T. Circular and square columns strengthened with FRCM under concentric load. Compos. Struct. 2021, 255, 113000. [Google Scholar] [CrossRef]

- Alhoubi, Y.; el Refai, A.; Abed, F.; El-Maaddawy, T.; Tello, N. Strengthening pre-damaged RC square columns with fabric-reinforced cementitious matrix (FRCM): Experimental investigation. Compos. Struct. 2022, 294, 115784. [Google Scholar] [CrossRef]

- Abed, F.; ElRefai, A.; El-Maaddawy, T.; Tello, N.; Alhoubi, Y. Strengthening Square and Circular Low-Strength Concrete Columns with Fiber-Reinforced Cementitious Matrix: Experimental Investigation. Pract. Period. Struct. Des. Constr. 2022, 27. [Google Scholar] [CrossRef]

- He, H.; Liu, J.; Wang, Y.; Zhao, Y.; Qin, Y.; Zhu, Z.; Yu, Z.; Wang, J. An Ultralight Self-Powered Fire Alarm e-Textile Based on Conductive Aerogel Fiber with Repeatable Temperature Monitoring Performance Used in Firefighting Clothing. ACS Nano 2022, 16, 2953–2967. [Google Scholar] [CrossRef] [PubMed]

- Trapko, T. The effect of high temperature on the performance of CFRP and FRCM confined concrete elements. Compos. B Eng. 2013, 54, 138–145. [Google Scholar] [CrossRef]

- Ombres, L. Structural performances of thermally conditioned PBO FRCM confined concrete cylinders. Compos. Struct. 2017, 176, 1096–1106. [Google Scholar] [CrossRef]

- Cerniauskas, G.; Tetta, Z.; Bournas, D.A.; Bisby, L.A. Concrete confinement with TRM versus FRP jackets at elevated temperatures. Mater. Struct. Mater. Constr. 2020, 53, 58. [Google Scholar] [CrossRef]

- ASTM C39/C39M-18; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2018. Available online: www.astm.org (accessed on 15 May 2021).

- EN 1992-1-2; Eurocode 2: Design of Concrete Structures—Part 1–2: General Rules—Structural Fire. European Committee for Standardization: Brussels, Belgium, 1992.

- Kodur, V. Properties of concrete at elevated temperatures. ISRN Civ. Eng. 2014, 2014, 468510. [Google Scholar] [CrossRef]

- Talo, R.T.; Kyaure, M.K.; Khalaf, S.K.; Refai, A.E.R.; Abed, F.A. FEM analysis of FRCM strengthened RC columns exposed to fire. In Proceedings of the ECCOMAS Congress 2022-8th European Congress on Computational Methods in Applied Sciences and Engineering, Oslo, Norway, 5–9 June 2022. [Google Scholar]

- Krishna, D.A.; Priyadarsini, R.S.; Narayanan, S. Effect of elevated temperatures on the mechanical properties of concrete. Procedia Struct. Integr. 2019, 14, 384–394. [Google Scholar] [CrossRef]

- Ghandehari, M.; Behnood, A.; Khanzadi, M. Residual Mechanical Properties of High-Strength Concretes after Exposure to Elevated Temperatures. J. Mater. Civ. Eng. 2009, 22. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Tayeh, B.A.; Adesina, A.; de Azevedo, A.R.G.; Amin, M.; Hadzima-Nyarko, M.; Agwa, I.S. Review on effect of steam curing on behavior of concrete. Clean. Mater. 2022, 3, 100042. [Google Scholar] [CrossRef]

- Chan, S.Y.N.; Peng, G.-F.; Chan, J.K.W. Comparison between high strength concrete and normal strength concrete subjected to high temperature. Mater. Struct. 1996, 29, 616–619. [Google Scholar] [CrossRef]

| Group | Concrete Strength (MPa) | Number of PBO-FRCM Layers | Exposure Temperatures (°C) |

|---|---|---|---|

| 1 | 30 | 0 | RT, 100, 400, 800 |

| 1 | RT, 100, 400, 800 | ||

| 2 | RT, 100, 400, 800 | ||

| 2 | 45 | 0 | RT, 100, 400, 800 |

| 1 | RT, 100, 400, 800 | ||

| 2 | RT, 400 | ||

| 3 | 70 | 0 | RT, 100, 400, 800 |

| 1 | RT, 100, 400, 800 | ||

| 2 | RT, 100, 400, 800 |

| Property | Ruregold PBO |

|---|---|

| Nominal thickness (mm) | 0.05 |

| Young’s modulus (GPa) | 270 |

| Tensile strength (MPa) | 5800 |

| Mesh elongation at rupture (%) | 2.5 |

| Property | Ruregold Matrix |

| Density (kg/m3) | 1800 |

| Max application time (min) | 45 |

| Mortar 28-day compressive strength (MPa) | 40 |

| Mortar 28-day flexural strength (MPa) | 4 |

| Mortar young’s modulus (GPa) | 15 |

| Group | Specimen ID | Ultimate Load (kN) | Compressive Strength (MPa) |

|---|---|---|---|

| 1 | RT_0L_30 | 527.7 | 29.9 |

| 100_0L_30 | 613.1 | 34.7 | |

| 400_0L_30 | 461.0 | 26.1 | |

| 800_0L_30 | 97.7 | 5.5 | |

| RT_1L_30 | 729.4 | 41.3 | |

| 100_1L_30 | 786.7 | 44.5 | |

| 400_1L_30 | 518.2 | 29.3 | |

| 800_1L_30 | 282.5 | 16.0 | |

| RT_2L_30 | 935.0 | 52.9 | |

| 100_2L_30 | 750.0 | 42.5 | |

| 400_2L_30 | 859.6 | 48.7 | |

| 800_2L_30 | 368.0 | 20.8 | |

| 2 | RT_0L_45 | 743.0 | 42.1 |

| 100_0L_45 | 877.1 | 49.7 | |

| 400_0L_45 | 676.3 | 38.3 | |

| 800_0L_45 | 344.6 | 19.5 | |

| RT_1L_45 | 838.1 | 47.5 | |

| 100_1L_45 | 906.8 | 51.3 | |

| 400_1L_45 | 903.0 | 51.1 | |

| 800_1L_45 | 587.3 | 33.3 | |

| RT_2L_45 | 938.9 | 53.2 | |

| 400_2L_45 | 983.7 | 55.7 | |

| 3 | RT_0L_70 | 1218.3 | 69.0 |

| 100_0L_70 | 1430.0 | 81.0 | |

| 400_0L_70 | 1306.9 | 74.0 | |

| 800_0L_70 | 848.6 | 48.0 | |

| RT_1L_70 | 1406.8 | 79.6 | |

| 100_1L_70 | 1692.8 | 95.8 | |

| 400_1L_70 | 1312.8 | 74.3 | |

| 800_1L_70 | 1024.2 | 58.0 | |

| RT_2L_70 | 1455.0 | 82.4 | |

| 100_2L_70 | 1434.7 | 81.2 | |

| 400_2L_70 | 1511.8 | 85.6 | |

| 800_2L_70 | 1026.8 | 58.1 |

| Group | Number of Layers | % Decrease/Increase in Compressive Strength | |||

|---|---|---|---|---|---|

| RT | 100 °C | 400 °C | 800 °C | ||

| 1 | 0 | - | +16% | −13% | −82% |

| 1 | - | +8% | −29% | −61% | |

| 2 | - | −20% | −8% | −61% | |

| 2 | 0 | - | +18% | −9% | −54% |

| 1 | - | +8% | +8% | −30% | |

| 2 | - | - | +5% | − | |

| 3 | 0 | - | +17% | +7% | −30% |

| 1 | - | +20% | −7% | −27% | |

| 2 | - | −1% | +4% | −29% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Talo, R.; Abed, F.; El Refai, A.; Alhoubi, Y. Experimental Investigation of Concrete Cylinders Confined with PBO FRCM Exposed to Elevated Temperatures. Fire 2023, 6, 322. https://doi.org/10.3390/fire6080322

Talo R, Abed F, El Refai A, Alhoubi Y. Experimental Investigation of Concrete Cylinders Confined with PBO FRCM Exposed to Elevated Temperatures. Fire. 2023; 6(8):322. https://doi.org/10.3390/fire6080322

Chicago/Turabian StyleTalo, Reem, Farid Abed, Ahmed El Refai, and Yazan Alhoubi. 2023. "Experimental Investigation of Concrete Cylinders Confined with PBO FRCM Exposed to Elevated Temperatures" Fire 6, no. 8: 322. https://doi.org/10.3390/fire6080322

APA StyleTalo, R., Abed, F., El Refai, A., & Alhoubi, Y. (2023). Experimental Investigation of Concrete Cylinders Confined with PBO FRCM Exposed to Elevated Temperatures. Fire, 6(8), 322. https://doi.org/10.3390/fire6080322